Extension of Elastic Models to Decagonal Quasicrystals

Abstract

1. Introduction

2. General Solution and Potential Function Theory

3. Applications

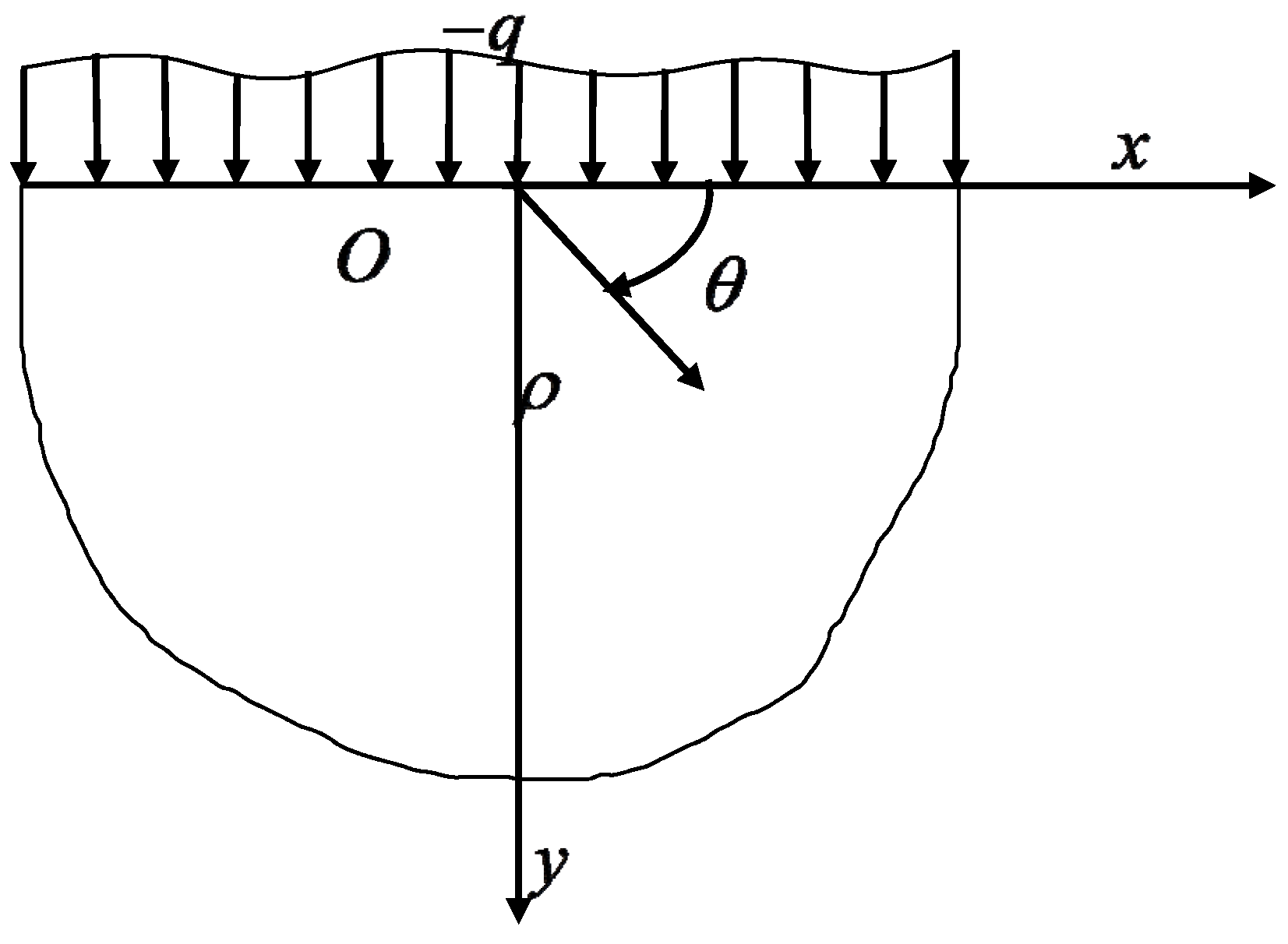

3.1. Problem and Analytical Solution of the Semi-Infinite Plane

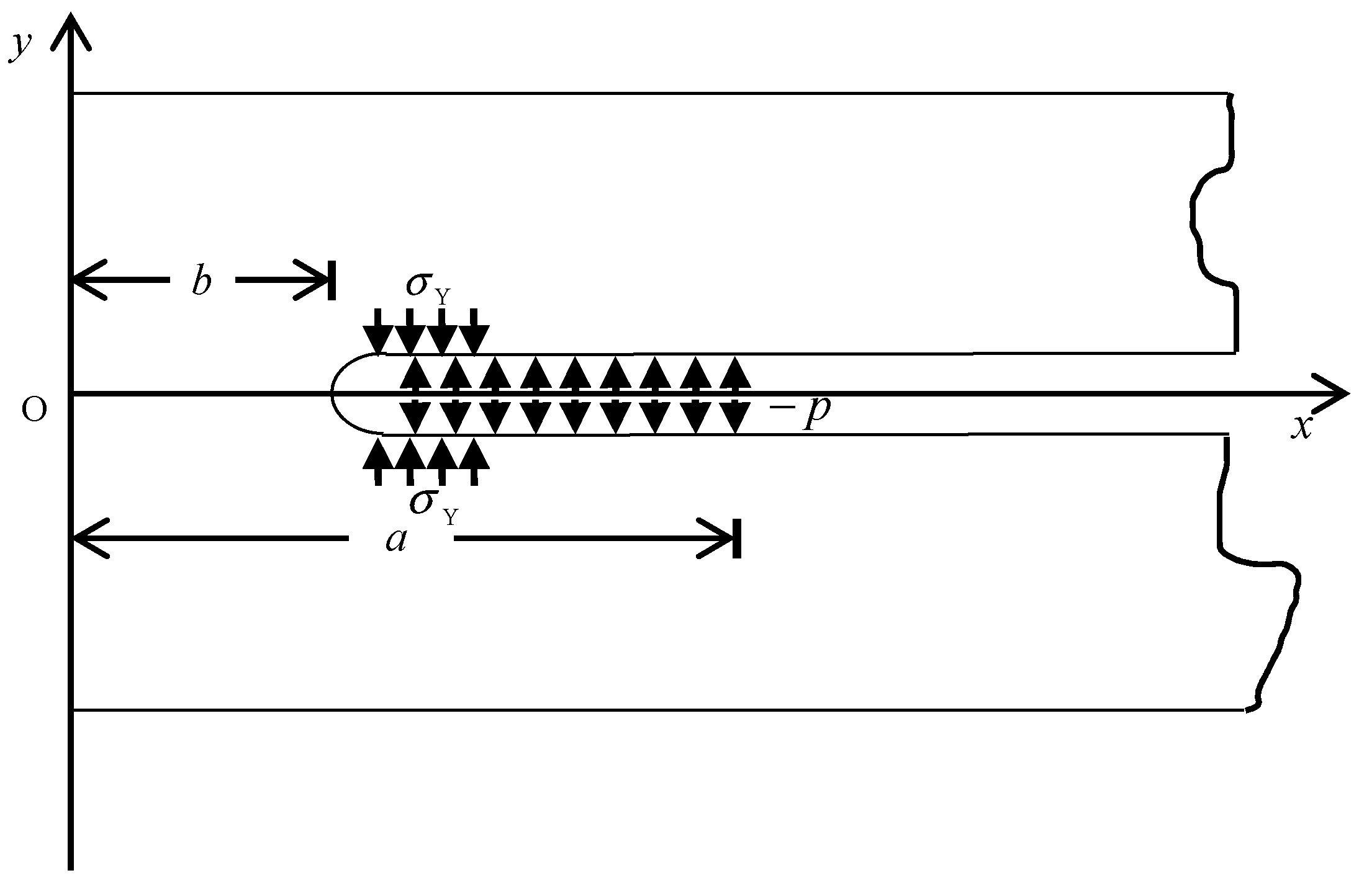

3.2. Solutions to Dugdale Hypothesis of a Semi-infinite Crack in a Decagonal Quasicrystal

3.2.1. Exact Solutions for Dugdale Hypothesis of a Semi-infinite Crack Based on Conformal Mapping

3.2.2. Exact Solutions for Dugdale Hypothesis of a Semi-Infinite Crack Based on Conformal Mapping

4. Discussion and Conclusion

Author Contributions

Funding

Conflicts of Interest

Appendix A. The Calculation Process of Equation (25) of Section 3

References

- Shechtman, D.; Blech, I.; Gratias, D.; Cahn, J.W. Metallic Phase with Long-Range Orientational Order and No Translational Symmetry. Phys. Rev. Lett. 1984, 53, 1951–1953. [Google Scholar] [CrossRef]

- Landau, L.D.; Lifshitz, E.M. Statistical Physics; Pergamon Press: New York, NY, USA, 1958. [Google Scholar]

- Bohsung, J.; Trebin, H.R. Disclinations in quasicrystals. Phys. Rev. Lett. 1987, 58, 1204–1207. [Google Scholar] [CrossRef] [PubMed]

- Bak, P. Phenomenological theory of icosahedral in commensurate (quasiperiodic) order in Mn-Al alloys. Phys. Rev. Lett. 1985, 54, 1517–1519. [Google Scholar] [CrossRef] [PubMed]

- Socolar, J.E.S.; Lubensky, T.C.; Steinhardt, P.J. Phonons, phasons, and dislocations in quasicrystals. Phys. Rev. B 1986, 34, 3345–3360. [Google Scholar] [CrossRef] [PubMed]

- Edagawa, K. Phonon–Phason coupling in decagonal quasicrystals. Philos. Mag. 2007, 87, 2789–2798. [Google Scholar] [CrossRef]

- Chernikov, M.A.; Ott, H.R.; Bianchi, A.; Migliori, A.; Darling, T.W. Elastic Moduli of a Single Quasicrystal of Decagonal Al-Ni-Co: Evidence for Transverse Elastic Isotropy. Phys. Rev. Lett. 1998, 80, 321–324. [Google Scholar] [CrossRef]

- Tanaka, K.; Mitara, Y.; Koiwa, M. Elastic constants of Al-based icosahedral quasicrystals. Philos. Mag. A 1996, 73, 1715–1723. [Google Scholar] [CrossRef]

- Ding, D.-H.; Yang, W.; Hu, C.; Wang, R. Generalized elasticity theory of quasicrystals. Phys. Rev. B 1993, 48, 7003–7010. [Google Scholar] [CrossRef]

- Hu, C.; Wang, R.; Ding, D.-H. Symmetry groups, physical property tensors, elasticity and dislocations in quasicrystals. Rep. Prog. Phys. 2000, 63, 1–39. [Google Scholar] [CrossRef]

- Jeong, H.-C.; Steinhardt, P.J. Finite-Temperature elasticity phase transition in decagonal quasicrystals. Phys. Rev. B 1993, 48, 9394–9403. [Google Scholar] [CrossRef]

- Levine, D.; Lubensky, T.C.; Östlund, S.; Ramaswamy, S.; Steinhardt, P.J.; Toner, J. Elasticity and Dislocations in Pentagonal and Icosahedral Quasicrystals. Phys. Rev. Lett. 1985, 54, 1520–1523. [Google Scholar] [CrossRef] [PubMed]

- Coddens, G. On the problem of the relation between phason elasticity and phason dynamics in quasicrystals. Eur. Phys. J. B 2006, 54, 37–65. [Google Scholar] [CrossRef]

- Fan, T.Y. Mathematical Theory of Elasticity of Quasicrystals and Its Applications; Springer: Berlin/Heidelberg, Germany, 2010. [Google Scholar]

- Li, X.-F.; Duan, X.-Y.; Fan, T.-Y.; Sun, Y.-F. Elastic field for a straight dislocation in a decagonal quasicrystal. J. Phys. Condens. Matter 1999, 11, 703–711. [Google Scholar] [CrossRef]

- Li, F.X.; Fan, T.Y.; Sun, Y.F. A decagonal quasicrystal with a Griffith crack. Philos. Mag. A 1999, 79, 1943–1952. [Google Scholar]

- Li, L.H.; Fan, T.Y. Complex function method for solving notch problem of point 10 two-Dimensional quasicrystal based on the stress potential function. J. Phys. Condens. Matter 2006, 18, 10631–10641. [Google Scholar]

- Gao, Y.; Ricoeur, A. The Refined Theory of One-Dimensional Quasi-Crystals in Thick Plate Structures. J. Appl. Mech. 2011, 78, 031021. [Google Scholar] [CrossRef]

- Wang, J.; Mancini, L.; Wang, R.; Gastaldi, J. Phonon and phason-type spherical inclusions in icosahedral quasicrystals. J. Phys. Condens. Matter 2003, 15, L363–L370. [Google Scholar] [CrossRef]

- Radi, E.; Mariano, P.M. Stationary straight cracks in quasicrystals. Int. J. Fract. 2010, 166, 102–120. [Google Scholar] [CrossRef]

- Radi, E.; Mariano, P.M. Steady-State propagation of dislocations in quasi-crystals. Proc. R. Soc. A Math. Phys. Eng. Sci. 2011, 467, 3490–3508. [Google Scholar] [CrossRef]

- Mariano, P.M.; Planas, J. Phason self-actions in quasicrystals. Phys. D Nonlinear Phenom. 2013, 249, 46–57. [Google Scholar] [CrossRef]

- Li, X.-Y. Fundamental solutions of penny-Shaped and half-Infinite plane cracks embedded in an infinite space of one-Dimensional hexagonal quasi-Crystal under thermal loading. Proc. R. Soc. A Math. Phys. Eng. Sci. 2013, 469. [Google Scholar] [CrossRef]

- Li, X. Elastic field in an infinite medium of one-dimensional hexagonal quasicrystal with a planar crack. Int. J. Solids Struct. 2014, 51, 1442–1455. [Google Scholar] [CrossRef]

- Li, W.; Xin, H.; Fan, T. Boundary Value Problems of Potential Functions in Decagonal Quasicrystals. Math. Probl. Eng. 2014, 2014, 1–8. [Google Scholar] [CrossRef]

- Li, W.; Fan, T.Y. Dynamic Analysis of Cracked Octagonal Quasicrystals. Math. Probl. Eng. 2011, 2011, 567489. [Google Scholar] [CrossRef]

- Wollgarten, M.; Beyss, M.; Urban, K.; Liebertz, H.; Koster, U. Direct evidence for plastic deformation of quasicrystals by means of a dislocationmechanism. Phys. Rev. Lett. 2003, 71, 549–552. [Google Scholar] [CrossRef] [PubMed]

- Feuerbacher, M.; Bartsch, M.; Grushko, B.; Messerschmidt, U.; Urban, K. Plastic deformation of decagonal Al-Ni-Co quasicrystals. Philos. Mag. Lett. 1997, 76, 369–376. [Google Scholar] [CrossRef]

- Messerschmidt, M.B.U. Friction mechanism of dislocation motion in icosahedral Al-Pd-Mn quasicrystals. Philos. Mag. A 1999, 79, 2123–2135. [Google Scholar] [CrossRef]

- Schall, P.; Feuerbacher, M.; Bartsch, M.; Messerschmidt, U.; Urban, K. Dislocation density evolution upon plastic deformation of Al-Pd-Mn single quasicrystals. Philos. Mag. Lett. 1999, 79, 785–796. [Google Scholar] [CrossRef]

- Geyer, B.; Bartsch, M.; Feuerbacher, M.; Urban, K.; Messerschmidt, U. Plastic deformation of icosahedral Al-Pd-Mn single quasicrystals I. Experimental results. Philos. Mag. A 2000, 80, 1151–1163. [Google Scholar] [CrossRef]

- Rosenfeld, R.; Feuerbacher, M.; Baufeld, B.; Bartsch, M.; Wollgarten, M.; Hanke, G.; Beyss, M.; Messerschmidt, U.; Urban, K. Study of plastically deformed icosahedral Al[sbnd]Pd[sbnd]Mn single quasicrystals by transmission electron microscopy. Philos. Mag. Lett. 1995, 72, 375–384. [Google Scholar] [CrossRef]

- Caillard, D.; Vanderschaeve, G.; Bresson, L.; Gratias, D. Transmission electron microscopy study of dislocations and extended defects in as-Grown icosahedral Al-Pd-Mn single grains. Philos. Mag. Lett. 2000, 80, 237–253. [Google Scholar] [CrossRef]

- Muskhelishvili, N.I. Some Basic Problems of Mathematical Theory of Elasticity; P Noordhoff: Groringen, The Netherlands, 1956. [Google Scholar]

- Mariano, P.M. Mechanics of Quasi-Periodic Alloys. J. Nonlinear Sci. 2005, 16, 45–77. [Google Scholar] [CrossRef]

- Mariano, P.M.; Stazi, F.L.; Augusti, G. Phason effects around a crack in Al-Pb-Mn quasicrystals: Stochastic aspects of the phonon-phason coupling. Comput. Struct. 2004, 82, 971–983. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, W.; Shi, Y. Extension of Elastic Models to Decagonal Quasicrystals. Crystals 2020, 10, 469. https://doi.org/10.3390/cryst10060469

Li W, Shi Y. Extension of Elastic Models to Decagonal Quasicrystals. Crystals. 2020; 10(6):469. https://doi.org/10.3390/cryst10060469

Chicago/Turabian StyleLi, Wu, and Yiqing Shi. 2020. "Extension of Elastic Models to Decagonal Quasicrystals" Crystals 10, no. 6: 469. https://doi.org/10.3390/cryst10060469

APA StyleLi, W., & Shi, Y. (2020). Extension of Elastic Models to Decagonal Quasicrystals. Crystals, 10(6), 469. https://doi.org/10.3390/cryst10060469