Enhanced Electrocaloric Effect in 0.73Pb(Mg1/3Nb2/3)O3-0.27PbTiO3 Single Crystals via Direct Measurement

Abstract

1. Introduction

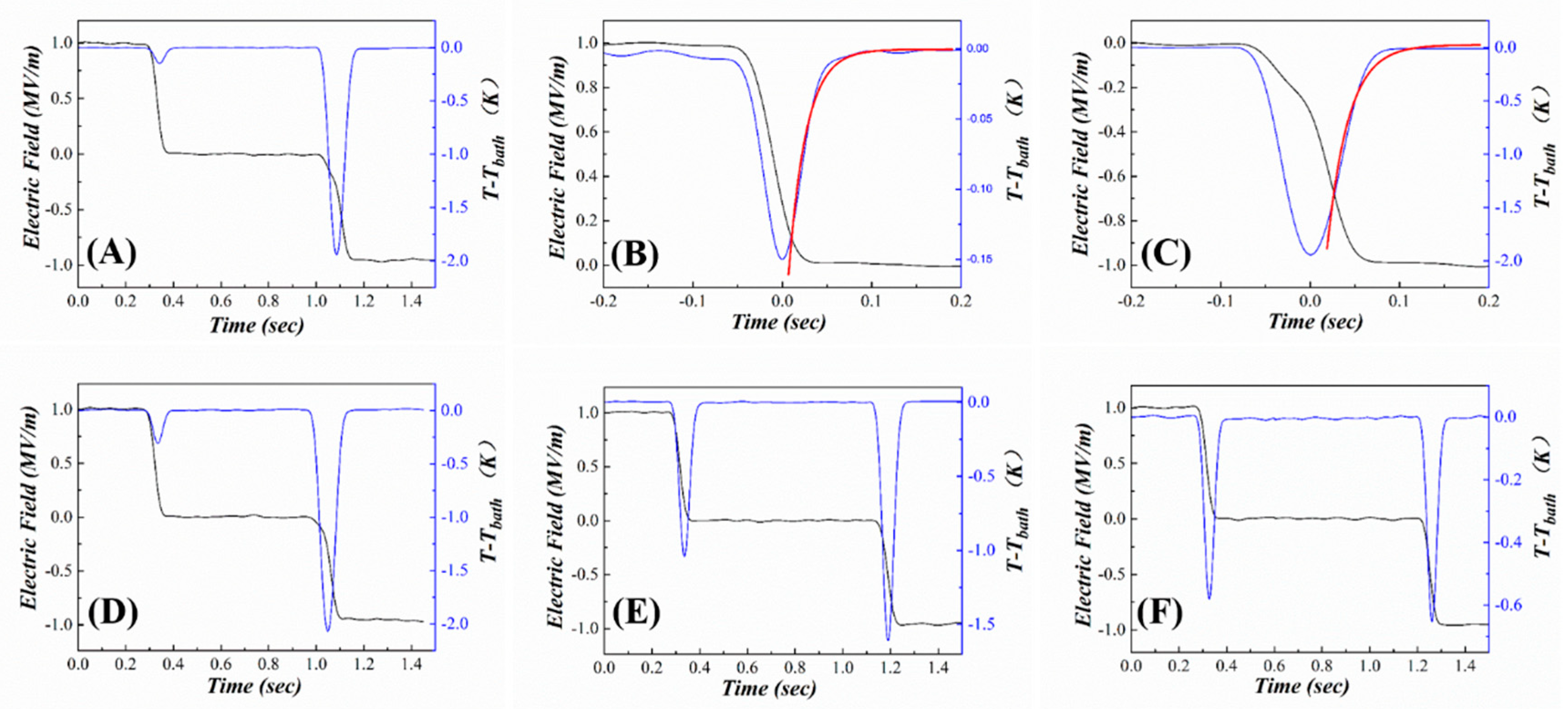

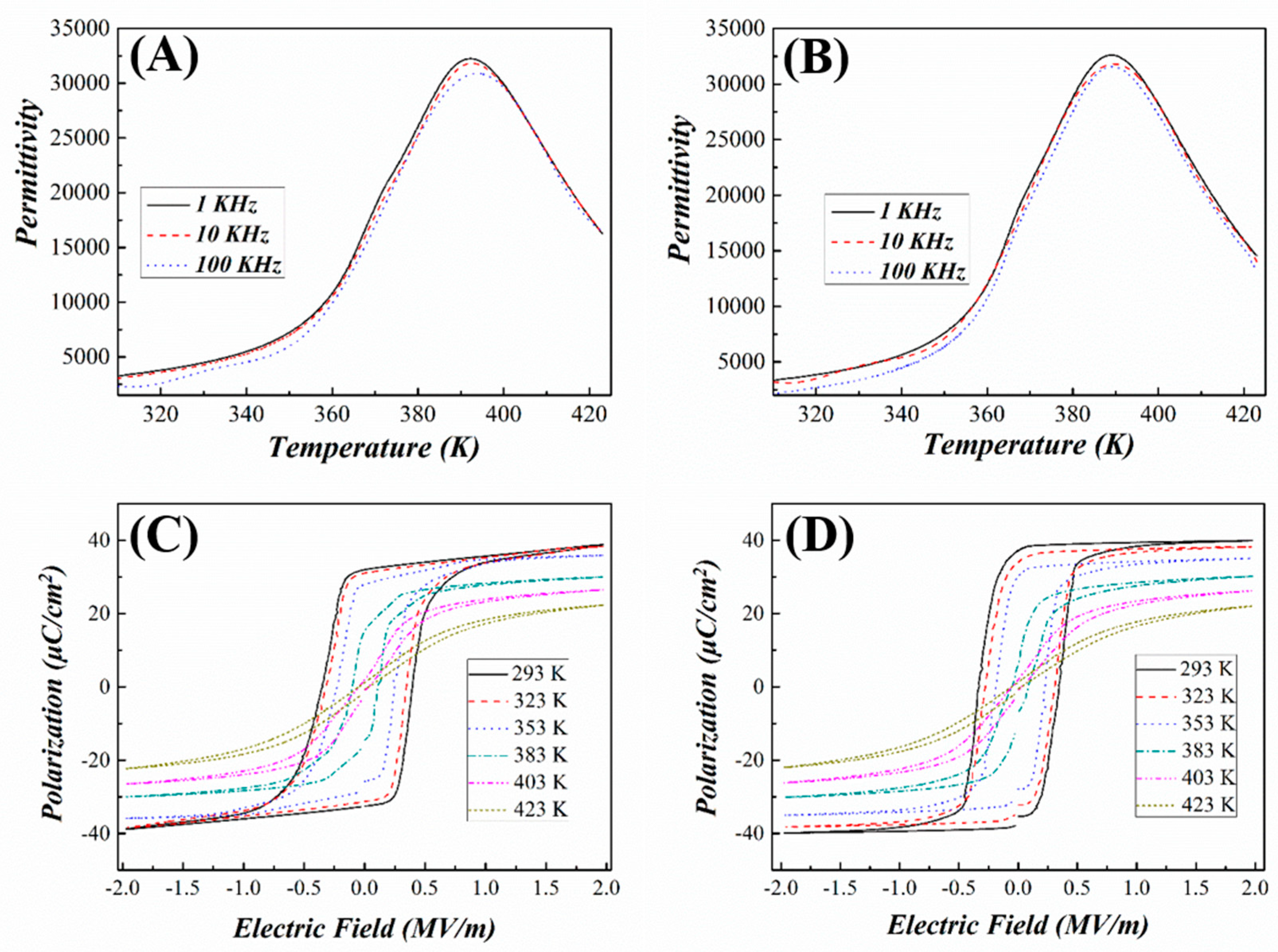

2. Materials and Methods

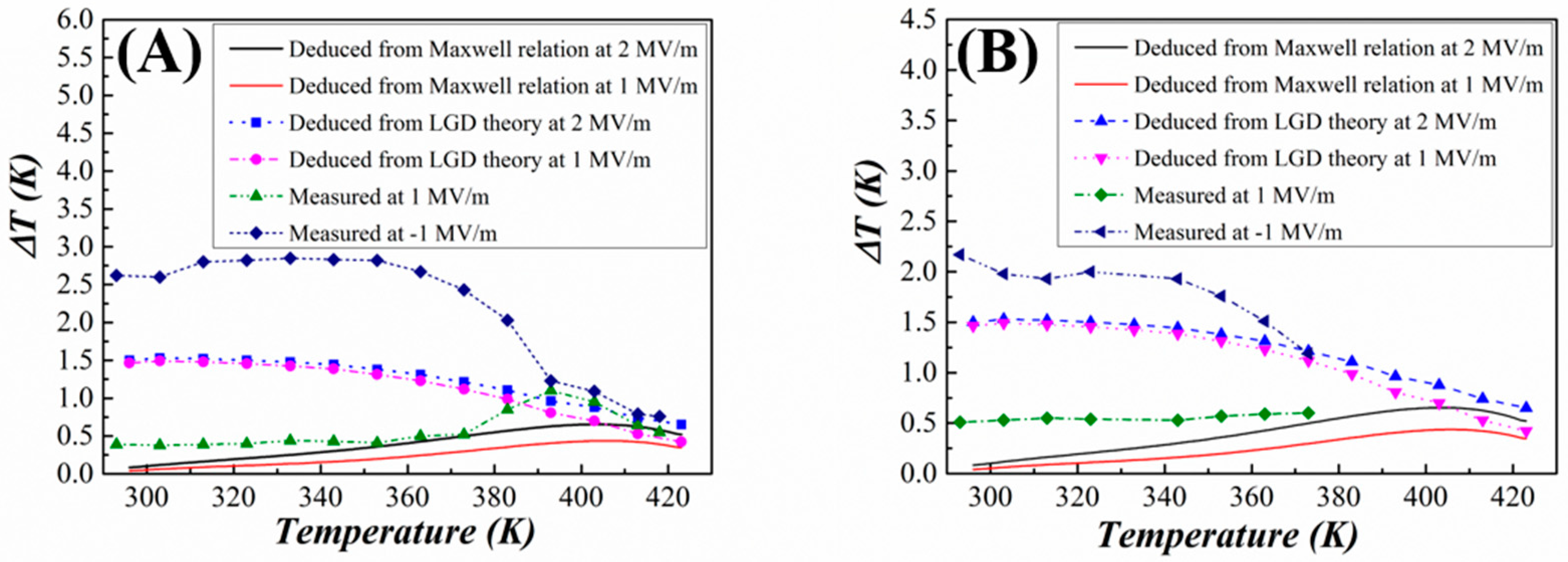

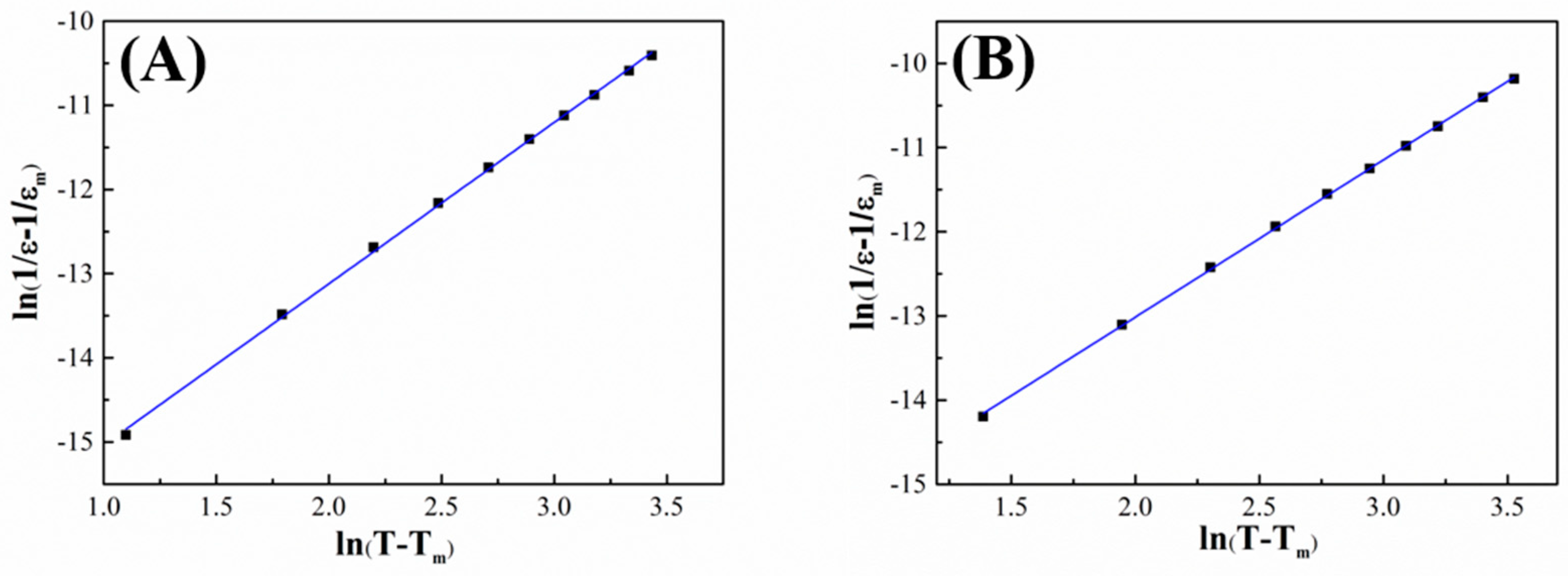

3. Results

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Lines, M.E.; Glass, A.M. Principles and Applications of Ferroelectrics and Related Materials; Clarendon Press: Oxford, UK, 1977. [Google Scholar]

- Pakhomov, O.V.; Karmanenko, S.F.; Semenov, A.A.; Starkov, A.S.; Es’kov, A.V. Thermodynamic estimation of cooling efficiency using an electrocaloric solid-state line. Tech. Phys. 2010, 55, 1155–1160. [Google Scholar] [CrossRef]

- Mischenko, A.S.; Zhang, Q.; Scott, J.F.; Whatmore, R.W.; Mathur, N.D. Giant electrocaloric effect in thin-film PbZr0.95Ti0.05O3. Science 2006, 311, 1270–1271. [Google Scholar] [CrossRef] [PubMed]

- Neese, B.; Chu, B.; Lu, S.G.; Wang, Y.; Furman, E.; Zhang, Q.M. Large electrocaloric effect in ferroelectric polymers near room temperature. Science 2008, 321, 821–823. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Scott, J.F.; Dkhil, B. Direct and indirect measurements on electrocaloric effect: Recent developments and perspectives. Appl. Phys. Rev. 2016, 3, 031102. [Google Scholar] [CrossRef]

- Ma, Y.B.; Novak, N.; Koruza, J.; Yang, T.Q.; Albe, K.; Xu, B.X. Enhanced electrocaloric cooling in ferroelectric single crystals by electric field reversal. Phys. Rev. B 2016, 94, 100104. [Google Scholar] [CrossRef]

- Zhang, T.F.; Tang, X.G.; Ge, P.Z.; Liu, Q.X.; Jiang, Y.P. Orientation related electrocaloric effect and dielectric phase transitions of relaxor PMN-PT single crystals. Ceram. Int. 2017, 43, 16300–16305. [Google Scholar] [CrossRef]

- Wu, H.H.; Cohen, R.E. Electric-field-induced phase transition and electrocaloric effect in PMN-PT. Phys. Rev. B 2017, 96, 054116. [Google Scholar] [CrossRef]

- Sebald, G.; Seveyrat, L.; Guyomar, D.; Lebrun, L.; Guiffard, B.; Pruvost, S. Electrocaloric and pyroelectric properties of 0.75Pb(Mg1/3Nb2/3)O3-0.25PbTiO3 single crystals. J. Appl. Phys. 2006, 100, 124112. [Google Scholar] [CrossRef]

- Lu, B.; Yao, Y.B.; Jian, X.D.; Tao, T.; Liang, B.; Zhang, Q.M.; Lu, S.G. Enhancement of the electrocaloric effect over a wide temperature range PLZT ceramics by doping with Gd3+ and Sn4+ ions. J. Eur. Ceram. Soc. 2019, 39, 1093–1102. [Google Scholar] [CrossRef]

- Kutnjak, Z.; Rožič, B. Indirect and direct measurements of the electrocaloric effect. In Electrocaloric Material; Correia, T., Zhang, Q., Eds.; Springer: Berlin/Heidelberg, Germany, 2014; pp. 147–182. [Google Scholar]

- Yao, H.; Ema, K.; Garland, C.W. Nonadiabatic scanning calorimeter. Rev. Sci. Instrum. 1998, 69, 172–178. [Google Scholar] [CrossRef]

- Lu, S.G.; Zhang, Q.M. Electrocaloric materials for solid state refrigeration. Adv. Mater. 2009, 21, 1983–1987. [Google Scholar] [CrossRef]

- Haun, M.J.; Furman, E.; McKinstry, H.A.; Cross, L.E. Thermodynamic theory of the lead zirconate-titanate solid solution system, part II: Tricritical behavior. Ferroelectrics 1989, 99, 27–44. [Google Scholar] [CrossRef]

- Haun, M.J.; Furman, E.; Jang, S.J.; Cross, L.E. Thermodynamic theory of the lead zirconate-titanate solid solution system, part I: Phenomenology. Ferroelectrics 1989, 99, 13–25. [Google Scholar] [CrossRef]

- Baerwald, H.G. Thermodynamic theory of ferroelectric ceramics. Phys. Rev. 1957, 105, 480–486. [Google Scholar] [CrossRef]

- Lu, S.G.; Rozic, B.; Kutnjak, Z.; Zhang, Q.M. Electrocaloric effect in ferroelectric P(VDF-TrFE) copolymers. Integr. Ferroelectr. 2011, 125, 176–185. [Google Scholar] [CrossRef]

- Marincel, D.M.; Zhang, H.R.; Kumar, A.; Jesse, S.; Kalinin, S.V.; Rainforth, W.M.; Reaney, I.M.; Randall, C.A.; Trolier-McKinstry, S. Influence of a single grain boundary on domain wall motion in ferroelectrics. Adv. Funct. Mater. 2014, 24, 1409–1417. [Google Scholar] [CrossRef]

- Zhang, S.; Sherlock, N.P.; Meyer, R.J.; Shrout, T.R. Crystallographic dependence of loss in domain engineered relaxor-PT single crystals. Appl. Phys. Lett. 2009, 94, 162906. [Google Scholar] [CrossRef]

- Davis, M.; Damjanovic, D.; Hayem, D.; Setter, N. Domain engineering of the transverse piezoelectric coefficient in perovskite ferroelectrics. J. Appl. Phys. 2005, 98, 014102. [Google Scholar] [CrossRef]

- Shi, Y.P.; Soh, A.K. Modeling of enhanced electrocaloric effect above the Curie temperature in relaxor ferroelectrics. Acta Mater. 2011, 59, 5574–5583. [Google Scholar] [CrossRef][Green Version]

- Khassaf, H.; Mantese, J.V.; Bassiri-Gharb, N.; Kutnjak, Z.; Alpay, S.P. Perovskite ferroelectrics and relaxor-ferroelectric solid solutions with large intrinsic electrocaloric response over broad temperature ranges. J. Mater. Chem. C 2016, 4, 4763. [Google Scholar] [CrossRef]

- Basso, V.; Gerard, J.-F.; Pruvost, S. Doubling the electrocaloric cooling of poled ferroelectric materials by bipolar cycling. Appl. Phys. Lett. 2014, 105, 052907. [Google Scholar] [CrossRef]

- Lu, S.G.; Zhang, Q.M. Large electrocaloric effect in relaxor ferroelectrics. J. Adv. Dielectr. 2012, 2, 123011. [Google Scholar] [CrossRef]

- Lu, B.; Li, P.L.; Tang, Z.H.; Yao, Y.B.; Gao, X.S.; Kleemann, W.; Lu, S.G. Large electrocaloric effect in relaxor ferroelectric and antiferroelectric lanthanum doped lead zirconate titanate ceramics. Sci. Rep. 2017, 7, 45335. [Google Scholar] [CrossRef] [PubMed]

- Hanrahan, B.; Espinal, Y.; Neville, C.; Rudy, R.; Rivas, M.; Smith, A.; Kesim, M.T.; Alpay, S.P. Accounting for the various contributions to pyroelectricity in lead zirconate titanate thin films. J. Appl. Phys. 2018, 123, 124104. [Google Scholar] [CrossRef]

- Bokov, A.A.; Ye, Z.G. Dielectric relaxation in relaxor ferroelectrics. J. Adv. Dielectr. 2012, 2, 1241010. [Google Scholar] [CrossRef]

- Viehland, D.; Jang, S.J.; Cross, L.E.; Wuttig, M. Deviation from Curie-Weiss behavior in relaxor ferroelectrics. Phys. Rev. B 1992, 46, 8003. [Google Scholar] [CrossRef]

- Lu, S.G.; Rožič, B.; Zhang, Q.M.; Kutnjak, Z.; Pirc, R.; Lin, M.R.; Li, X.Y.; Gorny, L.J. Comparison of directly and indirectly measured electrocaloric effect in the relaxor ferroelectric polymers. Appl. Phys. Lett. 2010, 97, 202901. [Google Scholar] [CrossRef]

- Valant, M. Electrocaloric materials for future solid-state refrigeration technologies. Prog. Mater. Sci. 2012, 57, 980–1009. [Google Scholar] [CrossRef]

- Birks, E.; Dunce, M.; Peräntie, J.; Hagberg, J.; Sternberg, A. Direct and indirect determination of electrocaloric effect in Na0.5Bi0.5TiO3. J. Appl. Phys. 2017, 121, 224102. [Google Scholar] [CrossRef]

- Pirc, R.; Kutnjak, Z.; Blinc, R.; Zhang, Q.M. Upper bounds on the electrocaloric effect in polar solids. Appl. Phys. Lett. 2011, 98, 021909. [Google Scholar] [CrossRef]

- Weyland, F.; Bradesko, A.; Ma, Y.B.; Koruza, J.; Xu, B.X.; Albe, K.; Rojac, T.; Novak, N. Impact of polarization dynamics and charged defects on the electrocaloric response of ferroelectric Pb(Zr,Ti)O3 ceramics. Energy Technol. 2018, 6, 1518–1525. [Google Scholar] [CrossRef]

- Lu, S.G.; Rozic, B.; Zhang, Q.M.; Kutnjak, Z.; Li, X.Y.; Furman, E.; Gorny, L.J.; Lin, M.R.; Malic, B.; Kosec, M.; et al. Organic and inorganic relaxor ferroelectrics with giant electrocaloric effect. Appl. Phys. Lett. 2010, 97, 162904. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, B.; Jian, X.; Lin, X.; Yao, Y.; Tao, T.; Liang, B.; Luo, H.; Lu, S.-G. Enhanced Electrocaloric Effect in 0.73Pb(Mg1/3Nb2/3)O3-0.27PbTiO3 Single Crystals via Direct Measurement. Crystals 2020, 10, 451. https://doi.org/10.3390/cryst10060451

Lu B, Jian X, Lin X, Yao Y, Tao T, Liang B, Luo H, Lu S-G. Enhanced Electrocaloric Effect in 0.73Pb(Mg1/3Nb2/3)O3-0.27PbTiO3 Single Crystals via Direct Measurement. Crystals. 2020; 10(6):451. https://doi.org/10.3390/cryst10060451

Chicago/Turabian StyleLu, Biao, Xiaodong Jian, Xiongwei Lin, Yingbang Yao, Tao Tao, Bo Liang, Haosu Luo, and Sheng-Guo Lu. 2020. "Enhanced Electrocaloric Effect in 0.73Pb(Mg1/3Nb2/3)O3-0.27PbTiO3 Single Crystals via Direct Measurement" Crystals 10, no. 6: 451. https://doi.org/10.3390/cryst10060451

APA StyleLu, B., Jian, X., Lin, X., Yao, Y., Tao, T., Liang, B., Luo, H., & Lu, S.-G. (2020). Enhanced Electrocaloric Effect in 0.73Pb(Mg1/3Nb2/3)O3-0.27PbTiO3 Single Crystals via Direct Measurement. Crystals, 10(6), 451. https://doi.org/10.3390/cryst10060451