Electromechanically Rotatable Cross-Shaped Mid-IR Metamaterial

Abstract

1. Introduction

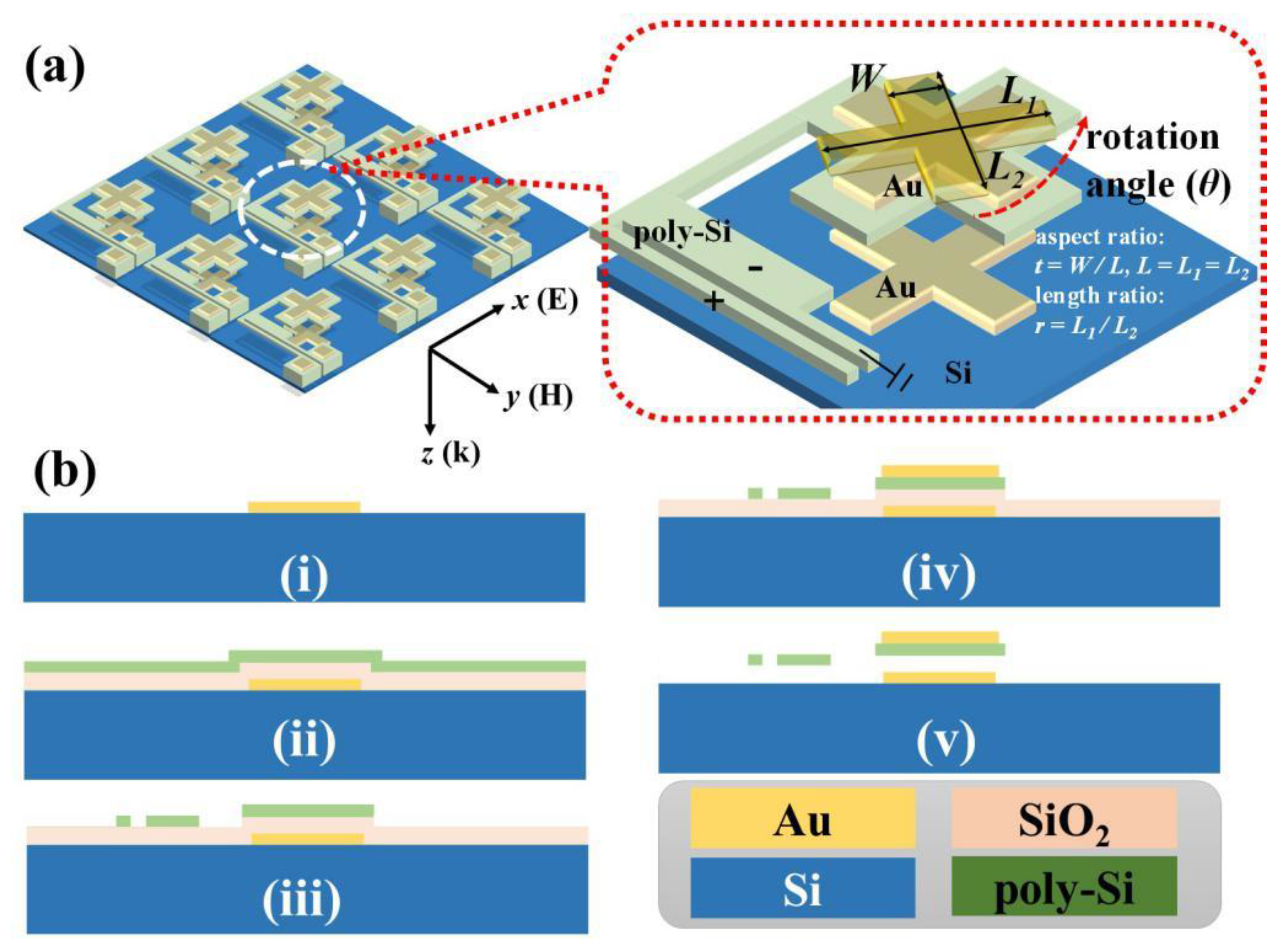

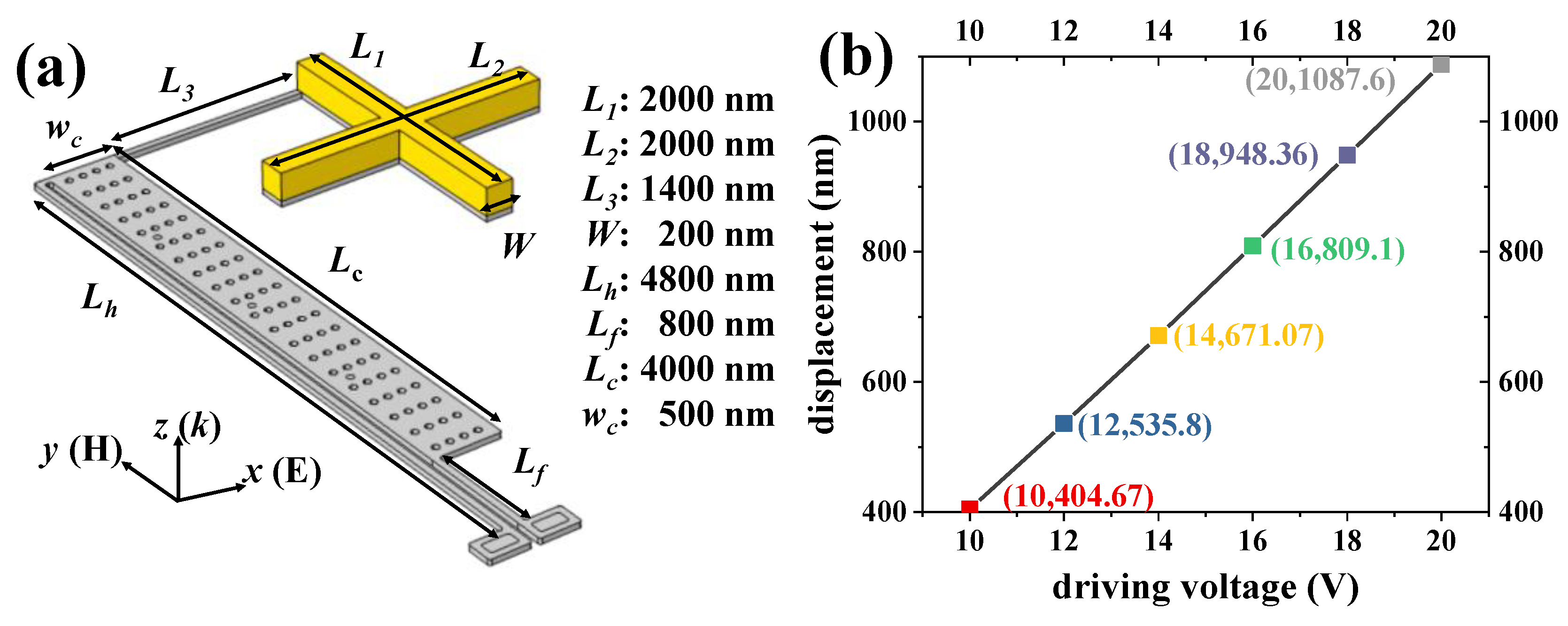

2. Materials and Methods

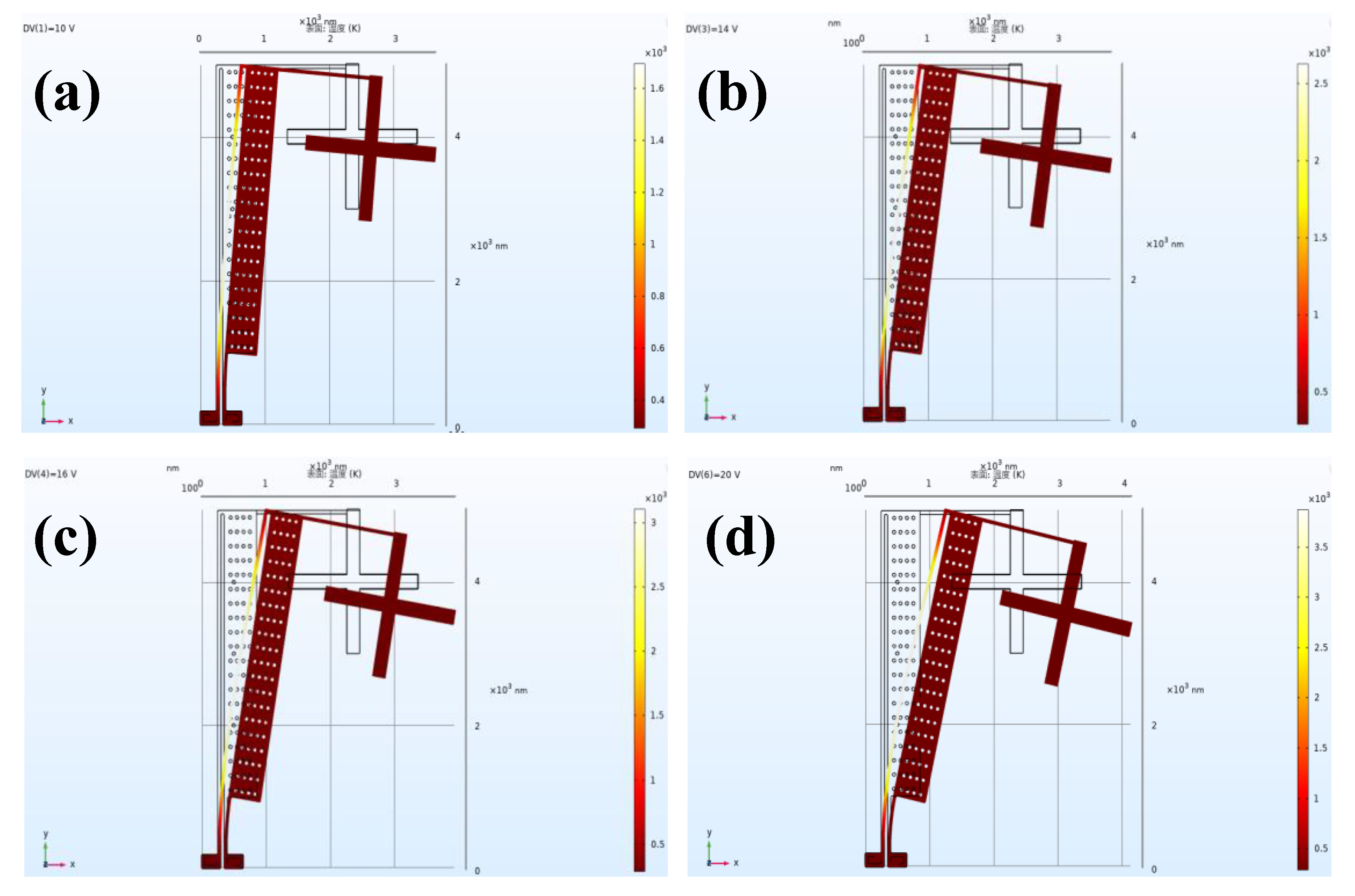

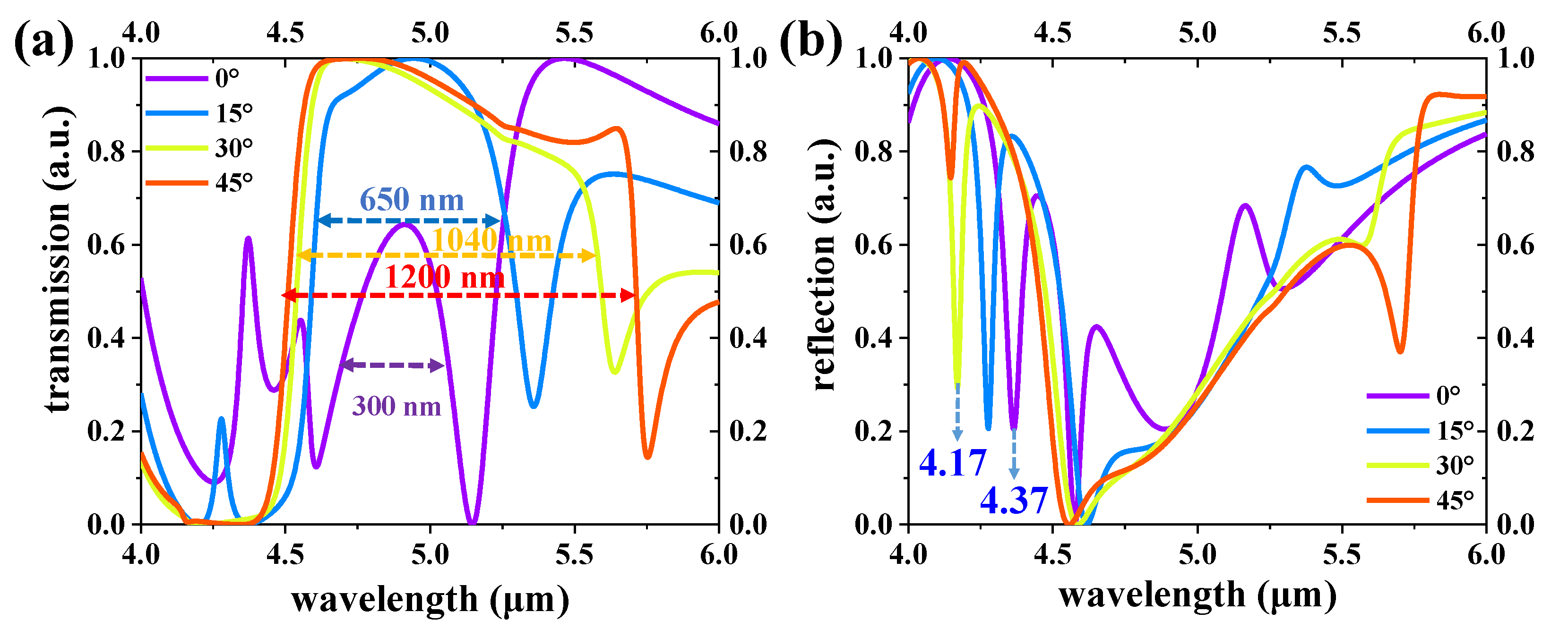

3. Results and Discussions

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kabashin, A.V.; Evans, P.; Pastkovsky, S.; Hendren, W.; Wurtz, G.A.; Atkinson, R.; Pollard, R.; Podolskiy, V.A.; Zayats, A.V. Plasmonic nanorod metamaterials for biosensing. Nat. Mater. 2009, 8, 867–871. [Google Scholar] [CrossRef] [PubMed]

- Sreekanth, K.V.; Alapan, Y.; ElKabbash, M.; Ilker, E.; Hinczewski, M.; Gurkan, U.A.; De Luca, A.; Strangi, G. Extreme sensitivity biosensing platform based on hyperbolic metamaterials. Nat. Mater. 2016, 15, 621–627. [Google Scholar] [CrossRef] [PubMed]

- Garoli, D.; Calandrini, E.; Giovannini, G.; Hubarevich, A.; Caligiuri, V.; De Angelis, F.; Hubarevich, A. Nanoporous gold metamaterials for high sensitivity plasmonic sensing. Nanoscale Horiz. 2019, 4, 1153–1157. [Google Scholar] [CrossRef]

- Lin, Y.-S.; Dai, J.; Zeng, Z.; Yang, B.-R. Metasurface Color Filters Using Aluminum and Lithium Niobate Configurations. Nanoscale Res. Lett. 2020, 15, 77. [Google Scholar] [CrossRef] [PubMed]

- Dai, J.; Xu, R.; Lin, Y.-S.; Chen, C.H. Tunable electromagnetic characteristics of suspended nanodisk metasurface. Opt. Laser Technol. 2020, 128, 106214. [Google Scholar] [CrossRef]

- Lochbaum, A.; Fedoryshyn, Y.; Dorodnyy, A.; Koch, U.; Hafner, C.; Leuthold, J. On-Chip Narrowband Thermal Emitter for Mid-IR Optical Gas Sensing. ACS Photonics 2017, 4, 1371–1380. [Google Scholar] [CrossRef]

- Liu, N.; Mesch, M.; Weiss, T.; Hentschel, M.; Giessen, H. Infrared Perfect Absorber and Its Application as Plasmonic Sensor. Nano Lett. 2010, 10, 2342–2348. [Google Scholar] [CrossRef] [PubMed]

- Mo, Y.; Zhong, J.; Lin, Y.-S. Tunable chevron-shaped infrared metamaterial. Mater. Lett. 2020, 263, 127291. [Google Scholar] [CrossRef]

- Hwang, I.; Yu, J.; Lee, J.; Choi, J.-H.; Choi, D.-G.; Jeon, S.; Lee, J.; Jung, J.-Y. Plasmon-Enhanced Infrared Spectroscopy Based on Metamaterial Absorbers with Dielectric Nanopedestals. ACS Photonics 2018, 5, 3492–3498. [Google Scholar] [CrossRef]

- Liu, P.; Liang, Z.; Lin, Z.; Xu, Z.; Xu, R.; Yao, D.; Lin, Y.-S. Actively tunable terahertz chain-link metamaterial with bidirectional polarization-dependent characteristic. Sci. Rep. 2019, 9, 9917. [Google Scholar] [CrossRef]

- Luo, J.; Lin, Y.-S. High-efficiency of infrared absorption by using composited metamaterial nanotubes. Appl. Phys. Lett. 2019, 114, 051601. [Google Scholar] [CrossRef]

- Lin, Y.-S.; Liao, S.; Liu, X.; Tong, Y.; Xu, Z.; Xu, R.; Yao, D.; Yu, Y. Tunable terahertz metamaterial by using three-dimensional double split-ring resonators. Opt. Laser Technol. 2019, 112, 215–221. [Google Scholar] [CrossRef]

- Dao, T.D.; Ishii, S.; Yokoyama, T.; Sawada, T.; Sugavaneshwar, R.P.; Chen, K.; Wada, Y.; Nabatame, T.; Nagao, T. Hole Array Perfect Absorbers for Spectrally Selective Midwavelength Infrared Pyroelectric Detectors. ACS Photonics 2016, 3, 1271–1278. [Google Scholar] [CrossRef]

- Lin, Y.-S.; Yan, K.; Yao, D.; Yu, Y. Investigation of electromagnetic response of terahertz metamaterial by using split-disk resonator. Opt. Laser Technol. 2019, 111, 509–514. [Google Scholar] [CrossRef]

- Lin, Y.-S. Complementary Infrared Metamaterials for Volatile Organic Solutions Sensing. Mater. Lett. 2017, 195, 55–57. [Google Scholar] [CrossRef]

- Lin, Y.-S.; Chen, W. Perfect meta-absorber by using pod-like nanostructures with ultra-broadband, omnidirectional, and polarization-independent characteristics. Sci. Rep. 2018, 8, 7150. [Google Scholar] [CrossRef]

- Lin, Y.-S.; Chen, W. A large-area, wide-incident-angle, and polarization-independent plasmonic color filter for glucose sensing. Opt. Mater. 2018, 75, 739–743. [Google Scholar] [CrossRef]

- Cheng, S.; Xu, Z.; Yao, D.; Zhang, X.; Zhang, Z.; Lin, Y.-S. Electromagnetically induced transparency in terahertz complementary spiral-shape metamaterials. OSA Contin. 2019, 2, 2137–2144. [Google Scholar] [CrossRef]

- Huang, W.; Xu, R.; Lin, Y.-S.; Chen, C.-H. Three-dimensional pyramid metamaterial with tunable broad absorption bandwidth. AIP Adv. 2020, 10, 035125. [Google Scholar] [CrossRef]

- Hu, X.; Zheng, D.; Lin, Y.-S. Actively tunable terahertz metamaterial with single-band and dual-band switching characteristic. Appl. Phys. A 2020, 126, 110. [Google Scholar] [CrossRef]

- Lin, Z.; Xu, Z.; Liu, P.; Liang, Z.; Lin, Y.-S. Polarization-sensitive terahertz resonator using asymmetrical F-shaped metamaterial. Opt. Laser Technol. 2020, 121, 105826. [Google Scholar] [CrossRef]

- Zheng, D.; Hu, X.; Lin, Y.-S.; Chen, C.-H. Tunable multi-resonance of terahertz metamaterial using split-disk resonators. AIP Adv. 2020, 10, 025108. [Google Scholar] [CrossRef]

- Ou, H.; Lu, F.; Liao, Y.; Zhu, F.; Lin, Y.-S. Tunable terahertz metamaterial for high-efficiency switch application. Results Phys. 2020, 16, 102897. [Google Scholar] [CrossRef]

- Liang, Z.; Wen, Y.; Zhang, Z.; Liang, Z.; Xu, Z.; Lin, Y.-S. Plasmonic metamaterial using metal-insulator-metal nanogratings for high-sensitive refraction index sensor. Results Phys. 2019, 15, 102602. [Google Scholar] [CrossRef]

- Xu, Z.; Lin, Z.; Cheng, S.; Lin, Y.-S. Reconfigurable and tunable terahertz wrench-shape metamaterial performing programmable characteristic. Opt. Lett. 2019, 44, 3944–3947. [Google Scholar] [CrossRef]

- Xu, R.; Lin, Y.-S. Characterizations of reconfigurable infrared metamaterial absorbers. Opt. Lett. 2018, 43, 4783–4786. [Google Scholar] [CrossRef]

- Pereira, M.J.; Matta, M.; Hirsch, L.; Dufour, I.; Briseno, A.L.; Gali, S.M.; Olivier, Y.; Muccioli, L.; Crosby, A.; Ayela, C.; et al. Application of Rubrene Air-Gap Transistors as Sensitive MEMS Physical Sensors. ACS Appl. Mater. Interfaces 2018, 10, 41570–41577. [Google Scholar] [CrossRef]

- Wen, Y.; Liang, Z.; Lin, Y.-S.; Chen, C.-H. Active modulation of polarization-sensitive infrared metamaterial. Opt. Commun. 2020, 463, 125489. [Google Scholar] [CrossRef]

- Manjappa, M.; Pitchappa, P.; Wang, N.; Lee, C.; Singh, R. Active Control of Resonant Cloaking in a Terahertz MEMS Metamaterial. Adv. Opt. Mater. 2018, 6, 1800141. [Google Scholar] [CrossRef]

- Cong, L.; Pitchappa, P.; Lee, C.; Singh, R. Active Phase Transition via Loss Engineering in a Terahertz MEMS Metamaterial. Adv. Mater. 2017, 29, 1700733. [Google Scholar] [CrossRef]

- Liu, M.; Susli, M.; Silva, D.; Putrino, G.; Kala, H.; Fan, S.; Cole, M.; Faraone, L.; Wallace, V.P.; Padilla, W.J.; et al. Ultrathin tunable terahertz absorber based on MEMS-driven metamaterial. Microsyst. Nanoeng. 2017, 3, 17033. [Google Scholar] [CrossRef] [PubMed]

- Cheng, Z.; Toshiyoshi, H. Design of CMOS-MEMS broadband infrared emitter arrays integrated with metamaterial absorbers based on CMOS back-end-of-line. Micro Nano Lett. 2016, 11, 602–605. [Google Scholar] [CrossRef]

- Pitchappa, P.; Manjappa, M.; Ho, C.P.; Singh, R.; Singh, N.; Lee, C. Active Control of Electromagnetically Induced Transparency Analog in Terahertz MEMS Metamaterial. Adv. Opt. Mater. 2016, 4, 541–547. [Google Scholar] [CrossRef]

- Luo, Y.; Kikuta, K.; Han, Z.; Takahashi, T.; Hirose, A.; Toshiyoshi, H. An Active Metamaterial Antenna with MEMS-modulated Scanning Radiation Beams. IEEE Electron Device Lett. 2016, 37, 920–923. [Google Scholar] [CrossRef]

- Haynes, W.M. (Ed.) CRC Handbook of Chemistry and Physics: A Ready-Reference Book of Chemical and Physical Data, 97th ed.; CRC Press: Boca Raton, FL, USA, 2016. [Google Scholar]

- Palik, E.D. Handbook of Optical Constants of Solids; Academic Press: London, UK, 1985. [Google Scholar]

- Huang, Q.-A.; Lee, N.K.S. Analysis and design of polysilicon thermal flexure actuator. J. Micromech. Microeng. 1999, 9, 64–70. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhong, J.; Lin, Y.-S. Electromechanically Rotatable Cross-Shaped Mid-IR Metamaterial. Crystals 2020, 10, 431. https://doi.org/10.3390/cryst10060431

Zhong J, Lin Y-S. Electromechanically Rotatable Cross-Shaped Mid-IR Metamaterial. Crystals. 2020; 10(6):431. https://doi.org/10.3390/cryst10060431

Chicago/Turabian StyleZhong, Jitong, and Yu-Sheng Lin. 2020. "Electromechanically Rotatable Cross-Shaped Mid-IR Metamaterial" Crystals 10, no. 6: 431. https://doi.org/10.3390/cryst10060431

APA StyleZhong, J., & Lin, Y.-S. (2020). Electromechanically Rotatable Cross-Shaped Mid-IR Metamaterial. Crystals, 10(6), 431. https://doi.org/10.3390/cryst10060431