Abstract

In this paper, the ohmic properties of Ti, Al, and Ti-Au composite electrodes on n-type (111) CdZnTe crystal deposited by vacuum evaporation method were first analyzed, and then the rapid annealing of Ti-Au electrode under Ar atmosphere with different temperature and time was explored. The ohmic property and barrier height were evaluated by current–voltage (I–V) and capacitance-voltage (C–V) measurements, and the adhesion strength of various electrodess to CdZnTe was compared. The Ti-Au electrode on CdZnTe showed the lowest leakage current and barrier height, and the highest adhesion strength among the three kinds of electrodes on (111) CdZnTe crystals. The rapid annealing of Ti-Au electrode under Ar atmosphere was proved to improve its ohmic property and adhesion strength, and the optimal annealing temperature and time were found to be 423 K and 6 min, respectively. The barrier height of the Ti-Au/CdZnTe electrode is 0.801 eV through rapid annealing for 6 min at 423 K annealing temperature, and the adhesion is 1225 MPa, which increases by 50% compared with that without rapid annealing.

1. Introduction

CdZnTe nuclear radiation detector can work at room temperature, with high detection efficiency and good energy resolution for X-ray and gamma rays [1,2,3,4,5,6,7,8]. The preparation of CdZnTe nuclear radiation detector with good performance is not only affected by the crystal quality of CdZnTe crystal, but also associated with the contact of electrode. The electrode can directly affect the electrical performance of the device, and the leakage current, electric field distribution, and carrier transport of the semiconductor device are closely related to the electrode [9,10].

At present, the contact performance between CdZnTe crystal and the electrode is mainly improved by the selection of electrode materials, surface treatment, and annealing process after the preparation of the electrode. Sun et al. [11] observed the crystal surface of CdZnTe by scanning electron microscopy and transmission electron microscopy. The results showed that there was a 9.2% lattice mismatch between Au atom and Te after chemical polishing. Tari et al. [12] studied the element composition of the interface between CdZnTe and Au electrodes by X-ray Photoelectron Spectroscopy (XPS). It was found that, when CdZnTe crystals were exposed to atmospheric environment for few hours, a native oxide layer formed on the surface of CdZnTe, which was harmful to the electrical properties of CdZnTe crystals. Yang et al. [13] found that evaporating Au-Zn composite electrodes on the (111) surface of CdZnTe crystal can effectively avoid the formation of an oxide layer. Ling et al. [14] indicated that the Au-Cd composite electrode evaporated on p-CdZnTe (111) plane can obtain better ohmic contact performance with a lower barrier height than the Au-Zn electrode. The adhesion between metal electrode and CdZnTe crystal is important for the detector fabrication process. Bell et al. [15] found that the electrode may adhere to the photoresist during the fabrication of pixel CdZnTe detectors, which causes the electrode to be lost before lithography.

In this paper, Ti, Al, and Ti-Au electrodes were selected to deposit on the surface of n-type (111) CdZnTe crystals by the vacuum evaporation method. The electric properties of the three kinds of electrodes are evaluated by current–voltage (I–V) measurement, and the potential barrier height between the three electrodes and the crystal interface is calculated by capacitance-voltage (C–V) measurement. The characteristics of the Ti-Au composite electrode through different annealing processes are analyzed. The results show that the best ohmic characteristics and adhesion are obtained after 6 min rapid annealing at 423 K annealing temperature.

2. Experimental

2.1. Electrodes Depositions

The In-doped CdZnTe crystals were grown by the vertical Bridgman method with n-type conductivity. For the ohmic contact of n-type CdZnTe crystal, according to the metal–semiconductor contact principle, metal with a small work function was selected to form the n-type anti-barrier layer between the metal and semiconductor. The work functions of metal Al and Ti are smaller than n-type CdZnTe [16]. Therefore, the Al and Ti electrodes were chosen to study the ohmic property with n-type CdZnTe crystals. In order to decrease the low thermal stability and oxidation effect of Ti electrodes, the Au film was deposited on the Ti electrode to form the Ti-Au composite electrode on CdZnTe crystal.

Three adjacent n-type (111) CdZnTe crystals with dimensions of 10 × 10 × 2 mm3 were used to prepare Ti, Al, and Ti-Au metal electrodes. The crystals were chemically and mechanically polished by a Logitech PM6 polisher. Then, the metal electrodes were deposited on CdZnTe crystals by the vacuum evaporation method with MBE-600. During the evaporation process, the vacuum degree was higher than 2 × 10−3 Pa, the current was lower than 130 A, and the evaporation time was controlled at about 10 min.

The Ti-Au composite electrode was prepared by depositing Ti layer on the chemical mechanical polished CdZnTe crystal, and then depositing Au on the Ti layer. The Ti-Au composite electrode was then held for 30 minutes to promote the alloying process. The I–V and C–V electrical performance test instruments used were as follows: Keithley 4200SCS (Shanghai, China) semiconductor property analysis system, with a bias range of –20~20 V and a minimum step size of 0.1V; HP4140B micro-current tester (Agilent Tech, Shanghai, China), with a measuring range of 10−5–10−2 A and a maximum resolution of 10−15 A.

2.2. Annealing of Ti-Au/CdZnTe Electrode

The Ti-Au/CdZnTe composite electrode was deposited on the surface of n-CdZnTe crystal by the vacuum evaporation method. Then, the crystals were placed in AG610, which is an atmosphere annealing furnace. The effects of annealing temperature and annealing time on the contact properties of Ti-Au/CdZnTe were studied under an argon (Ar) atmosphere.

Firstly, the annealing temperature was selected to be 373 K, 423 K, 473 K, 523 K, and 573 K, respectively, and the Ti-Au/CdZnTe electrode was annealed for 4 min to determine the optimal annealing temperature parameters. Secondly, the Ti-Au/CdZnTe electrode was rapidly annealed for 2 min, 4 min, 6 min, 8 min, and 10 min at the optimal temperature, respectively. In the process of rapid annealing, the temperature was rapidly raised to the target annealing temperature in 30 seconds, and then the annealing was conducted according to the set annealing time. After the annealing, the temperature was rapidly cooled to room temperature.

3. Results and Discussions

3.1. Comparison of Ti, Al, and Ti-Au Electrodes to CdZnTe Crystals

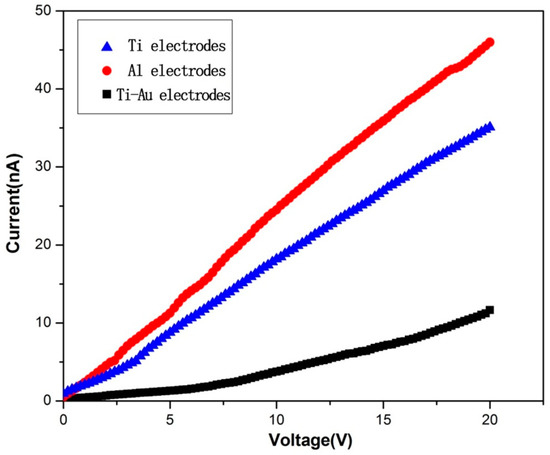

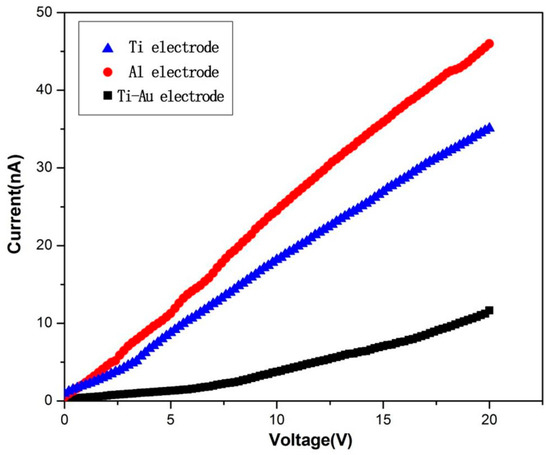

Figure 1 lists the I–V characteristic curves of Ti, Al, and Ti-Au composite electrodes, which are fitted according to the ohmic characteristic formula I(V) = aVb, where a is a constant, b is the ohmic coefficient, and b = 1 is the ideal ohmic contact. The fitting results are shown in Table 1. It can be seen that the ohmic characteristics of Al electrode are poor, and the leakage current at 20 V is the highest. The ohmic coefficient of Ti-Au composite electrode is the closest to 1, indicating that the ohmic characteristic is good and the leakage current is the lowest.

Figure 1.

The current–voltage (I–V) characteristic curves of Ti, Al, and Ti-Au electrodes to (111) CdZnTe crystals.

Table 1.

The current–voltage (I–V) curves fitting results of Ti, Al, and Ti-Au electrodes to n-type (111) CdZnTe crystals.

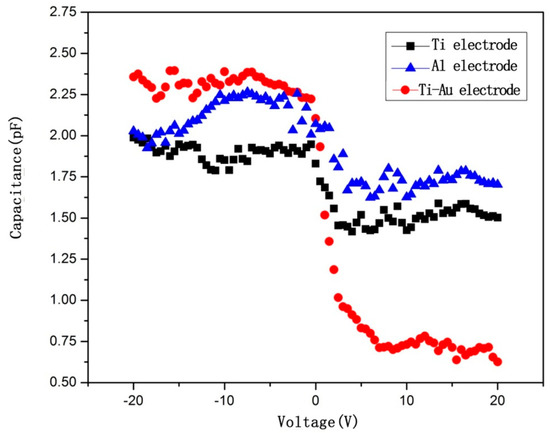

The C–V measurement was carried out on Ti, Al, and Ti-Au electrodes with the test frequency of 1 MHz, and the results are shown in Figure 2. It can be seen that the change trend of capacitance C of Ti-Au/CdZnTe with applied voltage is the most obvious, and its carrier concentration is the highest. The CdZnTe detector acts as a parallel plate capacitor. When the detector is applied with a positive voltage, electrons will enter the metal from the semiconductor, and the reverse current will increase. The hole concentration in the space charge region will decrease compared with the equilibrium. To achieve equilibrium, the width of the space charge region will increase continuously, and the capacitance C will decrease until the device is completely exhausted. Therefore, the carrier concentration can be determined by comparing the curve of capacitance C with applied voltage V [17].

Figure 2.

The capacitance-voltage (C–V) characteristic curves of Ti, Al, and Ti-Au electrodes to (111) CdZnTe crystals.

According to the C–V test, the barrier height ΦB can be calculated as follows:

where Vint is the intercept of the characteristic on axis V; q is the electron charge; and NA and NV are the acceptor impurity concentration and valence band effective state density, respectively, which are calculated by the following equations:

where is the relative dielectric constant of crystal, is the vacuum dielectric constant, V is the external voltage, and C is the junction capacitance. The calculation results are shown in Table 2. The barrier height of Al/CdZnTe is lower than that of Ti/CdZnTe. This may because of the higher diffusion of Al through the interface compared with Ti in CdZnTe, which lowers the barrier height of Al/CdZnTe, but also has the effect of increasing the leakage current, as shown in Figure 1. The Ti-Au/CdZnTe sample has the smallest barrier height, which indicates that the Ti-Au electrode can form better ohmic contact with n-type (111) CdZnTe crystalthan the other two electrodes. The barrier height is determined by the work functions of the metal and semiconductor and the presence of surface states. Owing to the low thermal stability of Al and Ti metal electrodes, oxidation will occur during the evaporation process, resulting in a rough electrode surface and formation of oxides, leading to degradation of ohmic contact properties. As the Au electrode is not easily oxidized, it is assumed that the Ti-Au composite electrode formed by Au coverage on Ti has the effect of decreasing the surface state, which favours the ohmic property.

Table 2.

The barrier heights of Ti, Al, and Ti-Au electrodes to n-type (111) CdZnTe crystals.

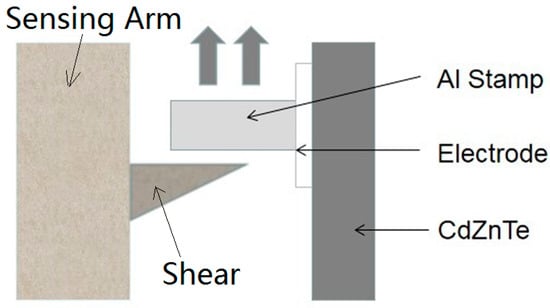

The adhesion strength between the Ti, Al, and Ti-Au electrodes and CdZnTe crystals was measured by a Dage PC 2400 microanalyzer. This experiment is destructive on contact electrodes by the shear-off method, which is generally used to measure the adhesion of two contact objects [18]. The test principle is shown in Figure 3.

Figure 3.

The schematic diagram of the film adhesion test.

The adhesion strength between the electrodes and CdZnTe crystals was calculated by the thrust (F) and the adhesion area (A) of the Al block. The formula is as follows:

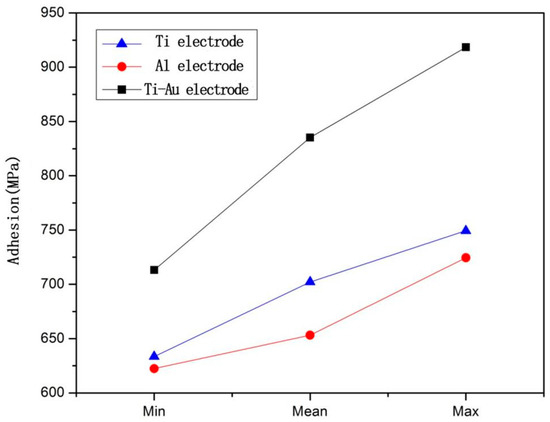

The adhesion strength between the Ti, Al, and Ti-Au electrodes and CdZnTe crystals was measured three times, and the average values were taken, which are shown in Figure 4. It can be seen that the adhesion between the Ti-Au electrode and CdZnTe crystal is significantly higher than that of the Ti and Al electrode, with the average adhesion strength of 835.3 Mpa.

Figure 4.

The adhesion between the Ti, Al, and Ti-Au electrodes and CdZnTe crystals.

3.2. Rapid Annealing of Ti-Au/CdZnTe

3.2.1. Effect of Annealing Temperature on Ti-Au/CdZnTe

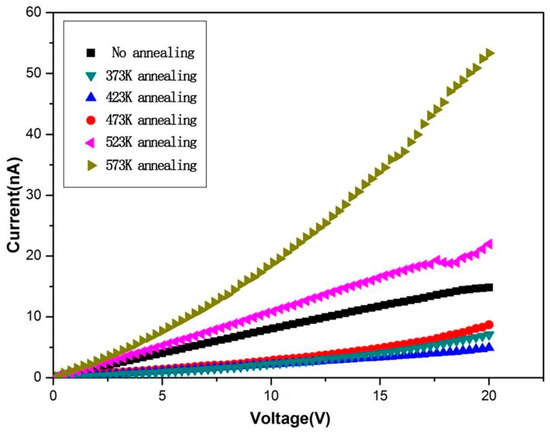

Five n-type CdZnTe crystals deposited with Ti-Au composite electrode are used for rapid annealing experiments at different annealing temperatures (373 K, 423 K, 473 K, 523 K, and 573 K) for 4 min. The effect of annealing temperature on the Ti-Au/CdZnTe electrode is first studied by I–V measurements, as shown in Figure 5. The fitting results of I–V curves are shown in Table 3. The results indicate that, with the increase of annealing temperature from no annealing to 423 K, the leakage current of the Ti-Au/CdZnTe sample decreases. When the annealing temperature is 423 K, the leakage current is the lowest. When the temperature continues to increase, however, the leakage current rises sharply. The results of the ohmic characteristic with different annealing temperature revealed the same trend, as the annealing temperature is 423 K, the ohmic coefficient b is closer to 1. When the annealing temperature is higher than 573 K, the ohmic contact property of the electrode decreases, and the leakage current is the highest. In the initial process of rapid annealing, the leakage current decreases and the ohmic contact performance improves, mainly because the annealing treatment reduces defects in the crystal, increases alloying of Ti-Au composite electrode, and finally forms a diffusion layer in the interface between the electrode and CdZnTe crystal [19]. However, when the temperature is further increased, the diffusion layer penetrates to the depth of the crystal, which leads to the increase of leakage current. Meanwhile, the high annealing temperature also reduces the uniformity of electrode surface and interface. Therefore, a suitable rapid annealing temperature with 423 K can effectively improve the ohmic property of the Ti-Au/CdZnTe sample.

Figure 5.

The I–V curves of the Ti-Au/CdZnTe sample after rapid annealing for 4 min at different temperatures.

Table 3.

The I–V curves fitting results of Ti-Au/CdZnTe after rapid annealing at different temperatures for 4 min.

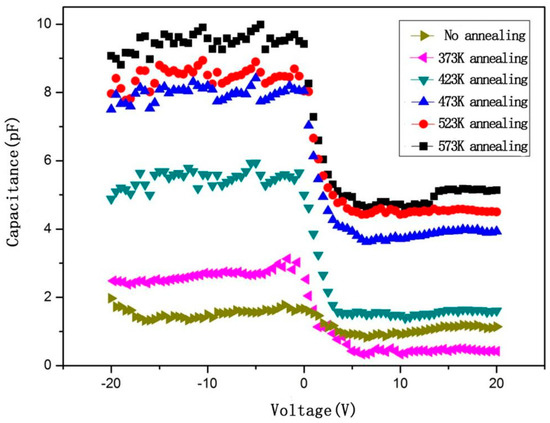

The C–V tests were carried out on Ti-Au/CdZnTe at different annealing temperatures, as shown in Figure 6. When the temperature rises to more than 423 K, the value of capacitance C becomes larger with the negative applied voltage. The barrier height ΦB is calculated by Equation (1), and is shown in Table 4. It was found that the barrier height of the Ti-Au electrode to CdZnTe decreases with the increase in temperature. As the annealing temperature increases, the concentration of the principal impurity NA gradually increases, and the width of the interface barrier decreases. When the NA value is high enough, the interface is close to heavy doping. Thus, the leakage current increases greatly owing to the tunneling effect, and the barrier height decreases at an elevated temperature.

Figure 6.

The C–V curves of the Ti-Au/CdZnTe sample after rapid annealing for 4 min at different temperatures.

Table 4.

The barrier heights of Ti-Au/CdZnTe after rapid annealing at different temperatures for 4 min.

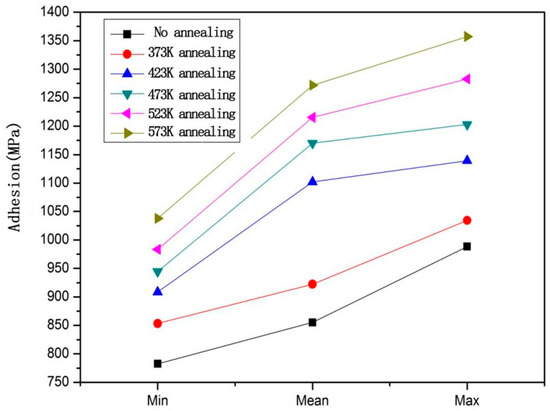

The metal electrode deposited on the CdZnTe crystal by the vacuum evaporation method can be easily peeled off in the process of electrode lead owing to its low adhesion, which will affect the subsequent device preparation process and detector performance. Therefore, it is very important to improve the adhesion strength between the electrode and CdZnTe crystal. Theoretically, rapid annealing can enhance the mutual diffusion movement between the electrode and CdZnTe crystal, and thus improve the adhesion between them. A Dage PC2400 microanalyzer was used to measure the adhesion strength of the Ti-Au/CdZnTe electrode, which is treated at different annealing temperatures for 4 min, and the calculated values of adhesion strength are shown in Figure 7. It was found that, from no annealing to 423 K annealing, the average adhesion strength between Ti-Au and CdZnTe crystals increases from 835.3 Mpa to 1100 Mpa, an increase of 30%. With the annealing temperature above 423 K, the increase of adhesion strength slows down.

Figure 7.

The adhesion between Ti-Au and CdZnTe after rapid annealing at different temperatures for 4 min.

3.2.2. Effect of Annealing Time on Ti-Au/CdZnTe

It was proved that the ohmic contact characteristics and adhesion of Ti-Au/CdZnTe were significantly improved after annealing at 423 K. Then, the Ti-Au/CdZnTe sample was rapidly annealed at 423 K with different annealing times (2 min, 4 min, 6 min, 8 min, and 10 min) to study the influence of annealing time on the contact performance of Ti-Au/CdZnTe.

Figure 8 shows the I–V characteristic curves of the sample after rapid annealing at 423 K for different times. The I–V characteristic curves are fitted according to the ohmic characteristic formula, and the results are shown in Table 5. It can be seen that, at the annealing temperature of 423 K, when the annealing time reaches 6 min, the leakage current is the lowest and the ohmic contact performance is the best. However, when the annealing time continues to increase to 8 min and 10 min, the leakage current increases obviously and the ohmic contact performance becomes worse.

Figure 8.

The I–V curves of the Ti-Au/CdZnTe sample annealed at 423 K for different times.

Table 5.

The I–V curves fitting results of Ti-Au/CdZnTe annealed at 423 K for different times.

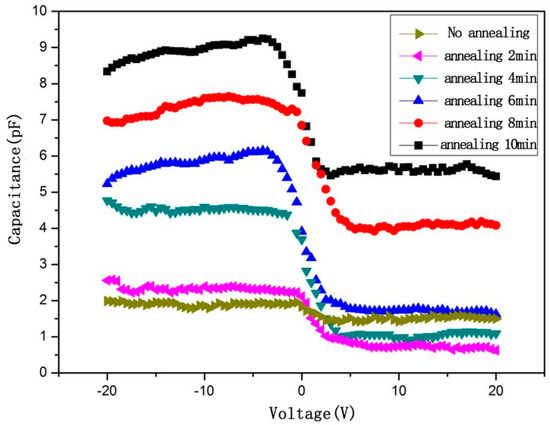

The C–V measurement was performed on the Ti-Au/CdZnTe sample annealed at 423 K for different times, and the results are shown in Figure 9. When the Ti-Au/CdZnTe sample is annealed at 423 K temperature for 4~10 min, the capacitance C changes significantly with the change of external bias voltage V. The potential barrier height ΦB is calculated by Equation (1), and the results are shown in Table 6. The barrier height ΦB of Ti-Au/CdZnTe decreases after different annealing times. When the annealing time is longer than 6 min, the ΦB value changes slowly, which may because of the increase in defects in the crystal and the production of the non-stoichiometric ratio during the long time annealing.

Figure 9.

The C–V curves of the Ti-Au/CdZnTe samples annealed at 423 K in an Ar atmosphere for different times.

Table 6.

The barrier heights of Ti-Au/CdZnTe annealed at 423 K for different times.

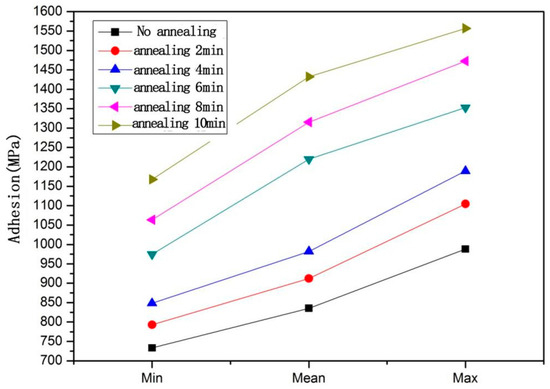

The relationship between the adhesion strength of Ti-Au/CdZnTe and annealing time at 423 K is compared, as shown in Figure 10. It was found that the adhesion strength between Ti-Au and CdZnTe was 1225 MPa after 6 min annealing, which is 10% higher than that after 4 min annealing and 50% higher than that without annealing. Then, when the annealing time is longer than 6 min, the increase rate of the adhesion strength of Ti-Au/CdZnTe decreases. Considering the effect of rapid annealing on the leakage current, ohmic characteristics, and adhesion strength of the Ti-Au/CdZnTe electrode, the optimal annealing temperature and time is 423 K and 6 min, respectively.

Figure 10.

The adhesion between Ti-Au and CdZnTe after rapid annealing at 423 K for different times.

4. Conclusions

Ti, Al, and Ti-Au electrodes were deposited on the surface of n-type (111) CdZnTe crystal by the vacuum evaporation method. I–V, C–V, and adhesion strength measurements between the various electrodes and CdZnTe crystals were investigated, which indicate that the Ti-Au electrode on CdZnTe shows the lowest leakage current and barrier height, and the highest adhesion strength. Then, the rapid annealing in the Ar atmosphere is used to optimize the contact properties of Ti-Au/CdZnTe. The I–V results show that the Ti-Au/CdZnTe electrode had the best ohmic characteristics after rapid annealing at 423 K annealing temperature for 6 min, with an ohmic coefficient of 0.9157 and leakage current of 3.12 nA at 20 V. The barrier height of the Ti-Au/CdZnTe electrode is 0.801 eV through rapid annealing for 6 min at 423 K annealing temperature, and the adhesion is 1225 MPa, which increases by 50% compared with that without rapid annealing. The results indicate that the Ti-Au composite electrode is a promising ohmic contact to n-type (111) CdZnTe crystal, and the rapid annealing in the Ar atmosphere could improve the ohmic property and adhesion of Ti-Au/CdZnTe contact, with the optimal annealing temperature and time found to be 423 K and 6 min, respectively.

Author Contributions

Conceptualization, H.S.; methodology, S.W.; formal analysis, J.H.; investigation, H.S.; data curation, Z.S. and J.M.; writing—original draft preparation, H.S.; writing—review and editing, S.W.; supervision, L.W.; project administration, J.Z. All authors have read and agree to the published version of the manuscript.

Funding

This research was funded by National Natural Science Foundation of China, grant number 51472155, 11675099, 11505109.

Acknowledgments

The authors are grateful to the National Natural Science Foundation of China under grant (No. 51472155, 11675099, 11505109).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Takahashi, T.; Watanabe, S. Recent progress in CdTe and CdZnTe detectors. IEEE Trans. Nucl. Sci. 2001, 48, 950–959. [Google Scholar] [CrossRef]

- Limousin, O. New trends in CdTe and CdZnTe detectors for X-and gamma-ray applications. Methods Phys. Res. A 2003, 504, 24–37. [Google Scholar]

- Amman, M.; Lee, J.S.; Luke, P.N.; Chen, H.; Awadalla, S.A.; Redden, R.; Bindley, G. Evaluation of THM-grown CdZnTe material for large-volume gamma-ray detector applications. IEEE Trans. Nucl. Sci. 2009, 56, 795–799. [Google Scholar] [CrossRef]

- Verger, L.; Bonnefoy, J.P.; Glasser, F.; Ouvrier-Buffet, P. New developments in CdTe and CdZnTe detectors for X and γ-ray applications. J. Electron. Mater. 1997, 26, 738–744. [Google Scholar] [CrossRef]

- Awadalla, S.A.; Mackenzie, J.; Chen, H.; Redden, B.; Bindley, G.; Duff, M.C.; Burger, A.; Groza, M.; Buliga, V.; Bradley, J.P.; et al. Characterization of detector-grade CdZnTe crystals grown by traveling heater method (THM). J. Cryst. Growth 2010, 312, 507–513. [Google Scholar] [CrossRef]

- Szeles, C. CdZnTe and CdTe materials for X-ray and gamma ray radiation detector applications. Stat. Sol. 2004, 241, 783–790. [Google Scholar] [CrossRef]

- Duff, M.C.; Hunter, D.B.; Burger, A.; Groza, M.; Buliga, V.; Bradley, J.P.; Graham, G.; Dai, Z.R.; Teslich, N.; Black, D.R.; et al. Characterization of heterogeneities in detector-grade CdZnTe crystals. J. Mater. Res. 2009, 24, 1361–1367. [Google Scholar] [CrossRef]

- Yu, P.; Chen, Y.; Li, W.; Liu, W.; Liu, B.; Yang, J.; Ni, K.; Luan, L.; Zheng, J.; Li, Z.; et al. Study of Detector-Grade CdMnTe: In Crystals Obtained by a Multi-Step Post-Growth Annealing Method. Crystals 2018, 8, 387. [Google Scholar] [CrossRef]

- Bolotnikov, A.E.; Camarda, G.C.; Carini, G.A.; Fiederle, M.; Li, L.; McGregor, D.S.; McNeil, W.; Wright, G.W.; James, R.B. Performance characteristics of Frisch-ring CdZnTe detectors. IEEE Trans. Nucl. Sci. 2006, 53, 607–614. [Google Scholar] [CrossRef]

- Chen, H.; Awadalla, S.A.; Iniewski, K.; Lu, P.H.; Harris, F.; Mackenzie, J.; Hasanen, T.; Chen, W.; Redden, R.; Bindley, G. Characterization of large cadmium zinc telluride crystals grown by traveling heater method. J. Appl. Phys. 2008, 103, 014903. [Google Scholar] [CrossRef]

- Sun, J.; Fu, L.; Nie, Z.; Shi, Y.; Li, Y. The effect of chemical polishing on the interface structure and electrical property of Au/Cd 0.9 Zn 0.1 Te contact. Appl. Phys. A 2014, 115, 1309–1316. [Google Scholar] [CrossRef]

- Tari, S.; Aqariden, F.; Chang, Y.; Ciani, A.; Grein, C.; Li, J.; Kioussis, N. Structural and electronic properties of gold contacts on CdZnTe with different surface finishes for radiation detector applications. J. Electron. Mater. 2014, 43, 2978–2983. [Google Scholar] [CrossRef]

- Yang, L.; Min, J.; Liang, X.; Liu, Z.; Lin, Y.; Zhang, J.; Wang, L.; Shen, Y.; Zhang, Y.; Li, M. Investigation on the contact interface of Au/Zn on CdZnTe (111) B surface. Mater. Sci. Semicond. Process. 2017, 67, 175–180. [Google Scholar] [CrossRef]

- Ling, L.; Zhang, J.; Zhao, S.; Zhang, D.; Zhang, J.; Shi, H.; Tang, K.; Liang, X.; Huang, J.; Min, J.; et al. Surface analysis and electrical measurement of the ohmic contact on p-CdZnTe (111) B face with Au/Cd composite electrode. Mater. Sci. Semicond. Process. 2019, 98, 90–94. [Google Scholar] [CrossRef]

- Bell, S. Fabrication and Characterisation of Gold Contacts on CdZnTe Radiation Detectors; University of Surrey: Guildford, UK, 2015. [Google Scholar]

- Liang, X.Y.; Min, J.H.; Chen, J.; Wang, D.; Li, H.; Wang, Y.; Wang, L.J.; Zhang, J.J. Metal/semiconductor contacts for schottky and photoconductive CdZnTe detector. Phys. Procedia 2012, 32, 545–550. [Google Scholar] [CrossRef][Green Version]

- Talasek, R.T. Electrochemistry of Semiconductors and Electronics; McHardy, J., Bahir, F.G., Eds.; Noyes Publications: Park Ridge, IL, USA, 1992; p. 127. [Google Scholar]

- Sang, W.; Wei, J.; Qi, Z.; Wanwan, L.; Jiahua, M.; Jianyong, T.; Yongbiao, Q. Primary study on the contact degradation mechanism of CdZnTe detectors. Nucl. Instrum. Methods Phys. Res. A 2004, 527, 487–492. [Google Scholar] [CrossRef]

- Xie, J.; Liu, Y.; Wang, C. Au Film Electrodes on CdZnTe Surface: Preparation and Ohmic Contact Property. J. Inog. Mater. 2018, 33, 273–278. [Google Scholar]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).