Designing (Ultra)Fine-Grained High-Entropy Alloys by Spark Plasma Sintering and Equal-Channel Angular Pressing

Abstract

1. Introduction

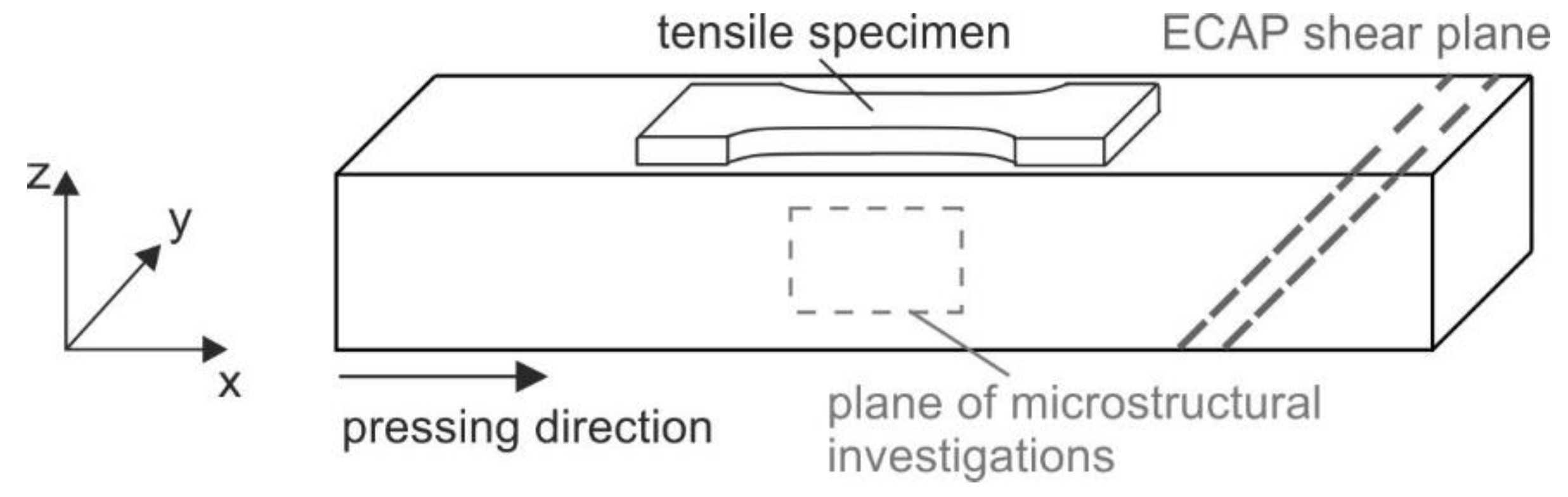

2. Materials and Methods

3. Results and Discussion

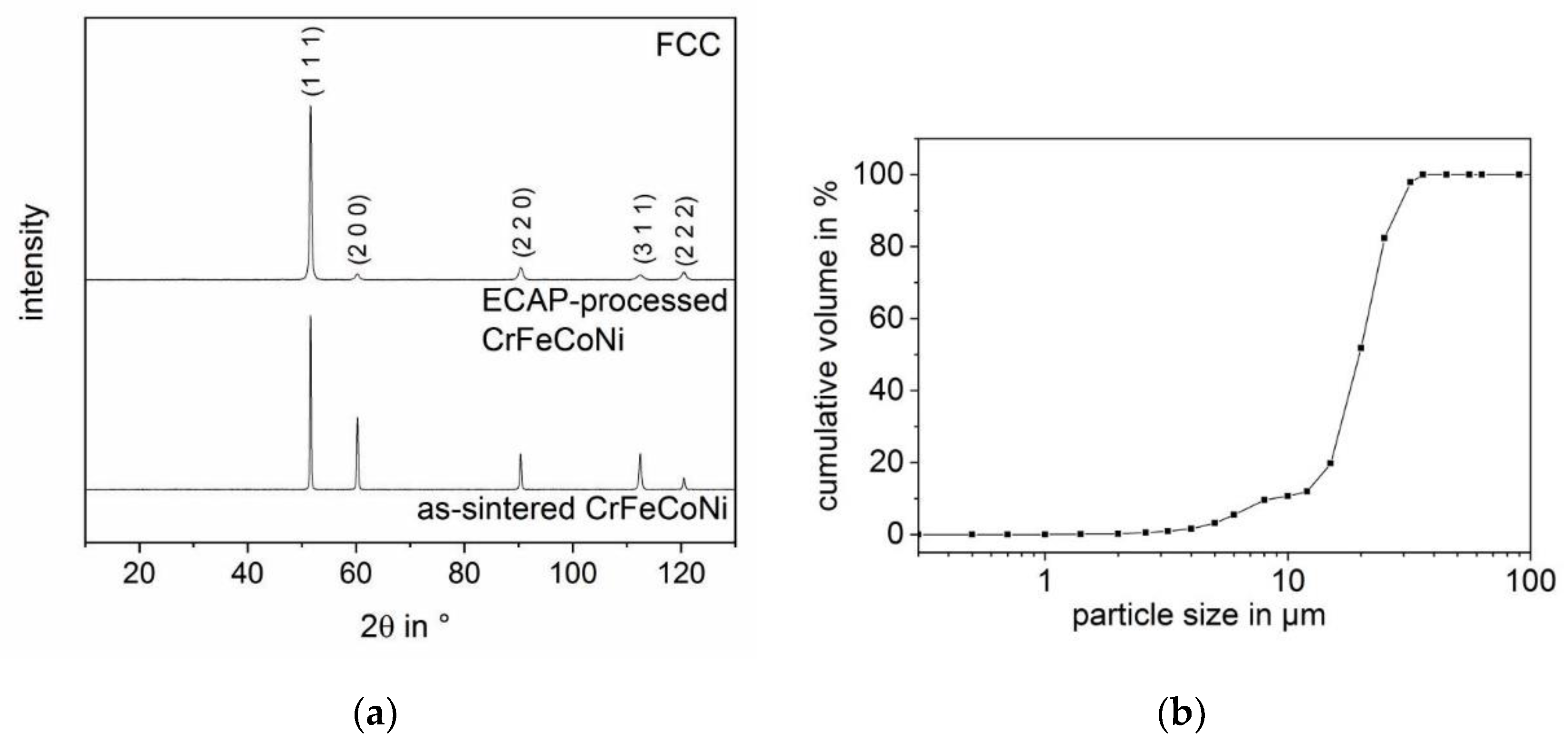

3.1. Phase Composition and Particle Size Distribution

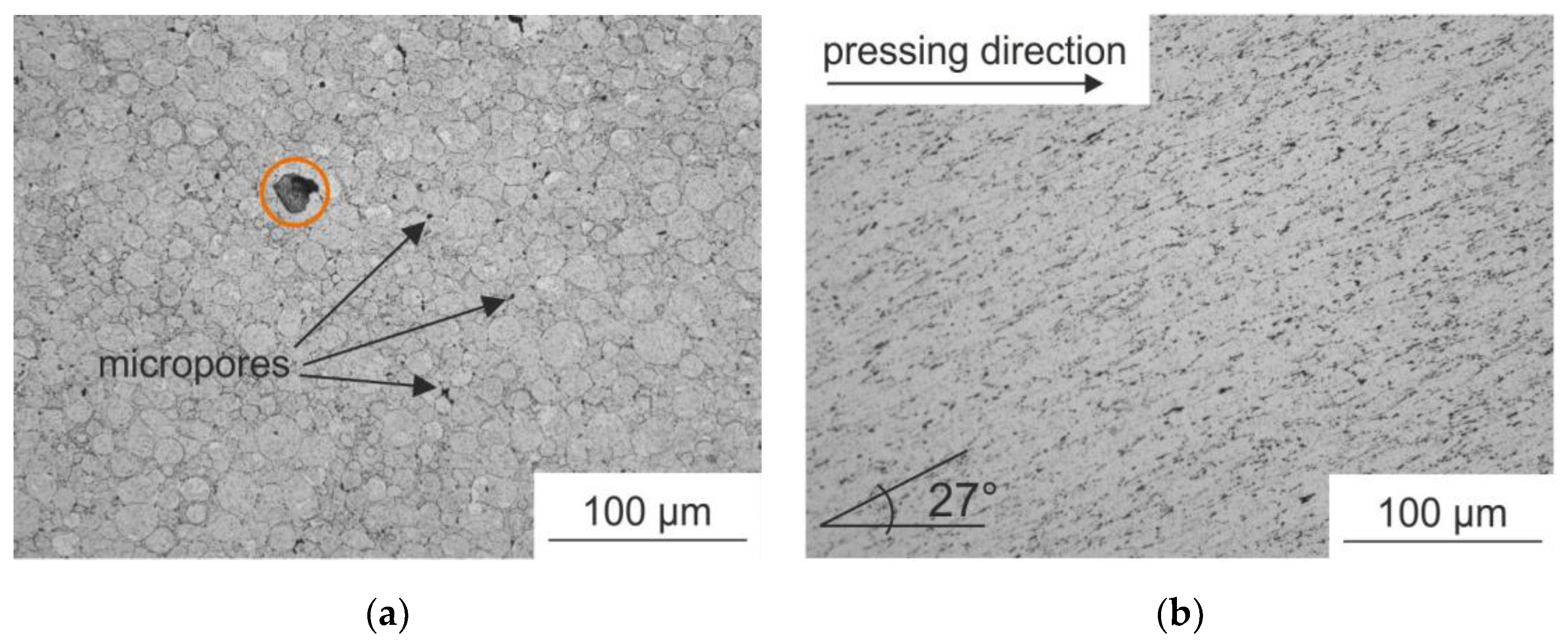

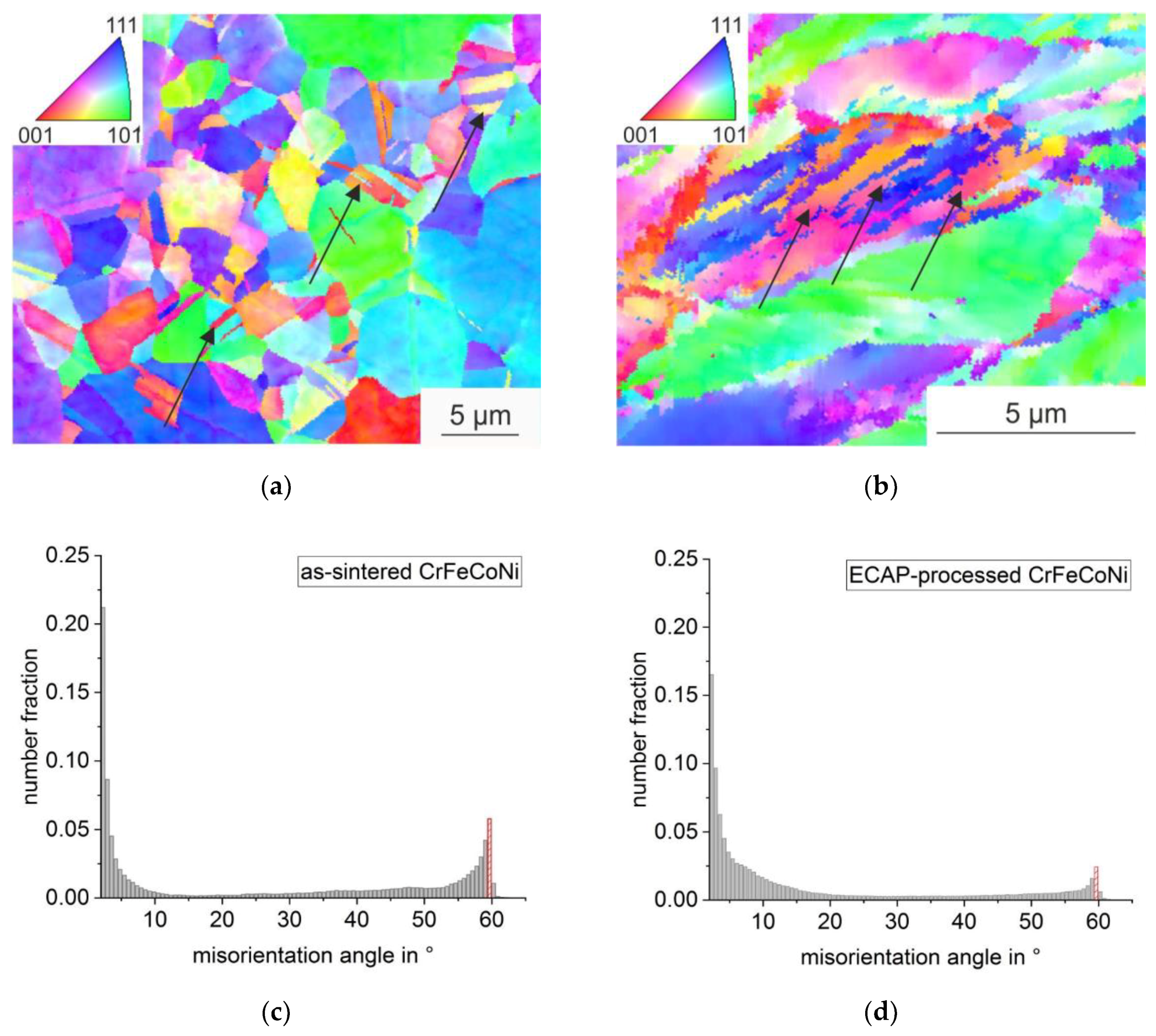

3.2. Microstructural Characterization

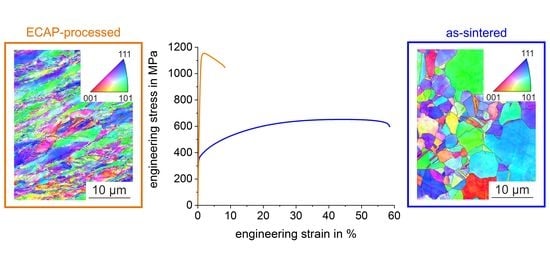

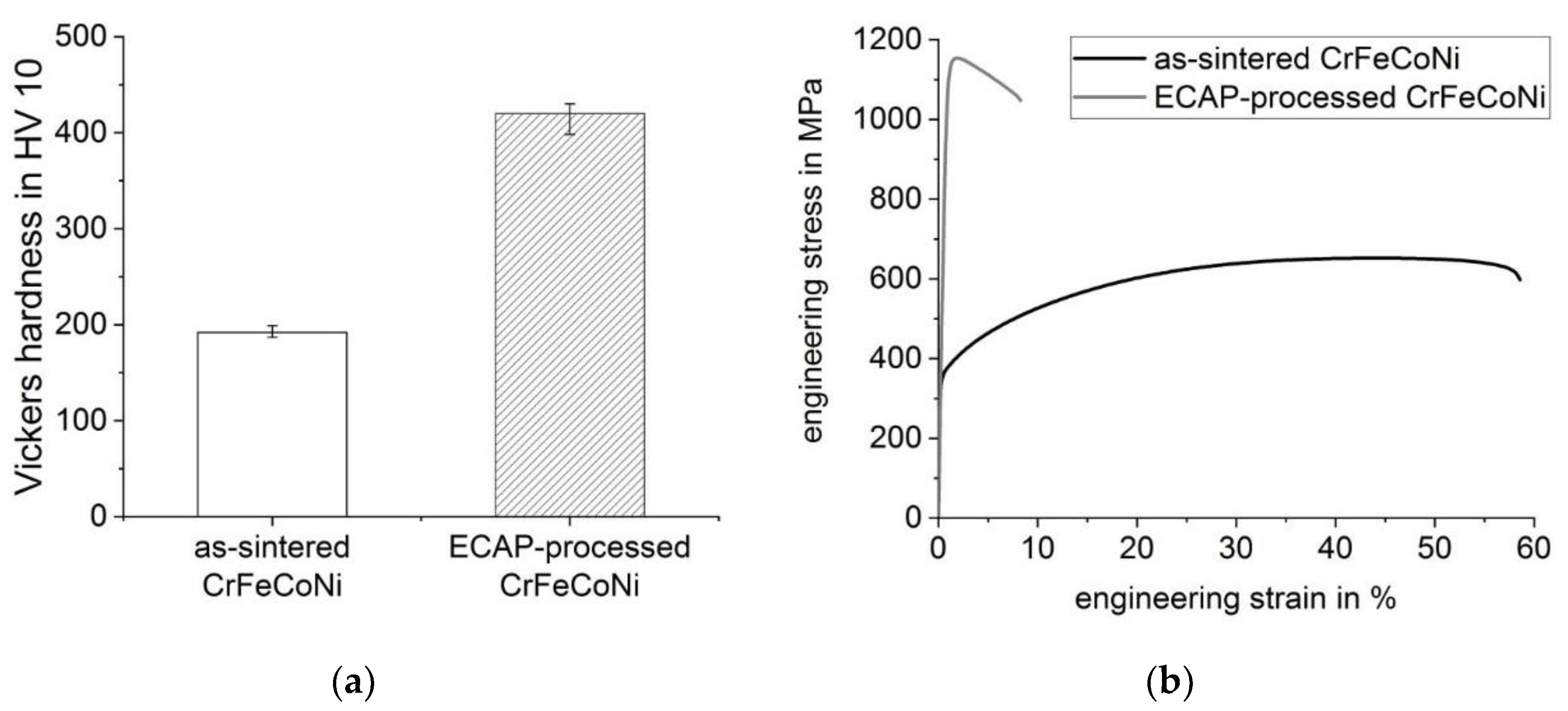

3.3. Mechanical Characterization

4. Conclusions

- (1)

- XRD measurements reveal an FCC structure before and after ECAP-processing of sintered CrFeCoNi, showing that the single-phase state was retained. However, the peaks of the ECAP-processed material are broadened, which is typical after ECAP-processing.

- (2)

- Microstructural investigations (by optical microscopy and EBSD) confirm a considerable grain refinement. ECAP-processing leads to a majority of grains with a size below 1 µm. The corresponding microstructure is characterized by elongated grains due to the induced simple shear deformation. Differently distorted areas are found. Fine-grained areas alternate with areas characterized by much coarser grains. Both areas are arranged under an angle of approximately 27° (to the pressing direction). The thickness of the large twins (up to several µm) in the as-sintered material was reduced by ECAP to approximately 100–300 nm. From the present study, it is assumed that the dominating deformation mechanism in the investigated CrFeCoNi HEA during ECAP-processing is dislocation slip.

- (3)

- The mechanical properties (hardness and tensile properties) are significantly increased due to the introduction of defects and the formation of HAGBs during ECAP. Compared to a cast condition of the same alloy, the sintered condition shows significantly different mechanical properties. For instance, the YS of the as-sintered HEA is 150% higher than that of a cast counterpart (reported in the literature). A further significant increase of YS and UTS is found after a single pass of ECAP. The YS is increased to more than 1 GPa. A comparison of both conditions (as-sintered, ECAP-deformed) reveals a fundamentally different strain hardening behavior of CrFeCoNi, which is discussed in detail.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Yeh, J.W.; Chen, S.K.; Lin, S.J.; Gan, J.Y.; Chin, T.S.; Shun, T.T.; Tsau, C.H.; Chang, S.Y. Nanostructured high-entropy alloys with multiple principal elements: Novel alloy design concepts and outcomes. Adv. Eng. Mater. 2004, 6, 299–303. [Google Scholar] [CrossRef]

- Miracle, D.B.; Senkov, O.N. A critical review of high entropy alloys and related concepts. Acta Mater. 2017, 122, 448–511. [Google Scholar] [CrossRef]

- Gwalani, B.; Soni, V.; Lee, M.; Mantri, S.A.; Ren, Y.; Banerjee, R. Optimizing the coupled effects of Hall-Petch and precipitation strengthening in a Al0.3CoCrFeNi high entropy alloy. Mater. Des. 2017, 121, 254–260. [Google Scholar] [CrossRef]

- Gwalani, B.; Gorsse, S.; Choudhuri, D.; Zheng, Y.; Mishra, R.S.; Banerjee, R. Tensile yield strength of a single bulk Al0.3CoCrFeNi high entropy alloy can be tuned from 160 MPa to 1800 MPa. Scr. Mater. 2019, 162, 18–23. [Google Scholar] [CrossRef]

- Liu, K.; Komarasamy, M.; Gwalani, B.; Shukla, S.; Mishra, R.S. Fatigue behavior of ultrafine grained triplex Al0.3CoCrFeNi high entropy alloy. Scr. Mater. 2019, 158, 116–120. [Google Scholar] [CrossRef]

- Shukla, S.; Mishra, R.S. Excellent high cycle fatigue properties of a novel ultrafine-grained medium entropy alloy. Mater. Sci. Eng. A 2020, 779, 139122. [Google Scholar] [CrossRef]

- Gubicza, J.; Hung, P.T.; Kawasaki, M.; Han, J.K.; Zhao, Y.; Xue, Y.; Lábár, J.L. Influence of severe plastic deformation on the microstructure and hardness of a CoCrFeNi high-entropy alloy: A comparison with CoCrFeNiMn. Mater. Charact. 2019, 154, 304–314. [Google Scholar] [CrossRef]

- Heczel, A.; Kawasaki, M.; Lábár, J.L.; Jang, J.-I.; Langdon, T.G.; Gubicza, J. Defect structure and hardness in nanocrystalline CoCrFeMnNi High-Entropy Alloy processed by High-Pressure Torsion. J. Alloys Compd. 2017, 711, 143–154. [Google Scholar] [CrossRef]

- Lee, D.H.; Choi, I.C.; Seok, M.Y.; He, J.; Lu, Z.; Suh, J.Y.; Kawasaki, M.; Langdon, T.G.; Jang, J.I. Nanomechanical behavior and structural stability of a nanocrystalline CoCrFeNiMn high-entropy alloy processed by high-pressure torsion. J. Mater. Res. 2015, 30, 2804–2815. [Google Scholar] [CrossRef]

- Schuh, B.; Mendez-Martin, F.; Völker, B.; George, E.P.; Clemens, H.; Pippan, R.; Hohenwarter, A. Mechanical properties, microstructure and thermal stability of a nanocrystalline CoCrFeMnNi high-entropy alloy after severe plastic deformation. Acta Mater. 2015, 96, 258–268. [Google Scholar] [CrossRef]

- Schuh, B.; Pippan, R.; Hohenwarter, A. Tailoring bimodal grain size structures in nanocrystalline compositionally complex alloys to improve ductility. Mater. Sci. Eng. A 2019, 748, 379–385. [Google Scholar] [CrossRef]

- Skrotzki, W.; Pukenas, A.; Joni, B.; Odor, E.; Ungar, T.; Hohenwarter, A.; Pippan, R.; George, E.P. Microstructure and texture evolution during severe plastic deformation of CrMnFeCoNi high-entropy alloy. IOP Conf. Ser. Mater. Sci. Eng. 2017, 194, 012028. [Google Scholar] [CrossRef]

- Wu, W.; Song, M.; Ni, S.; Wang, J.; Liu, Y.; Liu, B.; Liao, X. Dual mechanisms of grain refinement in a FeCoCrNi highentropy alloy processed by highpressure torsion. Sci. Rep. 2017, 7, 46720. [Google Scholar] [CrossRef] [PubMed]

- Kumar, N.; Komarasamy, M.; Nelaturu, P.; Tang, Z.; Liaw, P.K.; Mishra, R.S. Friction stir processing of a high entropy alloy Al0.1CoCrFeNi. JOM 2015, 67, 1007–1013. [Google Scholar] [CrossRef]

- Komarasamy, M.; Kumar, N.; Tang, Z.; Mishra, R.S.; Liaw, P.K. Effect of microstructure on the deformation mechanism of friction stir-processed Al0.1CoCrFeNi high entropy alloy. Mater. Res. Lett. 2014, 3, 30–34. [Google Scholar] [CrossRef]

- Nene, S.S.; Liu, K.; Frank, M.; Mishra, R.S.; Brennan, R.E.; Cho, K.C.; Li, Z.; Raabe, D. Enhanced strength and ductility in a friction stir processing engineered dual phase high entropy alloy. Sci. Rep. 2017, 7, 16167. [Google Scholar] [CrossRef]

- Nene, S.S.; Frank, M.; Liu, K.; Mishra, R.S.; McWilliams, B.A.; Cho, K.C. Extremely high strength and work hardening ability in a metastable high entropy alloy. Sci. Rep. 2018, 8, 9920. [Google Scholar] [CrossRef]

- Liu, K.; Nene, S.S.; Frank, M.; Sinha, S.; Mishra, R.S. Metastability-assisted fatigue behavior in a friction stir processed dual-phase high entropy alloy. Mater. Res. Lett. 2018, 6, 613–619. [Google Scholar] [CrossRef]

- Hammond, V.H.; Atwater, M.A.; Darling, K.A.; Nguyen, H.Q.; Kecskes, L.J. Equal-Channel Angular Extrusion of a Low-Density High-Entropy Alloy Produced by High-Energy Cryogenic Mechanical Alloying. JOM 2014, 66, 2021–2029. [Google Scholar] [CrossRef]

- Shahmir, H.; Mousavi, T.; He, J.; Lu, Z.; Kawasaki, M.; Langdon, T.G. Microstructure and properties of a CoCrFeNiMn high-entropy alloy processed by equal-channel angular pressing. Mater. Sci. Eng. A 2017, 705, 411–419. [Google Scholar] [CrossRef]

- Deng, H.W.; Xie, Z.M.; Zhao, B.L.; Wang, Y.K.; Wang, M.M.; Yang, J.F.; Zhang, T.; Xiong, Y.; Wang, X.P.; Fang, Q.F. Tailoring mechanical properties of a CoCrNi medium-entropy alloy by controlling nanotwin-HCP lamellae and annealing twins. Mater. Sci. Eng. A 2019, 744, 241–246. [Google Scholar] [CrossRef]

- Segal, V.M. Materials processing by simple shear. Mater. Sci. Eng. A 1995, 197, 157–164. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Langdon, T.G. Principles of equal-channel angular pressing as a processing tool for grain refinement. Prog. Mater. Sci. 2006, 51, 881–981. [Google Scholar] [CrossRef]

- Frint, P.; Hockauf, M.; Halle, T.; Strehl, G.; Lampke, T.; Wagner, M.F.X. Microstructural features and mechanical properties after industrial scale ECAP of an Al-6060 alloy. Mater. Sci. Forum 2011, 667–669, 1153–1158. [Google Scholar] [CrossRef]

- Frint, S.; Hockauf, M.; Frint, P.; Wagner, M.F.X. Scaling up Segal’s principle of Equal-Channel Angular Pressing. Mater. Des. 2016, 97, 502–511. [Google Scholar] [CrossRef]

- Furukawa, M.; Horita, Z.; Langdon, T.G. Developing ultrafine grain sizes using severe plastic deformation. Adv. Eng. Mater. 2001, 3, 121–125. [Google Scholar] [CrossRef]

- Löbel, M.; Lindner, T.; Pippig, R.; Lampke, T. High-temperature wear behaviour of spark plasma sintered AlCoCrFeNiTi0.5 high-entropy alloy. Entropy 2019, 21, 582. [Google Scholar] [CrossRef] [PubMed]

- Torralba, J.M.; Alvaredo, P.; García-Junceda, A. High-entropy alloys fabricated via powder metallurgy. A critical review. Powder Metall. 2019, 62, 84–114. [Google Scholar] [CrossRef]

- Löbel, M.; Lindner, T.; Hunger, R.; Berger, R.; Lampke, T. Precipitation hardening of the HVOF sprayed single-phase high-entropy alloy CrFeCoNi. Coatings 2020, 10, 701. [Google Scholar] [CrossRef]

- Iwahashi, Y.; Wang, J.; Horita, Z.; Nemoto, M.; Langdon, T.G. Principle of equal-channel angular pressing for the processing of ultra-fine grained materials. Scr. Mater. 1996, 35, 143–146. [Google Scholar] [CrossRef]

- Frint, P.; Wagner, M.F.X.; Weber, S.; Seipp, S.; Frint, S.; Lampke, T. An experimental study on optimum lubrication for large-scale severe plastic deformation of aluminum-based alloys. J. Mater. Process. Technol. 2017, 239, 222–229. [Google Scholar] [CrossRef]

- DIN ISO 13067:2015-12. Microbeam Analysis—Electron Backscatter Diffraction—Measurement of Average Grain Size; Beuth Verlag GmbH: Berlin, Germany, 2015. [Google Scholar]

- Beyerlein, I.J.; Tomé, C.N. Analytical modeling of material flow in equal channel angular extrusion (ECAE). Mater. Sci. Eng. A 2004, 380, 171–190. [Google Scholar] [CrossRef]

- Frint, P.; Wagner, M.F.X. Strain partitioning by recurrent shear localization during equal-channel angular pressing of an AA6060 aluminum alloy. Acta Mater. 2019, 176, 306–317. [Google Scholar] [CrossRef]

- Zolotorevsky, N.Y.; Rybin, V.V.; Matvienko, A.N.; Ushanova, E.A.; Philippov, S.A. Misorientation angle distribution of deformation-induced boundaries provided by their EBSD-based separation from original grain boundaries: Case study of copper deformed by compression. Mater. Charact. 2019, 147, 184–192. [Google Scholar] [CrossRef]

- Zhang, J.; Han, W.; Rui, W.; Li, J.; Huang, Z.; Sui, F. Deformation Mechanisms of 316L Austenitic Stainless Steel Tubes under Equal Channel Angular Pressing. J. Mater. Eng. Perform. 2020, 29, 1253–1261. [Google Scholar] [CrossRef]

- Salishchev, G.A.; Tikhonovsky, M.A.; Shaysultanov, D.G.; Stepanov, N.D.; Kuznetsov, A.V.; Kolodiy, I.V.; Tortika, A.S.; Senkov, O.N. Effect of Mn and v on structure and mechanical properties of high-entropy alloys based on CoCrFeNi system. J. Alloys Compd. 2014, 591, 11–21. [Google Scholar] [CrossRef]

- Segal, V. Review: Modes and processes of severe plastic deformation (SPD). Materials 2018, 11, 1175. [Google Scholar] [CrossRef]

- Pande, C.S.; Cooper, K.P. Nanomechanics of Hall-Petch relationship in nanocrystalline materials. Prog. Mater. Sci. 2009, 54, 689–706. [Google Scholar] [CrossRef]

- Schneider, M.; George, E.P.; Manescau, T.J.; Záležák, T.; Hunfeld, J.; Dlouhý, A.; Eggeler, G.; Laplanche, G. Analysis of strengthening due to grain boundaries and annealing twin boundaries in the CrCoNi medium-entropy alloy. Int. J. Plast. 2020, 124, 155–169. [Google Scholar] [CrossRef]

| Material | Cr | Fe | Co | Ni |

|---|---|---|---|---|

| Nominal CrFeCoNi | 25.0 | 25.0 | 25.0 | 25.0 |

| Measured CrFeCoNi [29] | 25.7 | 25.0 | 24.6 | 24.7 |

| Material | YS in MPa | UTS in MPa | UE in % | EF in % |

|---|---|---|---|---|

| As-sintered CrFeCoNi | 355 | 654 | 44 | 60 |

| ECAP-processed CrFeCoNi | 1032 | 1136 | ~1 | 7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rymer, L.-M.; Lindner, T.; Frint, P.; Löbel, M.; Lampke, T. Designing (Ultra)Fine-Grained High-Entropy Alloys by Spark Plasma Sintering and Equal-Channel Angular Pressing. Crystals 2020, 10, 1157. https://doi.org/10.3390/cryst10121157

Rymer L-M, Lindner T, Frint P, Löbel M, Lampke T. Designing (Ultra)Fine-Grained High-Entropy Alloys by Spark Plasma Sintering and Equal-Channel Angular Pressing. Crystals. 2020; 10(12):1157. https://doi.org/10.3390/cryst10121157

Chicago/Turabian StyleRymer, Lisa-Marie, Thomas Lindner, Philipp Frint, Martin Löbel, and Thomas Lampke. 2020. "Designing (Ultra)Fine-Grained High-Entropy Alloys by Spark Plasma Sintering and Equal-Channel Angular Pressing" Crystals 10, no. 12: 1157. https://doi.org/10.3390/cryst10121157

APA StyleRymer, L.-M., Lindner, T., Frint, P., Löbel, M., & Lampke, T. (2020). Designing (Ultra)Fine-Grained High-Entropy Alloys by Spark Plasma Sintering and Equal-Channel Angular Pressing. Crystals, 10(12), 1157. https://doi.org/10.3390/cryst10121157