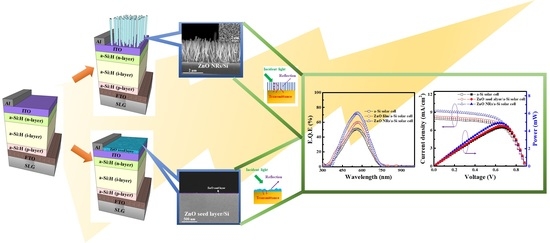

Enhanced Conversion Efficiency of a-Si:H Thin-Film Solar Cell Using ZnO Nanorods

Abstract

1. Introduction

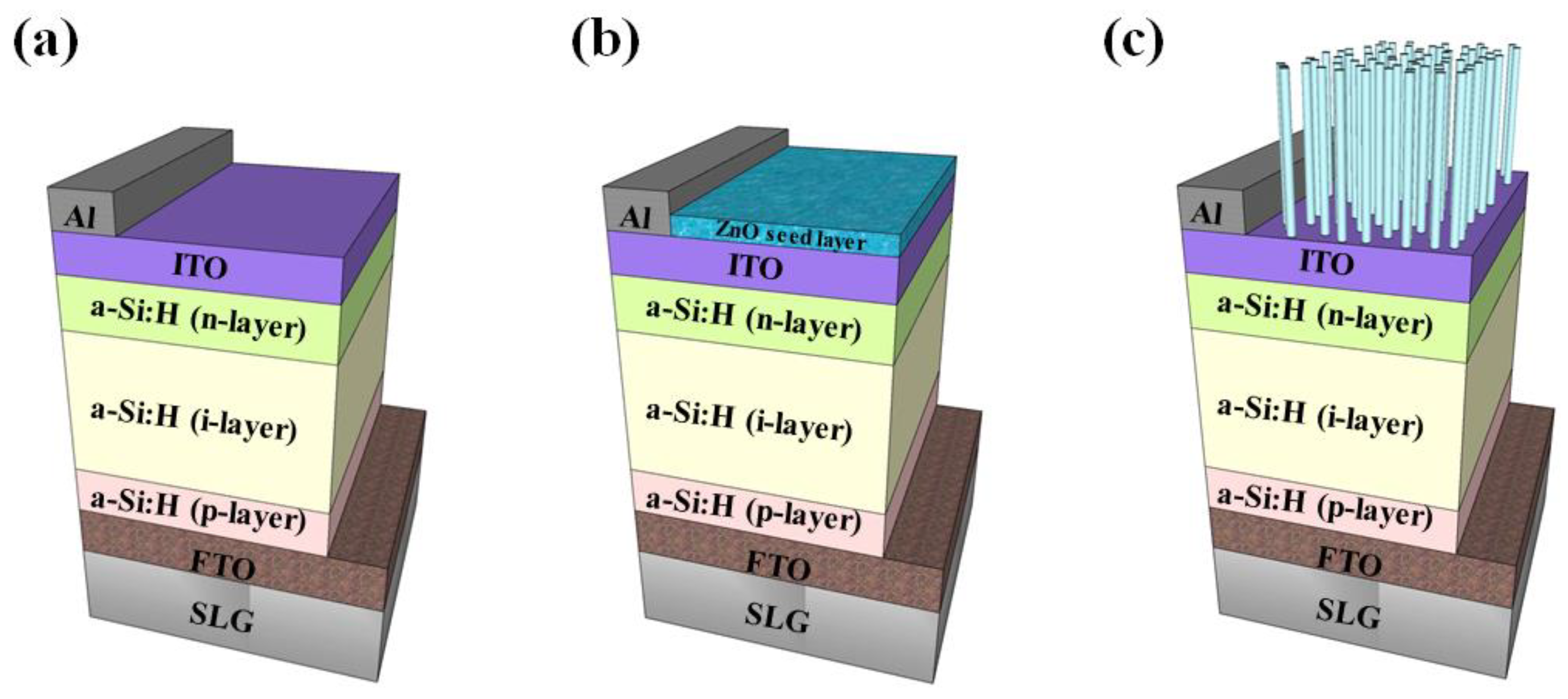

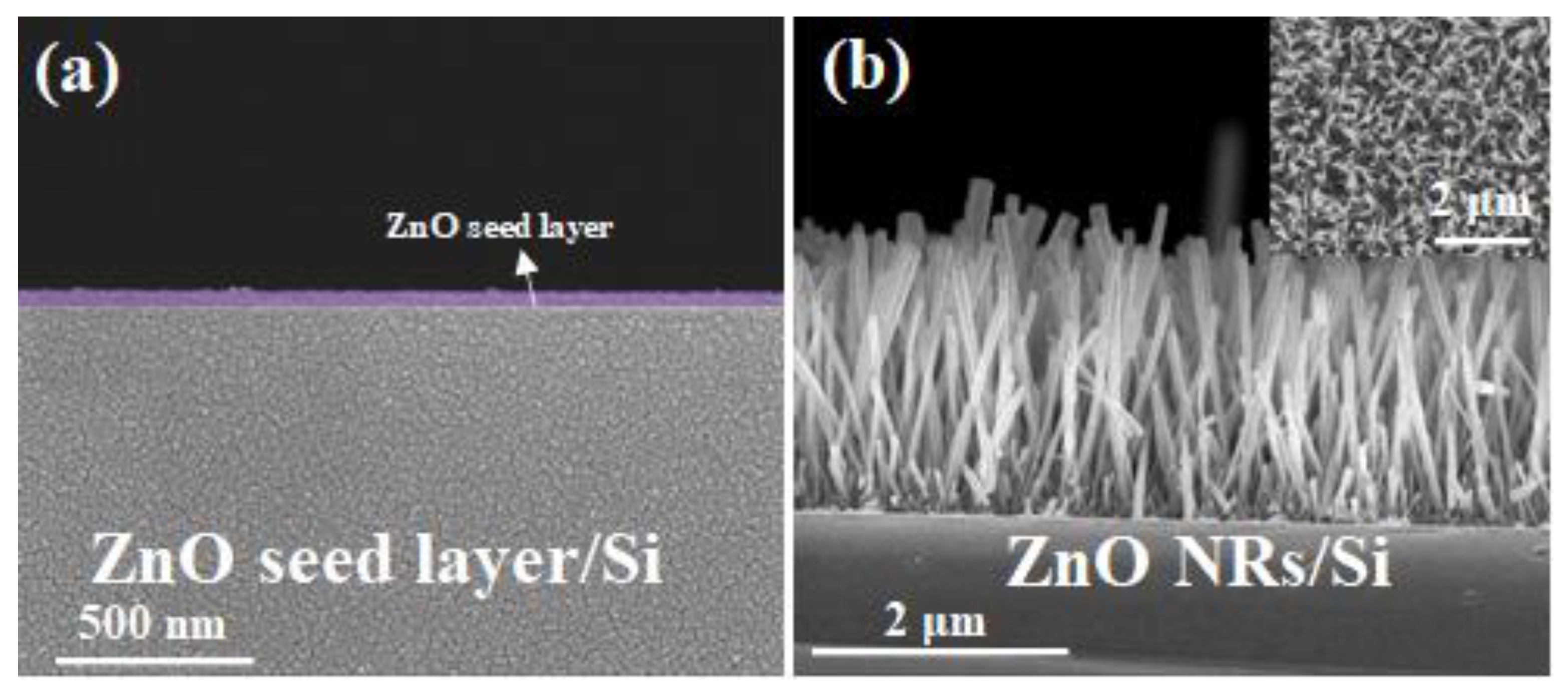

2. Materials and Methods

3. Results

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Matsui, T.; Maejima, K.; Bidiville, A.; Sai, H.; Koida, T.; Suezaki, T.; Matsumoto, M.; Saito, K.; Yoshida, I.; Kondo, M. High-efficiency thin-film silicon solar cells realized by integrating stable a-Si:H absorbers into improved device design. Jpn. J. Appl. Phys. 2015, 54, 08KB10. [Google Scholar] [CrossRef]

- Li, D.; Liu, Z.; Wang, Y.; Shan, Y.; Huang, F. Efficiency Enhancement of Cu(In,Ga)Se2 Solar Cells by Applying SiO2-PEG/PVP Antireflection Coatings. J. Mater. Sci. Technol. 2015, 31, 229–234. [Google Scholar] [CrossRef]

- Chang, Y.-A.; Li, Z.-Y.; Kuo, H.-C.; Lu, T.-C.; Yang, S.-F.; Lai, L.-W.; Lai, L.-H.; Wang, S.-C. Efficiency improvement of single-junction InGaP solar cells fabricated by a novel micro-hole array surface texture process. Semicond. Sci. Technol. 2009, 24, 085007. [Google Scholar] [CrossRef]

- Baek, S.-H.; Kim, S.-B.; Shin, J.-K.; Kim, J.-H. Preparation of hybrid silicon wire and planar solar cells having ZnO antireflection coating by all-solution processes. Sol. Energy Mater. Sol. Cells 2012, 96, 251–256. [Google Scholar] [CrossRef]

- Shao, T.; Tang, F.; Sun, L.; Ye, X.; He, J.; Yang, L.; Zheng, W. Fabrication of Antireflective Nanostructures on a Transmission Grating Surface Using a One-Step Self-Masking Method. Nanomaterials 2019, 9, 180. [Google Scholar] [CrossRef]

- Rouzo, J.-L.; Brückner, J.-B.; Ferchichi, A.; Gourgon, C.; Berginc, G.; Escoubas, L. Optical properties of antireflective flat or rough patterned topped silicon cones gratings. Adv. Device Mater. 2015, 1, 23–26. [Google Scholar] [CrossRef]

- Ducros, C.; Brodu, A.; Lorin, G.; Emieux, F.; Pereira, A. Optical performances of antireflective moth-eye structures. Comparison with standard vacuum antireflection coatings for application to outdoor lighting LEDs. Surf. Coat. Technol. 2019, 379, 125044. [Google Scholar] [CrossRef]

- Liu, Y.; Soltani, M.; Dey, R.-K.; Cui, B.; Lee, R.; Podmore, H. Moth-eye antireflection nanostructure on glass for CubeSats. J. Vac. Sci. Technol. B 2018, 36, 06JG01. [Google Scholar] [CrossRef]

- Lotz, M.-R.; Petersen, C.-R.; Markos, C.; Bang, O.; Jakobsen, M.-H.; Taboryski, R. Direct nanoimprinting of moth-eye structures in chalcogenide glass for broadband antireflection in the mid-infrared. Optica 2018, 5, 557–563. [Google Scholar] [CrossRef]

- Ren, X.; Sangle, A.; Zhang, S.; Yuan, S.; Zhao, Y.; Shi, L.; Hoye, R.-L.-Z.; Cho, S.; Li, D.; MacManus-Driscoll, J.-L. Photoelectrochemical water splitting strongly enhanced in fast-grown ZnO nanotree and nanocluster structures. J. Mater. Chem. A 2016, 4, 10203–10211. [Google Scholar] [CrossRef]

- Son, D.-Y.; Im, J.-H.; Kim, H.-S.; Park, N.-G. 11% Efficient Perovskite Solar Cell Based on ZnO Nanorods: An Effective Charge Collection System. J. Phys. Chem. C 2014, 118, 16567–16573. [Google Scholar] [CrossRef]

- Jin, D.; Gu, X.; Yu, X.; Ding, G.; Zhu, H.; Yao, K. Hydrothermal synthesis and characterization of hexagonal Mg(OH)2 nano-flake as a flame retardant. Mater. Chem. Phys. 2008, 112, 962–965. [Google Scholar] [CrossRef]

- Papadimitriou, D.-N. Structural, optical, electrical properties, and strain/stress of electrochemically deposited highly doped ZnO layers and nanostructured ZnO antireflective coatings for cost-effective photovoltaic device technology. Thin Solid Films 2016, 605, 215–231. [Google Scholar] [CrossRef]

- Yu, X.; Dong, W.; Dong, L.; Li, G.; Yang, D. Efficiency improvement of silicon solar cells enabled by ZnO nanowhisker array coating. Nanoscale Res. Lett. 2012, 7, 306. [Google Scholar] [CrossRef] [PubMed]

- Rupa, E.-J.; Kaliraj, L.; Abid, S.; Yang, D.-C.; Jung, S.-K. Synthesis of a Zinc Oxide Nanoflower Photocatalyst from Sea Buckthorn Fruit for Degradation of Industrial Dyes in Wastewater Treatment. Nanomaterials 2019, 9, 1692. [Google Scholar] [CrossRef]

- Upadhyay, A.; Yang, H.; Zaman, B.; Zhang, L.; Wu, Y.; Wang, J.; Zhao, J.; Liao, C.; Han, Q. ZnO Nanoflower-Based NanoPCR as an Efficient Diagnostic Tool for Quick Diagnosis of Canine Vector-Borne Pathogens. Pathogens 2020, 9, 122. [Google Scholar] [CrossRef]

- Bhushan, B.; Murty, B.-S.; Mondal, K. A new approach for synthesis of ZnO nanorod flowerets and subsequentpure free-standing ZnO nanorods. Adv. Powder Technol. 2019, 30, 30–41. [Google Scholar] [CrossRef]

- Li, X.; Chen, X.; Yi, Z.; Zhou, Z.; Tang, Y.; Yi, Y. Fabriction of ZnO Nanorods with Strong UV Absorption and Different Hydrophobicity on Foamed Nickel under Different Hydrothermal Conditions. Micromachines 2019, 10, 164. [Google Scholar] [CrossRef]

- Zhao, F.; Zheng, J.-G.; Yang, X.; Li, X.; Wang, J.; Zhao, F.; Wong, K.-S.; Liang, C.; Wu, M. Complex ZnO nanotree arrays with tunable top, stem and branch structures. Nanoscale 2010, 2, 1674–1683. [Google Scholar] [CrossRef]

- Zhao, F.; Li, X.; Zheng, J.-G.; Yang, X.; Zhao, F.; Wong, K.-S.; Wang, J.; Lin, W.; Wu, M.; Su, Q. ZnO Pine-Nanotree Arrays Grown from Facile Metal Chemical Corrosion and Oxidation. Chem. Mater. 2008, 20, 1197–1199. [Google Scholar] [CrossRef]

- Iqbal, T.; Khan, M.-A.; Mahmood, H. Facile synthesis of ZnO nanosheets: Structural, antibacterial and photocatalytic studies. Mater. Lett. 2018, 224, 59–63. [Google Scholar] [CrossRef]

- Dahiya, A.-S.; Sporea, R.-A.; Poulin-Vittrant, G.; Alquier, D. Stability evaluation of ZnO nanosheet based source-gated transistors. Sci. Rep. 2019, 9, 2979. [Google Scholar] [CrossRef] [PubMed]

- Shabannia, R. Vertically aligned ZnO nanorods on porous silicon substrates: Effect of growth time. Prog. Nat. Sci. Mater. Int. 2015, 25, 95–100. [Google Scholar] [CrossRef]

- Yao, I.-C.; Lin, P.; Tseng, T.-Y. Field Emission Properties and Reliability of ZnO Nanorod, Nanopagoda, and Nanotip Current Emitters. IEEE Trans. Nanotechnol. 2012, 11, 746–750. [Google Scholar] [CrossRef]

- Ye, Z.; Ji, X.; Zhang, Q. Enhanced field emission properties of ZnO nanorods by surface modification. RSC Adv. 2015, 5, 78502–78507. [Google Scholar] [CrossRef]

- Lai, F.-I.; Yang, J.-F.; Liao, W.-X.; Kuo, S.-Y. Enhanced omnidirectional and weatherability of Cu2ZnSnSe4 solar cells with ZnO functional nanorod arrays. Sci. Rep. 2017, 7, 14927. [Google Scholar] [CrossRef]

- Lalanne, P.; Morris, G.-M. Antireflection behavior of silicon subwavelength periodic structures for visible light. Nanotechnology 1997, 8, 53–56. [Google Scholar] [CrossRef]

- Chiu, M.-Y.; Chang, C.-H.; Tsai, M.-A.; Chang, F.-Y.; Yu, P. Improved optical transmission and current matching of a triple-junction solar cell utilizing sub-wavelength structures. Opt. Express 2010, 18, A308–A313. [Google Scholar] [CrossRef]

- Leem, J.-W.; Joo, D.-H.; Yu, J.-S. Biomimetic parabola-shaped AZO subwavelength grating structures for efficient antireflection of Si-based solar cells. Sol. Energy Mater. Sol. Cells 2011, 95, 2221–2227. [Google Scholar] [CrossRef]

| Sample | Efficiency (%) | Voc (mV) | Jsc (mA/cm2) | F.F. |

|---|---|---|---|---|

| a-Si:H solar cell | 4.42 | 885 | 8.02 | 62.27 |

| ZnO seed layer/a-Si:H solar cell | 4.57 | 885 | 8.3 | 62.21 |

| ZnO NRs/a-Si:H solar cell | 4.98 | 885 | 9.24 | 60.9 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lai, F.-I.; Yang, J.-F.; Hsu, Y.-C.; Kuo, S.-Y. Enhanced Conversion Efficiency of a-Si:H Thin-Film Solar Cell Using ZnO Nanorods. Crystals 2020, 10, 1082. https://doi.org/10.3390/cryst10121082

Lai F-I, Yang J-F, Hsu Y-C, Kuo S-Y. Enhanced Conversion Efficiency of a-Si:H Thin-Film Solar Cell Using ZnO Nanorods. Crystals. 2020; 10(12):1082. https://doi.org/10.3390/cryst10121082

Chicago/Turabian StyleLai, Fang-I, Jui-Fu Yang, Yu-Chao Hsu, and Shou-Yi Kuo. 2020. "Enhanced Conversion Efficiency of a-Si:H Thin-Film Solar Cell Using ZnO Nanorods" Crystals 10, no. 12: 1082. https://doi.org/10.3390/cryst10121082

APA StyleLai, F.-I., Yang, J.-F., Hsu, Y.-C., & Kuo, S.-Y. (2020). Enhanced Conversion Efficiency of a-Si:H Thin-Film Solar Cell Using ZnO Nanorods. Crystals, 10(12), 1082. https://doi.org/10.3390/cryst10121082