A Novel Method of Light Weighting Aluminium Using Magnesium Syntactic Composite Core

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Methods

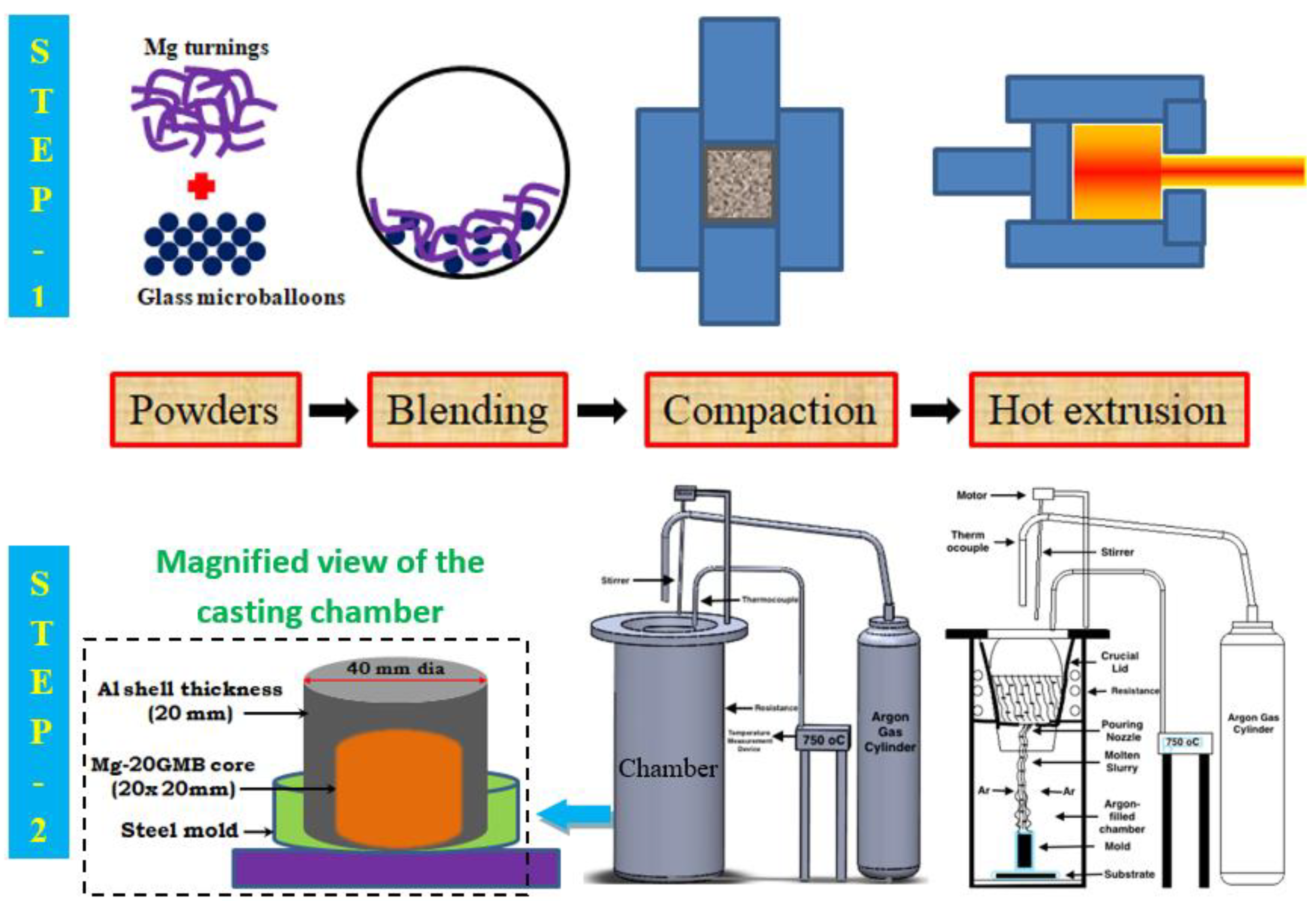

2.2. Processing

2.3. Characterization and Testing Methods

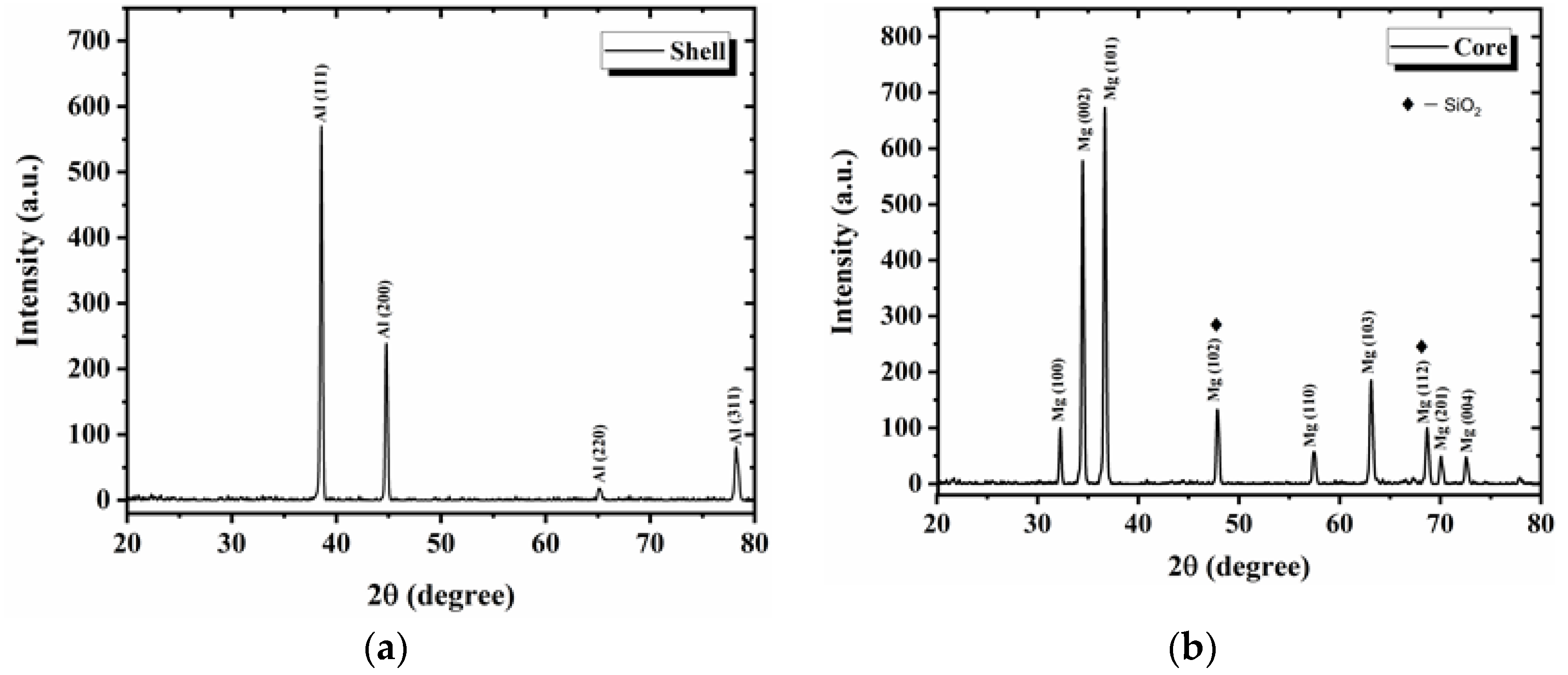

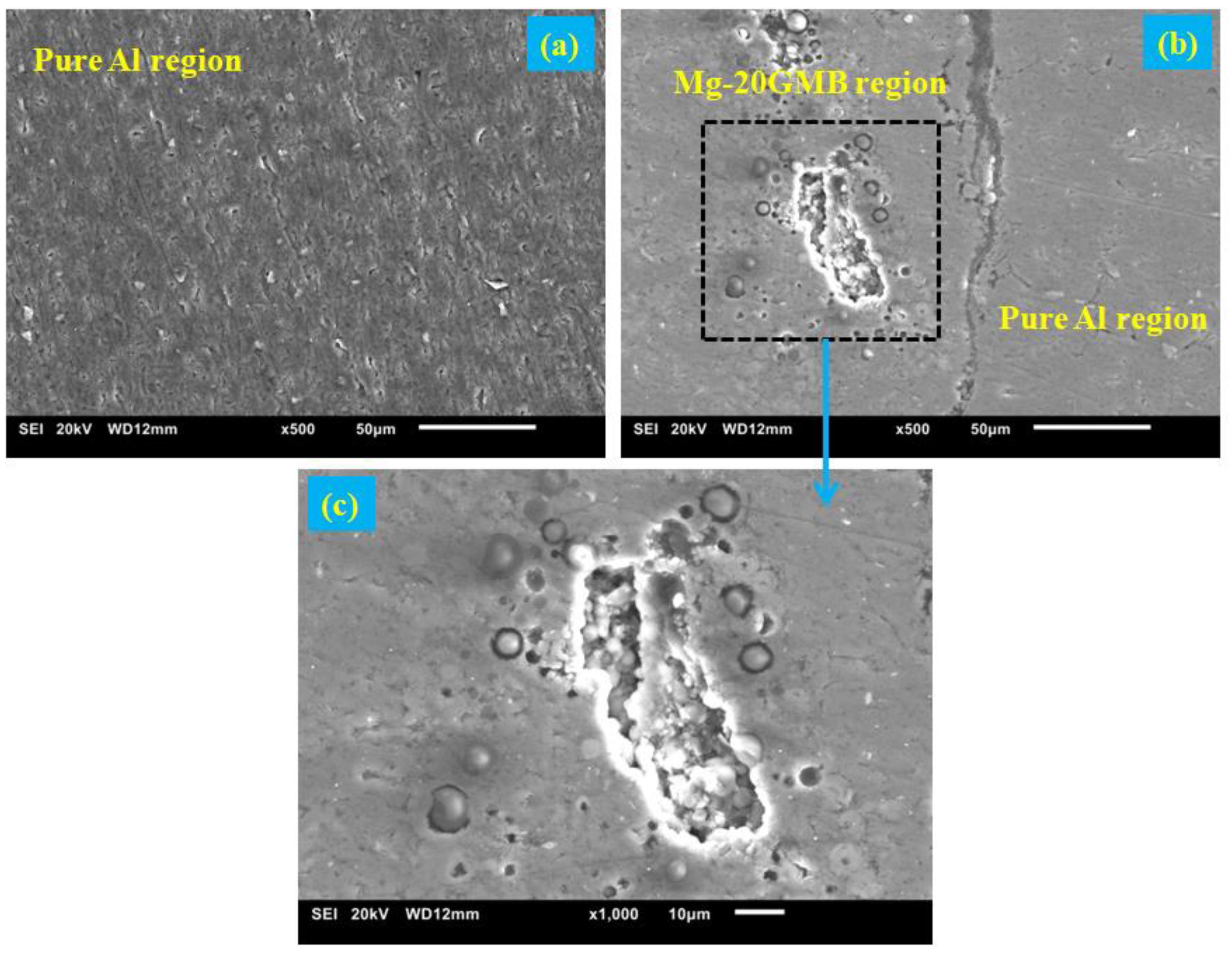

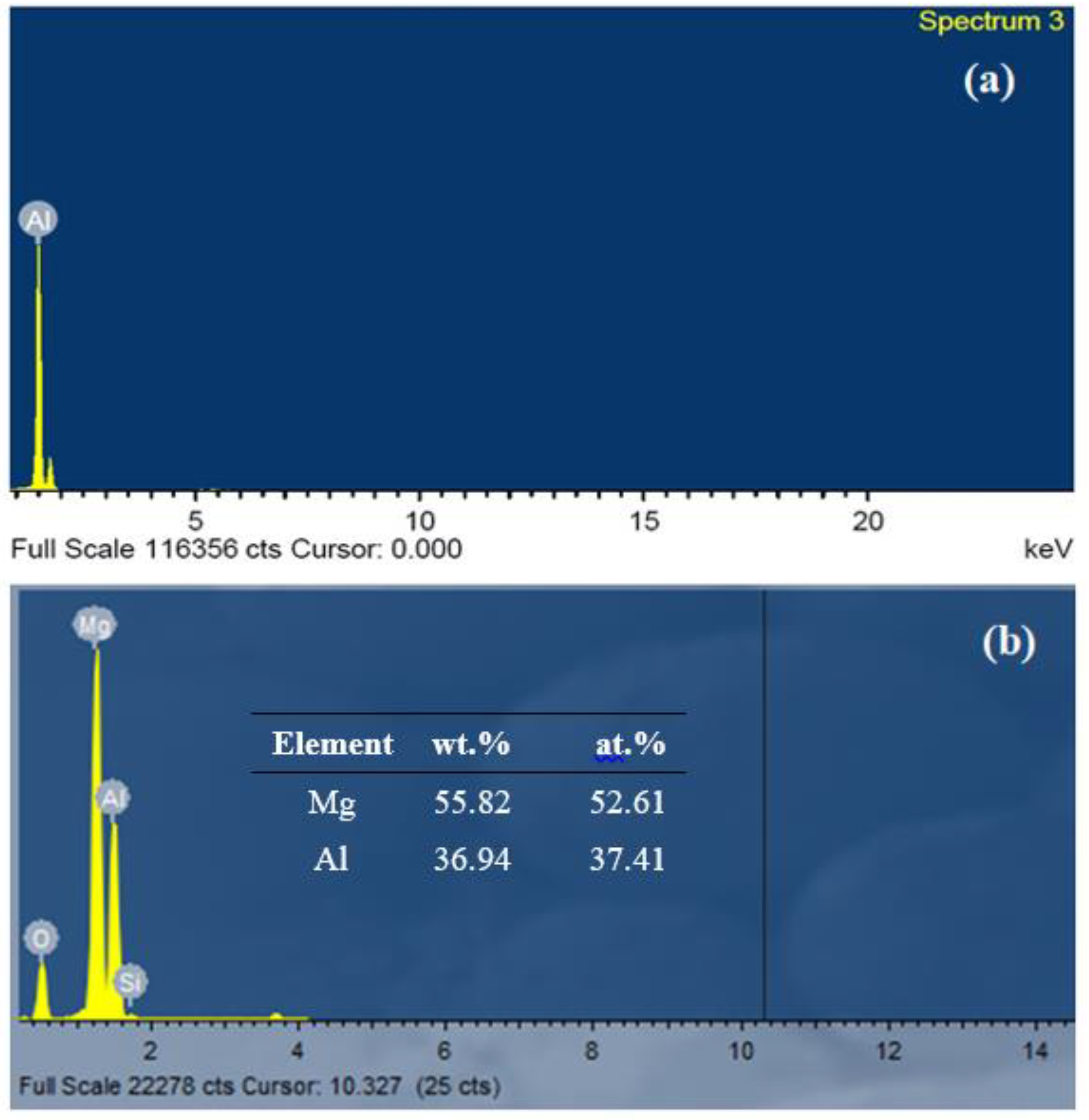

3. Results and Discussions

4. Conclusions

- The Mg-20GMB syntactic composite core material was successfully synthesized by a novel processing approach using a combination of compaction and hot extrusion.

- Pure Al and Al/Mg-20GMB hybrid composite samples were successfully produced by the disintegrated melt deposition (DMD) technique.

- When compared to as-cast pure aluminium with a slight increase in the porosity, as-cast Al/Mg-20GMB hybrid composite showed a decline in experimental density (~13%) due to the presence of Mg-20GMB.

- Reasonably good GMB/Mg and Mg-GMB/Al interfacial bonding was observed as evidenced by the limited reaction zones seen along the interface.

- The Mg-20GMB core exhibited higher hardness value (174 ± 5 HV) compared to the Al shell and the interface regions.

- The yield strength and ultimate compressive strength of as-cast Al/Mg-20GMB hybrid composite were enhanced by 65.4% and 60%, respectively. Both Al and hybrid composite did not fail till 33% engineering strain. Hybrid composite exhibited ~26% increase in the energy absorption capability that is reflection of his enhanced static toughness.

Author Contributions

Funding

Conflicts of Interest

References

- Matli, P.R.; Sheng, J.G.Y.; Parande, G.; Manakari, V.; Chua, B.W.; Wong, S.C.K.; Gupta, M. A New Method to Lightweight Magnesium Using Syntactic Composite Core. Appl. Sci. 2020, 10, 4773. [Google Scholar] [CrossRef]

- Vicario, I.; Crespo, I.; Plaza, L.M.; Caballero, P.; Idoiaga, I.K. Aluminium Foam and Magnesium Compound Casting Produced by High-Pressure Die Casting. Metals 2016, 6, 24. [Google Scholar] [CrossRef] [Green Version]

- Manakari, V.; Parande, G.; Gupta, M. Selective laser melting of magnesium and magnesium alloy powders: A review. Metals 2017, 7, 2. [Google Scholar] [CrossRef] [Green Version]

- Reddy, M.P.; Ubaid, F.; Shakoor, R.; Parande, G.; Manakari, V.; Mohamed, A.; Gupta, M. Effect of reinforcement concentration on the properties of hot extruded Al-Al2O3 composites synthesized through microwave sintering process. Mater. Sci. Eng. A 2017, 696, 60–69. [Google Scholar] [CrossRef]

- Parande, G.; Manakari, V.; Kopparthy, S.D.S.; Gupta, M. A study on the effect of low-cost eggshell reinforcement on the immersion, damping and mechanical properties of magnesium–zinc alloy. Compos. Part B Eng. 2020, 182, 107650. [Google Scholar] [CrossRef]

- Li, G.; Yang, W.; Jiang, W.; Guan, F.; Jiang, H.; Wu, Y.; Fan, Z. The role of vacuum degree in the bonding of Al/Mg bimetal prepared by a compound casting process. J. Mater. Process. Technol. 2019, 265, 112–121. [Google Scholar] [CrossRef]

- Feng, B.; Xin, Y.; Guo, F.; Yu, H.; Wu, Y.; Liu, Q. Compressive mechanical behavior of Al/Mg composite rods with different types of Al sleeve. Acta Mater. 2016, 120, 379–390. [Google Scholar] [CrossRef]

- Paramsothy, M.; Srikanth, N.; Gupta, M. Solidification processed Mg/Al bimetal macrocomposite: Microstructure and mechanical properties. J. Alloys Compd. 2008, 461, 200–208. [Google Scholar] [CrossRef]

- Elanchezhian, C.; Bhaskar, G.; Vivekanandhan, M. An Investigation of the Mechanical Properties of HybridComposites in Applications of Automotive Industry. Mater. Today Proc. 2019, 16, 875–882. [Google Scholar] [CrossRef]

- Ibrahim, I.; Mohamed, F.; Lavernia, E. Particulate reinforced metal matrix composites—A review. J. Mater. Sci. 1991, 26, 1137–1156. [Google Scholar] [CrossRef]

- Matli, P.R.; Ubaid, F.; Shakoor, R.A.; Parande, G.; Manakari, V.; Yusuf, M.; Mohamed, A.M.A.; Gupta, M. Improved properties of Al–Si3N4 nanocomposites fabricated through a microwave sintering and hot extrusion process. RSC Adv. 2017, 7, 34401–34410. [Google Scholar] [CrossRef] [Green Version]

- Mazahery, A.; Ostadshabani, M. Investigation on mechanical properties of nano-Al2O3-reinforced aluminum matrix composites. J. Compos. Mater. 2011, 45, 2579–2586. [Google Scholar] [CrossRef]

- Paramsothy, M.; Gupta, M.; Srikanth, N. Processing, microstructure, and properties of a Mg/Al bimetal macrocomposite. J. Compos. Mater. 2008, 42, 2567–2584. [Google Scholar] [CrossRef]

- Brendan, T.Z.M.; Parande, G.; Manakari, V.; Gupta, M. Using low-temperature sinterless powder method to develop exceptionally high amount of zinc containing Mg–Zn–Ca alloy and Mg–Zn–Ca/SiO2 nanocomposite. J. Alloys Compd. 2020, 853, 156957. [Google Scholar]

- Akinwamide, S.O.; Abe, B.T.; Akinribide, O.J.; Obadele, B.A.; Olubambi, P.A. Characterization of microstructure, mechanical properties and corrosion response of aluminium-based composites fabricated via casting—A review. Int. J. Adv. Manuf. Technol. 2020, 109, 975–991. [Google Scholar] [CrossRef]

- Reddy, M.P.; Manakari, V.; Parande, G.; Shakoor, R.; Mohamed, A.; Gupta, M. Structural, mechanical and thermal characteristics of Al-Cu-Li particle reinforced Al-matrix composites synthesized by microwave sintering and hot extrusion. Compos. Part B Eng. 2019, 164, 485–492. [Google Scholar] [CrossRef]

- Manakari, V.; Parande, G.; Doddamani, M.; Gupta, M. Evaluation of wear resistance of magnesium/glass microballoon syntactic foams for engineering/biomedical applications. Ceram. Int. 2019, 45, 9302–9305. [Google Scholar] [CrossRef]

- Omar, M.Y.; Xiang, C.; Gupta, N.; Strbik, O.M.; Cho, K. Syntactic foam core metal matrix sandwich composite under bending conditions. Mater. Des. 2015, 86, 536–544. [Google Scholar] [CrossRef] [Green Version]

- Read, S. Aerofoil and a Method of Manufacturing an Aerofoil. U.S. Patent 7594325B2, 29 September 2009. [Google Scholar]

- Manakari, V.; Parande, G.; Doddamani, M.; Gupta, M. Enhancing the ignition, hardness and compressive response of magnesium by reinforcing with hollow glass microballoons. Materials 2017, 10, 997. [Google Scholar] [CrossRef] [Green Version]

- Manakari, V.; Parande, G.; Gupta, M. Effects of hollow fly-ash particles on the properties of magnesium matrix syntactic foams: A review. Mater. Perform. Charact. 2016, 5, 116–131. [Google Scholar] [CrossRef]

- Xu, G.; Luo, A.A.; Chen, Y.; Sachdev, A.K. Interfacial phenomena in magnesium/aluminum bi-metallic castings. Mater. Sci. Eng. A 2014, 595, 154–158. [Google Scholar] [CrossRef]

- Zhang, J.; Luo, G.; Wang, Y.; Shen, Q.; Zhang, L. An investigation on diffusion bonding of aluminum and magnesium using a Ni interlayer. Mater. Lett. 2012, 83, 189–191. [Google Scholar] [CrossRef]

- Guan, F.; Jiang, W.; Li, G.; Jiang, H.; Zhu, J.; Fan, Z. Interfacial bonding mechanism and pouring temperature effect on Al/Cu bimetal prepared by a novel compound casting process. Mater. Res. Express 2019, 6, 096529. [Google Scholar] [CrossRef]

- Song, X.; Sun, J.; Zhong, D.; Yu, Y.; Wang, T.; Cao, Z.; Li, T. Study on Al/Mg compound materials by solid–liquid bonding method. Mater. Res. Innov. 2012, 16, 51–55. [Google Scholar] [CrossRef]

- Zhao, K.; Xu, D.; Li, H.; Zhang, J.; Chen, D. Microstructure and mechanical properties of Mg/Mg bimetal composites fabricated by hot-pressing diffusion and co-extrusion. Mater. Sci. Eng. A 2019, 764, 138194. [Google Scholar] [CrossRef]

- Emami, S.; Divandari, M.; Hajjari, E.; Arabi, H. Comparison between conventional and lost foam compound casting of Al/Mg light metals. Int. J. Cast Met. Res. 2013, 26, 43–50. [Google Scholar] [CrossRef]

- Hajjari, E.; Divandari, M.; Razavi, S.; Emami, S.; Homma, T.; Kamado, S. Dissimilar joining of Al/Mg light metals by compound casting process. J. Mater. Sci. 2011, 46, 6491–6499. [Google Scholar] [CrossRef]

- Hajjari, E.; Divandari, M.; Razavi, S.; Homma, T.; Kamado, S. Intermetallic compounds and antiphase domains in Al/Mg compound casting. Intermetallics 2012, 23, 182–186. [Google Scholar] [CrossRef]

- Nie, X.; Liu, J.; Li, H.; Du, Q.; Zhang, J.; Zhuang, L. An investigation on bonding mechanism and mechanical properties of Al/Ti compound materials prepared by insert moulding. Mater. Des. 2014, 63, 142–150. [Google Scholar] [CrossRef]

- He, K.; Zhao, J.; Li, P.; He, J.; Tang, Q. Investigation on microstructures and properties of arc-sprayed-Al/AZ91D bimetallic material by solid–liquid compound casting. Mater. Des. 2016, 112, 553–564. [Google Scholar] [CrossRef]

- Liu, T.; Wang, Q.; Sui, Y.; Wang, Q.; Ding, W. An investigation into aluminum–aluminum bimetal fabrication by squeeze casting. Mater. Des. 2015, 68, 8–17. [Google Scholar] [CrossRef]

- Rübner, M.; Günzl, M.; Körner, C.; Singer, R. Aluminium–aluminium compound fabrication by high pressure die casting. Mater. Sci. Eng. A 2011, 528, 7024–7029. [Google Scholar] [CrossRef]

- Gupta, M.; Parande, G.; Manakari, V. An insight into high performance magnesium alloy/nano-metastable-syntactic composites. In Proceedings of the 17th Australian International Aerospace Congress, AIAC, Melbourne, Australia, 26–28 February 2017; p. 270. [Google Scholar]

- Ghosh, P.; Ray, S. Effect of porosity and alumina content on the mechanical properties of compocast aluminium alloy-alumina particulate composite. J. Mater. Sci. 1986, 21, 1667–1674. [Google Scholar] [CrossRef]

- Suneesh, E.; Sivapragash, M. Comprehensive studies on processing and characterization of hybrid magnesium composites. Mater. Manuf. Process. 2018, 33, 1324–1345. [Google Scholar] [CrossRef]

- Tagliavia, G.; Porfiri, M.; Gupta, N. Vinyl ester—Glass hollow particle composites: Dynamic mechanical properties at high inclusion volume fraction. J. Compos. Mater. 2009, 43, 561–582. [Google Scholar] [CrossRef]

- Luong, D.D.; Strbik, O.M., III; Hammond, V.H.; Gupta, N.; Cho, K. Development of high performance lightweight aluminum alloy/SiC hollow sphere syntactic foams and compressive characterization at quasi-static and high strain rates. J. Alloys Compd. 2013, 550, 412–422. [Google Scholar] [CrossRef]

- Paramsothy, M.; Hassan, S.; Srikanth, N.; Gupta, M. Toughening mechanisms in Mg/Al macrocomposites: Texture and interfacial mechanical interlocking. J. Phys. D Appl. Phys. 2008, 41, 175402. [Google Scholar] [CrossRef]

- Avedesian, M.M.; Baker, H. ASM Specialty Handbook: Magnesium and Magnesium Alloys; ASM International: Materials Park, OH, USA, 1999. [Google Scholar]

- Zheng, S.; Wang, J.; Carpenter, J.; Mook, W.; Dickerson, P.; Mara, N.; Beyerlein, I. Plastic instability mechanisms in bimetallic nanolayered composites. Acta Mater. 2014, 79, 282–291. [Google Scholar] [CrossRef] [Green Version]

| Materials | Theoretical Density (g/cc) | Experimental Density (g/cc) | Porosity (%) |

|---|---|---|---|

| as-cast pure Al | 2.698 | 2.673 ± 0.007 | 0.93 |

| Mg-20 wt.%GMB syntactic composite | 1.537 | 1.492 ± 0.016 (↓44.18%) | 2.93 |

| as-cast Al/Mg-20 wt.%GMB | 2.355 | 2.324 ± 0.011 (↓13.05%) | 1.31 |

| Materials | Microhardness (HV) | ||

|---|---|---|---|

| Shell Region | Core Region | Interface Region | |

| Pure Al | 57 ± 2 | -- | -- |

| Al/Mg-20GMB hybrid composite | 68 ± 4 | 174 ± 5 | 109 ± 2 |

| Sample | CYS (MPa) | UCS (MPa) | Failure Strain (%) | Energy Absorbed (MJ/m3) | Specific Compressive Strength (MPa/g/cc) |

|---|---|---|---|---|---|

| As-cast pure Al | 52 ± 5 | 220 ± 4 | >33 | 44.7 ± 1.4 | 82.3 |

| As-cast Al/Mg-20GMB hybrid composite | 86 ± 2 (↑65.4%) | 352 ± 3 (↑60%) | >33 | 56.6 ± 1.1 (↑26.6%) | 151.5 (↑84%) |

| Al 1100/AZ31 hybrid composite | 25–81 | 106–335 | - | - | - |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Matli, P.R.; Sheng, J.G.Y.; Parande, G.; Manakari, V.; Chua, B.W.; Wong, S.C.K.; Gupta, M. A Novel Method of Light Weighting Aluminium Using Magnesium Syntactic Composite Core. Crystals 2020, 10, 917. https://doi.org/10.3390/cryst10100917

Matli PR, Sheng JGY, Parande G, Manakari V, Chua BW, Wong SCK, Gupta M. A Novel Method of Light Weighting Aluminium Using Magnesium Syntactic Composite Core. Crystals. 2020; 10(10):917. https://doi.org/10.3390/cryst10100917

Chicago/Turabian StyleMatli, Penchal Reddy, Joshua Goh Yong Sheng, Gururaj Parande, Vyasaraj Manakari, Beng Wah Chua, Stephen Chee Khuen Wong, and Manoj Gupta. 2020. "A Novel Method of Light Weighting Aluminium Using Magnesium Syntactic Composite Core" Crystals 10, no. 10: 917. https://doi.org/10.3390/cryst10100917

APA StyleMatli, P. R., Sheng, J. G. Y., Parande, G., Manakari, V., Chua, B. W., Wong, S. C. K., & Gupta, M. (2020). A Novel Method of Light Weighting Aluminium Using Magnesium Syntactic Composite Core. Crystals, 10(10), 917. https://doi.org/10.3390/cryst10100917