Performance of Catalysts of Different Nature in Model Tar Component Decomposition

Abstract

1. Introduction

2. Results and Discussion

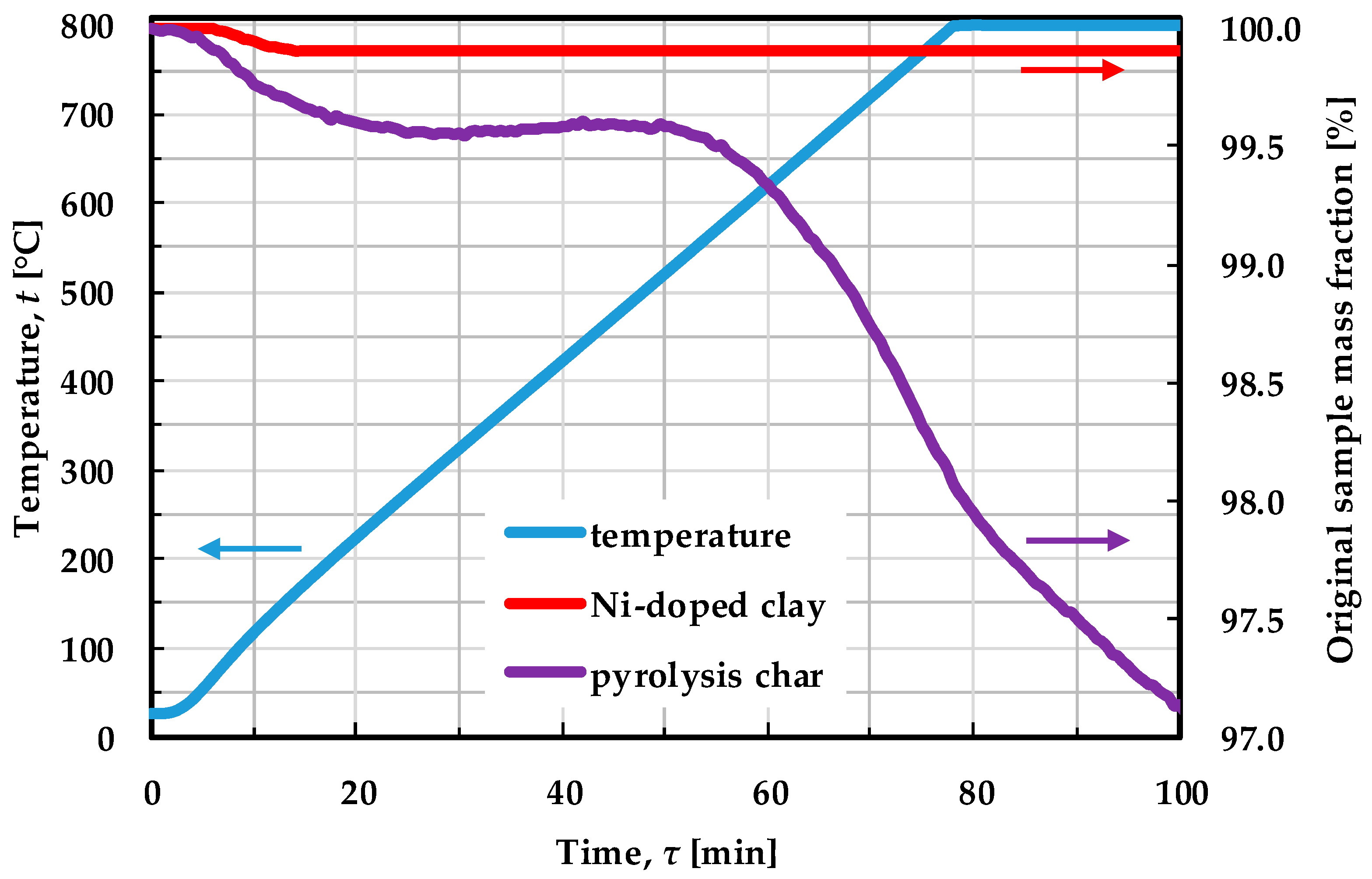

2.1. Catalysts Characterization

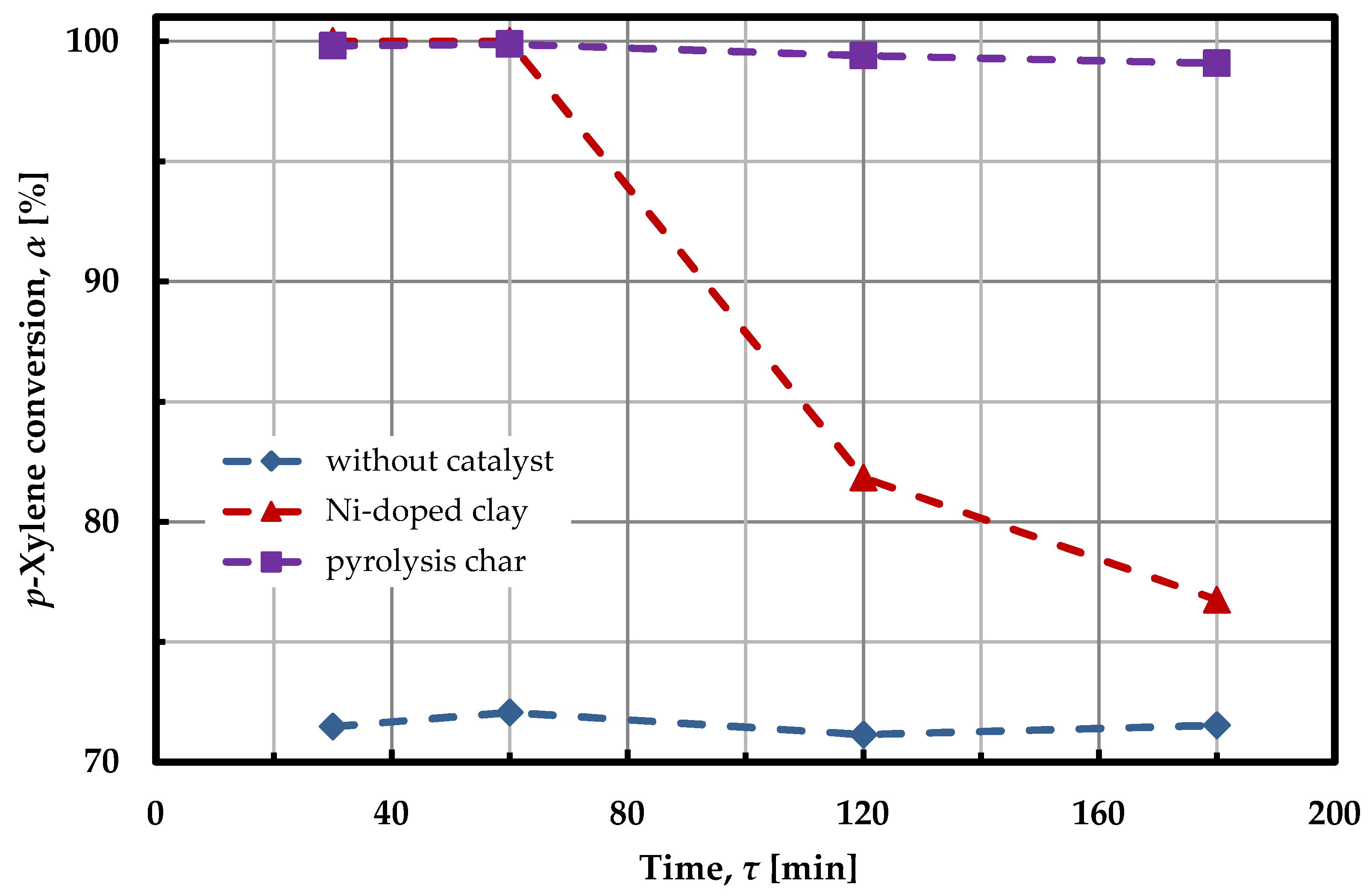

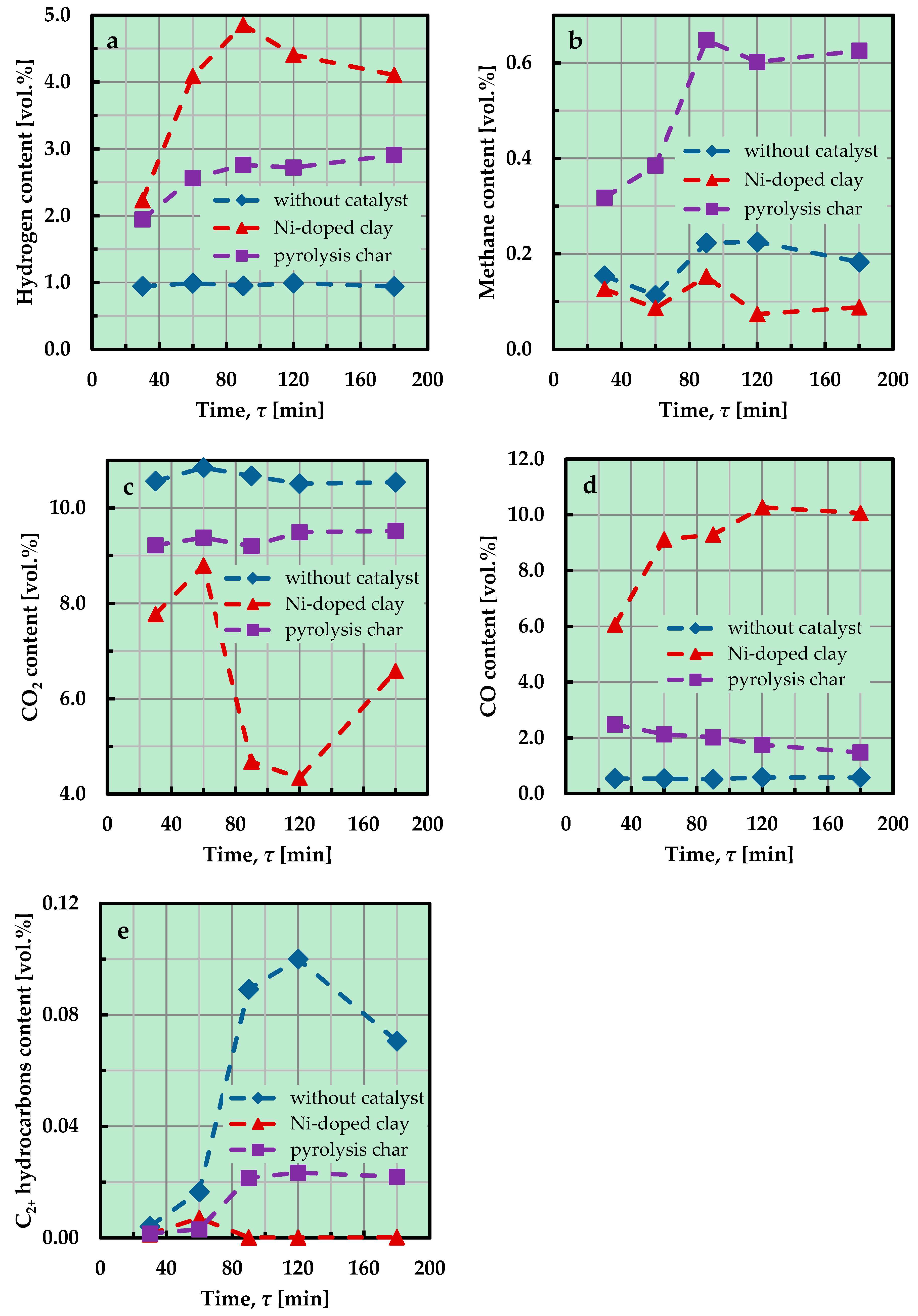

2.2. Model Tar Component Decomposition Experiments

3. Materials and Methods

3.1. Catalysts Preparation and Characterization

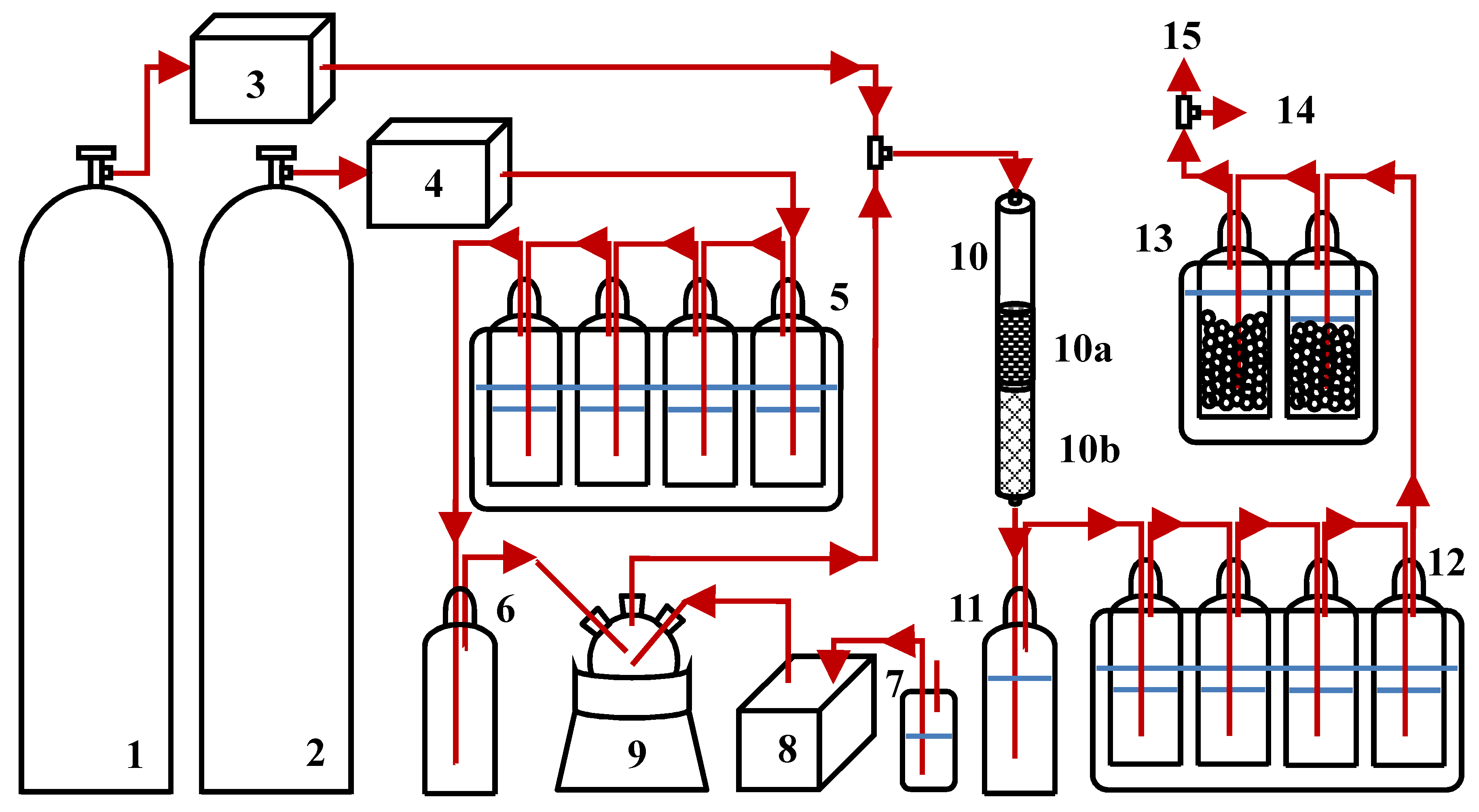

3.2. Experimental Set-Up of Model Tar Component Decomposition Unit

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Kaza, S.; Yao, L.C.; Bhada-Tata, P.; Van Woerden, F. What a Waste 2.0; World Bank: Washington, DC, USA, 2018; pp. 17–38. [Google Scholar]

- Fei, F.; Wen, Z.G.; Huang, S.B.; Clercq, D.D. Mechanical biological treatment of municipal solid waste: Energy efficiency, environmental impact and economic feasibility analysis. J. Clean. Prod. 2018, 178, 731–739. [Google Scholar] [CrossRef]

- Gallardo, A.; Carlos, M.; Bovea, M.D.; Colomer, F.J.; Albarrán, F. Analysis of refuse-derived fuel from the municipal solid waste reject fraction and its compliance with quality standards. J. Clean. Prod. 2014, 83, 118–125. [Google Scholar] [CrossRef]

- Šuhaj, P.; Husár, J.; Haydary, J. Modelling of syngas production from municipal solid waste (MSW) for methanol synthesis. Acta Chim. Slovaca 2017, 10, 107–114. [Google Scholar] [CrossRef]

- Kalita, P.; Baruah, D. Investigation of biomass gasifier product. Gas composition and its characterization. In Coal and Biomass Gasification; De, S., Agarwal, A.K., Moholkar, V.S., Thallada, B., Eds.; Springer: Singapore, 2018; pp. 115–150. [Google Scholar]

- Bridgwater, A.V. The technical and economic feasibility of biomass gasification for power generation. Fuel 1995, 74, 631–653. [Google Scholar] [CrossRef]

- Milne, T.A.; Evans, R.J.; Abatzoglou, N. Biomass Gasifier “Tars”: Their Nature, Formation, and Conversion; National Renewable Energy Laboratory: Golden, CO, USA, 1998. Available online: https://www.nrel.gov/docs/fy99osti/25357.pdf (accessed on 26 October 2019).

- Maniatis, K.; Beenackers, A.A.C. Tar protocols. IEA bioenergy gasification task. Biomass Bioenergy 2000, 18, 1–4. [Google Scholar] [CrossRef]

- Awais, M.; Li, W.; Arshad, A.; Haydar, Z.; Yaqoob, N.; Hussain, S. Evaluating removal of tar contents in syngas produced from downdraft biomass gasification system. Int. J. Green Energ. 2018, 15, 724–731. [Google Scholar] [CrossRef]

- Hai, I.U.; Sher, F.; Zarrena, G.; Liu, H. Experimental investigation of tar arresting techniques and their evaluation for product syngas cleaning from bubbling fluidized bed gasifier. J. Clean. Prod. 2019, 240, 118239. [Google Scholar] [CrossRef]

- Elliott, D.C. Relation of reaction time and temperature to chemical composition of pyrolysis oils. In Pyrolysis Oils from Biomass: Producing, Analyzing, and Upgrading; ACS Symposium Series; Soltes, E., Milne, T.A., Eds.; American Chemical Society: Washington, DC, USA, 1988; Volume 376, pp. 55–65. [Google Scholar]

- Schildhauer, T.J.; Biollaz, S.M.A. Synthetic Natural Gas from Coal, Dry Biomass, and Power-to-Gas Applications; Wiley: Hoboken, NJ, USA, 2016; pp. 47–76. [Google Scholar]

- Zhang, B.; Zhang, L.; Yang, Z.Q.; He, Z.X. An experiment study of biomass steam gasification over NiO/dolomite for hydrogen-rich gas production. Int. J. Hydrogen Energ. 2017, 42, 76–85. [Google Scholar] [CrossRef]

- Nam, H.S.; Wang, Z.H.; Shanmugam, S.R.; Adhikari, S.; Abdoulmoumine, N. Chemical looping dry reforming of benzene as a gasification tar model compound with Ni- and Fe-based oxygen carriers in a fluidized bed reactor. Int. J. Hydrogen Energ. 2018, 43, 18790–18800. [Google Scholar] [CrossRef]

- Zou, X.H.; Chen, T.H.; Liu, H.B.; Zhang, P.; Ma, Z.Y.; Xie, J.J.; Chen, D. An insight into the effect of calcination conditions on catalytic cracking of toluene over 3Fe8Ni/palygorskite: Catalysts characterization and performance. Fuel 2017, 190, 47–57. [Google Scholar] [CrossRef]

- Šuhaj, P.; Haydary, J.; Husár, J.; Steltenpohl, P.; Šupa, I. Catalytic gasification of refuse-derived fuel in a two-stage laboratory scale pyrolysis/gasification unit with catalyst based on clay minerals. Waste Manag. 2019, 85, 1–10. [Google Scholar] [CrossRef] [PubMed]

- Husár, J.; Haydary, J.; Šuhaj, P.; Steltenpohl, P. Potential of tire pyrolysis char as tar-cracking catalyst in solid waste and biomass gasification. Chem. Pap. 2019, 73, 2091–2101. [Google Scholar] [CrossRef]

- Artetxe, M.; Alvarez, J.; Nahil, M.A.; Olazar, M.; Williams, P.T. Steam reforming of different biomass tar model compounds over Ni/Al2O3 catalysts. Energ. Convers. Manage. 2017, 136, 119–126. [Google Scholar] [CrossRef]

- Zhang, R.Q.; Wang, Y.C.; Brown, R.C. Steam reforming of tar compounds over Ni/olivine catalysts doped with CeO2. Energ. Convers. Manage. 2007, 48, 68–77. [Google Scholar] [CrossRef]

- El-Rub, Z.A.; Bramer, E.; Al-Gharabli, S.; Brem, G. Impact of char properties and reaction parameters on naphthalene conversion in a macro-TGA fixed char bed reactor. Catalysts 2019, 9, 307. [Google Scholar] [CrossRef]

- Guo, F.Q.; Peng, K.Y.; Liang, S.A.; Jia, X.P.; Jiang, X.C.; Qian, L. Evaluation of the catalytic performance of different activated biochar catalysts for removal of tar from biomass pyrolysis. Fuel 2019, 258, 116204. [Google Scholar] [CrossRef]

- Tsubouchi, N.; Mochizuki, Y.; Byambajav, E.; Takahashi, S.; Hanaoka, Y.; Ohtsuka, Y. Catalytic performance of limonite ores in the decomposition of model compounds of biomass-derived tar. Energ. Fuel. 2017, 31, 3898–3904. [Google Scholar] [CrossRef]

- Lestinsky, P.; Grycova, B.; Pryszcz, A.; Martaus, A.; Matejova, L. Hydrogen production from microwave catalytic pyrolysis of spruce sawdust. J. Anal. Appl. Pyrol. 2017, 124, 175–179. [Google Scholar] [CrossRef]

- Al-Rahbi, A.S.; Williams, P.T. Hydrogen-rich syngas production and tar removal from biomass gasification using sacrificial tyre pyrolysis char. Appl. Energ. 2017, 190, 501–509. [Google Scholar] [CrossRef]

- Mui, E.L.K.; Ko, D.C.K.; McKay, G. Production of active carbons from waste tyres—A review. Carbon 2004, 42, 2789–2805. [Google Scholar] [CrossRef]

| Clay Mineral | ||||||

| Component | SiO2 | Fe2O3 | Al2O3 | CaO | MgO | Other |

| w [mass%] | 63.16 ± 0.14 | 8.89 ± 0.02 | 7.28 ± 0.04 | 6.15 ± 0.04 | 2.87 ± 0.03 | 11.65 |

| Pyrolysis Char | ||||||

| Element | C | S | H | N | O | Ash |

| w [mass%] | 72.91 ± 0.64 | 2.47 ± 0.03 | 0.47 ± 0.01 | 0.45 ± 0.01 | 1.16 | 22.54 |

| Catalyst | SBET [m2 g−1] | vp [cm3 g−1] | dp [nm] |

|---|---|---|---|

| Ni-doped clay | 28.6 | 0.17 | 7.8 |

| Pyrolysis char | 67.5 | 0.32 | 17.4 |

| Catalyst | Temperature, t [°C] | p-Xylene Conversion, α [%] | |

|---|---|---|---|

| τ = 30 min | τ = 180 min | ||

| None | 750 | 70.3 | 71.3 |

| 800 | 71.5 | 71.5 | |

| 850 | 71.1 | 73.0 | |

| Ni-doped clay (10 g) GHSV = 2400 h−1 | 750 | 100 | 76.4 |

| 800 | 100 | 76.8 | |

| 850 | n.a. | n.a. | |

| Pyrolysis char (10 g) GHSV = 1000 h−1 | 750 | 99.8 | 94.4 |

| 800 | 99.8 | 99.1 | |

| 850 | 99.9 | 99.9 | |

| Catalyst | None | Ni-Doped Clay | Pyrolysis Char | |

|---|---|---|---|---|

| Product Distribution | ||||

| Solid phase/% | 1.63 | 29.13 | 27.17 | |

| Liquid phase/% | 29.55 | 1.80 | 1.58 | |

| Gas phase/% | 68.82 | 69.08 | 71.26 | |

| Analyzed Components Content | ||||

| Mass, m [g] | Char | 0.0208 | 0.3495 | 0.3450 |

| p-Xylene | 0.3481 | 0.0027 | 0.0025 | |

| Toluene | 0.0342 | 0.0189 | 0.0175 | |

| Volume fraction, φ [vol.%] | N2 | 87.79 | 83.81 | 86,04 |

| CO2 | 10.56 | 7.77 | 9.22 | |

| CO | 0.54 | 6.06 | 2.48 | |

| H2 | 0.94 | 2.23 | 1.94 | |

| CH4 | 0.15 | 0.13 | 0.32 | |

| Other, C2+ | 0.00 | 0.00 | 0.00 | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Steltenpohl, P.; Husár, J.; Šuhaj, P.; Haydary, J. Performance of Catalysts of Different Nature in Model Tar Component Decomposition. Catalysts 2019, 9, 894. https://doi.org/10.3390/catal9110894

Steltenpohl P, Husár J, Šuhaj P, Haydary J. Performance of Catalysts of Different Nature in Model Tar Component Decomposition. Catalysts. 2019; 9(11):894. https://doi.org/10.3390/catal9110894

Chicago/Turabian StyleSteltenpohl, Pavol, Jakub Husár, Patrik Šuhaj, and Juma Haydary. 2019. "Performance of Catalysts of Different Nature in Model Tar Component Decomposition" Catalysts 9, no. 11: 894. https://doi.org/10.3390/catal9110894

APA StyleSteltenpohl, P., Husár, J., Šuhaj, P., & Haydary, J. (2019). Performance of Catalysts of Different Nature in Model Tar Component Decomposition. Catalysts, 9(11), 894. https://doi.org/10.3390/catal9110894