Catalyst Deactivation and Regeneration Processes in Biogas Tri-Reforming Process. The Effect of Hydrogen Sulfide Addition

Abstract

1. Introduction

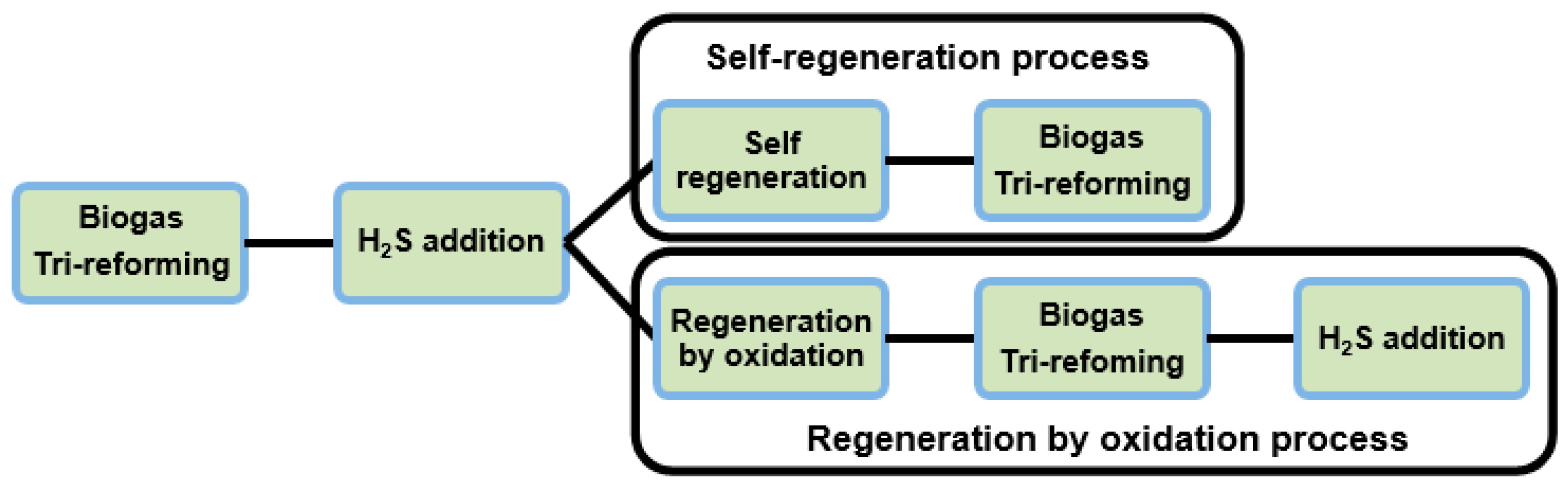

2. Results and Discussion

2.1. Fresh and Reduced Catalysts Characterization

2.2. Activity Results

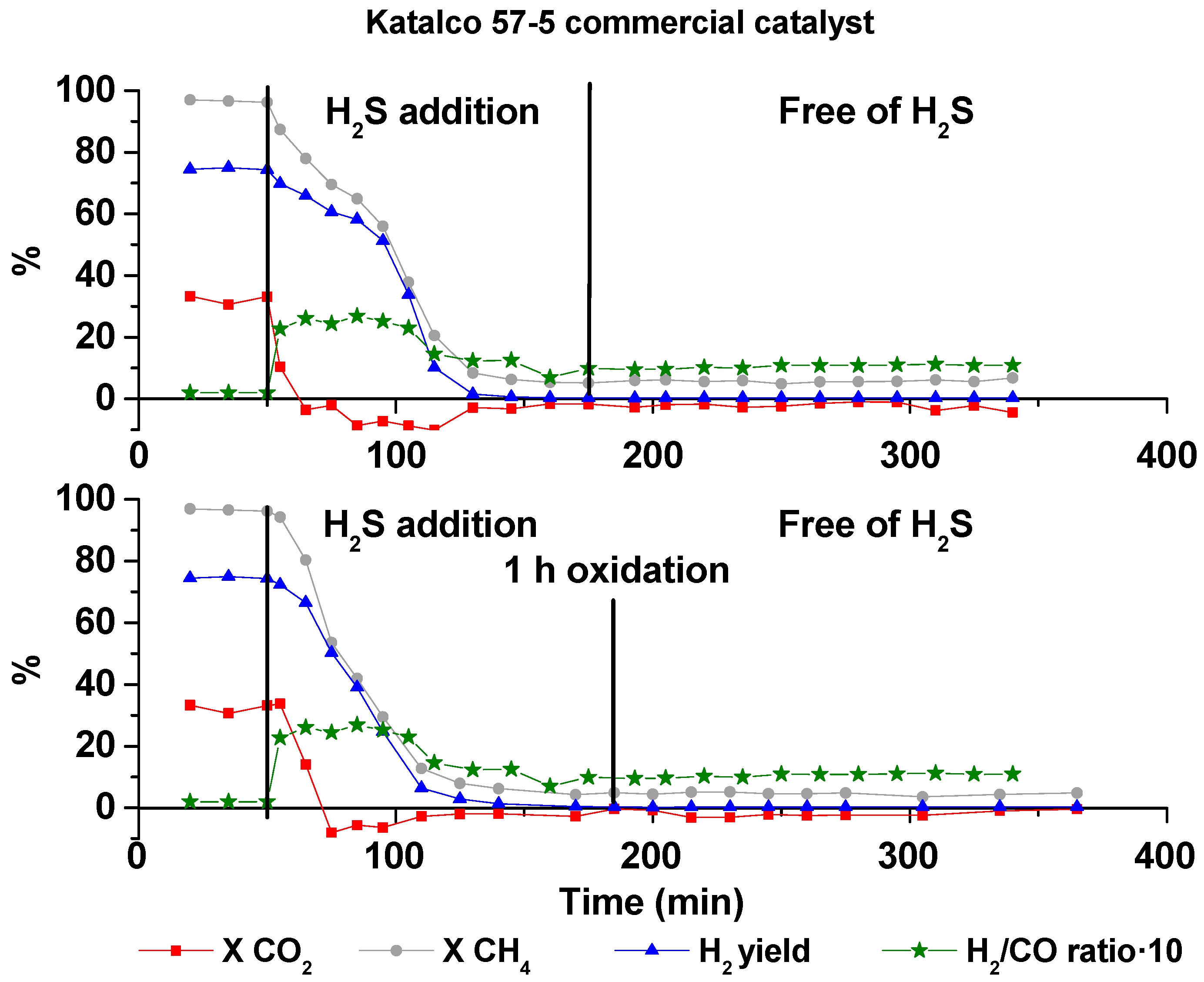

2.2.1. Katalco 57-5 Ni-Al2O3 Catalyst

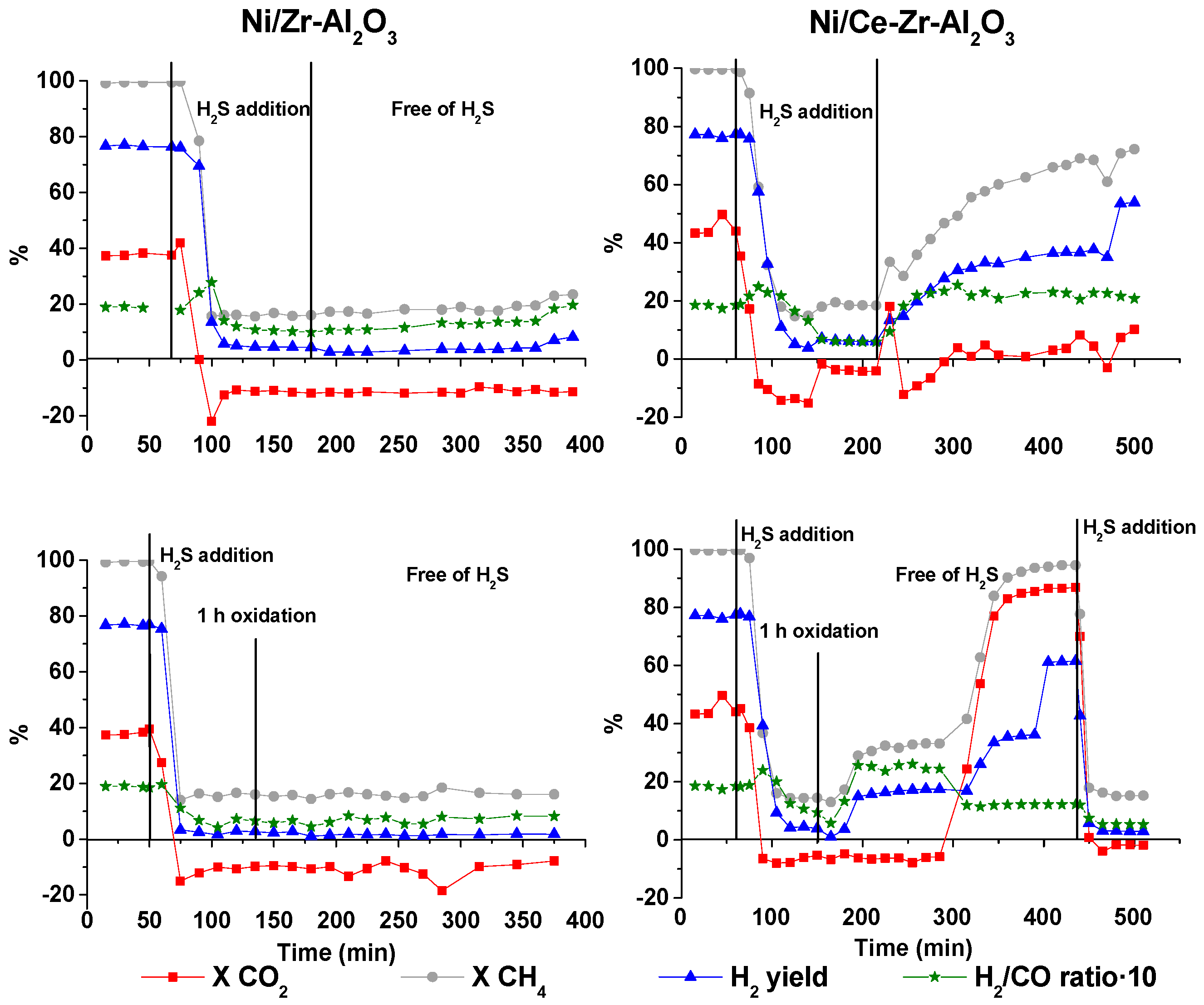

2.2.2. Ni/Zr-Al2O3 Catalyst

2.2.3. Ni/Ce-Zr-Al2O3 Catalyst

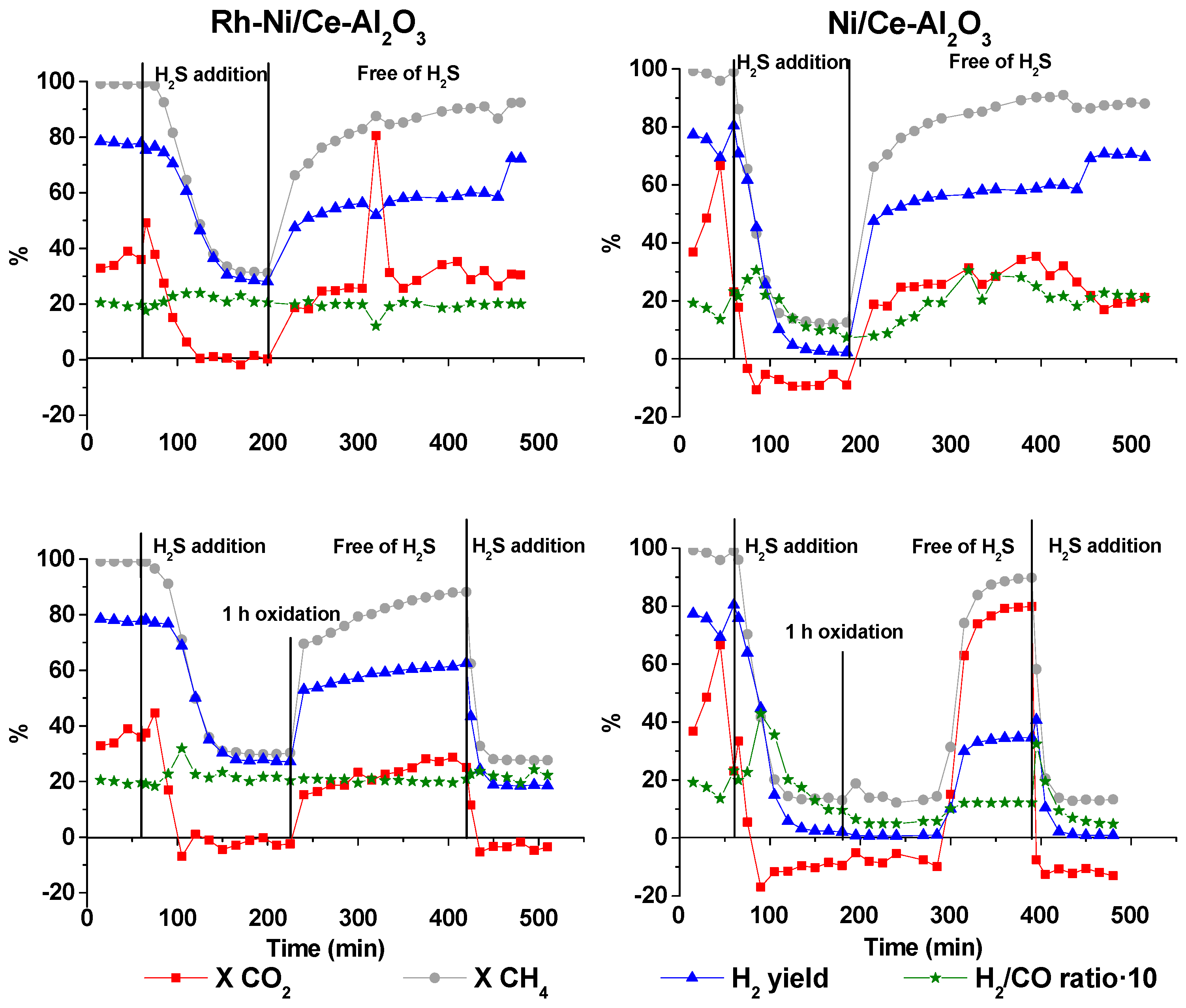

2.2.4. Ni/Ce-Al2O3 Catalyst

2.2.5. Rh-Ni/Ce-Al2O3 Catalyst

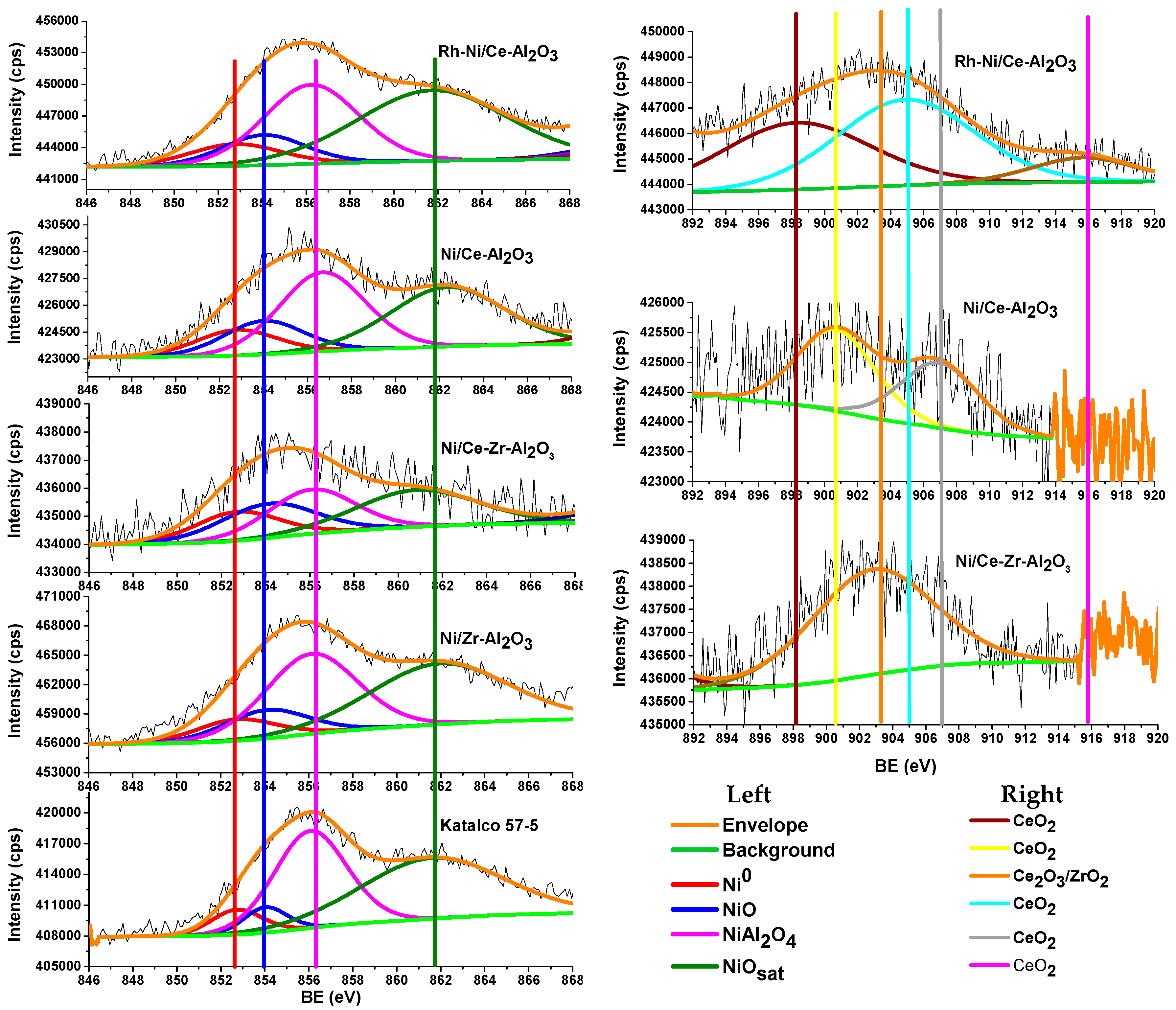

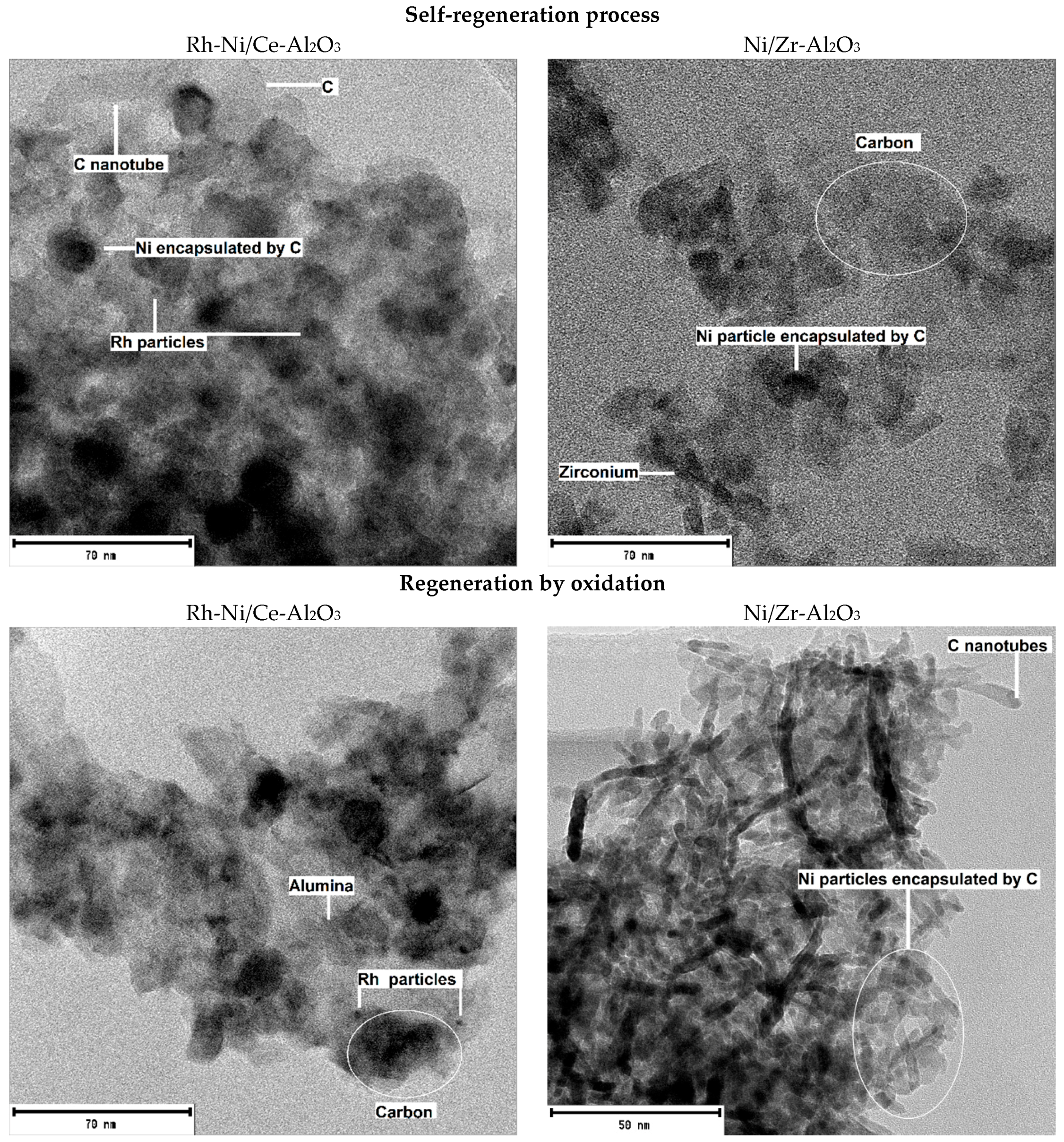

2.3. Fresh and Tested Catalysts Characterization by XPS

3. Materials and Methods

3.1. Catalysts Preparation

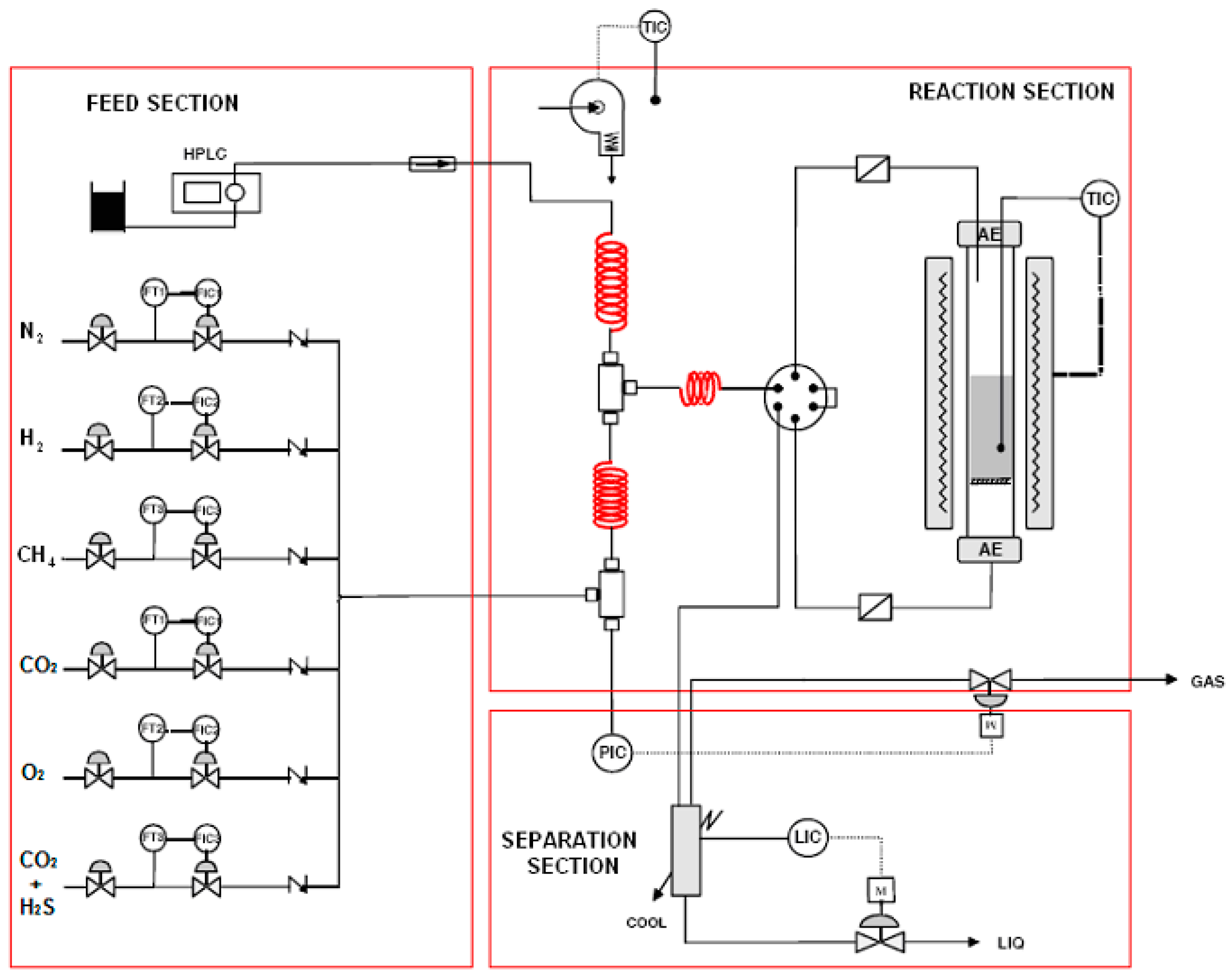

3.2. Activity Measurements

3.3. Catalysts Characterization Techniques

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Appendix A

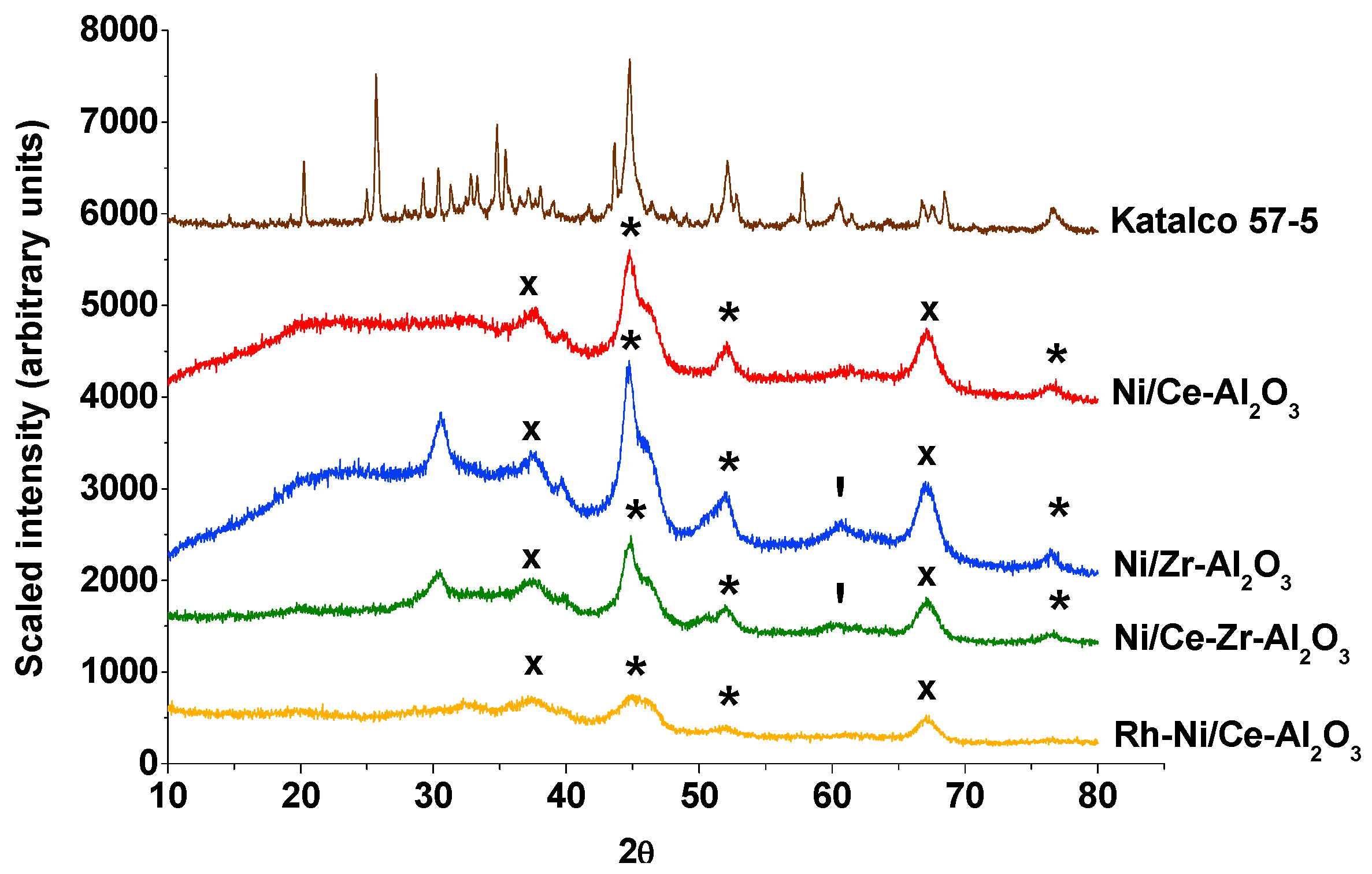

Appendix A.1. XRD Results

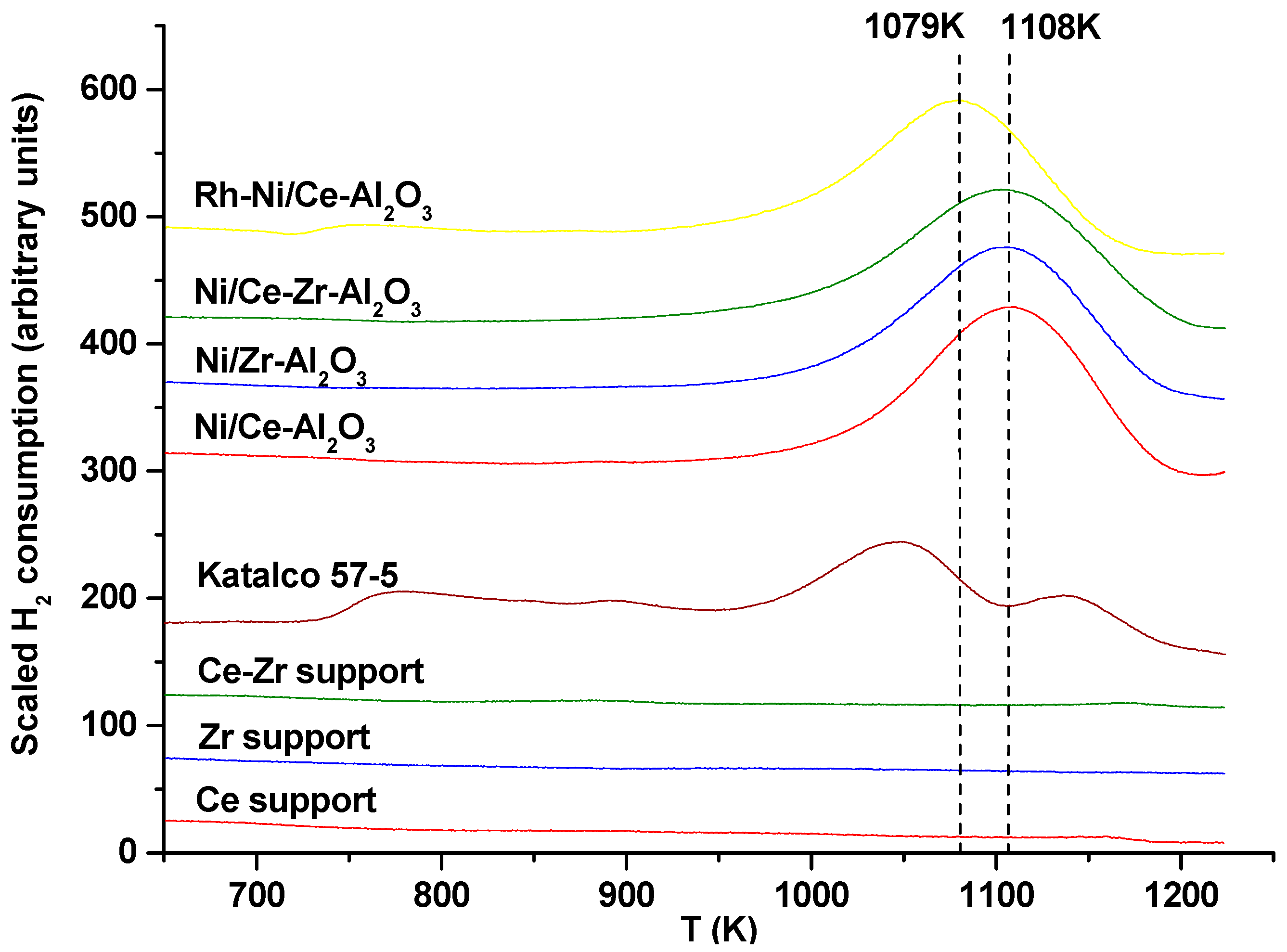

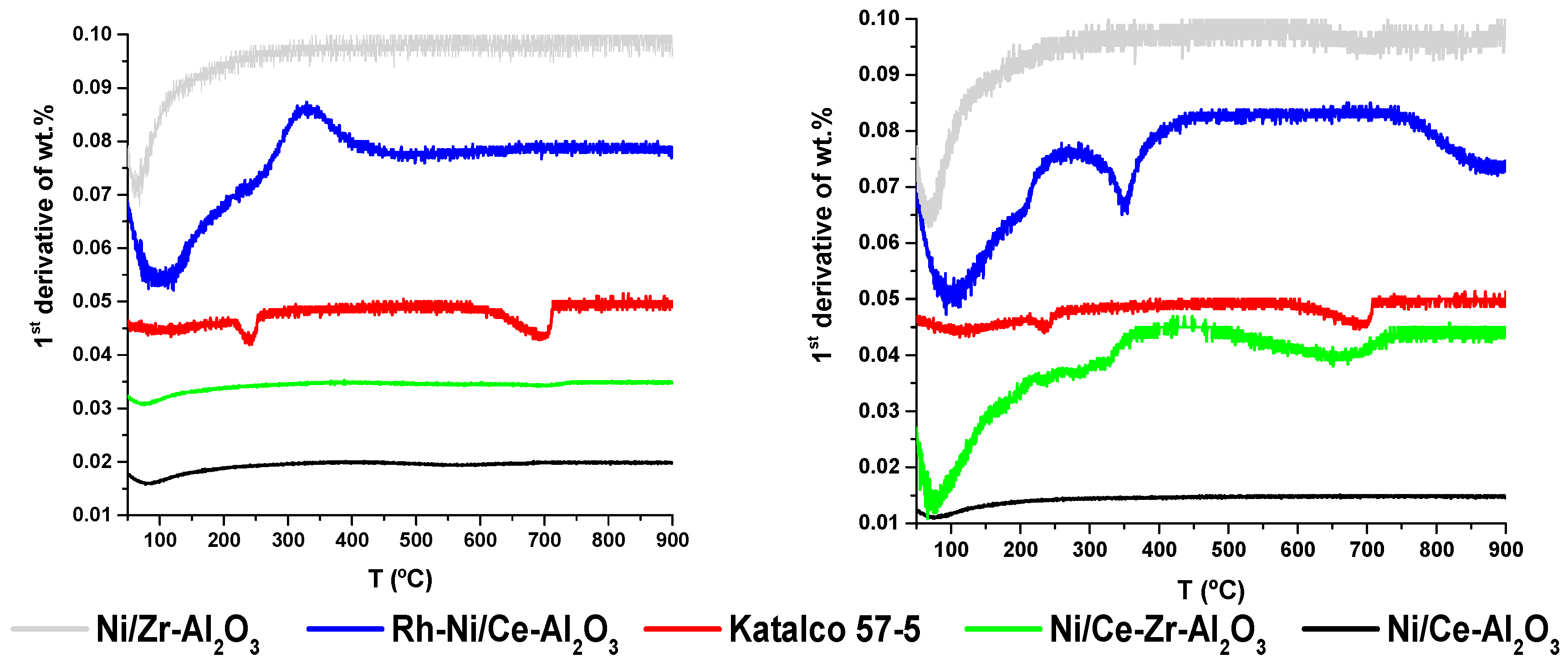

Appendix A.2. TPR Profiles

Appendix A.3. XPS Spectra

References

- Afonso, T.L.; Marques, A.C.; Fuinhas, J.A. Strategies to make renewable energy sources compatible with economic growth. Energy Strateg. Rev. 2017, 18, 121–126. [Google Scholar] [CrossRef]

- Foster, E.; Contestabile, M.; Blazquez, J.; Manzano, B.; Workman, M.; Shah, N. The unstudied barriers to widespread renewable energy deployment: Fossil fuel price responses. Energy Policy 2017, 103, 258–264. [Google Scholar] [CrossRef]

- Ryckebosch, E.; Drouillon, M.; Vervaeren, H. Techniques for transformation of biogas to biomethane. Biomass Bioenergy 2011, 35, 1633–1645. [Google Scholar] [CrossRef]

- Budzianowski, W.M.; Postawa, K. Renewable energy from biogas with reduced carbon dioxide footprint: Implications of applying different plant configurations and operating pressures. Renew. Sustain. Energy Rev. 2017, 68, 852–868. [Google Scholar] [CrossRef]

- Ramaraj, S.; Hemaiswarya, S.; Raja, R.; Ganesan, V.; Anbazhagan, C.; Carvalho, I.S.; Juntawong, N. Microalgae as an Attractive Source for Biofuel Production. In Environmental Sustainability; Thangavel, P., Sridevi, G., Eds.; Springer: New Delhi, India, 2015. [Google Scholar]

- Ullah Khan, I.; Hafiz Dzarfan Othman, M.; Hashim, H.; Matsuura, T.; Ismail, A.F.; Rezaei-DashtArzhandi, M.; Wan Azelee, I. Biogas as a renewable energy fuel—A review of biogas upgrading, utilisation and storage. Energy Convers. Manag. 2017, 150, 277–294. [Google Scholar] [CrossRef]

- REN 21. Renewables 2017: Global Status Report. Available online: http://www.ren21.net/wp-content/uploads/2017/06/17-8399_GSR_2017_Full_Report_0621_Opt.pdf (accessed on 3 January 2018).

- Hakawati, R.; Smyth, B.M.; Mccullough, G.; De Rosa, F.; Rooney, D. What is the most energy efficient route for biogas utilization: Heat, electricity or transport? Appl. Energy 2017, 206, 1076–1087. [Google Scholar] [CrossRef]

- Pino, L.; Vita, A.; Laganà, M.; Recupero, V. Hydrogen from biogas: Catalytic tri-reforming process with Ni/La–Ce–O mixed oxides. Appl. Catal. B Environ. 2014, 148–149, 91–105. [Google Scholar] [CrossRef]

- Vita, A.; Italiano, C.; Fabiano, C.; Pino, L.; Laganà, M.; Recupero, V. Hydrogen-rich gas production by steam reforming of n-dodecane: Part I: Catalytic activity of Pt/CeO2 catalysts in optimized bed configuration. Appl. Catal. B Environ. 2016, 199, 350–360. [Google Scholar] [CrossRef]

- García-Vargas, J.M.; Valverde, J.L.; De Lucas-Consuegra, A.; Gómez-Monedero, B.; Sánchez, P.; Dorado, F. Precursor influence and catalytic behaviour of Ni/CeO2 and Ni/SiC catalysts for the tri-reforming process. Appl. Catal. A Gen. 2012, 431–432, 49–56. [Google Scholar]

- Sie, S.T.; Krishna, R. Fundamentals and selection of advanced Fischer–Tropsch reactors. Appl. Catal. A Gen. 1999, 186, 55–70. [Google Scholar] [CrossRef]

- Nahar, G.; Mote, D.; Dupont, V. Hydrogen production from reforming of biogas: Review of technological advances and an Indian perspective. Renew. Sustain. Energy Rev. 2017, 76, 1032–1052. [Google Scholar] [CrossRef]

- Rasi, S.; Veijanen, A.; Rintala, J. Trace compounds of biogas from different biogas production plants. Energy 2007, 32, 1375–1380. [Google Scholar] [CrossRef]

- Saha, B.; Khan, A.; Ibrahim, H.; Idem, R. Evaluating the performance of non-precious metal based catalysts for sulfur-tolerance during the dry reforming of biogas. Fuel 2014, 120, 202–217. [Google Scholar] [CrossRef]

- Chattanathan, S.A.; Adhikari, S.; McVey, M.; Fasina, O. Hydrogen production from biogas reforming and the effect of H2S on CH4 conversion. Int. J. Hydrogen Energy 2014, 39, 19905–19911. [Google Scholar] [CrossRef]

- Appari, S.; Janardhanan, V.M.; Bauri, R.; Jayanti, S. Deactivation and regeneration of Ni catalyst during steam reforming of model biogas: An experimental investigation. Int. J. Hydrogen Energy 2014, 39, 297–304. [Google Scholar] [CrossRef]

- Hulteberg, C. Sulphur-tolerant catalysts in small-scale hydrogen production, a review. Int. J. Hydrogen Energy 2012, 37, 3978–3992. [Google Scholar] [CrossRef]

- Izquierdo, U.; Barrio, V.L.; Requies, J.; Cambra, J.F.; Güemez, M.B.; Arias, P.L. Tri-reforming: A new biogas process for synthesis gas and hydrogen production. Int. J. Hydrogen Energy 2013, 38, 7623–7631. [Google Scholar] [CrossRef]

- Fidalgo, B.; Muradov, N.; Menéndez, J.A. Effect of H2S on carbon-catalyzed methane decomposition and CO2 reforming reactions. Int. J. Hydrogen Energy 2012, 37, 14187–14194. [Google Scholar] [CrossRef]

- Albertazzi, S.; Basile, F.; Brandin, J.; Einvall, J.; Fornasari, G.; Hulteberg, C.; Sanati, M.; Trifirò, F.; Vaccari, A. Effect of fly ash and H2S on a Ni-based catalyst for the upgrading of a biomass-generated gas. Biomass Bioenergy 2008, 32, 345–353. [Google Scholar] [CrossRef]

- Packer, A.P.; Lariviere, D.; Li, C.; Chen, M.; Fawcett, A.; Nielsen, K.; Mattson, K.; Chatt, A.; Scriver, C.; Erhardt, L.S. Validation of an inductively coupled plasma mass spectrometry (ICP-MS) method for the determination of cerium, strontium, and titanium in ceramic materials used in radiological dispersal devices (RDDs). Anal. Chim. Acta 2007, 588, 166–172. [Google Scholar] [CrossRef] [PubMed]

- García-Diéguez, M.; Herrera, M.C.; Pieta, I.S.; Larrubia, M.A.; Alemany, L.J. NiBa catalysts for CO2-reforming of methane. Catal. Commun. 2010, 11, 1133–1136. [Google Scholar] [CrossRef]

- Tsipouriari, V.A.; Efstathiou, A.M.; Zhang, Z.L.; Verykios, X.E. Reforming of methane with carbon dioxide to synthesis gas over supported Rh catalysts. Catal. Today 1994, 21, 579–587. [Google Scholar] [CrossRef]

- Izquierdo, U.; Barrio, V.L.; Lago, N.; Requies, J.; Cambra, J.F.; Güemez, M.B.; Arias, P.L. Biogas steam and oxidative reforming processes for synthesis gas and hydrogen production in conventional and microreactor reaction systems. Int. J. Hydrogen Energy 2012, 37, 13829–13842. [Google Scholar] [CrossRef]

- San-José-Alonso, D.; Juan-Juan, J.; Illán-Gómez, M.J.; Román-Martínez, M.C. Ni, Co and bimetallic Ni–Co catalysts for the dry reforming of methane. Appl. Catal. A Gen. 2009, 371, 54–59. [Google Scholar] [CrossRef]

- Lau, C.S.; Tsolakis, A.; Wyszynski, M.L. Biogas upgrade to syn-gas (H2–CO) via dry and oxidative reforming. Int. J. Hydrogen Energy 2011, 36, 397–404. [Google Scholar] [CrossRef]

- Iriondo, A.; Barrio, V.L.; Cambra, J.F.; Arias, P.L.; Guemez, M.B.; Sanchez-Sanchez, M.C.; Navarro, R.M.; Fierro, J.L.G. Glycerol steam reforming over Ni catalysts supported on ceria and ceria-promoted alumina. Int. J. Hydrogen Energy 2010, 35, 11622–11633. [Google Scholar] [CrossRef]

- Iriondo, A.; Cambra, J.F.; Güemez, M.B.; Barrio, V.L.; Requies, J.; Sánchez-Sánchez, M.C.; Navarro, R.M. Effect of ZrO2 addition on Ni/Al2O3 catalyst to produce H2 from glycerol. Int. J. Hydrogen Energy 2012, 37, 7084–7093. [Google Scholar] [CrossRef]

- Sánchez-Sánchez, M.C.; Navarro, R.M.; Fierro, J.L.G. Ethanol steam reforming over Ni/La–Al2O3 catalysts: Influence of lanthanum loading. Catal. Today 2007, 129, 336–345. [Google Scholar] [CrossRef]

- Blanco, P.H.; Wu, C.; Onwudili, J.A.; Williams, P.T. Characterization and evaluation of Ni/SiO2 catalysts for hydrogen production and tar reduction from catalytic steam pyrolysis-reforming of refuse derived fue. Appl. Catal. B Environ. 2013, 134–135, 238–250. [Google Scholar] [CrossRef]

- Jablonski, W.S.; Villano, S.M.; Dean, A.M. A comparison of H2S, SO2, and COS poisoning on Ni/YSZ and Ni/K2O-CaAl2O4 during methane steam and dry reforming. Appl. Catal. A Gen. 2015, 502, 399–409. [Google Scholar] [CrossRef]

- Appari, S.; Janardhanan, V.M.; Bauri, R.; Jayanti, S.; Deutschmann, O. A detailed kinetic model for biogas steam reforming on Ni and catalyst deactivation due to sulfur poisoning. Appl. Catal. A Gen. 2014, 471, 118–125. [Google Scholar] [CrossRef]

- Effendi, A.; Zhang, Z.G.; Hellgardt, K.; Honda, K.; Yoshida, T. Steam reforming of a clean model biogas over Ni/Al2O3 in fluidized- and fixed-bed reactors. Catal. Today 2002, 77, 181–189. [Google Scholar] [CrossRef]

- Davis, E.M.; Davis, R.J. Fundamentals of Chemical Reaction Engineering; Glandt, E., Klein, T., Edgar, F., Eds.; McGraw-Hill: New York, NY, USA, 2003; Volume 43. [Google Scholar]

- National Institute of Standards and Technology. Available online: https://srdata.nist.gov/xps/Default.aspx (accessed on 28 November 2017).

| Catalyst | Specific Surface Area (m2/g) | Pore Volume (cm3/g) | Pore Diameter (Å) |

|---|---|---|---|

| Bare Al2O3 | 255.0 | 1.14 | - |

| 6Ce-Al Support | 195.0 | 0.76 | 150.1 |

| 8Zr-Al Support | 180.3 | 0.67 | 143.9 |

| 3Ce-4Zr-Al Support | 191.7 | 0.74 | 150.7 |

| 13Ni/Ce-Al2O3-calcined | 163.3 | 0.59 | 143.7 |

| 13Ni/Ce-Al2O3-reduced | 102.5 | 0.19 | 82.5 |

| 13Ni/Zr-Al2O3-calcined | 166.6 | 0.62 | 146.3 |

| 13Ni/Ce-Zr-Al2O3-calcined | 151.0 | 0.60 | 153.2 |

| 13Ni/Ce-Zr-Al2O3-reduced | 131.0 | 0.60 | 183.2 |

| 1Rh-13Ni/Ce-Al2O3-calcined | 156.8 | 0.60 | 150.1 |

| 1Rh-13Ni/Ce-Al2O3-reduced | 118.3 | 0.29 | 91.5 |

| Katalco 57-5-calcined | 21.6 | 0.09 | 169.5 |

| Catalyst | Chemical Composition (ICP-OES) | H2 Chemisorption * | XRD ** | ||

|---|---|---|---|---|---|

| Nominal/Real (wt. %) | MSA (m2/g) | D (%) | Ni CS (nm) | Ni CS (nm) | |

| Katalco 57-5 | -/12.4 (Ni) -/0.4 (Ca) | - | - | - | - |

| Ni/Ce-Al2O3 | 13.0/10.8 (Ni) 6.0/3.3 (Ce) | 5.6 | 6.4 | 15.7 | 8 |

| Ni/Zr-Al2O3 | 13.0/11.4 (Ni) 8.0/5.5 (Zr) | - | - | - | 7 |

| Ni/Ce-Zr-Al2O3 | 13.0/10.6 (Ni) 3.0/2.7 (Ce) 4.0/3.6 (Zr) | 5.1 | 7.3 | 13.9 | 7 |

| Rh-Ni/Ce-Al2O3 | 13.0/10.0 (Ni) 1.0/0.9 (Rh) 6.0/3.6 (Ce) | 8.0 | 11.6 | - | 5 |

| Catalysts | Fresh Catalyst | Ni/Al Atomic Ratio | C/Al Atomic Ratio | wt. % Loss | |||

|---|---|---|---|---|---|---|---|

| Self Regenerated | Regeneration by Oxidation | Self Regenerated | Regeneration by Oxidation | Self Regenerated | Regeneration by Oxidation | ||

| Katalco 57-5 | 0.17 | 0.15 | 0.14 | 0.95 | 0.88 | 1.98 | 1.69 |

| Ni/Ce-Al2O3 | 0.10 | 0.07 | 0.10 | 0.38 | 0.13 | 4.11 | 4.01 |

| Ni/Zr-Al2O3 | 0.13 | 0.16 | 0.15 | 0.19 | 0.17 | 3.79 | 5.35 |

| Ni/Ce-Zr-Al2O3 | 0.05 | 0.08 | 0.11 | 0.20 | 0.15 | 4.28 | 5.57 |

| Rh-Ni/Ce-Al2O3 | 0.16 | 0.10 | 0.16 | 0.20 | 0.16 | 4.27 | 9.01 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Izquierdo, U.; García-García, I.; Gutierrez, Á.M.; Arraibi, J.R.; Barrio, V.L.; Cambra, J.F.; Arias, P.L. Catalyst Deactivation and Regeneration Processes in Biogas Tri-Reforming Process. The Effect of Hydrogen Sulfide Addition. Catalysts 2018, 8, 12. https://doi.org/10.3390/catal8010012

Izquierdo U, García-García I, Gutierrez ÁM, Arraibi JR, Barrio VL, Cambra JF, Arias PL. Catalyst Deactivation and Regeneration Processes in Biogas Tri-Reforming Process. The Effect of Hydrogen Sulfide Addition. Catalysts. 2018; 8(1):12. https://doi.org/10.3390/catal8010012

Chicago/Turabian StyleIzquierdo, Urko, Iker García-García, Ángel María Gutierrez, Juan Ramón Arraibi, Victoria Laura Barrio, José Francisco Cambra, and Pedro Luis Arias. 2018. "Catalyst Deactivation and Regeneration Processes in Biogas Tri-Reforming Process. The Effect of Hydrogen Sulfide Addition" Catalysts 8, no. 1: 12. https://doi.org/10.3390/catal8010012

APA StyleIzquierdo, U., García-García, I., Gutierrez, Á. M., Arraibi, J. R., Barrio, V. L., Cambra, J. F., & Arias, P. L. (2018). Catalyst Deactivation and Regeneration Processes in Biogas Tri-Reforming Process. The Effect of Hydrogen Sulfide Addition. Catalysts, 8(1), 12. https://doi.org/10.3390/catal8010012