Influence of the Nanostructure of Gallium Oxide Catalysts on Conversion in the Green Synthesis of Carbamates

Abstract

:1. Introduction

2. Results and Discussion

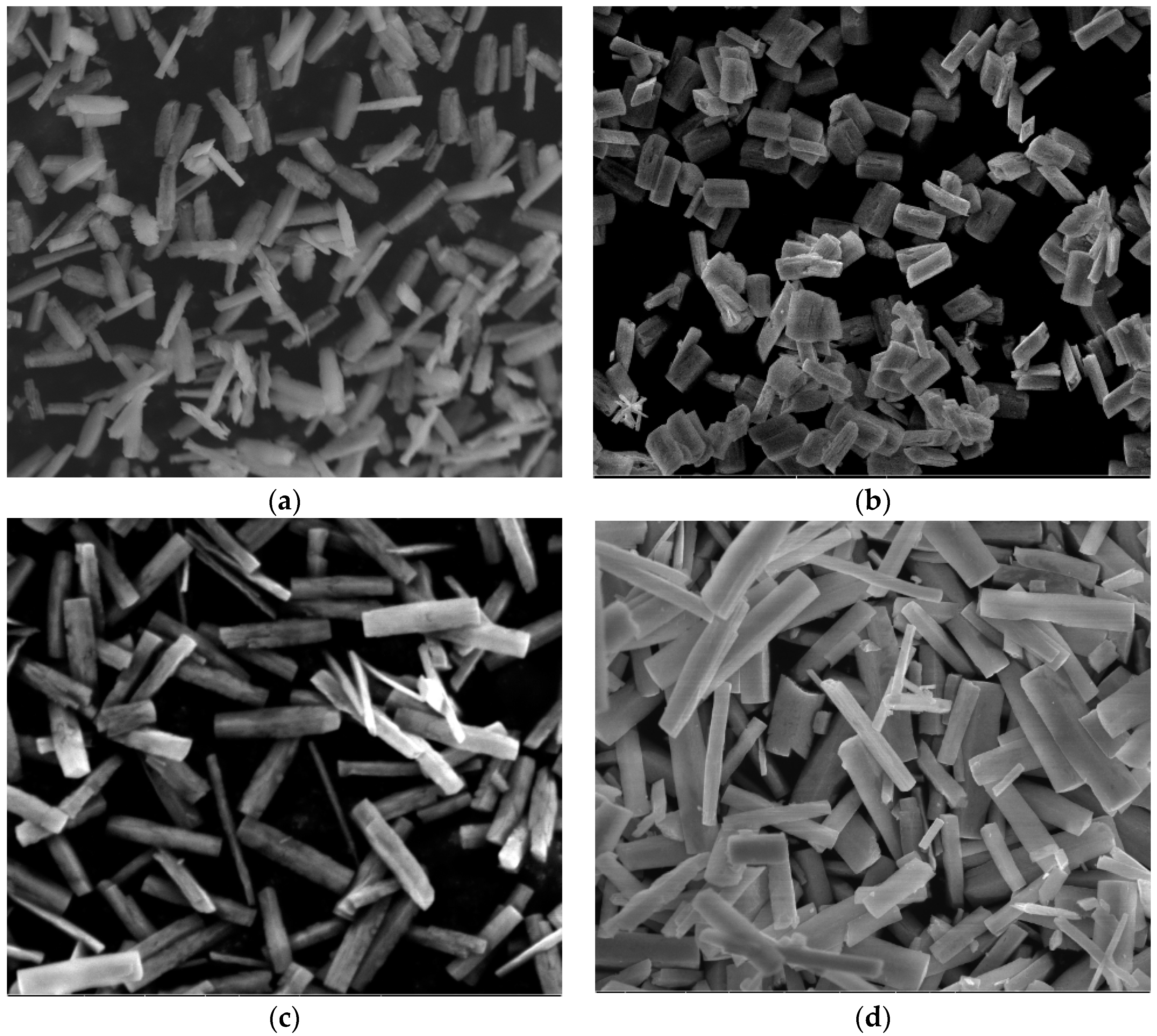

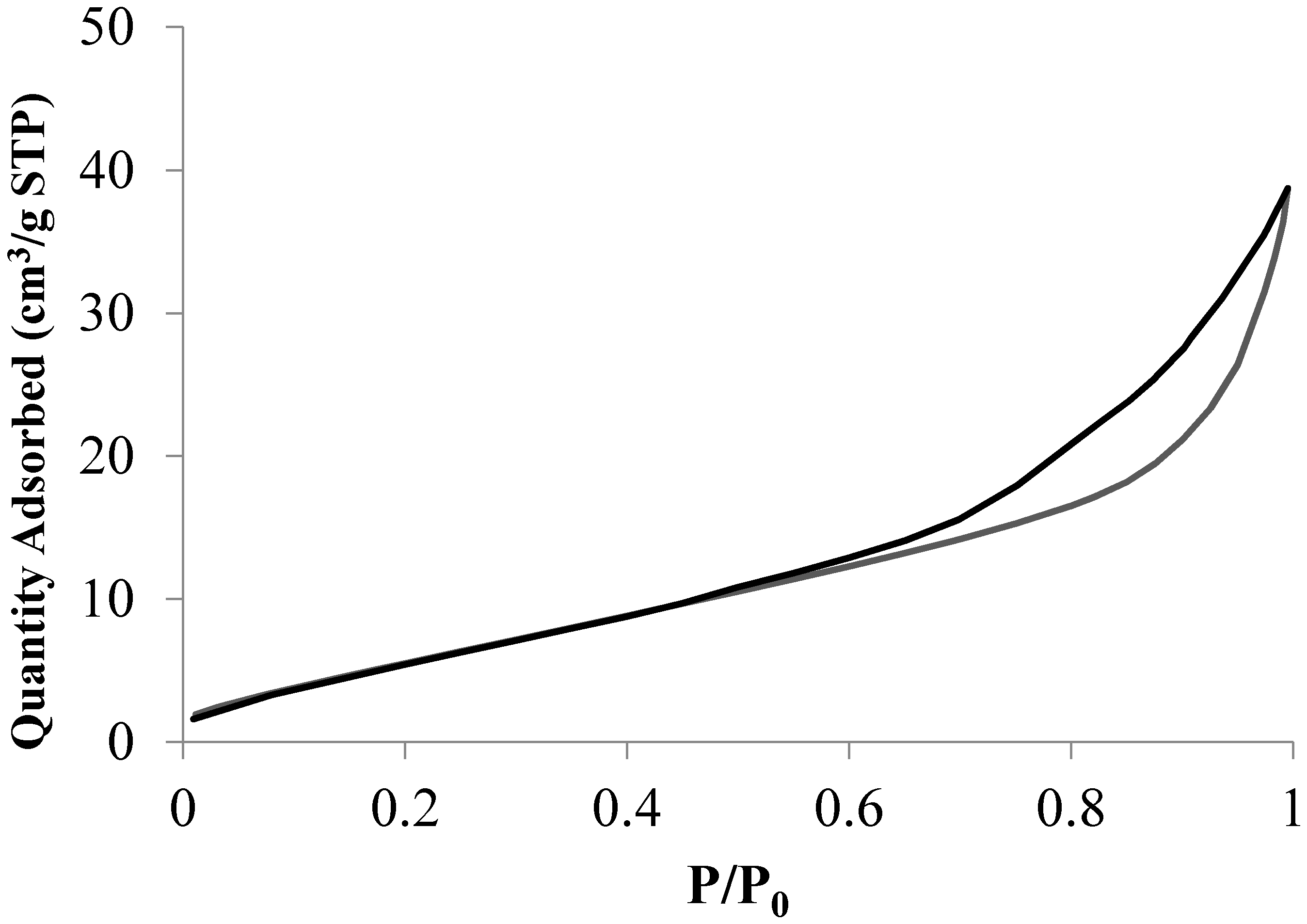

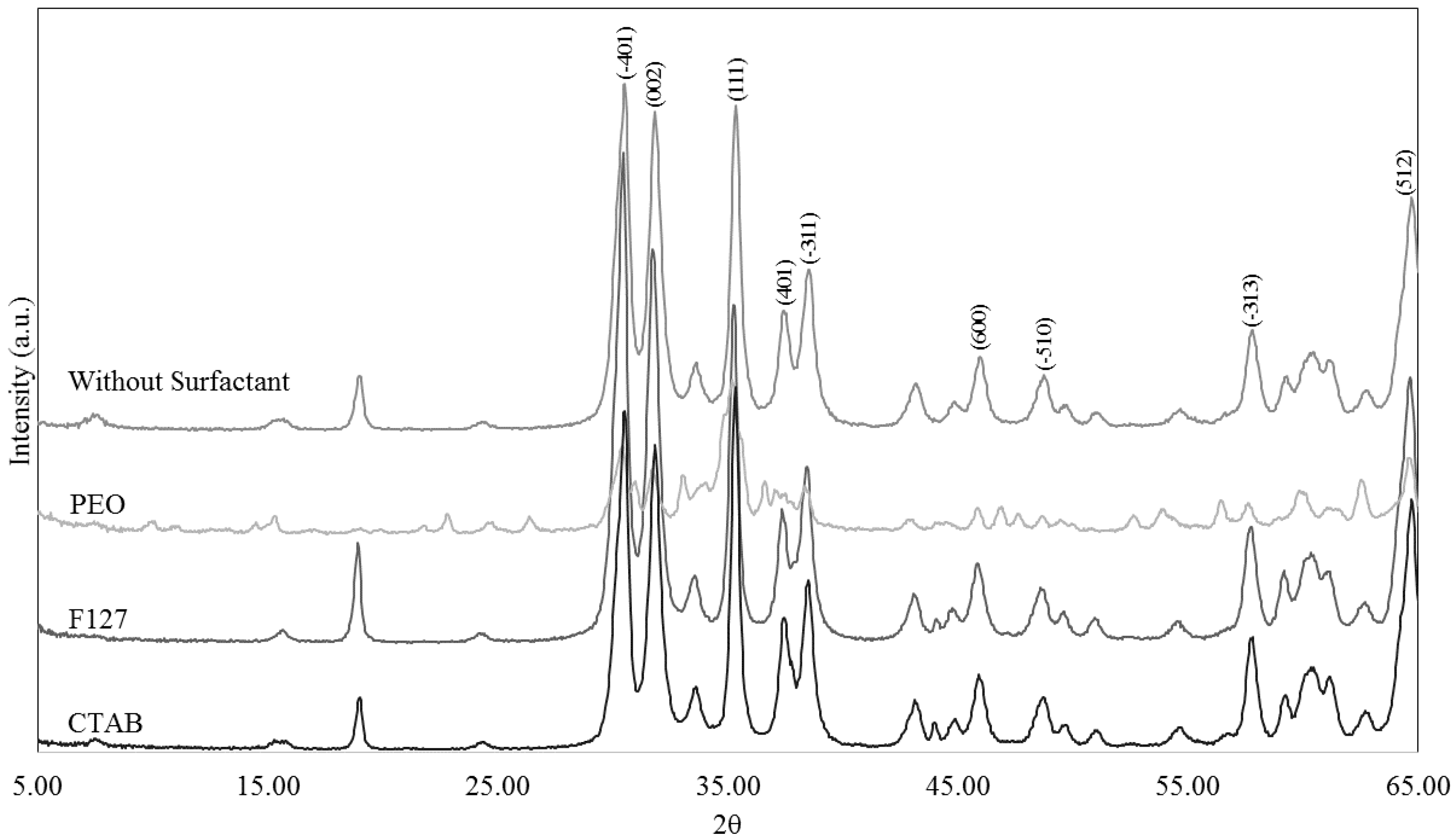

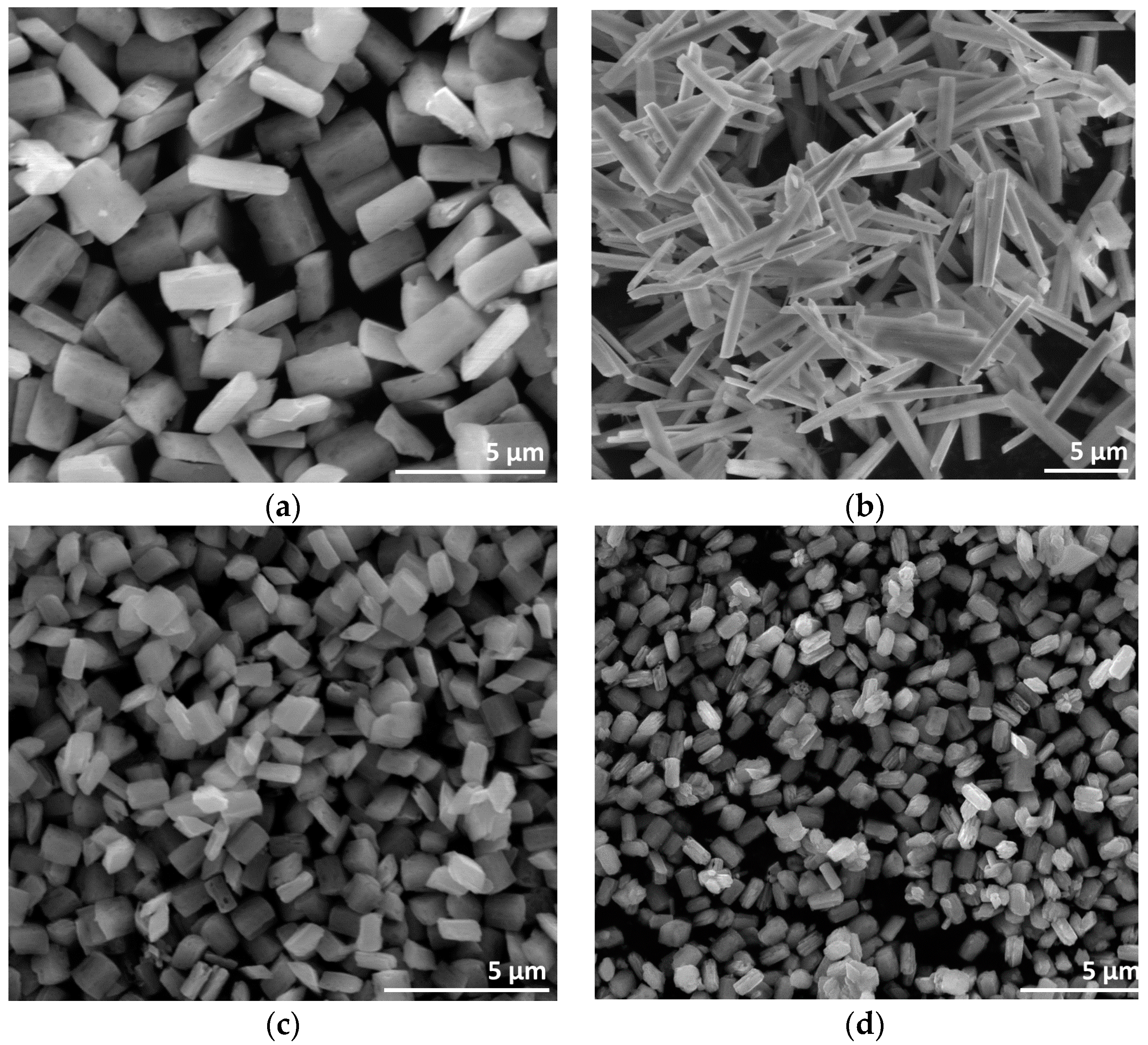

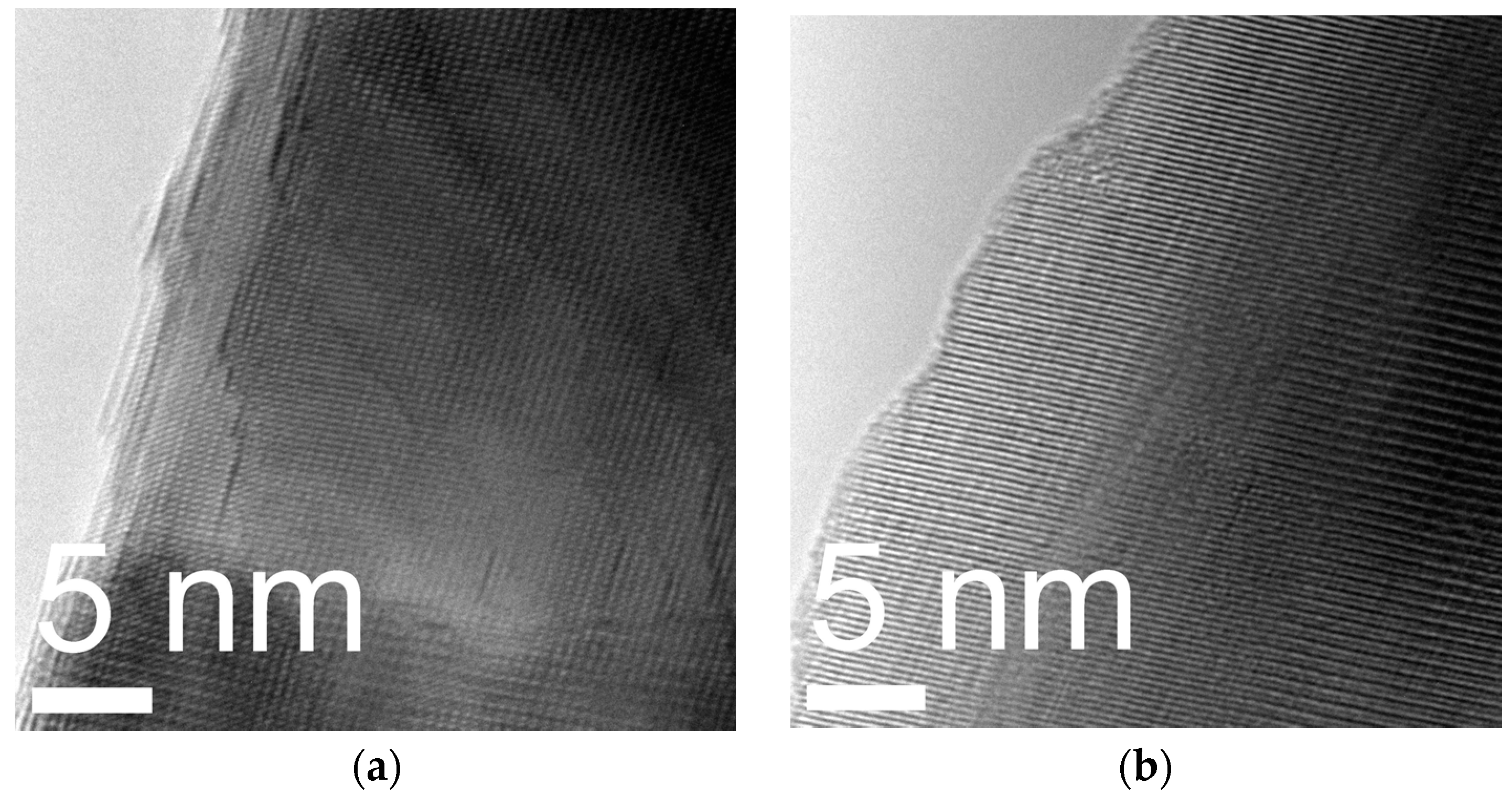

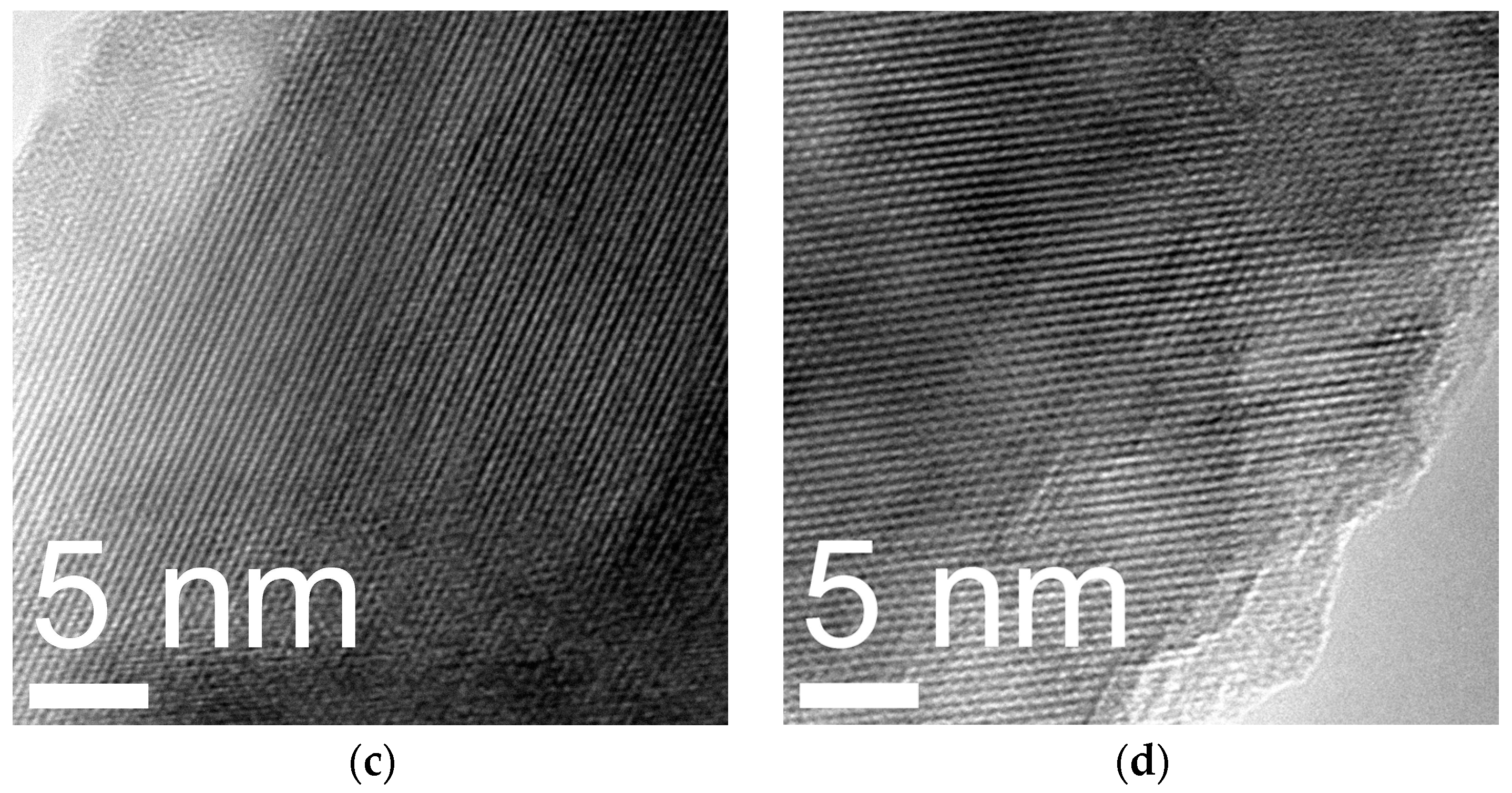

2.1. Catalyst Preparation and Characterization

2.2. Catalytic Activity

3. Materials and Methods

3.1. Catalyst Preparation

3.2. Characterization

3.3. Catalytic Activity

3.4. Product Analysis

4. Conclusions

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Åhman, J.; Svensson, G.; Albertsson, J. A reinvestigation of β-gallium oxide. Acta Crystallogr. Sect. C 1996, 52, 1336–1338. [Google Scholar] [CrossRef]

- Fleischer, M.; Hanrieder, W.; Meixner, H. Stability of semiconducting gallium oxide thin films. Thin Solid Films 1990, 190, 93–102. [Google Scholar] [CrossRef]

- Wu, X.; Song, W.; Huang, W.; Pu, M.; Zhao, B.; Sun, Y.; Du, J. Crystalline gallium oxide nanowires: Intensive blue light emitters. Chem. Phys. Lett. 2000, 328, 5–9. [Google Scholar] [CrossRef]

- Binet, L.; Gourier, D. Origin of the blue luminescence of β-Ga2O3. J. Phys. Chem. Solids 1998, 59, 1241–1249. [Google Scholar] [CrossRef]

- Li, Z.; De Groot, C.; Moodera, J.H. Gallium oxide as an insulating barrier for spin-dependent tunneling junctions. Appl. Phys. Lett. 2000, 77, 3630–3632. [Google Scholar] [CrossRef]

- Ogita, M.; Saika, N.; Nakanishi, Y.; Hatanaka, Y. Ga2O3 thin films for high-temperature gas sensors. Appl. Surf. Sci. 1999, 142, 188–191. [Google Scholar] [CrossRef]

- Jung, W.-S. Reaction intermediate(s) in the conversion of β-gallium oxide to gallium nitride under a flow of ammonia. Mater. Lett. 2002, 57, 110–114. [Google Scholar] [CrossRef]

- Vaidhyanathan, B.; Agrawal, D.; Roy, R. Novel synthesis of nitride powders by microwave-assisted combustion. J. Mater. Res. 2000, 15, 974–981. [Google Scholar] [CrossRef]

- Shimizu, K.-I.; Takamatsu, M.; Nishi, K.; Yoshida, H.; Satsuma, A.; Tanaka, T.; Yoshida, S.; Hattori, T. Alumina-supported gallium oxide catalysts for NO selective reduction: Influence of the local structure of surface gallium oxide species on the catalytic activity. J. Phys. Chem. B 1999, 103, 1542–1549. [Google Scholar] [CrossRef]

- Shimizu, K.-I.; Satsuma, A.; Hattori, T. Selective catalytic reduction of NO by hydrocarbons on Ga2O3/Al2O3 catalysts. Appl. Catal. B 1998, 16, 319–326. [Google Scholar] [CrossRef]

- Li, Y.; Armor, J.N. Selective catalytic reduction of NO with methane on gallium catalysts. J. Catal. 1994, 145, 1–9. [Google Scholar] [CrossRef]

- Hou, Y.; Wang, X.; Wu, L.; Ding, Z.; Fu, X. Efficient decomposition of benzene over a β-Ga2O3 photocatalyst under ambient conditions. Environ. Sci. Technol. 2006, 40, 5799–5803. [Google Scholar] [CrossRef] [PubMed]

- Saito, M.; Watanabe, S.; Takahara, I.; Inaba, M.; Murata, K. Dehydrogenation of propane over a silica-supported gallium oxide catalyst. Catal. Lett. 2003, 89, 213–217. [Google Scholar] [CrossRef]

- Zheng, B.; Hua, W.; Yue, Y.; Gao, Z. Dehydrogenation of propane to propene over different polymorphs of gallium oxide. J. Catal. 2005, 232, 143–151. [Google Scholar] [CrossRef]

- Nakagawa, K.; Okamura, M.; Ikenaga, N.; Suzuki, T.; Kobayashi, T. Dehydrogenation of ethane over gallium oxide in the presence of carbon dioxide. Chem. Commun. 1998, 9, 1025–1026. [Google Scholar] [CrossRef]

- Macias, E.E.; Deshmane, C.A.; Jasinski, J.B.; Carreon, M.A.; Ratnasamy, P. Catalytic transformations of methyl oleate and biodiesel over mesoporous gallium–niobium oxides. Catal. Commun. 2011, 12, 644–650. [Google Scholar] [CrossRef]

- Petre, A.; Auroux, A.; Gelin, P.; Caldararu, M.; Ionescu, N. Acid–base properties of supported gallium oxide catalysts. Thermochim. Acta 2001, 379, 177–185. [Google Scholar] [CrossRef]

- Xu, B.; Zheng, B.; Hua, W.; Yue, Y.; Gao, Z. Support effect in dehydrogenation of propane in the presence of CO2 over supported gallium oxide catalysts. J. Catal. 2006, 239, 470–477. [Google Scholar] [CrossRef]

- Tsuneoka, H.; Teramura, K.; Shishido, T.; Tanaka, T. Adsorbed Species of CO2 and H2 on Ga2O3 for the Photocatalytic Reduction of CO2. J. Phys. Chem. C 2010, 114, 8892–8898. [Google Scholar] [CrossRef]

- Huang, C.-C.; Yeh, C.-S.; Ho, C.-J. Laser ablation synthesis of spindle-like gallium oxide hydroxide nanoparticles with the presence of cationic cetyltrimethylammonium bromide. J. Phys. Chem. B 2004, 108, 4940–4945. [Google Scholar] [CrossRef]

- Hu, J.; Li, Q.; Meng, X.; Lee, C.; Lee, S. Synthesis of β-Ga2O3 nanowires by laser ablation. J. Phys. Chem. B 2002, 106, 9536–9539. [Google Scholar] [CrossRef]

- Higashiwaki, M.; Sasaki, K.; Kuramata, A.; Masui, T.; Yamakoshi, S. Gallium oxide (Ga2O3) metal-semiconductor field-effect transistors on single-crystal β-Ga2O3 (010) substrates. Appl. Phys. Lett. 2012, 100, 013504. [Google Scholar] [CrossRef]

- Valet, M.; Hoffman, D.M. Synthesis of homoleptic gallium alkoxide complexes and the chemical vapor deposition of gallium oxide films. Chem. Mater. 2001, 13, 2135–2143. [Google Scholar] [CrossRef]

- Battiston, G.; Gerbasi, R.; Porchia, M.; Bertoncello, R.; Caccavale, F. Chemical vapour deposition and characterization of gallium oxide thin films. Thin Solid Films 1996, 279, 115–118. [Google Scholar] [CrossRef]

- Kim, H.W.; Kim, N.H. Growth of gallium oxide thin films on silicon by the metal organic chemical vapor deposition method. Mater. Sci. Eng. B 2004, 110, 34–37. [Google Scholar] [CrossRef]

- Taş, A.C.; Majewski, P.J.; Aldinger, F. Synthesis of gallium oxide hydroxide crystals in aqueous solutions with or without urea and their calcination behavior. J. Am. Ceram. Soc. 2002, 85, 1421–1429. [Google Scholar] [CrossRef]

- Zhao, Y.; Frost, R.L.; Martens, W.N. Synthesis and characterization of gallium oxide nanostructures via a soft-chemistry route. J. Phys. Chem. C 2007, 111, 16290–16299. [Google Scholar] [CrossRef]

- Quan, Y.; Fang, D.; Zhang, X.; Liu, S.; Huang, K. Synthesis and characterization of gallium oxide nanowires via a hydrothermal method. Mater. Chem. Phys. 2010, 121, 142–146. [Google Scholar] [CrossRef]

- Zhao, Y.; Frost, R.L.; Yang, J.; Martens, W.N. Size and morphology control of gallium oxide hydroxide GaO (OH), nano-to micro-sized particles by soft-chemistry route without surfactant. J. Phys. Chem. C 2008, 112, 3568–3579. [Google Scholar] [CrossRef]

- Zhu, F.; Yang, Z.X.; Zhou, W.M.; Zhang, Y.F. Direct synthesis of beta gallium oxide nanowires, nanobelts, nanosheets and nanograsses by microwave plasma. Solid State Commun. 2006, 137, 177–181. [Google Scholar] [CrossRef]

- Dai, Z.; Pan, Z.; Wang, Z. Gallium oxide nanoribbons and nanosheets. J. Phys. Chem. B 2002, 106, 902–904. [Google Scholar] [CrossRef]

- Kumar, S.; Singh, R. Nanofunctional gallium oxide (Ga2O3) nanowires/nanostructures and their applications in nanodevices. Phys. Status Solidi (RRL)-Rapid Res. Lett. 2013, 7, 781–792. [Google Scholar] [CrossRef]

- He, H.; Blanco, M.A.; Pandey, R. Electronic and thermodynamic properties of β-Ga2O3. Appl. Phys. Lett. 2006, 88, 261904. [Google Scholar] [CrossRef]

- Srivastava, R.; Srinivas, D.; Ratnasamy, P. CO2 activation and synthesis of cyclic carbonates and alkyl/aryl carbamates over adenine-modified Ti-SBA-15 solid catalysts. J. Catal. 2005, 233, 1–15. [Google Scholar] [CrossRef]

- Areán, C.O.; Bellan, A.L.; Mentruit, M.P.; Delgado, M.R.; Palomino, G.T. Preparation and characterization of mesoporous γ-Ga2O3. Microporous Mesoporous Mater. 2000, 40, 35–42. [Google Scholar] [CrossRef]

- Lavalley, J.; Daturi, M.; Montouillout, V.; Clet, G.; Areán, C.O.; Delgado, M.R.; Sahibed-Dine, A. Unexpected similarities between the surface chemistry of cubic and hexagonal gallia polymorphs. Phys. Chem. Chem. Phys. 2003, 5, 1301–1305. [Google Scholar] [CrossRef]

- Delgado, M.R.; Areán, C.O. Surface chemistry and pore structure of β-Ga2O3. Mater. Lett. 2003, 57, 2292–2297. [Google Scholar] [CrossRef]

- Vimont, A.; Lavalley, J.; Sahibed-Dine, A.; Otero Areán, C.; Rodríguez Delgado, M.; Daturi, M. Infrared spectroscopic study on the surface properties of γ-gallium oxide as compared to those of γ-alumina. J. Phys. Chem. B 2005, 109, 9656–9664. [Google Scholar] [CrossRef] [PubMed]

- Collins, S.E.; Baltanás, M.A.; Bonivardi, A.L. Infrared spectroscopic study of the carbon dioxide adsorption on the surface of Ga2O3 polymorphs. J. Phys. Chem. B 2006, 110, 5498–5507. [Google Scholar] [CrossRef] [PubMed]

- Tsyganenko, A.A. Variable temperature IR spectroscopy in the studies of oxide catalysts. Top. Catal. 2013, 56, 905–913. [Google Scholar] [CrossRef]

- Busca, G.; Lorenzelli, V. Infrared spectroscopic identification of species arising from reactive adsorption of carbon oxides on metal oxide surfaces. Mater. Chem. 1982, 7, 89–126. [Google Scholar] [CrossRef]

- Lavalley, J. Infrared spectrometric studies of the surface basicity of metal oxides and zeolites using adsorbed probe molecules. Catal. Today 1996, 27, 377–401. [Google Scholar] [CrossRef]

- Stepanov, S.; Nikolaev, V.; Bougrov, V.; Romanov, A. Gallium Oxide: Properties and Applications a Review. Rev. Adv. Mater. Sci. 2016, 44, 63–86. [Google Scholar]

- Venna, S.R.; Carreon, M.A. Synthesis of SAPO-34 crystals in the presence of crystal growth inhibitors. J. Phys. Chem. B 2008, 112, 16261–16265. [Google Scholar] [CrossRef] [PubMed]

- Deshmane, C.A.; Jasinski, J.B.; Carreon, M.A. Microwave-assisted synthesis of nanocrystalline mesoporous gallium oxide. Microporous Mesoporous Mater. 2010, 130, 97–102. [Google Scholar] [CrossRef]

- Ion, A.; Van Doorslaer, C.; Parvulescu, V.; Jacobs, P.; De Vos, D. Green synthesis of carbamates from CO2, amines and alcohols. Green Chem. 2008, 10, 111–116. [Google Scholar] [CrossRef]

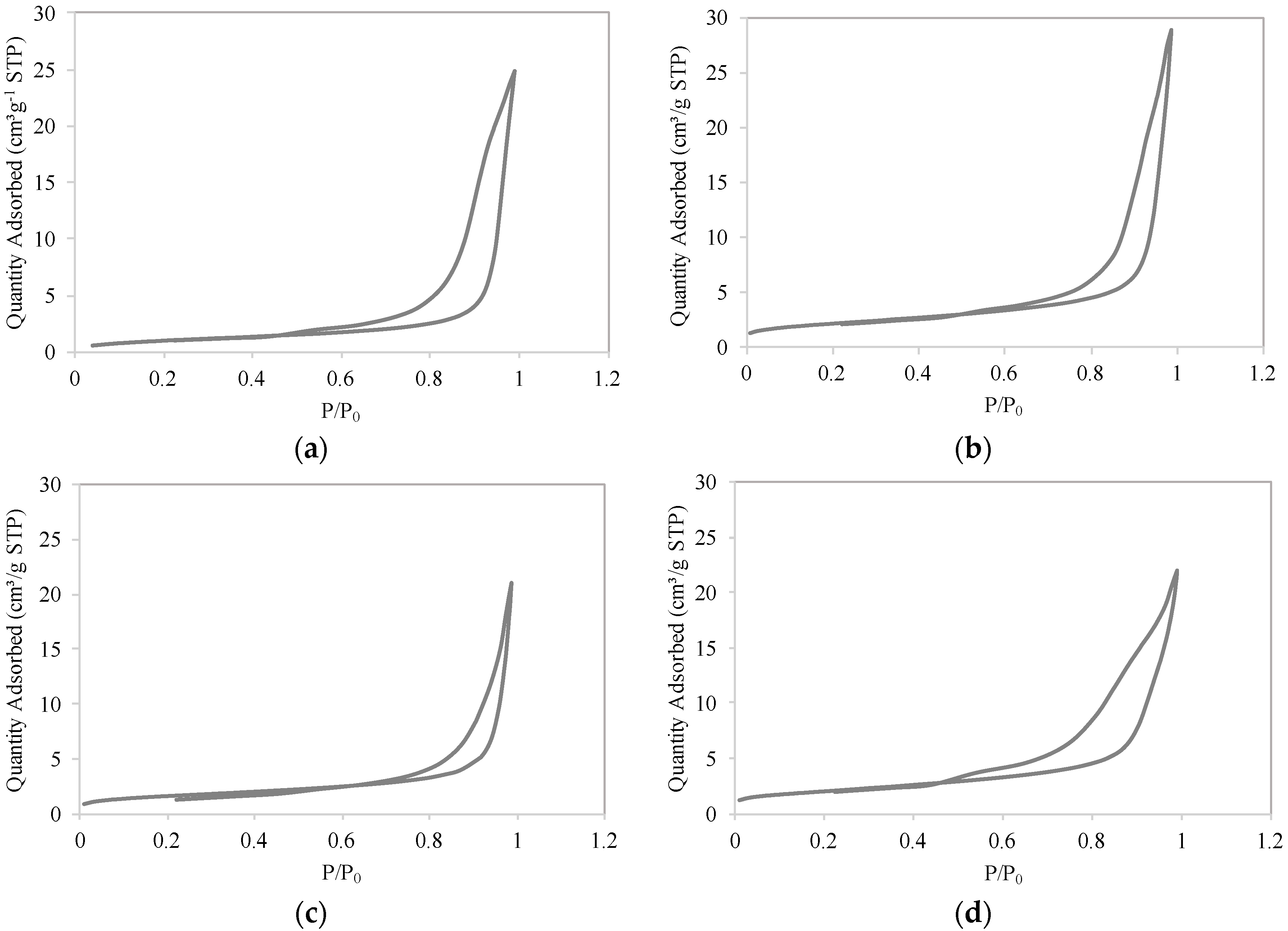

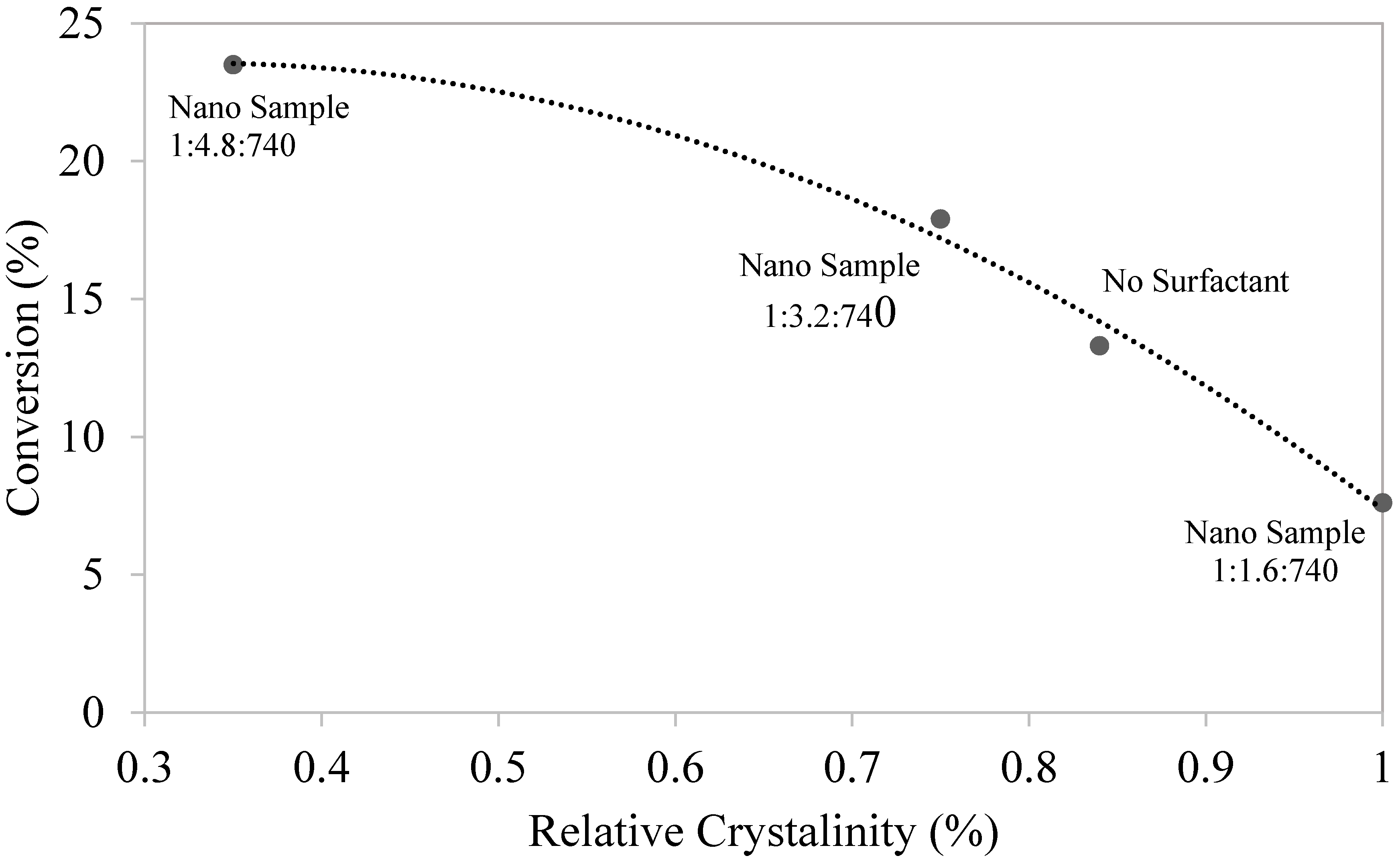

| Surfactant | Molar Ratio (Precursor:Surfactant:Solvent) | BET Surface Area (m2/g) |

|---|---|---|

| CTAB | 1:1.6:370 | 29.6 |

| F127 | 1:0.04:370 | 11.1 |

| PEO | 1:1.13:370 | 23.9 |

| None | 1:0:370 | 51.7 |

| Surfactant | Molar Ratio (Precursor:Surfactant:Solvent) | Aspect Ratio L/D |

|---|---|---|

| CTAB | 1:1.6:740 | 2 |

| 1:3.2:740 | 18 | |

| 1:4.8:40 | 4 |

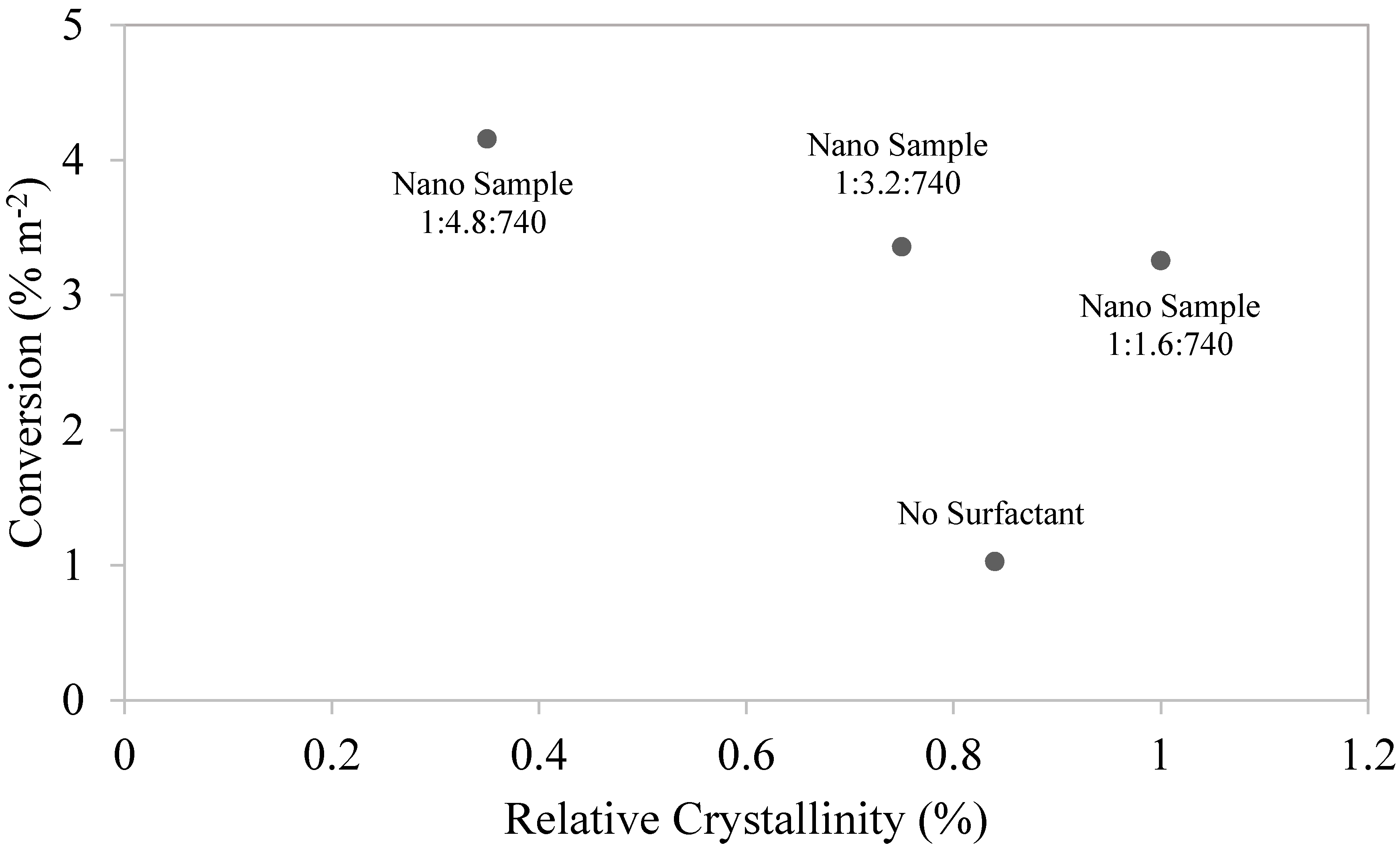

| Catalyst | Surface Area (m2/g) | Conversion (%) | Selectivity to Carbamate (%) | Yield to Carbamate (%) |

|---|---|---|---|---|

| Ga2O3-Sigma-Aldrich | 21.2 | 6.8 | 53.5 | 3.6 |

| Nano sample | 7.4 | 7.6 | 69.1 | 5.2 |

| precursor:surfactant:solvent | ||||

| 1:1.6:740 | ||||

| Nano sample | 5.5 | 17.9 | 69.3 | 12.4 |

| precursor:surfactant:solvent | ||||

| 1:3.2:740 | ||||

| Nano sample | 7.0 | 23.5 | 68.5 | 16.1 |

| precursor:surfactant:solvent | ||||

| 1:4.8:740 | ||||

| Nano sample | 3.2 | 13.3 | 9.4 | 1.2 |

| 1:0:740 (no surfactant) |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shah, J.; Ratnasamy, P.; Carreon, M.L. Influence of the Nanostructure of Gallium Oxide Catalysts on Conversion in the Green Synthesis of Carbamates. Catalysts 2017, 7, 372. https://doi.org/10.3390/catal7120372

Shah J, Ratnasamy P, Carreon ML. Influence of the Nanostructure of Gallium Oxide Catalysts on Conversion in the Green Synthesis of Carbamates. Catalysts. 2017; 7(12):372. https://doi.org/10.3390/catal7120372

Chicago/Turabian StyleShah, Javishk, Paul Ratnasamy, and Maria L. Carreon. 2017. "Influence of the Nanostructure of Gallium Oxide Catalysts on Conversion in the Green Synthesis of Carbamates" Catalysts 7, no. 12: 372. https://doi.org/10.3390/catal7120372

APA StyleShah, J., Ratnasamy, P., & Carreon, M. L. (2017). Influence of the Nanostructure of Gallium Oxide Catalysts on Conversion in the Green Synthesis of Carbamates. Catalysts, 7(12), 372. https://doi.org/10.3390/catal7120372