Efficient Electron Transfer in g-C3N4/TiO2 Heterojunction for Enhanced Photocatalytic CO2 Reduction

Abstract

1. Introduction

2. Results and Discussion

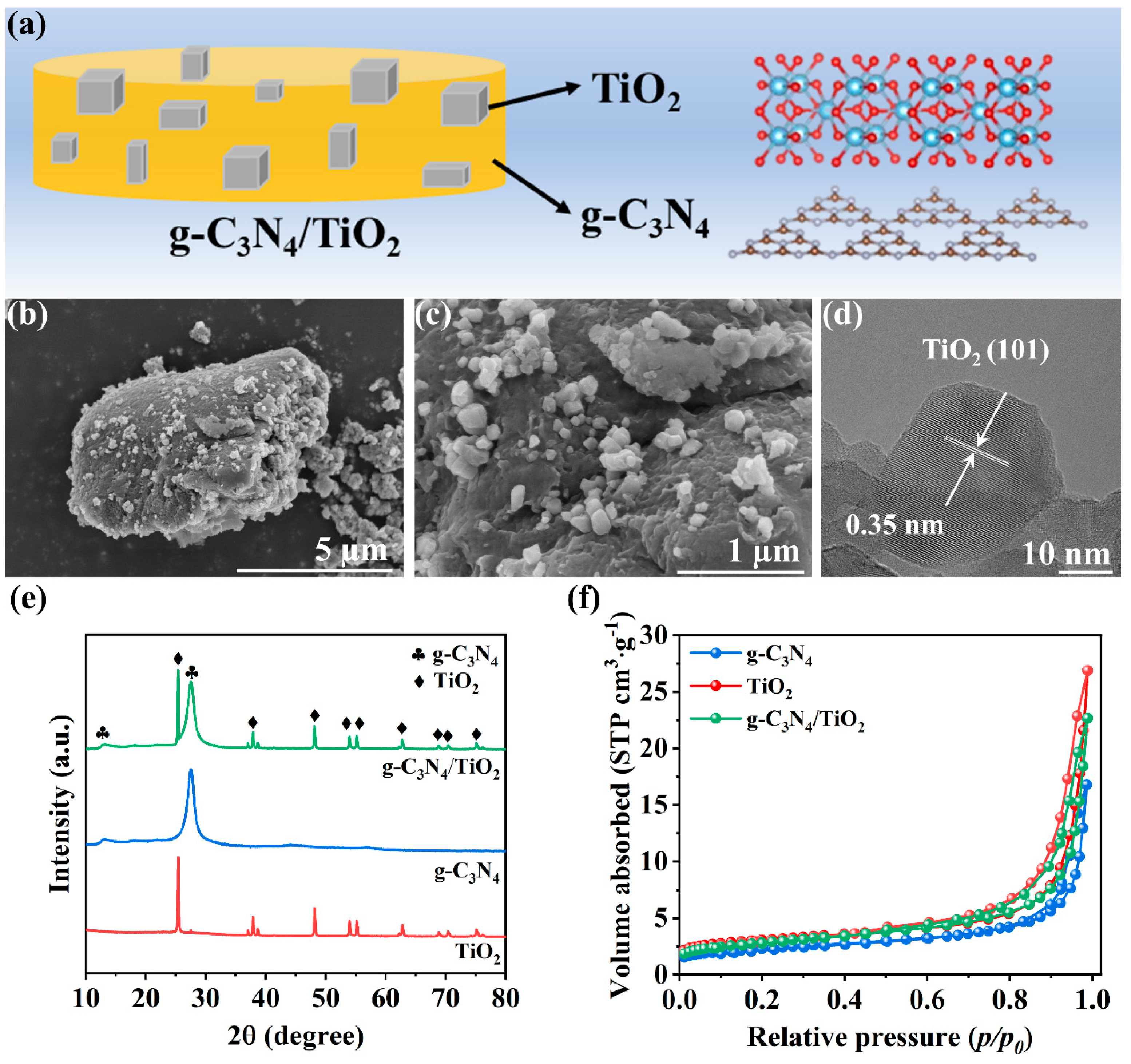

2.1. Microstructure and Analysis of Physical Properties

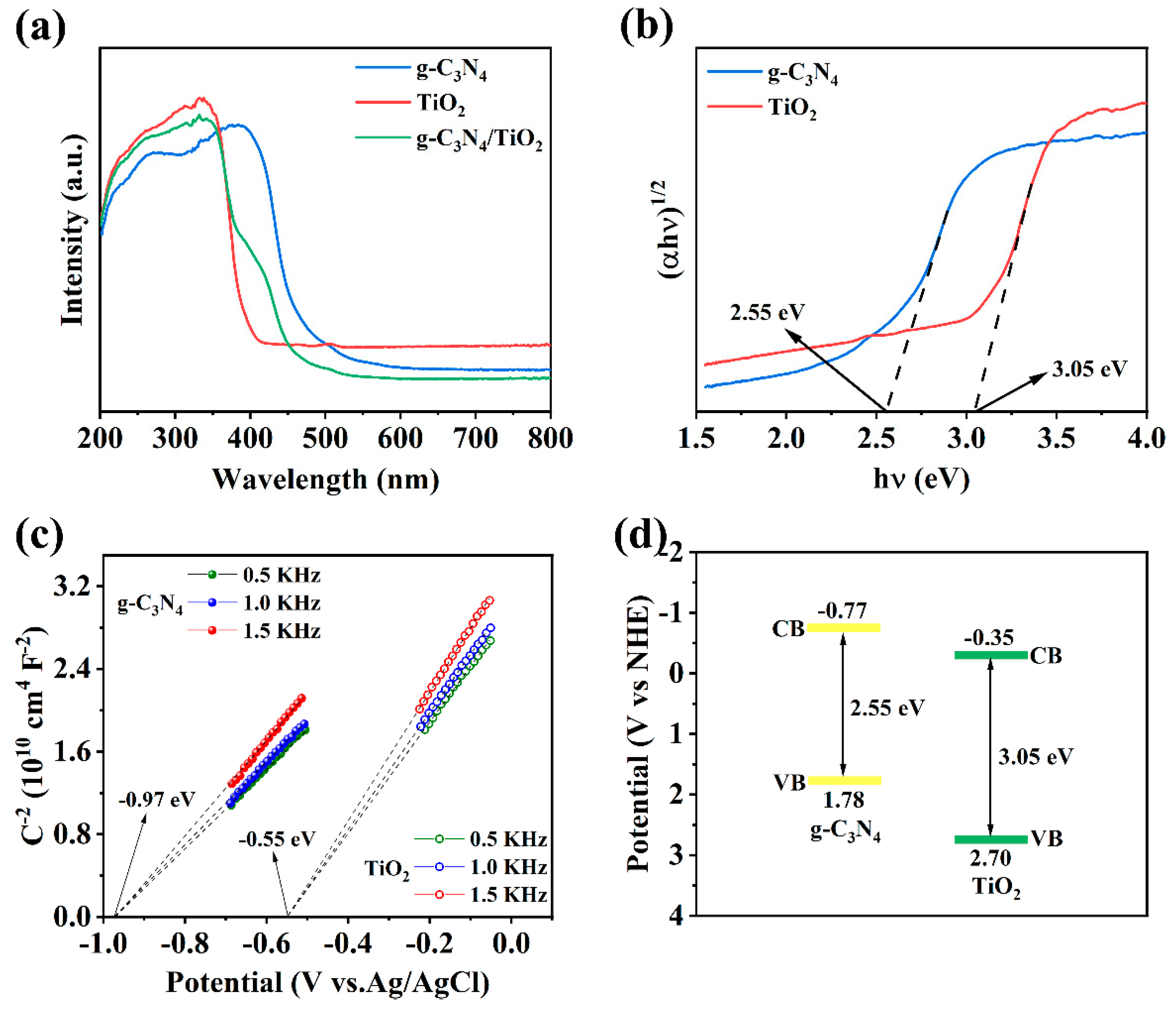

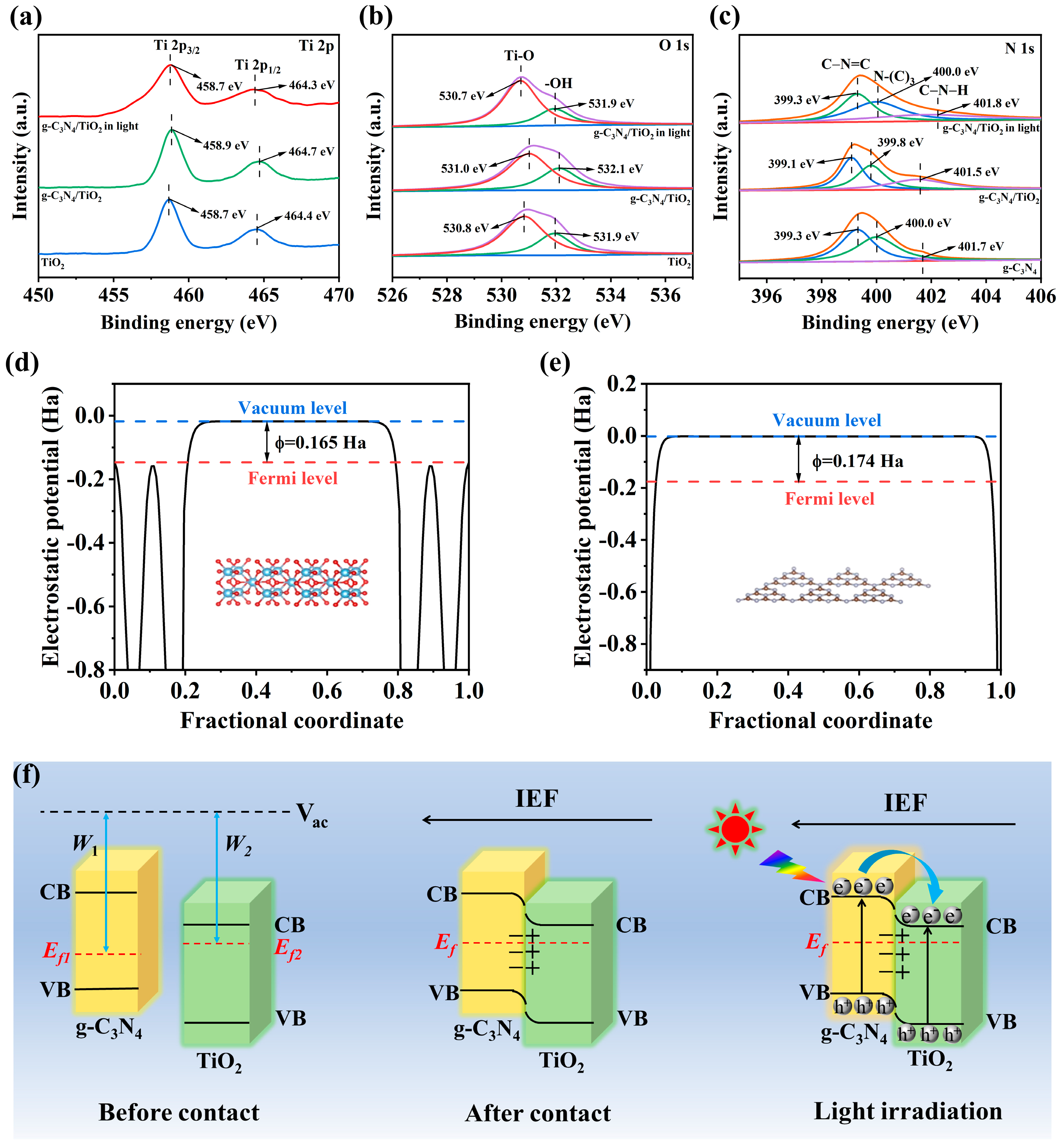

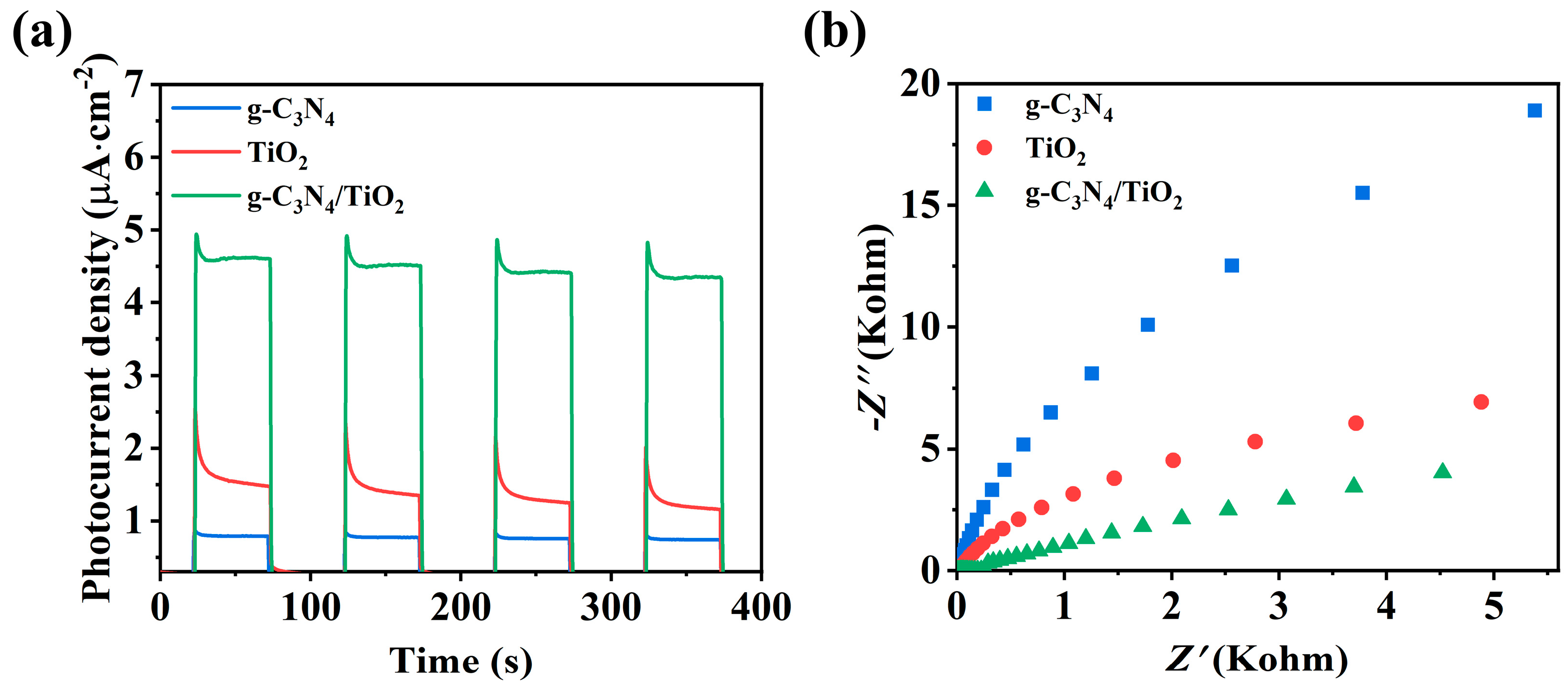

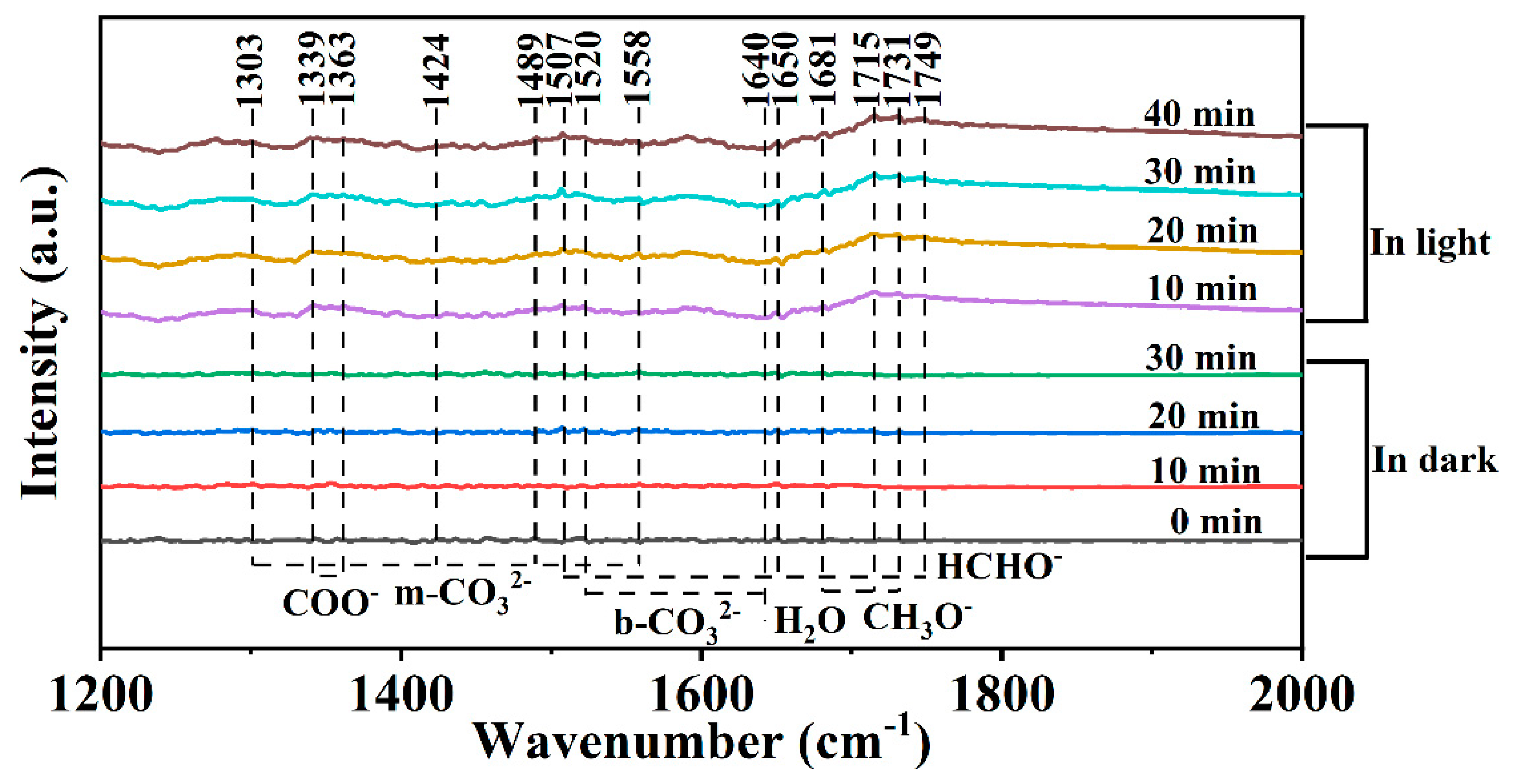

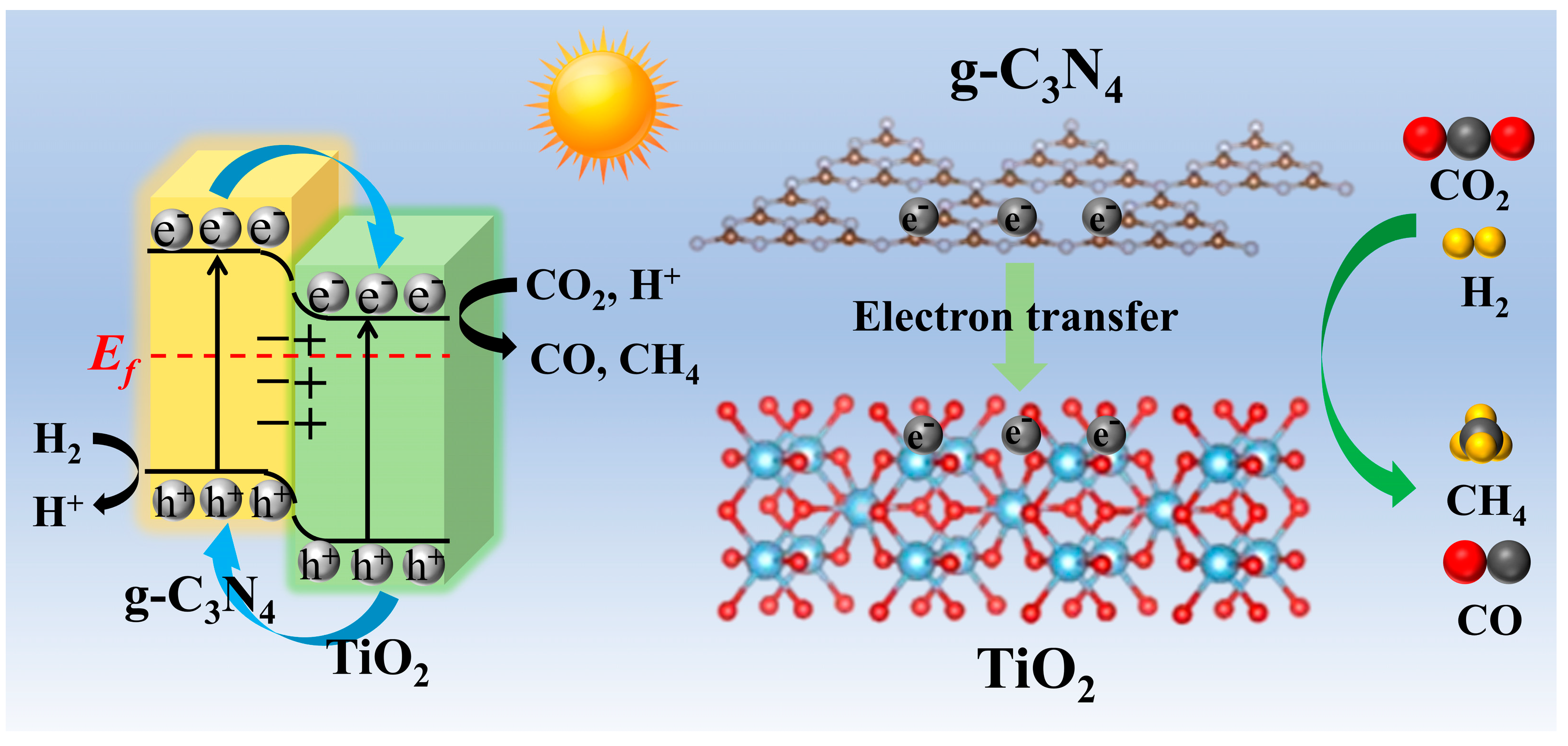

2.2. Electron Transfer Route

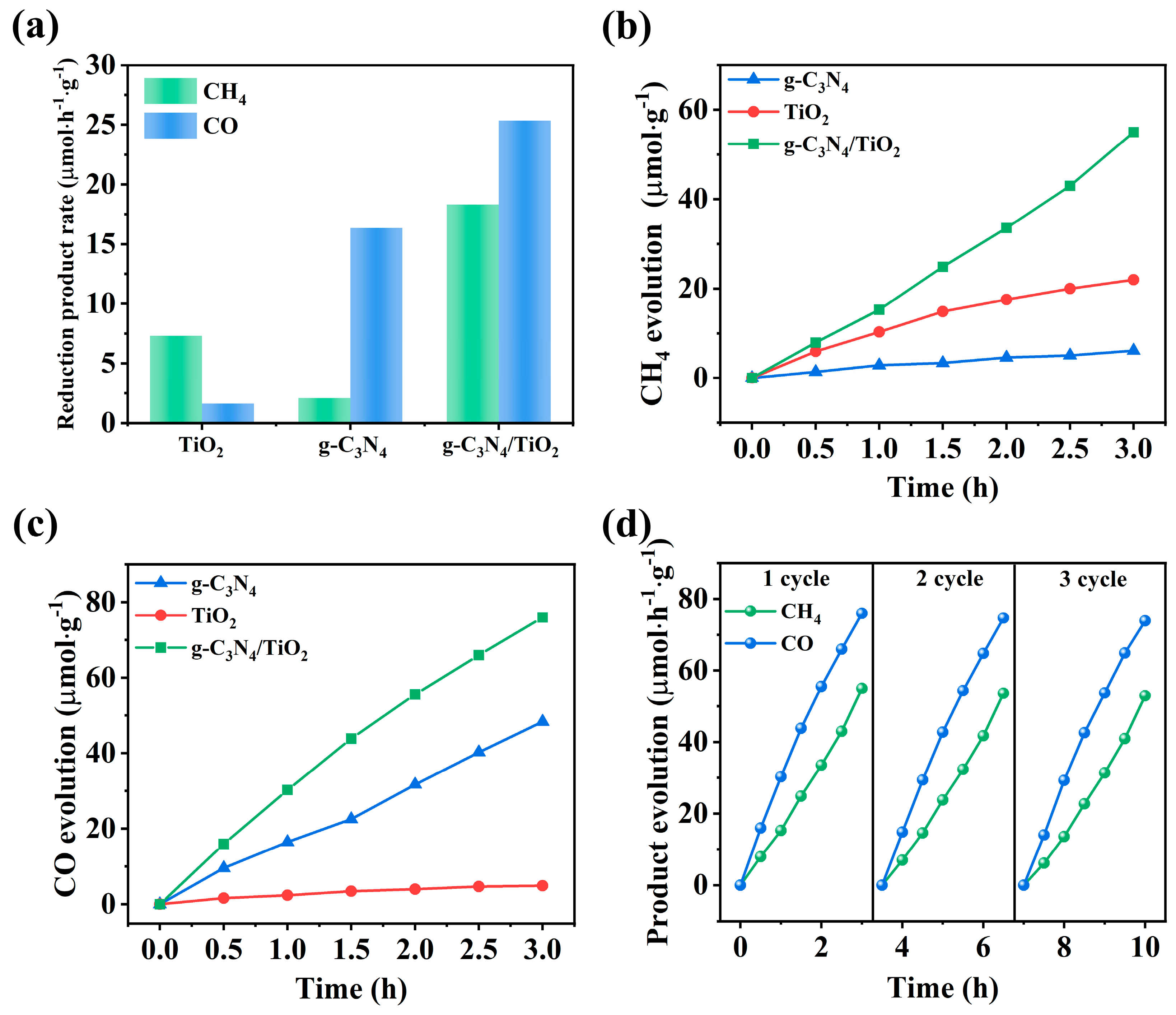

2.3. Photocatalytic CO2 Reduction Performance

3. Materials and Methods

3.1. Materials

3.2. Synthesis of g-C3N4/TiO2

3.3. Characterization

3.4. Photocatalytic CO2 Reduction

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Barral, A.; Gomez, B.; Fourel, F.; Daviero-Gomez, V.; Lécuyer, C. CO2 and temperature decoupling at the million-year scale during the Cretaceous Greenhouse. Sci. Rep. 2017, 7, 8310. [Google Scholar] [CrossRef]

- Nordt, L.; Breecker, D.; White, J. Jurassic greenhouse ice-sheet fluctuations sensitive to atmospheric CO2 dynamics. Nat. Geosci. 2022, 15, 54–59. [Google Scholar] [CrossRef]

- Ortega, T.; Jiménez-López, D.; Sierra, A.; Ponce, R.; Forja, J. Greenhouse gas assemblages (CO2, CH4 and N2O) in the continental shelf of the Gulf of Cadiz (SW Iberian Peninsula). Sci. Total Environ. 2023, 898, 165474. [Google Scholar] [CrossRef] [PubMed]

- Chen, B.; Tan, E.; Zou, W.; Han, L.-L.; Tian, L.; Kao, S.-J. The external/internal sources and sinks of greenhouse gases (CO2, CH4, N2O) in the Pearl River Estuary and adjacent coastal waters in summer. Water Res. 2024, 249, 120913. [Google Scholar] [CrossRef] [PubMed]

- Fang, S.; Rahaman, M.; Bharti, J.; Reisner, E.; Robert, M.; Ozin, G.A.; Hu, Y.H. Photocatalytic CO2 reduction. Nat. Rev. Methods Primers 2023, 3, 61. [Google Scholar] [CrossRef]

- Albero, J.; Peng, Y.; García, H. Photocatalytic CO2 Reduction to C2+ Products. ACS Catal. 2020, 10, 5734–5749. [Google Scholar] [CrossRef]

- Qu, T.; Wei, S.; Xiong, Z.; Zhang, J.; Zhao, Y. Progress and prospect of CO2 photocatalytic reduction to methanol. Fuel. Process. Technol. 2023, 251, 107933. [Google Scholar] [CrossRef]

- Low, J.; Zhang, C.; Karadas, F.; Xiong, Y. Photocatalytic CO2 conversion: Beyond the earth. Chin. J. Catal. 2023, 50, 1–5. [Google Scholar] [CrossRef]

- Zhao, J.; Xiong, Z.; Zhao, Y.; Chen, X.; Zhang, J. Two-dimensional heterostructures for photocatalytic CO2 reduction. Environ. Res. 2023, 216, 114699. [Google Scholar] [CrossRef]

- Zhang, J.; Shi, J.; Tao, S.; Wu, L.; Lu, J. Cu2O/Ti3C2MXene heterojunction photocatalysts for improved CO2 photocatalytic reduction performance. Appl. Surf. Sci. 2021, 542, 148685. [Google Scholar] [CrossRef]

- Liu, J.; Liu, Y.; Li, L.; Ye, X.; Zheng, X.; Pan, L.; Ren, W.; Meng, S.; Zhang, S.; Chen, S. Tailoring defects in In2S3/Zn0.3Cd0.7S heterojunctions for efficient photocatalytic CO2 conversion. Appl. Surf. Sci. 2023, 631, 157524. [Google Scholar] [CrossRef]

- Guo, R.-t.; Guo, S.-h.; Yu, L.-q.; Pan, W.-g. Recent Progress and Perspectives of S-Scheme Heterojunction Photocatalysts for Photocatalytic CO2 Reduction. Energy. Fuels 2024, 38, 869–894. [Google Scholar] [CrossRef]

- Wang, L.; Dong, Y.; Zhang, J.; Tao, F.; Xu, J. Construction of NiO/g-C3N4 p-n heterojunctions for enhanced photocatalytic CO2 reduction. J. Solid. State. Chem. 2022, 308, 122878. [Google Scholar] [CrossRef]

- Ye, L.; Wu, D.; Chu, K.H.; Wang, B.; Xie, H.; Yip, H.Y.; Wong, P.K. Phosphorylation of g-C3N4 for enhanced photocatalytic CO2 reduction. Chem. Eng. J. 2016, 304, 376–383. [Google Scholar] [CrossRef]

- Sun, Z.; Wang, H.; Wu, Z.; Wang, L. g-C3N4 based composite photocatalysts for photocatalytic CO2 reduction. Catal. Today. 2018, 300, 160–172. [Google Scholar] [CrossRef]

- Ghosh, U.; Majumdar, A.; Pal, A. Photocatalytic CO2 reduction over g-C3N4 based heterostructures: Recent progress and prospects. J. Environ. Chem. Eng. 2021, 9, 104631. [Google Scholar] [CrossRef]

- Wei, L.; Yu, C.; Zhang, Q.; Liu, H.; Wang, Y. TiO2-based heterojunction photocatalysts for photocatalytic reduction of CO2 into solar fuels. J. Mater. Chem. A 2018, 6, 22411–22436. [Google Scholar] [CrossRef]

- Xiong, Z.; Lei, Z.; Li, Y.; Dong, L.; Zhao, Y.; Zhang, J. A review on modification of facet-engineered TiO2 for photocatalytic CO2 reduction. J. Photoch. Photobio. C 2018, 36, 24–47. [Google Scholar] [CrossRef]

- Abdullah, H.; Khan, M.M.R.; Ong, H.R.; Yaakob, Z. Modified TiO2 photocatalyst for CO2 photocatalytic reduction: An overview. J. CO2 Util. 2017, 22, 15–32. [Google Scholar] [CrossRef]

- Feng, Y.; Wang, C.; Cui, P.; Li, C.; Zhang, B.; Gan, L.; Zhang, S.; Zhang, X.; Zhou, X.; Sun, Z.; et al. Ultrahigh Photocatalytic CO2 Reduction Efficiency and Selectivity Manipulation by Single-Tungsten-Atom Oxide at the Atomic Step of TiO2. Adv. Mater. 2022, 34, 2109074. [Google Scholar] [CrossRef]

- Adekoya, D.O.; Tahir, M.; Amin, N.A.S. g-C3N4/(Cu/TiO2) nanocomposite for enhanced photoreduction of CO2 to CH3OH and HCOOH under UV/visible light. J. CO2 Util. 2017, 18, 261–274. [Google Scholar] [CrossRef]

- Banitalebi Dehkordi, A.; Ziarati, A.; Ghasemi, J.B.; Badiei, A. Preparation of hierarchical g-C3N4@TiO2 hollow spheres for enhanced visible-light induced catalytic CO2 reduction. Solar. Energy 2020, 205, 465–473. [Google Scholar] [CrossRef]

- Hammoud, L.; Marchal, C.; Colbeau-Justin, C.; Toufaily, J.; Hamieh, T.; Caps, V.; Keller, V. Tuning CH4 Productivity from Visible Light-Driven Gas-Phase CO2 Photocatalytic Reduction on Doped g-C3N4/TiO2 Heterojunctions. Energy Technol. 2023, 11, 2201363. [Google Scholar] [CrossRef]

- Kumar, D.P.; Rangappa, A.P.; Shim, H.S.; Do, K.H.; Hong, Y.; Gopannagari, M.; Reddy, K.A.J.; Bhavani, P.; Reddy, D.A.; Song, J.K.; et al. Nanocavity-assisted single-crystalline Ti3+ self-doped blue TiO2(B) as efficient cocatalyst for high selective CO2 photoreduction of g-C3N4. Mater. Today Chem. 2022, 24, 100827. [Google Scholar] [CrossRef]

- Liu, C.; Raziq, F.; Li, Z.; Qu, Y.; Zada, A.; Jing, L. Synthesis of TiO2/g-C3N4 nanocomposites with phosphate–oxygen functional bridges for improved photocatalytic activity. Chin. J. Catal. 2017, 38, 1072–1078. [Google Scholar] [CrossRef]

- Mehregan, S.; Hayati, F.; Mehregan, M.; Isari, A.A.; Jonidi Jafari, A.; Giannakis, S.; Kakavandi, B. Exploring the visible light–assisted conversion of CO2 into methane and methanol, using direct Z-scheme TiO2@g-C3N4 nanosheets: Synthesis and photocatalytic performance. Environ. Sci. Pollut. Res. 2022, 29, 74951–74966. [Google Scholar] [CrossRef] [PubMed]

- Park, J.; Liu, H.; Piao, G.; Kang, U.; Jeong, H.W.; Janáky, C.; Park, H. Synergistic conversion of CO2 into C1 and C2 gases using hybrid in-doped TiO2 and g-C3N4 photocatalysts. Chem. Eng. J. 2022, 437, 135388. [Google Scholar] [CrossRef]

- Shi, H.; Du, J.; Hou, J.; Ni, W.; Song, C.; Li, K.; Gurzadyan, G.G.; Guo, X. Solar-driven CO2 conversion over Co2+ doped 0D/2D TiO2/g-C3N4 heterostructure: Insights into the role of Co2+ and cocatalyst. J. CO2 Util. 2020, 38, 16–23. [Google Scholar] [CrossRef]

- Thanh Truc, N.T.; Giang Bach, L.; Thi Hanh, N.; Pham, T.-D.; Thi Phuong Le Chi, N.; Tran, D.T.; Nguyen, M.V.; Nguyen, V.N. The superior photocatalytic activity of Nb doped TiO2/g-C3N4 direct Z-scheme system for efficient conversion of CO2 into valuable fuels. J. Colloid. Interf. Sci. 2019, 540, 1–8. [Google Scholar] [CrossRef]

- Tong, Z.; Hai, Y.; Wang, B.; Lv, F.; Zhong, Z.; Xiong, R. Activated g-C3N4 Photocatalyst with Defect Engineering for Efficient Reduction of CO2 in Water. J. Phys. Chem. C 2023, 127, 11067–11075. [Google Scholar] [CrossRef]

- Wang, C.; Zhao, Y.; Xu, H.; Li, Y.; Wei, Y.; Liu, J.; Zhao, Z. Efficient Z-scheme photocatalysts of ultrathin g-C3N4-wrapped Au/TiO2-nanocrystals for enhanced visible-light-driven conversion of CO2 with H2O. Appl. Catal. B-Environ. 2020, 263, 118314. [Google Scholar] [CrossRef]

- Yu, Y.; Hoshyar, A.N.; Samali, B.; Zhang, G.; Rashidi, M.; Mohammadi, M. Corrosion and coating defect assessment of coal handling and preparation plants (CHPP) using an ensemble of deep convolutional neural networks and decision-level data fusion. Neural. Comput. Appl. 2023, 35, 18697–18718. [Google Scholar] [CrossRef]

- Yu, Y.; Zhang, C.; Xie, X.; Yousefi, A.M.; Zhang, G.; Li, J.; Samali, B. Compressive strength evaluation of cement-based materials in sulphate environment using optimized deep learning technology. Dev. Built Environ. 2023, 16, 100298. [Google Scholar] [CrossRef]

- Zhang, H.; Bian, H.; Wang, F.; Zhu, L.; Zhang, S.; Xia, D. Enhanced photocatalytic reduction of CO2 over pg-C3N4-supported TiO2 nanoparticles with Ag modification. Colloid. Surf. A 2023, 674, 131989. [Google Scholar] [CrossRef]

- Zhou, S.; Liu, Y.; Li, J.; Wang, Y.; Jiang, G.; Zhao, Z.; Wang, D.; Duan, A.; Liu, J.; Wei, Y. Facile in situ synthesis of graphitic carbon nitride (g-C3N4)-N-TiO2 heterojunction as an efficient photocatalyst for the selective photoreduction of CO2 to CO. Appl. Catal. B-Environ. 2014, 158–159, 20–29. [Google Scholar] [CrossRef]

- Dong, W.-W.; Jia, J.; Wang, Y.; An, J.-R.; Yang, O.-Y.; Gao, X.-J.; Liu, Y.-L.; Zhao, J.; Li, D.-S. Visible-light-driven solvent-free photocatalytic CO2 reduction to CO by Co-MOF/Cu2O heterojunction with superior selectivity. Chem. Eng. J. 2022, 438, 135622. [Google Scholar] [CrossRef]

- Huang, Y.; Li, D.; Fang, Z.; Chen, R.; Luo, B.; Shi, W. Controlling carbon self-doping site of g-C3N4 for highly enhanced visible-light-driven hydrogen evolution. Appl. Catal. B-Environ. 2019, 254, 128–134. [Google Scholar] [CrossRef]

- Ma, X.; Liu, Y.; Wang, Y.; Jin, Z. Co3O4/CeO2 p-n heterojunction construction and application for efficient photocatalytic hydrogen evolution. Int. J. Hydrogen Energy 2021, 46, 33809–33822. [Google Scholar] [CrossRef]

- Shi, W.; Hao, C.; Fu, Y.; Guo, F.; Tang, Y.; Yan, X. Enhancement of synergistic effect photocatalytic/persulfate activation for degradation of antibiotics by the combination of photo-induced electrons and carbon dots. Chem. Eng. J. 2022, 433, 133741. [Google Scholar] [CrossRef]

- He, F.; Zhu, B.; Cheng, B.; Yu, J.; Ho, W.; Macyk, W. 2D/2D/0D TiO2/C3N4/Ti3C2 MXene composite S-scheme photocatalyst with enhanced CO2 reduction activity. Appl. Catal. B-Environ. 2020, 272, 119006. [Google Scholar] [CrossRef]

- He, T.; Wang, L.; Fabregat-Santiago, F.; Liu, G.; Li, Y.; Wang, C.; Guan, R. Electron trapping induced electrostatic adsorption of cations: A general factor leading to photoactivity decay of nanostructured TiO2. J. Mater. Chem. A. 2017, 5, 6455–6464. [Google Scholar] [CrossRef]

- He, Z.; Han, Y.; Liu, S.; Cui, W.; Qiao, Y.; He, T.; Wang, Q. Toward the Intrinsic Superiority of Aligned One-Dimensional TiO2 Nanostructures: The Role of Defect States in Electron Transport Process. ChemElectroChem 2020, 7, 4390–4397. [Google Scholar] [CrossRef]

- Wang, L.; Tan, H.; Zhang, L.; Cheng, B.; Yu, J. In-situ growth of few-layer graphene on ZnO with intimate interfacial contact for enhanced photocatalytic CO2 reduction activity. Chem. Eng. J. 2021, 411, 128501. [Google Scholar] [CrossRef]

- Low, J.; Dai, B.; Tong, T.; Jiang, C.; Yu, J. In Situ Irradiated X-Ray Photoelectron Spectroscopy Investigation on a Direct Z-Scheme TiO2/CdS Composite Film Photocatalyst. Adv. Mater. 2019, 31, e1802981. [Google Scholar] [CrossRef]

- Wang, L.; Cheng, B.; Zhang, L.; Yu, J. In situ Irradiated XPS Investigation on S-Scheme TiO2 @ZnIn2S4 Photocatalyst for Efficient Photocatalytic CO2 Reduction. Small 2021, 17, e2103447. [Google Scholar] [CrossRef]

- Zhang, P.; Li, Y.; Zhang, Y.; Hou, R.; Zhang, X.; Xue, C.; Wang, S.; Zhu, B.; Li, N.; Shao, G. Photogenerated Electron Transfer Process in Heterojunctions: In Situ Irradiation XPS. Small Methods 2020, 4, 2000214. [Google Scholar] [CrossRef]

- Bie, C.; Zhu, B.; Xu, F.; Zhang, L.; Yu, J. In Situ Grown Monolayer N-Doped Graphene on CdS Hollow Spheres with Seamless Contact for Photocatalytic CO2 Reduction. Adv. Mater. 2019, 31, e1902868. [Google Scholar] [CrossRef]

- Deng, Y.; Wan, C.; Li, C.; Wang, Y.; Mu, X.; Liu, W.; Huang, Y.; Wong, P.K.; Ye, L. Synergy Effect between Facet and Zero-Valent Copper for Selectivity Photocatalytic Methane Formation from CO2. ACS Catal. 2022, 12, 4526–4533. [Google Scholar] [CrossRef]

- Yin, G.; Huang, X.; Chen, T.; Zhao, W.; Bi, Q.; Xu, J.; Han, Y.; Huang, F. Hydrogenated Blue Titania for Efficient Solar to Chemical Conversions: Preparation, Characterization, and Reaction Mechanism of CO2 Reduction. ACS Catal. 2018, 8, 1009–1017. [Google Scholar] [CrossRef]

- Xu, F.; Zhu, B.; Cheng, B.; Yu, J.; Xu, J. 1D/2D TiO2/MoS2 Hybrid Nanostructures for Enhanced Photocatalytic CO2 Reduction. Adv. Optical. Mater. 2018, 26, 1800911. [Google Scholar] [CrossRef]

- Bian, J.; Qu, Y.; Zhang, X.; Sun, N.; Tang, D.; Jing, L. Dimension-Matched Plasmonic Au/TiO2/BiVO4 Nanocomposites as Efficient Wide-Visible-Light Photocatalysts to Convert CO2 and Mechanistic Insights. J. Mater. Chem. A 2018, 6, 11838–11845. [Google Scholar] [CrossRef]

- Jia, Y.; Tong, X.; Zhang, J.; Zhang, R.; Yang, Y.; Zhang, L.; Ji, X. A facile synthesis of coral tubular g-C3N4 for photocatalytic degradation RhB and CO2 reduction. J. Alloy. Compd. 2023, 965, 171432. [Google Scholar] [CrossRef]

- Xu, X.; Huang, Y.; Dai, K.; Wang, Z.; Zhang, J. Non-noble-metal CuSe promotes charge separation and photocatalytic CO2 reduction on porous g-C3N4 nanosheets. Sep. Purif. Technol. 2023, 317, 123887. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, P.; Yu, Y.; Wang, K.; Liu, W. Efficient Electron Transfer in g-C3N4/TiO2 Heterojunction for Enhanced Photocatalytic CO2 Reduction. Catalysts 2024, 14, 335. https://doi.org/10.3390/catal14060335

Jiang P, Yu Y, Wang K, Liu W. Efficient Electron Transfer in g-C3N4/TiO2 Heterojunction for Enhanced Photocatalytic CO2 Reduction. Catalysts. 2024; 14(6):335. https://doi.org/10.3390/catal14060335

Chicago/Turabian StyleJiang, Peng, Yang Yu, Kun Wang, and Wenrui Liu. 2024. "Efficient Electron Transfer in g-C3N4/TiO2 Heterojunction for Enhanced Photocatalytic CO2 Reduction" Catalysts 14, no. 6: 335. https://doi.org/10.3390/catal14060335

APA StyleJiang, P., Yu, Y., Wang, K., & Liu, W. (2024). Efficient Electron Transfer in g-C3N4/TiO2 Heterojunction for Enhanced Photocatalytic CO2 Reduction. Catalysts, 14(6), 335. https://doi.org/10.3390/catal14060335