Effect of Operating Conditions on the Performance of Rh/TiO2 Catalyst for the Reaction of LPG Steam Reforming

Abstract

1. Introduction

2. Results and Discussion

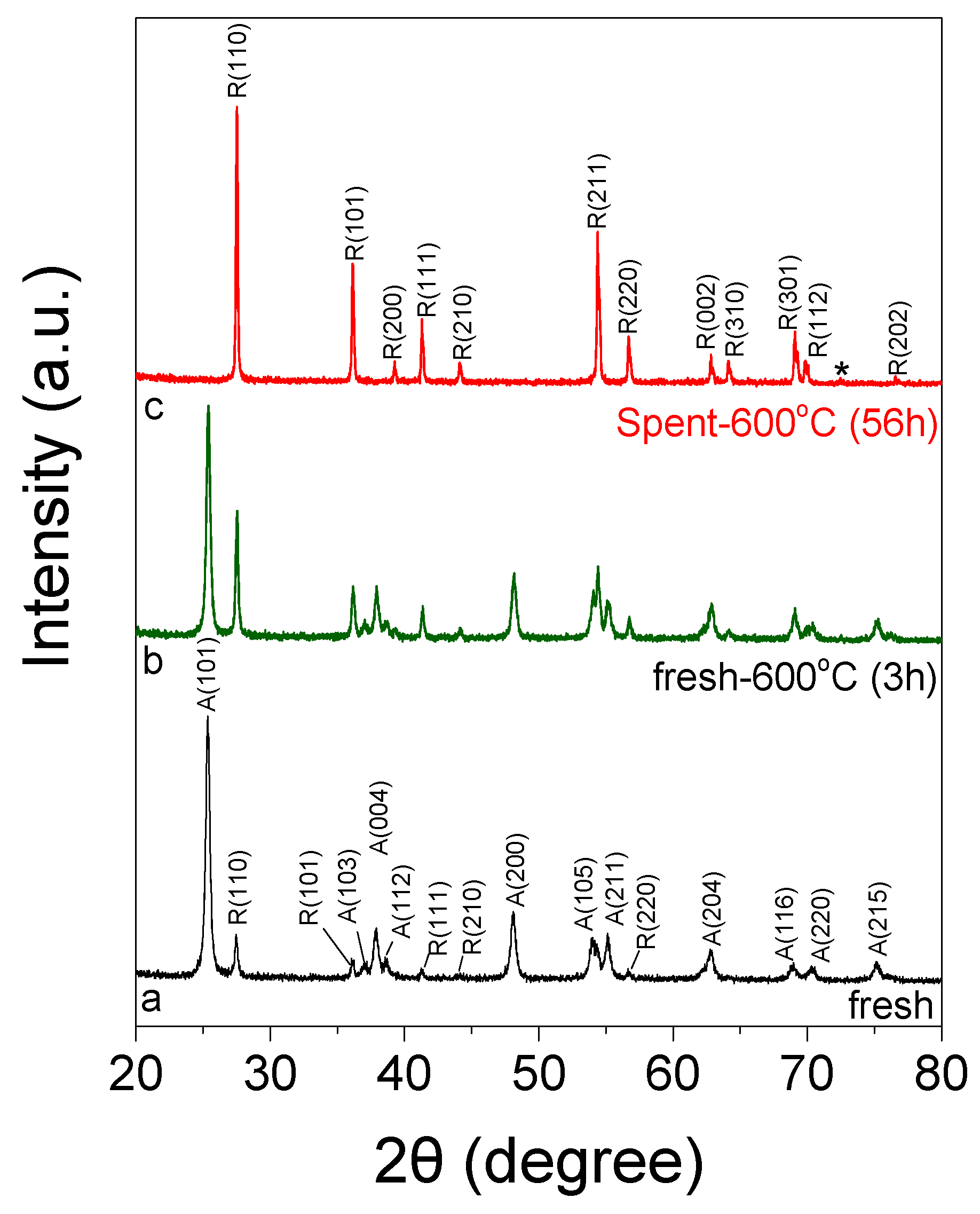

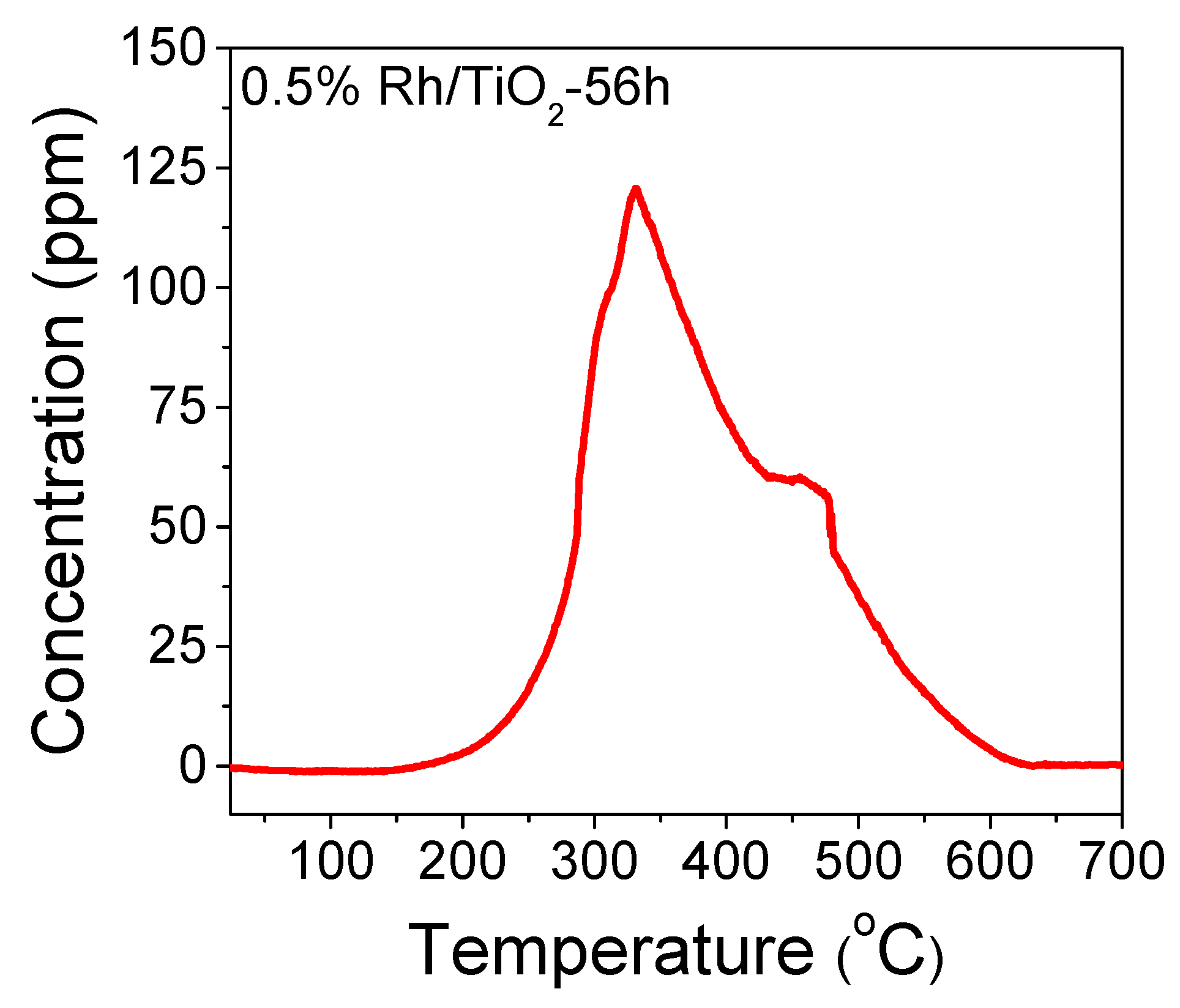

2.1. Catalyst Characterization

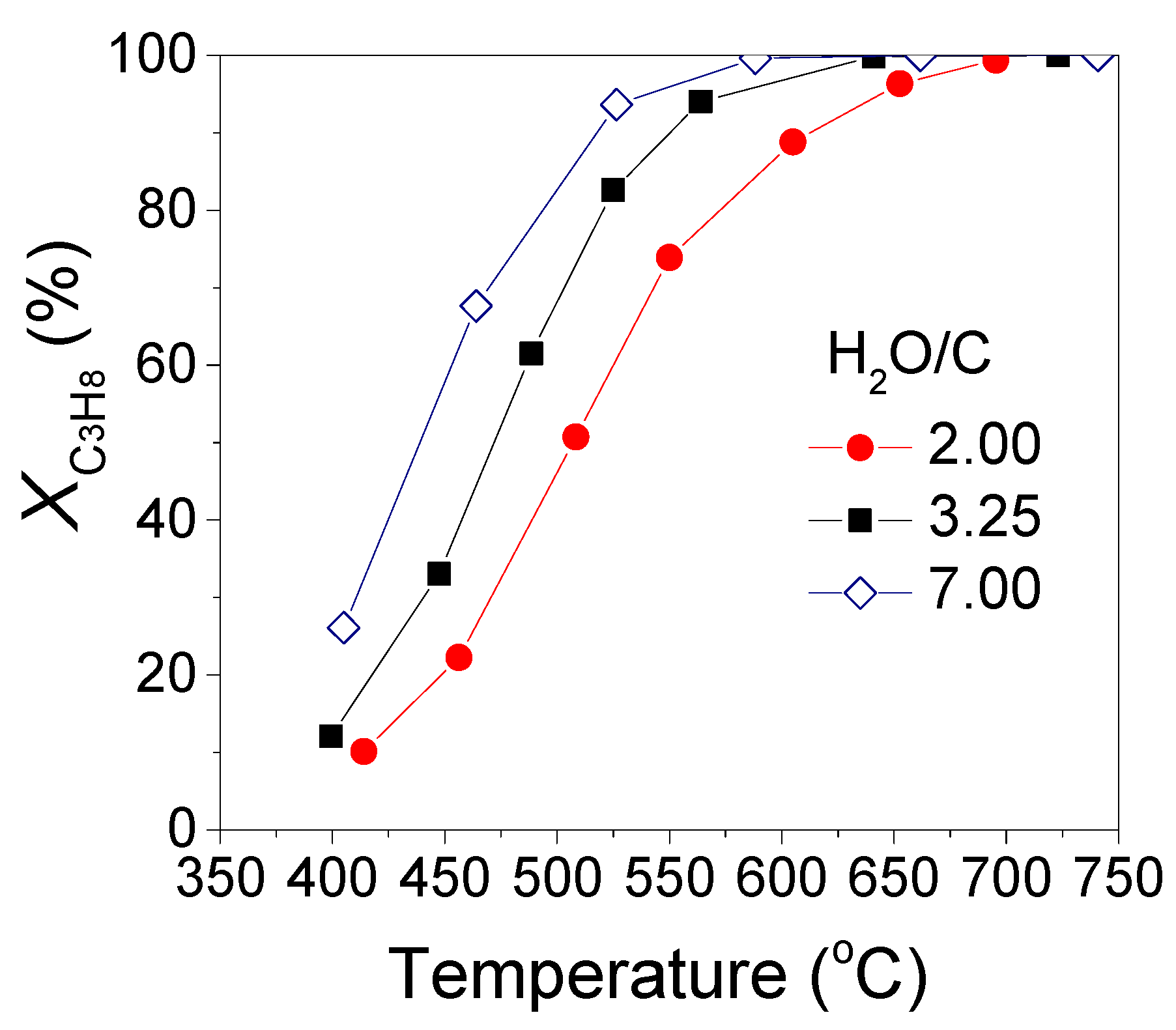

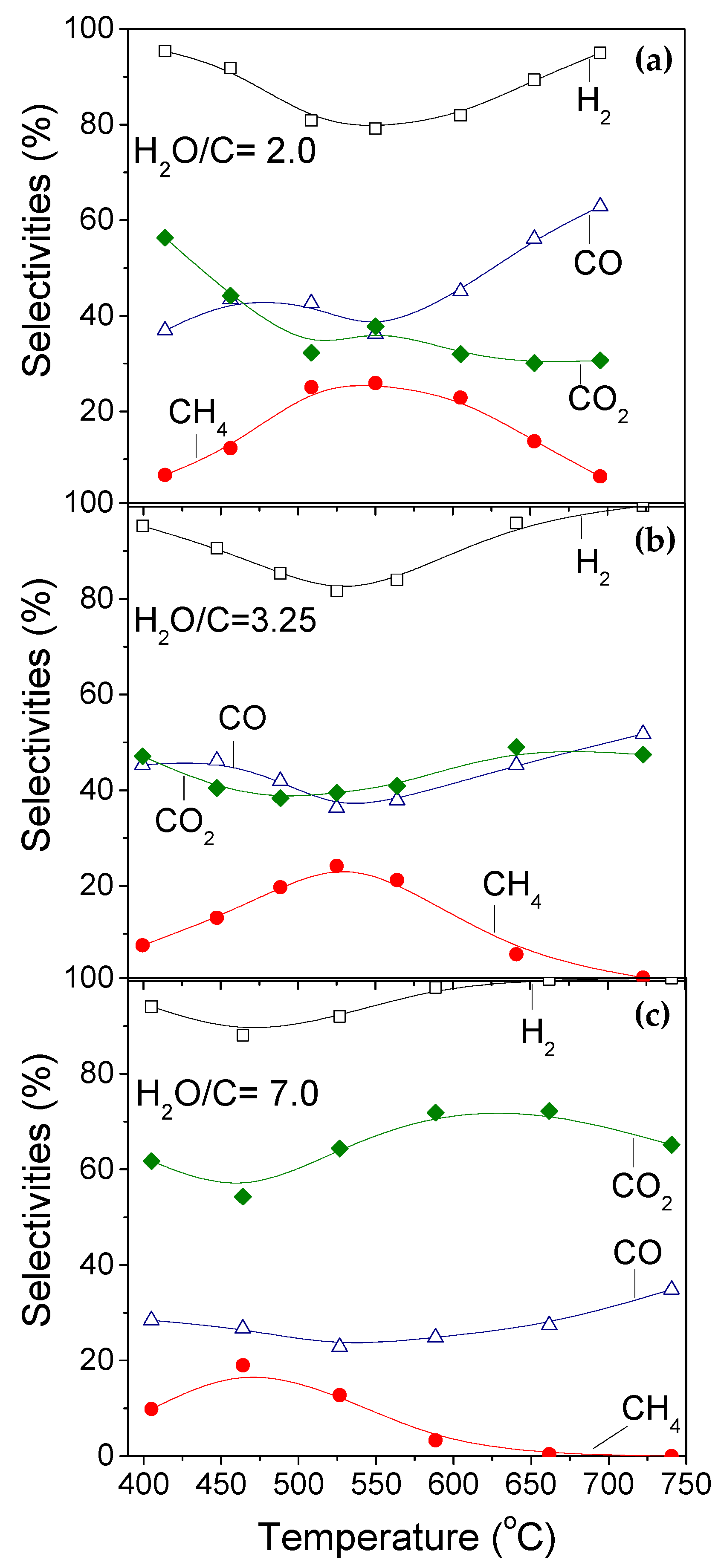

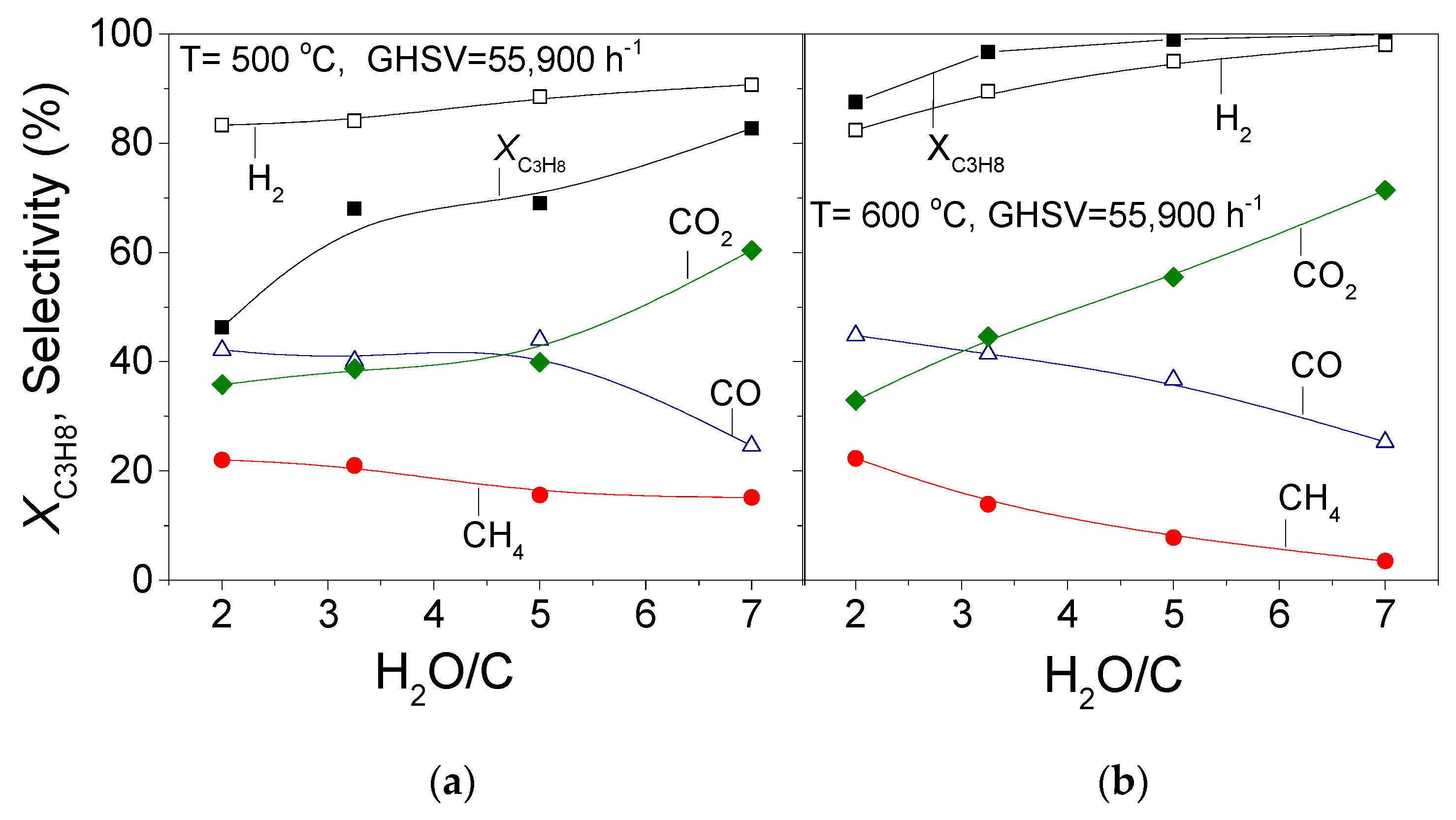

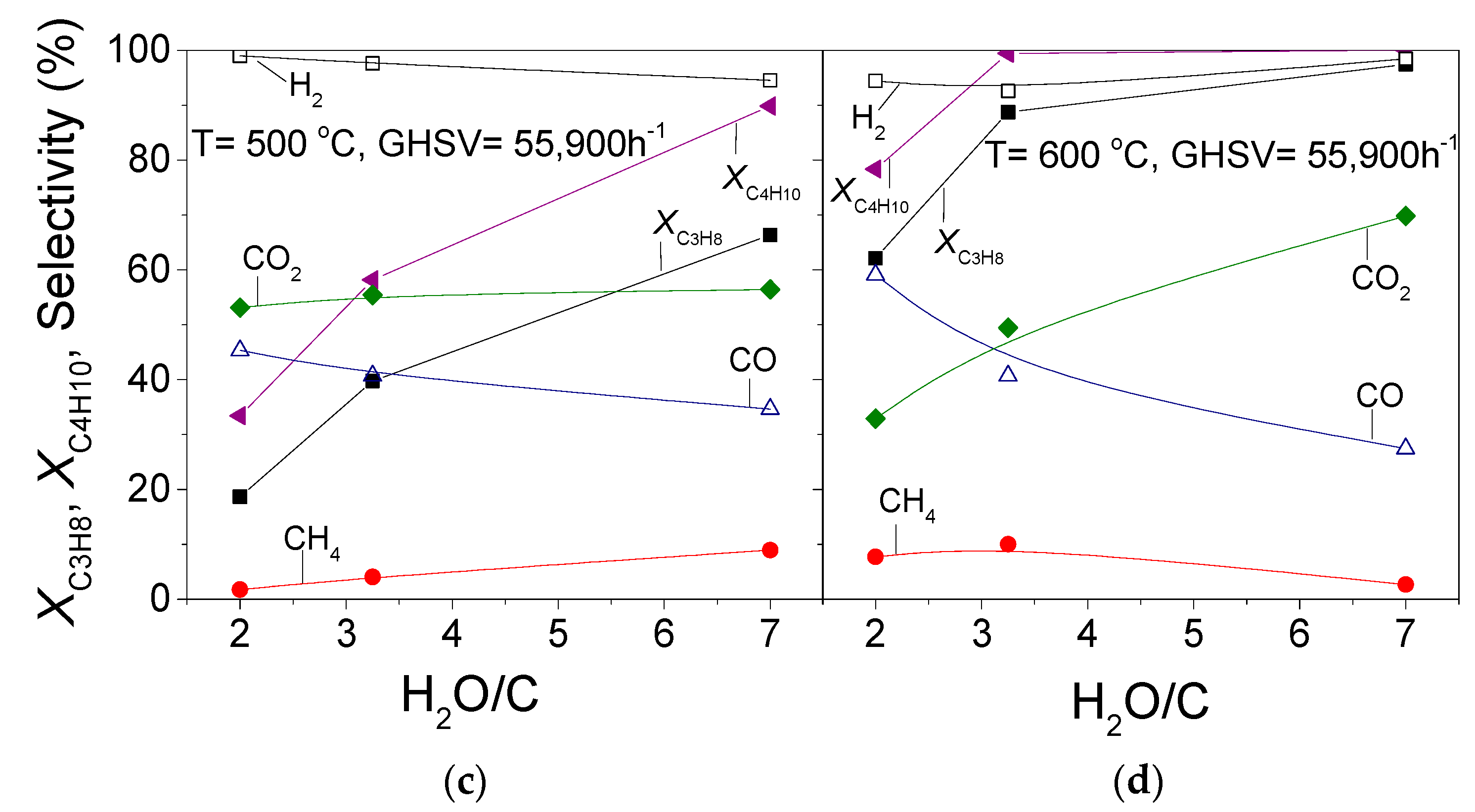

2.2. Effect of Steam/C Ratio on Catalytic Performance

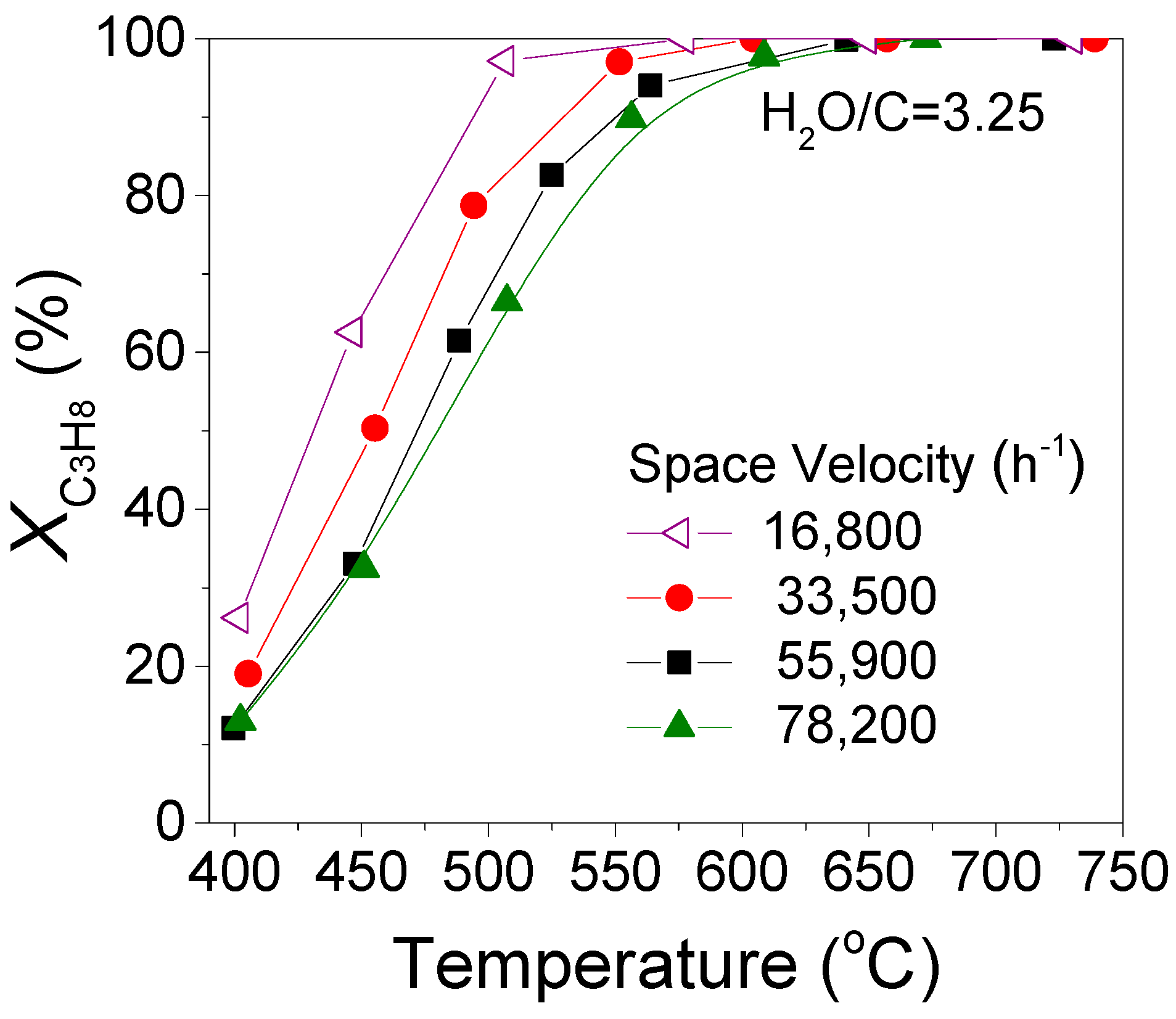

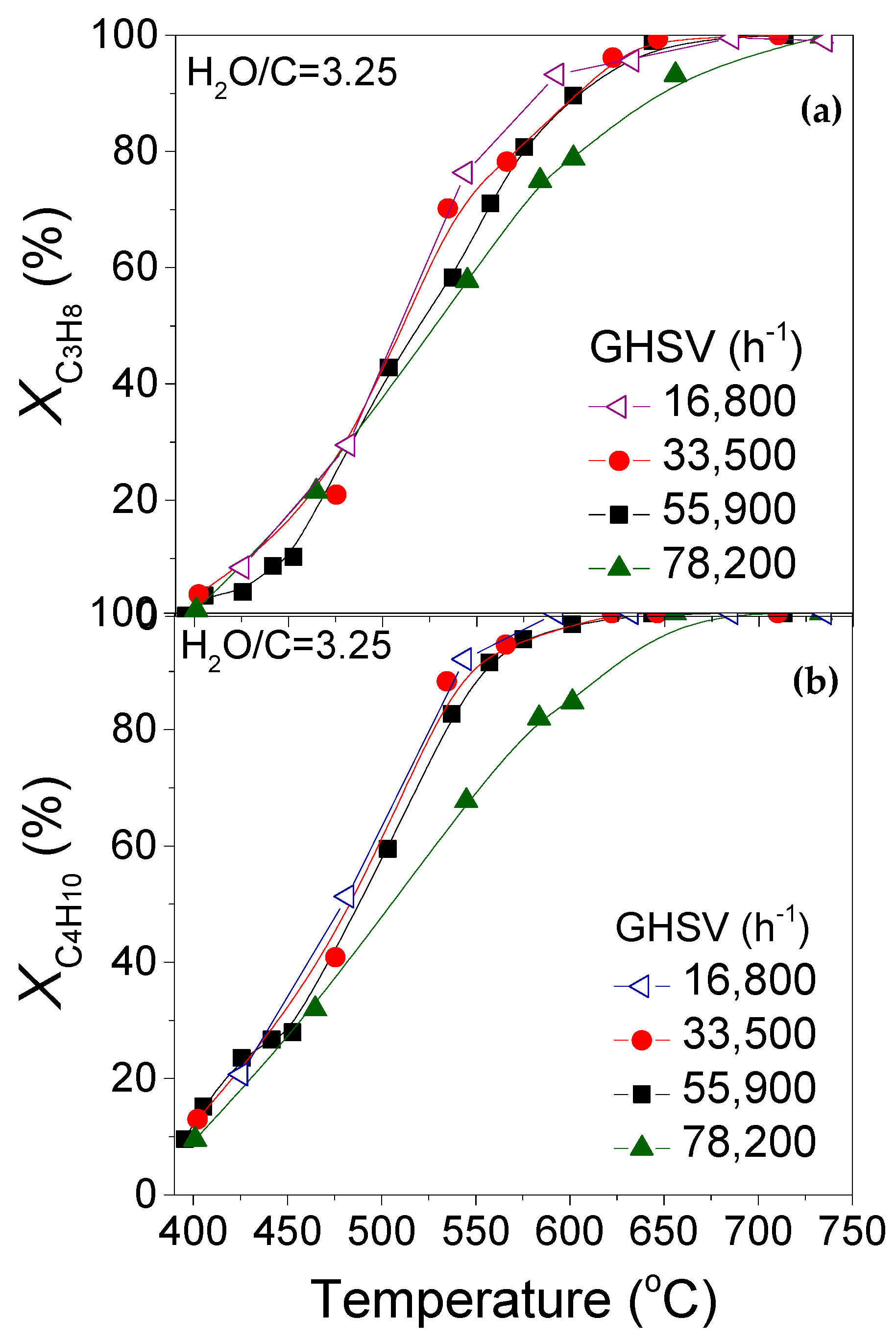

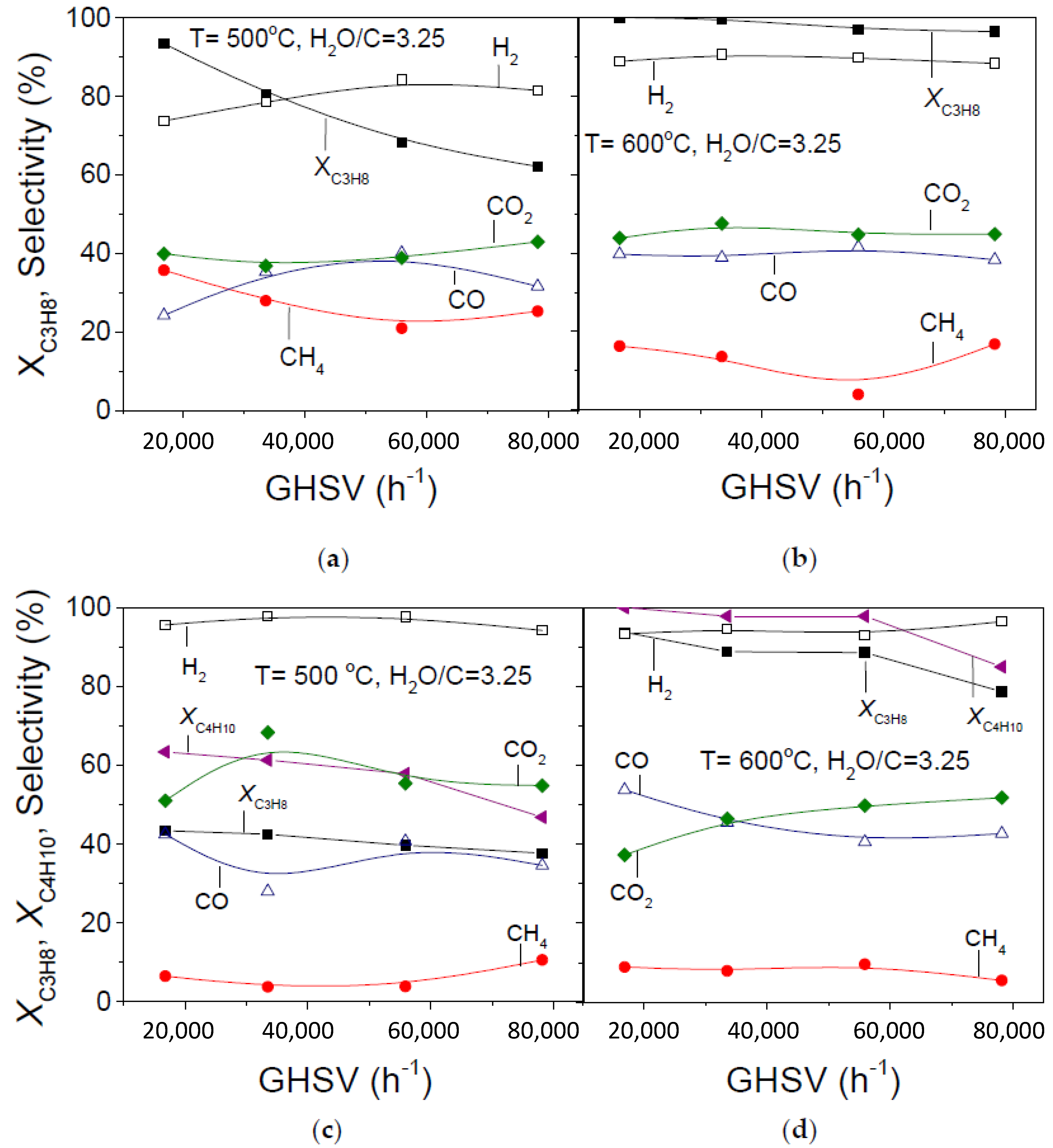

2.3. Effect of Gas Hourly Space Velocity on Catalytic Performance

2.4. Dynamic Response of Rh/TiO2 Catalyst to H2O/C Ratio

2.5. Dynamic Response of Rh/TiO2 Catalyst to Temperature

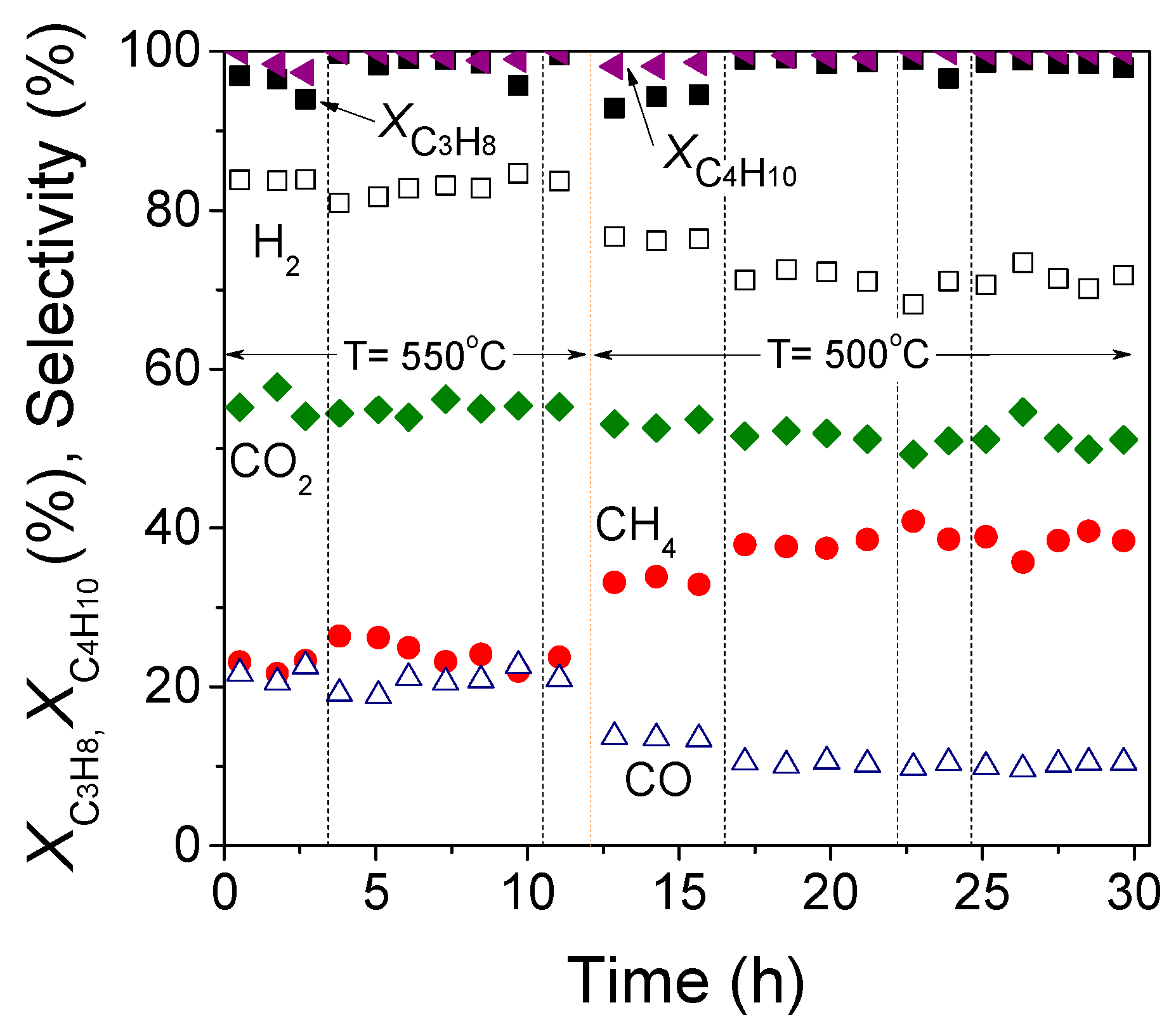

2.6. Catalytic Performance and Long-Term Stability Test of Rh/TiO2 Catalyst under Realistic Reaction Conditions

3. Materials and Methods

3.1. Catalyst Preparation and Characterization

3.2. Catalytic Performance Tests

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Al-Zuhair, S.; Hassan, M.; Djama, M.; Khaleel, A. Hydrogen Production by Steam Reforming of Commercially Available LPG in UAE. Chem. Eng. Commun. 2016, 204, 141–148. [Google Scholar] [CrossRef]

- Faria, E.C.; Rabelo-Neto, R.C.; Colman, R.C.; Ferreira, R.A.R.; Hori, C.E.; Noronha, F.B. Steam Reforming of LPG over Ni/Al2O3 and Ni/CexZr1−xO2/Al2O3 Catalysts. Catal. Lett. 2016, 146, 2229–2241. [Google Scholar] [CrossRef]

- Ipsakis, D.; Papadopoulou, S.; Voutetakis, S.; Seferlis, P. Analysis and Implementation of a Plant-Wide Control System for an LPG Reforming-Fuel Cell Power System. In Chemical Engineering Transactions; AIDIC Servizi S.r.l.: Milan, Italy, 2013; Volume 35, pp. 955–960. [Google Scholar]

- Panagiotopoulou, P.; Papadopoulou, C.; Matralis, H.; Verykios, X. Production of Renewable Hydrogen by Reformation of Biofuels. In Advances in Bioenergy: The Sustainability Challenge; Wiley: Hoboken, NJ, USA, 2015; pp. 109–130. [Google Scholar] [CrossRef]

- Liguras, D.K.; Kondarides, D.I.; Verykios, X.E. Production of hydrogen for fuel cells by steam reforming of ethanol over supported noble metal catalysts. Appl. Catal. B Environ. 2003, 43, 345–354. [Google Scholar] [CrossRef]

- Silva, P.P.; Ferreira, R.A.; Noronha, F.B.; Hori, C.E. Hydrogen production from steam and oxidative steam reforming of liquefied petroleum gas over cerium and strontium doped LaNiO3 catalysts. Catal. Today 2017, 289, 211–221. [Google Scholar] [CrossRef]

- Wang, G.; Yu, Y.; Liu, H.; Gong, C.; Wen, S.; Wang, X.; Tu, Z. Progress on design and development of polymer electrolyte membrane fuel cell systems for vehicle applications: A review. Fuel Process. Technol. 2018, 179, 203–228. [Google Scholar] [CrossRef]

- Kolb, G.; Keller, S.; O’Connell, M.; Pecov, S.; Schuerer, J.; Spasova, B.; Tiemann, D.; Ziogas, A. Microchannel Fuel Processors as a Hydrogen Source for Fuel Cells in Distributed Energy Supply Systems. Energy Fuels 2013, 27, 4395–4402. [Google Scholar] [CrossRef]

- Laosiripojana, N.; Sutthisripok, W.; Charojrochkul, S.; Assabumrungrat, S. Steam reforming of LPG over Ni and Rh supported on Gd-CeO2 and Al2O3: Effect of support and feed composition. Fuel 2011, 90, 136–141. [Google Scholar] [CrossRef]

- Afolabi, A.T.F.; Kechagiopoulos, P.N.; Liu, Y.; Li, C.-Z. Kinetic features of ethanol steam reforming and decomposition using a biochar-supported Ni catalyst. Fuel Process. Technol. 2021, 212, 106622. [Google Scholar] [CrossRef]

- Huang, T.-J.; Wu, C.-Y.; Wang, C.-H. Fuel processing in direct propane solid oxide fuel cell and carbon dioxide reforming of propane over Ni—YSZ. Fuel Process. Technol. 2011, 92, 1611–1616. [Google Scholar] [CrossRef]

- Remón, J.; Jarauta-Córdoba, C.; García, L.; Arauzo, J. Analysis and optimisation of H2 production from crude glycerol by steam reforming using a novel two step process. Fuel Process. Technol. 2016, 145, 130–147. [Google Scholar] [CrossRef]

- Haryanto, A.; Fernando, S.; Murali, N.; Adhikari, S. Current Status of Hydrogen Production Techniques by Steam Reforming of Ethanol: A Review. Energy Fuels 2005, 19, 2098–2106. [Google Scholar] [CrossRef]

- Douette, A.M.D.; Turn, S.Q.; Wang, W.; Keffer, V.I. Experimental Investigation of Hydrogen Production from Glycerin Reforming. Energy Fuels 2007, 21, 3499–3504. [Google Scholar] [CrossRef]

- Tang, R.; Tian, Y.; Qiao, Y.; Zhao, G.; Zhou, H. Light Products and H2-Rich Syngas over the Bifunctional Base Catalyst Derived from Petroleum Residue Cracking Gasification. Energy Fuels 2016, 30, 8855–8862. [Google Scholar] [CrossRef]

- Recupero, V.; Pino, L.; Vita, A.; Cipitı, F.; Cordaro, M.; Laganà, M. Development of a LPG fuel processor for PEFC systems: Laboratory scale evaluation of autothermal reforming and preferential oxidation subunits. Int. J. Hydrog. Energy 2005, 30, 963–971. [Google Scholar] [CrossRef]

- Borges, R.P.; Moura, L.G.; Spivey, J.J.; Noronha, F.B.; Hori, C.E. Hydrogen production by steam reforming of LPG using supported perovskite type precursors. Int. J. Hydrog. Energy 2020, 45, 21166–21177. [Google Scholar] [CrossRef]

- Rakib, M.A.; Grace, J.R.; Lim, C.J.; Elnashaie, S.S.E.H.; Ghiasi, B. Steam reforming of propane in a fluidized bed membrane reactor for hydrogen production. Int. J. Hydrog. Energy 2010, 35, 6276–6290. [Google Scholar] [CrossRef]

- Ahmed, K.; Gamman, J.; Föger, K. Demonstration of LPG-fueled solid oxide fuel cell systems. Solid State Ion. 2002, 152, 485–492. [Google Scholar] [CrossRef]

- Moura, L.G.; Borges, R.P.; Noronha, F.B.; Hori, C.E. Steam reforming of liquefied petroleum gas using catalysts supported on ceria-silica. Int. J. Hydrog. Energy 2020, 46, 1801–1814. [Google Scholar] [CrossRef]

- Im, Y.; Lee, J.H.; Kwak, B.S.; Do, J.Y.; Kang, M. Effective hydrogen production from propane steam reforming using M/NiO/YSZ catalysts (M = Ru, Rh, Pd, and Ag). Catal. Today 2018, 303, 168–176. [Google Scholar] [CrossRef]

- Laosiripojana, N.; Assabumrungrat, S. Hydrogen production from steam and autothermal reforming of LPG over high surface area ceria. J. Power Sources 2006, 158, 1348–1357. [Google Scholar] [CrossRef]

- Gökaliler, F.; Selen Çaǧlayan, B.; Ilsen Önsan, Z.; Erhan Aksoylu, A. Hydrogen production by autothermal reforming of LPG for PEM fuel cell applications. Int. J. Hydrog. Energy 2008, 33, 1383–1391. [Google Scholar] [CrossRef]

- Fard, A.A.; Arvaneh, R.; Alavi, S.M.; Bazyari, A.; Valaei, A. Propane steam reforming over promoted Ni—Ce/MgAl2O4 catalysts: Effects of Ce promoter on the catalyst performance using developed CCD model. Int. J. Hydrog. Energy 2019, 44, 21607–21622. [Google Scholar] [CrossRef]

- Fard, A.A.; Bazyari, A.; Alavi, S.M.; Aghamiri, A.R. The effects of cobalt and cerium promoters on hydrogen production performance of alumina-supported nickel catalysts in propane steam reforming. J. Chem. Technol. Biotechnol. 2020, 95, 3241–3251. [Google Scholar] [CrossRef]

- Shoynkhorova, T.B.; Rogozhnikov, V.N.; Ruban, N.V.; Shilov, V.A.; Potemkin, D.I.; Simonov, P.A.; Belyaev, V.D.; Snytnikov, P.V.; Sobyanin, V.A. Composite Rh/Zr0.25Ce0.75O2-δ-η-Al2O3/Fecralloy wire mesh honeycomb module for natural gas, LPG and diesel catalytic conversion to syngas. Int. J. Hydrog. Energy 2019, 44, 9941–9948. [Google Scholar] [CrossRef]

- Yu, L.; Sato, K.; Nagaoka, K. Rh/Ce0.25Zr0.75O2 Catalyst for Steam Reforming of Propane at Low Temperature. ChemCatChem 2019, 11, 1472–1479. [Google Scholar] [CrossRef]

- Yu, L.; Sato, K.; Toriyama, T.; Yamamoto, T.; Matsumura, S.; Nagaoka, K. Influence of the Crystal Structure of Titanium Oxide on the Catalytic Activity of Rh/TiO2 in Steam Reforming of Propane at Low Temperature. Chem. A Eur. J. 2018, 24, 8742–8746. [Google Scholar] [CrossRef]

- Kokka, A.; Katsoni, A.; Yentekakis, I.V.; Panagiotopoulou, P. Hydrogen production via steam reforming of propane over supported metal catalysts. Int. J. Hydrog. Energy 2020, 45, 14849–14866. [Google Scholar] [CrossRef]

- Chein, R.-Y.; Yu, C.-T. Thermodynamic equilibrium analysis of water-gas shift reaction using syngases-effect of CO2 and H2S contents. Energy 2017, 141, 1004–1018. [Google Scholar] [CrossRef]

- Hou, T.; Yu, B.; Zhang, S.; Zhang, J.; Wang, D.; Xu, T.; Cui, L.; Cai, W. Hydrogen production from propane steam reforming over Ir/Ce0.75Zr0.25O2 catalyst. Appl. Catal. B Environ. 2015, 168, 524–530. [Google Scholar] [CrossRef]

- Tabrizi, F.F.; Mousavi, S.A.H.S.; Atashi, H. Thermodynamic analysis of steam reforming of methane with statistical approaches. Energy Convers. Manag. 2015, 103, 1065–1077. [Google Scholar] [CrossRef]

- Wang, X.; Wang, N.; Zhao, J.; Wang, L. Thermodynamic analysis of propane dry and steam reforming for synthesis gas or hydrogen production. Int. J. Hydrog. Energy 2010, 35, 12800–12807. [Google Scholar] [CrossRef]

- Çağlayan, B.S.; Avci, A.K.; Önsan, Z.I.; Aksoylu, A.E. Production of hydrogen over bimetallic Pt—Ni/δ-Al2O3: I. Indirect partial oxidation of propane. Appl. Catal. A Gen. 2005, 280, 181–188. [Google Scholar] [CrossRef]

- Burra, K.G.; Gupta, A.K. Sorption Enhanced Steam Reforming of Propane Using Calcium Looping. In Proceedings of the ASME 2017 Power Conference Joint with ICOPE-17 collocated with the ASME 2017 11th International Conference on Energy Sustainability, the ASME 2017 15th International Conference on Fuel Cell Science, Engineering and Technology, and the ASME 2017 Nuclear Forum, Charlotte, NC, USA, 26–30 June 2017. [Google Scholar]

- Kolb, G.; Zapf, R.; Hessel, V.; Löwe, H. Propane steam reforming in micro-channels—Results from catalyst screening and optimisation. Appl. Catal. A Gen. 2004, 277, 155–166. [Google Scholar] [CrossRef]

- Kim, N.H.; Park, Y.-K.; Sohn, J.M. The promotion effect of catalytic activity by Ru substitution at the B site of La1−xSrxCr1−yRuyO3−z for propane steam reforming. Res. Chem. Intermed. 2011, 37, 1313. [Google Scholar] [CrossRef]

- Anzelmo, B.; Wilcox, J.; Liguori, S. Hydrogen production via natural gas steam reforming in a Pd-Au membrane reactor. Investigation of reaction temperature and GHSV effects and long-term stability. J. Membr. Sci. 2018, 565, 25–32. [Google Scholar] [CrossRef]

- Park, K.S.; Son, M.; Park, M.-J.; Kim, D.H.; Kim, J.H.; Park, S.H.; Choi, J.-H.; Bae, J.W. Adjusted interactions of nickel nanoparticles with cobalt-modified MgAl2O4-SiC for an enhanced catalytic stability during steam reforming of propane. Appl. Catal. A Gen. 2018, 549, 117–133. [Google Scholar] [CrossRef]

- Panagiotopoulou, P.; Kondarides, D.I.; Verykios, X.E. Selective methanation of CO over supported Ru catalysts. Appl. Catal. B Environ. 2009, 88, 470–478. [Google Scholar] [CrossRef]

- Petala, A.; Tsikritzis, D.; Kollia, M.; Ladas, S.; Kennou, S.; Kondarides, D.I. Synthesis and characterization of N-doped TiO2 photocatalysts with tunable response to solar radiation. Appl. Surf. Sci. 2014, 305, 281–291. [Google Scholar] [CrossRef]

- Panagiotopoulou, P.; Kondarides, D.I. Effects of alkali additives on the physicochemical characteristics and chemisorptive properties of Pt/TiO2 catalysts. J. Catal. 2008, 260, 141–149. [Google Scholar] [CrossRef]

- Hanaor, D.A.H.; Sorrell, C.C. Review of the anatase to rutile phase transformation. J. Mater. Sci. 2011, 46, 855–874. [Google Scholar] [CrossRef]

- Alphonse, P.; Ansart, F. Catalytic coatings on steel for low-temperature propane prereforming to solid oxide fuel cell (SOFC) application. J. Colloid Interface Sci. 2009, 336, 658–666. [Google Scholar] [CrossRef]

- Qiu, T.; Yang, J.-G.; Bai, X.-J.; Wang, Y.-L. The preparation of synthetic graphite materials with hierarchical pores from lignite by one-step impregnation and their characterization as dye absorbents. RSC Adv. 2019, 9, 12737–12746. [Google Scholar] [CrossRef]

- Huang, W.; Li, J.; Xu, Y. Nucleation/Growth Mechanisms and Morphological Evolution of Porous MnO2 Coating Deposited on Graphite for Supercapacitor. Materials 2017, 10, 1205. [Google Scholar] [CrossRef]

- Kourtelesis, M.; Panagiotopoulou, P.; Ladas, S.; Verykios, X.E. Influence of the Support on the Reaction Network of Ethanol Steam Reforming at Low Temperatures Over Pt Catalysts. Top. Catal. 2015, 58, 1202–1217. [Google Scholar] [CrossRef]

- Bradford, M.C.J.; Vannice, M.A. Catalytic reforming of methane with carbon dioxide over nickel catalysts I. Catalyst characterization and activity. Appl. Catal. A Gen. 1996, 142, 73–96. [Google Scholar] [CrossRef]

- Guo, C.; Wu, Y.; Qin, H.; Zhang, J. CO methanation over ZrO2/Al2O3 supported Ni catalysts: A comprehensive study. Fuel Process. Technol. 2014, 124, 61–69. [Google Scholar] [CrossRef]

- Swaan, H.M.; Kroll, V.C.H.; Martin, G.A.; Mirodatos, C. Deactivation of supported nickel catalysts during the reforming of methane by carbon dioxide. Catal. Today 1994, 21, 571–578. [Google Scholar] [CrossRef]

- Zhang, Z.L.; Tsipouriari, V.A.; Efstathiou, A.M.; Verykios, X.E. Reforming of Methane with Carbon Dioxide to Synthesis Gas over Supported Rhodium Catalysts: I. Effects of Support and Metal Crystallite Size on Reaction Activity and Deactivation Characteristics. J. Catal. 1996, 158, 51–63. [Google Scholar] [CrossRef]

- Carlsson, M. Carbon Formation in Steam Reforming and Effect of Potassium Promotion. Johns. Matthey Technol. Rev. 2015, 59, 313–318. [Google Scholar] [CrossRef]

| 0.5%Rh/TiO2 | SSA 1 (m2/g) | Composition 2 (% Rutile) | Primary Crystallite Size of TiO2 3 (nm) | |

|---|---|---|---|---|

| Anatase | Rutile | |||

| Fresh | 43 | 17.3 | 21.2 | 34.0 |

| Fresh 600 °C (3 h) | 30 | 41 | 23 | 35.0 |

| Spent 600 °C (56 h) | 6.6 | 100.0 | - | 49.6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kokka, A.; Ramantani, T.; Panagiotopoulou, P. Effect of Operating Conditions on the Performance of Rh/TiO2 Catalyst for the Reaction of LPG Steam Reforming. Catalysts 2021, 11, 374. https://doi.org/10.3390/catal11030374

Kokka A, Ramantani T, Panagiotopoulou P. Effect of Operating Conditions on the Performance of Rh/TiO2 Catalyst for the Reaction of LPG Steam Reforming. Catalysts. 2021; 11(3):374. https://doi.org/10.3390/catal11030374

Chicago/Turabian StyleKokka, Aliki, Theodora Ramantani, and Paraskevi Panagiotopoulou. 2021. "Effect of Operating Conditions on the Performance of Rh/TiO2 Catalyst for the Reaction of LPG Steam Reforming" Catalysts 11, no. 3: 374. https://doi.org/10.3390/catal11030374

APA StyleKokka, A., Ramantani, T., & Panagiotopoulou, P. (2021). Effect of Operating Conditions on the Performance of Rh/TiO2 Catalyst for the Reaction of LPG Steam Reforming. Catalysts, 11(3), 374. https://doi.org/10.3390/catal11030374