Abatement of Toluene Using a Sequential Adsorption-Catalytic Oxidation Process: Comparative Study of Potential Adsorbent/Catalytic Materials

Abstract

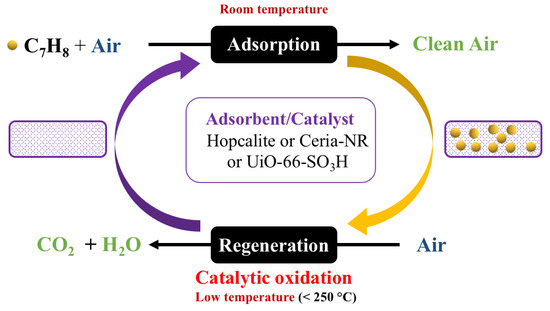

1. Introduction

2. Results and Discussion

2.1. Catalyst Characterization

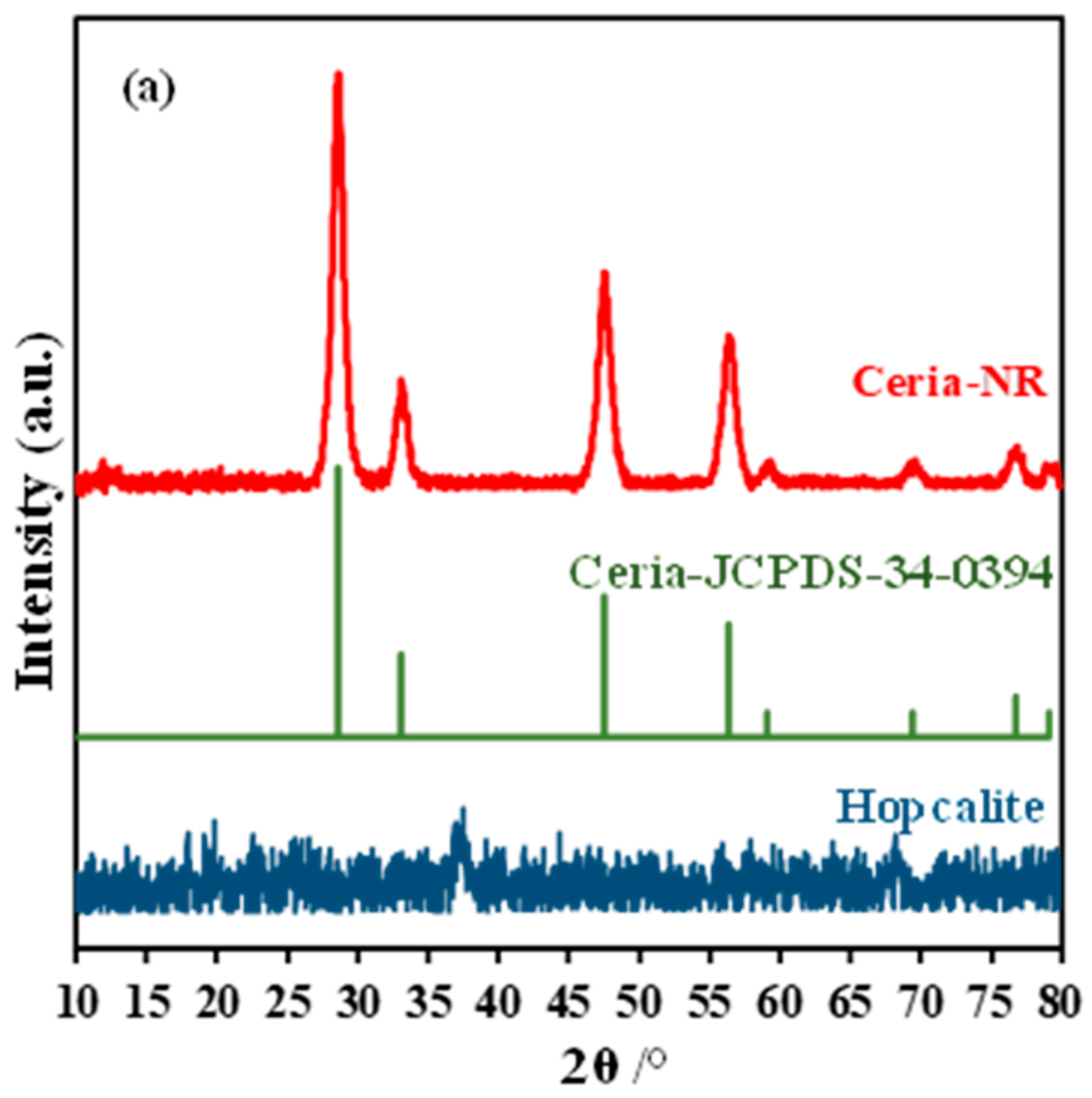

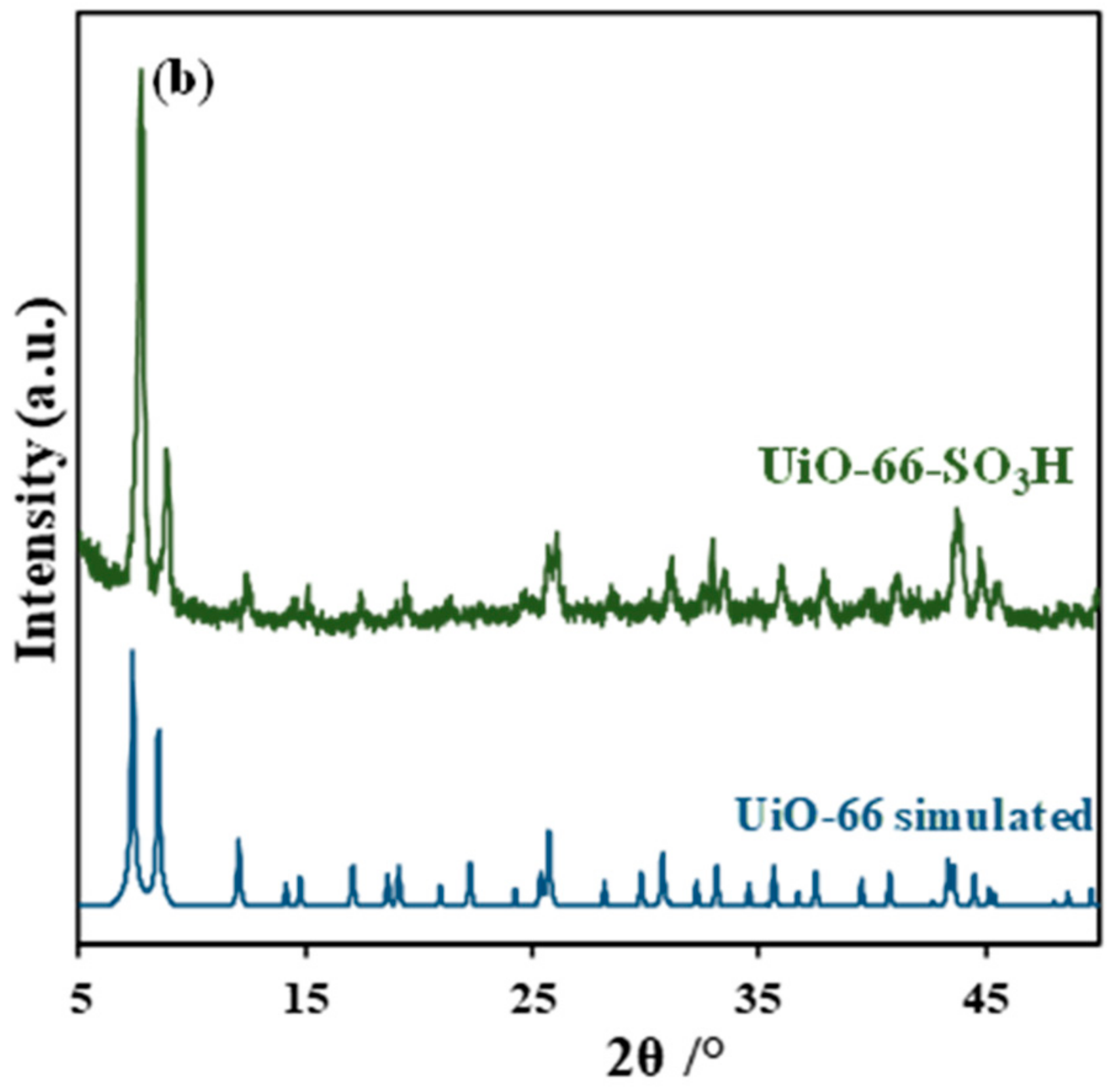

2.1.1. Structural Properties

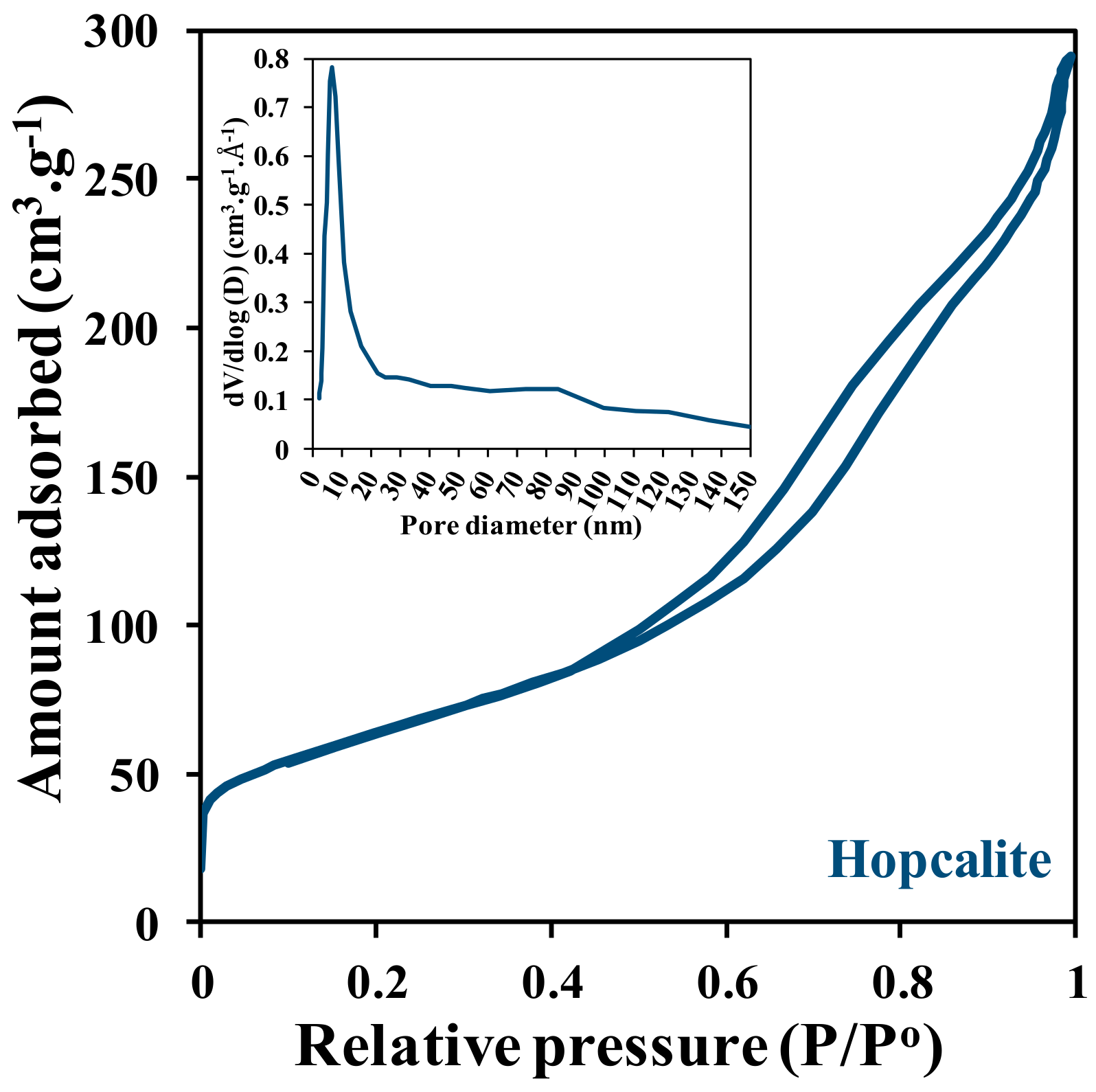

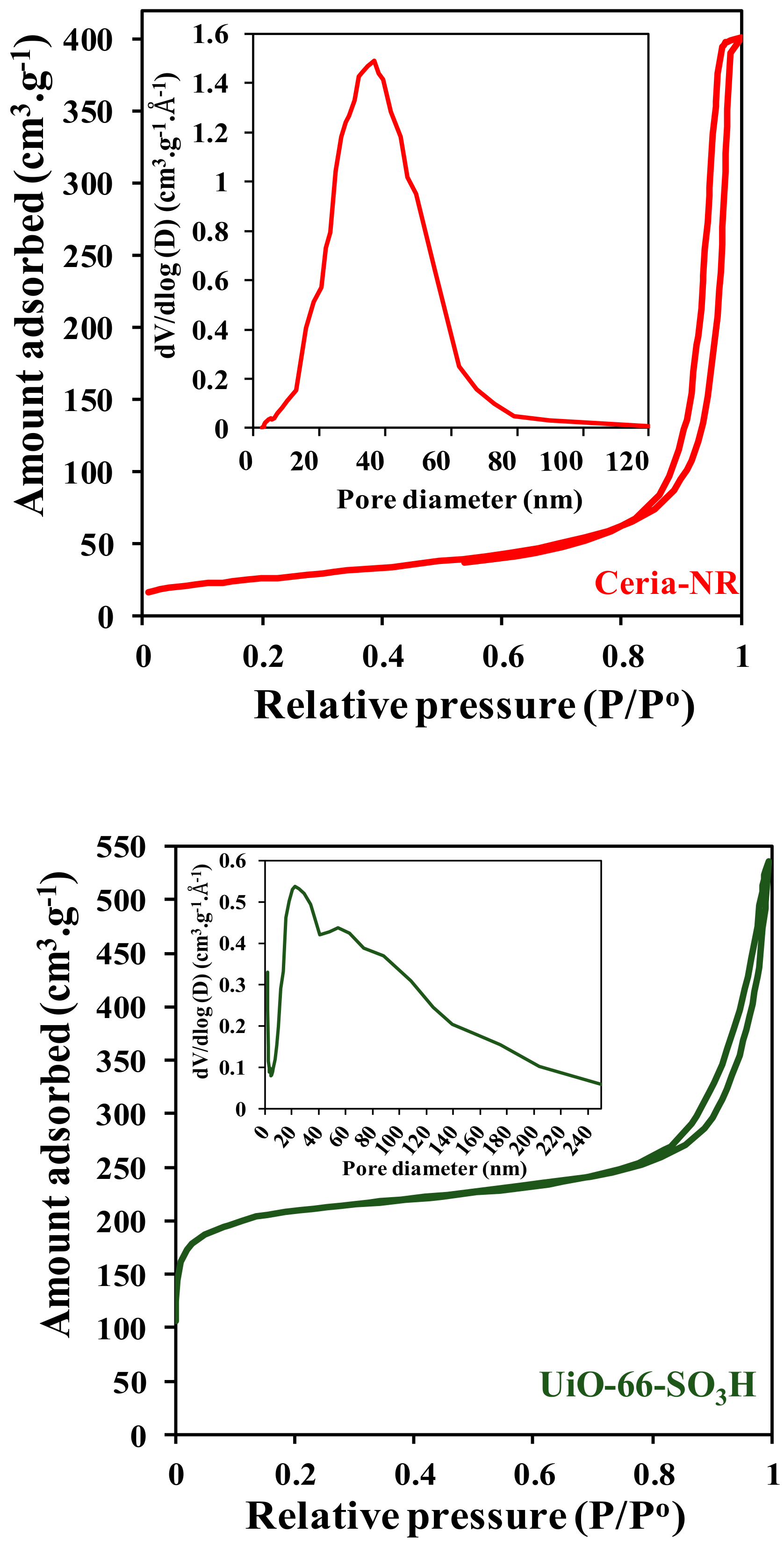

2.1.2. Textural Properties

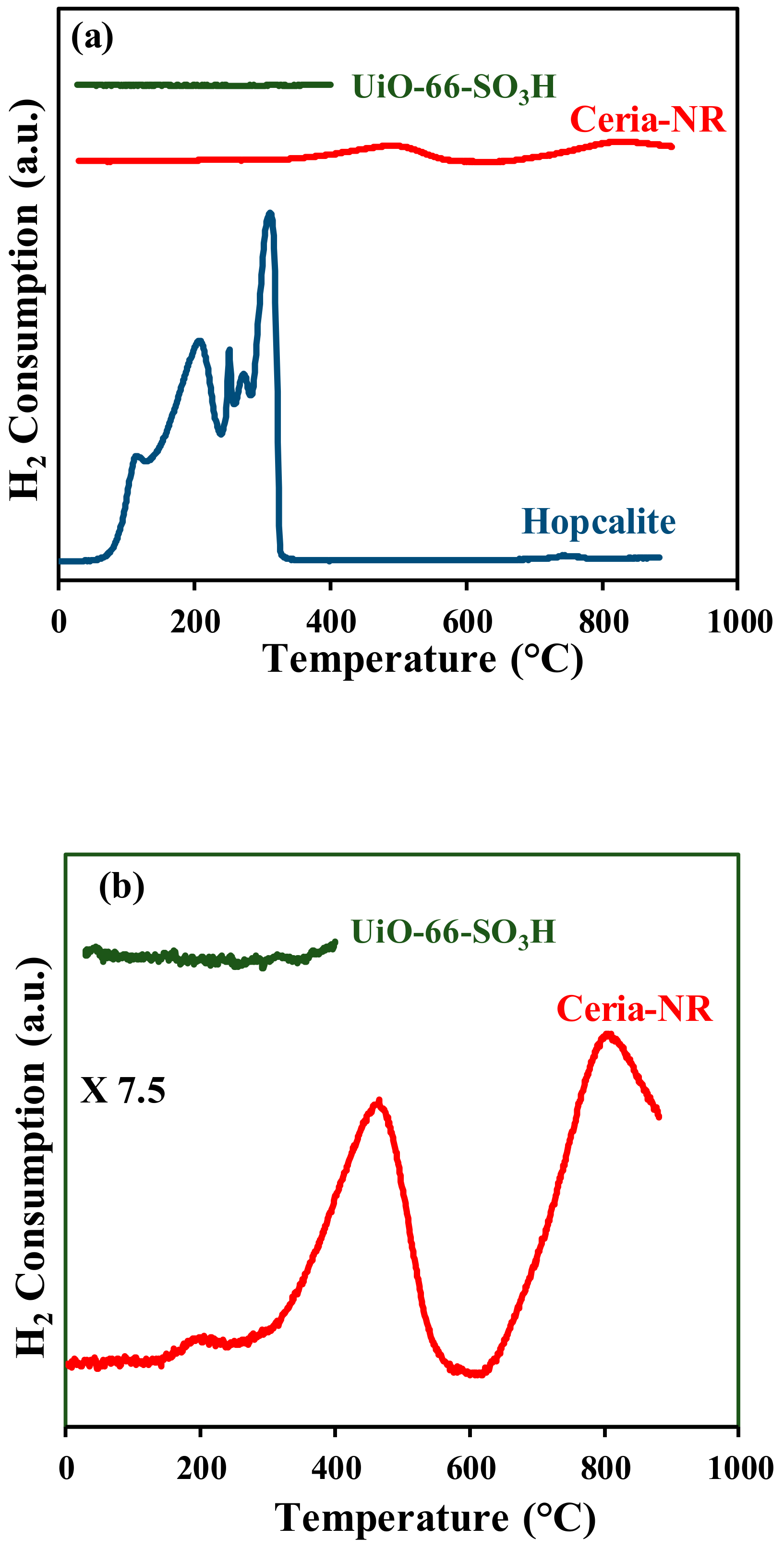

2.1.3. Redox Properties

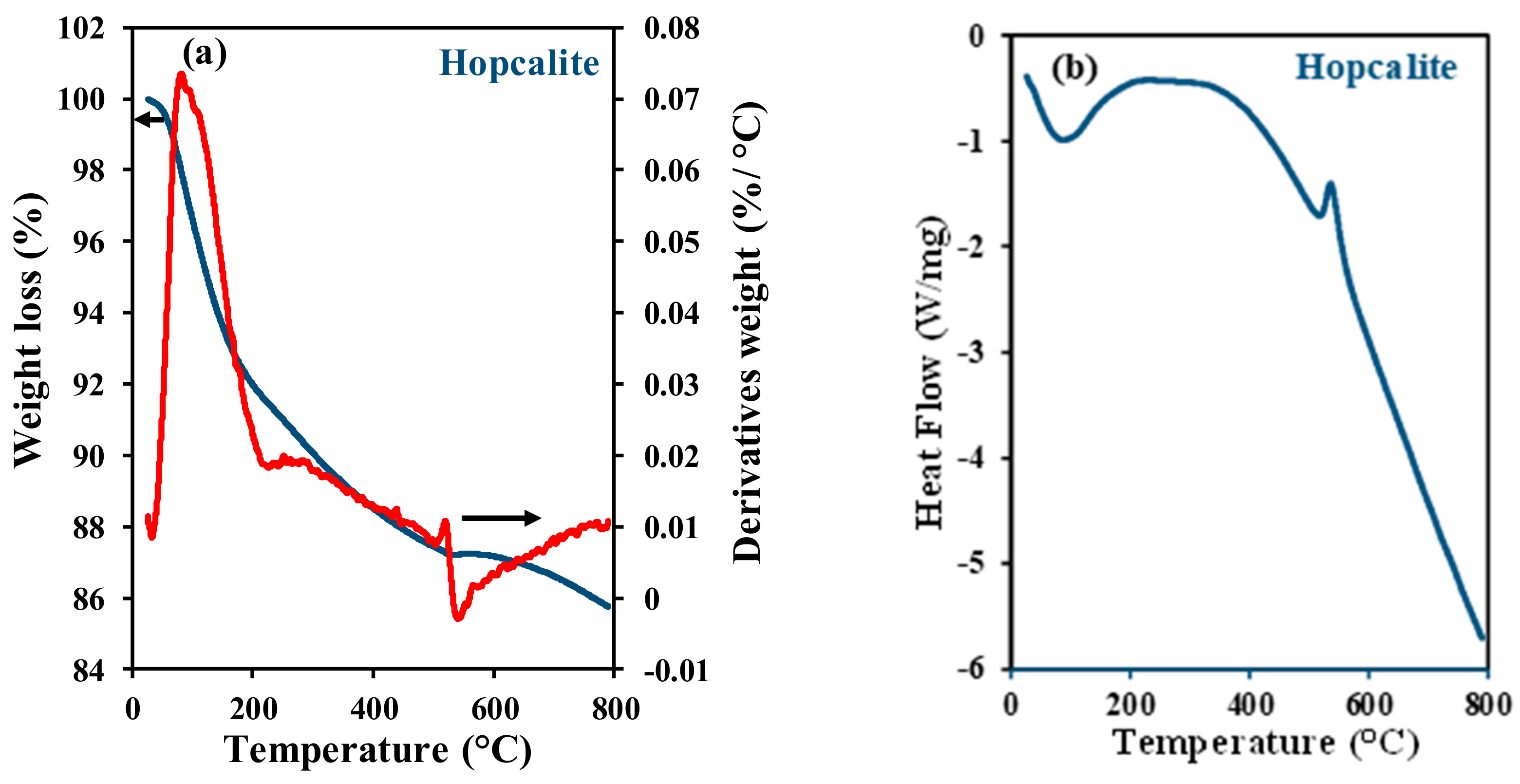

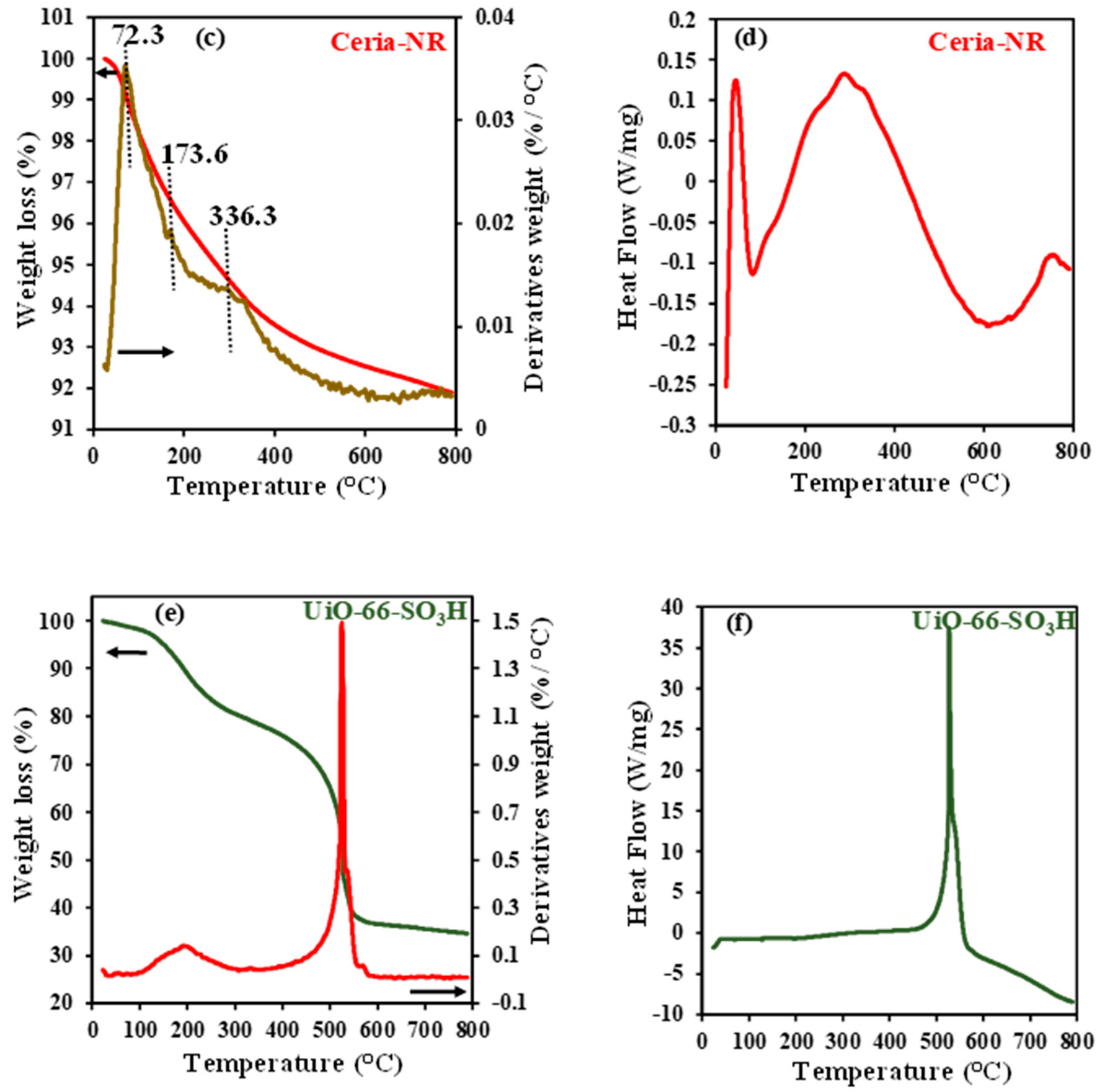

2.1.4. Thermal Stabilities Properties

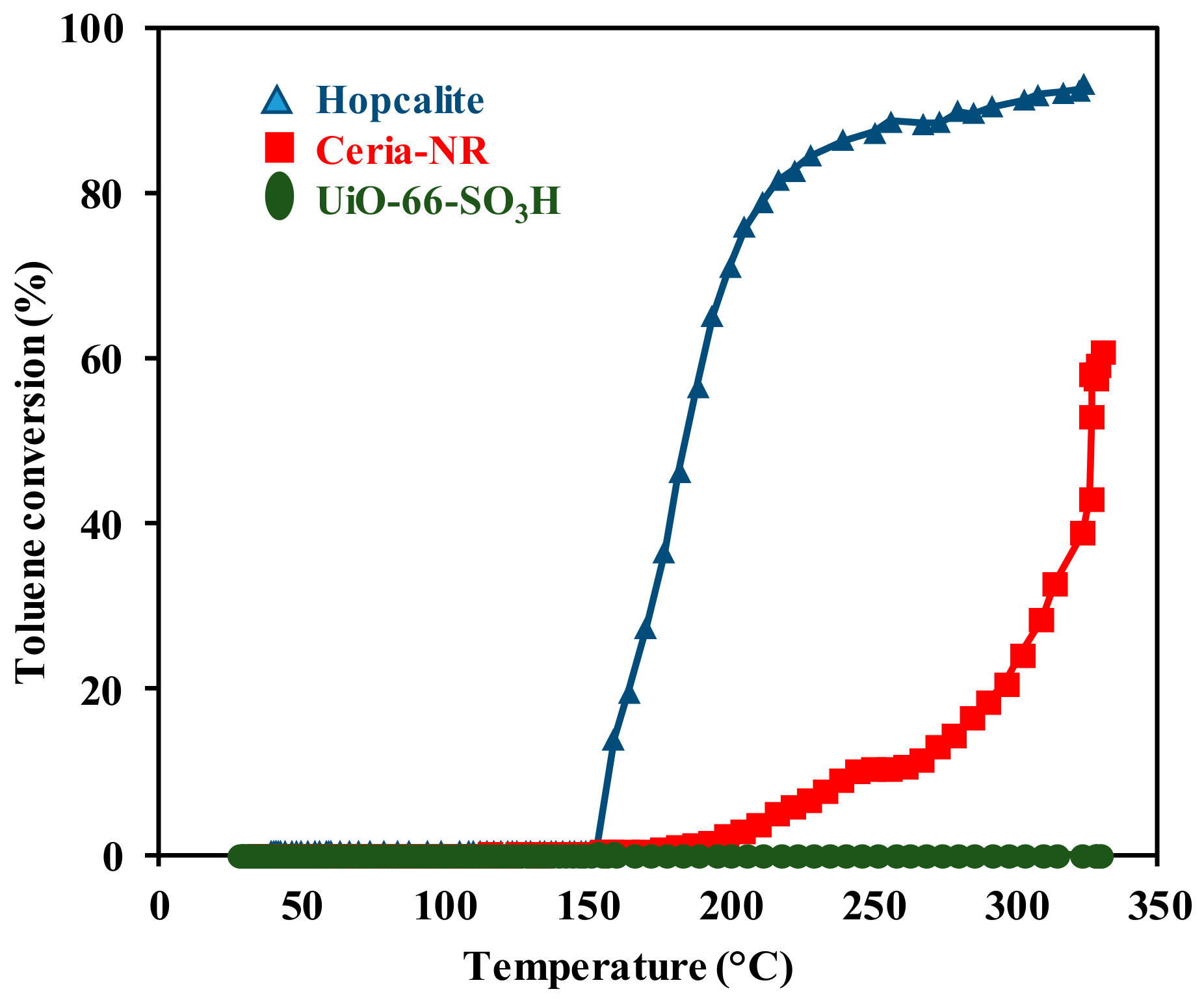

2.2. Catalytic Oxidation of Toluene

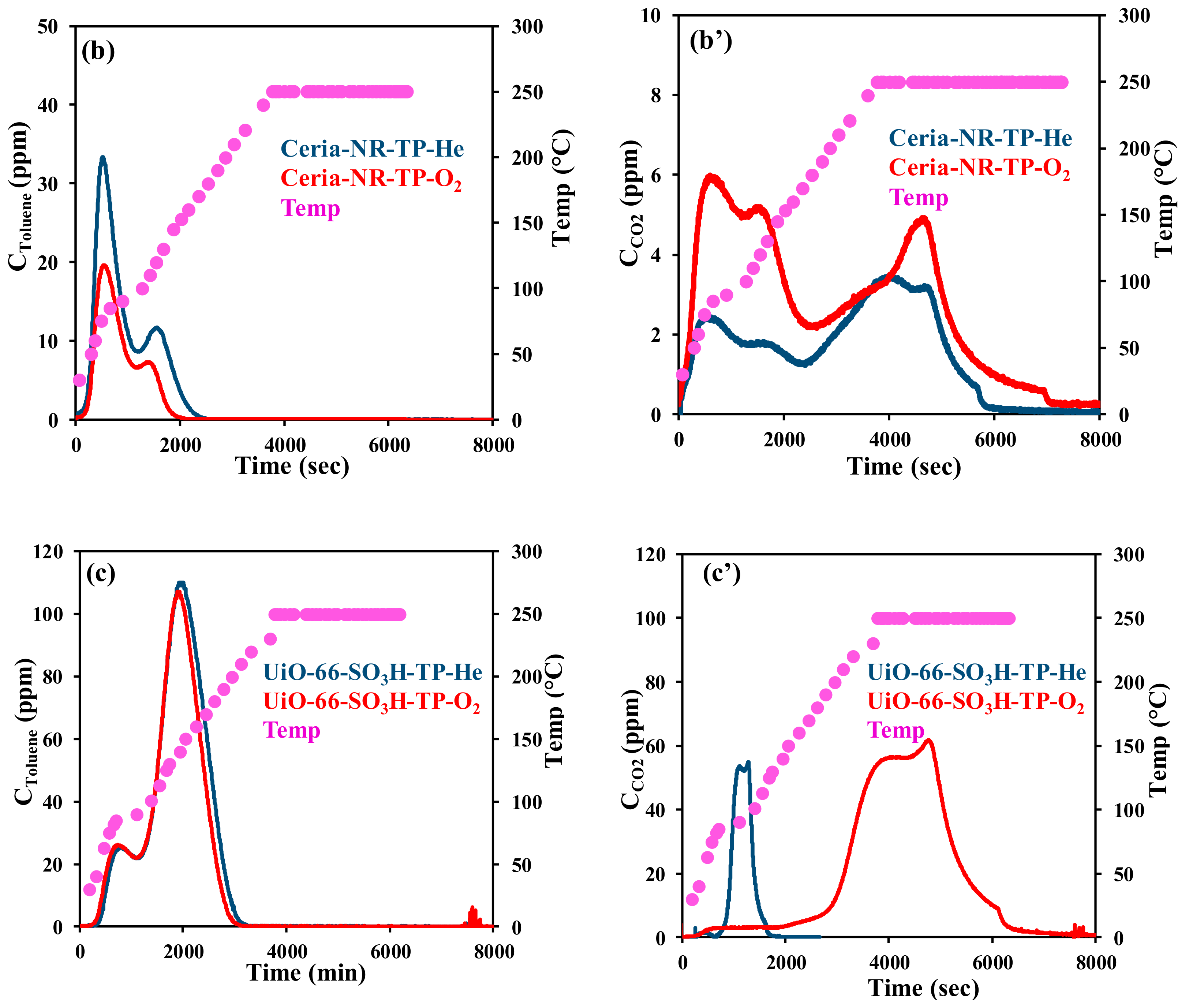

2.3. Sequential Adsorption/Thermal Conversion

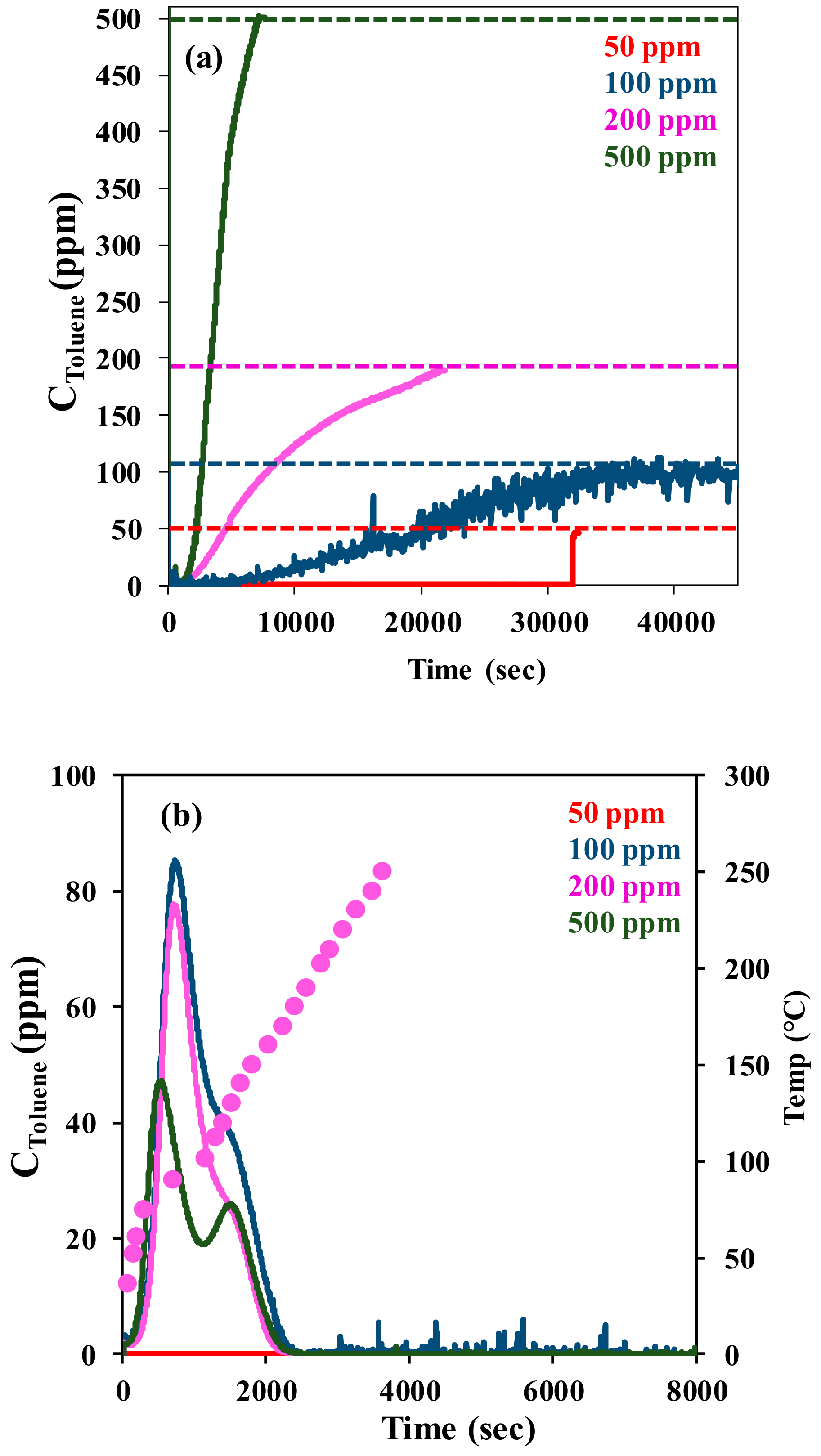

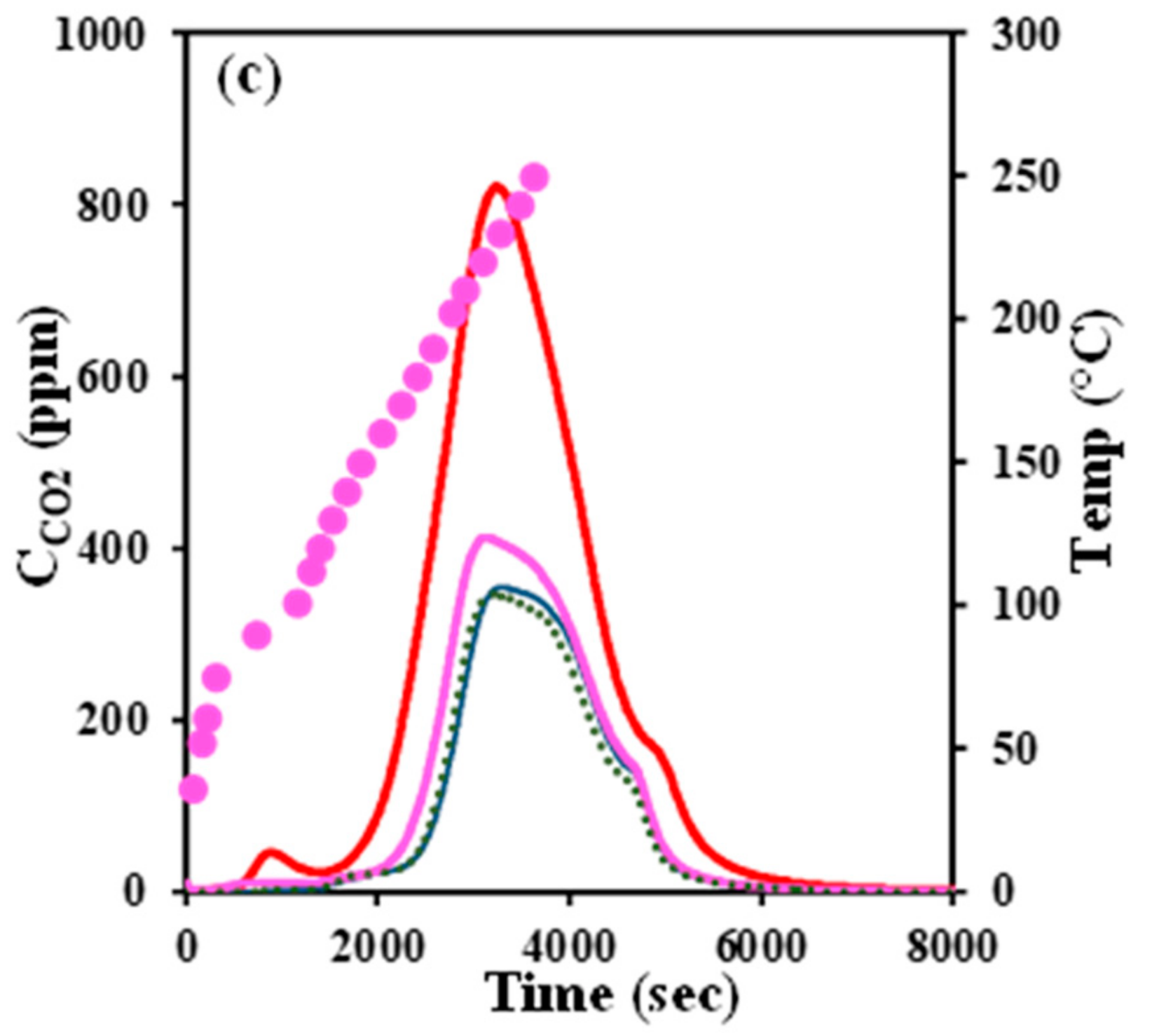

2.3.1. Effect of the Initial Toluene Concentration on Hopcalite

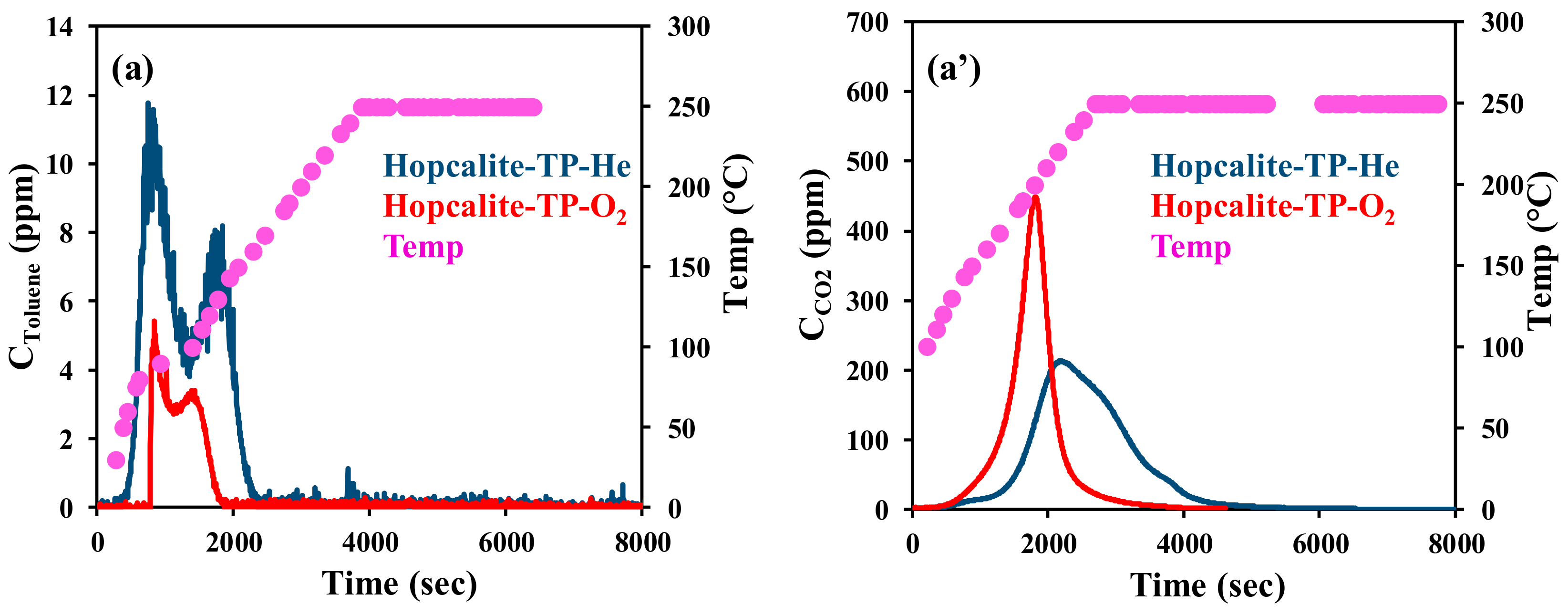

2.3.2. Comparative Study of the Different Materials

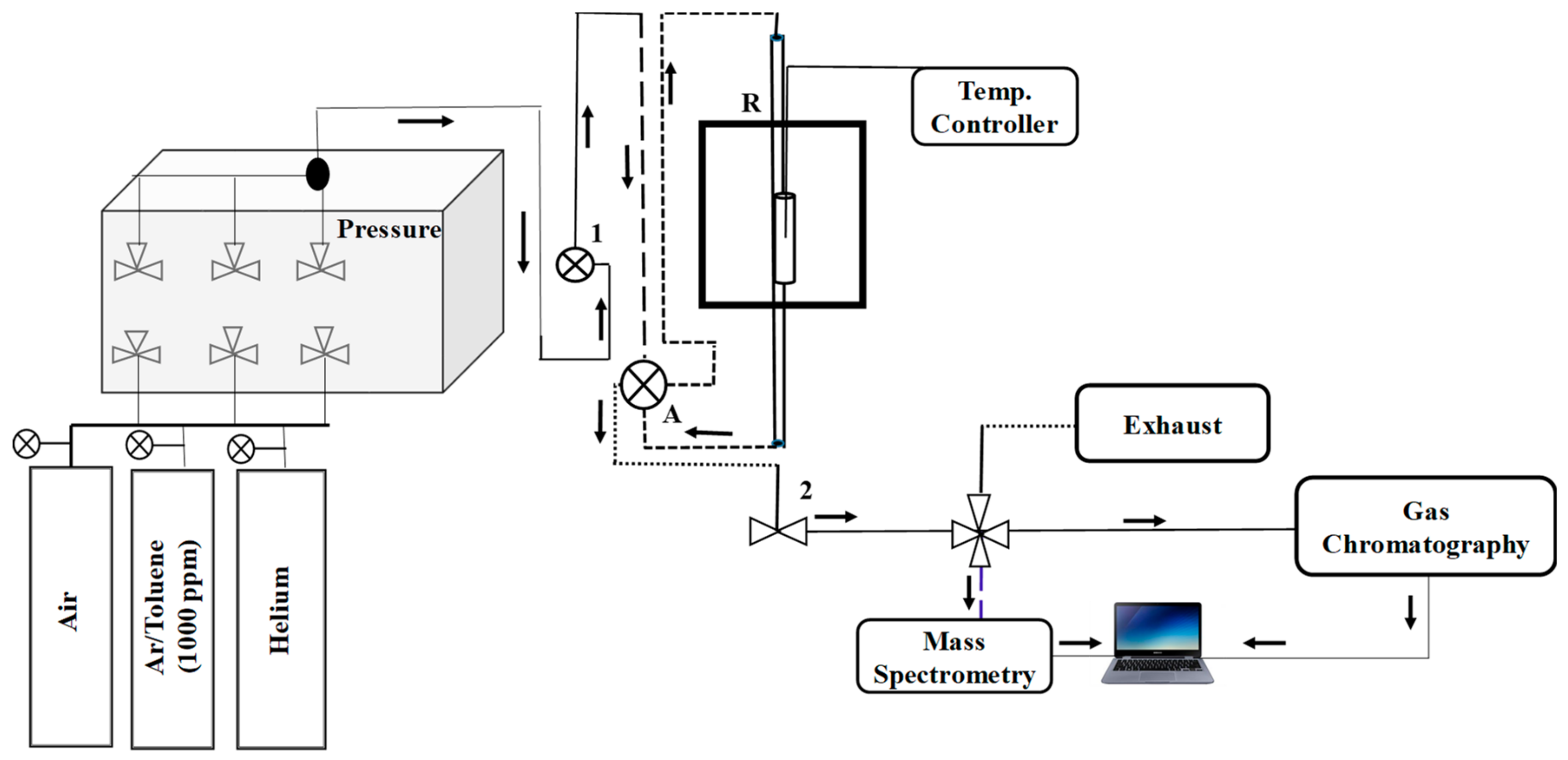

3. Materials and Methods

3.1. Catalyst Preparation

3.2. Characterization of the Materials

3.3. Catalytic Activity Tests

3.3.1. Catalytic Oxidation

3.3.2. Sequential Adsorption/Thermal Oxidation

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Dinh, T.V.; Choi, I.Y.; Son, Y.S.; Song, K.Y.; Sunwoo, Y.; Kim, J.C. Volatile organic compounds (VOCs) in surface coating materials: Their compositions and potential as an alternative fuel. J. Environ. Manag. 2016, 168, 157–164. [Google Scholar] [CrossRef] [PubMed]

- Liu, G.; Ji, J.; Huang, H.; Xie, R.; Feng, Q.; Shu, Y.; Zhan, Y.; Fang, R.; He, M.; Liu, S.; et al. UV/H2O2: An efficient aqueous advanced oxidation process for VOCs removal. Chem. Eng. J. 2017, 324, 44–50. [Google Scholar] [CrossRef]

- He, C.; Cheng, J.; Zhang, X.; Douthwaite, M.; Pattisson, S.; Hao, Z. Recent Advances in the Catalytic Oxidation of Volatile Organic Compounds: A Review Based on Pollutant Sorts and Sources. Chem. Rev. 2019, 119, 4471–4568. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Su, X.; Xu, Z.; Wen, K.; Zhang, P.; Zhu, J.; He, H. Preparation of surface-functionalized porous clay heterostructures via carbonization of soft-template and their adsorption performance for toluene. Appl. Surf. Sci. 2016, 363, 113–121. [Google Scholar] [CrossRef]

- Romero, D.; Chlala, D.; Labaki, M.; Royer, S.; Bellat, J.P.; Bezverkhyy, I.; Giraudon, J.M.; Lamonier, J.F. Removal of toluene over naX zeolite exchanged with Cu2+. Catalysts 2015, 5, 1479–1497. [Google Scholar] [CrossRef]

- Darracq, G.; Couvert, A.; Couriol, C.; Amrane, A.; Le Cloirec, P. Removal of hydrophobic volatile organic compounds in an integrated process coupling absorption and biodegradation-selection of an organic liquid phase. Water. Air. Soil Pollut. 2012, 223, 4969–4997. [Google Scholar] [CrossRef]

- Liu, B.; Li, X.; Zhao, Q.; Liu, J.; Liu, S.; Wang, S.; Tadé, M. Insight into the mechanism of photocatalytic degradation of gaseous o-dichlorobenzene over flower-type V2O5 hollow spheres. J. Mater. Chem. A 2015, 3, 15163–15170. [Google Scholar] [CrossRef]

- Yang, C.; Miao, G.; Pi, Y.; Xia, Q.; Wu, J.; Li, Z.; Xiao, J. Abatement of various types of VOCs by adsorption/catalytic oxidation: A review. Chem. Eng. J. 2019, 370, 1128–1153. [Google Scholar] [CrossRef]

- Chen, B.; Wu, L.; Wu, B.; Wang, Z.; Yu, L.; Crocker, M.; Zhu, A.; Shi, C. Catalytic Materials for Low Concentration VOCs Removal through “Storage-Regeneration” Cycling. ChemCatChem 2019, 11, 3646–3661. [Google Scholar] [CrossRef]

- Sultana, S.; Vandenbroucke, A.M.; Leys, C.; De Geyter, N.; Morent, R. Abatement of VOCs with alternate adsorption and plasma-assisted regeneration: A review. Catalysts 2015, 5, 718–746. [Google Scholar] [CrossRef]

- Xu, W.; Xu, X.; Wu, J.; Fu, M.; Chen, L.; Wang, N.; Xiao, H.; Chen, X.; Ye, D. Removal of toluene in adsorption–discharge plasma systems over a nickel modified SBA-15 catalyst. RSC Adv. 2016, 6, 104104–104111. [Google Scholar] [CrossRef]

- Reungoat, J.; Pic, J.S.; Manro, M.H.; Debellefontaine, H. Adsorption of nitrobenzene from water onto high silica zeolites and regeneration by ozone. Sep. Sci. Technol. 2007, 42, 1447–1463. [Google Scholar] [CrossRef]

- Guillemot, M.; Mijoin, J.; Mignard, S.; Magnoux, P. Volatile organic compounds (VOCs) removal over dual functional adsorbent/catalyst system. Appl. Catal. B Environ. 2007, 75, 249–255. [Google Scholar] [CrossRef]

- Dey, S.; Chandra, G.D. A Review of Synthesis, Structure and Applications in Hopcalite Catalysts for Carbon Monoxide Oxidation; Springer: Singapore, 2019; Volume 3, ISBN 0123456789. [Google Scholar]

- Pei, J.; Han, X.; Lu, Y. Performance and kinetics of catalytic oxidation of formaldehyde over copper manganese oxide catalyst. Build. Environ. 2015, 84, 134–141. [Google Scholar] [CrossRef]

- Wei, G.; Zhang, Q.; Zhang, D.; Wang, J.; Tang, T.; Wang, H.; Liu, X.; Song, Z.; Ning, P. The influence of annealing temperature on copper-manganese catalyst towards the catalytic combustion of toluene: The mechanism study. Appl. Surf. Sci. 2019, 497, 143777. [Google Scholar] [CrossRef]

- Hu, Z.; Liu, X.; Meng, D.; Guo, Y.; Guo, Y.; Lu, G. Effect of Ceria Crystal Plane on the Physicochemical and Catalytic Properties of Pd / Ceria for CO and Propane Oxidation. ACS Catal. 2016, 6, 2265–2279. [Google Scholar] [CrossRef]

- Biswas, S.; Van Der Voort, P. A General Strategy for the Synthesis of Functionalised UiO-66 Frameworks: Characterisation, Stability and CO2 Adsorption Properties. Eur. J. Inorg. Chem 2013, 2154–2160. [Google Scholar] [CrossRef]

- Zhang, X.; Yang, Y.; Lv, X.; Wang, Y.; Liu, N.; Chen, D.; Cui, L. Adsorption/desorption kinetics and breakthrough of gaseous toluene for modified microporous-mesoporous UiO-66 metal organic framework. J. Hazard. Mater. 2019, 366, 140–150. [Google Scholar] [CrossRef]

- Nguyen, H.G.T.; Mao, L.; Peters, A.W.; Audu, C.O.; Brown, Z.J.; Farha, O.K.; Hupp, J.T.; Nguyen, S.T. Comparative study of titanium-functionalized UiO-66: Support effect on the oxidation of cyclohexene using hydrogen peroxide. Catal. Sci. Technol. 2015, 5, 4444–4451. [Google Scholar] [CrossRef]

- Wei, C.; Hou, H.; Wang, E.; Lu, M. Preparation of a Series of PdatUIO-66 by a double-solvent method and its catalytic performance for toluene oxidation. Materials 2020, 13, 88. [Google Scholar] [CrossRef]

- Zhang, X.; Song, L.; Bi, F.; Zhang, D.; Wang, Y.; Cui, L. Catalytic oxidation of toluene using a facile synthesized Ag nanoparticle supported on UiO-66 derivative. J. Colloid Interface Sci. 2020, 571, 38–47. [Google Scholar] [CrossRef] [PubMed]

- Njagi, E.C.; Chen, C.H.; Genuino, H.; Galindo, H.; Huang, H.; Suib, S.L. Total oxidation of CO at ambient temperature using copper manganese oxide catalysts prepared by a redox method. Appl. Catal. B Environ. 2010, 99, 103–110. [Google Scholar] [CrossRef]

- Désaunay, T.; Bonura, G.; Chiodo, V.; Freni, S.; Couzinié, J.P.; Bourgon, J.; Ringuedé, A.; Labat, F.; Adamo, C.; Cassir, M. Surface-dependent oxidation of H2 on CeO2 surfaces. J. Catal. 2013, 297, 193–201. [Google Scholar] [CrossRef]

- Cavka, J.H.; Jakobsen, S.; Olsbye, U.; Guillou, N.; Lamberti, C.; Bordiga, S.; Lillerud, K.P. A New Zirconium Inorganic Building Brick Forming Metal Organic Frameworks with Exceptional Stability. J. Am. Chem. Soc. 2008, 130, 13850–13851. [Google Scholar] [CrossRef]

- Silva, C.G.; Luz, I.; Llabrés I Xamena, F.X.; Corma, A.; García, H. Water stable Zr-Benzenedicarboxylate metal-organic frameworks as photocatalysts for hydrogen generation. Chem. A Eur. J. 2010, 16, 11133–11138. [Google Scholar] [CrossRef]

- Øien, S.; Wragg, D.; Reinsch, H.; Svelle, S.; Bordiga, S.; Lamberti, C.; Lillerud, K.P. Detailed Structure Analysis of Atomic Positions and Defects in Zirconium Metal—Organic Frameworks. Cryst. Growth Des. 2014, 14, 5370–5372. [Google Scholar] [CrossRef]

- Yuan, Z.; Idakiev, V.; Tabakova, T.; Ren, T.; Su, B. Mesoporous and nanostructured CeO2 as supports of nano-sized gold catalysts for low-temperature water-gas shift reaction. Catal. Today 2008, 131, 203–210. [Google Scholar] [CrossRef]

- Du, X.; Zhang, D.; Shi, L.; Gao, R.; Zhang, J. Morphology Dependence of Catalytic Properties of Ni/CeO2 Nanostructures for Carbon Dioxide Reforming of Methane. J.Phys.Chem.C. 2012, 116, 10009–10016. [Google Scholar] [CrossRef]

- Xiao, Z.; Ji, S.; Li, Y.; Hou, F.; Zhang, H.; Zhang, X. Tuning oxygen vacancies on mesoporous ceria nanorods by metal doping: Controllable magnetic property. Appl. Surf. Sci. 2018, 455, 1037–1044. [Google Scholar] [CrossRef]

- Liang, W.; Coghlan, C.J.; Ragon, F.; Rubio-Martinez, M.; D’Alessandro, D.M.; Babarao, R. Defect engineering of UiO-66 for CO2 and H2O uptake—A combined experimental and simulation study. Dalt. Trans. 2016, 4496–4500. [Google Scholar] [CrossRef]

- Yang, F.; Huang, H.; Wang, X.; Li, F.; Gong, Y.; Zhong, C.; Li, J.R. Proton Conductivities in Functionalized UiO-66: Tuned Properties, Thermogravimetry Mass, and Molecular Simulation Analyses. Cryst. Growth Des. 2015, 15, 5827–5833. [Google Scholar] [CrossRef]

- Donnadio, A.; Narducci, R.; Casciola, M.; Marmottini, F.; D’Amato, R.; Jazestani, M.; Chiniforoshan, H.; Costantino, F. Mixed Membrane Matrices Based on Nafion/UiO-66/SO3H-UiO-66 Nano-MOFs: Revealing the Effect of Crystal Size, Sulfonation, and Filler Loading on the Mechanical and Conductivity Properties. ACS Appl. Mater. Interfaces 2017, 9, 42239–42246. [Google Scholar] [CrossRef] [PubMed]

- Lin, Z.; Cai, X.; Fu, Y.; Zhu, W.; Zhang, F. Cascade catalytic hydrogenation-cyclization of methyl levulinate to form γ-valerolactone over Ru nanoparticles supported on a sulfonic acid-functionalized UiO-66 catalyst. RSC Adv. 2017, 7, 44082–44088. [Google Scholar] [CrossRef]

- Kim, J.; Min, Y.H.; Lee, N.; Cho, E.; Kim, K.Y.; Jeong, G.; Moon, S.K.; Joo, M.; Kim, D.B.; Kim, J.; et al. In situ spectroscopic and computational studies on a MnO2-CuO catalyst for use in volatile organic compound decomposition. ACS Omega 2017, 2, 7424–7432. [Google Scholar] [CrossRef]

- Perrichon, V.; Laachir, A.; Bergeret, G.; Frety, R.; Tournayan, L. Reduction of Cerias with Different Textures by Hydrogen and their Reoxidation by Oxygen. J. Chem. Soc. Faraday Trans. 1994, 90, 773–781. [Google Scholar] [CrossRef]

- Santos, V.P.; Pereira, M.F.R. Catalytic oxidation of ethyl acetate over a cesium modified cryptomelane catalyst. Appl. Catal. B Environ. 2009, 88, 550–556. [Google Scholar] [CrossRef]

- Wagner, C.D.; Naumkin, A.V.; Kraut-Vass, A.; Allison, J.W.; Powell, C.J.; Rumble, J.R., Jr. NIST Standard Reference Database 20. NIST XPS Database Version 2003, 3, 251–252. [Google Scholar]

- Vepřek, S.; Cocke, D.L.; Kehl, S.; Oswald, H.R. Mechanism of the deactivation of Hopcalite catalysts studied by XPS, ISS, and other techniques. J. Catal. 1986, 100, 250–263. [Google Scholar] [CrossRef]

- Shearer, G.C.; Chavan, S.; Bordiga, S.; Svelle, S.; Olsbye, U.; Lillerud, K.P. Defect Engineering: Tuning the Porosity and Composition of the Metal—Organic Framework UiO-66 via Modulated Synthesis. Chem. Mater. 2016, 28, 3749–3761. [Google Scholar] [CrossRef]

- Ye, Z.; Giraudon, J.M.; Nuns, N.; Simon, P.; De Geyter, N.; Morent, R.; Lamonier, J.F. Influence of the preparation method on the activity of copper-manganese oxides for toluene total oxidation. Appl. Catal. B Environ. 2018, 223, 154–166. [Google Scholar] [CrossRef]

- Manuel, J.; Gilbank, A.L.; García, T.; Solsona, B.; Agouram, S.; Torrente-murciano, L. The prevalence of surface oxygen vacancies over the mobility of bulk oxygen in nanostructured ceria for the total toluene oxidation. Appl. Catal. B Environ. 2015, 174–175, 403–412. [Google Scholar]

- Zhao, X.; Li, X.; Zhu, T.; Tang, X. Adsorption behavior of chloroform, carbon disulfide, and acetone on coconut shell-derived carbon: Experimental investigation, simulation, and model study. Environ. Sci. Pollut. Res. 2018, 25, 31219–31229. [Google Scholar] [CrossRef] [PubMed]

- Ruthven, D.M. Principles of Adsorption and adsorption processes; John Wiley & Sons: Hoboken, NJ, USA, 1984; p. 464. [Google Scholar]

- Dey, S.; Dhal, G.C. Synthesis of Hopcalite catalysts by various methods for improved catalytic conversion of carbon monoxide. Mater. Sci. Energy Technol. 2020, 3, 377–389. [Google Scholar] [CrossRef]

- Feng, X.; Hajek, J.; Jena, H.S.; Wang, G.; Veerapandian, S.K.P.; Morent, R.; De Geyter, N.; Leyssens, K.; Ho, A.E.J.; Meynen, V.; et al. Engineering a Highly Defective Stable UiO-66 with Tunable Lewis-Brønsted Acidity: The Role of the Hemilabile Linker. J. Am. Chem. Soc. 2020, 142, 3174–3183. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Gan, L.; Si, R. Effect of Tungsten Oxide on Ceria Nanorods to Support Copper Species as CO Oxidation Catalysts. J. Rare Earths 2019. [Google Scholar] [CrossRef]

| Materials | SBET (m2 g−1) | Vp a (cm3 g−1) | H2 Consumption (mmol g−1) |

|---|---|---|---|

| Hopcalite | 229 | 0.45 | 11.1 |

| Ceria-NR | 91 | 0.63 | 0.65 |

| UiO-66-SO3H | 685 | 0.82 | 0.60 |

| Catalyst | T10(°C) | T50(°C) | T90(°C) |

|---|---|---|---|

| Hopcalite | 157 | 185 | 291 |

| Ceria-NR | 232 | 321 | - |

| UiO-66-SO3H | - | - | - |

| Toluene Initial Concentration (ppm) | Tol. ADS at RT (µmol g−1) | Tol. DES at RT (µmol g−1) | Tol. DES during TPR (µmol g−1) | CO2 Formed during TPR (µmol g−1) | CO2 Yield (%) |

|---|---|---|---|---|---|

| 50 | 472 | 0.0 | 0.6 | 3306 | 99.9 |

| 100 | 384 | 38 | 160 | 1300 | 48.4 |

| 200 | 392 | 74 | 115 | 1421 | 51.8 |

| 500 | 379 | 73 | 107 | 1392 | 52.5 |

| Materials and TP Atmosphere | Tol. ADS at RT (µmol g−1) | Tol. DES at RT (µmol g−1) | Tol. DES during TPR (µmol g−1) | CO2 Formed during TPR (µmol g−1) | CO2 Yield (%) |

|---|---|---|---|---|---|

| Hopcalite-He | 136 | 1.4 | 23.8 | 780 | 81.9 |

| Hopcalite-He:O2 | 108 | 1.8 | 6.8 | 698 | 92.3 |

| Ceria-He | 73 | 8.6 | 60.5 | 28.0 | 5.5 |

| Ceria-He:O2 | 51 | 2.6 | 34.8 | 53.8 | 15.1 |

| UiO-66-SO3H-He | 339 | 1.6 | 301 | 258 | 10.9 |

| UiO-66-SO3H-He:O2 | 315 | 2.3 | 267 | 315 | 14.3 |

| Materials | H2-TPR O Consumption (mmol g−1) | Oext/Oglo a | He-TPR (Toluene) O Consumption (mmol g−1) | Oext/Oglo a |

|---|---|---|---|---|

| Hopcalite | 11.1 | 0.47 | 2.00 | 0.08 |

| CeO2-NR | 0.65 | 0.056 | 0.07 | 0.006 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sonar, S.; Giraudon, J.-M.; Kaliya Perumal Veerapandian, S.; Bitar, R.; Leus, K.; Van Der Voort, P.; Lamonier, J.-F.; Morent, R.; De Geyter, N.; Löfberg, A. Abatement of Toluene Using a Sequential Adsorption-Catalytic Oxidation Process: Comparative Study of Potential Adsorbent/Catalytic Materials. Catalysts 2020, 10, 761. https://doi.org/10.3390/catal10070761

Sonar S, Giraudon J-M, Kaliya Perumal Veerapandian S, Bitar R, Leus K, Van Der Voort P, Lamonier J-F, Morent R, De Geyter N, Löfberg A. Abatement of Toluene Using a Sequential Adsorption-Catalytic Oxidation Process: Comparative Study of Potential Adsorbent/Catalytic Materials. Catalysts. 2020; 10(7):761. https://doi.org/10.3390/catal10070761

Chicago/Turabian StyleSonar, Shilpa, Jean-Marc Giraudon, Savita Kaliya Perumal Veerapandian, Rim Bitar, Karen Leus, Pascal Van Der Voort, Jean-François Lamonier, Rino Morent, Nathalie De Geyter, and Axel Löfberg. 2020. "Abatement of Toluene Using a Sequential Adsorption-Catalytic Oxidation Process: Comparative Study of Potential Adsorbent/Catalytic Materials" Catalysts 10, no. 7: 761. https://doi.org/10.3390/catal10070761

APA StyleSonar, S., Giraudon, J.-M., Kaliya Perumal Veerapandian, S., Bitar, R., Leus, K., Van Der Voort, P., Lamonier, J.-F., Morent, R., De Geyter, N., & Löfberg, A. (2020). Abatement of Toluene Using a Sequential Adsorption-Catalytic Oxidation Process: Comparative Study of Potential Adsorbent/Catalytic Materials. Catalysts, 10(7), 761. https://doi.org/10.3390/catal10070761