Electrochemical Response of Highly Porous Percolative CGO Electrospun Membranes

Abstract

1. Introduction

2. Results and Discussion

3. Experimental

3.1. Materials and Methods

3.2. Materials Characterization

3.3. Electrochemical Characterization

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Campbell, C.T.; Peden, C.H.F. Oxygen Vacancies and Catalysis on Ceria Surfaces. Science 2005, 309, 713–714. [Google Scholar] [CrossRef] [PubMed]

- Schmitt, R.; Nenning, A.; Kraynis, O.; Korobko, R.; Frenkel, A.I.; Lubomirsky, I.; Hailef, S.M.; Rupp, J.L.M. A review of defect structure and chemistry in ceria and its solid solutions. Chem. Soc. Rev. 2020, 49, 554–592. [Google Scholar] [CrossRef] [PubMed]

- Seal, S.; Jeyaranjan, A.; Neal, C.J.; Kumar, U.; Sakthivel, T.S.; Sayle, D.C. Engineered defects in cerium oxides: Tuning chemical reactivity for biomedical, environmental, & energy applications. Nanoscale 2020, 12, 6879–6899. [Google Scholar] [PubMed]

- Ma, Y.; Gao, W.; Zhang, Z.; Zhang, S.; Tian, Z.; Liu, Y.; Ho, J.C.; Qu, Y. Regulating the surface of nanoceria and its applications in heterogeneous catalysis. Surf. Sci. Rep. 2018, 73, 1–36. [Google Scholar] [CrossRef]

- Ni, D.W.; de Florio, D.Z.; Marani, D.; Kaiser, A.; Tinti, V.B.; Esposito, V. Effect of chemical redox on Gd-doped ceria mass diffusion. J Mater. Chem. A 2015, 3, 18835–18838. [Google Scholar] [CrossRef]

- Paier, J.; Penschke, C.; Sauer, J. Oxygen Defects and Surface Chemistry of Ceria: Quantum Chemical Studies Compared to Experiment. Chem. Rev. 2013, 113, 3949–3985. [Google Scholar] [CrossRef]

- Lee, J.G.; Park, J.H.; Shul, Y.G. Tailoring gadolinium-doped ceria-based solid oxide fuel cells to achieve 2 W cm−2 at 550 °C. Nat. Commun. 2014, 5, 4045. [Google Scholar] [CrossRef]

- Ahna, M.; Chob, J.; Lee, W. One-step fabrication of composite nanofibers for solid oxide fuel cell electrodes. J. Power Sources 2019, 434, 226749. [Google Scholar] [CrossRef]

- Schmidt, C.G.; Hansen, K.K.; Andersen, K.B.; Fu, Z.; Roosen, A.; Kaiser, A. Effect of pore formers on properties of tape cast porous sheets for electrochemical flue gas purification. J. Eur. Ceram. Soc 2016, 36, 645–653. [Google Scholar] [CrossRef]

- Kabir, A.; Santucci, S.; van Nong, N.; Varenik, M.; Lubomirsky, I.; Nigon, R.; Muralt, P.; Esposito, V. Effect of oxygen defects blocking barriers on gadolinium doped ceria (GDC) electro-chemo-mechanical properties. Acta Mater. 2019, 174, 53–60. [Google Scholar] [CrossRef]

- Santucci, S.; Zhang, H.; Sanna, S.; Pryds, N.; Esposito, V. Enhanced electro-mechanical coupling of TiN/Ce0.8Gd0.2O1.9 thin film electrostrictor. APL Mater. 2019, 7, 071104. [Google Scholar] [CrossRef]

- Rodriguez, J.A.; Grinter, D.C.; Liu, Z.; Palomino, R.M.; Senanayake, S.D. Ceria-based model catalysts: Fundamental studies on the importance of the metal–ceria interface in CO oxidation, the water–gas shift, CO2 hydrogenation, and methane and alcohol reforming. Chem. Soc. Rev. 2017, 46, 1824–1841. [Google Scholar] [CrossRef] [PubMed]

- Trovarelli, A. Catalytic Properties of Ceria and CeO2-Containing Materials. Catal Rev. Sci. Eng. 1996, 38, 439–520. [Google Scholar] [CrossRef]

- Wu, K.; Sun, L.-D.; Yan, C.-H. Recent Progress in Well-Controlled Synthesis of Ceria-Based Nanocatalysts towards Enhanced Catalytic Performance. Adv. Energy Mater. 2016, 6, 1600501. [Google Scholar] [CrossRef]

- Dankeaw, A.; Gualandris, F.; Silva, R.H.; Norrman, K.; Gudik-Sørensen, M.; Hansen, K.K.; Ksapabutr, B.; Esposito, V.; Marani, D. Amorphous saturated cerium–tungsten–titanium oxide nanofiber catalysts for NOx selective catalytic reaction. New J. Chem. 2018, 42, 9501–9509. [Google Scholar] [CrossRef]

- Dankeaw, A.; Gualandris, F.; Silva, R.H.; Scipioni, R.; Hansen, K.K.; Ksapabutr, B.; Esposito, V.; Marani, D. Highly porous Ce–W–TiO2 free-standing electrospun catalytic membranes for efficient de-NOx via ammonia selective catalytic reduction. Environ. Sci. Nano 2019, 6, 94–104. [Google Scholar] [CrossRef]

- Castano, C.E.; O’Keefe, M.J.; Fahrenholtz, W.G. Photo-assisted reduction in nanostructured cerium-based coatings. Scrip. Mater. 2013, 69, 489–492. [Google Scholar] [CrossRef]

- Corma, A.; Atienzar, P.; Garcia, H.; Chane-Ching, J.Y. Hierarchically mesostructured doped CeO2 with potential for solar-cell use. Nat. Mater. 2004, 3, 394–397. [Google Scholar] [CrossRef]

- Kargozar, S.; Baino, F.; Hoseini, S.J.; Hamzehlou, S.; Darroudi, M.; Verdi, J.; Hasanzadeh, L.; Kim, H.W.; Mozafari, M. Biomedical applications of nanoceria: New roles for an old player. Nanomedicine 2018, 13, 3051–3069. [Google Scholar] [CrossRef]

- Naganuma, T.; Traversa, E. The effect of cerium valence states at cerium oxide nanoparticle surfaces on cell proliferation. Biomaterials 2014, 35, 4441–4453. [Google Scholar] [CrossRef]

- Caputo, F.; Mameli, M.; Sienkiewicz, A.; Licoccia, S.; Stellacci, F.; Ghibelli, L.; Traversa, E. A novel synthetic approach of cerium oxide nanoparticles with improved biomedical activity. Sci. Rep. 2017, 7, 4636. [Google Scholar] [CrossRef]

- Suresh, R.; Ponnuswamy, V.; Mariappan, R. Nanostructured cerium oxide thin films by nebulised spray pyrolysis (NSP) technique: Impact of surfactants on the structural, optical and compositional properties. Ceram. Int. 2014, 40, 13515–13527. [Google Scholar]

- Vorokhta, M.; Matolínová, I.; Dubau, M.; Haviar, S.; Khalakhan, I.; Ševčíková, K.; Mori, T.; Yoshikawa, H.; Matolín, V. HAXPES study of CeOx thin film–silicon oxide interface. Appl. Surf. Sci. 2014, 303, 46–53. [Google Scholar] [CrossRef]

- Xie, S.L.; Wang, Z.L.; Cheng, F.L.; Zhang, P.; Mai, W.J.; Tong, Y.X. Ceria and ceria-based nanostructured materials for photoenergy applications. Nano Energy 2017, 34, 313–337. [Google Scholar] [CrossRef]

- Marani, D.; Silva, R.H.; Dankeaw, A.; Norrman, K.; Werchmeister, R.M.L.; Ippolito, D.; Gudik-Sørensen, M.; Hansen, K.K.; Esposito, V. NOx selective catalytic reduction (SCR) on self-supported V–W-doped TiO2 nanofibers. New J. Chem. 2017, 41, 3466–3472. [Google Scholar] [CrossRef]

- Marani, D.; Silva, R.H.; Dankeaw, A.; Gudik-Sørensen, M.; Norrman, K.; Hansen, K.K.; Esposito, V. Effect of the sol-gel conditions on the morphology and SCR performance of electrospun VW-TiO2 catalysts. J. Phys. Chem. Solids 2018, 118, 255–261. [Google Scholar] [CrossRef]

- Shahreen, L.; Chase, G.G.; Turinske, A.J.; Nelson, S.A.; Stojilovic, N. NO decomposition by CO over Pd catalyst supported on TiO2 nanofibers. Chem. Eng. J. 2013, 225, 340–349. [Google Scholar] [CrossRef]

- Kong, Y.; Sun, C.; Wu, X.; Sun, K.; Yin, X.; Zhang, N. One-Dimensional CuCo2O4−Er0.4Bi1.6O3 Composite Fiber as Cathode of Intermediate Temperature Solid Oxide Fuel Cells. ACS Sustain. Chem. Eng. 2020, 8, 3950–3958. [Google Scholar] [CrossRef]

- Marani, D.; Hjelm, J.; Wandel, M. Rheological analysis of stabilised cerium-gadolinium oxide (CGO) dispersons. J. Eur. Ceram. Soc. 2014, 34, 695–702. [Google Scholar] [CrossRef]

- Marani, D.; Gadea, C.; Hjelm, J.; Hjalmarsson, P.; Wandel, M.; Kiebach, R. Influence of hydroxyl groups of binders on rheological properties of cerium-gadolinium oxide (CGO) screen printing inks. J. Eur. Ceram. Soc. 2015, 35, 1495–1504. [Google Scholar] [CrossRef]

- Teocoli, F.; Marani, D.; Kiebach, R.; Esposito, V. Effect of spherical porosity on co-fired dense/porous zirconia bi-layers cambering. J. Eur. Ceram. Soc. 2018, 38, 173–179. [Google Scholar] [CrossRef]

- Thenmozhi, S.; Dharmaraj, N.; Kadirvelu, K.; Kim, H.Y. Electrospun nanofibers: New generation of materials for advanced applications. Mater. Sci. Eng. B 2017, 217, 39–48. [Google Scholar] [CrossRef]

- Sahay, R.; Kumar, P.S.; Sridhar, R.; Sundaramurthy, J.; Venugopal, J.; Mhaisalkar, S.G.; Ramakrishn, S. Electrospun composite nanofibers and their multifaceted applications. J. Mater. Chem. 2012, 22, 12953–12971. [Google Scholar] [CrossRef]

- Xue, J.; Xie, J.; Liu, W.; Xia, Y. Electrospun Nanofibers: New Concepts, Materials, and Applications. Acc. Chem. Res. 2017, 50, 1976–1987. [Google Scholar] [CrossRef] [PubMed]

- Agarwal, S.; Greiner, A.; Wendorff, J.H. Functional materials by electrospinning of polymers. Prog. Polym. Sci. 2013, 38, 963–991. [Google Scholar] [CrossRef]

- Jung, J.-W.; Lee, C.-L.; Yu, S.; Kim, I.-D. Electrospun nanofibers as a platform for advanced secondary batteries: A comprehensive review. J. Mater. Chem. A 2016, 4, 703–750. [Google Scholar] [CrossRef]

- Ahn, M.; Han, S.; Lee, J.; Lee, W. Electrospun composite nanofibers for intermediate-temperature solid oxide fuel cell electrodes. Ceram. Int. 2020, 46, 6006–6011. [Google Scholar] [CrossRef]

- Zhi, M.; Mariani, N.; Gemmen, R.; Gerdes, K.; Wu, N. Nanofiber scaffold for cathode of solid oxide fuel cell. Energy Environ. Sci. 2011, 4, 417–420. [Google Scholar] [CrossRef]

- Lee, J.G.; Lee, C.M.; Park, M.G.; Jung, S.-J.; Shul, Y.G. Performance evaluation of anode-supported Gd0.1Ce0.9O1.95 cell with electrospun La0.6Sr0.4Co0.2Fe0.8O3−ı-Gd0.1Ce0.9O1.95 cathode. Electrochim. Acta 2013, 108, 356–360. [Google Scholar] [CrossRef]

- Lee, J.G.; Lee, C.M.; Park, M.; Shul, Y.G. Direct methane fuel cell with La2Sn2O7–Ni– Gd0.1Ce0.9O1.95 anode and electrospun La0.6Sr0.4Co0.2Fe0.8O3-δ–Gd0.1Ce0.9O1.95 cathode. RSC Adv. 2013, 3, 11816–11822. [Google Scholar] [CrossRef]

- Zhou, H.; Ding, X.; Yin, Z.; Xu, G.; Xue, Q.; Li, J.; Jiao, S.; Wang, X. Fabrication and electrochemical characteristics of electrospun LiMn2O4 nanofiber cathode for Li-ion batteries. Mater. Lett. 2014, 117, 175–178. [Google Scholar] [CrossRef]

- Wang, Y.; Li, W.; Xia, Y.; Jiao, X.; Chen, D. Electrospun flexible self-supporting γ-alumina fibrous membranes and their potential as high efficiency fine particulate filtration media. J. Mater. Chem. A 2014, 2, 15124–15131. [Google Scholar] [CrossRef]

- Wen, Q.; Di, J.; Zhao, Y.; Wang, Y.; Jiang, L.; Yu, J. Flexible inorganic nanofibrous membranes with hierarchical porosity for efficient water purification. Chem. Sci. 2013, 4, 4378–4382. [Google Scholar] [CrossRef]

- Mao, X.; Si, Y.; Chen, Y.; Yang, L.; Zhao, F.; Ding, B.; Yu, J. Silica nanofibrous membranes with robust flexibility and thermal stability for high-efficiency fine particulate filtration. RSC Adv. 2012, 2, 12216–12223. [Google Scholar] [CrossRef]

- Li, W.; Wang, Y.; Ji, B.; Jiao, X.; Chen, D. Flexible Pd/CeO2–TiO2 nanofibrous membrane with high efficiency ultrafine particulate filtration and improved CO catalytic oxidation performance. RSC Adv. 2014, 5, 58120–58127. [Google Scholar] [CrossRef]

- Chen, Y.; Bu, Y.; Zhao, B.; Zhang, Y.; Ding, D.; Hua, R.; Wei, T.; Rainwater, B.; Ding, Y.; Chen, F.; et al. High-Performance Hollow-Nanofiber Cathode for Intermediate Temperature Fuel Cells. Nano Energy 2016, 26, 90–99. [Google Scholar] [CrossRef]

- Zhi, M.; Lee, S.; Miller, N.; Menzler, N.H.; Wu, N. An intermediate-temperature solid oxide fuel cell with electrospun nanofiber cathode. Energy Environ. Sci. 2012, 5, 7066–7071. [Google Scholar] [CrossRef]

- Park, S.-J.; Chase, G.G.; Jeong, K.-U.; Kim, H.Y. Mechanical properties of titania nanofiber mats fabricated by electrospinning of sol–gel precursor. J. Sol. Gel. Sci. Technol. 2010, 54, 188–194. [Google Scholar] [CrossRef]

- Kumar, A.; Jose, R.; Fujihara, K.; Wang, J.; Ramakrishna, S. Structural and Optical Properties of Electrospun TiO2 Nanofibers. Chem. Mater. 2007, 19, 6536–6542. [Google Scholar] [CrossRef]

- Zhang, M.F.; Li, T.J.; Zhao, X.H.; Zhou, H.J. Enhanced ionic conductivity in ce0.8gd0.2o2-δ nanofiber: Effect of the crystallite size. Solid State Phenom 2017, 281, 761–766. [Google Scholar] [CrossRef]

- Ou, G.; Liu, W.; Yao, L.; Wu, H.; Pan, W. High conductivity of La2Zr2O7 nanofibers by phase control. J. Mater. Chem. A 2014, 2, 1855–1861. [Google Scholar] [CrossRef]

- Yao, L.; Liu, W.; Ou, G.; Nishijima, H.; Pan, W. Phase stability and high conductivity of ScSZ nanofibers: Effect of the crystallite size. J. Mater. Chem. A 2015, 3, 10795–10800. [Google Scholar] [CrossRef]

- Thompson, C.J.; Chase, G.G.; Yarin, A.L.; Reniker, D.H. Effects of parameters on nanofiber diameters determined from electrospinning model. Polymer 2007, 48, 6913–6922. [Google Scholar] [CrossRef]

- Gazquez, G.C.; Smulders, V.; Veldhuis, S.A.; Wieringa, P.; Moroni, L.; Boukamp, B.A.; Elshof, J.E.t. Influence of Solution Properties and Process Parameters on the Formation and Morphology of YSZ and NiO Ceramic Nanofibers by Electrospinning. Nanomaterials 2017, 7, 16. [Google Scholar] [CrossRef] [PubMed]

- Artini, C.; Pani, M.; Lausi, A.; Masini, R.; Costa, G.A. High Temperature Structural Study of Gd-Doped Ceria by Synchrotron X-ray Diffraction (673 K ≤ T ≤ 1073 K). Inorg. Chem. 2014, 53, 10140–10149. [Google Scholar] [CrossRef]

- Tomadakis, M.M.; Robertson, T.J. Viscous Permeability of Random Fiber Structures: Comparison of Electrical and Diffusional Estimates with Experimental and Analytical Results. J. Compos. Mater. 2005, 39, 163. [Google Scholar] [CrossRef]

- Esposito, V.; Traversa, E. Design of Electroceramics for Solid Oxides Fuel Cell Applications: Playing with Ceria. J. Am. Ceram. Soc. 2008, 91, 1037–1051. [Google Scholar] [CrossRef]

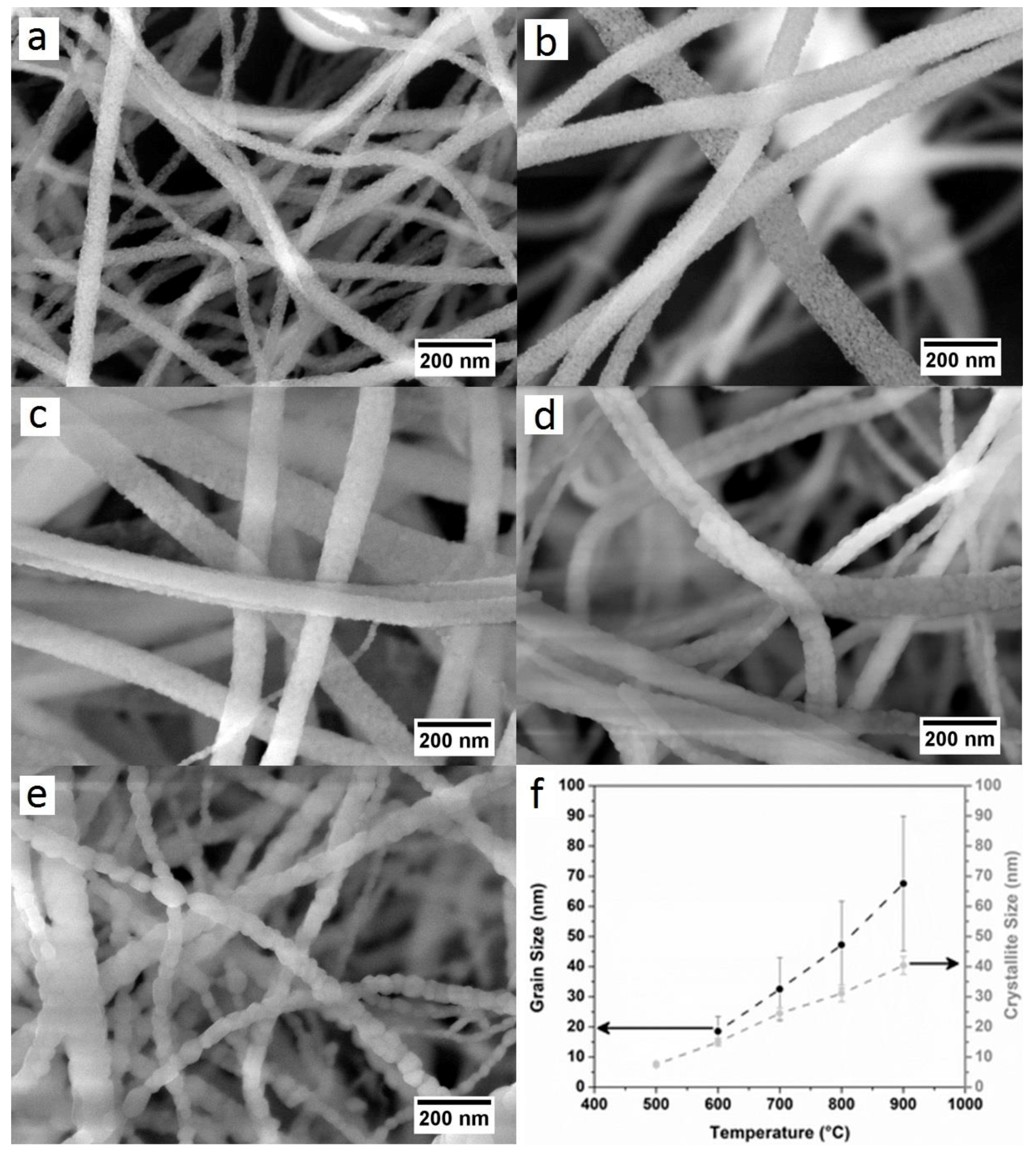

| Sample | Crystallite Sizes (nm) (XRD) | Grain Sizes (nm) (SEM) | Nanofibers Diameters (nm) (SEM) | Membrane Porosity (%) (SEM) |

|---|---|---|---|---|

| CGO500 | 7.57 ± 0.82 | - | 42.71 ± 11.49 | 86.60 ± 1.38 |

| CGO600 | 14.96 ± 1.26 | 18.56 ± 4.90 | 76.50 ± 14.61 | 88.10 ± 1.38 |

| CGO700 | 24.49 ± 1.92 | 32.53 ± 10.48 | 97.25 ± 31.06 | 87.30 ± 1.38 |

| CG0800 | 31.08 ± 2.71 | 47.21 ± 14.46 | 65.84 ± 19.16 | 84.40 ± 1.38 |

| CGO900 | 40.40 ± 2.98 | 67.57 ± 22.32 | 60.45 ± 15.56 | 86.60 ± 1.38 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hubert Silva, R.; Esposito, V.; Dankeaw, A.; Bergmann, C.P.; Marani, D. Electrochemical Response of Highly Porous Percolative CGO Electrospun Membranes. Catalysts 2020, 10, 756. https://doi.org/10.3390/catal10070756

Hubert Silva R, Esposito V, Dankeaw A, Bergmann CP, Marani D. Electrochemical Response of Highly Porous Percolative CGO Electrospun Membranes. Catalysts. 2020; 10(7):756. https://doi.org/10.3390/catal10070756

Chicago/Turabian StyleHubert Silva, Rafael, Vincenzo Esposito, Apiwat Dankeaw, Carlos Pérez Bergmann, and Debora Marani. 2020. "Electrochemical Response of Highly Porous Percolative CGO Electrospun Membranes" Catalysts 10, no. 7: 756. https://doi.org/10.3390/catal10070756

APA StyleHubert Silva, R., Esposito, V., Dankeaw, A., Bergmann, C. P., & Marani, D. (2020). Electrochemical Response of Highly Porous Percolative CGO Electrospun Membranes. Catalysts, 10(7), 756. https://doi.org/10.3390/catal10070756