Hardware–Software System for Biomass Slow Pyrolysis: Characterization of Solid Yield via Optimization Algorithms

Abstract

1. Introduction

2. Materials and Methods

2.1. Use of Biomass for Sustainability

Property Characterization

2.2. Theoretical Background

2.2.1. Smith Predictive Control

2.2.2. Two-Step Kinetic Model

2.2.3. Particle Swarm Optimization (PSO) Algorithm

- Evaluation of the objective function: Each particle’s position corresponds to a candidate set of kinetic parameters of the two-step model, and the quality of the solution is evaluated by employing the Objective Function (OF), Equation (13), between the experimental data and model predictions . It ensures that the OF reflects the average discrepancy between experimental and simulated values, regardless of the dataset size.

- Update of personal and global bests: After the evaluation, each particle updates its personal best position , and the swarm updates the global best position if the current solution yields better performance.

- Velocity update: The velocity of each particle is updated according towhere ω is the inertia weight, c1 and c2 are acceleration coefficients (cognitive and social, respectively), and r1, r2 are random numbers in the range [0, 1].

- Position update: Once the velocity is updated, the new position of the particle is calculated as follows:

- Stopping criterion: The algorithm ends when a stopping condition is met, i.e., a maximum number of iterations Tmax, or when the OF drops below a predefined threshold ε:

2.2.4. Genetic Algorithm (GA)

- Initialization: The initial population of N individuals is defined asEach individual, denoted as xi(0), is a candidate solution encoded as a real-valued vector (Arrhenius kinetic parameters). It is worth noting that these vectors are initialized randomly within specified bounds for each parameter, the search space is defined in a range from −20 to 0 dB regardless of the selected biomass.

- Fitness evaluation: Later, each individual is evaluated using a fitness function designed to quantify the degree of agreement between the model and experimental data. In kinetic parameter estimation, OF(T) Equation (13) is used for this task.

- Selection: Following fitness evaluation, individuals are selected to form a mating pool. The probability of selection is typically biased toward individuals with superior fitness. One common method is roulette wheel selection, where the selection probability of the i-th individual is calculated aswhen solving minimization problems, a scaling or transformation of the fitness function is applied to ensure proper selection dynamics.

- Crossover: Selected individuals are paired and recombined to produce new offspring. For real-coded chromosomes, arithmetic crossover can be utilized:where α ∈ [0, 1] is a crossover coefficient randomly selected for each pair.

- Mutation: In order to introduce variability and prevent premature convergence, mutation is applied by perturbing individual genes as follows:where xi,k is the k-th gene of chromosome xi, and δ is a small random noise sampled from a predefined distribution (e.g., Gaussian).

- Replacement and termination: The new generation, composed of the offspring, replaces the current population. This iterative cycle is repeated until a termination condition is satisfied, such as reaching a maximum number of generations Gmax or achieving a minimum fitness threshold ε:The best-performing individual at the final generation is considered the optimal solution.

2.2.5. Nelder–Mead Algorithm (N-M)

- Simplex initialization and ordering: An initial simplex S = {x1 + x2 + … + xm+1} is formed using n + 1 points in the parameter space, and the objective function f(xi) is evaluated at each vertex. The points are then sorted such thatwhere x1 denotes the best solution and xn+1 the worst within the current simplex.

- Centroid and transformation: The centroid xc of all points except the worst one is computed asUsing xc, the algorithm attempts reflection, and if necessary, expansion or contraction, which are estimated as follows:Reflection: a reflection point xr is generated by reflecting the worst point through the centroid:Expansion: it is applied if xr is better than the best as follows:Contraction: it is employed if xr is worse as follows:It is worth noting that the parameter values α = 1, γ = 2, and β = 0.5 are commonly used, as they have been shown to yield suitable results in optimization problems [61].

- Shrinkage: If no transformation improves the simplex, it is contracted around the best point:with δ = 0.5.

- Convergence check: The iteration continues until the spread of function values or vertex distances falls below a threshold ε:

3. Methodology

3.1. Hardware System

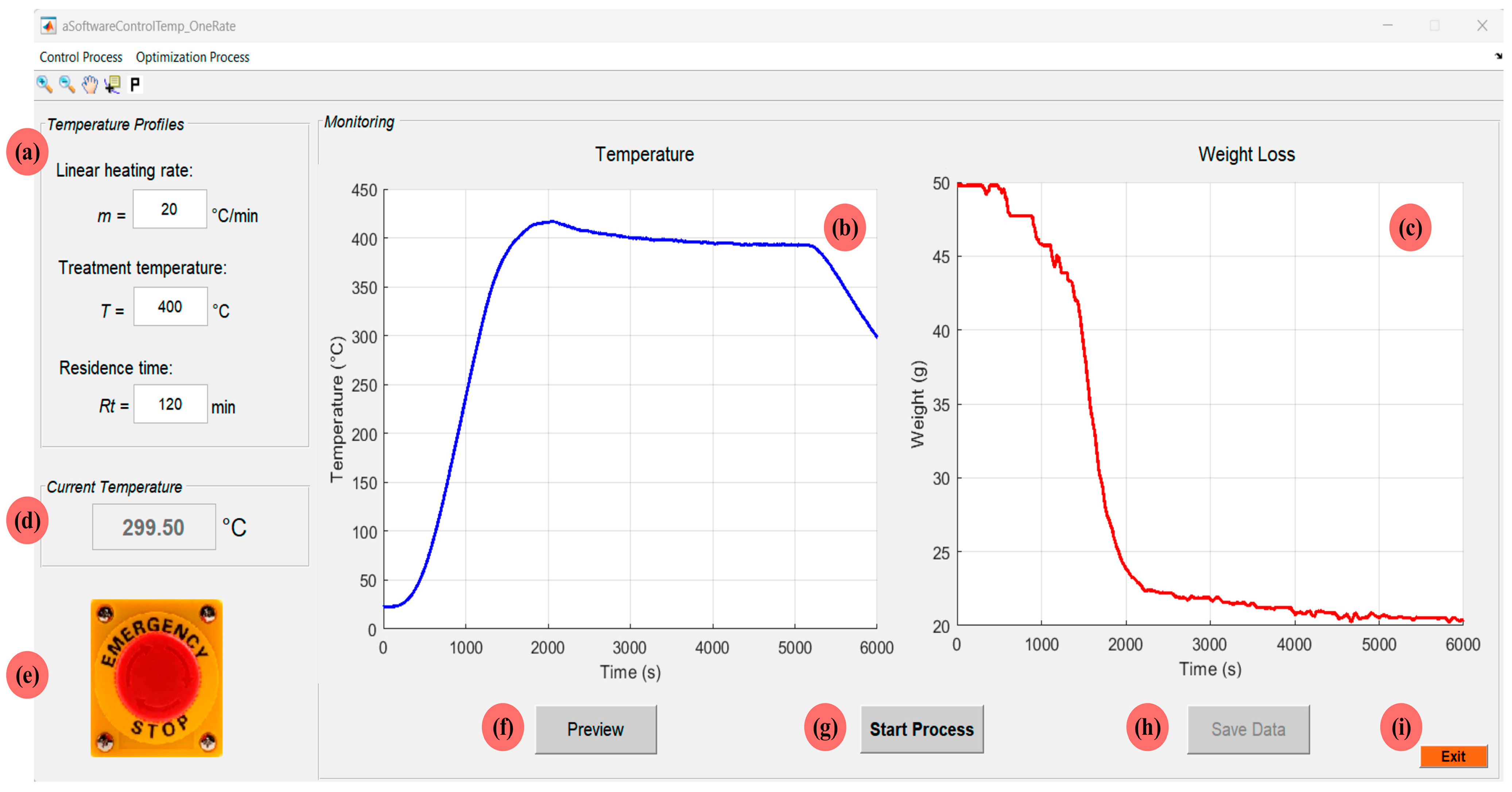

3.2. Software System

4. Experimentation and Results

4.1. Experimental Setup and Test Design

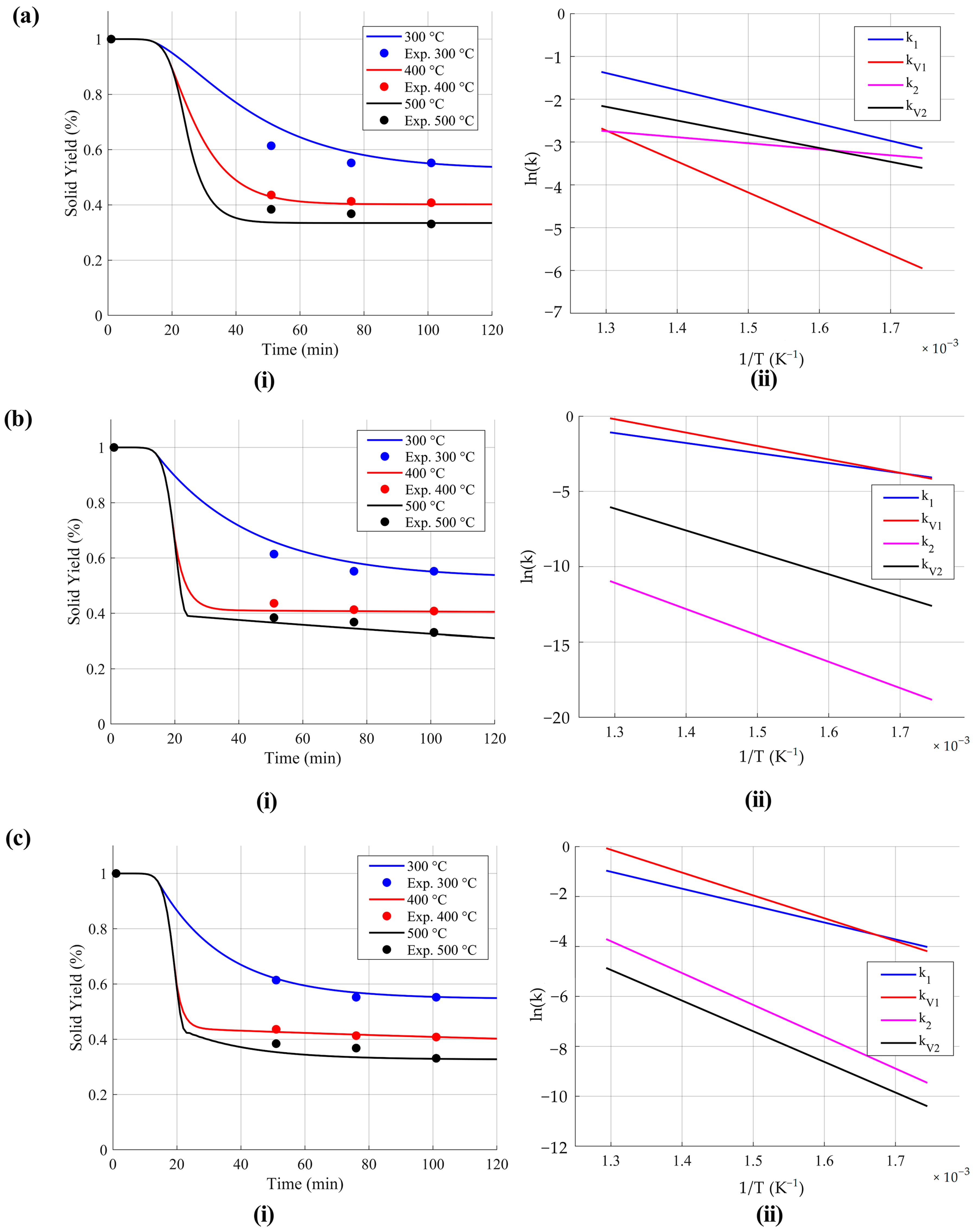

4.2. Analysis of Biomass Data from the Optimization Process

4.2.1. Wheat Straw (WS)

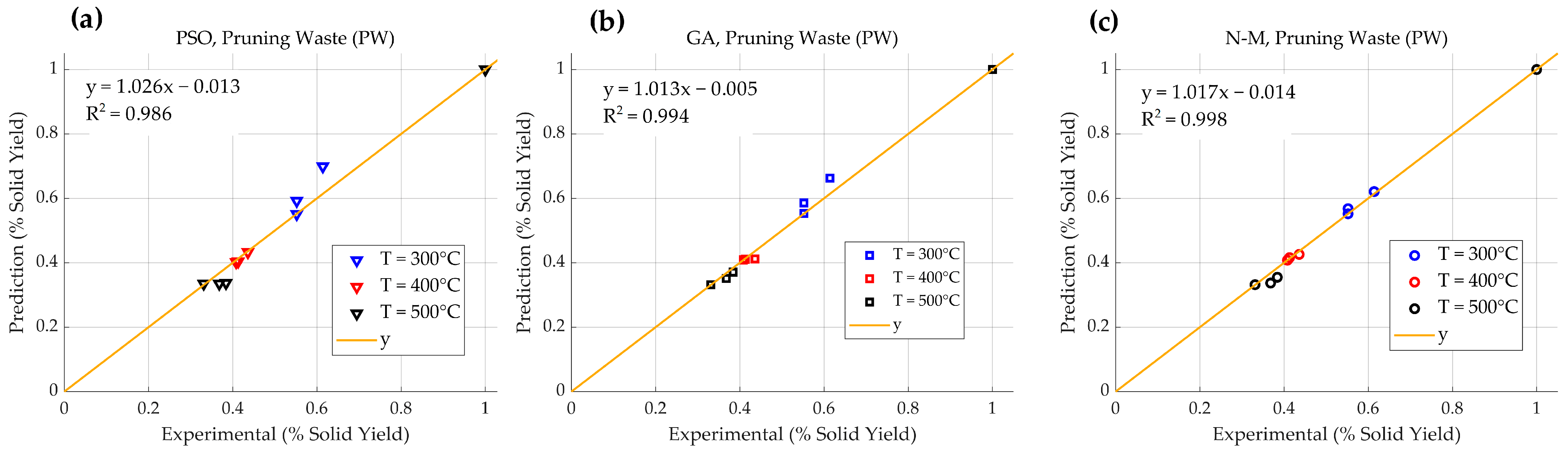

4.2.2. Pruning Waste (PW)

4.2.3. Biosolids (BS)

4.3. Quantitative Comparison of Biochar Yield

5. Discussion

- (a)

- Integration of Real-Time Product Characterization: Future system iterations could incorporate online analytical techniques (e.g., FTIR, GC-MS) for simultaneous monitoring of bio-oil and syngas composition, enabling comprehensive mass balance closure and product valorization assessment.

- (b)

- Machine Learning Enhancement: Expanding beyond traditional optimization algorithms to incorporate machine learning approaches (e.g., neural networks, random forests) could improve prediction accuracy across diverse biomass types and mixed feedstocks.

- (c)

- Economic and Environmental Impact Assessment: Subsequent research should integrate techno-economic analysis (TEA) and life cycle assessment (LCA) to evaluate the economic viability and environmental benefits of implementing the optimized parameters identified by the system.

- (d)

- Expansion to Co-Pyrolysis and Catalytic Pyrolysis: The platform’s adaptability provides opportunities to explore synergistic effects in co-pyrolysis of biomass-plastic mixtures and catalytic pyrolysis for enhanced bio-oil quality.

5.1. Unique Value of Integrated Hardware–Software Platform for Slow Biomass Pyrolysis Research

- Automated optimization for biomass: Determines optimal kinetic parameters (A, Ea) under operating conditions (m, T, Rt) to maximize yield and quality of biochar in biomass (WS, PW, BS), using computational intelligence algorithms (PSO, GA) and optimization (N-M) that explore multimodal search spaces.

- Advanced validation of kinetic models: Evaluates the behavior of complex kinetic models (e.g., two-step) under customized conditions and unconventional or region-specific biomasses, through full integration between hardware (data generation) and software (real-time adjustment).

- Rational selection of algorithms: Establishes practical guidelines for choosing the optimal algorithm (PSO, GA, N-M) according to the type of biomass, balancing accuracy, speed, and computational cost.

- Accessibility and generalization of advanced research: The platform promotes cutting-edge pyrolysis research for institutions with limited budgets by offering an accessible solution specialized in the study of local biomass, overcoming the limitations of traditional commercial systems.

5.2. Selection of Optimization Algorithms for Slow Pyrolysis Kinetics

- Selection according to biomass type:

- For homogeneous lignocellulosic biomass (e.g., wheat straw—WS, pruning waste—PW): The N-M algorithm is recommended, as it achieved good accuracy (R2 = 0.996 and 0.998), making it the optimal choice for these systems with convex search spaces.

- For complex and heterogeneous biomass (e.g., biosolids—BS), PSO and N-M show a similar fit. However, the kinetic parameters obtained with N-M exhibit greater physical consistency with actual thermal decomposition mechanisms, offering not only optimization but also a relevant thermochemical interpretation.

- Selection based on objective (Accuracy vs. Speed):

- For maximum accuracy (especially in complex biomasses): PSO is the preferred option, despite its higher computational cost.

- For maximum speed and efficiency (in homogeneous biomasses): N-M offers the best performance, providing exceptional accuracy with minimal resource consumption.

- For a balance between accuracy and speed: GA is a robust option, although in this work, it was consistently outperformed by PSO or N-M in one of the two aspects.

- Selection based on computational resources:

- For limited resources: N-M is the most efficient alternative.

- For sufficient resources: PSO justifies its computational investment in complex systems.

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Misbahuddin, M.; Cokrowati, N.; Iqbal, M.S.; Farobie, O.; Amrullah, A.; Ernawati, L. Kalman Filter-Enhanced Data Aggregation in LoRaWAN-Based IoT Framework for Aquaculture Monitoring in Sargassum sp. Cultivation. Computers 2025, 14, 151. [Google Scholar] [CrossRef]

- Vance, J.; Rasheed, K.; Missaoui, A.; Maier, F.W. Data Synthesis for Alfalfa Biomass Yield Estimation. AI 2022, 4, 1–15. [Google Scholar] [CrossRef]

- Whitmire, C.D.; Vance, J.M.; Rasheed, H.K.; Missaoui, A.; Rasheed, K.M.; Maier, F.W. Using machine learning and feature selection for alfalfa yield prediction. AI 2021, 2, 71–88. [Google Scholar] [CrossRef]

- Rathnayake, N.; Patel, S.; Hakeem, I.G.; Veluswamy, G.; Al-Waili, I.; Agnihotri, S.; Shah, K. The pyrolysis of biosolids in a novel closed coupled pyrolysis and gasification technology: Pilot plant trials, Aspen plus modelling, and a techno-economic analysis. Water 2024, 16, 3399. [Google Scholar] [CrossRef]

- Navarrete, C.G.; Galione, K.P.; Curto, R.P. Two-Stage Global Biomass Pyrolysis Model for Combustion Applications: Predicting Product Composition with a Focus on Kinetics, Energy, and Mass Balances Consistency. Energies 2024, 17, 4982. [Google Scholar] [CrossRef]

- Lau, H.C.; Tsai, S.C. Net zero by 2050: A tale of three economies. Energy Fuels 2024, 38, 21079–21094. [Google Scholar] [CrossRef]

- Li, C.; Hayashi, J.I.; Sun, Y.; Zhang, L.; Zhang, S.; Wang, S.; Hu, X. Impact of heating rates on the evolution of function groups of the biochar from lignin pyrolysis. J. Anal. Appl. Pyrolysis 2021, 155, 105031. [Google Scholar] [CrossRef]

- Silveira, E.A.; Luz, S.; Candelier, K.; Macedo, L.A.; Rousset, P. An assessment of biomass torrefaction severity indexes. Fuel 2021, 288, 119631. [Google Scholar] [CrossRef]

- Thengane, S.K.; Kung, K.S.; Gomez, B.A.; Ghoniem, A.F. Advances in biomass torrefaction: Parameters, models, reactors, applications, deployment, and market. Prog. Energy Combust. Sci. 2022, 93, 101040. [Google Scholar] [CrossRef]

- Ayaz, M.; Feizienė, D.; Tilvikienė, V.; Akhtar, K.; Stulpinaitė, U.; Iqbal, R. Biochar role in the sustainability of agriculture and environment. Sustainability 2021, 13, 1330. [Google Scholar] [CrossRef]

- Muravyev, N.V.; Vyazovkin, S. The status of pyrolysis kinetics studies by thermal analysis: Quality is not as good as it should and can readily be. Thermo 2022, 2, 435–452. [Google Scholar] [CrossRef]

- Santos, D.C.; Evaristo, R.B.; Dutra, R.C.; Suarez, P.A.; Silveira, E.A.; Ghesti, G.F. Advancing biochar applications: A review of production processes, analytical methods, decision criteria, and pathways for scalability and certification. Sustainability 2025, 17, 2685. [Google Scholar] [CrossRef]

- Khairy, M.; Amer, M.; Ibrahim, M.; Ookawara, S.; Sekiguchi, H.; Elwardany, A. The influence of torrefaction on the biochar characteristics produced from sesame stalks and bean husk. Biomass Convers. Biorefinery 2024, 14, 17127–17148. [Google Scholar] [CrossRef]

- Talwar, P.; Agudelo, M.A.; Nanda, S. Pyrolysis Process, Reactors, Products, and Applications: A Review. Energies 2025, 18, 2979. [Google Scholar] [CrossRef]

- Babu, K.K.B.S.; Nataraj, M.; Tayappa, M.; Vyas, Y.; Mishra, R.K.; Acharya, B. Production of biochar from waste biomass using slow pyrolysis: Studies of the effect of pyrolysis temperature and holding time on biochar yield and properties. Mater. Sci. Energy Technol. 2024, 7, 318–334. [Google Scholar] [CrossRef]

- Adelawon, B.O.; Latinwo, G.K.; Eboibi, B.E.; Agbede, O.O.; Agarry, S.E. Comparison of the slow, fast, and flash pyrolysis of recycled maize-cob biomass waste, box-benhken process optimization and characterization studies for the thermal fast pyrolysis production of bio-energy. Chem. Eng. Commun. 2022, 209, 1246–1276. [Google Scholar] [CrossRef]

- Abdullah, N.; Taib, R.M.; Aziz, N.S.M.; Omar, M.R.; Disa, N.M. Banana pseudo-stem biochar derived from slow and fast pyrolysis process. Heliyon 2023, 9, e12940. [Google Scholar] [CrossRef] [PubMed]

- Wang, P.; Wang, S.; Chen, F.; Zhang, T.; Kong, W. Preparation of two types plant biochars and application in soil quality improvement. Sci. Total Environ. 2024, 906, 167334. [Google Scholar] [CrossRef]

- Zhang, K.; Khan, Z.; Khan, M.N.; Luo, T.; Luo, L.; Bi, J.; Hu, L. The application of biochar improves the nutrient supply efficiency of organic fertilizer, sustains soil quality and promotes sustainable crop production. Food Energy Secur. 2024, 13, e520. [Google Scholar] [CrossRef]

- Wang, S.; Dai, G.; Yang, H.; Luo, Z. Lignocellulosic biomass pyrolysis mechanism: A state-of-the-art review. Prog. Energy Combust. Sci. 2017, 62, 33–86. [Google Scholar] [CrossRef]

- Deng, L.; Ngo, H.H.; Guo, W.; Chang, S.W.; Nguyen, D.D.; Pandey, A.; Hoang, N.B. Recent advances in circular bioeconomy based clean technologies for sustainable environment. J. Water Process Eng. 2022, 46, 102534. [Google Scholar] [CrossRef]

- Skrzyniarz, M.; Sajdak, M.; Biniek-Poskart, A.; Skibiński, A.; Krakowiak, M.; Piotrowski, A.; Zajemska, M. Methods and validation techniques of chemical kinetics models in waste thermal conversion processes. Energies 2024, 17, 3067. [Google Scholar] [CrossRef]

- Piazza, V.; da Silva Junior, R.B.; Frassoldati, A.; Lietti, L.; Chiaberge, S.; Gambaro, C.; Beretta, A. Detailed speciation of biomass pyrolysis products with a novel TGA-based methodology: The case-study of cellulose. J. Anal. Appl. Pyrolysis 2024, 178, 106413. [Google Scholar] [CrossRef]

- Suratman, A.; Astuti, D.N.; Kusumastuti, P.P.; Sudiono, S.; Wijaya, H.W.; Wibowo, A.H. Comprehensive study of thermochemical conversion of biomass okara into biochar. J. Anal. Appl. Pyrolysis 2024, 181, 106594. [Google Scholar] [CrossRef]

- El-Sayed, S.A.; Khass, T.M.; Mostafa, M.E. Thermal degradation behaviour and chemical kinetic characteristics of biomass pyrolysis using TG/DTG/DTA techniques. Biomass Convers. Biorefinery 2024, 14, 17779–17803. [Google Scholar] [CrossRef]

- Volli, V.; Gollakota, A.R.K.; Shu, C.M. Comparative studies on thermochemical behavior and kinetics of lignocellulosic biomass residues using TG-FTIR and Py-GC/MS. Sci. Total Environ. 2021, 792, 148392. [Google Scholar] [CrossRef] [PubMed]

- Călin, C.; Sîrbu, E.E.; Tănase, M.; Győrgy, R.; Popovici, D.R.; Banu, I. A thermogravimetric analysis of biomass conversion to biochar: Experimental and kinetic modeling. Appl. Sci. 2024, 14, 9856. [Google Scholar] [CrossRef]

- Fischer, O.; Lemaire, R.; Bensakhria, A. Thermogravimetric analysis and kinetic modeling of the pyrolysis of different biomass types by means of model-fitting, model-free and network modeling approaches. J. Therm. Anal. Calorim. 2024, 149, 10941–10963. [Google Scholar] [CrossRef]

- Liu, J.; Guo, X. ReaxFF molecular dynamics simulation of pyrolysis and combustion of pyridine. Fuel Process. Technol. 2017, 161, 107–115. [Google Scholar] [CrossRef]

- Di Blasi, C.; Lanzetta, M. Intrinsic kinetics of isothermal xylan degradation in inert atmosphere. J. Anal. Appl. Pyrolysis 1997, 40, 287–303. [Google Scholar] [CrossRef]

- Wibowo, W.A.; Waluyo, J.; Cahyono, R.B.; Rochmadi, R.; Budiman, A. Modified Koufopanos’ Mechanism in the Kinetics of In-Situ Catalytic Pyrolysis of Co-Pelletized Rice Husks and Ash. Period. Polytech. Chem. Eng. 2024, 68, 491–506. [Google Scholar] [CrossRef]

- Horsfall, I.T.; Ndukwu, M.C.; Abam, F.I.; Olatunji, O.M.; Ojong, O.E.; Osa-Aria, K. Validation of MATLAB algorithm to implement a two-step parallel pyrolysis model for the prediction of maximum% char yield. Discov. Chem. Eng. 2021, 1, 3. [Google Scholar] [CrossRef]

- Silveira, E.A.; Lamas, G.C.; Rodrigues, P.P.D.O.; Souto, N.P.; Chaves, B.S.A.; Galvao, L.G.O.; de Paula Protásio, T. Effect of torrefaction severity on the energy recovery from amazonian wood residues for decentralized energy conversion systems. Biomass Bioenergy 2025, 193, 107515. [Google Scholar] [CrossRef]

- Barbosa, T.; Chaves, B.S.A.; Galvão, L.G.O.; Lamas, G.C.; de Oliveira, R.P.P.; Moreira, M.G.; Silveira, E.A. Waste-to-energy in the civil-construction sector toward the valuation of wood construction residues: Integration of torrefaction process. Fuel 2024, 371, 132029. [Google Scholar] [CrossRef]

- Rodríguez, D.A.; Nam, H.; Granados, D.; Wang, S.; Hwang, S.C.; Nam, H.; Capareda, S.C. Experimental and numerical investigation on a solar-driven torrefaction reactor using woody waste (Ashe Juniper). Energy Convers. Manag. 2023, 288, 117114. [Google Scholar] [CrossRef]

- Silveira, E.A.; Luz, S.M.; Leão, R.M.; Rousset, P.; Caldeira, A. Numerical modeling and experimental assessment of sustainable woody biomass torrefaction via coupled TG-FTIR. Biomass Bioenergy 2021, 146, 105981. [Google Scholar] [CrossRef]

- Lin, B.J.; Silveira, E.A.; Colin, B.; Chen, W.H.; Lin, Y.Y.; Leconte, F.; Petrissans, M. Modeling and prediction of devolatilization and elemental composition of wood during mild pyrolysis in a pilot-scale reactor. Ind. Crops Prod. 2019, 131, 357–370. [Google Scholar] [CrossRef]

- Silveira, E.A.; Lin, B.J.; Colin, B.; Chaouch, M.; Pétrissans, A.; Rousset, P.; Pétrissans, M. Heat treatment kinetics using three-stage approach for sustainable wood material production. Ind. Crops Prod. 2018, 124, 563–571. [Google Scholar] [CrossRef]

- Shang, L.; Ahrenfeldt, J.; Holm, J.K.; Barsberg, S.; Zhang, R.Z.; Luo, Y.H.; Henriksen, U.B. Intrinsic kinetics and devolatilization of wheat straw during torrefaction. J. Anal. Appl. Pyrolysis 2013, 100, 145–152. [Google Scholar] [CrossRef]

- Urbina, I.; Granados, D.; Valtierra, M.; Ramírez, C.A.; Rodríguez, D.A. Modeling of Global and Individual Kinetic Parameters in Wheat Straw Torrefaction: Particle Swarm Optimization and Its Impact on Elemental Composition Prediction. Algorithms 2025, 18, 283. [Google Scholar] [CrossRef]

- Chen, W.H.; Eng, C.F.; Lin, Y.Y.; Bach, Q.V.; Ashokkumar, V.; Show, P.L. Two-step thermodegradation kinetics of cellulose, hemicelluloses, and lignin under isothermal torrefaction analyzed by particle swarm optimization. Energy Convers. Manag. 2021, 238, 114116. [Google Scholar] [CrossRef]

- Yen, S.W.; Chen, W.H.; Chang, J.S.; Eng, C.F.; Raza Naqvi, S.; Show, P.L. Torrefaction thermogravimetric analysis and kinetics of sorghum distilled residue for sustainable fuel production. Sustainability 2021, 13, 4246. [Google Scholar] [CrossRef]

- de Oliveira, P.P.; Lamas, G.C.; Ghesti, G.F.; Macedo, L.A.; Luz, S.M.; Alves, J.L.F.; Silveira, E.A. Effect of extractive removal and heating rates on pequi seed torrefaction: A detailed kinetic and predictive study for biofuel production. Energy 2025, 321, 135521. [Google Scholar] [CrossRef]

- Bach, Q.V.; Chen, W.H.; Chu, Y.S.; Skreiberg, Ø. Predictions of biochar yield and elemental composition during torrefaction of forest residues. Bioresour. Technol. 2016, 215, 239–246. [Google Scholar] [CrossRef] [PubMed]

- Gul, S.; Ramzan, N.; Hanif, M.A.; Bano, S. Kinetic, volatile release modeling and optimization of torrefaction. J. Anal. Appl. Pyrolysis 2017, 128, 44–53. [Google Scholar] [CrossRef]

- Moraes, T.A.; da Silva, M.T.; Euzébio, T.A. Delay Compensation in a Feeder–Conveyor System Using the Smith Predictor: A Case Study in an Iron Ore Processing Plant. Sensors 2024, 24, 3870. [Google Scholar] [CrossRef]

- Mejía, C.; Salazar, E.; Camacho, O. A comparative experimental evaluation of various Smith predictor approaches for a thermal process with large dead time. Alex. Eng. J. 2022, 61, 9377–9394. [Google Scholar] [CrossRef]

- Feliu, V.; Rivas, R. Control of the temperature in a petroleum refinery heating furnace based on a robust modified Smith predictor. ISA Trans. 2021, 112, 251–270. [Google Scholar] [CrossRef] [PubMed]

- SIAP. Avance de Siembras y Cosechas por Estado y Ciclo, Serv. Inf. Agroaliment. y Pesq. Ciudad México, México. 2024. Available online: https://www.gob.mx/siap (accessed on 2 March 2025).

- CONAGUA. Comisión Nacional del Agua: Ciudad de México, México. 2023. Available online: https://www.gob.mx/conagua (accessed on 2 March 2025).

- SEMARNAT. NOM-004-SEMARNAT-2002. Límite Máximo Permisible de Contaminantes en Los Biosólidos y Especificaciones para su Manejo y Disposición Final. D. Of. la Fed. 2003. Available online: https://www.dof.gob.mx/nota_detalle.php?codigo=695604 (accessed on 2 March 2025).

- Li, B.; Guo, Y.; Liang, F.; Liu, W.; Wang, Y.; Cao, W.; Guo, J. Global integrative meta-analysis of the responses in soil organic carbon stock to biochar amendment. J. Environ. Manag. 2024, 351, 119745. [Google Scholar] [CrossRef]

- Sun, Z.; Hu, Y.; Shi, L.; Li, G.; Pang, Z.H.E.; Liu, S.; Jia, B. Effects of biochar on soil chemical properties: A global meta-analysis of agricultural soil. Plant Soil Environ. 2022, 68, 272–289. [Google Scholar] [CrossRef]

- Khan, Y.A.; Kateb, F.; Rehman, A.U.; Khan, A.S.; Khan, F.Q.; Jan, S.; Alkhathlan, A.N. Enhancing Smart Home Efficiency with Heuristic-Based Energy Optimization. Computers 2025, 14, 149. [Google Scholar] [CrossRef]

- SMAOT. Informe de Avances en la Estrategia de Economía Circular del Estado de Guanajuato; Secretaría de Medio Ambiente y Ordenamiento Territorial: Guanajuato, México, 2023; Available online: https://smaot.guanajuato.gob.mx (accessed on 13 April 2025).

- SENER. Programa Nacional para el Aprovechamiento Sustentable de la Bioenergía; Secretaría de Energía: Ciudad de México, México, 2021; Available online: https://www.gob.mx/sener/articulos/proyecto-de-evaluacion-del-programa-nacional-para-el-aprovechamiento-sustentable-de-la-energia-2021-2024-370969 (accessed on 13 April 2025).

- Korupu, V.L.; Muthukumarasamy, M. A comparative study of various Smith predictor configurations for industrial delay processes. Chem. Prod. Process Model. 2022, 17, 701–732. [Google Scholar] [CrossRef]

- Mezura, E.; Coello, C.A.C. Constraint-handling in nature-inspired numerical optimization: Past, present and future. Swarm Evol. Comput. 2011, 1, 173–194. [Google Scholar] [CrossRef]

- Holland, J.H. Adaptation in Natural and Artificial Systems: An Introductory Analysis with Applications to Biology, Control, and Artificial Intelligence; MIT Press: Cambridge, MA, USA, 1992. [Google Scholar]

- Nelder, J.A.; Mead, R. A simplex method for function minimization. Comput. J. 1965, 7, 308–313. [Google Scholar] [CrossRef]

- Lagarias, J.C.; Reeds, J.A.; Wright, M.H.; Wright, P.E. Convergence properties of the Nelder--Mead simplex method in low dimensions. SIAM J. Optim. 1998, 9, 112–147. [Google Scholar] [CrossRef]

- Type-K Thermocouple. Available online: https://www.tc-inc.com/thermocouples/thermocouple_pot_seal.html (accessed on 6 May 2025).

- MAX6675. Available online: https://www.analog.com/en/products/max6675.html (accessed on 6 May 2025).

- Arduino UNO Board. Available online: https://store.arduino.cc/products/arduino-uno-rev3?srsltid=AfmBOoo7nAXHL0zC-snKQd0wCNXdRgoQh5-4cDSXIej-CYC_L1AaLja6 (accessed on 6 May 2025).

- AUTONICS SPC1-50. Available online: https://www.autonics.com/mx/model/SPC1-50 (accessed on 1 September 2025).

- Scale Rhino Baco 30. Available online: https://www.rhino.mx/producto/bascula-electronica-contadora-30-kg/ (accessed on 6 May 2025).

- SEMARNAT. Diagnóstico Básico para la Gestión Integral de Residuos. Gob. México. 2023. Available online: https://www.gob.mx/inecc/acciones-y-programas/diagnostico-basico-para-la-gestion-integral-de-los-residuos-2020 (accessed on 8 May 2025).

- Mian, R.U.H.; Shintani, M.; Inoue, M. Hardware–software co-design for decimal multiplication. Computers 2021, 10, 17. [Google Scholar] [CrossRef]

- Saleh, K.; Darweesh, D.; Darwish, O.; Hammad, E.; Amsaad, F. Hardware and Software Methods for Secure Obfuscation and Deobfuscation: An In-Depth Analysis. Computers 2025, 14, 251. [Google Scholar] [CrossRef]

| Biomass | Temperature Profiles | Optimization Algorithm | Fit (%) | Ref. | ||

|---|---|---|---|---|---|---|

| Temperature (°C) | Heating Rate (°C/min) | Residence Time (min) | ||||

| Wood Waste | 225–375 | 5, 10, 20, 30, and 40 | 60 | N-M | 0.9996 | [33] |

| Wood Waste | 200–300 | 20 | 60 | 0.99 | [34] | |

| Ashe Juniper | 210–380 | 6 and 7 | 160 | >0.98 | [35] | |

| Eucalyptus Grandis | 210–290 | 5 | 80 | -- | [36] | |

| Poplar and Fir | 200–230 | 0.2 | 1740 | 0.9997 | [37] | |

| Poplar and Xylan | 200–240 | 1 | 600 | >0.97 | [38] | |

| Wheat Straw | 250–300 | 10 and 50 | 100 | -- | [39] | |

| Wheat Straw | 250–325 | 20 | 100 | PSO | >0.98 | [40] |

| Xylan | 200–300 | 20 | 120 | >0.98 | [41] | |

| Sorghum residue | 200–300 | 20 | 60 | >0.8469 | [42] | |

| Pequi Seed (PS) and oil-PS | 200–300 | 7–15 | 80 | L-M | 0.97 | [43] |

| Spruce and Birch | 220–300 | -- | 120 | SSE | >0.971 | [44] |

| Beech, Pine, Wheat, and Willow | 200–300 | -- | 100 | LSR | -- | [45] |

| Biomass Characteristics | WS | PW | BS | Method |

|---|---|---|---|---|

| Proximate analysis (wt.%) (dry basis) | ||||

| VCM | 76.51 ± 0.256 | 85.75 ± 0.200 | 63.16 ± 0.332 | ASTM E871-82 |

| Ash | 3.52 ± 0.351 | 5.15 ± 0.100 | 27.70 ± 0.235 | E1775 |

| FC | 19.97 ± 1.670 | 9.06 ± 0.159 | 9.14 ± 0.398 | E871-82 |

| Ultimate Analysis (wt.%) | ||||

| C | 46.205 | 42.167 | 34.178 | Thermo Scientific iCAP 74000 ICP-OES analyzer, CA-USA |

| H | 6.275 | 5.275 | 4.966 | |

| N | 3.612 | 2.179 | 6.304 | |

| S | 0.000 | 0.000 | 0.452 | |

| O* | 43.908 | 50.379 | 54.100 | |

| O:C | 0.714 | 0.896 | 1.187 | |

| H:C | 1.629 | 1.501 | 1.743 | |

| Biomass | Heating Rate (°C/min) | Residence Time (min) | Set of Temperatures (°C) | Solid Yield (%), Equation (3) | Instantaneous Solid Yield Time (min) | Heat Treatment |

|---|---|---|---|---|---|---|

| WS | 20 | 120 | 250 | 1, 0.834, 0.746, and 0.638 | 1, 33, 53, and 83 | Torrefaction and Slow Pyrolysis |

| 275 | 1, 0.748, 0.645, and 0.543 | 1, 40, 60, and 80 | ||||

| 300 | 1, 0.604, 0.504, and 0.469 | 1, 48, 68, and 88 | ||||

| 325 | 1, 0.478, 0.471, and 0.450 | 1, 57, 77, and 97 | ||||

| PW | 300 | 1, 0.614, 0.552, and 0.552 | 1, 51, 76, and 101 | Slow Pyrolysis | ||

| 400 | 1, 0.436, 0.413, and 0.408 | 1, 51, 76, and 101 | ||||

| 500 | 1, 0.384, 0.368, and 0.331 | 1, 51, 76, and 101 | ||||

| BS | 300 | 1, 0.958, 0.719, 0.645, and 0.620 | 1, 26, 51, 76, and 101 | Slow Pyrolysis | ||

| 400 | 1, 0.810, 0.551, 0.530, and 0.511 | 1, 26, 51, 76, and 101 | ||||

| 500 | 1, 0.782, 0.437, 0.431, and 0.429 | 1, 26, 51, 76, and 101 |

| Algorithms | Temperatures (°C) | Arrhenius Constants (s−1) | Arrhenius Parameters | Fit (%) | Processing Time (min) | |

|---|---|---|---|---|---|---|

| A0 (s−1) | Ea (J·mol−1) | |||||

| PSO | 250, 275, 300, and 325 | k1 | 1.141 × 1011 | 1.310 × 105 | 99.999 | 6.280 |

| kV1 | 9.789 × 105 | 8.087 × 104 | ||||

| k2 | 9.724 × 106 | 9.762 × 104 | ||||

| kV2 | 6.763 × 105 | 8.557 × 104 | ||||

| GA | k1 | 5.321 × 101 | 1.994 × 104 | 99.996 | 1.870 | |

| kV1 | 2.455 × 102 | 3.764 × 104 | ||||

| k2 | 1.852 × 103 | 5.453 × 104 | ||||

| kV2 | 2.307 × 103 | 5.492 × 104 | ||||

| N-M | k1 | 6.090 × 108 | 1.080 × 105 | 100.000 | 4.053 | |

| kV1 | 3.660 × 103 | 5.710 × 104 | ||||

| k2 | 7.450 × 103 | 6.280 × 104 | ||||

| kV2 | 2.980 × 103 | 5.900 × 104 | ||||

| Algorithms | Temperatures (°C) | Arrhenius Constants (s−1) | Arrhenius Parameters | Fit (%) | Processing Time (min) | |

|---|---|---|---|---|---|---|

| A0 (s−1) | Ea (J·mol−1) | |||||

| PSO | 300, 400, and 500 | k1 | 4.280 × 101 | 3.290 × 104 | 99.830 | 6.426 |

| kV1 | 7.990 × 102 | 6.020 × 104 | ||||

| k2 | 4.000 × 10−1 | 1.170 × 104 | ||||

| kV2 | 7.380 × 100 | 2.670 × 104 | ||||

| GA | k1 | 1.861 × 103 | 5.526 × 104 | 99.999 | 1.805 | |

| kV1 | 8.839 × 104 | 7.408 × 104 | ||||

| k2 | 1.090 × 105 | 1.454 × 105 | ||||

| kV2 | 3.546 × 105 | 1.214 × 105 | ||||

| N-M | k1 | 3.438 × 103 | 5.630 × 104 | 100.000 | 2.345 | |

| kV1 | 1.810 × 105 | 7.597 × 104 | ||||

| k2 | 5.062 × 105 | 1.058 × 105 | ||||

| kV2 | 8.553 × 104 | 1.021 × 105 | ||||

| Algorithms | Temperatures (°C) | Arrhenius Constants (s−1) | Arrhenius Parameters | Fit (%) | Processing Time (min) | |

|---|---|---|---|---|---|---|

| A0 (s−1) | Ea (J·mol−1) | |||||

| PSO | 300, 400, and 500 | k1 | 2.865 × 102 | 5.017 × 104 | 100.000 | 6.520 |

| kV1 | 3.637 × 100 | 2.968 × 104 | ||||

| k2 | 7.620 × 10−1 | 1.857 × 100 | ||||

| kV2 | 8.298 × 102 | 4.584 × 104 | ||||

| GA | k1 | 6.721 × 101 | 3.566 × 104 | 99.921 | 1.351 | |

| kV1 | 4.174 × 101 | 3.760 × 104 | ||||

| k2 | 5.273 × 10−1 | 1.675 × 104 | ||||

| kV2 | 8.609 × 100 | 3.737 × 104 | ||||

| N-M | k1 | 4.145 × 103 | 5.677 × 104 | 100.000 | 6.449 | |

| kV1 | 2.471 × 103 | 5.707 × 104 | ||||

| k2 | 4.501 × 102 | 4.967 × 104 | ||||

| kV2 | 8.244 × 104 | 8.648 × 104 | ||||

| Biomass | Tmax (°C) | Final Solid Yields (%) | |||

|---|---|---|---|---|---|

| Exp. | Algorithms/Predictions | ||||

| PSO | GA | N-M | |||

| WS | 325 | 0.450 | 0.449 | 0.449 | 0.455 |

| PW | 500 | 0.331 | 0.335 | 0.332 | 0.332 |

| BS | 500 | 0.429 | 0.429 | 0.431 | 0.429 |

| Biomass | Standard Metrics | Algorithms | Performance Hierarchy | ||

|---|---|---|---|---|---|

| PSO | GA | N-M | |||

| WS | R2 | 0.990 | 0.994 | 0.996 | N-M > GA > PSO |

| fit (%) | 99.999 | 99.996 | 100 | N-M > PSO > GA | |

| tp (min) | 6.280 | 1.870 | 4.053 | GA < N-M < PSO | |

| PW | R2 | 0.986 | 0.994 | 0.998 | N-M > GA > PSO |

| fit (%) | 99.830 | 99.999 | 100 | N-M > GA > PSO | |

| tp (min) | 6.426 | 1.805 | 2.435 | GA < N-M < PSO | |

| R2 | 0.980 | 0.955 | 0.860 | PSO > GA > N-M | |

| BS | fit (%) | 100 | 99.921 | 100 | PSO = N-M > GA |

| tp (min) | 6.520 | 1.351 | 6.449 | GA < N-M < PSO | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Urbina-Salas, I.; Granados-Lieberman, D.; Amezquita-Sanchez, J.P.; Valtierra-Rodriguez, M.; Rodriguez-Alejandro, D.A. Hardware–Software System for Biomass Slow Pyrolysis: Characterization of Solid Yield via Optimization Algorithms. Computers 2025, 14, 426. https://doi.org/10.3390/computers14100426

Urbina-Salas I, Granados-Lieberman D, Amezquita-Sanchez JP, Valtierra-Rodriguez M, Rodriguez-Alejandro DA. Hardware–Software System for Biomass Slow Pyrolysis: Characterization of Solid Yield via Optimization Algorithms. Computers. 2025; 14(10):426. https://doi.org/10.3390/computers14100426

Chicago/Turabian StyleUrbina-Salas, Ismael, David Granados-Lieberman, Juan Pablo Amezquita-Sanchez, Martin Valtierra-Rodriguez, and David Aaron Rodriguez-Alejandro. 2025. "Hardware–Software System for Biomass Slow Pyrolysis: Characterization of Solid Yield via Optimization Algorithms" Computers 14, no. 10: 426. https://doi.org/10.3390/computers14100426

APA StyleUrbina-Salas, I., Granados-Lieberman, D., Amezquita-Sanchez, J. P., Valtierra-Rodriguez, M., & Rodriguez-Alejandro, D. A. (2025). Hardware–Software System for Biomass Slow Pyrolysis: Characterization of Solid Yield via Optimization Algorithms. Computers, 14(10), 426. https://doi.org/10.3390/computers14100426