Surface Finish and Back-Wall Dross Behavior during the Fiber Laser Cutting of AZ31 Magnesium Alloy

Abstract

1. Introduction

2. Methods and Materials

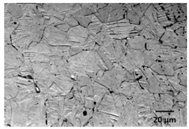

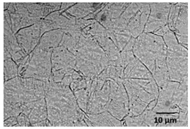

2.1. AZ31 Magnesium Alloy

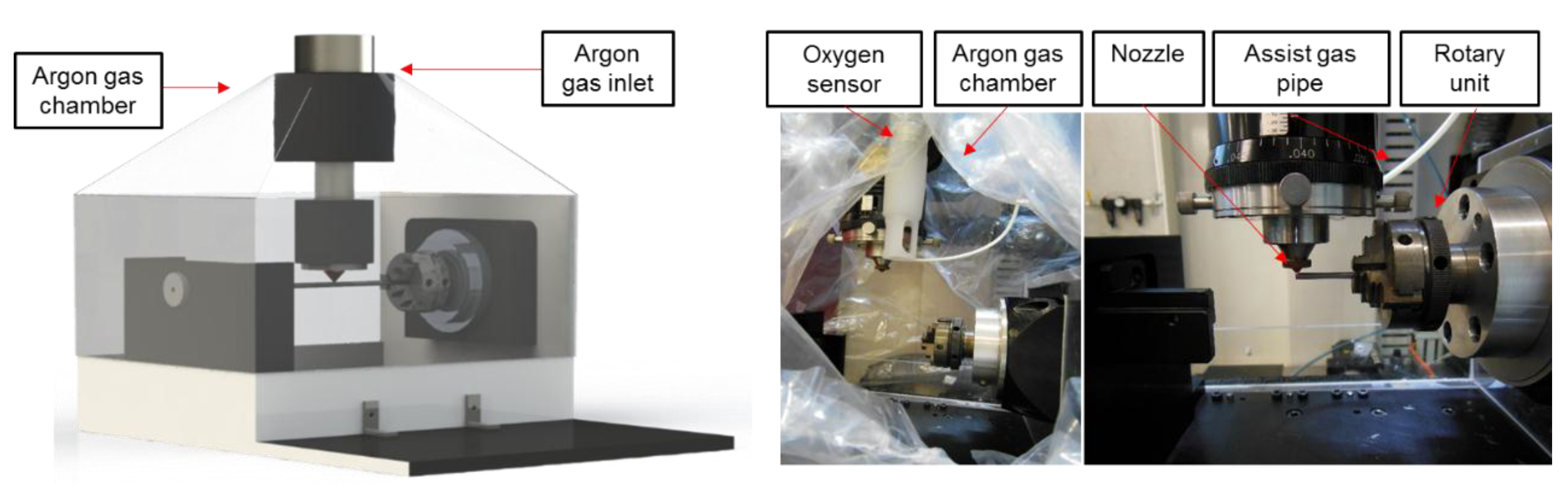

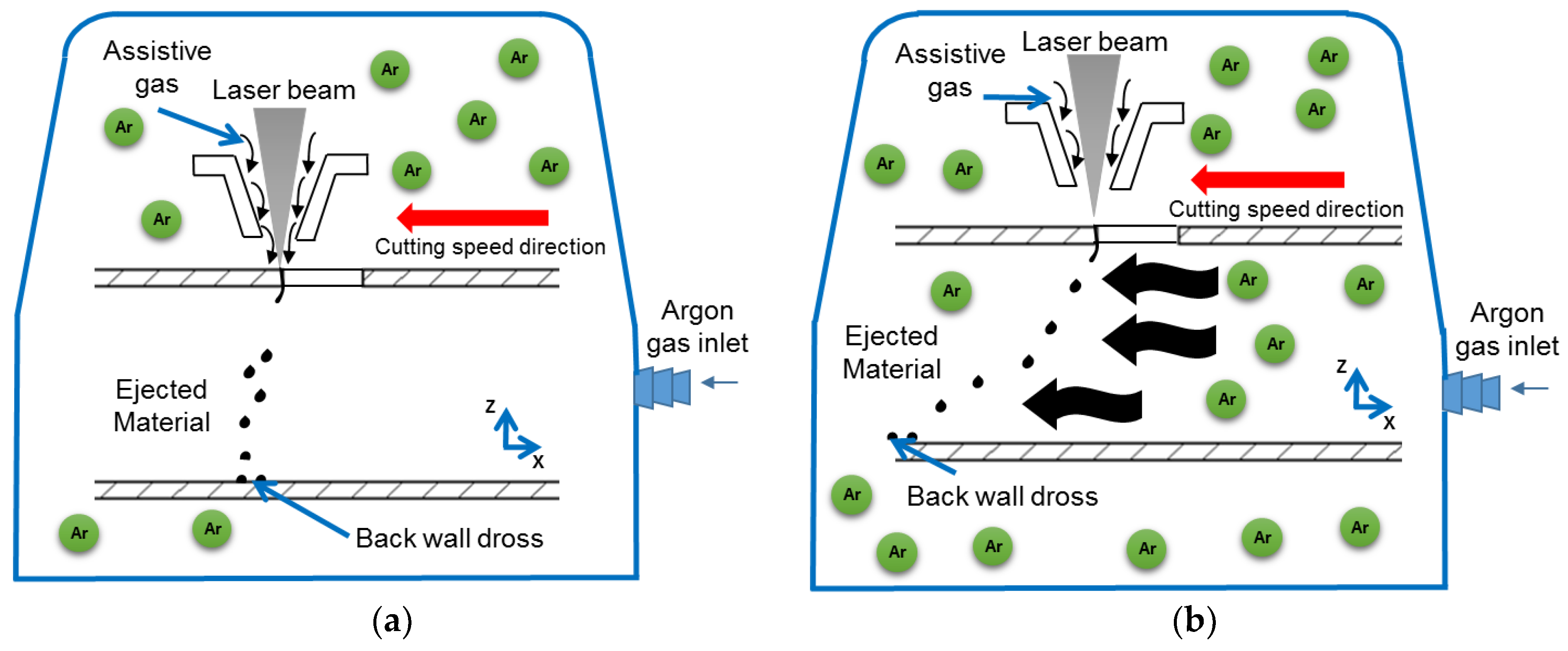

2.2. Fiber Laser and Experimental Setup

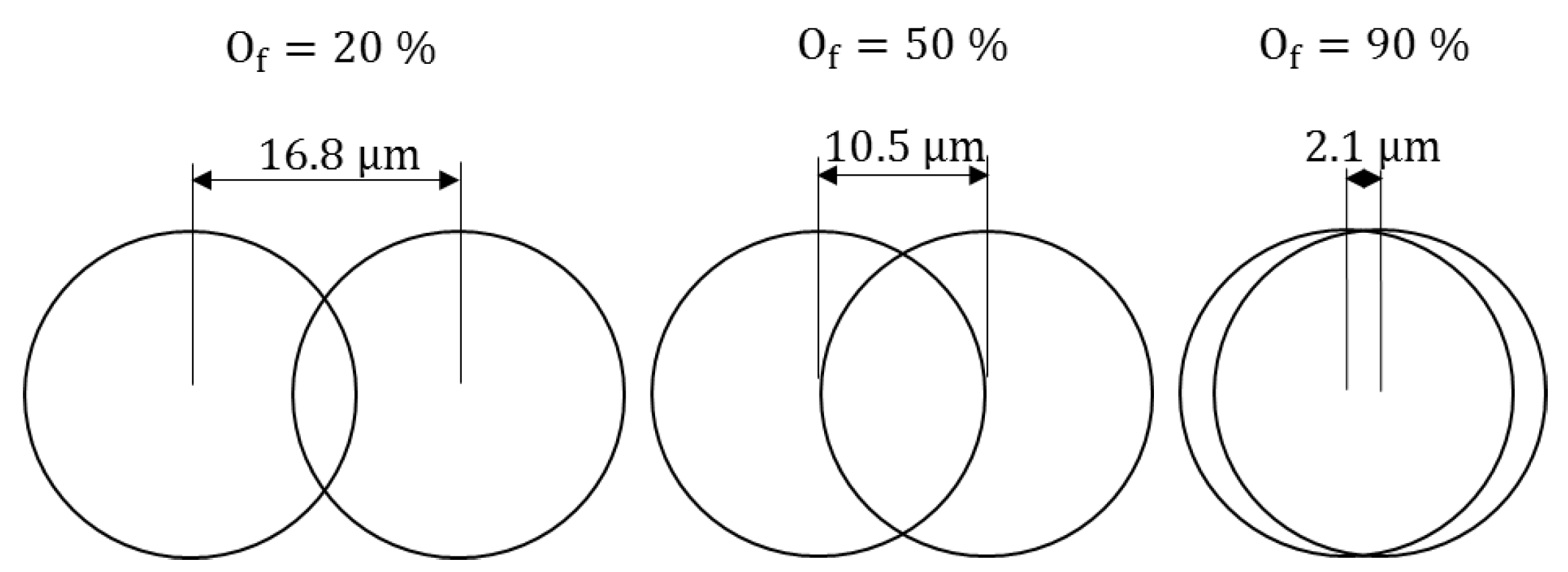

2.3. Experimental Factors

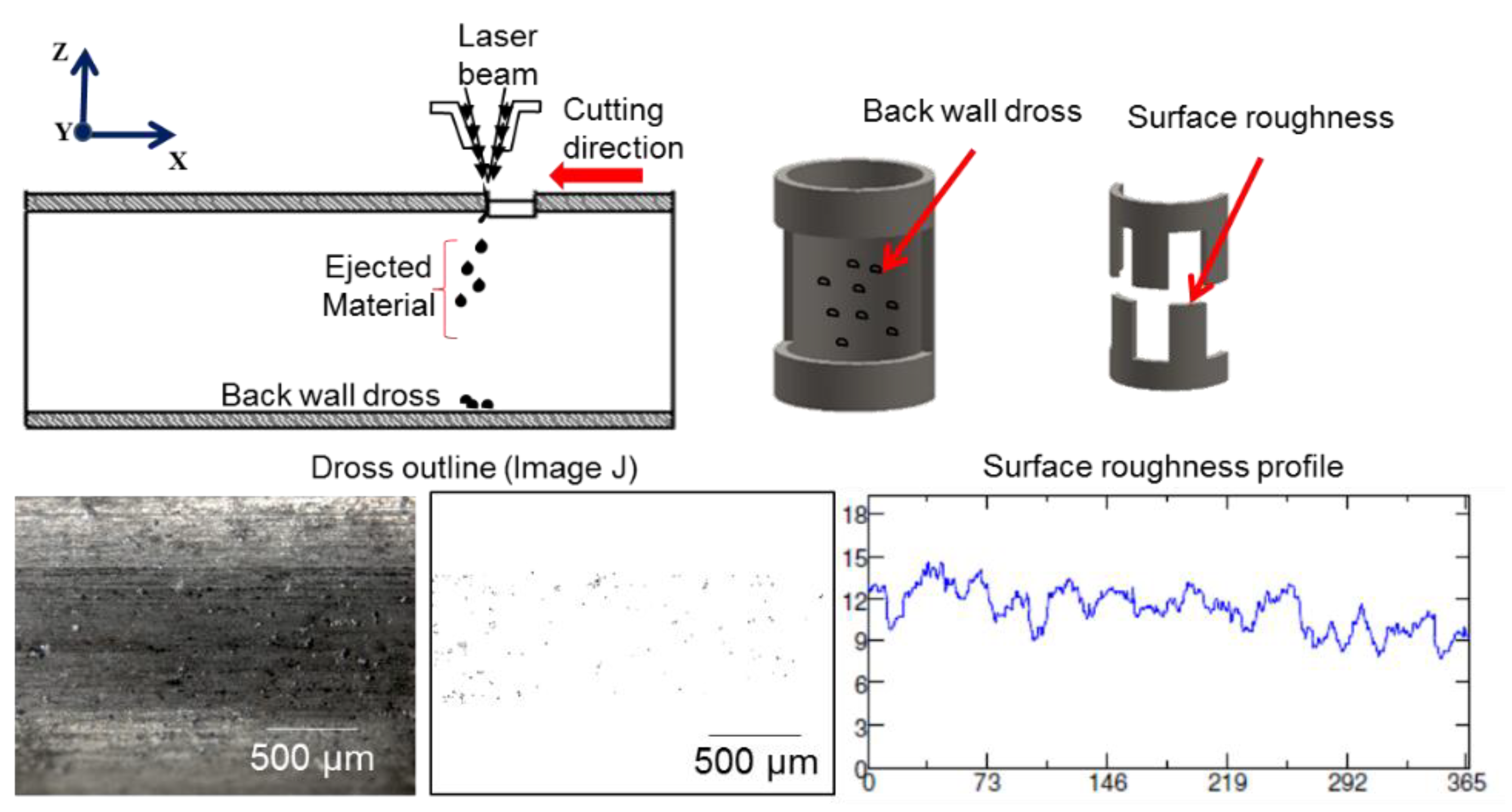

2.4. Response Variables

3. Results

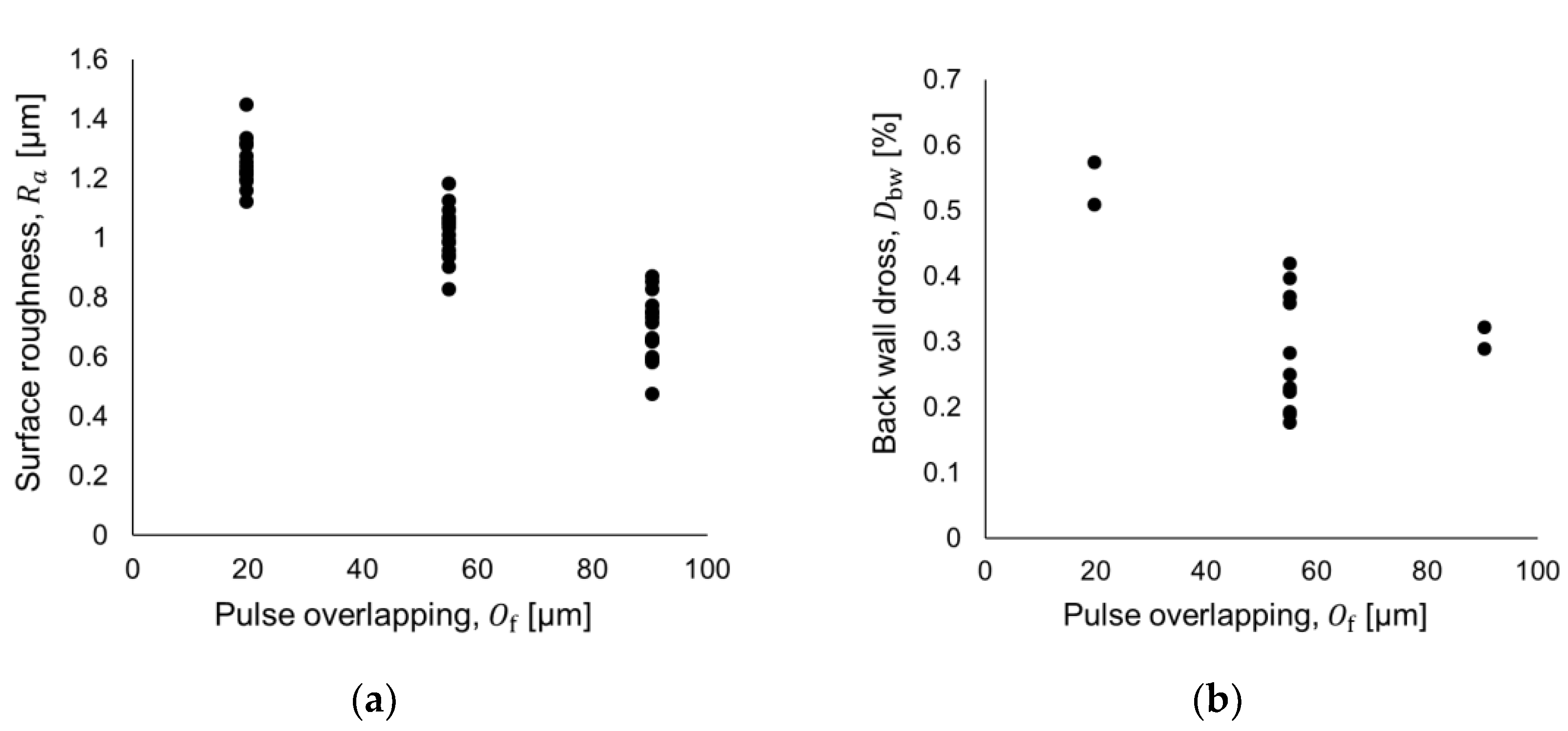

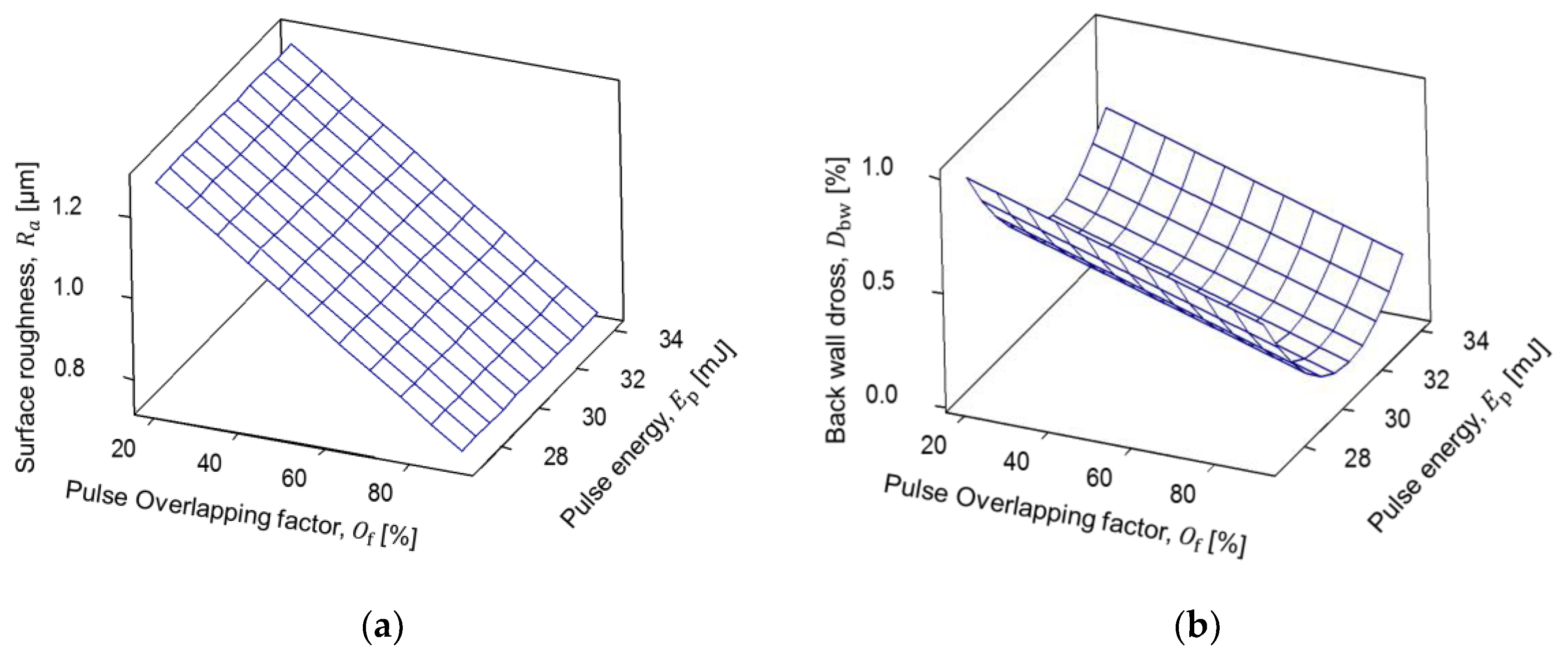

3.1. Cutting with No Gas Blowing through the Tube

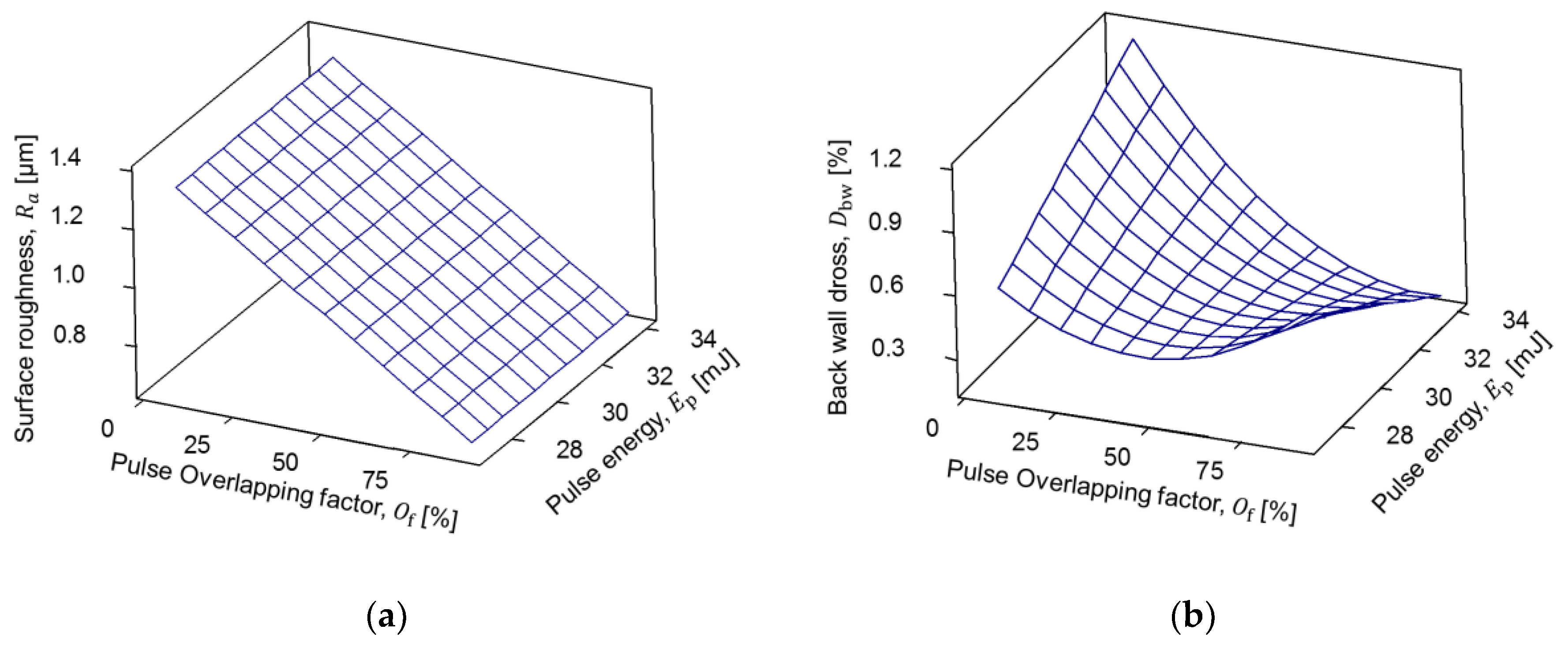

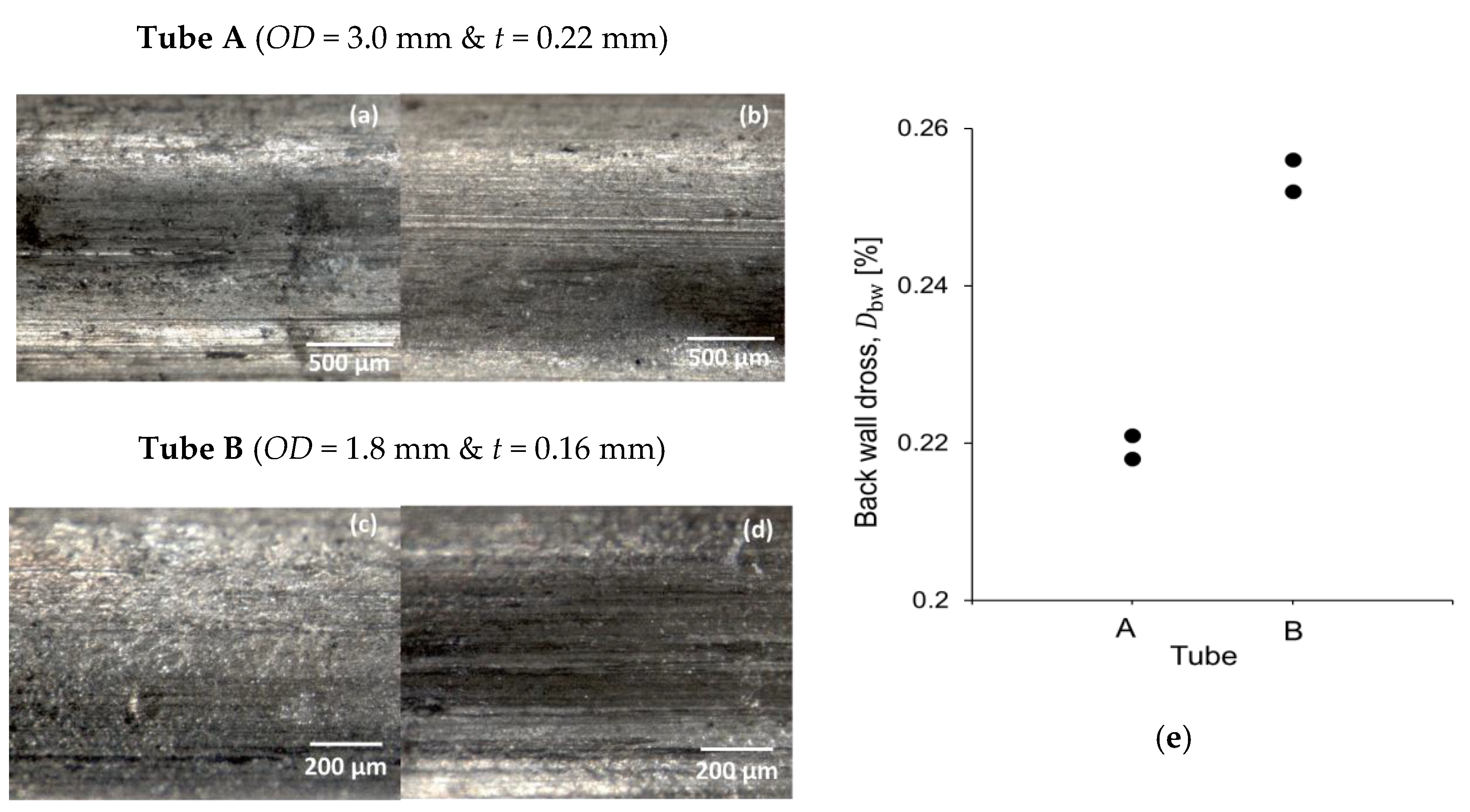

3.2. Cutting Using Gas Blowing through the Tube

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Sigwart, U.; Puel, J.; Mirkovitch, V.; Joffre, F.; Kappenberger, L. Intravascular stents to prevent occlusion and re-stenosis after transluminal angioplasty. N. Engl. J. Med. 1987, 316, 701–706. [Google Scholar] [CrossRef] [PubMed]

- Roubin, G.S.; Cannon, A.D.; Agrawal, S.K.; Macander, P.J.; Dean, L.S.; Baxley, W.A.; Breland, J. Intracoronary stenting for acute and threatened closure complicating percutaneous transluminal coronary angioplasty. Circulation 1992, 85, 916–927. [Google Scholar] [CrossRef] [PubMed]

- Moravej, M.; Mantovani, D. Biodegradable metals for cardiovascular stent application: Interests and new opportunities. Int. J. Mol. Sci. 2011, 12, 4250–4270. [Google Scholar] [CrossRef] [PubMed]

- Schatz, R.A.; Goldberg, S.; Leon, M.; Baim, D.; Hirshfeld, J.; Cleman, M.; Ellis, S.; Topol, E. Clinical experience with the Palmaz-Schatz coronary stent. J. Am. Coll. Cardiol. 1991, 17, 155–159. [Google Scholar] [CrossRef]

- Byrne, R.A.; Stone, G.W.; Ormiston, J.; Kastrati, A. Coronary balloon angioplasty, stents, and scaffolds. Lancet 2017, 390, 781–792. [Google Scholar] [CrossRef]

- Waksman, R.; Erbel, R.; Di Mario, C.; Bartunek, J.; de Bruyne, B.; Eberli, F.R.; Erne, P.; Haude, M.; Horrigan, M.; Ilsley, C.; et al. Early- and long-term intravascular ultrasound and angiographic findings after bioabsorbable magnesium stent implantation in human coronary arteries. JACC Cardiovasc. Interv. 2009, 2, 312–320. [Google Scholar] [CrossRef] [PubMed]

- Gastaldi, D.; Sassi, V.; Petrini, L.; Vedani, M.; Trasatti, S.; Migliavacca, F. Continuum damage model for bioresorbable magnesium alloy devices—Application to coronary stents. J. Mech. Behav. Biomed. Mater. 2011, 4, 352–365. [Google Scholar] [CrossRef] [PubMed]

- Staiger, M.P.; Pietak, A.M.; Huadmai, J.; Dias, G. Magnesium and its alloys as orthopedic biomaterials: A review. Biomaterials 2006, 27, 1728–1734. [Google Scholar] [CrossRef] [PubMed]

- Wong, H.M.; Yeung, K.W.; Lam, K.O.; Tam, V.; Chu, P.K.; Luk, K.D.; Cheung, K.M. A biodegradable polymer-based coating to control the performance of magnesium alloy orthopedic implants. Biomaterials 2010, 31, 2084–2096. [Google Scholar] [CrossRef] [PubMed]

- Kitabata, H.; Waksman, R.; Warnack, B. Bioresorbable metal scaffold for cardiovascular application: Current knowledge and future perspectives. Cardiovasc. Revascularization Med. Mol. Interv. 2014, 15, 109–116. [Google Scholar] [CrossRef] [PubMed]

- Persaud-Sharma, D.; McGoron, A. Biodegradable Magnesium Alloys: A review of material development and applications. J. Biomim. Biomater. Tissue Eng. 2012, 12, 25–39. [Google Scholar] [CrossRef] [PubMed]

- Erbel, R.; Di Mario, C.; Bartunek, J.; Bonnier, J.; de Bruyne, B.; Eberli, F.R.; Erne, P.; Haude, M.; Heublein, B.; Horrigan, M.; et al. Temporary scaffolding of coronary arteries with bioabsorbable magnesium stents: A prospective, non-randomised multicentre trial. Lancet 2007, 369, 1869–1875. [Google Scholar] [CrossRef]

- Witte, F. The history of biodegradable magnesium implants: A review. Acta Biomater. 2010, 6, 1680–1692. [Google Scholar] [CrossRef] [PubMed]

- Demir, A.G.; Previtali, B.; Ge, Q.; Vedani, M.; Wu, W.; Migliavacca, F.; Bestetti, M. Biodegradable magnesium coronary stents: Material, design and fabrication. Int. J. Comput. Integr. Manuf. 2014, 27, 936–945. [Google Scholar] [CrossRef]

- Demir, A.G.; Previtali, B.; Colombo, D.; Ge, Q.; Vedani, M.; Petrini, L.; Biffi, C.A. Fiber laser micromachining of magnesium alloy tubes for biocompatible and biodegradable cardiovascular stents. In Proceedings of the Fiber Lasers IX: Technology, Systems, and Applications, San Francisco, CA, USA, 15 February 2012; p. 823730. [Google Scholar]

- Scintilla, L.D.; Tricarico, L. Laser cutting of lightweight alloys sheets with 1μm laser wavelength. In Proceedings of the High-Power Laser Materials Processing: Lasers, Beam Delivery, Diagnostics, and Applications II, San Francisco, CA, USA, 22 February 2013; p. 86030U. [Google Scholar]

- Scintilla, L.D.; Tricarico, L. Experimental investigation on fiber and CO2 inert gas fusion cutting of AZ31 magnesium alloy sheets. Opt. Laser Technol. 2013, 46, 42–52. [Google Scholar] [CrossRef]

- Demir, A.G.; Previtali, B.; Biffi, C.A. Fibre laser cutting and chemical etching of AZ31 for manufacturing biodegradable stents. Adv. Mater. Sci. Eng. 2013, 2013, 1–11. [Google Scholar] [CrossRef]

- Grogan, J.A.; Leen, S.B.; McHugh, P.E. Comparing coronary stent material performance on a common geometric platform through simulated bench testing. J. Mech. Behav. Biomed. Mater. 2012, 12, 129–138. [Google Scholar] [CrossRef] [PubMed]

- Demir, A.G.; Previtali, B. Comparative study of CW, nanosecond- and femtosecond-pulsed laser microcutting of AZ31 magnesium alloy stents. Biointerphases 2014, 9, 029004. [Google Scholar] [CrossRef] [PubMed]

- Demir, A.G.; Previtali, B. Dross-free submerged laser cutting of AZ31 Mg alloy for biodegradable stents. J. Laser Appl. 2016, 28, 032001. [Google Scholar] [CrossRef]

- Sealy, M.P.; Guo, M.P.; Liu, J.F.; Li, C. Pulsed laser cutting of magnesium for biodegradable stents. Procedia CIRP 2016, 42, 67–72. [Google Scholar] [CrossRef]

- Farè, S.; Ge, Q.; Vedani, M.; Vimercati, G.; Gastaldi, D.; Migliavacca, F.; Petrini, L.; Trasatti, S. Evaluation of material properties and design requirements for biodegradable magnesium stents. Matéria (Rio de Janeiro) 2010, 15, 96–103. [Google Scholar]

- Li, N.; Guo, C.; Wu, Y.H.; Zheng, Y.F.; Ruan, L.Q. Comparative study on corrosion behavior of pure Mg and WE43 alloy in static, stirring and flowing Hank’s solution. Corros. Eng. Sci. Technol. 2010, 47, 346–351. [Google Scholar] [CrossRef]

- Haude, M.; Ince, H.; Abizaid, A.; Toelg, R.; Lemos, P.A.; von Birgelen, C.; Waksman, R. Safety and performance of the second-generation drug-eluting absorbable metal scaffold in patients with de-novo coronary artery lesions (BIOSOLVE-II): 6 month results of a prospective, multicentre, non-randomised, first-in-man trial. Lancet 2016, 387, 31–39. [Google Scholar] [CrossRef]

- Di Mario, C.; Griffiths, H.U.W.; Goktekin, O.; Peeters, N.; Verbist, J.A.N.; Bosiers, M.; Deloose, K.; Heublein, B.; Rohde, R.; Kasese, V.; et al. Drug-eluting bioabsorbable magnesium stent. J. Interv. Cardiol. 2004, 17, 391–395. [Google Scholar] [CrossRef] [PubMed]

- Muhammad, N.; Whitehead, D.; Boor, A.; Li, L. Comparison of dry and wet fibre laser profile cutting of thin 316L stainless steel tubes for medical device applications. J. Mater. Process. Technol. 2010, 210, 2261–2267. [Google Scholar] [CrossRef]

- Muhammad, N.; Li, L. Underwater femtosecond laser micromachining of thin nitinol tubes for medical coronary stent manufacture. Appl. Phys. A 2012, 107, 849–861. [Google Scholar] [CrossRef]

- Preco (2012). Beam Final Test Results; Model Number: YLR 1501500QC WMMACY11, Serial Number: PLMP1202236; IPG Photonics: Oxford, MA, USA, 2012; pp. 1–5. [Google Scholar]

- IPG photonics (2012). YLR User Guide. Available online: http://docshare04.docshare.tips/files/25907/259076862.pdf (accessed on 24 September 2018).

- Ghany, K.A.; Newishy, M. Cutting of 1.2 mm thick austenitic stainless steel sheet using pulsed and CW Nd: YAG laser. J. Mater. Process. Technol. 2005, 168, 438–447. [Google Scholar] [CrossRef]

- Criales, L.E.; Orozco, P.F.; Medrano, A.; Rodríguez, C.A.; Özel, T. Effect of fluence and pulse overlapping on fabrication of microchannels in PMMA/PDMS via UV laser micromachining: Modeling and experimentation. Mater. Manuf. Process. 2015, 30, 890–901. [Google Scholar] [CrossRef]

- García-López, E.; Medrano-Tellez, A.G.; Ibarra-Medina, J.R.; Siller, H.R.; Rodriguez, C.A. Experimental study of back wall dross and surface roughness in fiber laser microcutting of 316l miniature tubes. Micromachines 2017, 9, 4. [Google Scholar] [CrossRef]

- Image, J. Available online: https://imagej.nih.gov/ij/ (accessed on 3 September 2018).

- Box, G.E.; Draper, N.R. A basis for the selection of a response surface design. J. Am. Stat. Assoc. 1959, 54, 622–654. [Google Scholar] [CrossRef]

- Sharma, A.; Yadava, V. Experimental analysis of Nd-YAG laser cutting of sheet materials—A review. Opt. Laser Technol. 2018, 98, 264–280. [Google Scholar] [CrossRef]

- Li, Y.; Chen, Y.; Cui, H.; Xiong, B.; Zhang, J. Microstructure and mechanical properties of spray-formed AZ91 magnesium alloy. Mater. Charact. 2009, 60, 240–245. [Google Scholar] [CrossRef]

| Ref. | Test Alloy, OD (t) * | Process Parameters | Response | |

|---|---|---|---|---|

| [15] | AZ31 Mg, Tube OD = 2.5 mm (200 μm) | Laser mode | Pulsed-QCW | Surface quality |

| Laser power (W) | 50 | |||

| Pulse frequency, f (kHz) | 20–80 | |||

| Pulse width, τ (ms) | 0.0001 | |||

| Gas type & pressure (bar) | O2, Ar (6.9) | |||

| Cut speed, vf (mm/min) | 120 | |||

| [16] | AZ31 Mg, Sheet (1000 μm) | Laser mode | CW | Dross height Ra |

| Laser power (W) | 2000 | |||

| Gas type & pressure (bar) | Ar (3–6) | |||

| Cut speed, vf (mm/min) | 10,000–30,000 | |||

| [17] | AZ31 Mg, Sheet (1000–3000 μm) | Laser mode | CW | Striation inclination Dross height Ra |

| Laser power (W) | 2000 | |||

| Gas type & pressure (bar) | Ar (3–6) | |||

| Cut speed, vf (mm/min) | 2000–30,000 | |||

| [18] | AZ31 Mg, Tube OD = 2.5 mm (200 μm) | Laser mode | Pulsed-QCW | Ra |

| Laser power (W) | 4.5–7.5 | |||

| Pulse frequency, f (KHz) | 25 | |||

| Pulse width, τ (ms) | 0.0001 | |||

| Gas type & pressure (bar) | O2, Ar (6.9) | |||

| Cut speed, vf (mm/min) | 120 | |||

| [19] | AZ31 Mg, Sheet (400 μm) | Laser mode | CW | Ra Dross Kerf width |

| Laser power (W) | 150 | |||

| Gas type & pressure (bar) | N2 (6) | |||

| Cut speed, vf (mm/min) | 1200 | |||

| [20] | AZ31 Mg, Tube OD = 2.5 mm (200 µm) | Laser mode | Pulsed | n/a |

| Laser power (W) | 7.5 | |||

| Pulse frequency, f (KHz) | 25 | |||

| Pulse width, τ (ms) | 0.0001 | |||

| Gas type & pressure (bar) | Ar (6.9) | |||

| Cut speed, vf (mm/min) | 120 | |||

| [20] | AZ31 Mg, Tube OD = 2.5 mm (200 µm) | Laser mode | Pulsed | Ra Dross Kerf width |

| Laser power (W) | 5 | |||

| Pulse frequency, f (KHz) | 200 | |||

| Pulse width, τ (fs) | 800 | |||

| Gas type & pressure (bar) | Ar (6) | |||

| Cut speed, vf (mm/min) | 300 | |||

| [21] | AZ31 Mg, Sheet (250 µm) | Laser mode | Pulsed | Dross Kerf width Taper angle |

| Laser power (W) | 6 | |||

| Pulse frequency, f (KHz) | 300 | |||

| Pulse width, τ (ns) | 1 | |||

| Cut speed, vf (mm/min) | 15–315 | |||

| [22] | MgCa Sheet (700 µm) | Laser mode | Pulsed | Kerf width Taper angle Ra |

| Laser power (W) | 300–1500 | |||

| Pulse frequency, f (KHz) | 1000 | |||

| Pulse width, τ (ns) | 0.1–0.5 | |||

| Gas type & pressure (bar) | Ar (8.2) | |||

| Cut speed, vf (mm/min) | 100–1000 | |||

| Tube A (OD = 3 mm & t = 0.22 mm) | Tube B (OD = 1.8 mm & t = 0.16 mm) | ||

|---|---|---|---|

|  | ||

| %Al | 2.819 | %Al | 2.608 |

| %Zn | 1.082 | %Zn | 1.023 |

| %Si | 0.052 | %Si | 0.036 |

| %Ca | 0.035 | %Ca | 0.039 |

| %Cu | 0.034 | %Cu | 0.0017 |

| %Mn | 0.016 | %Mn | 0.016 |

| %Fe | 0.012 | %Fe | 0.014 |

| %Mg | 95.80 | %Mg | 95.90 |

| Characteristic | Conditions | Unit |

|---|---|---|

| Operation mode | Continuous wave (CW) | - |

| Operation sub-mode | Modulated/rectangular waveform | - |

| Fiber core diameter | 50 | μm |

| Wavelength (λ) | 1070 | nm |

| Maximum peak power (CW with modulation) | 250 | W |

| Minimum pulse width (CW with modulation) | 0.01 | ms |

| Beam parameter product | 1 | mm × mrad |

| M2 | 2.82 | - |

| Nozzle diameter | 0.50 | mm |

| Tube | Process Parameter | Level Code | ||||

|---|---|---|---|---|---|---|

| −1.414 | −1 | 0 | 1 | 1.414 | ||

| Tube A (OD = 3.0 mm & t = 0.22 mm) | Pulse Overlap, Of (%) | 19.65 | 30.00 | 55.00 | 80.00 | 90.36 |

| Pulse energy, Ep (mJ) | 26.97 | 28.00 | 30.50 | 33.00 | 34.04 | |

| Tube B (OD = 1.8 mm & t = 0.16 mm) | Pulse Overlap, Of (%) | 7.99 | 20.00 | 49.00 | 78.00 | 90.01 |

| Pulse energy, Ep (mJ) | 26.97 | 28.00 | 30.50 | 33.00 | 34.04 | |

| Tube | Pulse Overlapping, Of (%) | Pulse Energy, Ep (mJ) |

|---|---|---|

| Tube A (OD = 3.0 mm & t = 0.22 mm) | 90.36 | 30.5 |

| Tube B (OD = 1.8 mm & t = 0.16 mm) | 78.0 | 33.0 |

| Tube | Parameter | Level Code | ||||

|---|---|---|---|---|---|---|

| −1.414 | −1 | 0 | 1 | 1.414 | ||

| Tube A (OD = 3.0 mm & t = 0.22 mm) | Pulse frequency, f (Hz) | 1000 | 1000 | 1100 | 1200 | 1200 |

| Cutting speed, vf (mm/min) | 1000 | 875 | 625 | 300 | 150 | |

| Pulse Overlapping, Of (%) | 19.87 | 30.00 | 54.47 | 80.00 | 90.00 | |

| Peak power, Ppeak (W) | 150 | 150 | 160 | 170 | 170 | |

| Pulse width, τ (ms) | 0.180 | 0.187 | 0.190 | 0.194 | 0.200 | |

| Pulse energy, Ep (mJ) | 27.00 | 28.05 | 30.40 | 32.98 | 34.00 | |

| Tube B (OD = 1.8 mm & t = 0.16 mm) | Pulse frequency, f (Hz) | 600 | 600 | 700 | 800 | 800 |

| Cutting speed, vf (mm/min) | 690 | 600 | 450 | 220 | 100 | |

| Pulse Overlapping, Of (%) | 7.85 | 20.00 | 48.49 | 78.00 | 90.00 | |

| Peak power, Ppeak (W) | 150 | 150 | 160 | 170 | 170 | |

| Pulse width, τ (ms) | 0.180 | 0.187 | 0.190 | 0.194 | 0.200 | |

| Pulse energy, Ep (mJ) | 27.00 | 28.05 | 30.40 | 32.98 | 34.00 | |

| Trial | Tube | |||||||

|---|---|---|---|---|---|---|---|---|

| Tube A (OD = 3.0 mm & t = 0.22 mm) | Tube B (OD = 1.8 mm & t = 0.16 mm) | |||||||

| Of (%) | Ep (mJ) | Ra (μm) | Dbw (%) | Of (%) | Ep (mJ) | Ra (μm) | Dbw (%) | |

| 1 | 30.00 | 28.00 | 1.12 | 0.81 | 20.00 | 28.00 | 1.24 | 0.67 |

| 2 | 80.00 | 28.00 | 0.71 | 0.52 | 78.00 | 28.00 | 0.66 | 0.72 |

| 3 | 30.00 | 33.00 | 1.05 | 0.61 | 20.00 | 33.00 | 1.15 | 0.78 |

| 4 | 80.00 | 33.00 | 0.73 | 0.10 | 78.00 | 33.00 | 0.68 | 0.28 |

| 5 | 55.00 | 30.50 | 1.00 | 0.37 | 49.00 | 30.50 | 1.00 | 0.57 |

| 6 | 55.00 | 30.50 | 1.05 | 0.19 | 49.00 | 30.50 | 1.05 | 0.41 |

| 7 | 55.00 | 30.50 | 1.02 | 0.24 | 49.00 | 30.50 | 0.89 | 0.57 |

| 8 | 19.64 | 30.50 | 1.26 | 0.54 | 7.99 | 30.50 | 1.33 | 0.94 |

| 9 | 90.36 | 30.50 | 0.71 | 0.31 | 90.01 | 30.50 | 0.71 | 0.36 |

| 10 | 55.00 | 26.96 | 1.17 | 0.74 | 49.00 | 26.96 | 0.93 | 0.51 |

| 11 | 55.00 | 34.04 | 0.96 | 0.58 | 49.00 | 34.04 | 0.99 | 0.46 |

| 12 | 55.00 | 30.50 | 0.99 | 0.31 | 49.00 | 30.50 | 1.03 | 0.35 |

| 13 | 55.00 | 30.50 | 1.08 | 0.24 | 49.00 | 30.50 | 1.06 | 0.28 |

| 14 | 55.00 | 30.50 | 0.96 | 0.33 | 49.00 | 30.50 | 0.98 | 0.27 |

| Tube | Tube A (OD = 3.0 mm & t = 0.22 mm) | Tube B (OD = 1.8 mm & t = 0.16 mm) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Response | Ra | Dbw | Ra | Dbw | |||||

| R2 | 90.7 | 88.7 | 95.1 | 87.1 | |||||

| Source | DF | SS | P | SS | P | SS | P | SS | P |

| Blocks | 1 | 0.01 | 0.13 | 0.00 | 0.56 | 0.01 | 0.16 | 0.05 | 0.07 |

| Regression | 5 | 0.31 | 0.00 | 0.52 | 0.00 | 0.47 | 0.00 | 0.44 | 0.01 |

| Linear | 2 | 0.30 | 0.00 | 0.24 | 0.01 | 0.46 | 0.00 | 0.22 | 0.01 |

| Of | 1 | 0.28 | 0.00 | 0.16 | 0.01 | 0.46 | 0.00 | 0.20 | 0.00 |

| Ep | 1 | 0.01 | 0.13 | 0.09 | 0.02 | 0.00 | 0.97 | 0.02 | 0.20 |

| Quadratic | 2 | 0.02 | 0.25 | 0.27 | 0.00 | 0.01 | 0.34 | 0.14 | 0.02 |

| Of ×Of | 1 | 0.02 | 0.11 | 0.02 | 0.11 | 0.00 | 0.84 | 0.12 | 0.01 |

| Ep × Ep | 1 | 0.00 | 0.80 | 0.25 | 0.00 | 0.01 | 0.15 | 0.02 | 0.23 |

| Interaction | 1 | 0.00 | 0.54 | 0.01 | 0.30 | 0.00 | 0.38 | 0.07 | 0.03 |

| Of × Ep | 1 | 0.00 | 0.54 | 0.01 | 0.30 | 0.00 | 0.38 | 0.07 | 0.03 |

| Res. error | 7 | 0.03 | - | 0.07 | - | 0.02 | - | 0.07 | - |

| Lack of fit | 3 | 0.02 | 0.14 | 0.05 | 0.18 | 0.01 | 0.62 | 0.05 | 0.15 |

| Pure error | 4 | 0.01 | - | 0.02 | - | 0.02 | - | 0.02 | - |

| Total | 13 | 0.36 | - | 0.59 | - | 0.51 | - | 0.56 | - |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

García-López, E.; Ibarra-Medina, J.R.; Siller, H.R.; Lammel-Lindemann, J.A.; Rodriguez, C.A. Surface Finish and Back-Wall Dross Behavior during the Fiber Laser Cutting of AZ31 Magnesium Alloy. Micromachines 2018, 9, 485. https://doi.org/10.3390/mi9100485

García-López E, Ibarra-Medina JR, Siller HR, Lammel-Lindemann JA, Rodriguez CA. Surface Finish and Back-Wall Dross Behavior during the Fiber Laser Cutting of AZ31 Magnesium Alloy. Micromachines. 2018; 9(10):485. https://doi.org/10.3390/mi9100485

Chicago/Turabian StyleGarcía-López, Erika, Juansethi R. Ibarra-Medina, Hector R. Siller, Jan A. Lammel-Lindemann, and Ciro A. Rodriguez. 2018. "Surface Finish and Back-Wall Dross Behavior during the Fiber Laser Cutting of AZ31 Magnesium Alloy" Micromachines 9, no. 10: 485. https://doi.org/10.3390/mi9100485

APA StyleGarcía-López, E., Ibarra-Medina, J. R., Siller, H. R., Lammel-Lindemann, J. A., & Rodriguez, C. A. (2018). Surface Finish and Back-Wall Dross Behavior during the Fiber Laser Cutting of AZ31 Magnesium Alloy. Micromachines, 9(10), 485. https://doi.org/10.3390/mi9100485