Automatic Path Tracking and Target Manipulation of a Magnetic Microrobot

Abstract

:1. Introduction

2. Methods

2.1. Theoretical Background of Magnetic Microrobot

2.2. Close-Loop Control of the Microrobot

3. Experiments

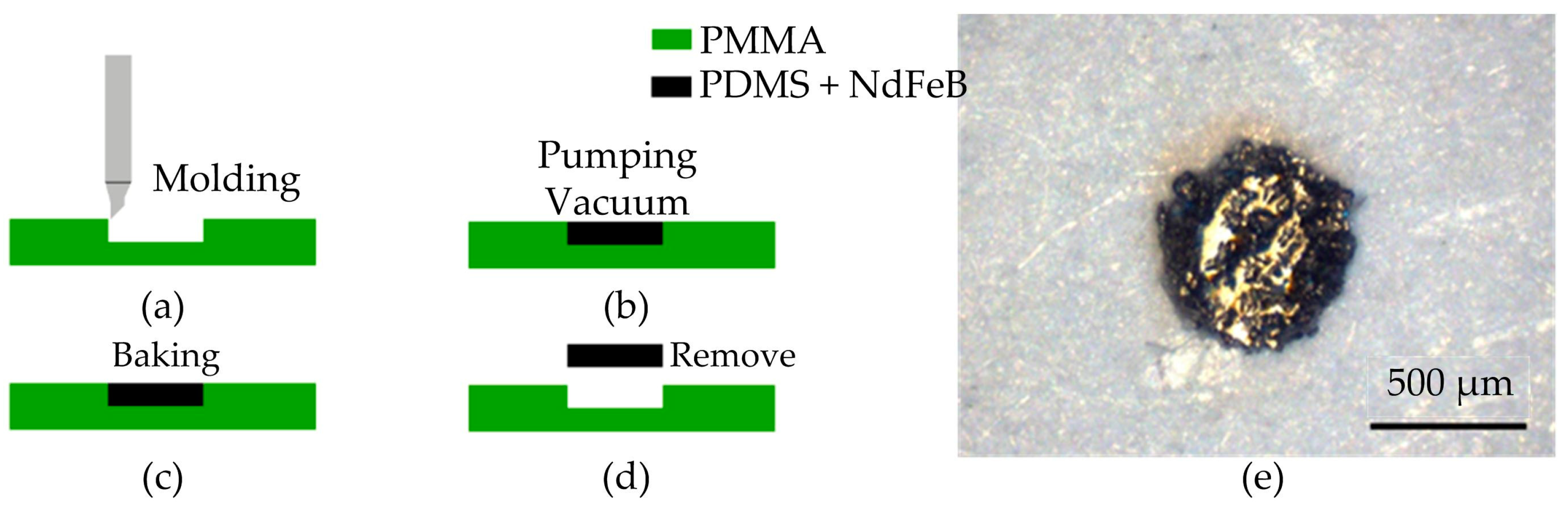

3.1. Theoretical Background of Magnetic Microrobot

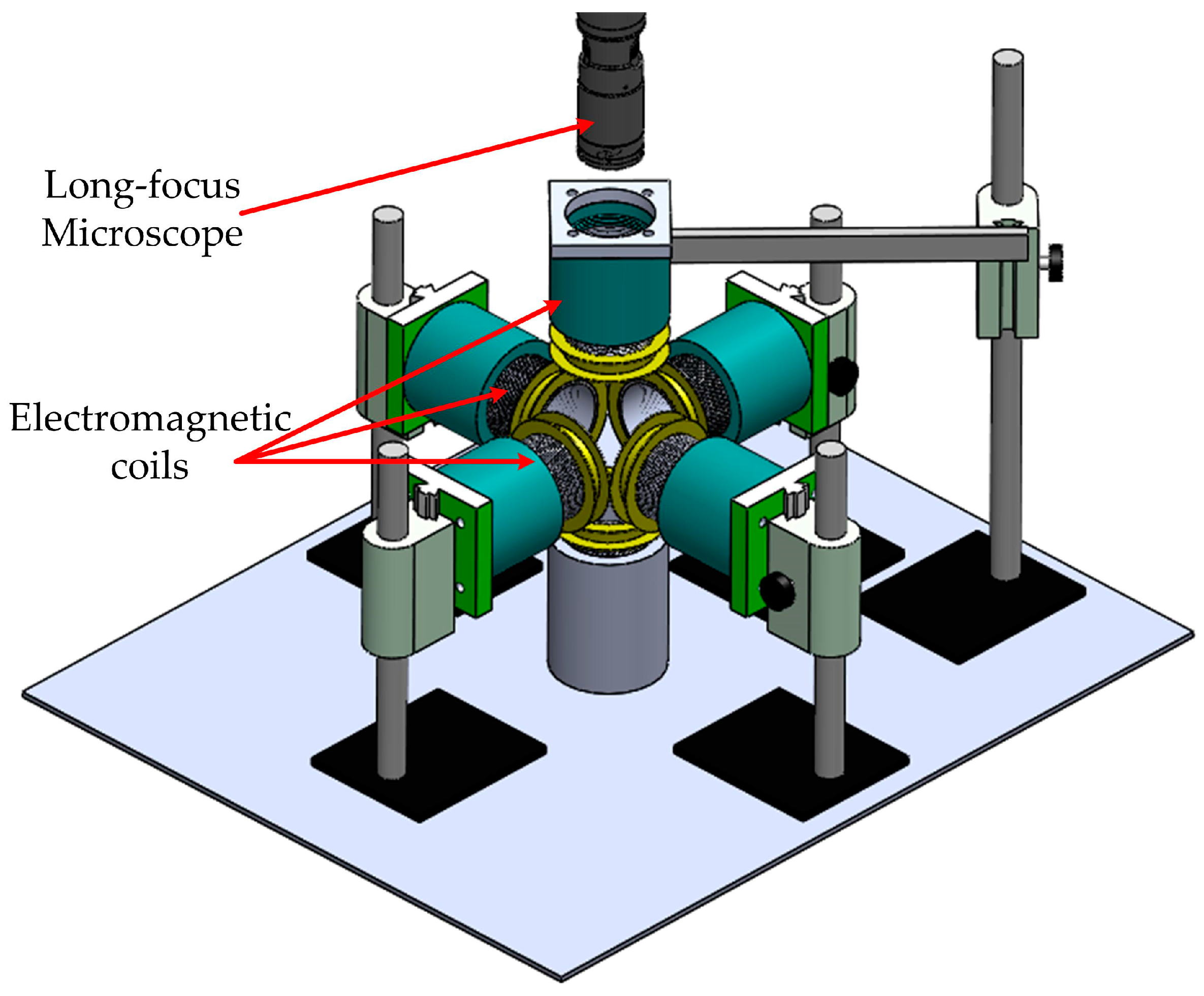

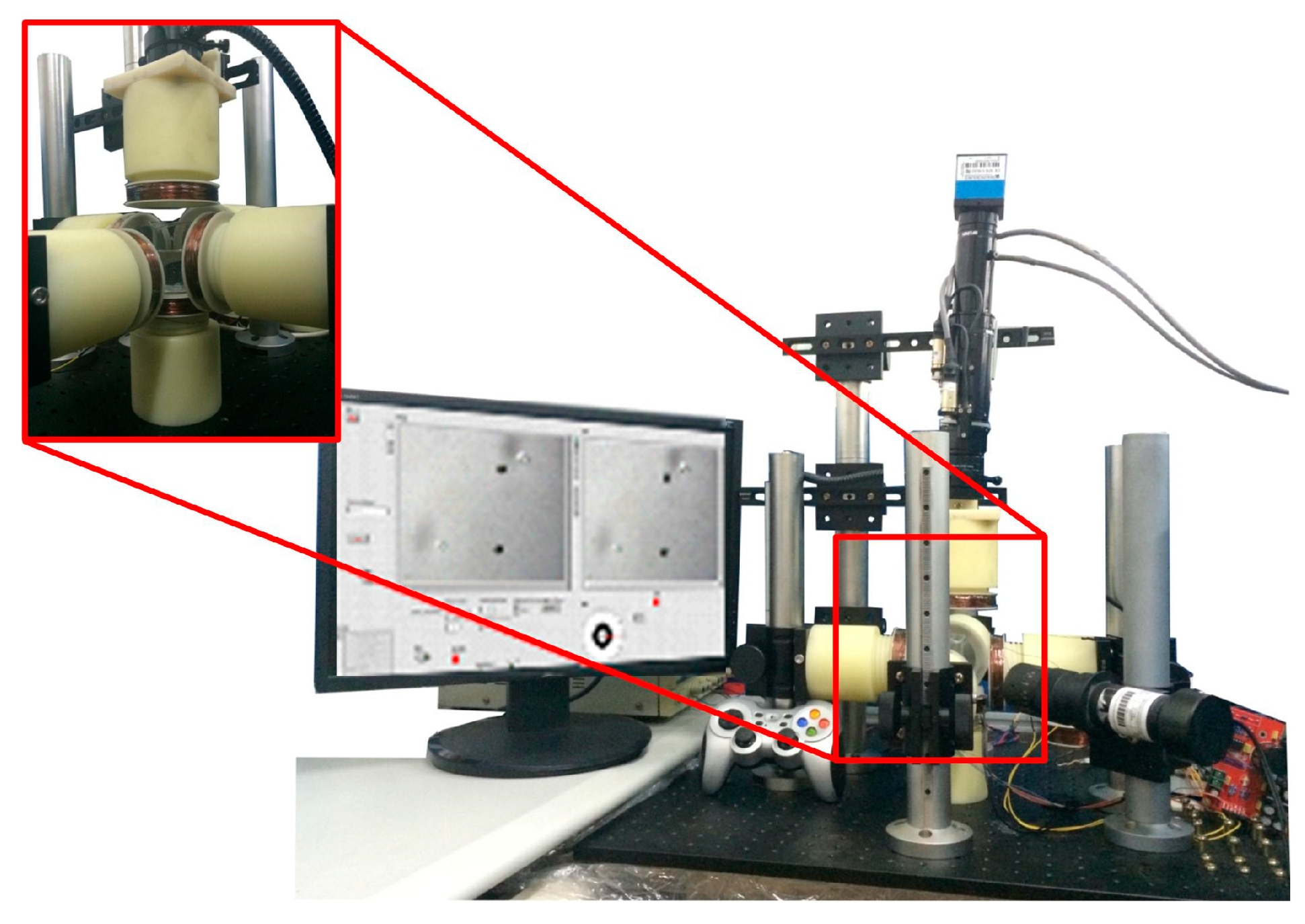

3.2. Design of the Electromagnetic Manipulation System

4. Results

4.1. Velocity Measurement

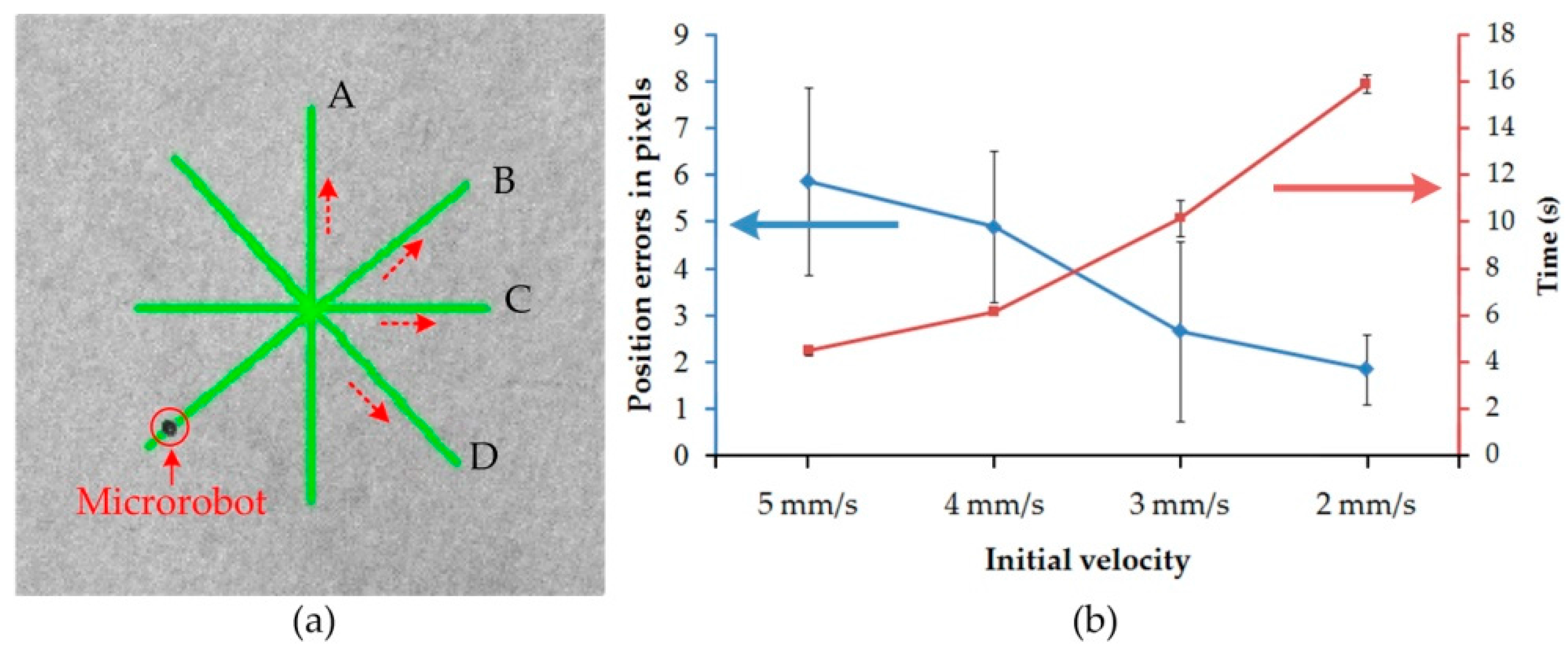

4.2. Performance of the Close-Loop Control

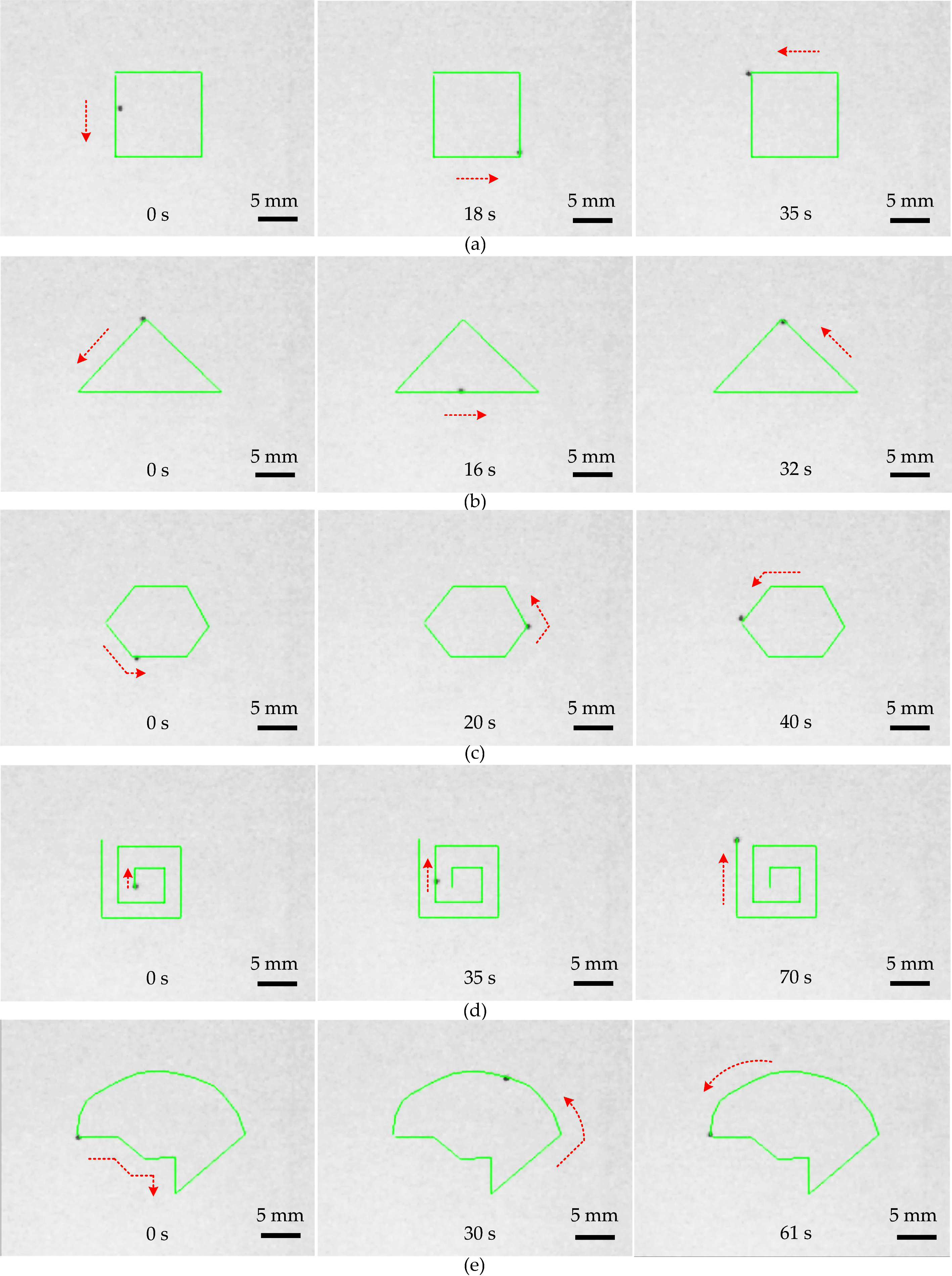

4.3. Close-Loop Tracking Performance of Microrobot

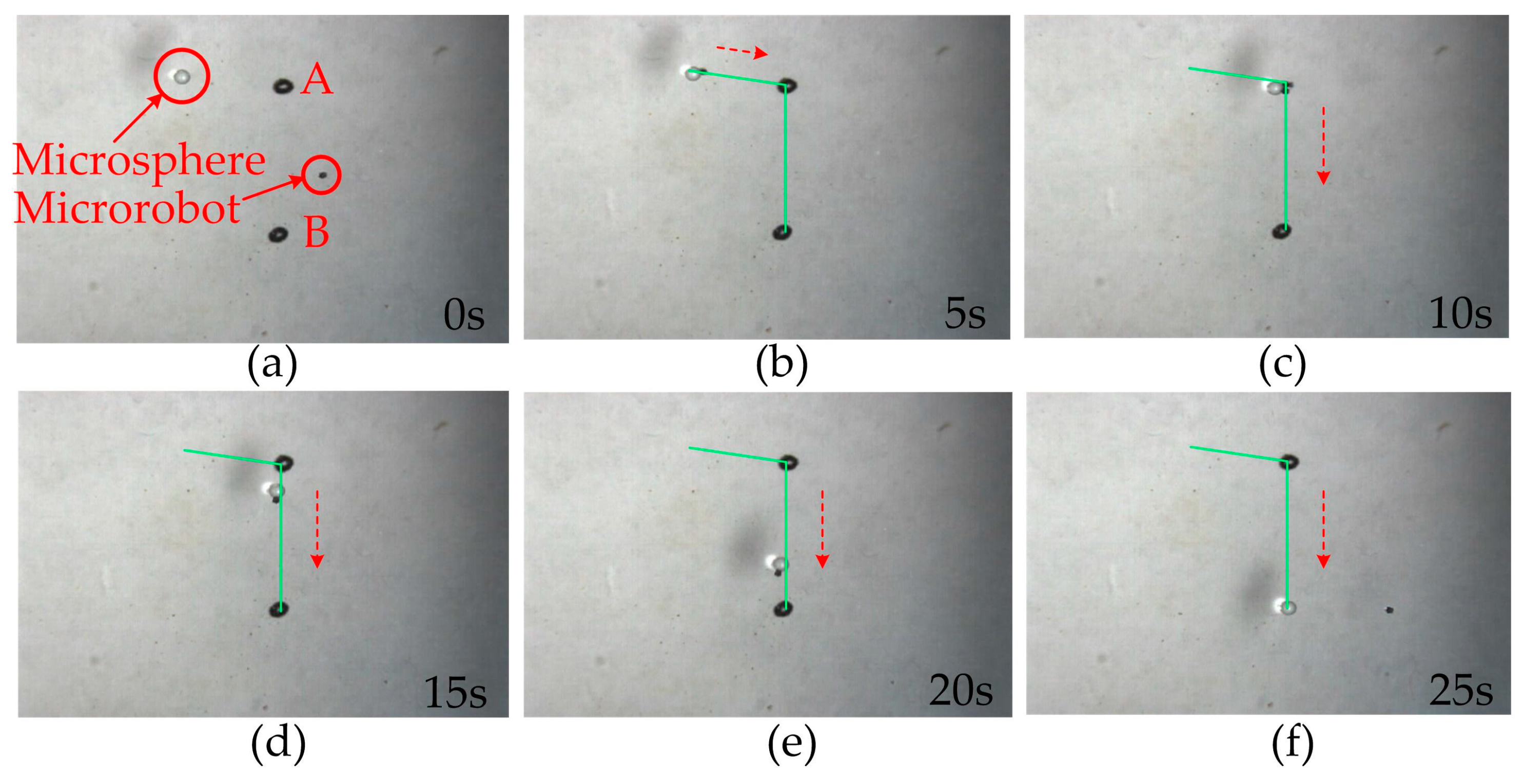

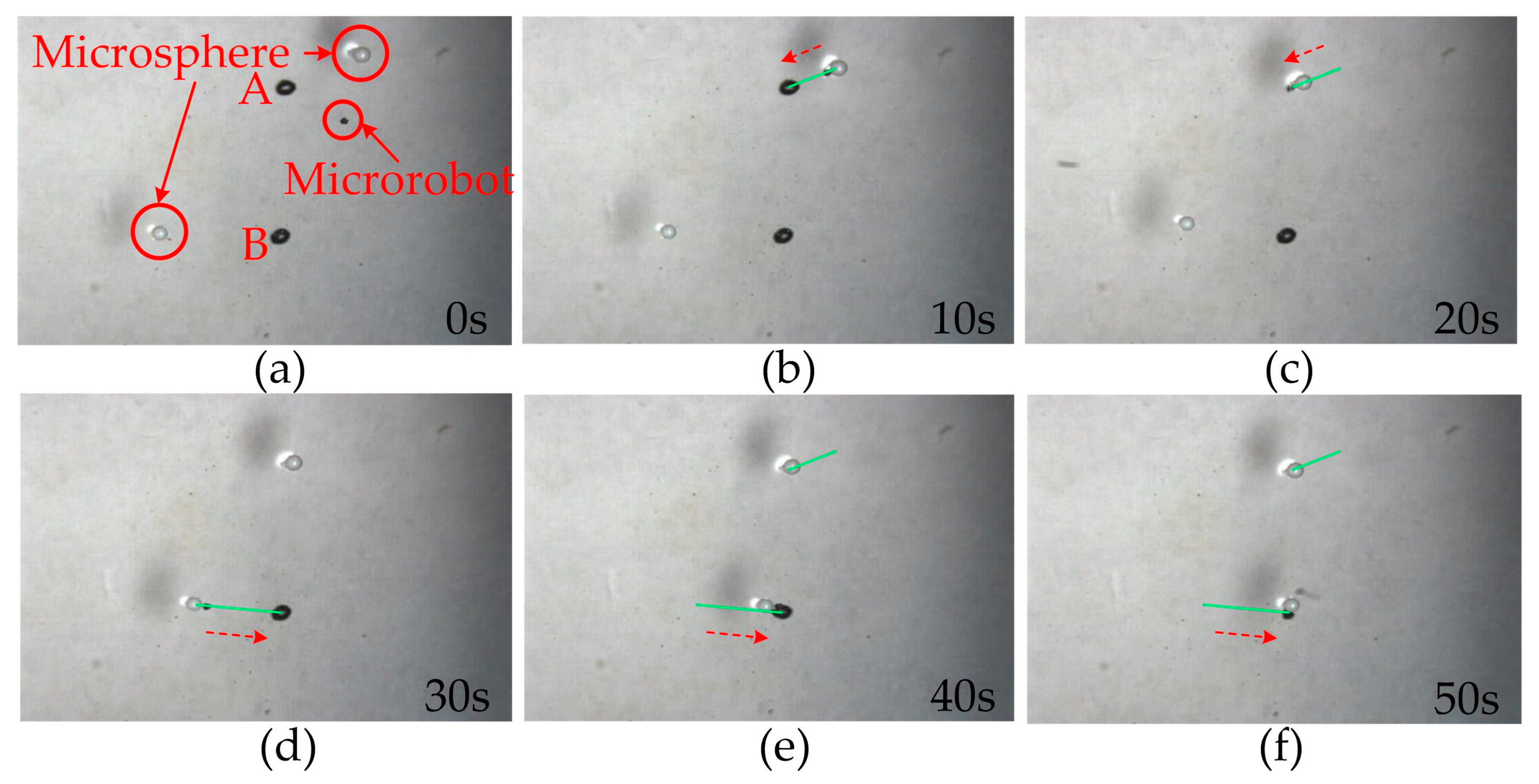

4.4. Manipulating Microspheres

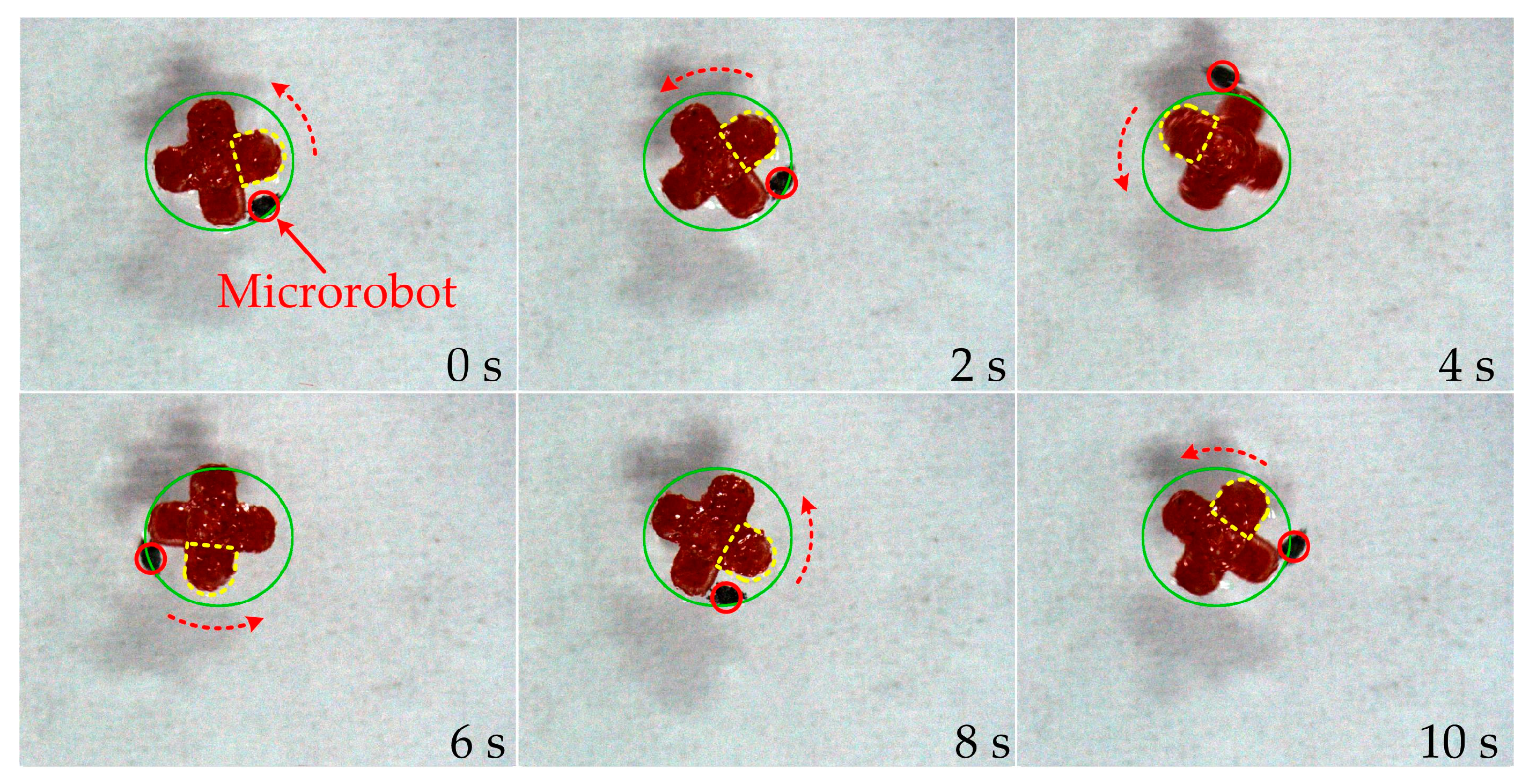

4.5. Manipulating Microgear

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Nelson, B.J.; Kaliakatsos, I.K.; Abbott, J.J. Microrobots for minimally invasive medicine. Annu. Rev. Biomed. Eng. 2010, 12, 55–85. [Google Scholar] [CrossRef] [PubMed]

- Go, G.; Choi, H.; Jeong, S.; Lee, C.; Ko, S.Y.; Park, J.-O.; Park, S. Electromagnetic navigation system using simple coil structure (4 Coils) for 3-D locomotive microrobot. IEEE Trans. Magn. 2015, 51, 1–7. [Google Scholar]

- Tottori, S.; Zhang, L.; Qiu, F.; Krawczyk, K.K.; Franco-Obregón, A.; Nelson, B.J. Magnetic helical micromachines: Fabrication, controlled swimming, and cargo transport. Adv. Mater. 2012, 24, 811–816. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.; Qiu, F.; Kim, S.; Ghanbari, A.; Moon, C.; Zhang, L.; Nelson, B.J.; Choi, H. Fabrication and characterization of magnetic microrobots for three-dimensional cell culture and targeted transportation. Adv. Mater. 2013, 25, 5863–5868. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Yue, M.; Guo, D.; Wang, D.; Yu, H.; Jiang, S.; Zhang, X. Characteristics of spatial magnetic torque of an intestine capsule micro robot with a variable diameter. Sci. China Ser. E Technol. Sci. 2009, 52, 2079–2086. [Google Scholar] [CrossRef]

- Diller, E.; Floyd, S.; Pawashe, C.; Sitti, M. Control of multiple heterogeneous magnetic microrobots in two dimensions on nonspecialized surfaces. IEEE Trans. Robot. 2012, 28, 172–182. [Google Scholar] [CrossRef]

- Chowdhury, S.; Jing, W.; Cappelleri, D.J. Controlling multiple microrobots: Recent progress and future challenges. J. Micro-Bio Robot. 2015, 10, 1–11. [Google Scholar] [CrossRef]

- Shen, X.; Viney, C.; Johnson, E.R.; Wang, C.; Lu, J.Q. Large negative thermal expansion of a polymer driven by a submolecular conformational change. Nat. Chem. 2013, 5, 1035–1041. [Google Scholar] [CrossRef] [PubMed]

- Búzás, A.; Kelemen, L.; Mathesz, A.; Oroszi, L.; Vizsnyiczai, G.; Vicsek, T.; Ormos, P. Light sailboats: Laser driven autonomous microrobots. Appl. Phys. Lett. 2012, 101, 041111. [Google Scholar] [CrossRef]

- Hwang, G.; Braive, R.; Couraud, L.; Cavanna, A.; Abdelkarim, O.; Robert-Philip, I.; Beveratos, A.; Sagnes, I.; Haliyo, S.; Régnier, S. Electro-osmotic propulsion of helical nanobelt swimmers. Int. J. Robot. Res. 2011, 30, 806–819. [Google Scholar] [CrossRef]

- Huang, C.; Lv, J.-A.; Tian, X.; Wang, Y.; Yu, Y.; Liu, J. Miniaturized swimming soft robot with complex movement actuated and controlled by remote light signals. Sci. Rep. 2015, 5, 17414. [Google Scholar] [CrossRef] [PubMed]

- Martel, S.; Felfoul, O.; Mathieu, J.-B.; Chanu, A.; Tamaz, S.; Mohammadi, M.; Mankiewicz, M.; Tabatabaei, N. Mri-based medical nanorobotic platform for the control of magnetic nanoparticles and flagellated bacteria for target interventions in human capillaries. Int. J. Robot. Res. 2009, 28, 1169–1182. [Google Scholar] [CrossRef] [PubMed]

- Martel, S.; Tremblay, C.C.; Ngakeng, S.; Langlois, G. Controlled manipulation and actuation of micro-objects with magnetotactic bacteria. Appl. Phys. Lett. 2006, 89, 233904. [Google Scholar] [CrossRef]

- Li, D.; Choi, H.; Cho, S.; Jeong, S.; Jin, Z.; Lee, C.; Ko, S.Y.; Park, J.O.; Park, S. A hybrid actuated microrobot using an electromagnetic field and flagellated bacteria for tumor-targeting therapy. Biotechnol. Bioeng. 2015, 112, 1623–1631. [Google Scholar] [CrossRef] [PubMed]

- Shull, P.; Niemeyer, G. Open-loop bilateral teleoperation for stable force tracking. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems, St. Louis, MO, USA, 10–15 October 2009; pp. 5121–5126.

- Wang, J.; Jiao, N.; Tung, S.; Liu, L. Magnetic microrobot and its application in a microfluidic system. Robot. Biomim. 2014, 1, 1–8. [Google Scholar] [CrossRef]

- Diller, E.; Sitti, M. Three-dimensional programmable assembly by untethered magnetic robotic micro-grippers. Adv. Funct. Mater. 2014, 24, 4397–4404. [Google Scholar] [CrossRef]

- Servant, A.; Qiu, F.; Mazza, M.; Kostarelos, K.; Nelson, B.J. Controlled in vivo swimming of a swarm of bacteria-like microrobotic flagella. Adv. Mater. 2015, 27, 2981–2988. [Google Scholar] [CrossRef] [PubMed]

- Xu, T.; Yu, J.; Yan, X.; Choi, H.; Zhang, L. Magnetic actuation based motion control for microrobots: An overview. Micromachines 2015, 6, 1346–1364. [Google Scholar] [CrossRef]

- Kim, S.J.; Jeon, S.M.; Nam, J.K.; Jang, G.H. Closed-loop control of a self-positioning and rolling magnetic microrobot on 3D thin surfaces using biplane imaging. IEEE Trans. Magn. 2014, 50, 1–4. [Google Scholar] [CrossRef]

- Ghanbari, A.; Chang, P.H.; Nelson, B.J.; Choi, H. Magnetic actuation of a cylindrical microrobot using time-delay-estimation closed-loop control: Modeling and experiments. Smart Mater. Struct. 2014, 23, 35013–35024. [Google Scholar] [CrossRef]

- Wong, D.; Steager, E.B.; Kumar, V. Independent control of identical magnetic robots in a plane. IEEE Robot. Autom. Lett. 2016, 1, 554–561. [Google Scholar] [CrossRef]

- Steager, E.B.; Sakar, M.S.; Magee, C.; Kennedy, M.; Cowley, A.; Kumar, V. Automated biomanipulation of single cells using magnetic microrobots. Int. J. Robot. Res. 2013, 32, 346–359. [Google Scholar] [CrossRef]

- Jiles, D.C. Introduction to Magnetism and Magnetic Materials; CRC Press: Boca Raton, FL, USA, 1998. [Google Scholar]

- Han, B.; Park, S.; Lee, S. Gradient waveform synthesis for magnetic propulsion using MRI gradient coils. Phys. Med. Biol. 2008, 53, 4639–4649. [Google Scholar] [CrossRef] [PubMed]

- Ocegueda, K.; Rodriguez, A. A simple method to calculate the signal-to-noise ratio of a circular-shaped coil for MRI. Concepts Magn. Reson. Part A 2006, 28, 422–429. [Google Scholar] [CrossRef]

- Yesin, K.B.; Vollmers, K.; Nelson, B.J. Modeling and control of untethered biomicrorobots in a fluidic environment using electromagnetic fields. Int. J. Robot. Res. 2006, 25, 527–536. [Google Scholar] [CrossRef]

| Coils | Coils Turns | Insider Radius/Outsider Radius (mm) | Diameter of Copper Wires (mm) | Resistance (Ω) | Iron Cores |

|---|---|---|---|---|---|

| Horizontal | 500 | 55/60 | 0.51 | 16 | Yes |

| Vertical | 500 | 55/60 | 0.51 | 16 | No |

© 2016 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Jiao, N.; Tung, S.; Liu, L. Automatic Path Tracking and Target Manipulation of a Magnetic Microrobot. Micromachines 2016, 7, 212. https://doi.org/10.3390/mi7110212

Wang J, Jiao N, Tung S, Liu L. Automatic Path Tracking and Target Manipulation of a Magnetic Microrobot. Micromachines. 2016; 7(11):212. https://doi.org/10.3390/mi7110212

Chicago/Turabian StyleWang, Jingyi, Niandong Jiao, Steve Tung, and Lianqing Liu. 2016. "Automatic Path Tracking and Target Manipulation of a Magnetic Microrobot" Micromachines 7, no. 11: 212. https://doi.org/10.3390/mi7110212

APA StyleWang, J., Jiao, N., Tung, S., & Liu, L. (2016). Automatic Path Tracking and Target Manipulation of a Magnetic Microrobot. Micromachines, 7(11), 212. https://doi.org/10.3390/mi7110212