Differential Single-Crystal Waveguide Ultrasonic Temperature Measurements Based on Magnetostriction

Abstract

1. Introduction

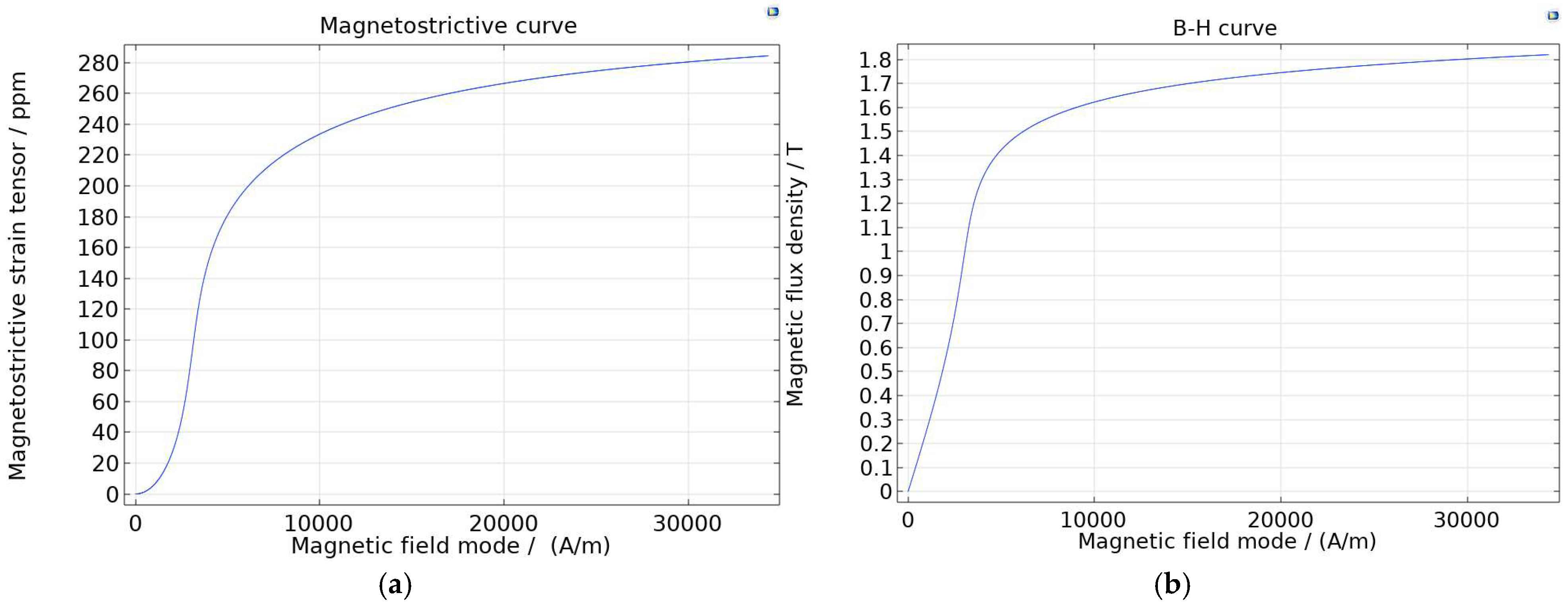

2. Experimental Principle

3. Preparation of Sensors

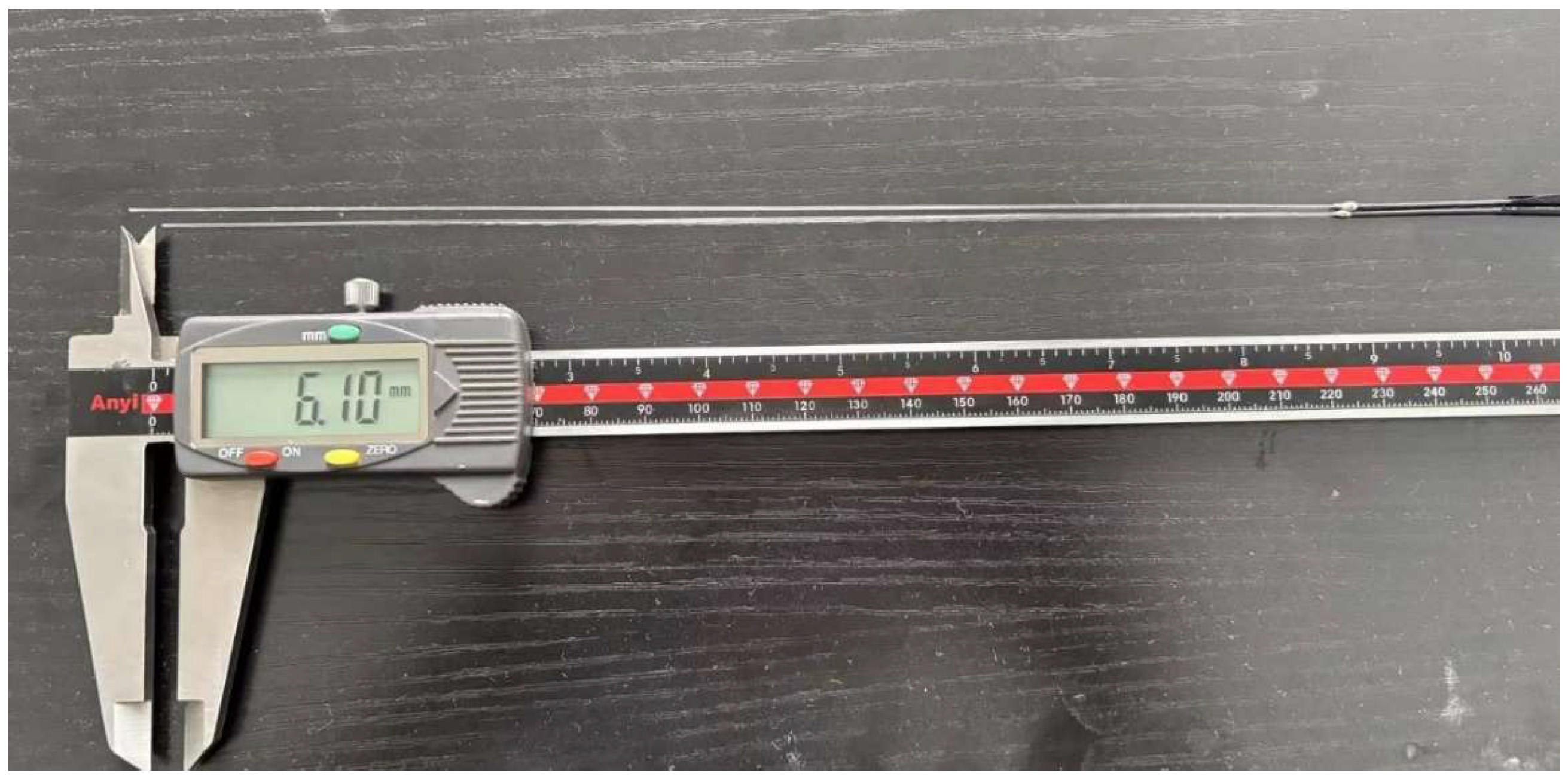

3.1. Sensor Selection

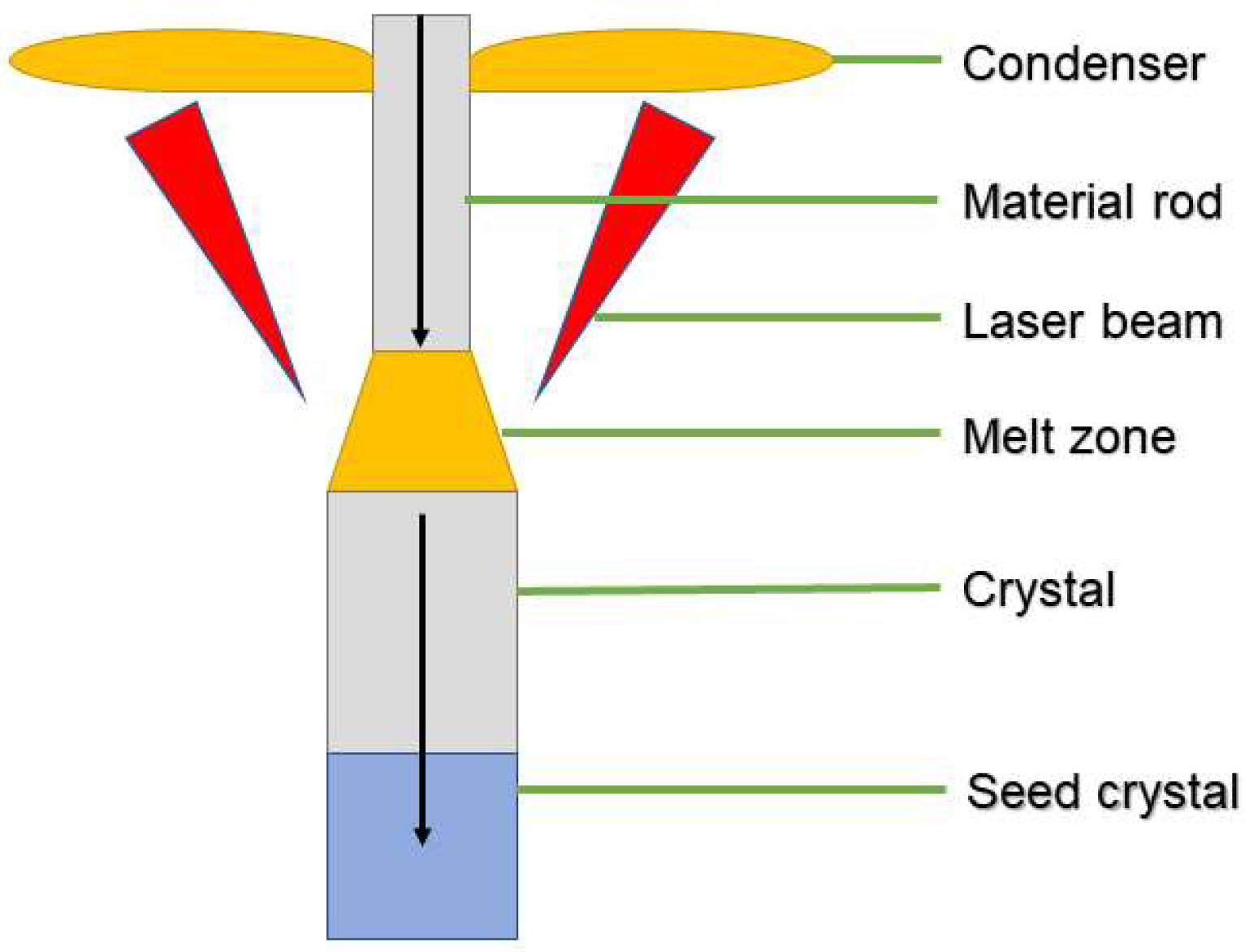

3.2. Sensor Fabrication

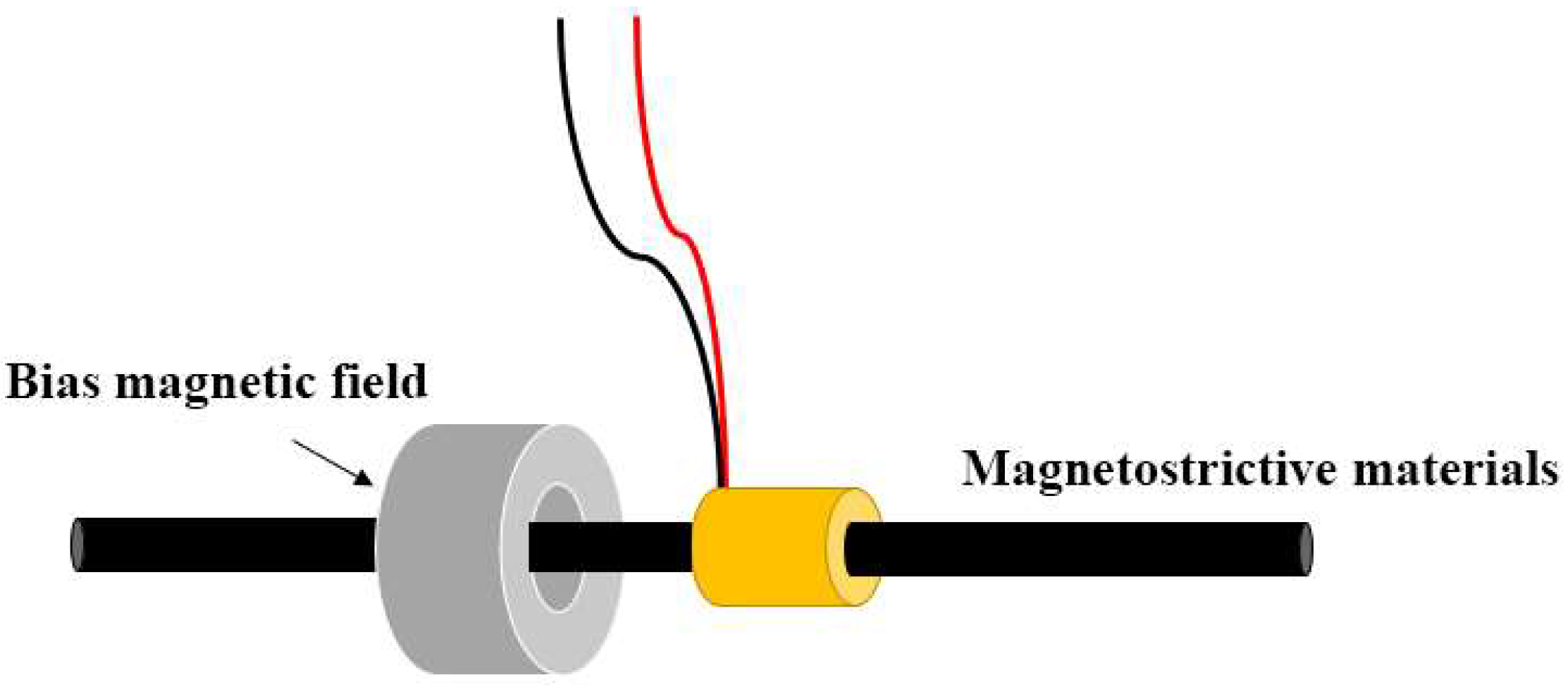

3.3. Preparation of Transducers

4. Experiment Details

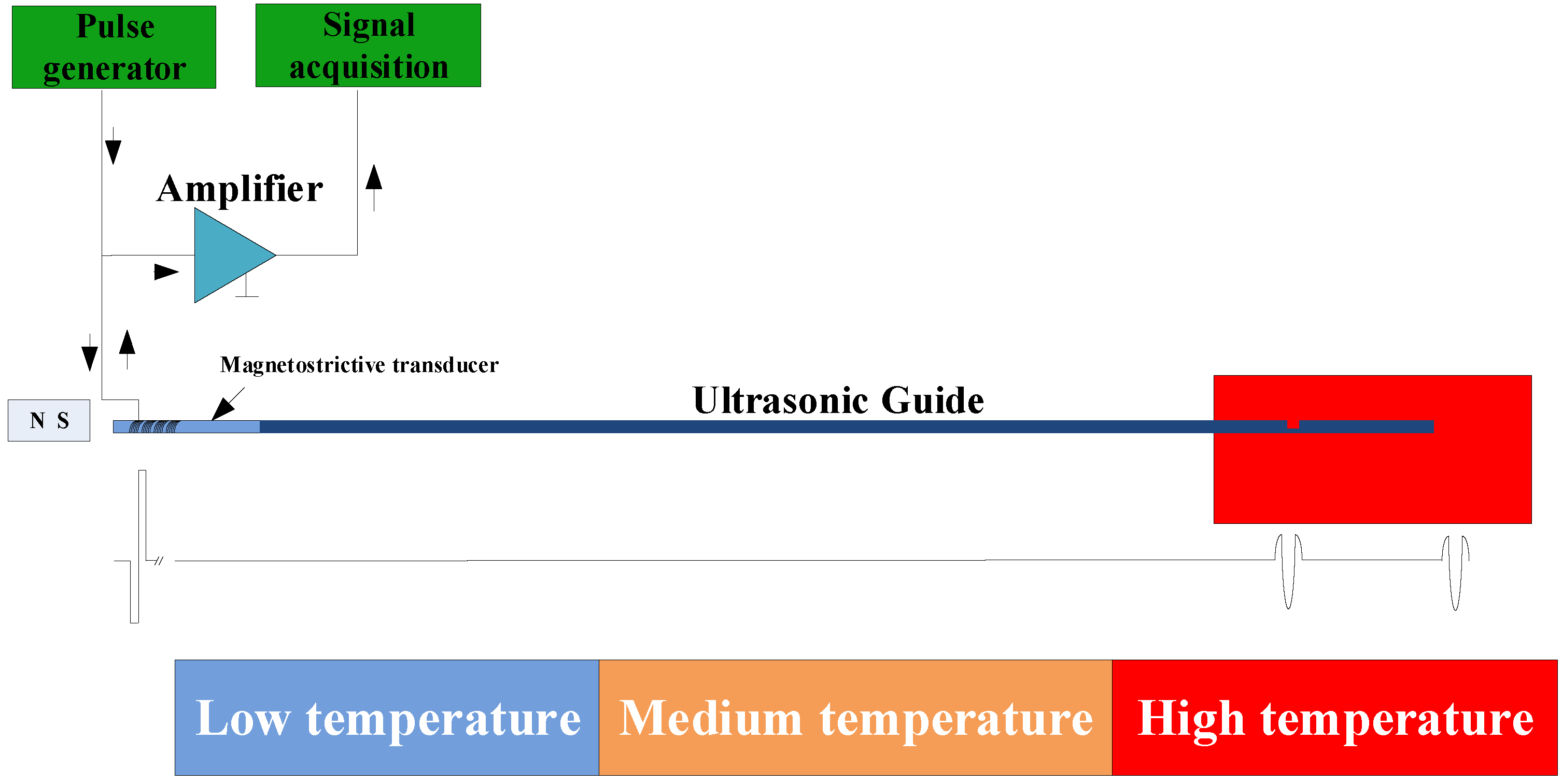

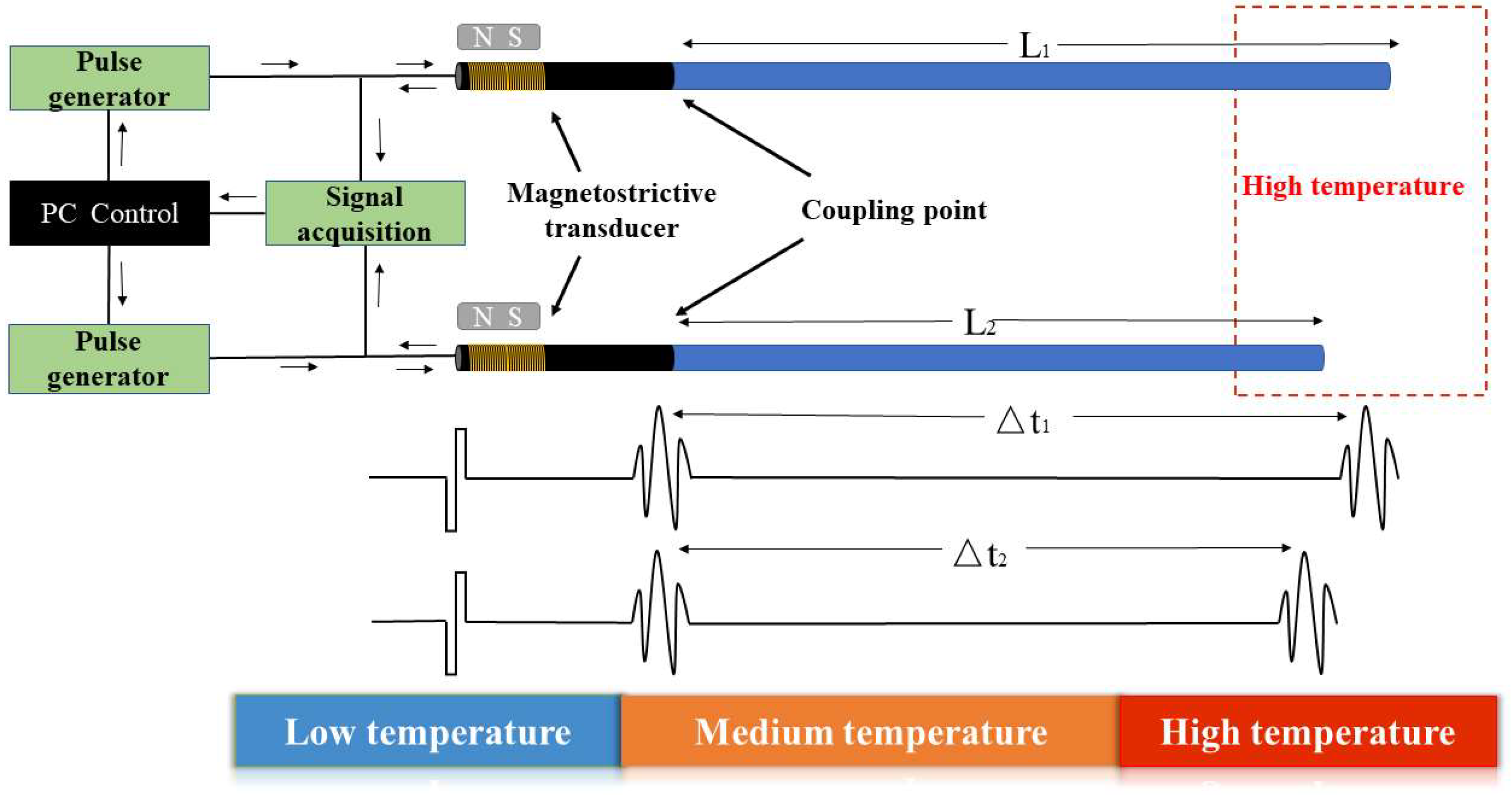

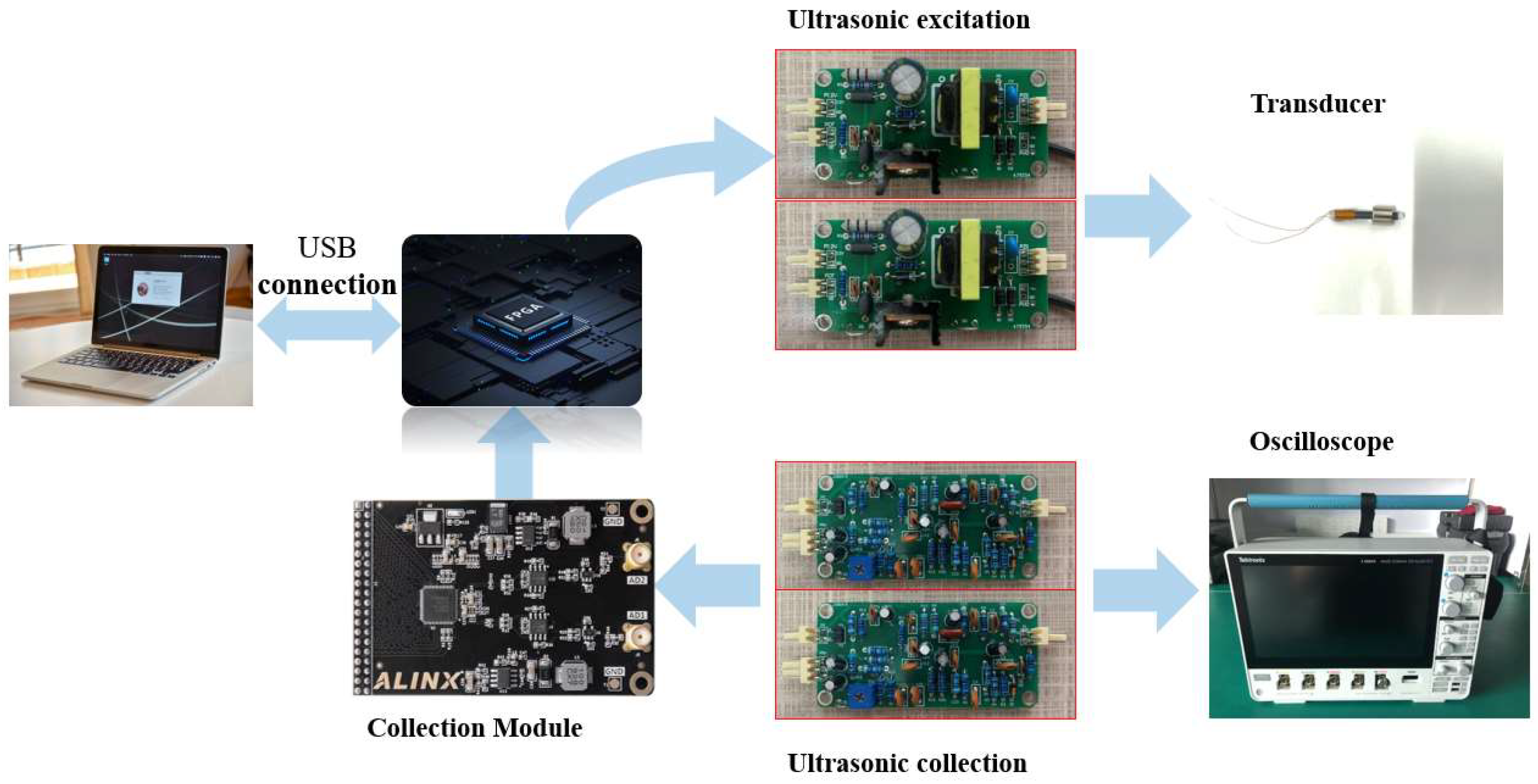

4.1. Differential Ultrasonic Excitation System

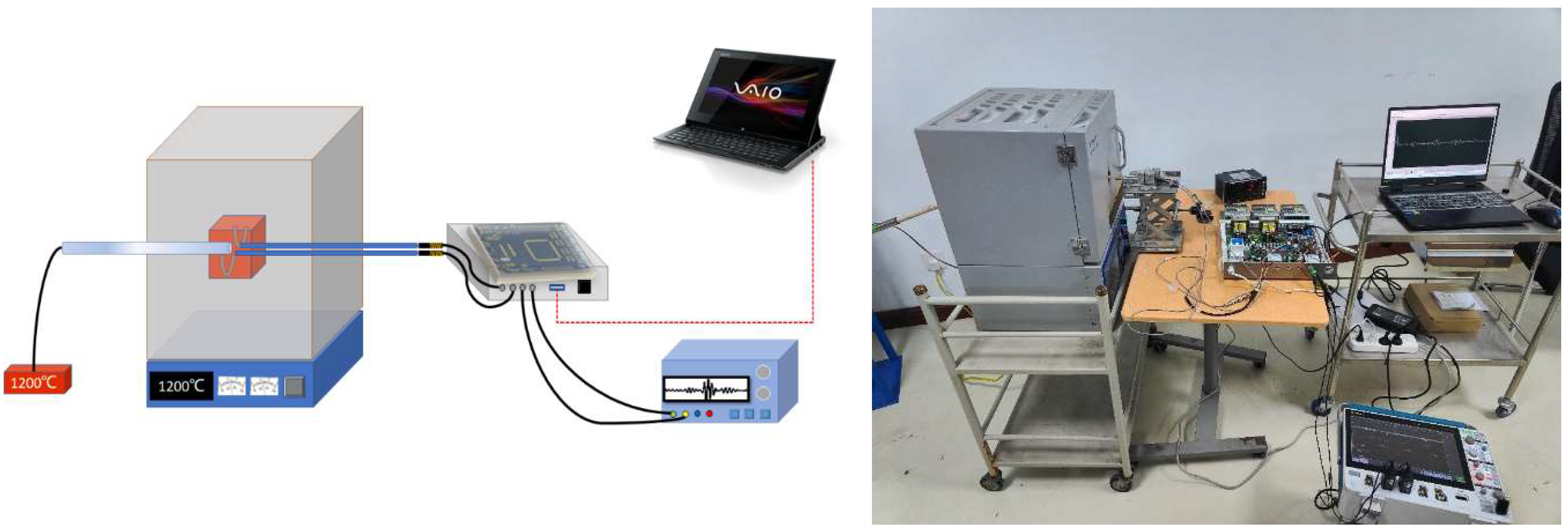

4.2. Experiment Setup

5. Data Processing and Analysis

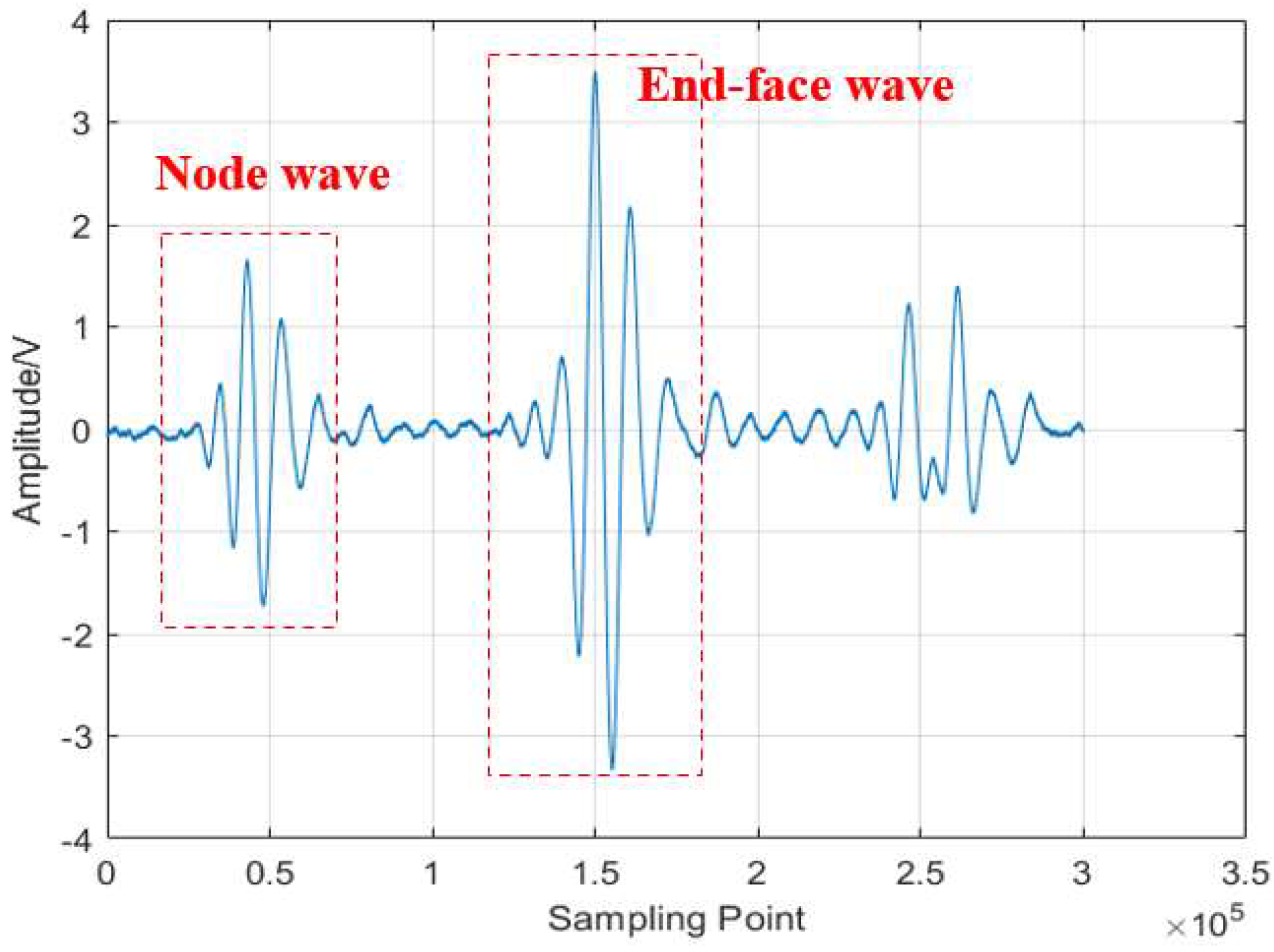

5.1. Data Processing

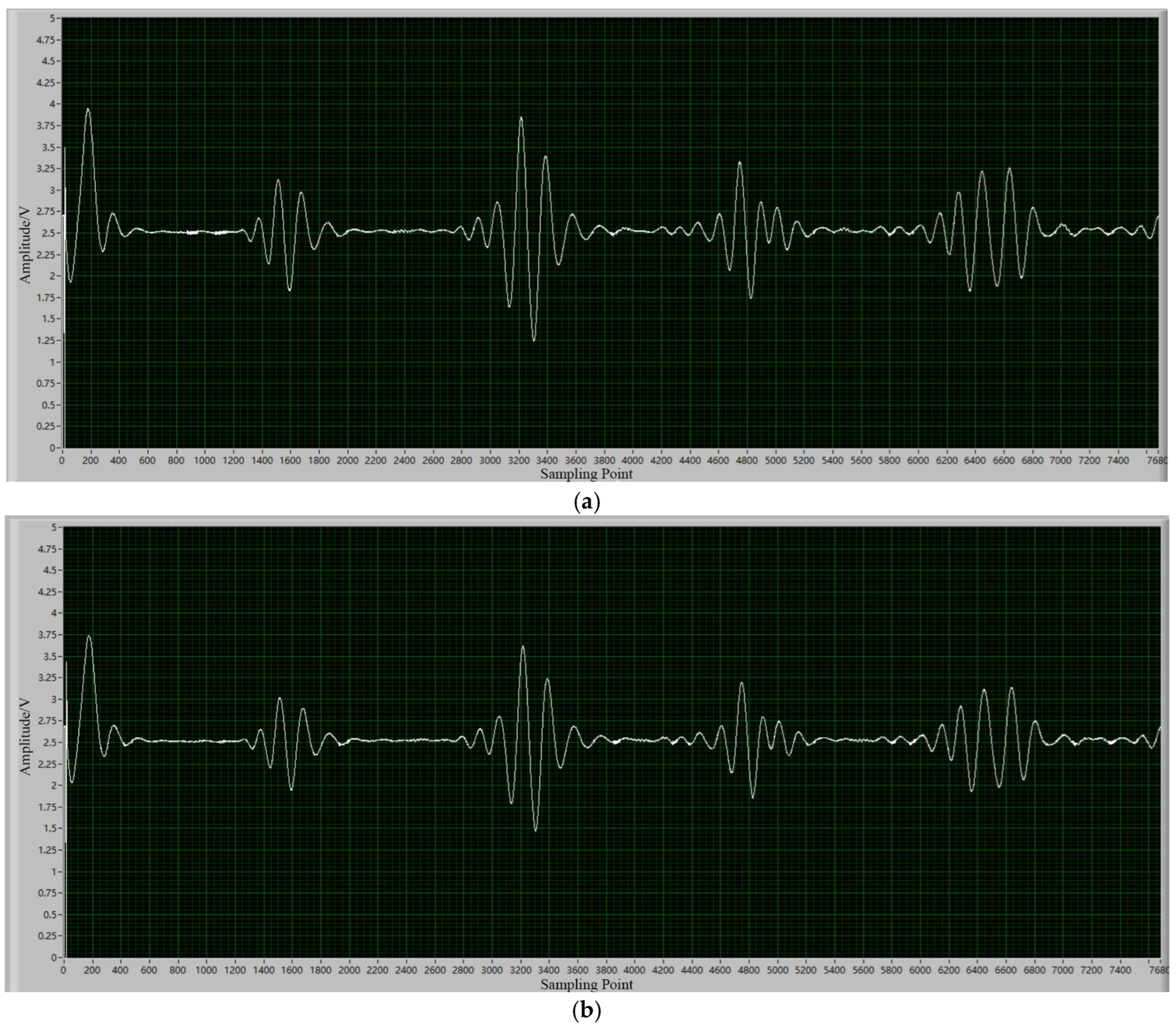

5.2. Discussion on Sensor Structure and Long-Term Stability of Transducer

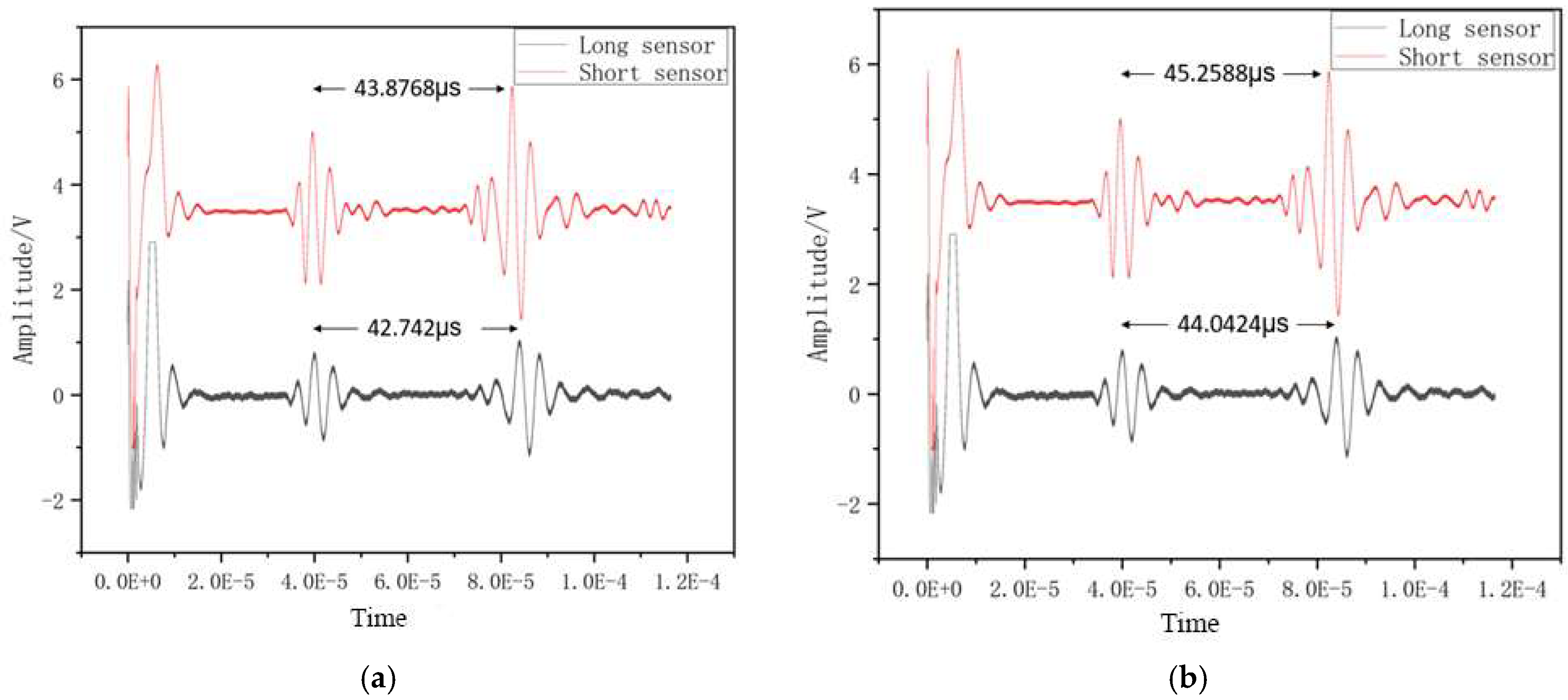

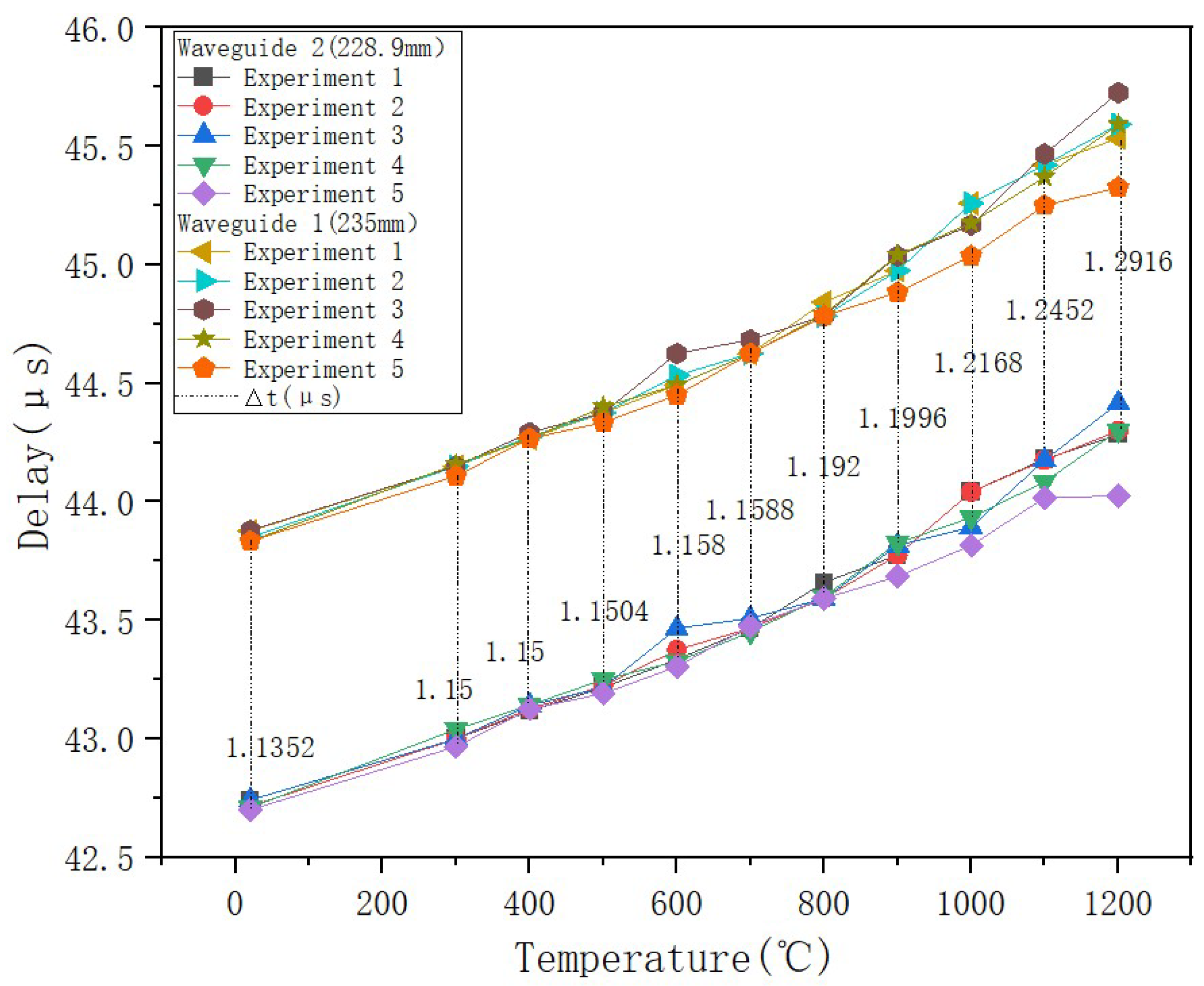

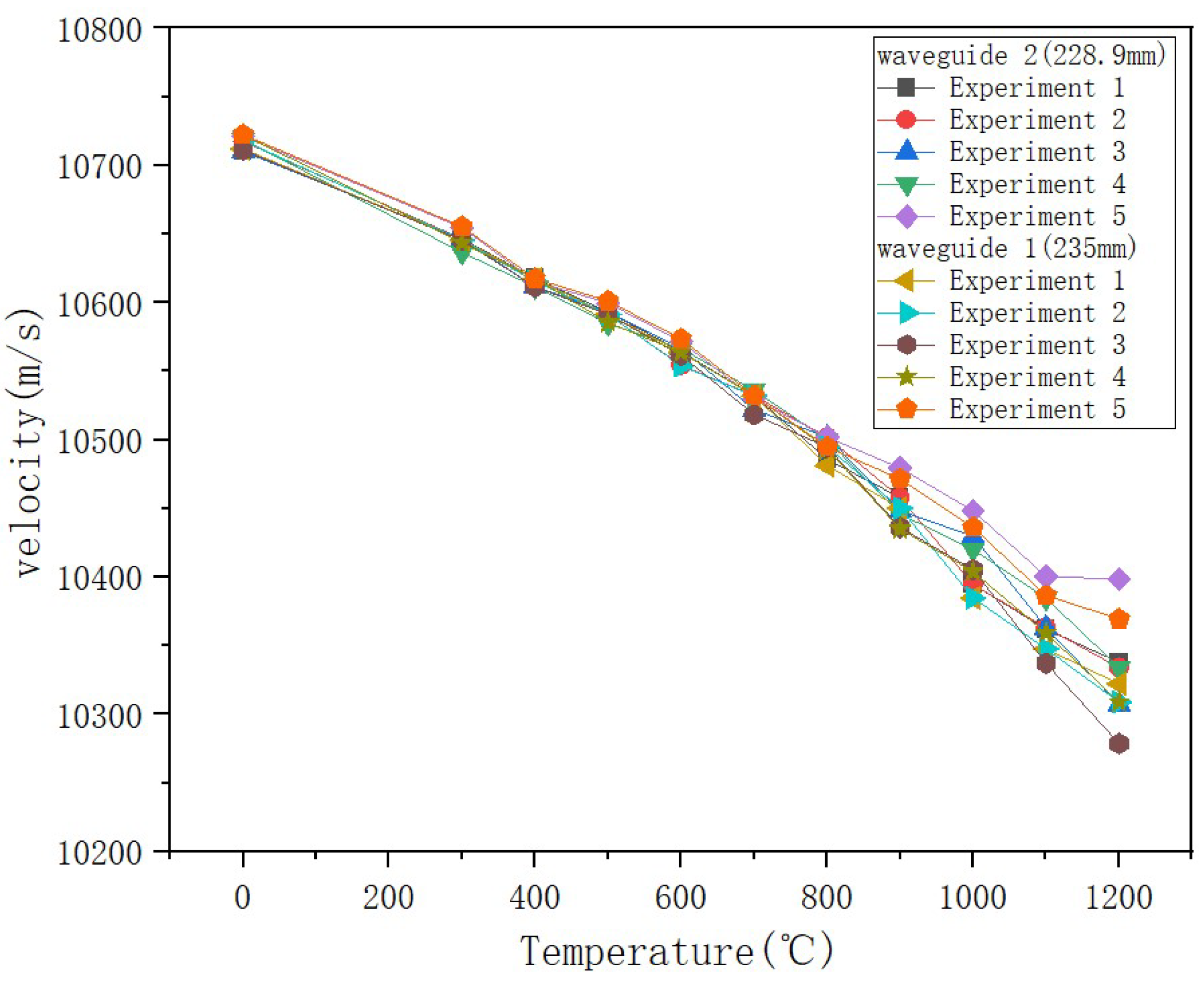

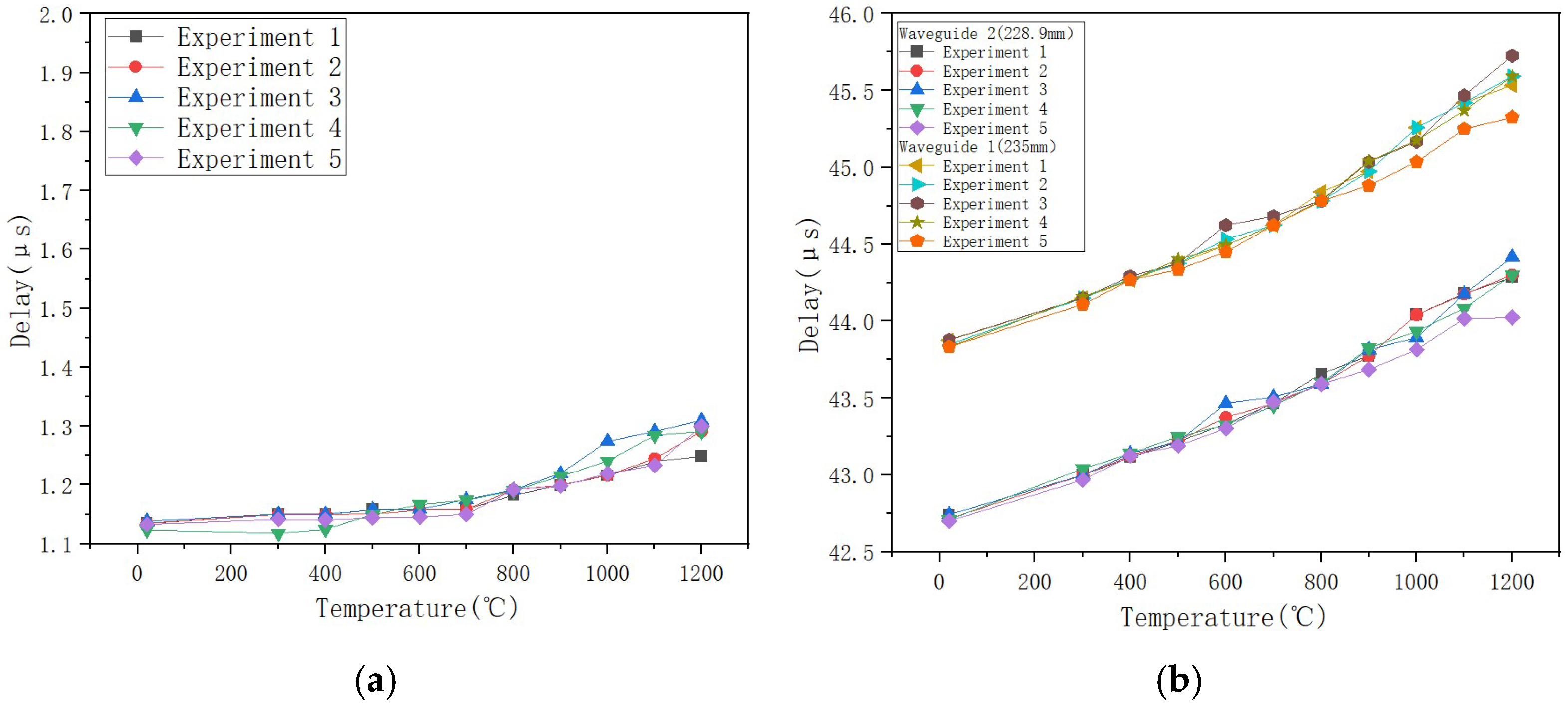

5.3. Data Analysis

5.4. An In-Depth Discussion of Differential Signal Fluctuations at High Temperatures

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wei, Y.; Gao, Y.; Xiao, Z.; Wang, G.; Tian, M.; Liang, H. Ultrasonic Al2O3 ceramic thermometry in high-temperature oxidation environment. Sensors 2016, 16, 1905. [Google Scholar] [CrossRef] [PubMed]

- Wang, T.; Zhang, J.; Yang, L.; Wang, G.; Zhang, N.; Wang, S.; Yin, Y.; Jia, Z.; Tao, X. Antioxidation and high-resolution ultrasonic temperature sensor based on Cr3+: MgAl2O4 single crystal fiber. Cryst. Growth Des. 2020, 20, 6763–6768. [Google Scholar] [CrossRef]

- Mayer, A.M., II. On an acoustic pyrometer. Lond. Edinb. Dublin Philos. Mag. J. Sci. 1873, 45, 18–22. [Google Scholar] [CrossRef]

- Wilkins, S.C. A single-crystal tungsten ultrasonic thermometer. In Proceedings of the Seventh International Symposium on Temperature: Its Measurement and Control in Science and Industry, Toronto, ON, Canada, 28 April–1 May 1992. [Google Scholar]

- Periyannan, S.; Balasubramaniam, K. Ultrasonic waveguide technique for temperature measurement using T (0, 1) wave mode. In Advances in Non-Destructive Evaluation: Proceedings of NDE 2019; Springer: Singapore, 2021; pp. 97–105. [Google Scholar]

- Lu, H.; Feng, Y.; Wang, S.; Liu, J.; Han, Q.; Meng, Q. A high-performance, sensitive, low-cost LIG/PDMS strain sensor for impact damage monitoring and localization in composite structures. Nanotechnology 2024, 35, 355702. [Google Scholar] [CrossRef]

- Xizhen, X.; Jun, H.; Jia, H.; Xu, B.; Chen, R.; Wang, Y.; Yang, Y.; Wang, Y. Efficient point-by-point Bragg grating inscription in sapphire fiber using femtosecond laser filaments. Opt. Lett. 2021, 46, 2742–2745. [Google Scholar]

- Wei, Y.L.; Liang, H.J.; Wang, G.; Wang, X.; Yang, L.; Zhou, H.; Yang, L.; Mu, X.; Yin, G. Ultrasonic thermometric measurement system for solid rocket combustion chambers. Ultrasonics 2021, 113, 106361. [Google Scholar] [CrossRef] [PubMed]

- Amini, M.H.; Sinclair, A.N.; Coyle, T.W. A new high-temperature ultrasonic transducer for continuous inspection. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2016, 63, 448–455. [Google Scholar] [CrossRef]

- Foudzi, F.M.; Ihara, I. Development of polygonal buffer rods for ultrasonic pulse-echo measurements. J. Phys. Conf. Ser. 2014, 520, 012025. [Google Scholar] [CrossRef]

- Hashmi, A.; Kalashnikov, A.N. Sensor data fusion for responsive high resolution ultrasonic temperature measurement using piezoelectric transducers. Ultrasonics 2019, 99, 105969. [Google Scholar] [CrossRef]

- Zhao, J.; Lan, Y.; Wiercigroch, M.; Li, W.; Chen, S.; Riemer, O.; Karpuschewski, B. Material removal and deformation mechanism in multiple nanoscratches of single crystal MgAl2O4. Mater. Des. 2025, 252, 113717. [Google Scholar] [CrossRef]

- Zeng, L.; Sun, X.; Hu, Y.; Duan, J. High sensitivity microdisplacement sensor based on fiber Bragg grating and amplification substrate. J. Cent. South Univ. 2022, 29, 3361–3367. [Google Scholar] [CrossRef]

- Bowler, A.L.; Pound, M.P.; Watson, N.J. A review of ultrasonic sensing and machine learning methods to monitor industrial processes. Ultrasonics 2022, 124, 106776. [Google Scholar] [CrossRef]

- Carnevale, E.H.; Lynnworth, L.C.; Larson, G.S. Ultrasonic measurement of elastic moduli at elevated temperatures, using momentary contact. J. Acoust. Soc. Am. 1964, 36, 1678–1684. [Google Scholar] [CrossRef]

- Amini, M.H.; Sinclair, A.N.; Coyle, T.W. High temperature ultrasonic transducer for real-time inspection. Phys. Procedia 2015, 70, 343–347. [Google Scholar] [CrossRef]

- Periyannan, S.; Balasubramaniam, K. Multi-level temperature measurements using ultrasonic waveguides. Measurement 2015, 61, 185–191. [Google Scholar] [CrossRef]

- Jia, Y.; Chernyshev, V.; Skliar, M. Ultrasound measurements of segmental temperature distribution in solids: Method and its high-temperature validation. Ultrasonics 2016, 66, 91–102. [Google Scholar] [CrossRef]

- Tanner, M.W. Multidimensional Modeling of Solid Propellant Burning Rates and Aluminum Agglomeration and One-Dimensional Modeling of RDX/GAP and AP/HTPB. Diss. Theses Gradworks 2008, 9, 1245–1256. [Google Scholar]

- David, R.; Hunter, I.W. A liquid-in-glass thermometer read by an interferometer. Sens. Actuators A Phys. 2005, 121, 31–34. [Google Scholar] [CrossRef]

- Zhou, J.; Guo, X.; Du, C.; Cao, C.; Wang, X. A Fiber Optic Ultrasonic Sensing System for High Temperature Monitoring Using Optically Generated Ultrasonic Waves. Sensors 2019, 19, 404–416. [Google Scholar] [CrossRef]

- Lynnworth, L.C.; Papadakis, E.P.; Patch, D.R.; Fowler, K.A.; Shepard, R.L. Nuclear Reactor Applications of New Ultrasonic Transducers. IEEE Trans. Nucl. Sci. 2007, 18, 351–362. [Google Scholar] [CrossRef]

- Jia, Y.; Skliar, M. Noninvasive Ultrasound Measurements of Temperature Distribution and Heat Fluxes in Solids. Energy Fuels 2016, 30, 4363–4371. [Google Scholar] [CrossRef]

- Liang, H.; Yang, F.; Yang, L.; Liu, Z.; Wang, G.; Wei, Y.; Xue, H. Research and implementation of a 1800 °C sapphire ultrasonic thermometer. J. Sens. 2017, 7, 9710763. [Google Scholar] [CrossRef]

| Density (g·cm−3) | Bending Hardness (MPa) | Young’s Modulus (GPa) | Melting Point (°C) | Thermal Conductivity (W·m−1 K−1) | Thermal Expansion Coefficient (K) |

|---|---|---|---|---|---|

| 3.98 | 300–400 | 300–400 | 2053 | 35 | 5.8 × 10−6 |

| Temperature (°C) | Time Delay (μs) | ||||

|---|---|---|---|---|---|

| First Experiment | Second Experiment | Third Experiment | Fourth Experiment | Fifth Experiment | |

| 20 | 43.8768 | 43.8512 | 43.88 | 43.834 | 43.834 |

| 300 | 44.1504 | 44.1504 | 44.1508 | 44.1588 | 44.1092 |

| 400 | 44.2676 | 44.2756 | 44.292 | 44.2664 | 44.2664 |

| 500 | 44.3756 | 44.3756 | 44.3756 | 44.4008 | 44.3352 |

| 600 | 44.4924 | 44.5336 | 44.6252 | 44.4924 | 44.4504 |

| 700 | 44.6252 | 44.6256 | 44.6836 | 44.625 | 44.6256 |

| 800 | 44.8424 | 44.784 | 44.784 | 44.7904 | 44.784 |

| 900 | 44.9748 | 44.9748 | 45.0364 | 45.0412 | 44.8836 |

| 1000 | 45.2588 | 45.2588 | 45.1684 | 45.1756 | 45.036 |

| 1100 | 45.4208 | 45.4208 | 45.4672 | 45.37 | 45.2504 |

| 1200 | 45.5336 | 45.592 | 45.726 | 45.592 | 45.3256 |

| Temperature (°C) | Time Delay (μs) | ||||

|---|---|---|---|---|---|

| First Experiment | Second Experiment | Third Experiment | Fourth Experiment | Fifth Experiment | |

| 20 | 42.742 | 42.716 | 42.7412 | 42.7104 | 42.7008 |

| 300 | 43.0004 | 43.0004 | 43.0004 | 43.0408 | 42.9676 |

| 400 | 43.1168 | 43.1256 | 43.1416 | 43.1416 | 43.1256 |

| 500 | 43.2172 | 43.2252 | 43.2172 | 43.2508 | 43.1908 |

| 600 | 43.3344 | 43.3756 | 43.4664 | 43.3256 | 43.3048 |

| 700 | 43.4664 | 43.4668 | 43.5084 | 43.4508 | 43.4756 |

| 800 | 43.6596 | 43.592 | 43.592 | 43.6 | 43.592 |

| 900 | 43.7752 | 43.7752 | 43.8164 | 43.826 | 43.6852 |

| 1000 | 44.0424 | 44.042 | 43.8936 | 43.9344 | 43.8164 |

| 1100 | 44.1808 | 44.1756 | 44.1756 | 44.085 | 44.0172 |

| 1200 | 44.284 | 44.3004 | 44.416 | 44.3004 | 44.0256 |

| Temperature (°C) | Speed of Sound (m/s) | ||||

|---|---|---|---|---|---|

| First Experiment | Second Experiment | Third Experiment | Fourth Experiment | Fifth Experiment | |

| 20 | 10,711.81125 | 10,718.06473 | 10,711.03008 | 10,722.27038 | 10,722.27038 |

| 300 | 10,645.43017 | 10,645.43017 | 10,645.33372 | 10,643.40516 | 10,655.37348 |

| 400 | 10,617.24602 | 10,615.32763 | 10,611.39709 | 10,617.53384 | 10,617.53384 |

| 500 | 10,591.40609 | 10,591.40609 | 10,591.40609 | 10,585.39486 | 10,601.0574 |

| 600 | 10,563.60187 | 10,553.82902 | 10,561.70282 | 10,563.60187 | 10,573.58314 |

| 700 | 10,532.16568 | 10,532.07128 | 10,518.40049 | 10,532.21289 | 10,532.07128 |

| 800 | 10,481.15177 | 10,494.81958 | 10,494.81958 | 10,493.32 | 10,494.81958 |

| 900 | 10,450.29661 | 10,450.29661 | 10,436.00288 | 10,434.89072 | 10,471.5308 |

| 1000 | 10,384.72076 | 10,384.72076 | 10,405.50473 | 10,403.84632 | 10,436.09557 |

| 1100 | 10,347.68212 | 10,347.68212 | 10,337.12215 | 10,359.26824 | 10,386.64852 |

| 1200 | 10,322.04789 | 10,320.14404 | 10,278.6161 | 10,308.82611 | 10,369.41596 |

| Temperature (°C) | Speed of Sound (m/s) | ||||

|---|---|---|---|---|---|

| First Experiment | Second Experiment | Third Experiment | Fourth Experiment | Fifth Experiment | |

| 20 | 10,710.77629 | 10,717.29563 | 10,709.97445 | 10,718.70083 | 10,721.11061 |

| 300 | 10,646.41259 | 10,646.41259 | 10,646.41259 | 10,636.4194 | 10,654.5397 |

| 400 | 10,617.67107 | 10,615.50448 | 10,611.56749 | 10,611.56749 | 10,615.50448 |

| 500 | 10,593.00464 | 10,591.04411 | 10,593.00464 | 10,584.77531 | 10,599.47952 |

| 600 | 10,564.35534 | 10,554.32086 | 10,566.5011 | 10,566.5011 | 10,571.57636 |

| 700 | 10,532.2732 | 10,532.17628 | 10,522.10608 | 10,536.05457 | 10,530.04444 |

| 800 | 10,485.66638 | 10,501.92696 | 10,501.92696 | 10,500 | 10,501.92696 |

| 900 | 10,457.97621 | 10,457.97621 | 10,448.1427 | 10,445.85406 | 10,479.52167 |

| 1000 | 10,394.52891 | 10,394.62331 | 10,429.76653 | 10,420.08085 | 10,448.1427 |

| 1100 | 10,361.96719 | 10,363.18692 | 10,363.18692 | 10,384.48452 | 10,400.47981 |

| 1200 | 10,337.81953 | 10,333.99247 | 10,307.09654 | 10,333.99247 | 10,398.49542 |

| Temperature (°C) | Speed of Sound (m/s) | ||||

|---|---|---|---|---|---|

| First Experiment | Second Experiment | Third Experiment | Fourth Experiment | Fifth Experiment | |

| 20 | 10,750.79309 | 10,747.00493 | 10,750.79309 | 10,857.95657 | 10,765.97247 |

| 300 | 10,608.69565 | 10,608.69565 | 10,605.00695 | 10,912.34347 | 10,686.75543 |

| 400 | 10,601.32082 | 10,608.69565 | 10,605.00695 | 10,846.37269 | 10,694.24965 |

| 500 | 10,531.76796 | 10,605.00695 | 10,531.76796 | 10,608.69565 | 10,660.60818 |

| 600 | 10,535.40587 | 10,535.40587 | 10,384.74634 | 10,455.94789 | 10,649.44134 |

| 700 | 10,528.13255 | 10,528.13255 | 10,381.21171 | 10,390.0528 | 10,608.69565 |

| 800 | 10,314.50795 | 10,234.89933 | 10,234.89933 | 10,248.65591 | 10,234.89933 |

| 900 | 10,170.05669 | 10,170.05669 | 10,000 | 10,039.49967 | 10,180.24032 |

| 1000 | 10,029.59553 | 10,026.29849 | 9570.128648 | 9829.197551 | 10,003.27976 |

| 1100 | 9838.709677 | 9797.622872 | 9445.648808 | 9494.163424 | 9892.961401 |

| 1200 | 9763.1242 | 9445.648808 | 9312.977099 | 9445.648808 | 9384.615385 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wei, Y.; Yang, G.; Wang, G.; Liang, H.; Qi, H.; Mu, X.; Tian, Z.; Yuan, F.; Zhang, Q. Differential Single-Crystal Waveguide Ultrasonic Temperature Measurements Based on Magnetostriction. Micromachines 2025, 16, 1274. https://doi.org/10.3390/mi16111274

Wei Y, Yang G, Wang G, Liang H, Qi H, Mu X, Tian Z, Yuan F, Zhang Q. Differential Single-Crystal Waveguide Ultrasonic Temperature Measurements Based on Magnetostriction. Micromachines. 2025; 16(11):1274. https://doi.org/10.3390/mi16111274

Chicago/Turabian StyleWei, Yanlong, Gang Yang, Gao Wang, Haijian Liang, Hui Qi, Xiaofang Mu, Zhen Tian, Fujiang Yuan, and Qianxiang Zhang. 2025. "Differential Single-Crystal Waveguide Ultrasonic Temperature Measurements Based on Magnetostriction" Micromachines 16, no. 11: 1274. https://doi.org/10.3390/mi16111274

APA StyleWei, Y., Yang, G., Wang, G., Liang, H., Qi, H., Mu, X., Tian, Z., Yuan, F., & Zhang, Q. (2025). Differential Single-Crystal Waveguide Ultrasonic Temperature Measurements Based on Magnetostriction. Micromachines, 16(11), 1274. https://doi.org/10.3390/mi16111274