On the Development of a New Flexible Pressure Sensor

Abstract

1. Introduction

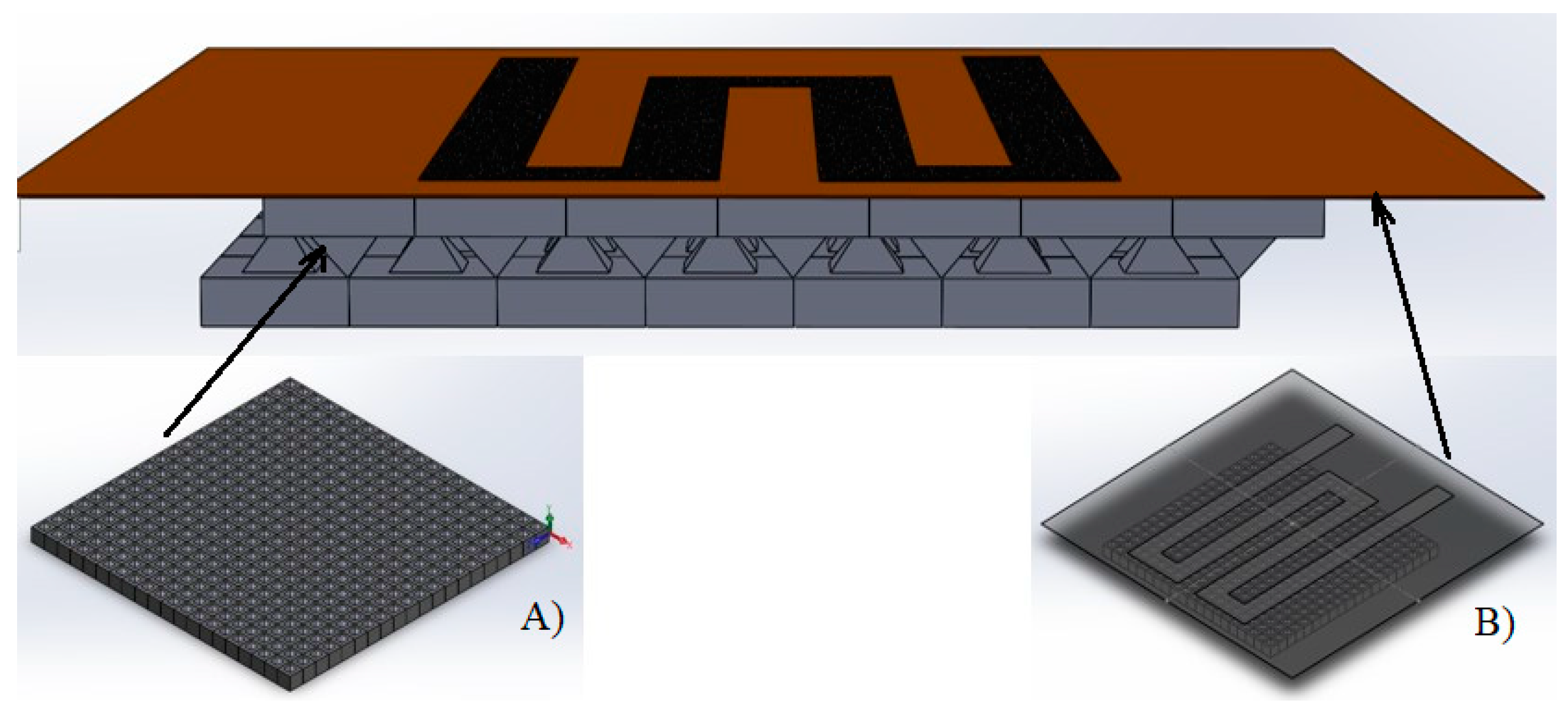

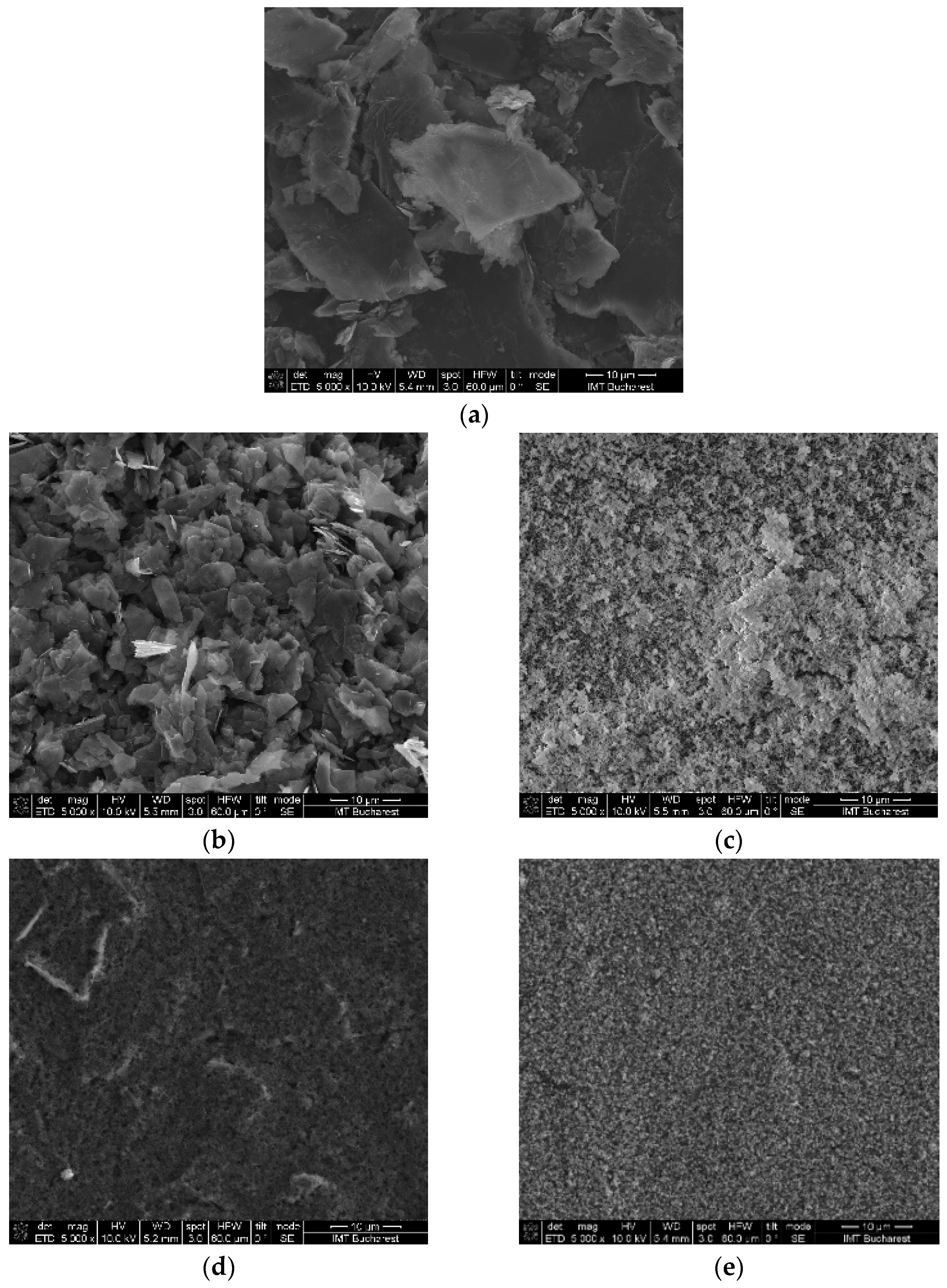

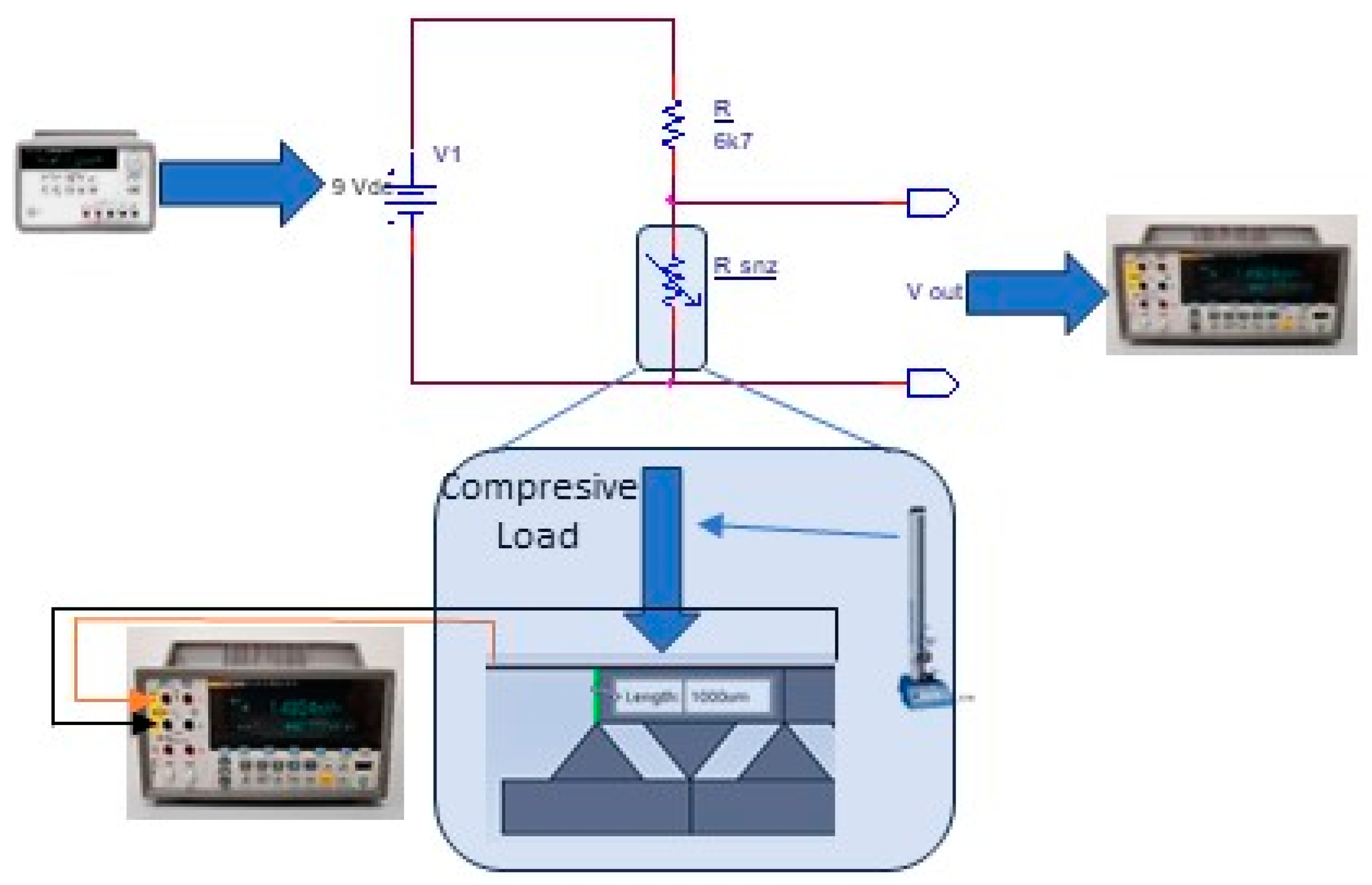

2. Materials and Methods

Method of Testing

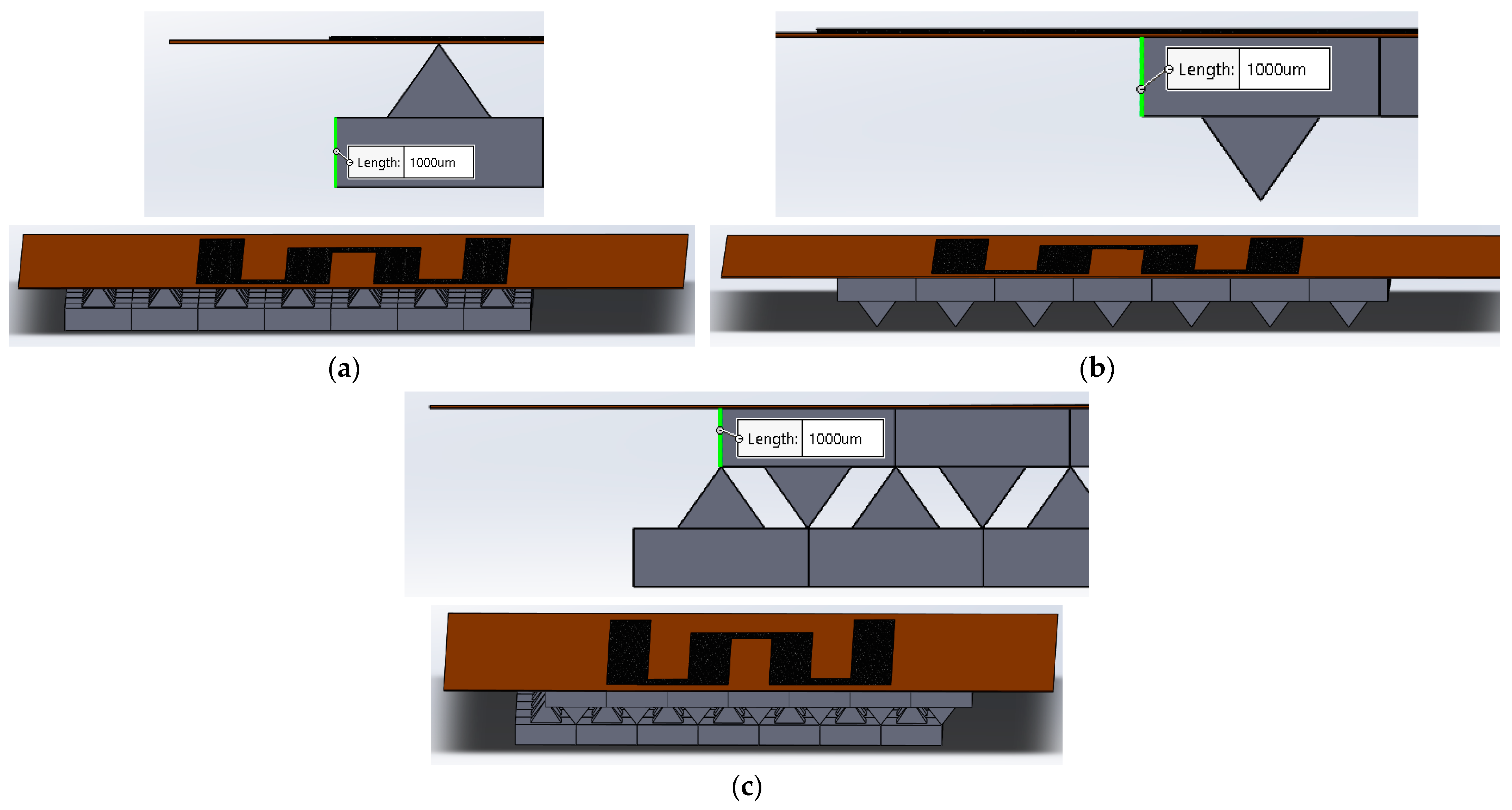

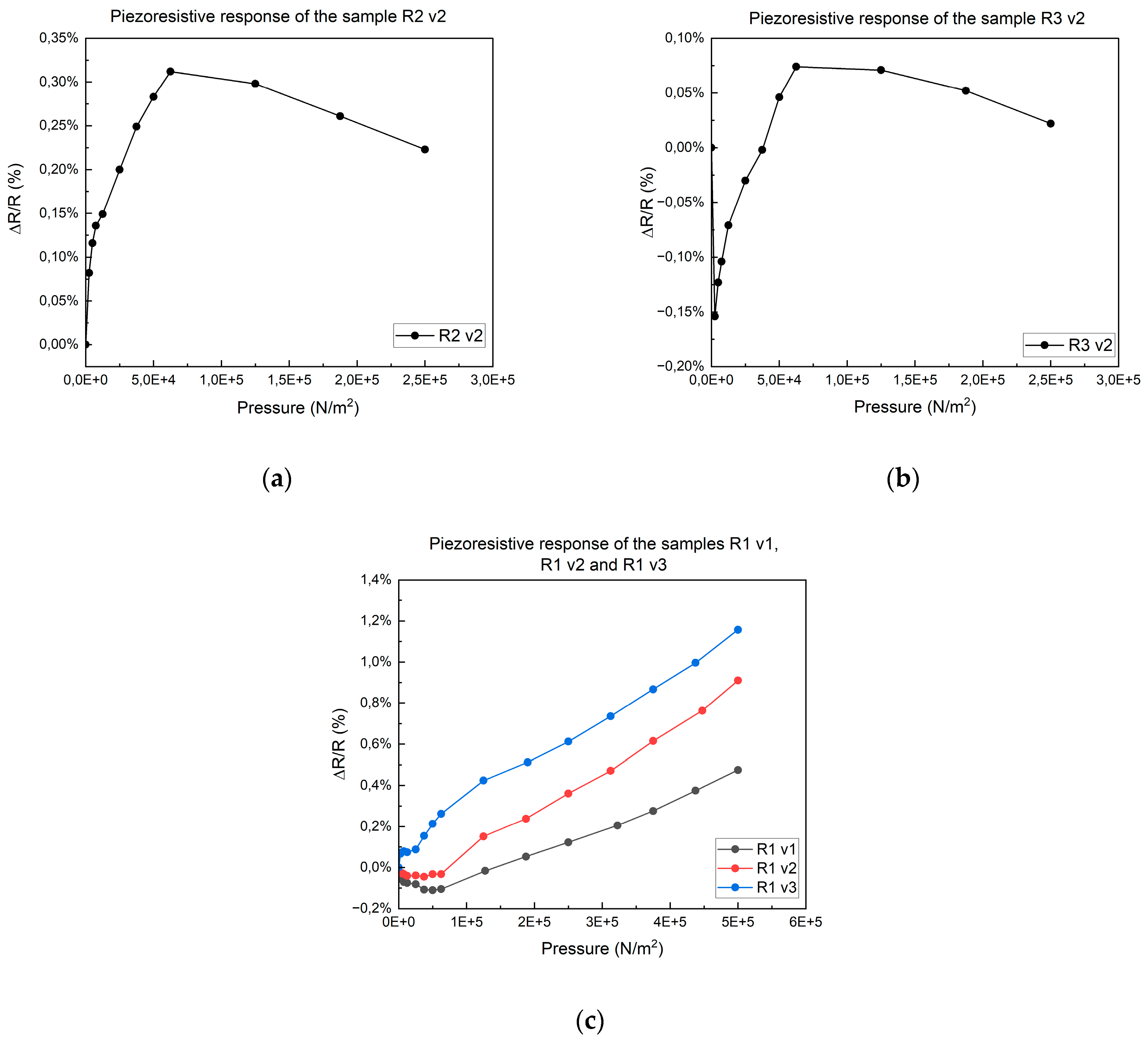

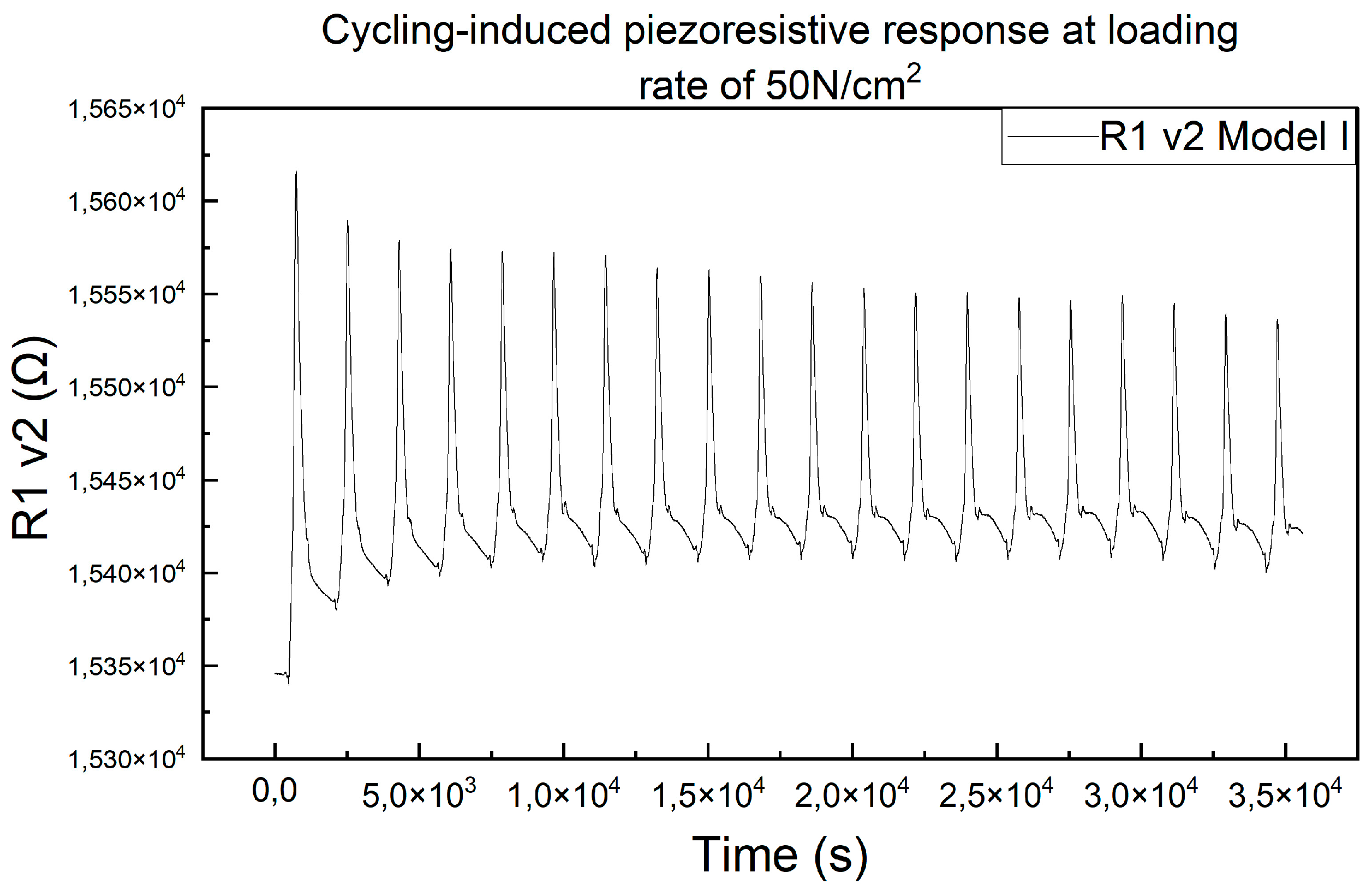

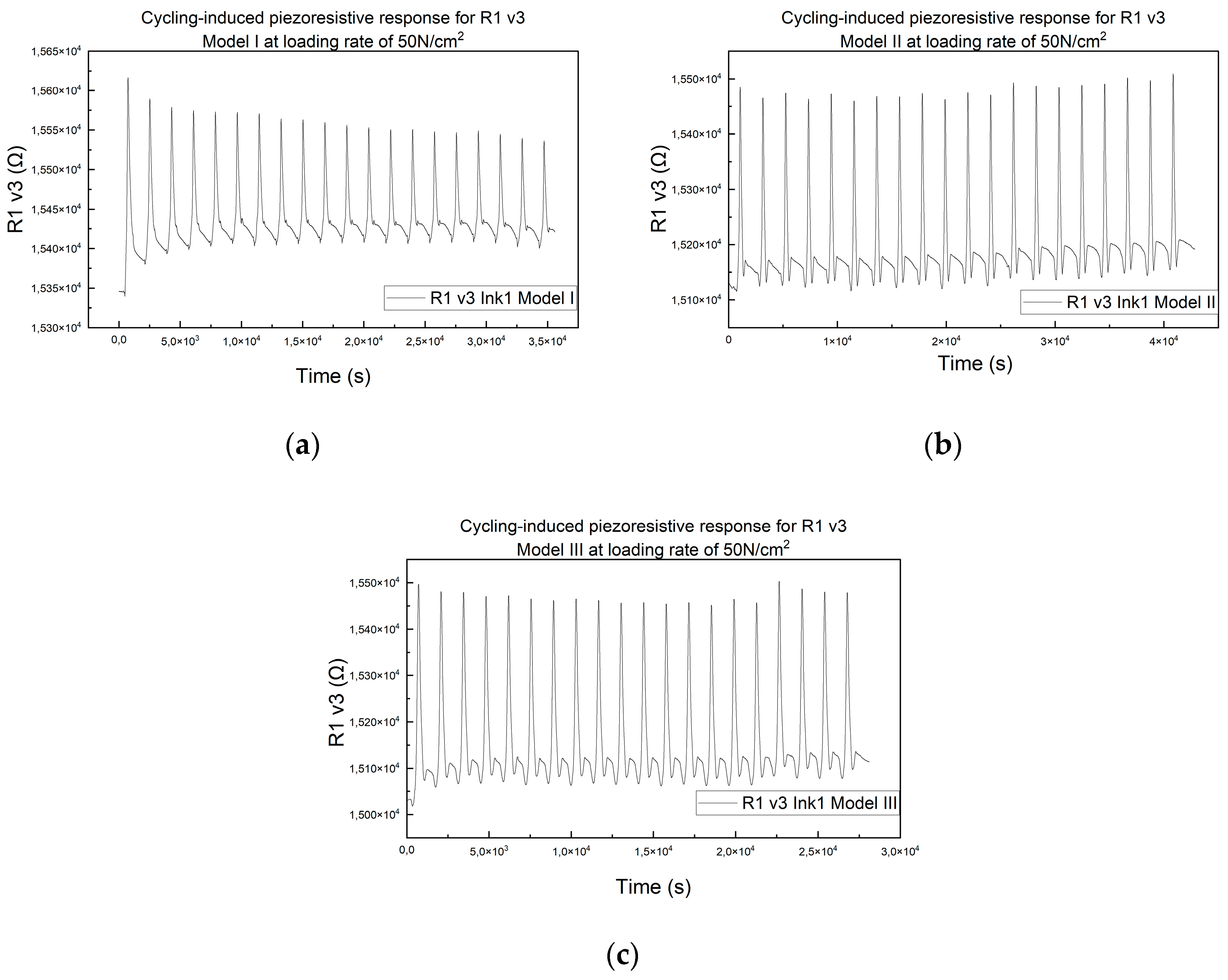

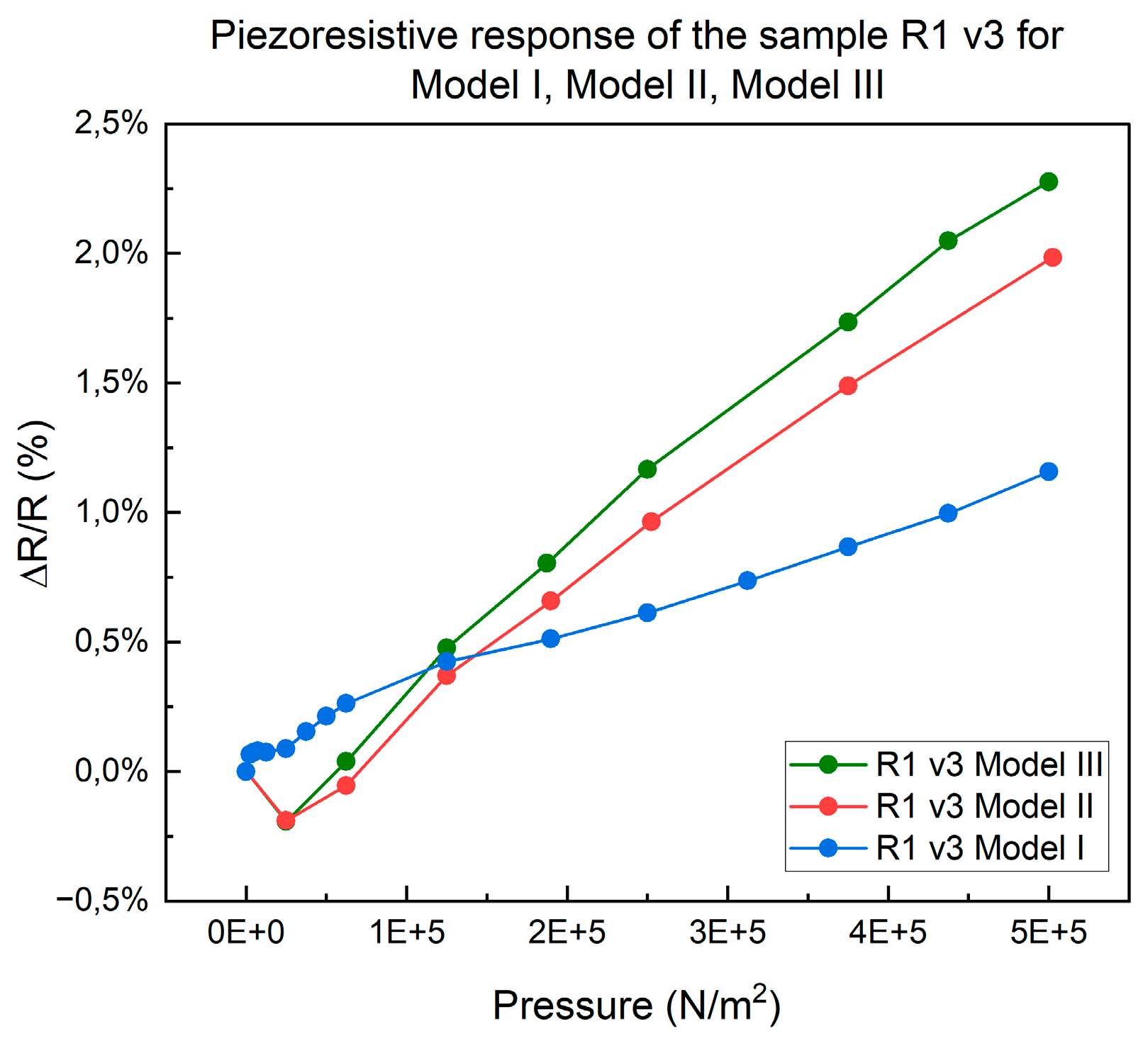

3. Results and Discussion

- Model I: The resistive film was placed on top of the elastomeric substrate with the micro-pyramidal structure oriented tip up (see Figure 4a).

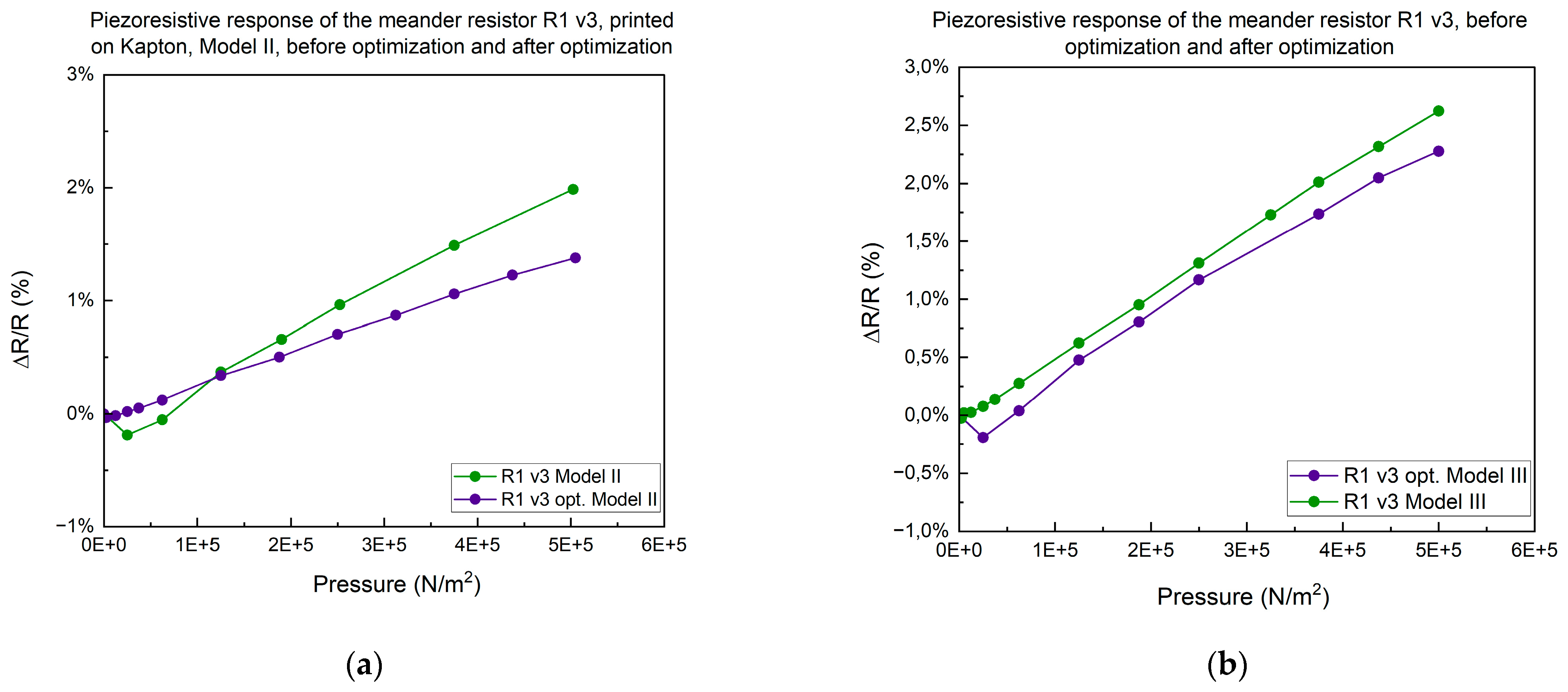

- Model II: The resistive film was placed above the elastomeric substrate with the micro-pyramidal structure oriented tip down (see Figure 4b).

- Model III: The resistive film was placed on an elastomeric substrate featuring an interlocked, paired pyramid structure (see Figure 4c).

4. Conclusions

- Linearity of Response: The Kapton substrate significantly improved the linearity of the meander resistor’s response, making it the preferred choice for the sensor’s base material.

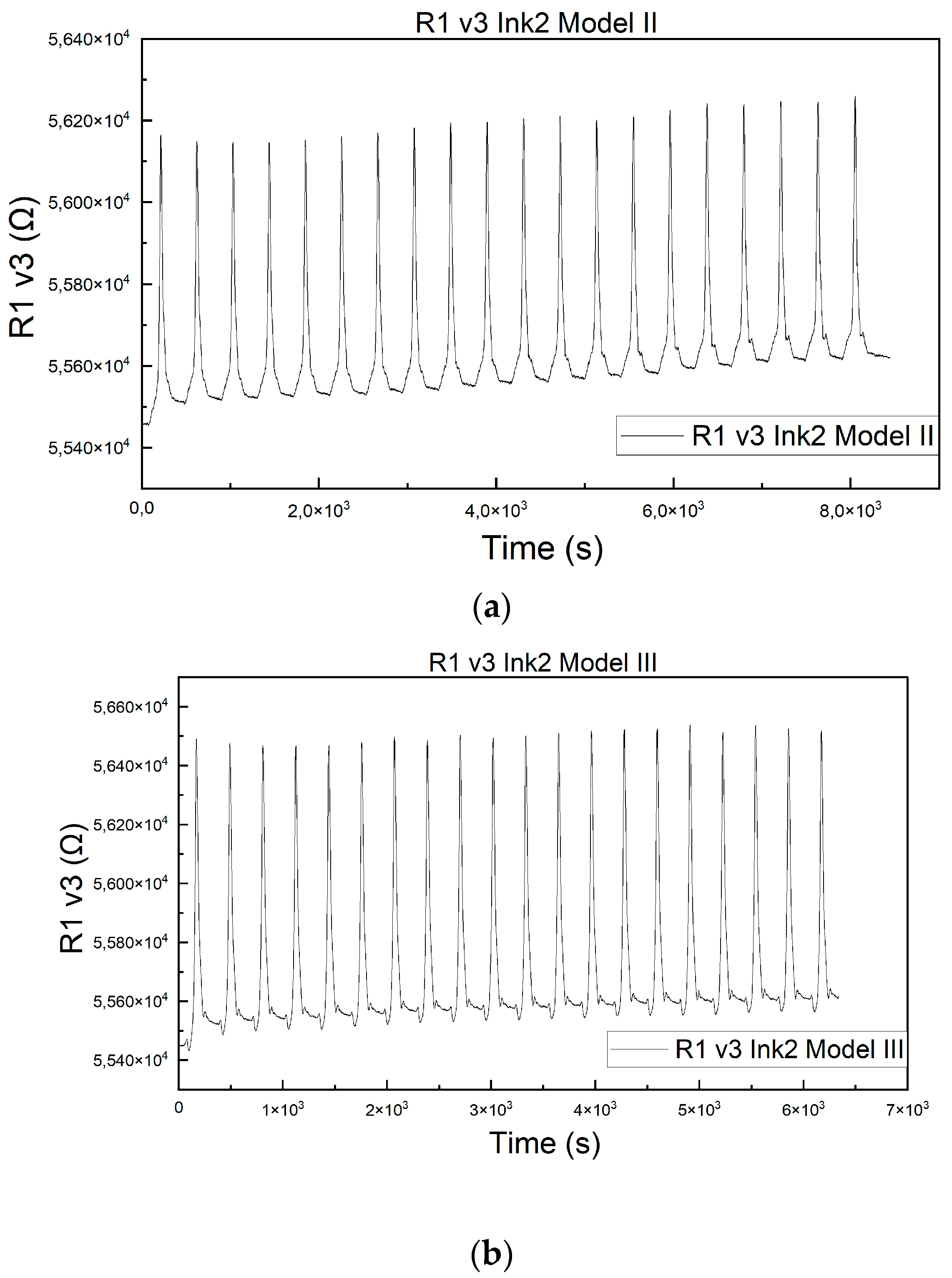

- Elastomeric Substrate Optimization: Model II and Model III assembly models provided the best results, showing a consistent and reliable performance under cyclic loading.

- Pressure Response: The optimized sensor showed enhanced sensitivity to low compression pressures, up to 50 N/cm2, ensuring accurate pressure measurements in this range.

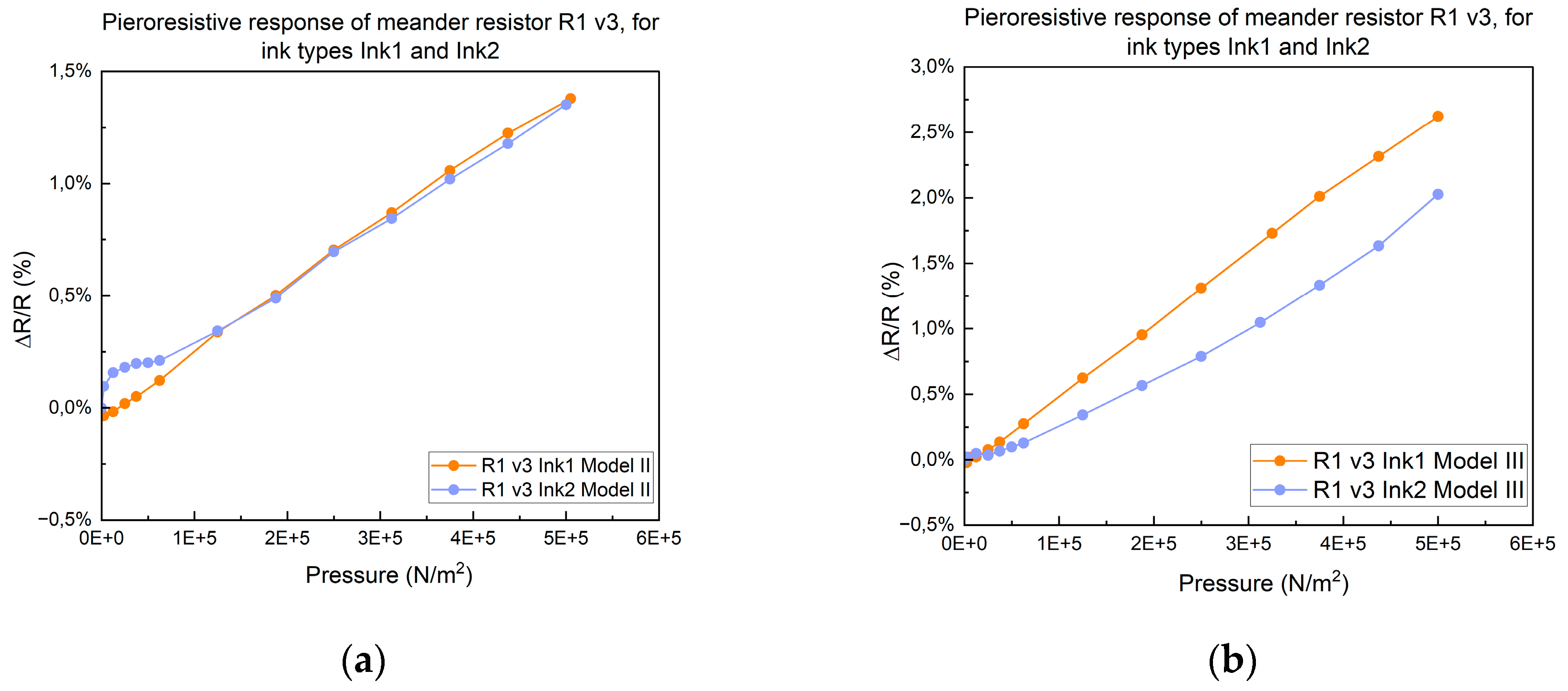

- Ink Performance: While Ink 2 increased the resistor’s value, it did not notably improve overall performance, indicating that both Ink 1 and Ink 2 are viable options for the sensor.

- Assembly and Soldering: The use of silver paste for soldering at 70 °C was crucial to preserving the behaviour and performance of Ink 1, highlighting the importance of the assembly process in sensor fabrication.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, K.; Zhang, Y.; Li, H.; He, Z.; Zang, J.; Du, C.; Yu, Y. Friction for flexible pressure sensors and arrays on polymers. J. Sci. Adv. Mater. Devices 2022, 7, 100512. [Google Scholar] [CrossRef]

- Wu, K.; Li, X. Wearable pressure sensor for athletes’ full-range motion signal monitoring. Mater. Res. Express 2020, 7, 10. [Google Scholar] [CrossRef]

- Yan, X. A flexible pressure sensor based on electrospun fiber for gait monitoring in football training. AIP Adv. 2023, 13, 105036. [Google Scholar] [CrossRef]

- Gong, S.; Schwalb, W.; Wang, Y.; Chen, Y.; Tang, Y.; Si, J.; Shirinzadeh, B.; Cheng, W. A wearable and highly sensitive pressure sensor with ultrathin gold nanowires. Nat. Commun. 2014, 5, 3132. [Google Scholar] [CrossRef] [PubMed]

- Park, H.; Jeong, Y.R.; Yun, J.; Hong, S.Y.; Jin, S.; Lee, S.-J.; Zi, G.; Ha, J.S. Stretchable Array of Highly Sensitive Pressure Sensors Consisting of Polyaniline Nanofibers and Au-Coated Polydimethylsiloxane Micropillars. ACS Nano 2015, 9, 9974–9985. [Google Scholar] [CrossRef] [PubMed]

- Dan, L.; Shi, S.; Chung, H.J.; Elias, A. Porous Polydimethylsiloxane–Silver Nanowire Devices for Wearable Pressure Sensors. ACS Appl. Nano Mater. 2019, 2, 4869–4878. [Google Scholar] [CrossRef]

- Chang, X. A wearable electronic based on flexible pressure sensor for running motion monitoring. Discov. Nano 2023, 18, 28. [Google Scholar] [CrossRef] [PubMed]

- Amjadi, M.; Pichitpajongkit, A.; Lee, S.; Ryu, S.; Park, I. Highly Stretchable and Sensitive Strain Sensor Based on Silver Nanowire–Elastomer Nanocomposite. ACS Nano 2014, 8, 5154–5163. [Google Scholar] [CrossRef] [PubMed]

- Lo, L.W.; Shi, H.; Wan, H.; Xu, Z.; Tan, X.; Wang, C. Inkjet-printed soft resistive pressure sensor patch for wearable electronics applications. Adv. Mater. Technol. 2020, 5, 1900717. [Google Scholar] [CrossRef]

- Gardner, S.D.; Alexander, J.I.D.; Massoud, Y.; Haider, M.R. An inkjet-printed paper-based flexible sensor for pressure mapping applications. In Proceedings of the 2020 IEEE International Symposium on Circuits and Systems (ISCAS), Seville, Spain, 12–14 October 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 1–5. [Google Scholar]

- Wang, X.; Zhang, M.; Zhang, L.; Xu, J.; Xiao, X.; Zhang, X. Inkjet-printed flexible sensors: From function materials, manufacture process, and applications perspective. Mater. Today Commun. 2022, 31, 103263. [Google Scholar] [CrossRef]

- Huang, Y.; Fan, X.; Chen, S.C.; Zhao, N. Emerging technologies of flexible pressure sensors: Materials, modeling, devices, and manufacturing. Adv. Funct. Mater. 2019, 29, 1808509. [Google Scholar] [CrossRef]

- Sekertekin, Y.; Bozyel, I.; Gokcen, D. A Flexible and Low-Cost Tactile Sensor Produced by Screen Printing of Carbon Black/PVA Composite on Cellulose Paper. Sensors 2020, 20, 2908. [Google Scholar] [CrossRef] [PubMed]

- Zavanelli, N.; Yeo, W.-H. Advances in Screen Printing of Conductive Nanomaterials for Stretchable Electronics. ACS Omega 2021, 6, 9344–9351. [Google Scholar] [CrossRef] [PubMed]

- Yoon, S.; Kim, H.K. Cost-effective stretchable Ag nanoparticles electrodes fabrication by screen printing for wearable strain sensors. Surf. Coat. Technol. 2020, 384, 125308. [Google Scholar] [CrossRef]

- Ali, M.M.; Maddipatla, D.; Narakathu, B.B.; Chlaihawi, A.A.; Emamian, S.; Janabi, F.; Bazuin, B.J.; Atashbar, M.Z. Printed strain sensor based on silver nanowire/silver flake composite on flexible and stretchable TPU substrate. Sens. Actuators A Phys. 2018, 274, 109–115. [Google Scholar]

- Gräbner, D.; Tintelott, M.; Schön, K.; Lang, W. Screen-Printed Resistive Pressure Sensors: Influence of Electrode Geometry on the Performance and on Cross-Sensitivity to Strain and Temperature. J. Phys. Conf. Ser. 2021, 1837, 012004. [Google Scholar] [CrossRef]

- Maddipatla, D.; Narakathu, B.B.; Ali, M.M.; Chlaihawi, A.A.; Atashbar, M.Z. Development of a novel carbon nanotube based printed and flexible pressure sensor. In Proceedings of the 2017 IEEE Sensors Applications Symposium (SAS), Glassboro, NJ, USA, 13–15 March 2017; pp. 1–4. [Google Scholar] [CrossRef]

- Emamian, S.; Narakathu, B.B.; Chlaihawi, A.A.; Bazuin, B.J.; Atashbar, M.Z. Screen printing of flexible piezoelectric based device on polyethylene terephthalate (PET) and paper for touch and force sensing applications. Sens. Actuators A Phys. 2017, 263, 639–647. [Google Scholar] [CrossRef]

- Zhang, Y.; Guo, X.; Wang, W.; Chen, L.; Liu, L.; Liu, H.; He, Y. Highly Sensitive, Low Hysteretic and Flexible Strain Sensor Based on Ecoflex-AgNWs- MWCNTs Flexible Composite Materials. IEEE Sens. J. 2020, 20, 14118–14125. [Google Scholar] [CrossRef]

- Berthier, E.; Young, E.W.K.; Beebe, D. Engineers are from PDMS-land, Biologists are from Polystyrenia. Lab A Chip 2012, 12, 1224–1237. [Google Scholar] [CrossRef] [PubMed]

- Khan, S.; Dahiya, R.; Lorenzelli, L. Technologies for Printing Sensors and Electronics Over Large Flexible Substrates: A Review. IEEE Sens. J. 2014, 15, 3164–3185. [Google Scholar] [CrossRef]

| Resistor Number | Resistor Version (Replication) | Initial Value Ω | Final Value Ω | Variation of the Resistor Value % |

|---|---|---|---|---|

| R1 | V1 | 14,587.0 ± 1.45 | 17,804.0 ± 1.78 | 22.05 |

| V2 | 12,168.0 ± 1.21 | 14,733.0 ± 1.47 | 21.08 | |

| V3 | 12,641.0 ± 1.26 | 15,040.0 ± 1.5 | 18.98 | |

| R3 | V1 | 8117.0 ± 0.81 | 11,232.0 ± 1.12 | 38.38 |

| V2 | 6350.0 ± 0.63 | 8836.0 ± 0.88 | 39.15 | |

| R2 | V1 | 7517.0 ± 0.75 | 9758.0 ± 0.97 | 29.81 |

| V2 | 2709.0 ± 0.27 | 4424.0 ± 0.44 | 63.31 | |

| V3 | 6468.0 ± 0.64 | 8030.0 ± 0.8 | 24.14 | |

| R4 | V1 | 5602.0 ± 0.56 | - | - |

| V2 | 9840.0 ± 0.98 | - | - | |

| V3 | 7480.0 ± 0.74 | - | - |

| Material | Initial Value Ω | Bending 45° Ω | Bending 90° Ω | Total Variation % |

|---|---|---|---|---|

| Kapton | 14,400.0 ± 1.44 | 14,250.0 ± 1.42 | 14,080.0 ± 1.40 | 2222 |

| ABS | 11,042.0 ± 1.10 | 10,827.0 ± 1.08 | 10,560.0 ± 1.05 | 4365 |

| Kapton | 14,808.0 ± 1.48 | 14,616.0 ± 1.46 | 14,485.0 ± 1.44 | 2181 |

| PET | 9615.0 ± 0.96 | 9384.0 ± 0.93 | 9180.0 ± 0.91 | 4524 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pistriţu, F.; Gheorghe, M.; Ion, M.; Brincoveanu, O.; Romanitan, C.; Suchea, M.P.; Schiopu, P.; Ionescu, O.N. On the Development of a New Flexible Pressure Sensor. Micromachines 2024, 15, 847. https://doi.org/10.3390/mi15070847

Pistriţu F, Gheorghe M, Ion M, Brincoveanu O, Romanitan C, Suchea MP, Schiopu P, Ionescu ON. On the Development of a New Flexible Pressure Sensor. Micromachines. 2024; 15(7):847. https://doi.org/10.3390/mi15070847

Chicago/Turabian StylePistriţu, Florian, Marin Gheorghe, Marian Ion, Oana Brincoveanu, Cosmin Romanitan, Mirela Petruta Suchea, Paul Schiopu, and Octavian Narcis Ionescu. 2024. "On the Development of a New Flexible Pressure Sensor" Micromachines 15, no. 7: 847. https://doi.org/10.3390/mi15070847

APA StylePistriţu, F., Gheorghe, M., Ion, M., Brincoveanu, O., Romanitan, C., Suchea, M. P., Schiopu, P., & Ionescu, O. N. (2024). On the Development of a New Flexible Pressure Sensor. Micromachines, 15(7), 847. https://doi.org/10.3390/mi15070847