Fabrication of Micro Carbon Mold for Glass-Based Micro Hole Array

Abstract

1. Introduction

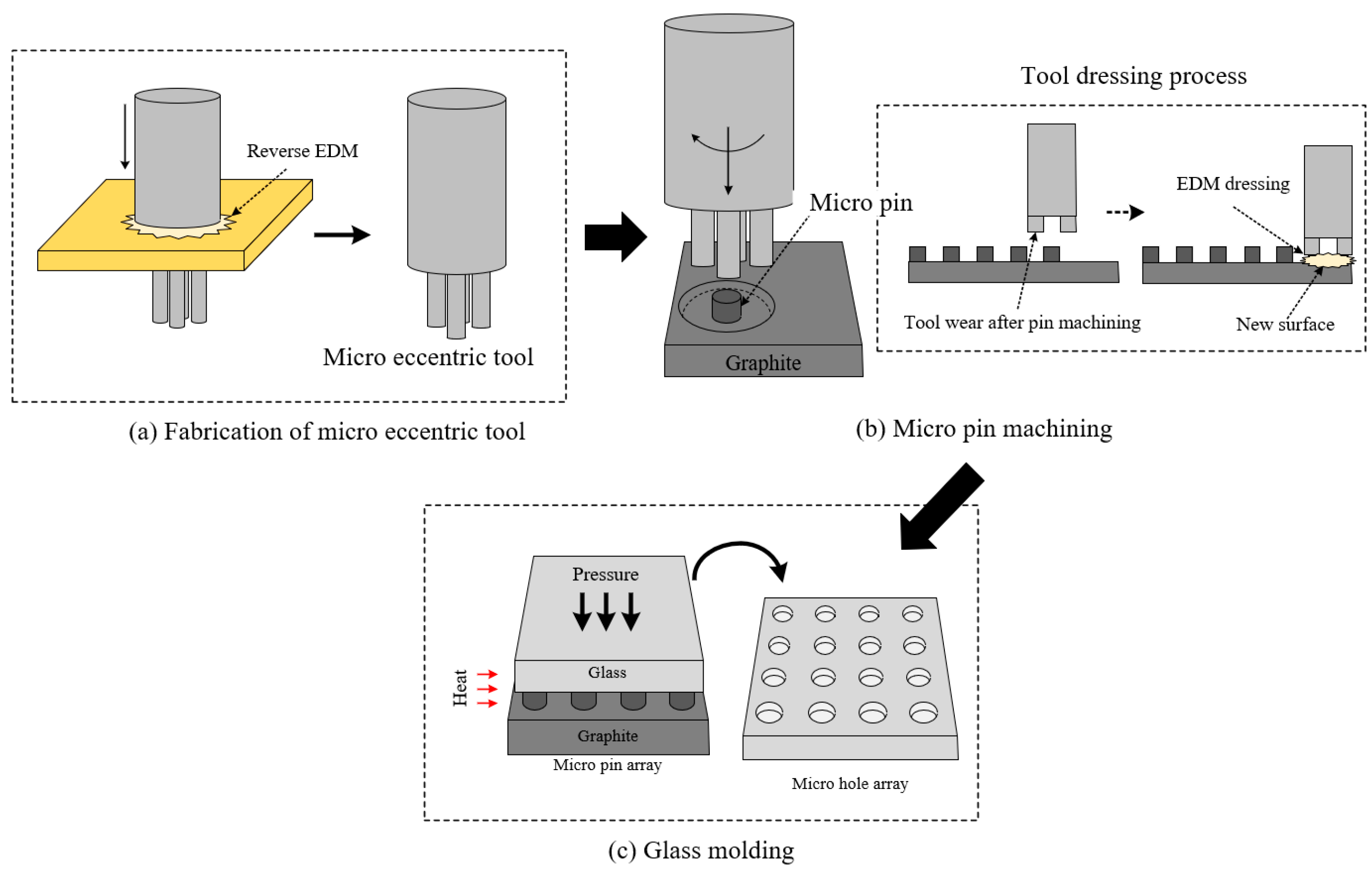

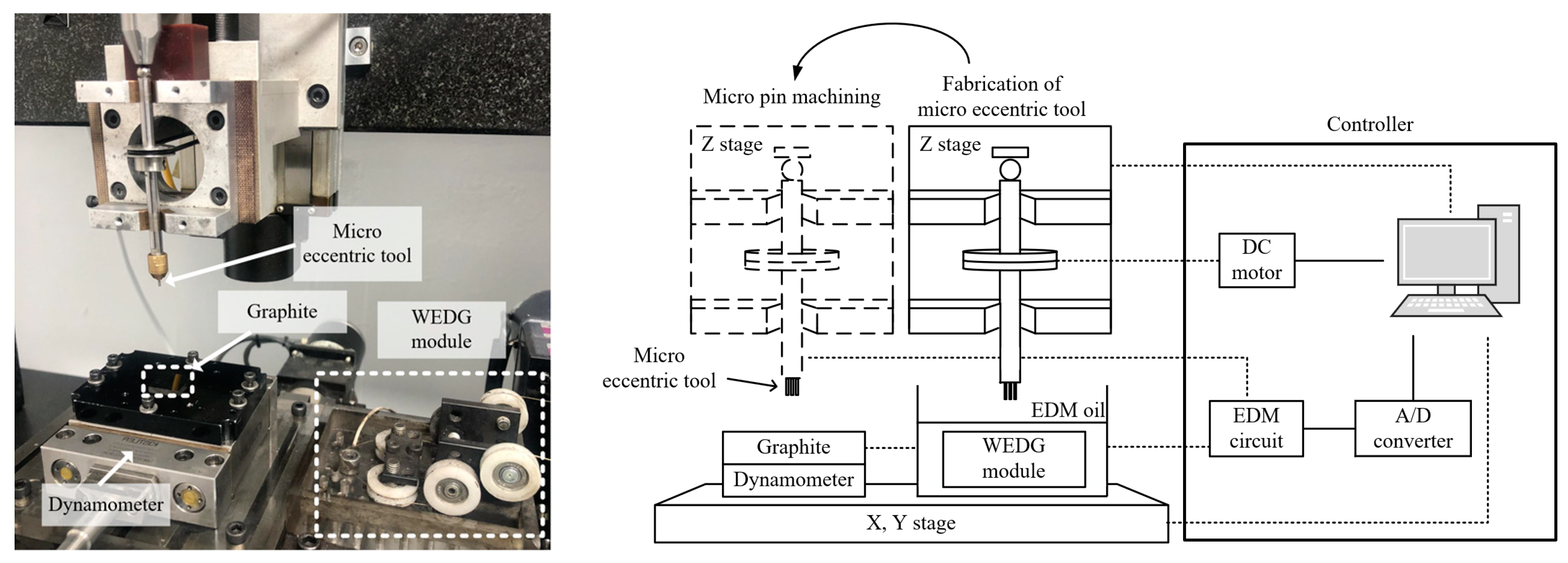

2. Materials and Methods

2.1. Experimental Setup

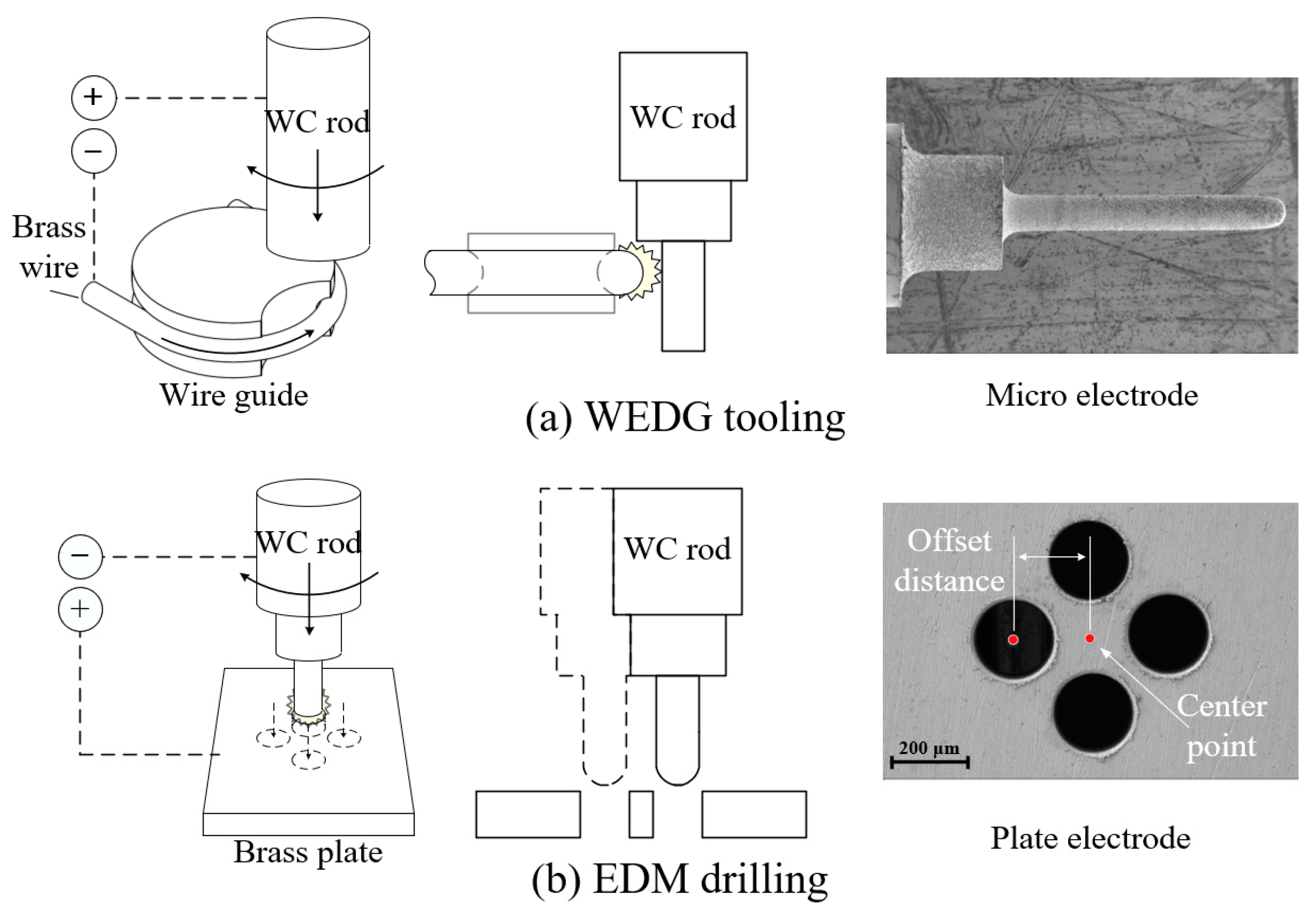

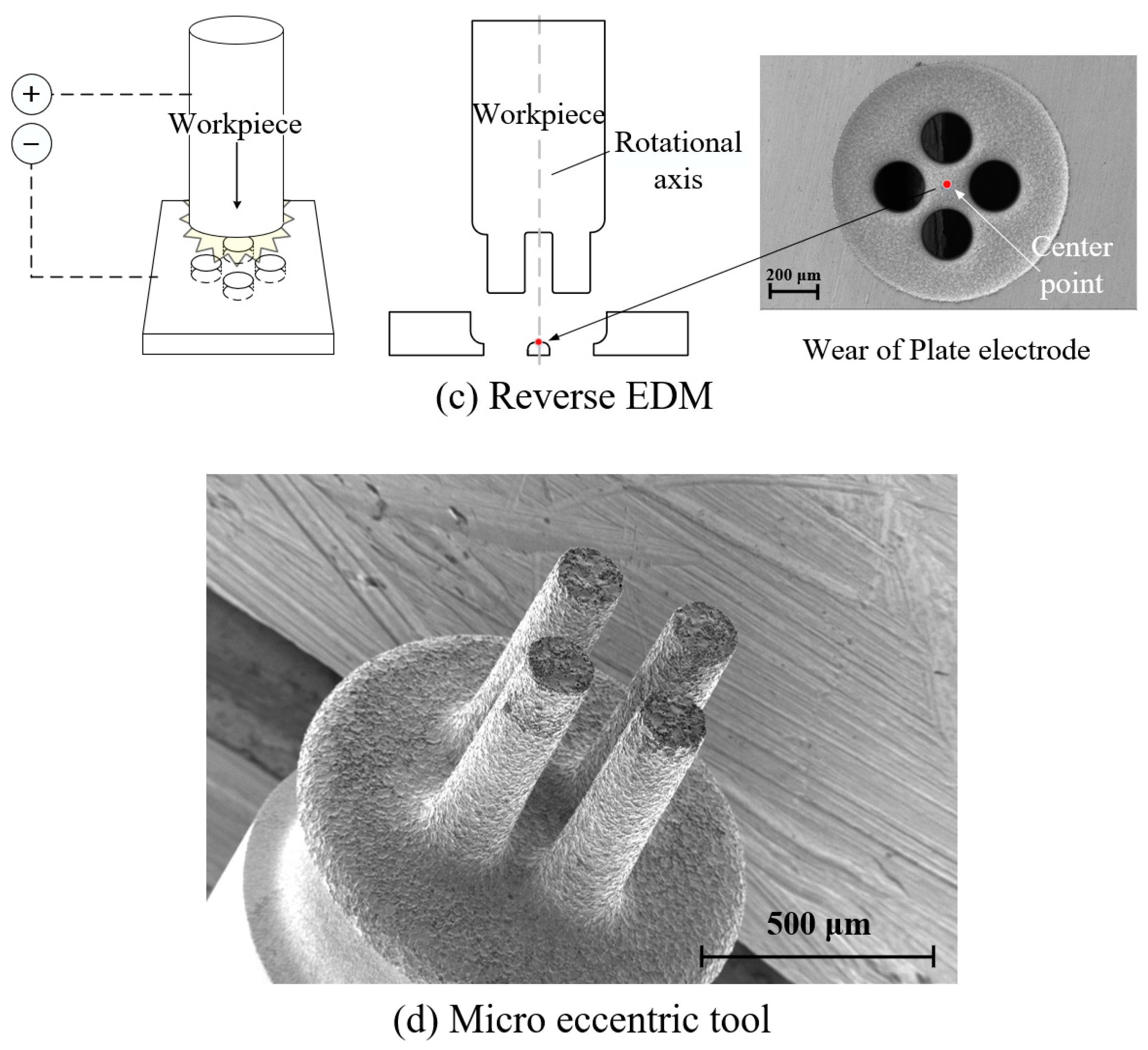

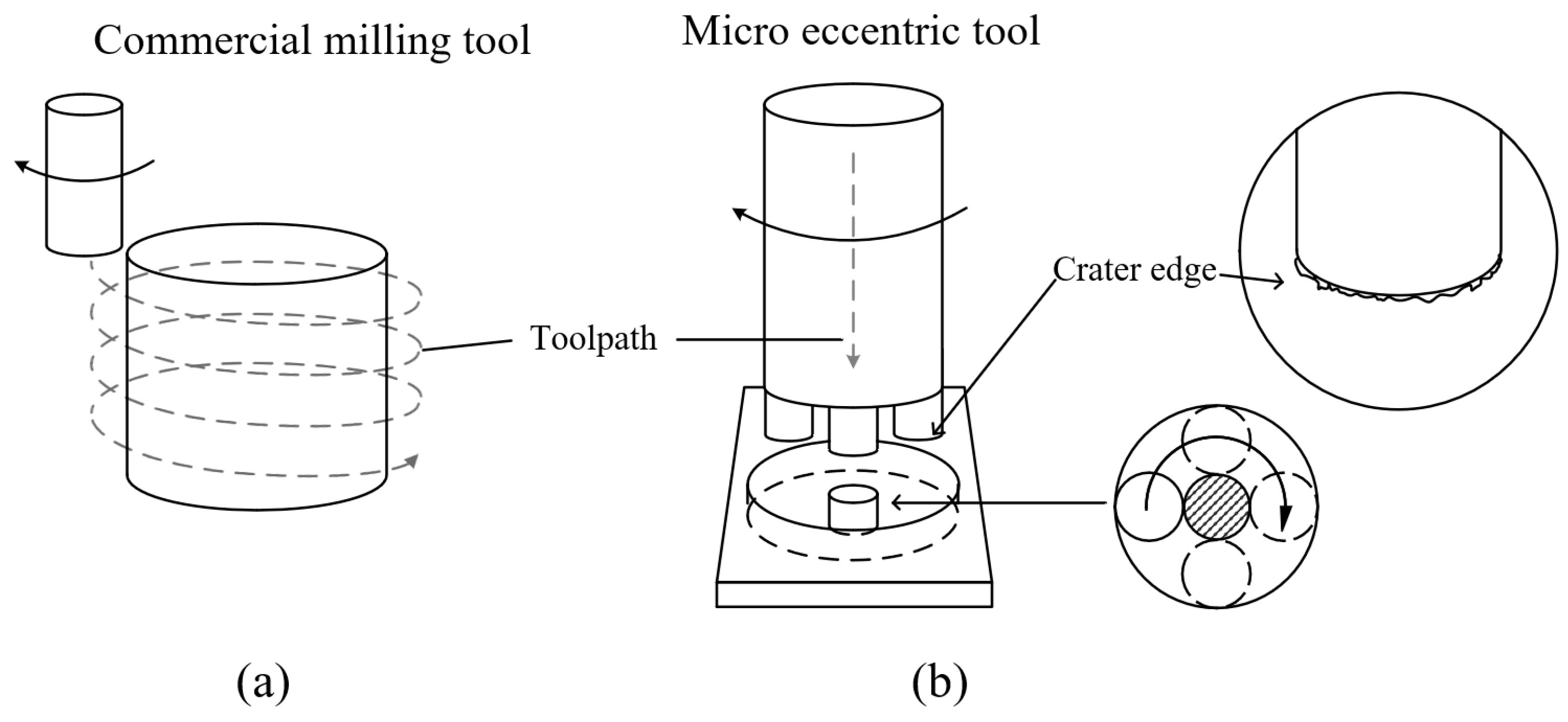

2.2. Fabrication of Micro Eccentric Tool

2.3. Micro Pin Machining by Eccentric Tool

3. Results

3.1. Effects of Tool Axial Feedrate and Rotational Speed

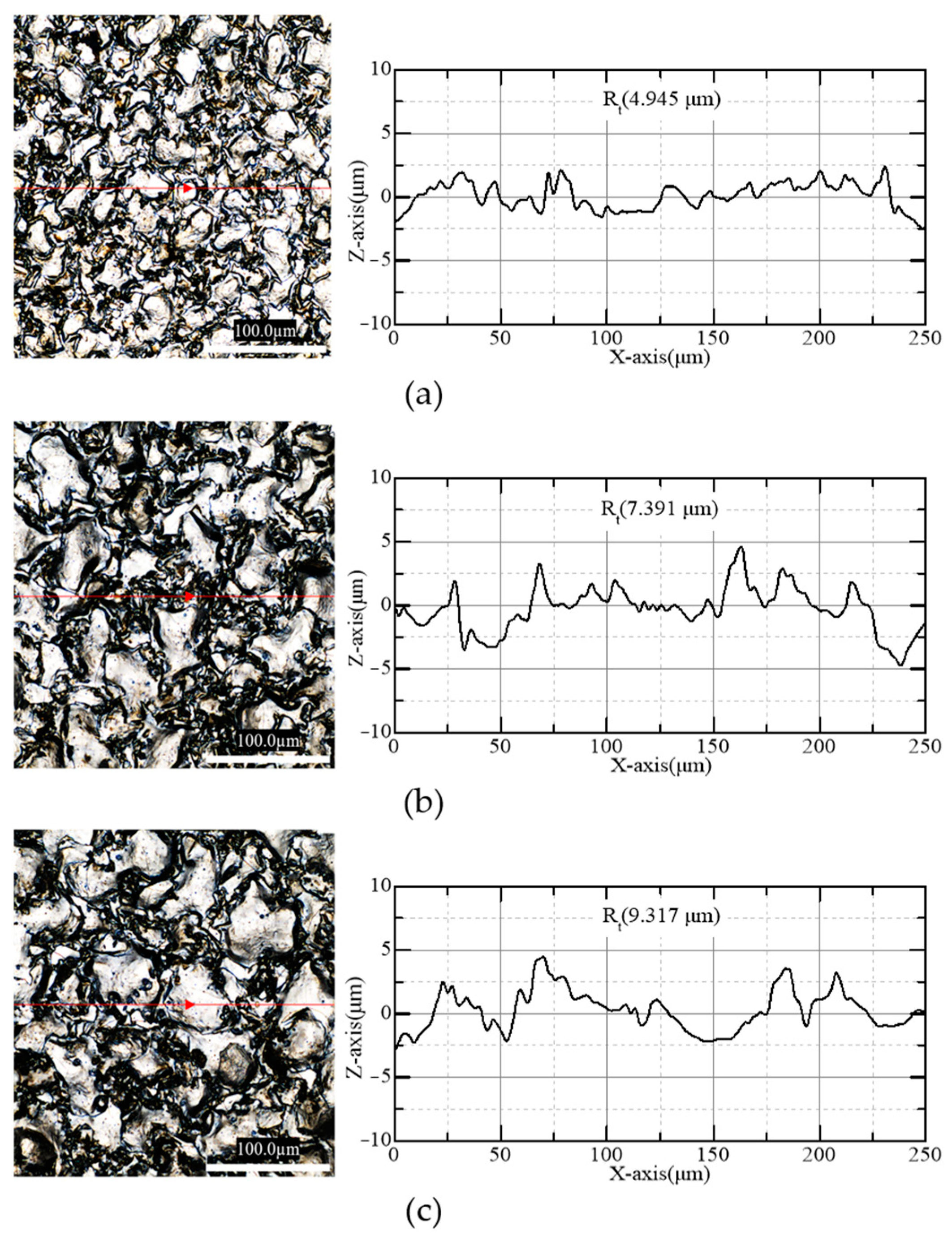

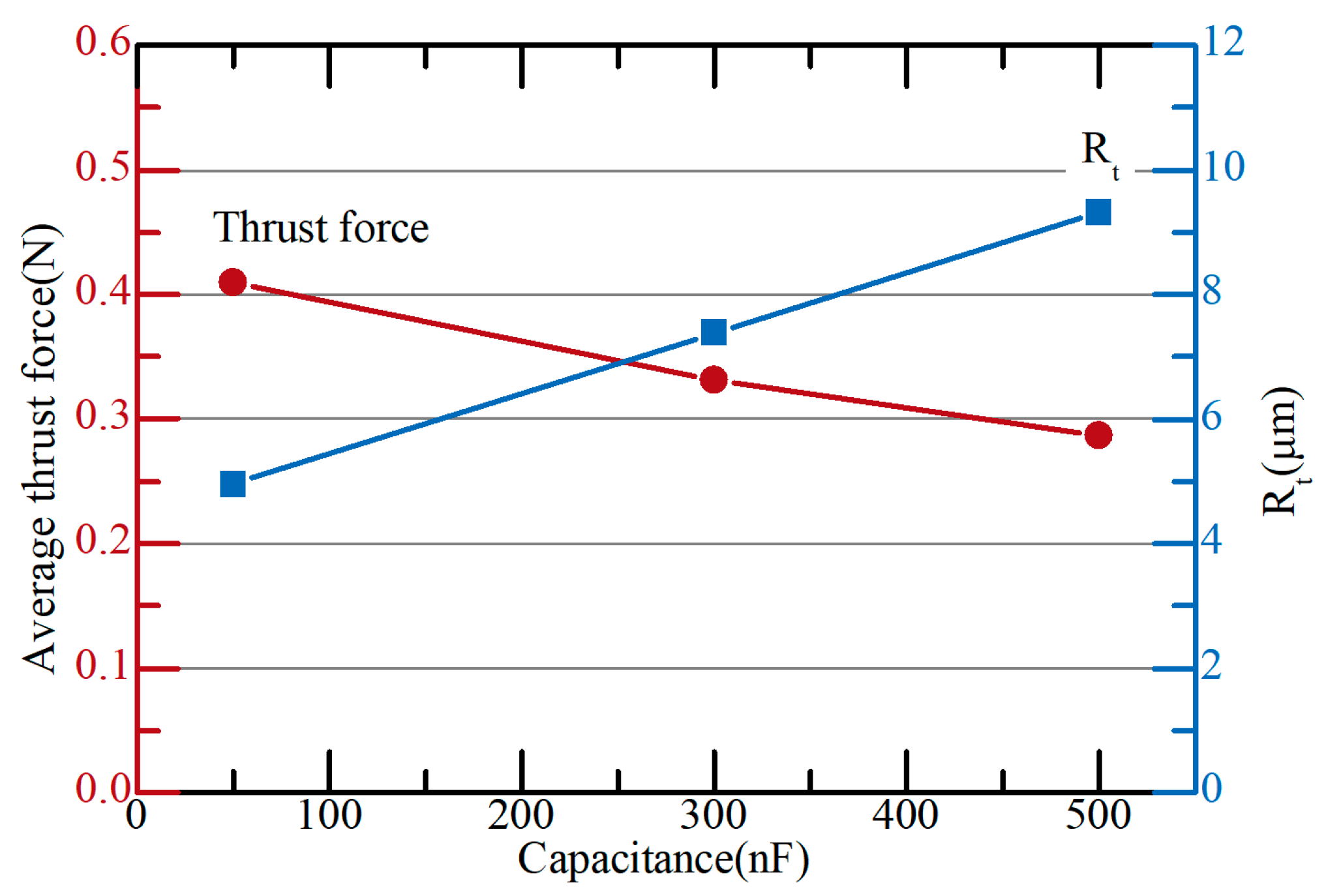

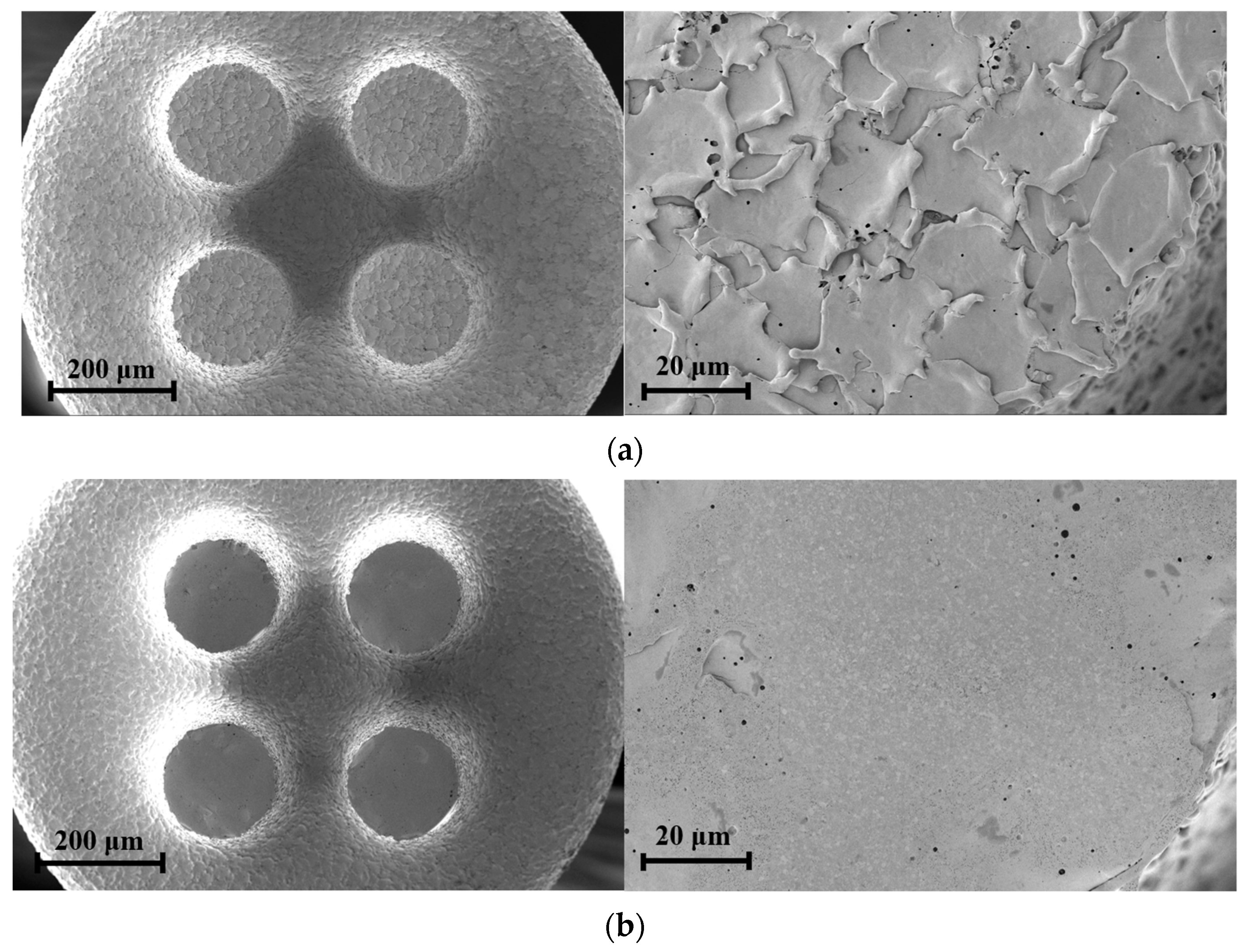

3.2. Effect of Surface Roughness of the Tool Bottom

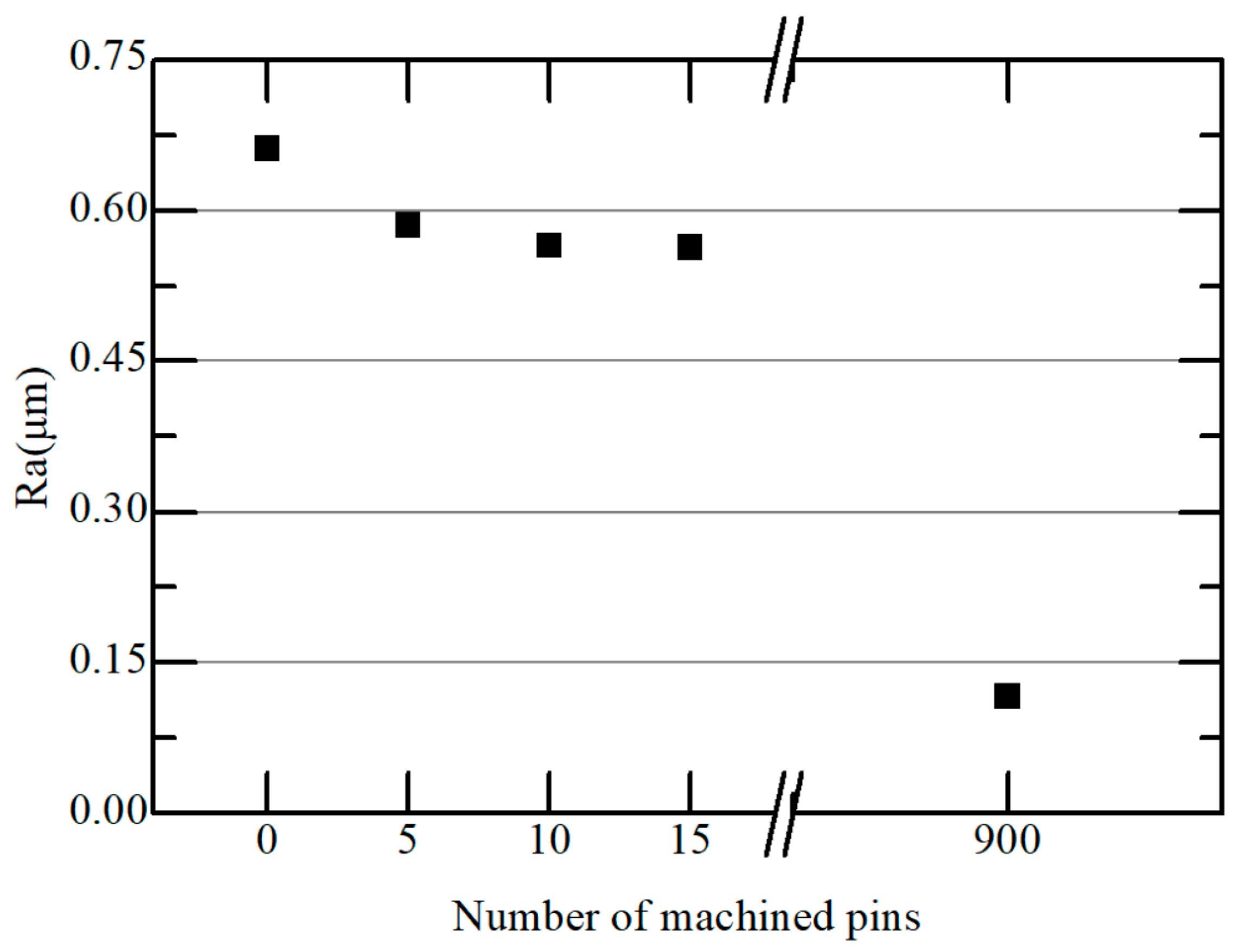

3.3. Tool Wear

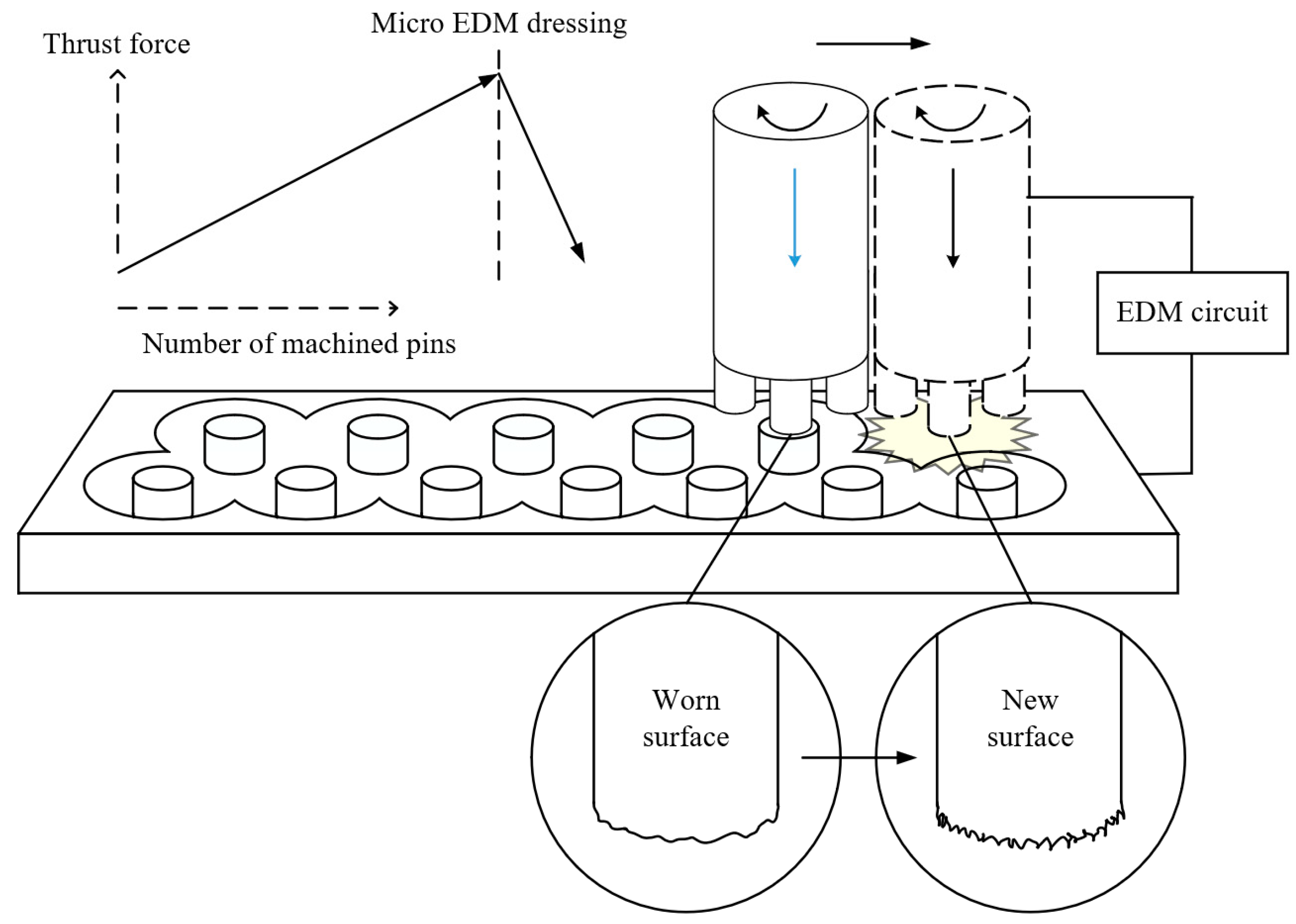

3.4. Tool Dressing

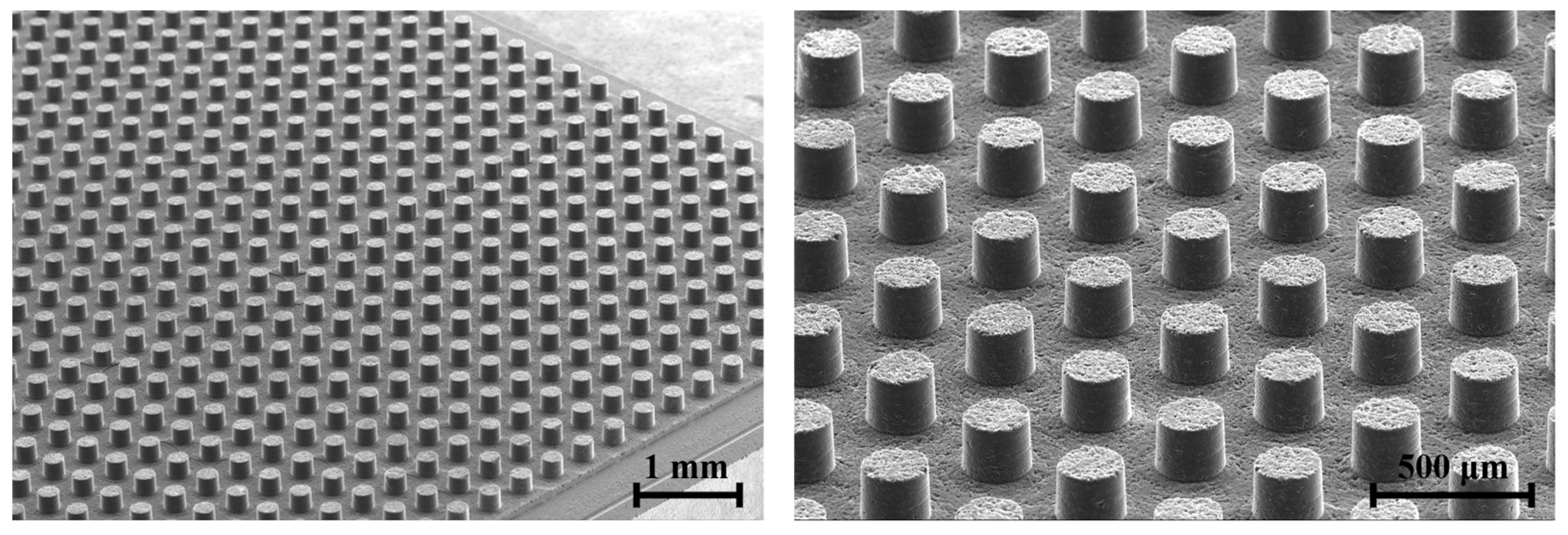

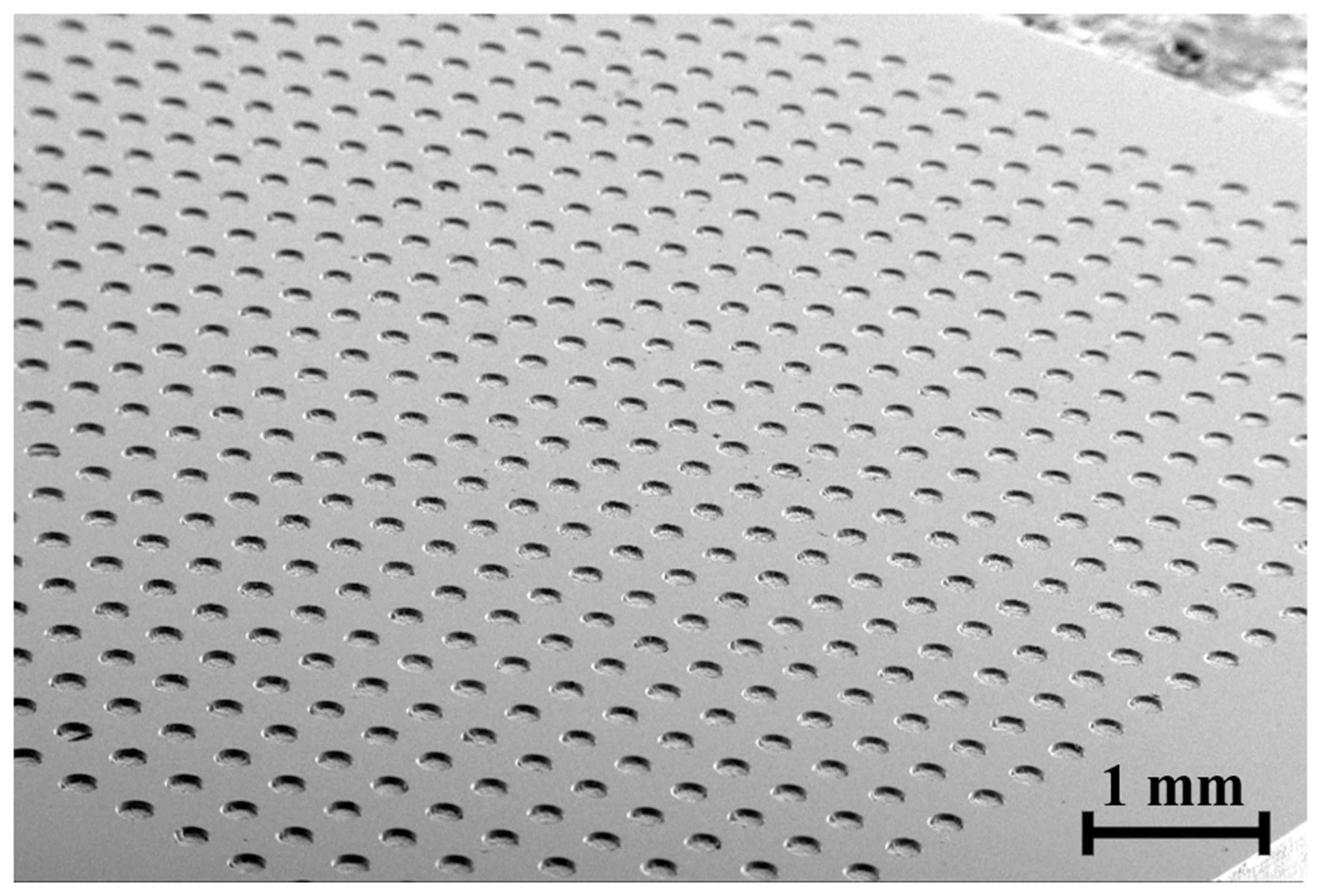

3.5. Micro Pin Array for Molding

4. Conclusions

- As the depth increased during the machining of a micro pin, the thrust force gradually increased. This was because it became difficult to evacuate graphite chips as the depth increased.

- As the tool rotation speed increased from 1500 to 3000 and 4500 rpm, the thrust force decreased by 57% and 66%. The thrust force showed an unstable increase at a rotational speed of 1500 rpm (feed per revolution: 400 nm/rev). Therefore, it is necessary to machine using a rotational speed over 3000 rpm.

- The surface roughness of the bottom of the tool increased as the capacitance increased. When the capacitance was 500 nF, the surface roughness (Rt) was 9.317 µm and the grinding force decreased by 30% compared to the capacitance of 50 nF. Therefore, it is advantageous to use rough-surface tools with high capacitance.

- When the number of machined micro pins increased to 5, the thrust force increased from 0.2 N to 1 N due to wear of the tool bottom. When the number of machined pins was 15, the surface roughness decreased by 14.95%, and when the number of machined pins was 900, the surface roughness of the tool bottom decreased by 82.48%.

- To prevent tool breakage caused by the increasing of thrust force, EDM dressing was conducted to generate discharge craters on the worn surface. The dressed tool significantly reduced the force, allowing the machining of 900 pins using a single eccentric tool.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kim, S.-H.; Lee, G.H.; Park, J.Y. Microwell fabrication methods and applications for cellular studies. Biomed. Eng. Lett. 2013, 3, 131–137. [Google Scholar] [CrossRef]

- Park, H.; Kim, H.; Doh, J. Multifunctional microwell arrays for single cell level functional analysis of lymphocytes. Bioconjugate Chem. 2017, 29, 672–679. [Google Scholar] [CrossRef] [PubMed]

- Aralekallu, S.; Boddula, R.; Singh, V. Development of glass-based microfluidic devices: A review on its fabrication and biologic applications. Mater. Des. 2023, 225, 111517. [Google Scholar] [CrossRef]

- Lindström, S.; Andersson-Svahn, H. Miniaturization of biological assays—Overview on microwell devices for single-cell analyses. Biochim. Biophys. Acta (BBA)-Gen. Subj. 2011, 1810, 308–316. [Google Scholar] [CrossRef] [PubMed]

- Hwang, J.; Cho, Y.H.; Park, M.S.; Kim, B.H. Microchannel Fabrication on Glass Materials for Microfluidic Devices. International J. Precis. Eng. Manuf. 2019, 20, 479–495. [Google Scholar] [CrossRef]

- Hof, L.; Abou Ziki, J. Micro-Hole Drilling on Glass Substrates—A Review. Micromachines 2017, 8, 53. [Google Scholar] [CrossRef]

- Wang, T.; Chen, J.; Zhou, T.; Song, L. Fabricating Microstructures on Glass for Microfluidic Chips by Glass Molding Process. Micromachines 2018, 9, 269. [Google Scholar] [CrossRef]

- Kim, H.-H.; Chung, S.; Kim, S.-C.; Jee, W.-H.; Chung, S.-C. Condition monitoring of micro-drilling processes on glass by using machine vision. Proceeding ASPE 2006, 21, 535–538. [Google Scholar]

- Egashira, K.; Mizutani, K.; Nagao, T. Ultrasonic Vibration Drilling of Microholes in Glass. CIRP Ann. 2002, 51, 339–342. [Google Scholar] [CrossRef]

- Cheng, C.C.; Sheu, D.Y. Small holes fabrication on soda glass by self-elastic polycrystalline diamond tool. Key Eng. Mater. 2012, 516, 516–521. [Google Scholar] [CrossRef]

- Schorderet, A.; Deghilage, E.; Agbeviade, K. Tool Type and Hole Diameter Influence in Deep Ultrasonic Drilling of Micro-Holes in Glass. Procedia CIRP 2013, 6, 565–570. [Google Scholar] [CrossRef]

- Suresh, R.; Sohit Reddy, K.; Shapur, K. Abrasive Jet Machining for Micro-hole Drilling on Glass and GFRP Composites. Mater. Today Proc. 2018, 5, 5757–5761. [Google Scholar] [CrossRef]

- Wensink, H.; Berenschot, J.W.; Jansen, H.V.; Elwenspoek, M.C. High resolution powder blast micromachining. In Proceedings of the IEEE Thirteenth Annual International Conference on Micro Electro Mechanical Systems (Cat. No. 00CH36308), Miyazaki, Japan, 23–27 January 2000; pp. 769–774. [Google Scholar]

- Schwartzentruber, J.; Papini, M. Abrasive waterjet micro-piercing of borosilicate glass. J. Mater. Process. Technol. 2015, 219, 143–154. [Google Scholar] [CrossRef]

- Yen, M.-H.; Cheng, J.-Y.; Wei, C.-W.; Chuang, Y.-C.; Young, T.-H. Rapid cell-patterning and microfluidic chip fabrication by crack-free CO2 laser ablation on glass. J. Micromech. Microeng. 2006, 16, 1143–1153. [Google Scholar] [CrossRef]

- Kuriakose, A.; Bollani, M.; Di Trapani, P.; Jedrkiewicz, O. Study of through-hole micro-drilling in sapphire by means of pulsed Bessel beams. Micromachines 2022, 13, 624. [Google Scholar] [CrossRef] [PubMed]

- Zhou, W.; Li, R.; Li, M.; Tao, P.; Wang, X.; Dai, S.; Song, B.; Zhang, W.; Lin, C.; Xu, T. Fabrication of microlens array on chalcogenide glass by wet etching-assisted femtosecond laser direct writing. Ceram. Int. 2022, 48, 18983–18988. [Google Scholar] [CrossRef]

- Bhargav, K.; Balaji, P.; Sahu, R.K.; Katiyar, J.K. Multi-response optimization and effect of tool rotation on micromachining of PMMA using an in-house developed µ-ECDM system. CIRP J. Manuf. Sci. Technol. 2022, 38, 473–490. [Google Scholar] [CrossRef]

- Edelmann, J.; Worsch, C.; Schubert, A.; Rüssel, C. Micro structuring of inorganic glass by hot embossing of coated glass wafers. Microsyst. Technol. 2010, 16, 553–560. [Google Scholar] [CrossRef]

- Huang, C.-Y.; Kuo, C.-H.; Hsiao, W.-T.; Huang, K.-C.; Tseng, S.-F.; Chou, C.-P. Glass biochip fabrication by laser micromachining and glass-molding process. J. Mater. Process. Technol. 2012, 212, 633–639. [Google Scholar] [CrossRef]

- Tseng, S.-F.; Chen, M.-F.; Hsiao, W.-T.; Huang, C.-Y.; Yang, C.-H.; Chen, Y.-S. Laser micromilling of convex microfluidic channels onto glassy carbon for glass molding dies. Opt. Lasers Eng. 2014, 57, 58–63. [Google Scholar] [CrossRef]

- Pierson, H.O. Handbook of Carbon, Graphite, Diamonds and Fullerenes; William Andrew Publishing: Oxford, UK, 1993; pp. 122–140. [Google Scholar]

- Zhou, L.; Wang, C.Y.; Qin, Z. Tool wear characteristics in high-speed milling of graphite using a coated carbide micro endmill. Proc. Inst. Mech.Eng. Part B J. Eng. Manuf. 2008, 223, 267–277. [Google Scholar] [CrossRef]

- Huo, D.; Lin, C.; Dalgarno, K. An experimental investigation on micro machining of fine-grained graphite. Int. J. Adv. Manuf. Technol. 2014, 72, 943–953. [Google Scholar] [CrossRef]

- Lee, P.A.; Lee, U.S.; Sim, D.B.; Kim, B.H. Microfluidic Chip Fabrication of Fused Silica Using Microgrinding. Micromachines 2022, 14, 96. [Google Scholar] [CrossRef] [PubMed]

- Masuzawa, T. State of the Art of Micromachining. CIRP Ann. 2000, 49, 473–488. [Google Scholar] [CrossRef]

- Prakash, L.J. Application of fine grained tungsten carbide based cemented carbides. Int. J. Refract. Met. Hard Mater. 1995, 13, 257–264. [Google Scholar] [CrossRef]

- Kim, B.H.; Park, B.J.; Chu, C.N. Fabrication of multiple electrodes by reverse EDM and their application in micro ECM. J. Micromechanics Microengineering 2006, 16, 843–850. [Google Scholar] [CrossRef]

- Waldorf, D.J. A simplified model for ploughing forces in turning. J. Manuf. Process. 2006, 8, 76–82. [Google Scholar] [CrossRef]

- Chen, S.-T.; Chen, S.-Y. Development of a High-Frequency Discharge Power Source with Non-Equal Energy Relaxation Oscillator Circuit Applied to β-Ga2O3 Microstructure Array Wire Electric Discharge Machining. Int. J. Precis. Eng. Manuf.-Green Technol. 2023, 10, 1511–1528. [Google Scholar] [CrossRef]

- Chen, Y.; Li, C.; Li, S.; Xu, M.; Huang, L.; Li, S.; Li, P.; Qiu, X.; Ko, T.J. Study on the Formation of the Crater and Modified Layer in EDM Titanium Alloys Based on Fluid–Solid Coupled Temperature Field Model. Int. J. Precis. Eng. Manuf. 2023, 24, 337–351. [Google Scholar] [CrossRef]

- Rowe, W.B. Principles of Modern Grinding Technology; William Andrew Publishing: Oxford, UK, 2014; pp. 63–82. [Google Scholar]

- Wei, S.; Zhang, T.; Wei, H.; Wang, W.; Wang, H.; Liu, Y. Simulation Study on Removal Mechanism of Si3N4 Ceramic in Rotary Ultrasonic Grinding. Int. J. Precis. Eng. Manuf. 2023, 24, 945–965. [Google Scholar] [CrossRef]

- Ding, Z.; Sun, J.; Guo, W.; Jiang, X.; Wu, C.; Liang, S.Y. Thermal Analysis of 3J33 Grinding Under Minimum Quantity Lubrication Condition. Int. J. Precis. Eng. Manuf.-Green Technol. 2022, 9, 1247–1265. [Google Scholar] [CrossRef]

| Parameters | Value |

|---|---|

| Voltage (V) | 100 |

| Rotational speed (rpm) | 2500 |

| Feedrate (µm/s) | 5 |

| Capacitance (pF) | 20,000 (Finish) |

| Dielectric fluid | Kerosene |

| Conditions | Value |

|---|---|

| Workpiece | Graphite |

| Feedrate (µm/s) | 5, 10, 15 |

| Rotational speed (rpm) | 1500, 3000, 4500 |

| Surface roughness of tool bottom (Ra) | 0.628, 1.975, 2.713 µm |

| EDM dressing condition | 100 V, 300 nF |

| Cutting oil | Kerosene |

| Conditions | Value |

|---|---|

| Workpiece | Graphite |

| Feedrate (µm/s) | 5 |

| Machining depth (µm) | 5 |

| Machining time (s) | 2.3 |

| Rotational speed (rpm) | 3000 |

| EDM dressing condition | 100 V, 300 nF |

| Cutting oil | Kerosene |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, U.S.; Sim, D.B.; Lee, J.H.; Kim, B.H. Fabrication of Micro Carbon Mold for Glass-Based Micro Hole Array. Micromachines 2024, 15, 194. https://doi.org/10.3390/mi15020194

Lee US, Sim DB, Lee JH, Kim BH. Fabrication of Micro Carbon Mold for Glass-Based Micro Hole Array. Micromachines. 2024; 15(2):194. https://doi.org/10.3390/mi15020194

Chicago/Turabian StyleLee, Ui Seok, Dae Bo Sim, Ji Hyo Lee, and Bo Hyun Kim. 2024. "Fabrication of Micro Carbon Mold for Glass-Based Micro Hole Array" Micromachines 15, no. 2: 194. https://doi.org/10.3390/mi15020194

APA StyleLee, U. S., Sim, D. B., Lee, J. H., & Kim, B. H. (2024). Fabrication of Micro Carbon Mold for Glass-Based Micro Hole Array. Micromachines, 15(2), 194. https://doi.org/10.3390/mi15020194