Evolution of Tribotronics: From Fundamental Concepts to Potential Uses

Abstract

1. Introduction

2. Origin of Tribotronics

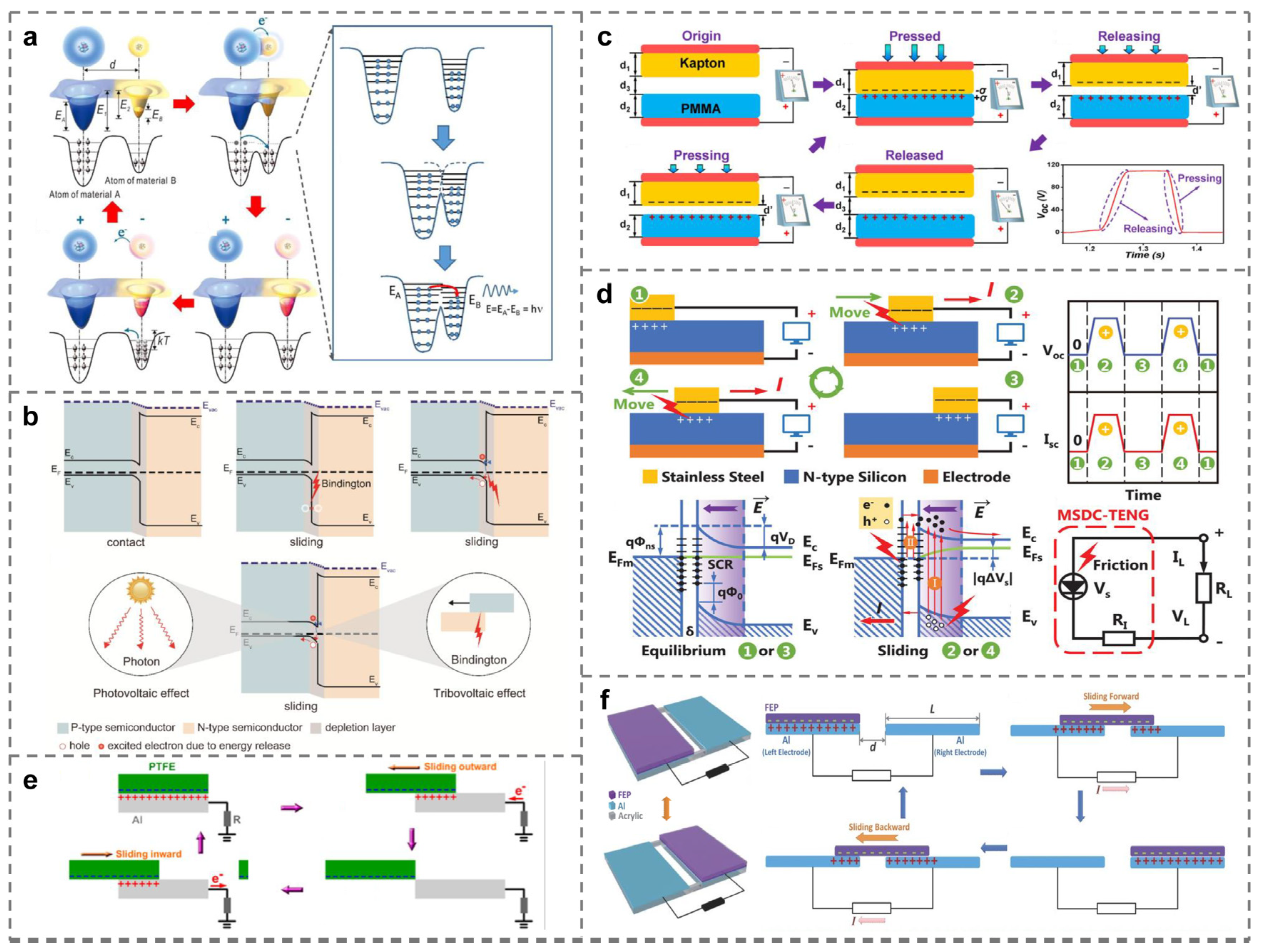

2.1. Contact Electrification (CE) Effect

2.2. Triboelectric Nanogenerator (TENG)

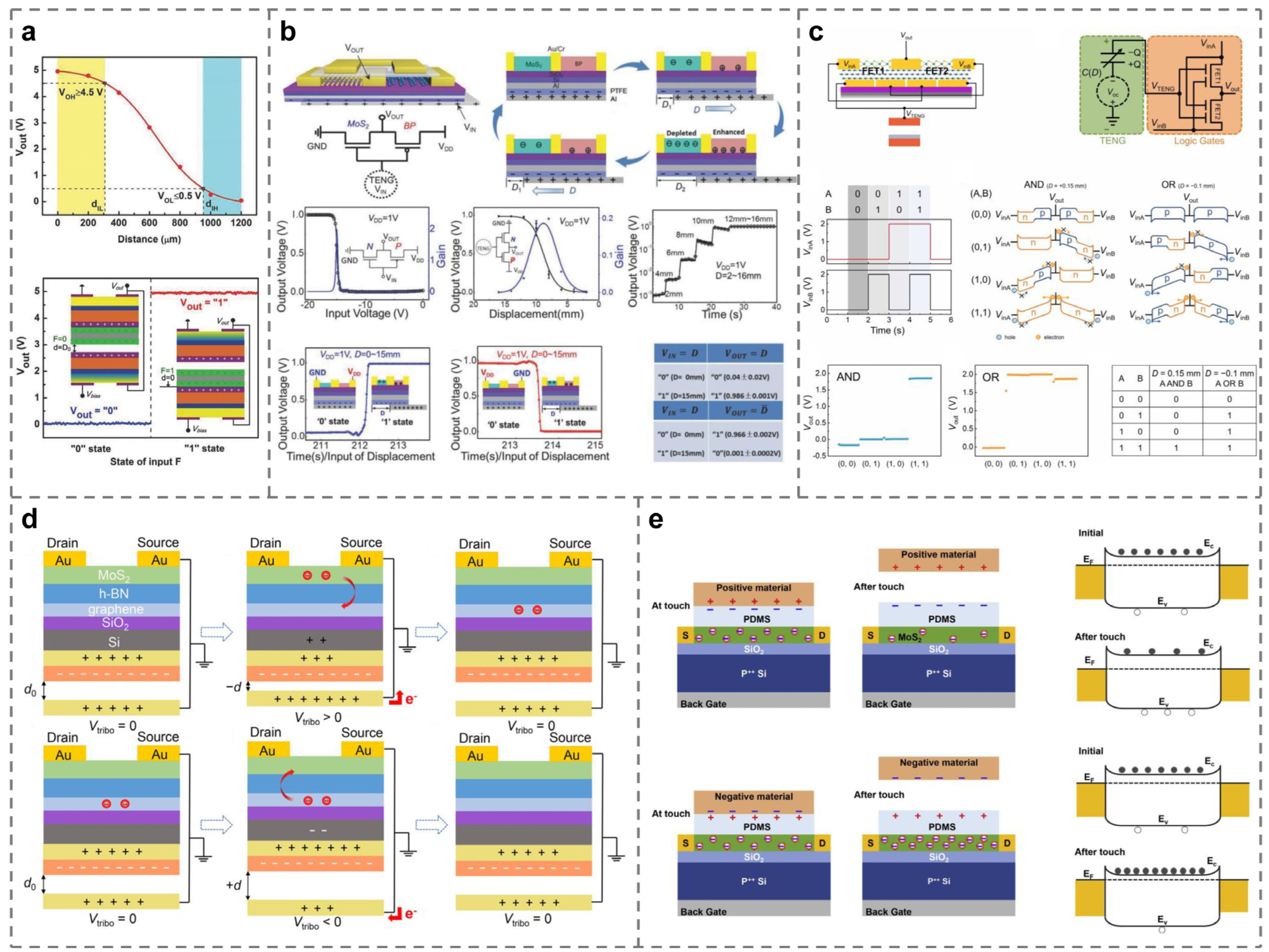

3. Tribotronics and Tribo-Potential Modulated Devices

3.1. Fundamentals of Tribotronics

| Tribotronic Device | Parameter | Experimental Data | Theoretical Result |

|---|---|---|---|

| TPG NMOS [56] | — | d → dth Typical Ids-Vds curves | Vgs → Vth MOSFET output characteristic |

| SG NMOS [57] | — | x → xth Typical Ids-Vds curves | Vgs → Vth MOSFET output characteristic |

| Tribotronic inverter | VOH | 4.933 V [58] 0.99 V [59] 1.0 V [60] | ≥0.9 V [57] |

| VOL | 0.022 V [58] 0.01 V [59] 0.02 V [60] | ≤0.1 V [57] |

3.2. Tribotronic Field-Effect Transistor (TFET)

| Transistor Type | Traditional FET | CE-FET |

|---|---|---|

| Structure | 3-terminal (Source, drain, and gate) | 2-terminal (Source and drain) |

| Gate voltage | External voltage applied by the external circuit outside the FET | Contact voltage generated by the relative motion of the contact layers inside the CE-FET |

| Control | External circuit | Environmental, mechanical behavior |

| Performance controlled factor | Channel length, channel width, channel doping concentration, gate capacitance… | Vertical distance, triboelectric charge density, channel length, channel width, channel doping concentration, gate capacitance… |

| Switching speed | Fast (GHz) | Slow (MHz) |

| Applications | Amplification, variable resistor, electronic switch | Human/environmental interfacing, sensors, MEMS, flexible electronics, tribotronics, tribophotonics, tribo-phototronics, tribotromagnetism |

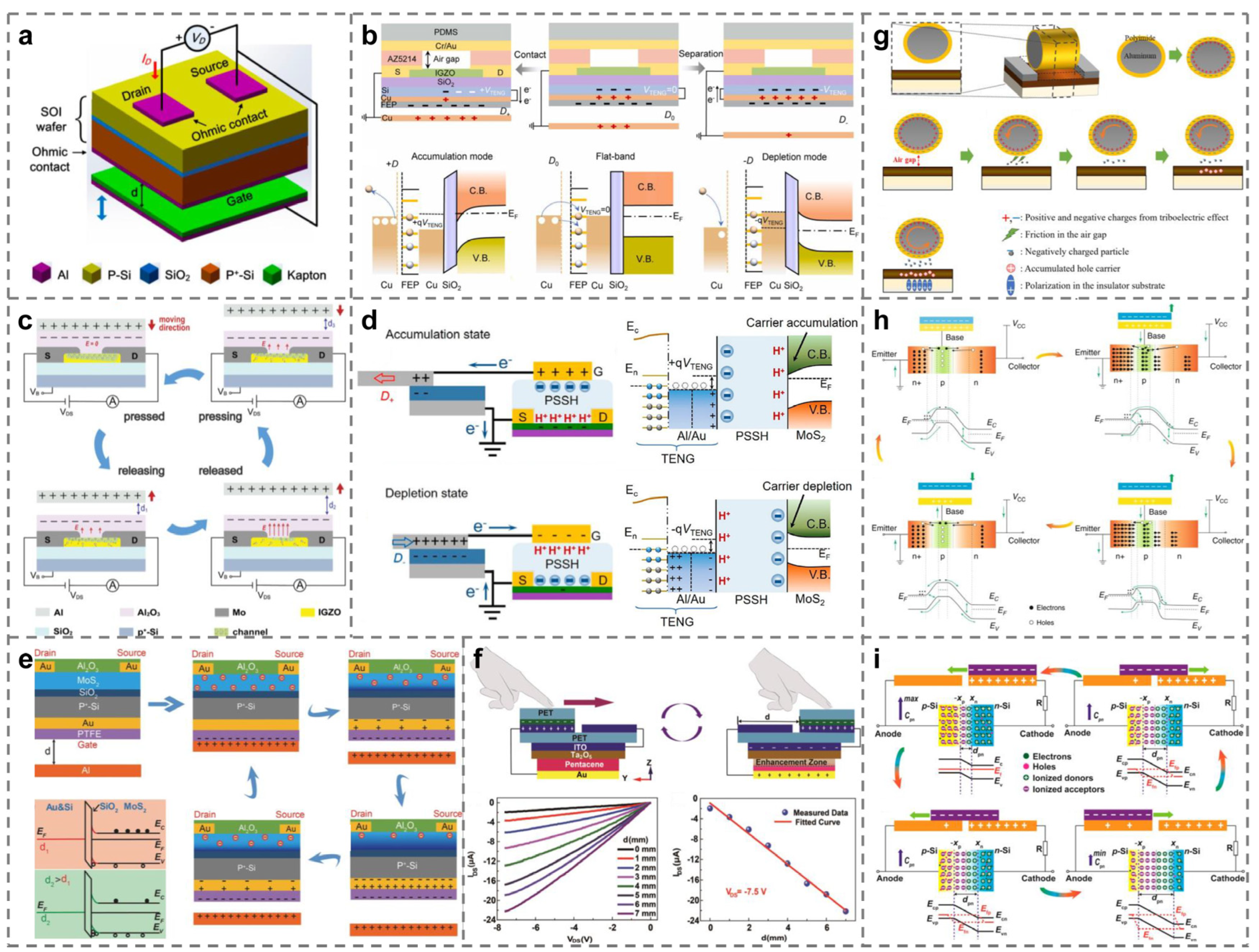

3.2.1. Contact–Separation Mode Tribotronic Field-Effect Transistor (CS-TFET)

3.2.2. Lateral Sliding Mode Tribotronic Field-Effect Transistor (LS-TFET)

3.2.3. Single-Electrode Mode Tribotronic Field-Effect Transistor (SE-TFET)

3.2.4. Freestanding Triboelectric-Layer Mode Tribotronic Field-Effect Transistor (FT-TFET)

3.2.5. Typical Performance Indicators of TFETs

3.3. Other Tribotronic Devices

4. Tribotronic Applications

4.1. Logic Circuits and Memory Devices

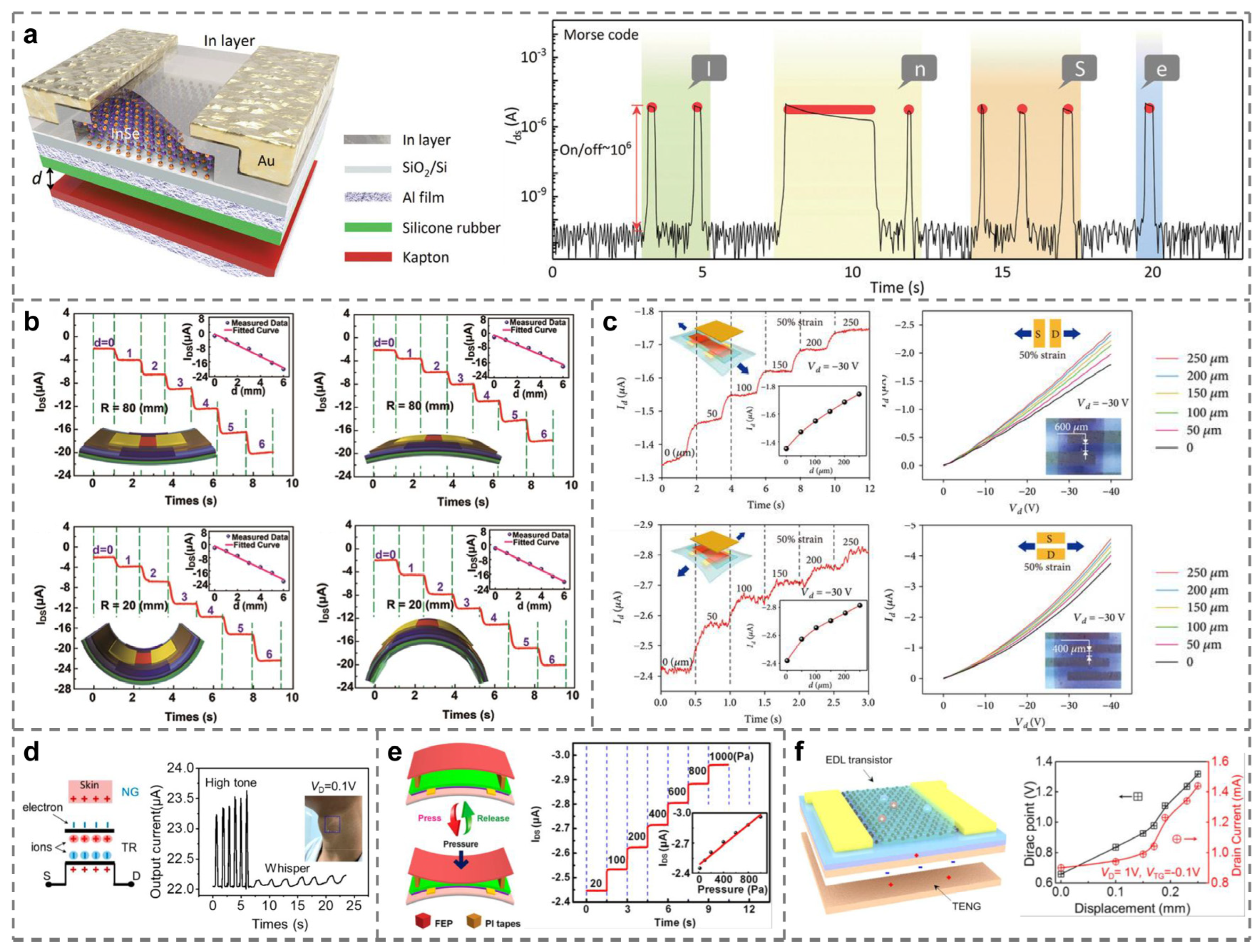

4.2. Smart Sensors

| Application | TFET Type | Test Condition | Range of ID (ΔID) | Setting Condition |

|---|---|---|---|---|

| Temperature sensor | CS-TFET [81] (GSFET) | 25~45 °C | 252~277 μA (25 μA) | VD = 0.5 V |

| CS-TFET [81] (GFET) | 25~45 °C | 78.5~82.4 μA (3.9 μA) | VD = 0.5 V | |

| Pressure sensor | CS-TFET [67] (Triboelectric potential tuned dual-gate IGZO transistor) | 55.5~344.4 kPa | 1.9~3.2 nA (1.3 nA) | VD = 15 V DCS = 0.07 mm |

| LS-TFET [86] (NTT) | 0~2.5 nN | 139~272 μA (133 μA) | — | |

| CS-TFET [77] (FOTT) | 20~1000 Pa | ≈ 0.52 μA | hFEP film = 100 μm | |

| Photodetector | CS-TFET [104] (TPT) | 0~1 mW | 0~16 μA (16 μA) | λ = 680 nm DCS = 2 mm |

| LS-TFET [69] (MoS2 phototransistor) | 10~400 mW/cm2 | 2~4 μA (2 μA) | VD = 1 V DLS = 8 mm | |

| Magnetic field sensor | CS-TFET [80] (GFET) | 7~14.6 mT | 25.1~20.1 μA (5 μA) | — |

| CS-TFET [77] (FOTT) | 1~150 mT | −2.44~−2.83 μA | VD = 0.1 V hPDMS/Fe3O4 film = 250 μm |

4.3. Artificial Synapses

4.4. Applications Coupled with Other Effects

5. Summary and Perspectives

Author Contributions

Funding

Conflicts of Interest

References

- Kocakulak, M.; Butun, I. An overview of Wireless Sensor Networks towards internet of things. In Proceedings of the 2017 IEEE 7th Annual Computing and Communication Workshop and Conference, Las Vegas, NV, USA, 9–11 January 2017; IEEE: Piscataway, NJ, USA; pp. 1–6. [Google Scholar]

- Stankovic, J.A. Research Directions for the Internet of Things. IEEE Int. Things J. 2014, 1, 3–9. [Google Scholar] [CrossRef]

- Atzori, L.; Iera, A.; Morabito, G. The Internet of Things: A survey. Comput. Netw. 2010, 54, 2787–2805. [Google Scholar] [CrossRef]

- Gao, W.; Emaminejad, S.; Nyein, H.Y.Y.; Challa, S.; Chen, K.; Peck, A.; Fahad, H.M.; Ota, H.; Shiraki, H.; Kiriya, D.; et al. Fully integrated wearable sensor arrays for multiplexed in situ perspiration analysis. Nature 2016, 529, 509–514. [Google Scholar] [CrossRef] [PubMed]

- Fu, Y.; Hoang, T.; Mechitov, K.; Kim, J.R.; Zhang, D.; Spencer, B.F. Sudden Event Monitoring of Civil Infrastructure Using Demand-Based Wireless Smart Sensors. Sensors 2018, 18, 4480. [Google Scholar] [CrossRef] [PubMed]

- Assawaworrarit, S.; Yu, X.; Fan, S. Robust wireless power transfer using a nonlinear parity-time-symmetric circuit. Nature 2017, 546, 387–390. [Google Scholar] [CrossRef]

- Yang, S.R.; Zhang, X.L.; Sun, H.B. Exceptional point protected robust on-chip optical logic gates. Exploration 2022, 2, 20210243. [Google Scholar] [CrossRef]

- Fan, F.R.; Tian, Z.Q.; Lin Wang, Z. Flexible triboelectric generator. Nano Energy 2012, 1, 328–334. [Google Scholar] [CrossRef]

- Chen, Y.; Gao, Z.; Zhang, F.; Wen, Z.; Sun, X. Recent progress in self-powered multifunctional e-skin for advanced applications. Exploration 2022, 2, 20210112. [Google Scholar] [CrossRef]

- Nguyen, T.M.H.; Shin, S.G.; Choi, H.W.; Bark, C.W. Recent advances in self-powered and flexible UVC photodetectors. Exploration 2022, 2, 20210078. [Google Scholar] [CrossRef]

- Zhang, C.; Tang, W.; Han, C.; Fan, F.; Wang, Z.L. Theoretical Comparison, Equivalent Transformation, and Conjunction Operations of Electromagnetic Induction Generator and Triboelectric Nanogenerator for Harvesting Mechanical Energy. Adv. Mater. 2014, 26, 3580–3591. [Google Scholar] [CrossRef]

- Xi, F.; Pang, Y.; Liu, G.; Wang, S.; Li, W.; Zhang, C.; Wang, Z.L. Self-powered intelligent buoy system by water wave energy for sustainable and autonomous wireless sensing and data transmission. Nano Energy 2019, 61, 26. [Google Scholar] [CrossRef]

- Tang, W.; Zhang, C.; Han, C.B.; Wang, Z.L. Enhancing Output Power of Cylindrical Triboelectric Nanogenerators by Segmentation Design and Multilayer Integration. Adv. Funct. Mater. 2014, 24, 6684–6690. [Google Scholar] [CrossRef]

- Zhang, C.; Tang, W.; Zhang, L.; Han, C.; Wang, Z.L. Contact Electrification Field-Effect Transistor. ACS Nano 2014, 8, 8702–8709. [Google Scholar] [CrossRef]

- Wang, Z.L. Entropy theory of distributed energy for internet of things. Nano Energy 2019, 58, 669–672. [Google Scholar] [CrossRef]

- McCarty, L.S.; Whitesides, G.M. Electrostatic Charging Due to Separation of Ions at Interfaces: Contact Electrification of Ionic Electrets. Angew. Chem. Int. Ed. 2008, 47, 2188–2207. [Google Scholar] [CrossRef]

- Xu, C.; Zi, Y.; Wang, A.C.; Zou, H.; Dai, Y.; He, X.; Wang, P.; Wang, Y.C.; Feng, P.; Li, D.; et al. On the Electron-Transfer Mechanism in the Contact-Electrification Effect. Adv. Mater. 2018, 30, 1706790. [Google Scholar] [CrossRef] [PubMed]

- Xu, C.; Zhang, B.; Wang, A.C.; Cai, W.; Zi, Y.; Feng, P.; Wang, Z.L. Effects of Metal Work Function and Contact Potential Difference on Electron Thermionic Emission in Contact Electrification. Adv. Funct. Mater. 2019, 29, 1903142. [Google Scholar] [CrossRef]

- Lin, S.; Xu, L.; Zhu, L.; Chen, X.; Wang, Z.L. Electron Transfer in Nanoscale Contact Electrification: Photon Excitation Effect. Adv. Mater. 2019, 31, 1901418. [Google Scholar] [CrossRef]

- Zhou, Y.S.; Liu, Y.; Zhu, G.; Lin, Z.-H.; Pan, C.; Jing, Q.; Wang, Z.L. In Situ Quantitative Study of Nanoscale Triboelectrification and Patterning. Nano Lett. 2013, 13, 2771–2776. [Google Scholar] [CrossRef]

- Wang, Z.L.; Wang, A.C. On the origin of contact-electrification. Mater. Today 2019, 30, 34–51. [Google Scholar] [CrossRef]

- Zhang, Y.; Shao, T. Effect of contact deformation on contact electrification: A first-principles calculation. J. Phys. D Appl. Phys. 2013, 46, 235304. [Google Scholar] [CrossRef]

- Duke, C.B.; Fabish, T.J. Contact electrification of polymers: A quantitative model. J. Appl. Phys. 1978, 49, 315–321. [Google Scholar] [CrossRef]

- Shen, X.; Wang, A.E.; Sankaran, R.M.; Lacks, D.J. First-principles calculation of contact electrification and validation by experiment. J. Electrost. 2016, 82, 11–16. [Google Scholar] [CrossRef]

- Lin, S.; Xu, L.; Chi Wang, A.; Wang, Z.L. Quantifying electron-transfer in liquid-solid contact electrification and the formation of electric double-layer. Nat. Commun. 2020, 11, 399. [Google Scholar] [CrossRef] [PubMed]

- Nie, J.; Ren, Z.; Xu, L.; Lin, S.; Zhan, F.; Chen, X.; Wang, Z.L. Probing Contact-Electrification-Induced Electron and Ion Transfers at a Liquid-Solid Interface. Adv. Mater. 2019, 32, 1905696. [Google Scholar] [CrossRef]

- Lin, S.; Chen, X.; Wang, Z.L. Contact Electrification at the Liquid-Solid Interface. Chem. Rev. 2022, 122, 5209–5232. [Google Scholar] [CrossRef]

- Zhang, R.; Lin, H.; Pan, Y.; Li, C.; Yang, Z.; Tian, J.; Shum, H.C. Liquid-Liquid Triboelectric Nanogenerator for Harvesting Distributed Energy. Adv. Funct. Mater. 2022, 32, 2208393. [Google Scholar] [CrossRef]

- Zhang, Q.; Xu, R.; Cai, W. Pumping electrons from chemical potential difference. Nano Energy 2018, 51, 698–703. [Google Scholar] [CrossRef]

- Xu, R.; Zhang, Q.; Wang, J.Y.; Liu, D.; Wang, J.; Wang, Z.L. Direct current triboelectric cell by sliding an n-type semiconductor on a p-type semiconductor. Nano Energy 2019, 66, 104185. [Google Scholar] [CrossRef]

- Lin, S.; Chen, X.; Wang, Z.L. The tribovoltaic effect and electron transfer at a liquid-semiconductor interface. Nano Energy 2020, 76, 105070. [Google Scholar] [CrossRef]

- Lin, S.; Lin Wang, Z. The tribovoltaic effect. Mater. Today 2023, 62, 111–128. [Google Scholar] [CrossRef]

- Zheng, M.; Lin, S.; Tang, Z.; Feng, Y.; Wang, Z.L. Photovoltaic effect and tribovoltaic effect at liquid-semiconductor interface. Nano Energy 2021, 83, 105810. [Google Scholar] [CrossRef]

- Zheng, M.; Lin, S.; Xu, L.; Zhu, L.; Wang, Z.L. Scanning Probing of the Tribovoltaic Effect at the Sliding Interface of Two Semiconductors. Adv. Mater. 2020, 32, 2000928. [Google Scholar] [CrossRef] [PubMed]

- Huang, Y.; Liu, D.; Gao, X.; Zhu, J.; Zhang, Y.; Zhang, M. Flexible Liquid-Based Continuous Direct-Current Tribovoltaic Generators Enable Self-Powered Multi-Modal Sensing. Adv. Funct. Mater. 2023, 33, 2209484. [Google Scholar] [CrossRef]

- Deng, S.; Xu, R.; Seh, W.; Sun, J.; Cai, W.; Zou, J.; Zhang, Q. Current degradation mechanism of tip contact metal-silicon Schottky nanogenerator. Nano Energy 2022, 94, 106888. [Google Scholar] [CrossRef]

- Xia, J.; Luo, X.; Li, J.; Zhu, L.; Wang, Z.L. Wear-Resisting and Stable 4H-SiC/Cu-Based Tribovoltaic Nanogenerators for Self-Powered Sensing in a Harsh Environment. ACS Appl. Mater. Interfaces 2022, 14, 55192–55200. [Google Scholar] [CrossRef]

- Lee, Y.-S.; Jeon, S.; Kim, D.; Lee, D.-M.; Kim, D.; Kim, S.-W. High performance direct current-generating triboelectric nanogenerators based on tribovoltaic p-n junction with ChCl-passivated CsFAMA perovskite. Nano Energy 2023, 106, 108066. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, Z.; Wang, Z.; Bu, T.; Dong, S.; Wei, W.; Chen, Z.; Lin, Y.; Lv, Y.; Zhou, H.; et al. Friction-Dominated Carrier Excitation and Transport Mechanism for GaN-Based Direct-Current Triboelectric Nanogenerators. ACS Appl. Mater. Interfaces 2022, 14, 24020–24027. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, Z.; Chen, Y.; Gong, L.; Dong, S.; Zhou, H.; Lin, Y.; Lv, Y.; Liu, G.; Zhang, C. Achieving an ultrahigh direct-current voltage of 130 V by semiconductor heterojunction power generation based on the tribovoltaic effect. Energy Environ. Sci. 2022, 15, 2366–2373. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, Z.; Chen, Y.; Feng, Y.; Dong, S.; Zhou, H.; Wang, Z.L.; Zhang, C. Semiconductor Contact-Electrification-Dominated Tribovoltaic Effect for Ultrahigh Power Generation. Adv. Mater. 2022, 34, 2200146. [Google Scholar] [CrossRef]

- Zhu, G.; Pan, C.; Guo, W.; Chen, C.Y.; Zhou, Y.; Yu, R.; Wang, Z.L. Triboelectric-generator-driven pulse electrodeposition for micropatterning. Nano Lett. 2012, 12, 4960–4965. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Lin, L.; Wang, Z.L. Nanoscale triboelectric-effect-enabled energy conversion for sustainably powering portable electronics. Nano Lett. 2012, 12, 6339–6346. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Lin, L.; Xie, Y.; Jing, Q.; Niu, S.; Wang, Z.L. Sliding-triboelectric nanogenerators based on in-plane charge-separation mechanism. Nano Lett. 2013, 13, 2226–2233. [Google Scholar] [CrossRef]

- Zhang, Z.; Jiang, D.; Zhao, J.; Liu, G.; Bu, T.; Zhang, C.; Wang, Z.L. Tribovoltaic Effect on Metal-Semiconductor Interface for Direct-Current Low-Impedance Triboelectric Nanogenerators. Adv. Energy Mater. 2020, 10, 1903713. [Google Scholar] [CrossRef]

- Mallineni, S.S.K.; Behlow, H.; Dong, Y.; Bhattacharya, S.; Rao, A.M.; Podila, R. Facile and robust triboelectric nanogenerators assembled using off-the-shelf materials. Nano Energy 2017, 35, 263–270. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, H.; Chen, J.; Jing, Q.; Zhou, Y.S.; Wen, X.; Wang, Z.L. Single-Electrode-Based Sliding Triboelectric Nanogenerator for Self-Powered Displacement Vector Sensor System. ACS Nano 2013, 7, 7342–7351. [Google Scholar] [CrossRef]

- Niu, S.; Wang, Z.L. Theoretical systems of triboelectric nanogenerators. Nano Energy 2015, 14, 161–192. [Google Scholar] [CrossRef]

- Wang, S.; Xie, Y.; Niu, S.; Lin, L.; Wang, Z.L. Freestanding triboelectric-layer-based nanogenerators for harvesting energy from a moving object or human motion in contact and non-contact modes. Adv. Mater. 2014, 26, 2818–2824. [Google Scholar] [CrossRef]

- Tang, Q.; Wang, Z.; Chang, W.; Sun, J.; He, W.; Zeng, Q.; Guo, H.; Hu, C. Interface Static Friction Enabled Ultra-Durable and High Output Sliding Mode Triboelectric Nanogenerator. Adv. Funct. Mater. 2022, 32, 2202055. [Google Scholar] [CrossRef]

- Li, S.; Wang, S.; Zi, Y.; Wen, Z.; Lin, L.; Zhang, G.; Wang, Z.L. Largely Improving the Robustness and Lifetime of Triboelectric Nanogenerators through Automatic Transition between Contact and Noncontact Working States. ACS Nano 2015, 9, 7479–7487. [Google Scholar] [CrossRef]

- Lin, L.; Wang, S.; Niu, S.; Liu, C.; Xie, Y.; Wang, Z.L. Noncontact Free-Rotating Disk Triboelectric Nanogenerator as a Sustainable Energy Harvester and Self-Powered Mechanical Sensor. ACS Appl. Mater. Interfaces 2014, 6, 3031–3038. [Google Scholar] [CrossRef] [PubMed]

- Lin, L.; Xie, Y.; Niu, S.; Wang, S.; Yang, P.-K.; Wang, Z.L. Robust triboelectric nanogenerator based on rolling electrification and electrostatic induction at an instantaneous energy conversion efficiency of ~55%. ACS Nano 2015, 9, 922–930. [Google Scholar] [CrossRef] [PubMed]

- Xi, F.; Pang, Y.; Li, W.; Jiang, T.; Zhang, L.; Guo, T.; Liu, G.; Zhang, C.; Wang, Z.L. Universal power management strategy for triboelectric nanogenerator. Nano Energy 2017, 37, 168–176. [Google Scholar] [CrossRef]

- Zhang, C.; Bu, T. Tribotronics for active mechanosensation. Sci. Sin. Technol. 2023, 53, 902–916. [Google Scholar] [CrossRef]

- Peng, W.; Yu, R.; He, Y.; Wang, Z.L. Theoretical Study of Triboelectric-Potential Gated/Driven Metal-Oxide-Semiconductor Field-Effect Transistor. ACS Nano 2016, 10, 4395–4402. [Google Scholar] [CrossRef]

- Jiang, T.; Zhang, L.; Zhang, X.; Zhang, C.; Peng, W.; Xiao, T.; Wang, Z.L. Theoretical Study of Sliding-Electrification-Gated Tribotronic Transistors and Logic Device. Adv. Electron. Mater. 2018, 4, 1700337. [Google Scholar] [CrossRef]

- Zhang, C.; Zhang, L.M.; Tang, W.; Han, C.B.; Wang, Z.L. Tribotronic Logic Circuits and Basic Operations. Adv. Mater. 2015, 27, 3533–3540. [Google Scholar] [CrossRef]

- Gao, G.; Wan, B.; Liu, X.; Sun, Q.; Yang, X.; Wang, L.; Pan, C.; Wang, Z.L. Tunable Tribotronic Dual-Gate Logic Devices Based on 2D MoS2 and Black Phosphorus. Adv. Mater. 2018, 30, 1705088. [Google Scholar] [CrossRef]

- Cheng, L.; Yu, J.; Wei, Y.; Feng, Z.; Li, Y.; Wang, Y.; Xu, N.; Wang, Z.L.; Sun, Q. Triboelectric-potential configurable MoTe2 homojunction for photovoltaic device and logic circuits. Nano Energy 2023, 114, 108632. [Google Scholar] [CrossRef]

- Zhang, C.; Wang, Z.L. Tribotronics-A new field by coupling triboelectricity and semiconductor. Nano Today 2016, 11, 521–536. [Google Scholar] [CrossRef]

- Liu, Y.; Niu, S.; Wang, Z.L. Theory of Tribotronics. Adv. Electron. Mater. 2015, 1, 1500124. [Google Scholar] [CrossRef]

- Zhang, C.; Li, J.; Han, C.B.; Zhang, L.M.; Chen, X.Y.; Wang, L.D.; Dong, G.F.; Wang, Z.L. Organic Tribotronic Transistor for Contact-Electrification-Gated Light-Emitting Diode. Adv. Funct. Mater. 2015, 25, 5625–5632. [Google Scholar] [CrossRef]

- Qu, W.; Liu, W.; Li, X.; Wang, X. A triboelectric charge top-gated graphene transistor. Diam. Relat. Mater. 2017, 73, 33–38. [Google Scholar] [CrossRef]

- Gao, G.; Yu, J.; Yang, X.; Pang, Y.; Zhao, J.; Pan, C.; Sun, Q.; Wang, Z.L. Triboiontronic Transistor of MoS2. Adv. Mater. 2019, 31, 1806905. [Google Scholar] [CrossRef] [PubMed]

- Lei, H.; Cao, Y.X.; Zhao, C. Thin-film Transistor-based Tribotronic Artificial Synapse with Neurosensory Behavior. In Proceedings of the 2023 International Conference on IC Design and Technology (ICICDT), Tokyo, Japan, 25–28 September 2023; IEEE: Piscataway, NJ, USA; pp. 136–140. [Google Scholar]

- Tan, F.; Xiong, Y.; Yu, J.; Wang, Y.; Li, Y.; Wei, Y.; Sun, J.; Xie, X.; Sun, Q.; Wang, Z.L. Triboelectric potential tuned dual-gate IGZO transistor for versatile sensory device. Nano Energy 2021, 90, 106617. [Google Scholar] [CrossRef]

- Cao, Y.; Bu, T.; Fang, C.; Zhang, C.; Huang, X.; Zhang, C. High-Resolution Monolithic Integrated Tribotronic InGaZnO Thin-Film Transistor Array for Tactile Detection. Adv. Funct. Mater. 2020, 30, 2002613. [Google Scholar] [CrossRef]

- Pang, Y.; Xue, F.; Wang, L.; Chen, J.; Luo, J.; Jiang, T.; Zhang, C.; Wang, Z.L. Tribotronic Enhanced Photoresponsivity of a MoS2 Phototransistor. Adv. Sci. 2016, 3, 1500419. [Google Scholar] [CrossRef] [PubMed]

- Yang, X.; Han, J.; Yu, J.; Chen, Y.; Zhang, H.; Ding, M.; Jia, C.; Sun, J.; Sun, Q.; Wang, Z.L. Versatile Triboiontronic Transistor via Proton Conductor. ACS Nano 2020, 14, 8668–8677. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Yu, J.; Wei, Y.; Wang, Y.; Cheng, L.; Feng, Z.; Yang, Y.; Wang, Z.L.; Sun, Q. Ambipolar tribotronic transistor of MoTe2. Nano Res. 2023, 16, 11907–11913. [Google Scholar] [CrossRef]

- Wang, Y.; Lin, X.; Gao, G.; Yu, J.; Wei, Y.; Gong, J.; Sun, J.; Wang, Z.L.; Sun, Q. Tribotronic Vertical Field-Effect Transistor Based on van der Waals Heterostructures. Adv. Funct. Mater. 2024, 34, 2313210. [Google Scholar] [CrossRef]

- Xue, F.; Chen, L.; Wang, L.; Pang, Y.; Chen, J.; Zhang, C.; Wang, Z.L. MoS2 Tribotronic Transistor for Smart Tactile Switch. Adv. Funct. Mater. 2016, 26, 2104–2109. [Google Scholar] [CrossRef]

- Khan, U.; Kim, T.H.; Ryu, H.; Seung, W.; Kim, S.W. Graphene Tribotronics for Electronic Skin and Touch Screen Applications. Adv. Mater. 2017, 29, 1603544. [Google Scholar] [CrossRef]

- Pang, Y.; Li, J.; Zhou, T.; Yang, Z.; Luo, J.; Zhang, L.; Dong, G.; Zhang, C.; Wang, Z.L. Flexible transparent tribotronic transistor for active modulation of conventional electronics. Nano Energy 2017, 31, 533–540. [Google Scholar] [CrossRef]

- Pang, Y.; Chen, L.; Hu, G.; Luo, J.; Yang, Z.; Zhang, C.; Wang, Z.L. Tribotronic transistor sensor for enhanced hydrogen detection. Nano Res. 2017, 10, 3857–3864. [Google Scholar] [CrossRef]

- Zhao, J.; Guo, H.; Pang, Y.K.; Xi, F.; Yang, Z.W.; Liu, G.; Guo, T.; Dong, G.; Zhang, C.; Wang, Z.L. Flexible Organic Tribotronic Transistor for Pressure and Magnetic Sensing. ACS Nano 2017, 11, 11566–11573. [Google Scholar] [CrossRef]

- Li, M.; Yang, F.S.; Hsiao, Y.C.; Lin, C.Y.; Wu, H.M.; Yang, S.H.; Li, H.R.; Lien, C.H.; Ho, C.H.; Liu, H.J.; et al. Low-Voltage Operational, Low-Power Consuming, and High Sensitive Tactile Switch Based on 2D Layered InSe Tribotronics. Adv. Funct. Mater. 2019, 29, 1809119. [Google Scholar] [CrossRef]

- Yang, Z.W.; Pang, Y.; Zhang, L.; Lu, C.; Chen, J.; Zhou, T.; Zhang, C.; Wang, Z.L. Tribotronic Transistor Array as an Active Tactile Sensing System. ACS Nano 2016, 10, 10912–10920. [Google Scholar] [CrossRef] [PubMed]

- Meng, Y.; Gao, G.; Zhu, J. Self-powered bifunctional sensor based on tribotronic planar graphene transistors. Sci. Rep. 2021, 11, 21483. [Google Scholar] [CrossRef]

- Meng, Y. Highly Stretchable Graphene Scrolls Transistors for Self-Powered Tribotronic Non-Mechanosensation Application. Nanomaterials 2023, 13, 528. [Google Scholar] [CrossRef]

- Meng, Y.; Zhao, J.; Yang, X.; Zhao, C.; Qin, S.; Cho, J.H.; Zhang, C.; Sun, Q.; Wang, Z.L. Mechanosensation-Active Matrix Based on Direct-Contact Tribotronic Planar Graphene Transistor Array. ACS Nano 2018, 12, 9381–9389. [Google Scholar] [CrossRef]

- Zhao, J.; Bu, T.; Zhang, X.; Pang, Y.; Li, W.; Zhang, Z.; Liu, G.; Wang, Z.L.; Zhang, C. Intrinsically Stretchable Organic-Tribotronic-Transistor for Tactile Sensing. Research 2020, 2020, 1398903. [Google Scholar] [CrossRef] [PubMed]

- Zhao, J.; Zeng, J.; Chen, L.; Lin, Y.; Zhang, Z.B.; Zhang, C. Intrinsically stretchable and self-healable tribotronic transistor for bioinspired e-skin. Mater. Today Phys. 2022, 28, 100877. [Google Scholar] [CrossRef]

- Zhang, H.; Yu, J.; Yang, X.; Gao, G.; Qin, S.; Sun, J.; Ding, M.; Jia, C.; Sun, Q.; Wang, Z.L. Ion Gel Capacitively Coupled Tribotronic Gating for Multiparameter Distance Sensing. ACS Nano 2020, 14, 3461–3468. [Google Scholar] [CrossRef]

- Bu, T.; Xu, L.; Yang, Z.; Yang, X.; Liu, G.; Cao, Y.; Zhang, C.; Wang, Z.L. Nanoscale triboelectrification gated transistor. Nat. Commun. 2020, 11, 1054. [Google Scholar] [CrossRef] [PubMed]

- Zhou, T.; Yang, Z.W.; Pang, Y.; Xu, L.; Zhang, C.; Wang, Z.L. Tribotronic Tuning Diode for Active Analog Signal Modulation. ACS Nano 2017, 11, 882–888. [Google Scholar] [CrossRef]

- Shin, H.; Kim, D.Y. Energy-efficient electronics with an air-friction-driven rotating gate transistor using tribotronics. iScience 2024, 27, 109029. [Google Scholar] [CrossRef]

- Xi, F.; Pang, Y.; Li, W.; Bu, T.; Zhao, J.; Liu, G.; Guo, T.; Liu, W.; Zhang, C. Tribotronic bipolar junction transistor for mechanical frequency monitoring and use as touch switch. Microsyst. Nanoeng. 2018, 4, 25. [Google Scholar] [CrossRef]

- Luo, X.; Liu, L.; Wang, Y.C.; Li, J.; Berbille, A.; Zhu, L.; Wang, Z.L. Tribovoltaic Nanogenerators Based on MXene-Silicon Heterojunctions for Highly Stable Self-Powered Speed, Displacement, Tension, Oscillation Angle, and Vibration Sensors. Adv. Funct. Mater. 2022, 32, 2113149. [Google Scholar] [CrossRef]

- Lee, W.H.; Yoon, S.G.; Jin, H.; Yoo, J.; Han, J.; Cho, Y.H.; Kim, Y.S. Electron Density-Change in Semiconductor by Ion-Adsorption at Solid-Liquid Interface. Adv. Mater. 2021, 33, 2007581. [Google Scholar] [CrossRef]

- Zhang, X.; Ren, D.; Wu, H.; Wang, J.; Li, X.; Yang, H.; Li, Q.; Yang, Q.; Zhu, J.; Xi, Y. Ultrahigh voltage direct current quasi-tribovoltaic nanogenerator by switchable tribo-bias induction and deposited charge extraction. Energy Environ. Sci. 2024, 17, 4175–4186. [Google Scholar] [CrossRef]

- Zhang, Z.; Wu, N.; Gong, L.; Luan, R.; Cao, J.; Zhang, C. An Ultrahigh Power Density and Ultralow Wear GaN-Based Tribovoltaic Nanogenerator for Sliding Ball Bearing as Self-Powered Wireless Sensor Node. Adv. Mater. 2023, 36, 2310098. [Google Scholar] [CrossRef] [PubMed]

- Huang, H.H.; Wang, R.C.; Chen, Y.J. Fluorinated graphite paper used for self-powered water speed sensors by immersion-type tribovoltaic effect-dominated triboelectric nanogenerators. Nano Energy 2022, 93, 106887. [Google Scholar] [CrossRef]

- Benner, M.; Yang, R.; Lin, L.; Liu, M.; Li, H.; Liu, J. Mechanism of In-Plane and Out-of-Plane Tribovoltaic Direct-Current Transport with a Metal/Oxide/Metal Dynamic Heterojunction. ACS Appl. Mater. Interfaces 2022, 14, 2968–2978. [Google Scholar] [CrossRef] [PubMed]

- Xu, X.; Li, J.; Tao, X.; Yan, Q.; Wu, H.; Guan, Z.; Liu, L.; Chen, X.; Ou-Yang, W. Study of interfacial design for direct-current tribovoltaic generators. Nano Energy 2022, 94, 106957. [Google Scholar] [CrossRef]

- Yang, R.; He, Z.; Lin, S.; Dou, W.; Wang, Z.L.; Wang, H.; Liu, J. Tunable Tribovoltaic Effect via Metal-Insulator Transition. Nano Lett. 2022, 22, 9084–9091. [Google Scholar] [CrossRef]

- Zhao, Z.; Zhang, J.; Qiao, W.; Zhou, L.; Guo, Z.; Li, X.; Wang, Z.L.; Wang, J. Contact efficiency optimization for tribovoltaic nanogenerators. Mater. Horiz. 2023, 10, 5962–5968. [Google Scholar] [CrossRef]

- Zhang, L.M.; Yang, Z.W.; Pang, Y.K.; Zhou, T.; Zhang, C.; Wang, Z.L. Tribotronic triggers and sequential logic circuits. Nano Res. 2017, 10, 3534–3542. [Google Scholar] [CrossRef]

- Li, J.; Zhang, C.; Duan, L.; Zhang, L.M.; Wang, L.D.; Dong, G.F.; Wang, Z.L. Flexible Organic Tribotronic Transistor Memory for a Visible and Wearable Touch Monitoring System. Adv. Mater. 2016, 28, 106–110. [Google Scholar] [CrossRef] [PubMed]

- Khan, U.; Kim, T.-H.; Khan, M.A.; Kim, J.; Falconi, C.; Kim, S.-W. Zero-writing-power tribotronic MoS2 touch memory. Nano Energy 2020, 75, 104936. [Google Scholar] [CrossRef]

- Jia, M.; Yu, J.; Liu, Y.; Guo, P.; Lei, Y.; Wang, W.; Yu, A.; Zhu, Y.; Sun, Q.; Zhai, J.; et al. Multibit tribotronic nonvolatile memory based on van der Waals heterostructures. Nano Energy 2021, 83, 105785. [Google Scholar] [CrossRef]

- Zhao, J.; Wei, Z.; Yang, X.; Zhang, G.; Wang, Z. Mechanoplastic tribotronic two-dimensional multibit nonvolatile optoelectronic memory. Nano Energy 2021, 82, 105692. [Google Scholar] [CrossRef]

- Zhang, C.; Zhang, Z.H.; Yang, X.; Zhou, T.; Han, C.B.; Wang, Z.L. Tribotronic Phototransistor for Enhanced Photodetection and Hybrid Energy Harvesting. Adv. Funct. Mater. 2016, 26, 2554–2560. [Google Scholar] [CrossRef]

- Yang, X.; Yu, J.; Zhao, J.; Chen, Y.; Gao, G.; Wang, Y.; Sun, Q.; Wang, Z.L. Mechanoplastic Tribotronic Floating-Gate Neuromorphic Transistor. Adv. Funct. Mater. 2020, 30, 2002506. [Google Scholar] [CrossRef]

- Zeng, J.; Zhao, J.; Bu, T.; Liu, G.; Qi, Y.; Zhou, H.; Dong, S.; Zhang, C. A Flexible Tribotronic Artificial Synapse with Bioinspired Neurosensory Behavior. Nano-Micro Lett. 2023, 15, 18. [Google Scholar] [CrossRef]

- Jia, M.; Guo, P.; Wang, W.; Yu, A.; Zhang, Y.; Wang, Z.L.; Zhai, J. Tactile tribotronic reconfigurable p-n junctions for artificial synapses. Sci. Bull. 2022, 67, 803–812. [Google Scholar] [CrossRef]

- Zeng, J.; Chen, L.; Bu, T.; Wang, Z.; Gong, L.; Zhang, Z.-B.; Zhao, J.; Lin Wang, Z.; Zhang, C. Intrinsically stretchable tribotronic mechanoplastic artificial synapse. Chem. Eng. J. 2024, 492, 152412. [Google Scholar] [CrossRef]

- Bu, T.; Jiang, D.; Yang, X.; Liu, W.; Liu, G.; Guo, T.; Pang, Y.; Zhao, J.; Xi, F.; Zhang, C. Liquid Metal Gated Tribotronic Transistors as an Electronic Gradienter for Angle Measurement. Adv. Electron. Mater. 2018, 4, 1800269. [Google Scholar] [CrossRef]

- Zhou, W.; Zeng, J.; Dong, Z.; Xiao, C.; Gong, L.; Fan, B.; Li, Y.; Chen, Y.; Zhao, J.; Zhang, C. A Degradable Tribotronic Transistor for Self-Destructing Intelligent Package e-Labels. ACS Appl. Mater. Interfaces 2024, 16, 30255–30263. [Google Scholar] [CrossRef]

| Performance Indicator | CS-TFET [67,68,77,78,79,80,81,82,83,84,85] | LS-TFET [59,69,70,71,72,86] | SE-TFET [73,74] | FT-TFET [75,76,87] |

|---|---|---|---|---|

| Operational current | 2 μA~10 mA | 0.5~20 μA | 15~300 μA | 20~30 μA |

| Operational voltage | 0.1~10 V | 0.1~1.5 V | 0.5~1 V | 1~8 V |

| Response time | 10~150 ms | 150~800 ms | 30~400 ms | 300~500 ms |

| Durability | 1000~10,000 cycles | 20~100 cycles | 1000~2000 cycles | 1000 cycles |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, Y.; Tian, J.; Li, F.; Peng, W.; He, Y. Evolution of Tribotronics: From Fundamental Concepts to Potential Uses. Micromachines 2024, 15, 1259. https://doi.org/10.3390/mi15101259

He Y, Tian J, Li F, Peng W, He Y. Evolution of Tribotronics: From Fundamental Concepts to Potential Uses. Micromachines. 2024; 15(10):1259. https://doi.org/10.3390/mi15101259

Chicago/Turabian StyleHe, Yue, Jia Tian, Fangpei Li, Wenbo Peng, and Yongning He. 2024. "Evolution of Tribotronics: From Fundamental Concepts to Potential Uses" Micromachines 15, no. 10: 1259. https://doi.org/10.3390/mi15101259

APA StyleHe, Y., Tian, J., Li, F., Peng, W., & He, Y. (2024). Evolution of Tribotronics: From Fundamental Concepts to Potential Uses. Micromachines, 15(10), 1259. https://doi.org/10.3390/mi15101259