Research on Improved Quantitative Identification Algorithm in Odor Source Searching Based on Gas Sensor Array

Abstract

:1. Introduction

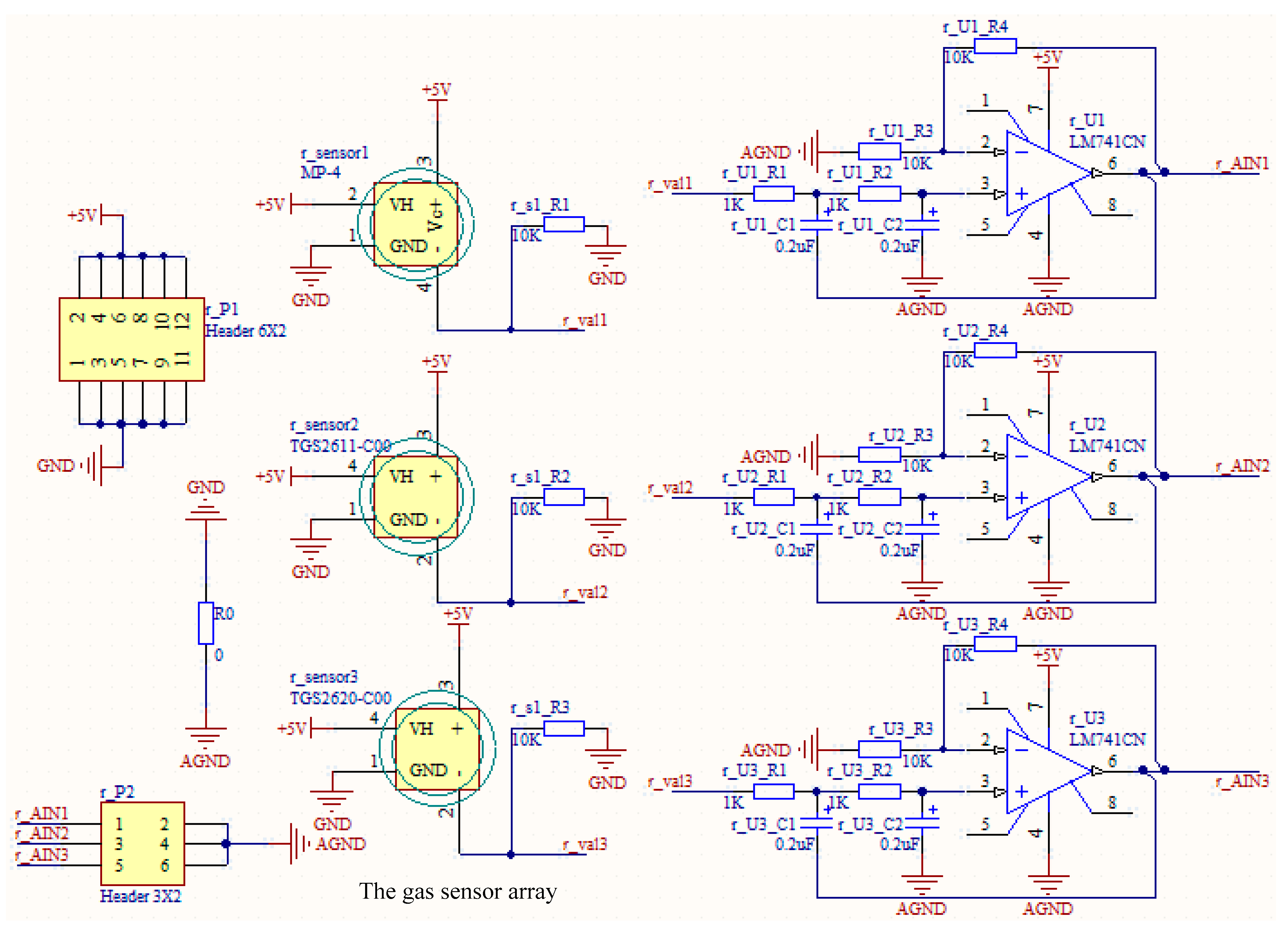

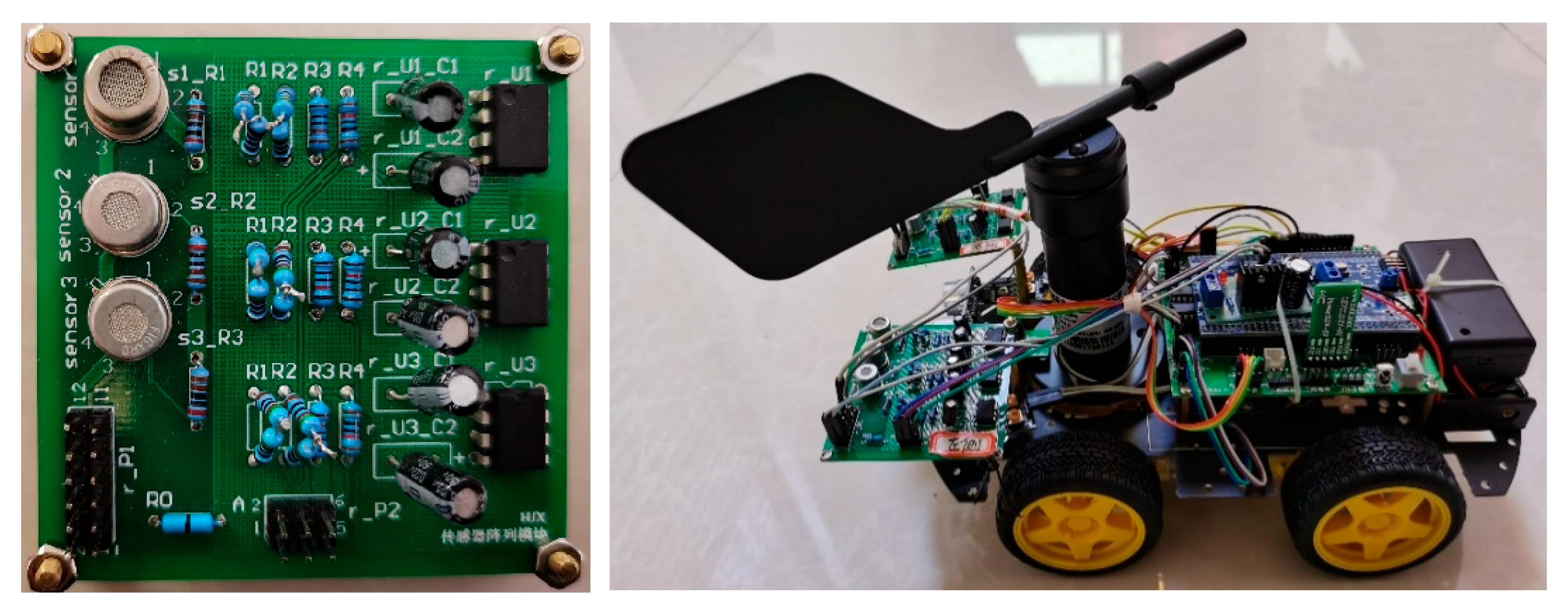

2. Gas Sensor Array Construction and Neural Network Design

2.1. Gas Sensor Array Construction and Calibration

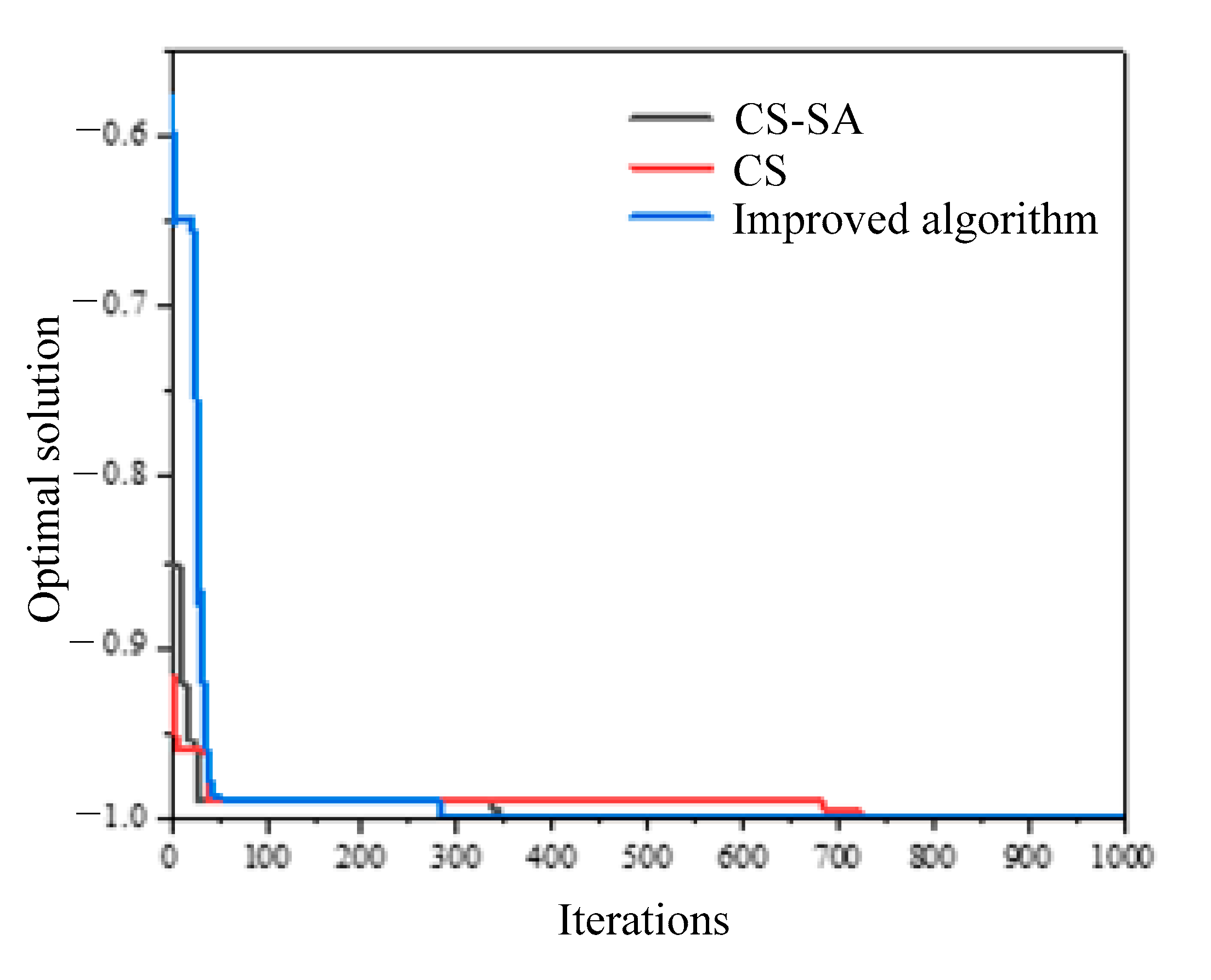

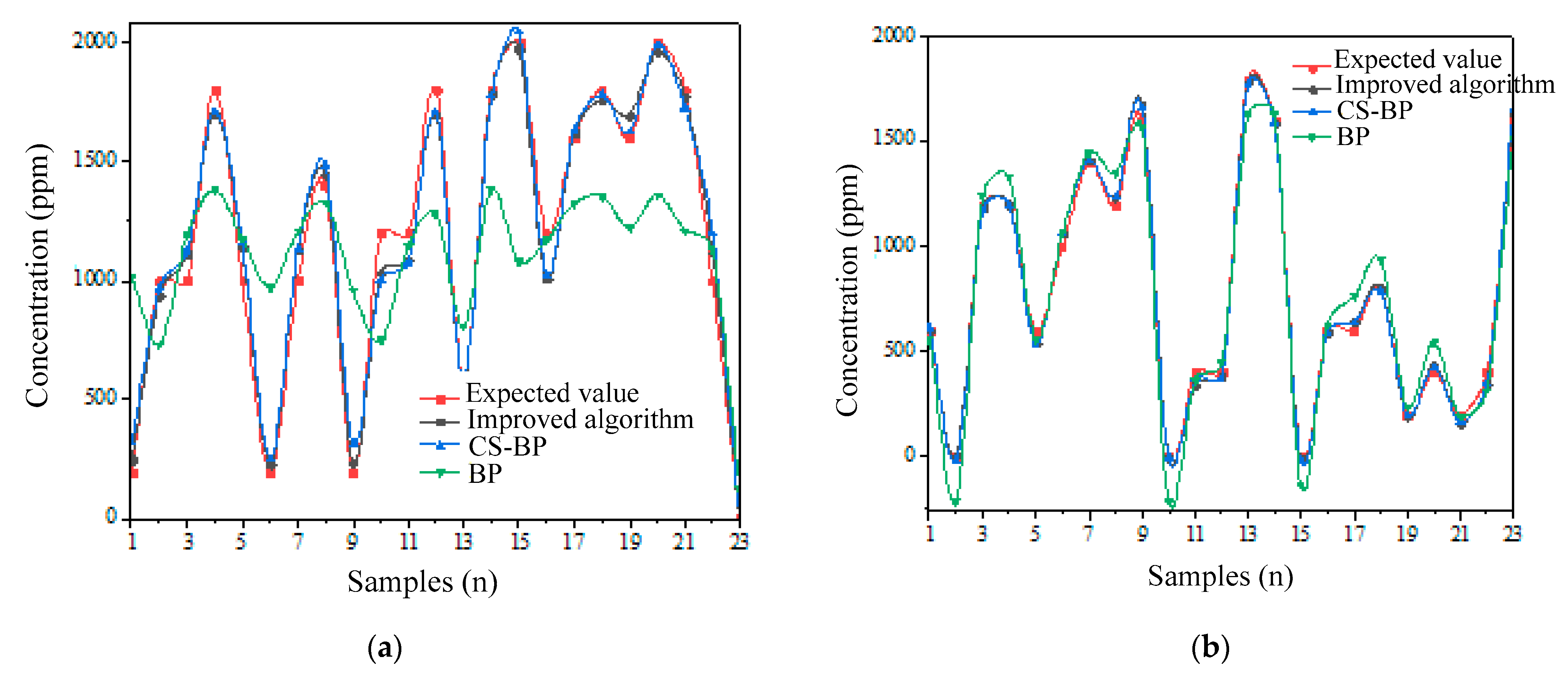

2.2. Improved Quantitative Identification Algorithm Propose and Design

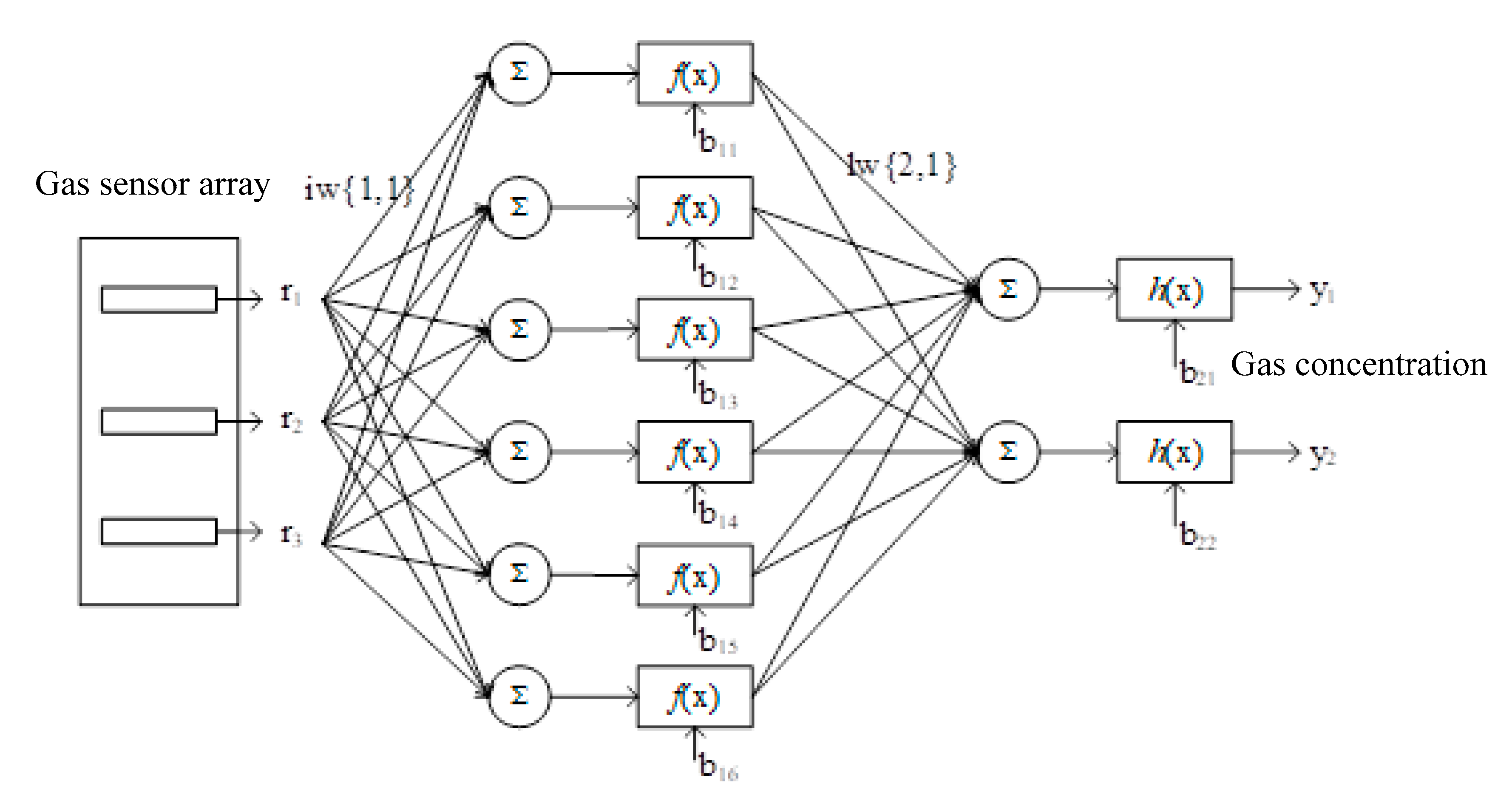

2.3. Neural Network Design

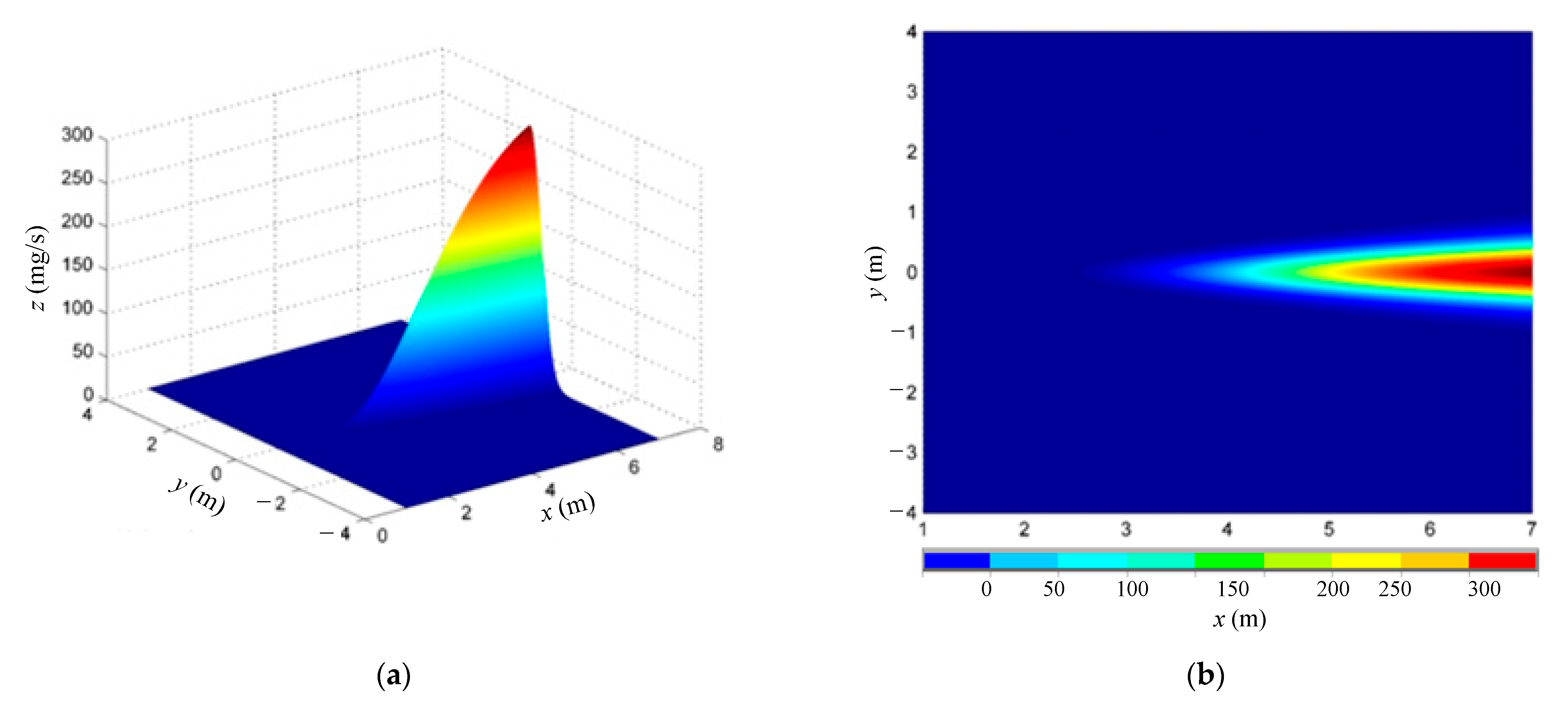

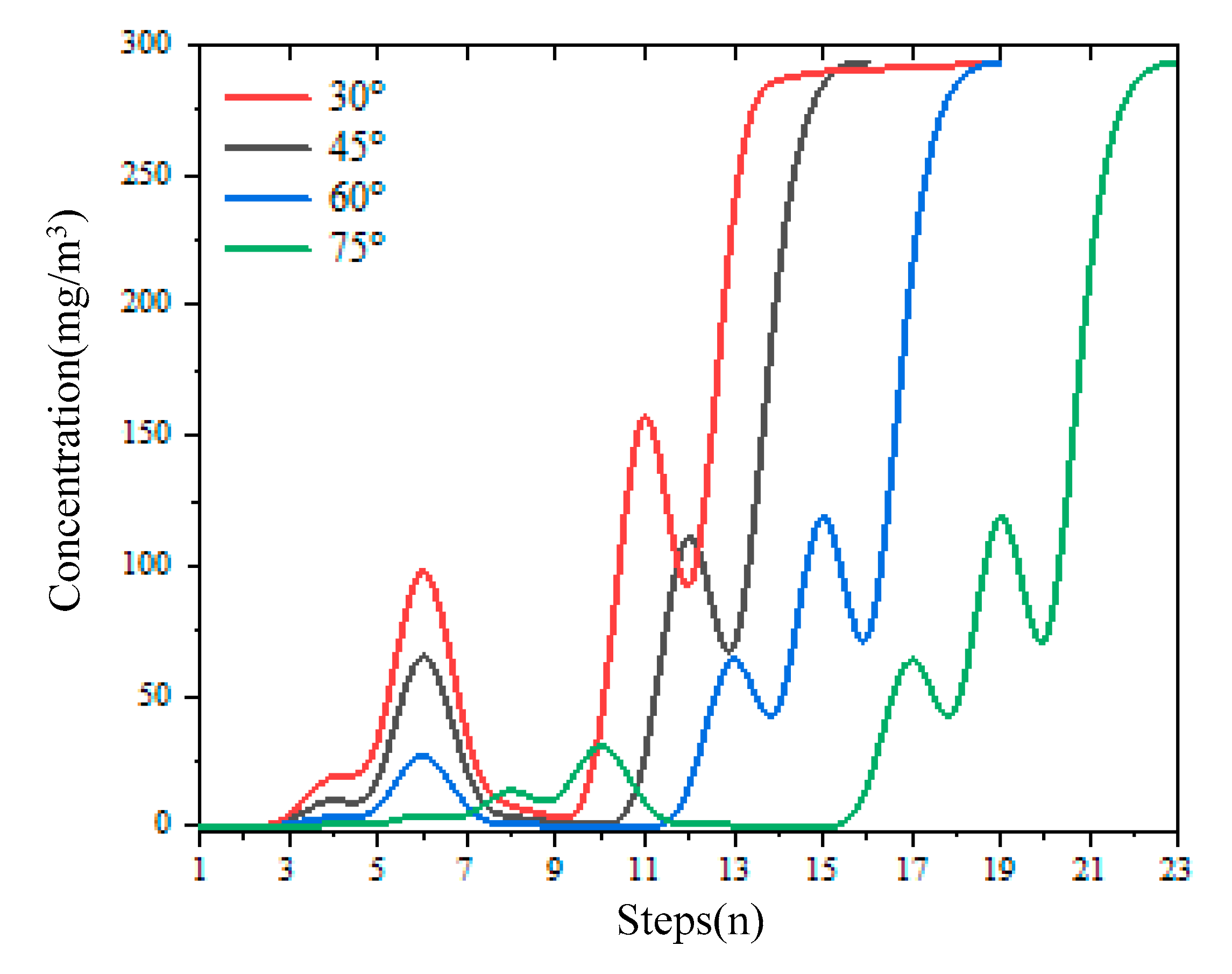

3. Odor Source Searching Algorithm Design and Experiment Verification

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Weng, W.; Aldén, M.; Li, Z. Simultaneous quantitative detection of HCN and C2H2 in combustion environment using TDLAS. Processes 2021, 9, 2033. [Google Scholar] [CrossRef]

- Goldschmidt, J.; Nitzsche, L.; Wolf, S.; Lambrecht, A.; Wöllenstein, J. Rapid Quantitative Analysis of IR Absorption Spectra for Trace Gas Detection by Artificial Neural Networks Trained with Synthetic Data. Sensors 2022, 22, 857. [Google Scholar] [CrossRef] [PubMed]

- Xu, X.; Ma, W.; Yan, B. An electrodeposited nano-porous and neural network-like Ln@HOF film for SO2 gas quantitative detection via fluorescent sensing and machine learning. J. Mater. Chem. A 2021, 9, 26391–26400. [Google Scholar] [CrossRef]

- Duan, Z.; Zhang, Y.; Tong, Y.; Zou, H.; Peng, J.; Zheng, X. Mixed-Potential-Type Gas Sensors Based on Pt/YSZ Film/LaFeO3 for Detecting NO2. J. Electron. Mater. 2017, 46, 6895–6900. [Google Scholar] [CrossRef]

- Dmitrzak, M.; Kalinowski, P.; Jasinski, P.; Jasinski, G. Identification of defected sensors in an array of amperometric gas sensors. Sens. Rev. 2022, 42, 195–203. [Google Scholar] [CrossRef]

- Dobrzyniewski, D.; Szulczyński, B.; Dymerski, T.; Gębicki, J. Development of gas sensor array for methane reforming process monitoring. Sensors 2021, 21, 4983. [Google Scholar] [CrossRef] [PubMed]

- Chu, J.; Li, W.; Yang, X.; Wu, Y.; Wang, D.; Yang, A.; Yuan, H.; Wang, X.; Li, Y.; Rong, M. Identification of gas mixtures via sensor array combining with neural networks. Sens. Actuators B Chem. 2021, 329, 129090. [Google Scholar] [CrossRef]

- Liu, X.; Wang, Y.; Gao, Y.; Song, Y. Gas-propelled biosensors for quantitative analysis. Analyst 2021, 146, 1115–1126. [Google Scholar] [CrossRef] [PubMed]

- Strickland, E. A Bionic Nose to Smell the Roses Again: Covid Survivors Drive Demand for a Neuroprosthetic Nose. IEEE Spectr. 2022, 59, 22–27. [Google Scholar] [CrossRef]

- Zhang, H.; Lee, S. Robot Bionic Vision Technologies: A Review. Appl. Sci. 2022, 12, 7970. [Google Scholar] [CrossRef]

- Wang, C.; Li, H.; Zhang, Z.; Yu, P.; Yang, L.; Du, J.; Niu, Y.; Jiang, J. Review of Bionic Crawling Micro-Robots. J. Intell. Robot. Syst. 2022, 105, 56. [Google Scholar] [CrossRef]

- Horibe, J.; Ando, N.; Kanzaki, R. Odor-searching Robot with Insect-behavior-based Olfactory Sensor. Sens. Mater. 2021, 33, 4185. [Google Scholar] [CrossRef]

- Qin, C.; Wang, Y.; Hu, J.; Wang, T.; Liu, D.; Dong, J.; Lu, Y. Artificial Olfactory Biohybrid System: An Evolving Sense of Smell. Adv. Sci. 2023, 10, 1–20. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Ju, P.; Wu, F.; Lei, S.; Pan, X. Best response-based individually look-ahead scheduling for natural gas and power systems. Appl. Energy 2021, 304, 117673. [Google Scholar] [CrossRef]

- Gholami, A.; Seyedali, S.M.; Ansari, H.R. Estimation of shear wave velocity from post-stack seismic data through committee machine with cuckoo search optimized intelligence models. J. Pet. Sci. Eng. 2020, 189, 106939. [Google Scholar] [CrossRef]

- Lei, G.; Stanko, M.; Silva, T.L. Formulations for automatic optimization of decommissioning timing in offshore oil and gas field development planning. Comput. Chem. Eng. 2022, 165, 107910. [Google Scholar] [CrossRef]

- Han, J.; Kang, M.; Jeong, J.; Cho, I.; Yu, J.; Yoon, K.; Park, I.; Choi, Y. Artificial Olfactory Neuron for an In-Sensor Neuromorphic Nose. Adv. Sci. 2022, 9, 2106017. [Google Scholar] [CrossRef] [PubMed]

- Zolfaghari, A.; Izadi, M.; Razavi, H. Optimum design of natural gas trunk line using simulated annealing algorithm. Int. J. Oil Gas Coal Technol. 2021, 26, 281–301. [Google Scholar] [CrossRef]

- Wang, S.-H.; Chou, T.-I.; Chiu, S.-W.; Tang, K.-T. Using a Hybrid Deep Neural Network for Gas Classification. IEEE Sens. J. 2021, 21, 6401–6407. [Google Scholar] [CrossRef]

- Kopbayev, A.; Khan, F.; Yang, M.; Halim, S.Z. Gas leakage detection using spatial and temporal neural network model. Process Saf. Environ. Prot. 2022, 160, 968–975. [Google Scholar] [CrossRef]

| Sensor Model | Sensitive Gas | Detection Concentration /ppm | Main Application Areas |

|---|---|---|---|

| TGS2611 | Methane, Natural gas | 500–10,000 | Portable gas detector, Gas leakage detection |

| TGS2620 | Alcohol | 50–5000 | Ethanol detector |

| MP-4 | Methane, Natural gas, Biogas | 300–10,000 | Fire prevention, Safety detection system, Gas leak detector |

| Sample Number | Actual Concentration /ppm | Predictive Concentration /ppm | Relative Error | |||

|---|---|---|---|---|---|---|

| Alcohol | Methane | Alcohol | Methane | Alcohol | Methane | |

| 15 | 200 | 600 | 249.461 | 601.364 | 0.247 | 0.002 |

| 56 | 1000 | 0 | 938.766 | 7.656 | 0.061 | — |

| 62 | 1000 | 1200 | 1114.090 | 1186.792 | 0.114 | 0.011 |

| 106 | 1800 | 1200 | 1699.340 | 1202.177 | 0.056 | 0.002 |

| 59 | 1000 | 600 | 1142.322 | 541.263 | 0.142 | 0.098 |

| 17 | 200 | 1000 | 229.694 | 1066.200 | 0.148 | 0.066 |

| 63 | 1000 | 1400 | 1126.808 | 1412.638 | 0.127 | 0.009 |

| 84 | 1400 | 1200 | 1450.702 | 1236.539 | 0.036 | 0.030 |

| 20 | 200 | 1600 | 230.013 | 1675.077 | 0.150 | 0.047 |

| 67 | 1200 | 0 | 1030.963 | −3.478 | 0.141 | — |

| 69 | 1200 | 400 | 1085.969 | 336.564 | 0.095 | 0.159 |

| 102 | 1800 | 400 | 1694.531 | 380.455 | 0.059 | 0.049 |

| 43 | 600 | 1800 | 591.252 | 1788.003 | 0.015 | 0.007 |

| 108 | 1800 | 1600 | 1783.638 | 1589.684 | 0.009 | 0.006 |

| 111 | 2000 | 0 | 1972.889 | −6.885 | 0.014 | — |

| 70 | 1200 | 600 | 1027.848 | 580.465 | 0.143 | 0.033 |

| 92 | 1600 | 600 | 1620.111 | 643.626 | 0.013 | 0.073 |

| 103 | 1800 | 800 | 1756.625 | 799.729 | 0.024 | 0.0003 |

| 90 | 1600 | 200 | 1694.422 | 186.427 | 0.059 | 0.068 |

| 113 | 2000 | 400 | 1958.524 | 438.380 | 0.021 | 0.096 |

| 101 | 1800 | 200 | 1773.025 | 155.565 | 0.015 | 0.222 |

| 58 | 1000 | 400 | 1120.502 | 347.112 | 0.121 | 0.1322 |

| 9 | 0 | 1600 | −18.593 | 1631.091 | — | 0.019 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, Y.; Wang, D.; Huang, X. Research on Improved Quantitative Identification Algorithm in Odor Source Searching Based on Gas Sensor Array. Micromachines 2023, 14, 1215. https://doi.org/10.3390/mi14061215

Zhao Y, Wang D, Huang X. Research on Improved Quantitative Identification Algorithm in Odor Source Searching Based on Gas Sensor Array. Micromachines. 2023; 14(6):1215. https://doi.org/10.3390/mi14061215

Chicago/Turabian StyleZhao, Yanru, Dongsheng Wang, and Xiaojie Huang. 2023. "Research on Improved Quantitative Identification Algorithm in Odor Source Searching Based on Gas Sensor Array" Micromachines 14, no. 6: 1215. https://doi.org/10.3390/mi14061215

APA StyleZhao, Y., Wang, D., & Huang, X. (2023). Research on Improved Quantitative Identification Algorithm in Odor Source Searching Based on Gas Sensor Array. Micromachines, 14(6), 1215. https://doi.org/10.3390/mi14061215