Temperature Performance Study of SAW Sensors Based on AlN and AlScN

Abstract

1. Introduction

2. Materials and Methods

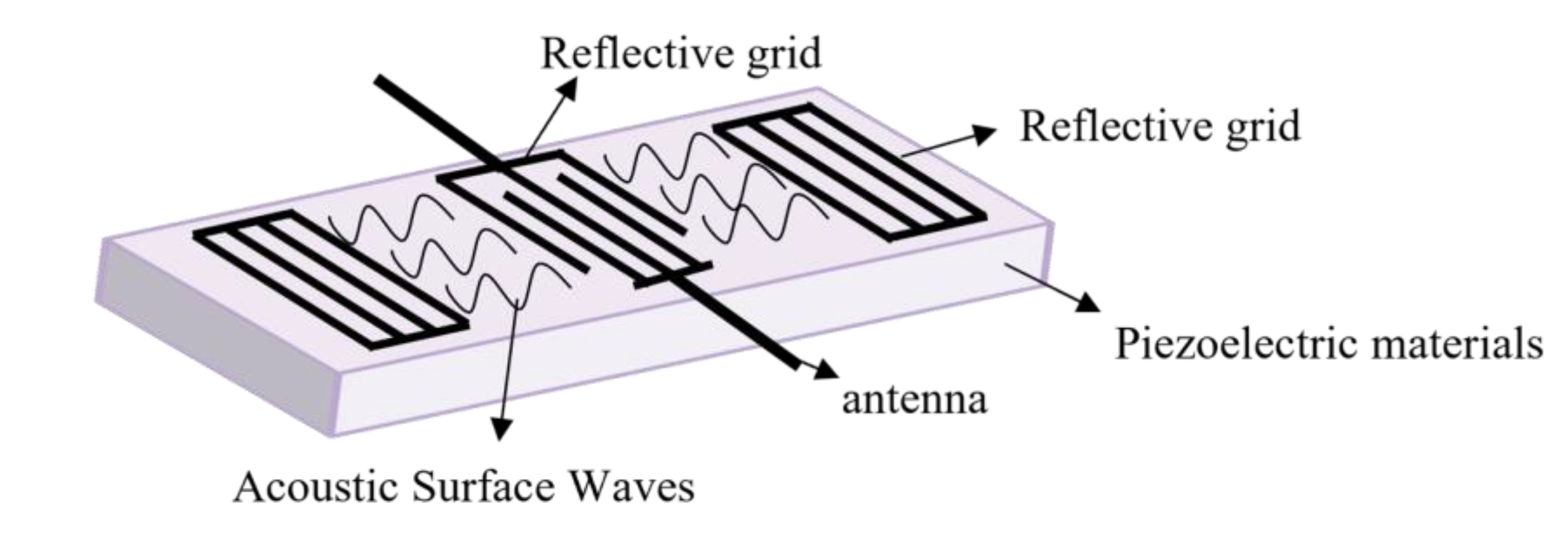

2.1. Temperature Measurement Principle of SAW Sensor

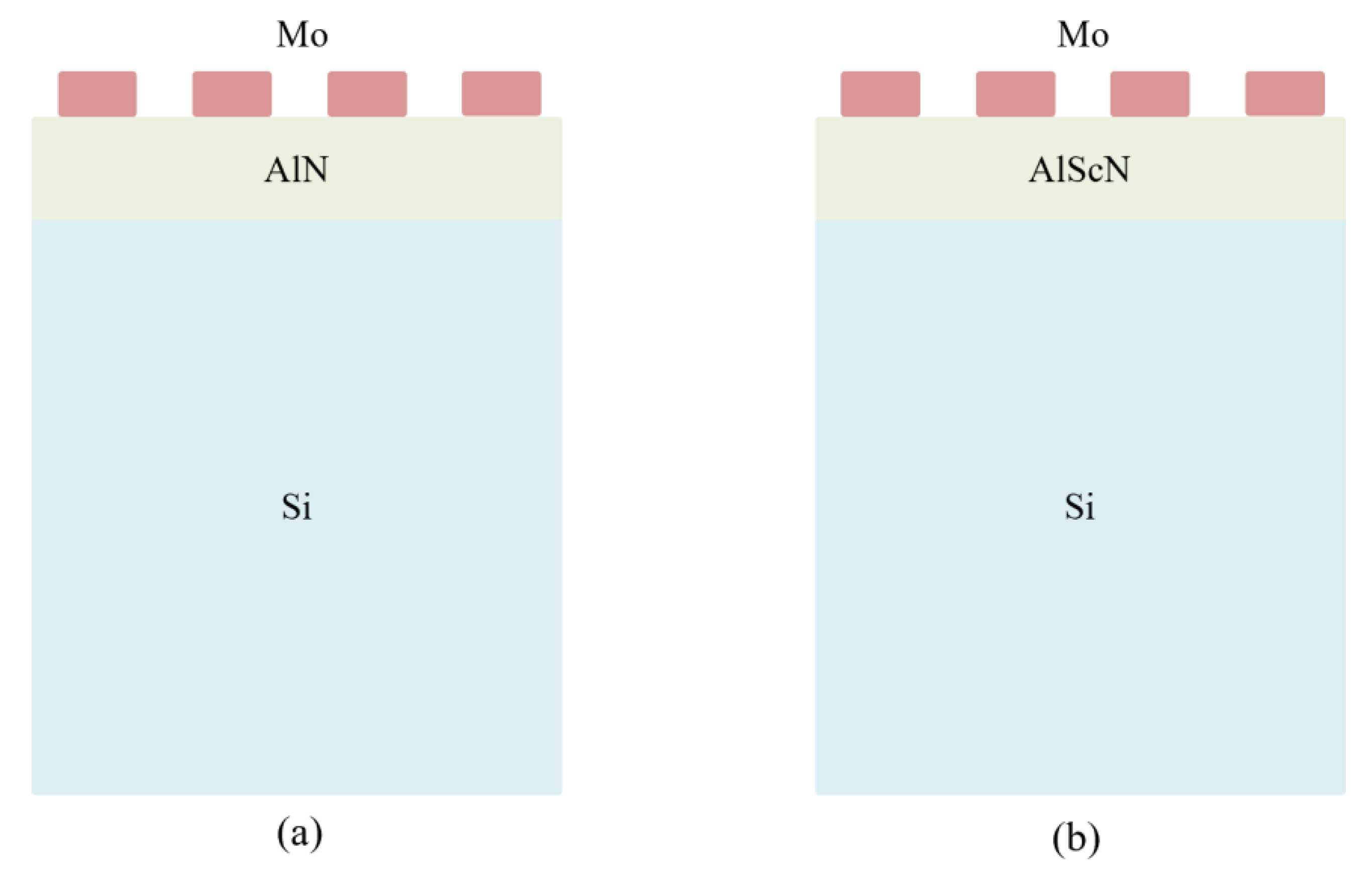

2.2. Simulation Model of the Sensor

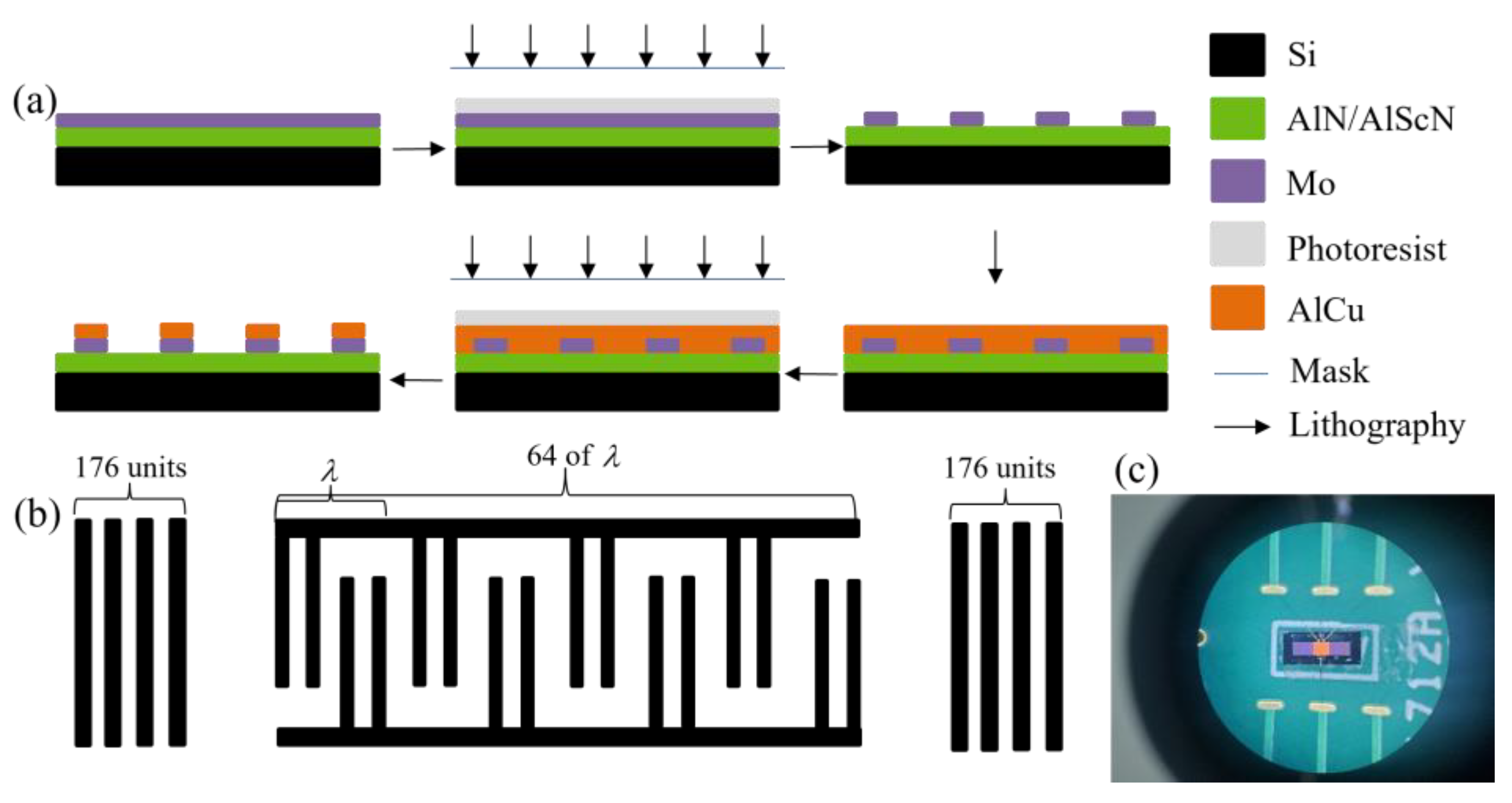

2.3. Fabrication

2.4. Test Platform

3. Results and Discussion

3.1. Reflection Coefficient S11

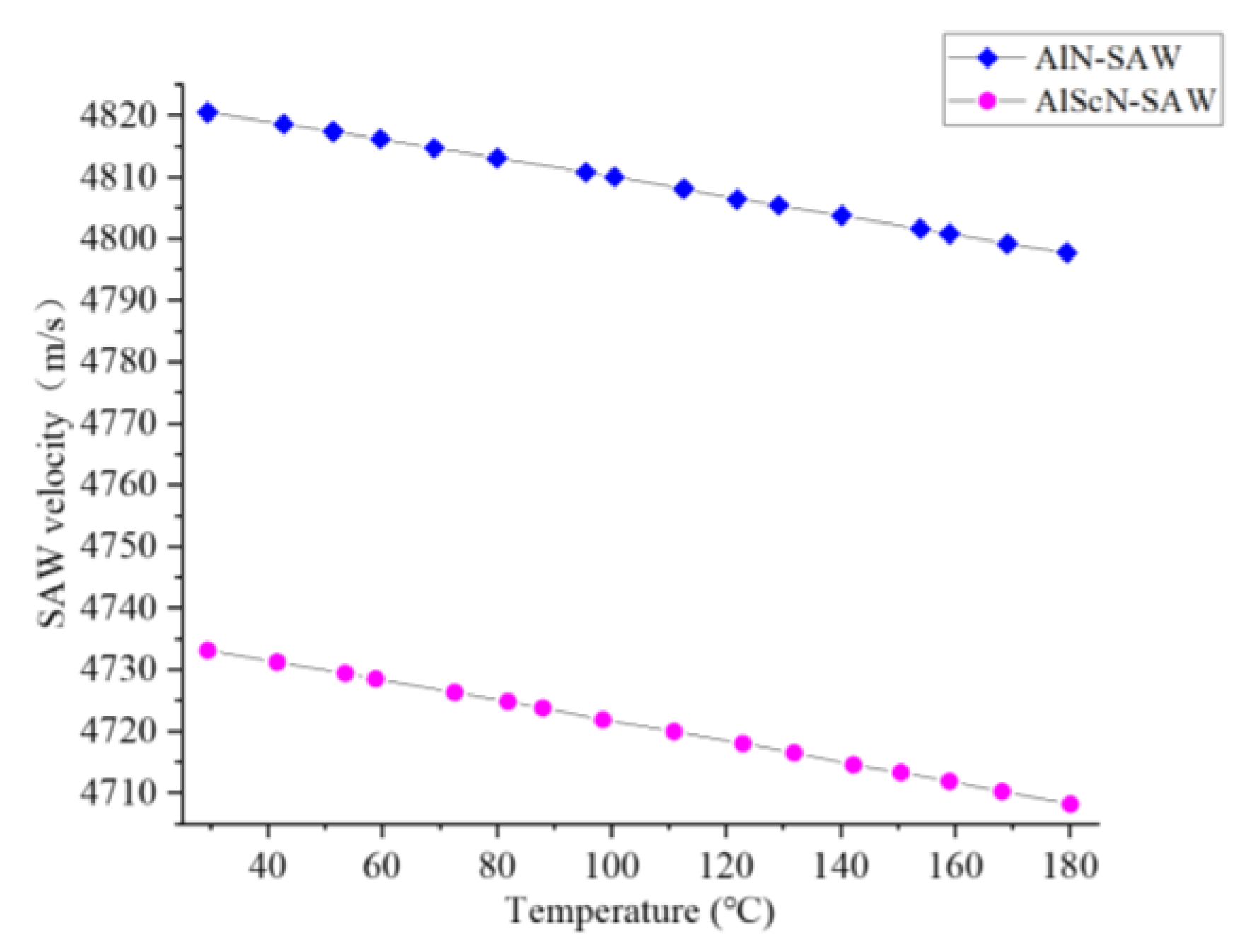

3.2. Phase Velocity

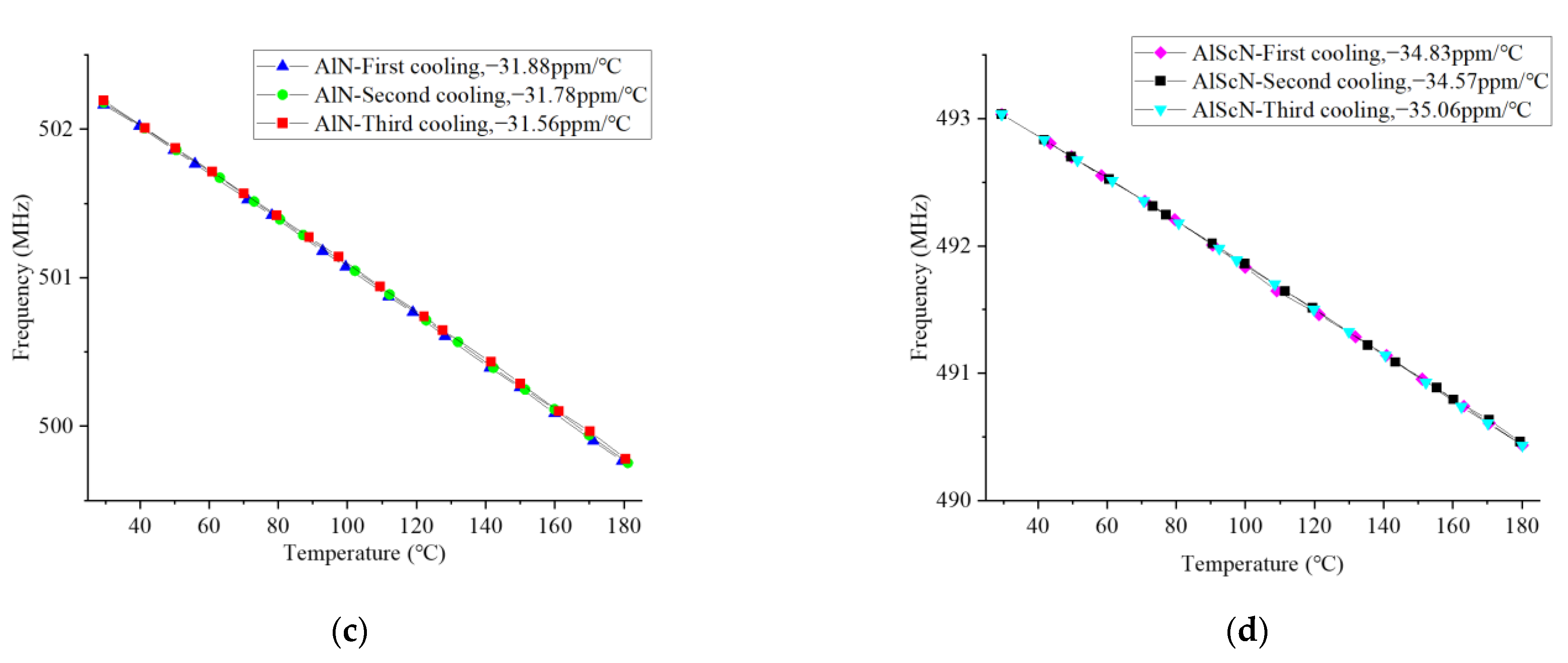

3.3. Temperature–Frequency Relationship

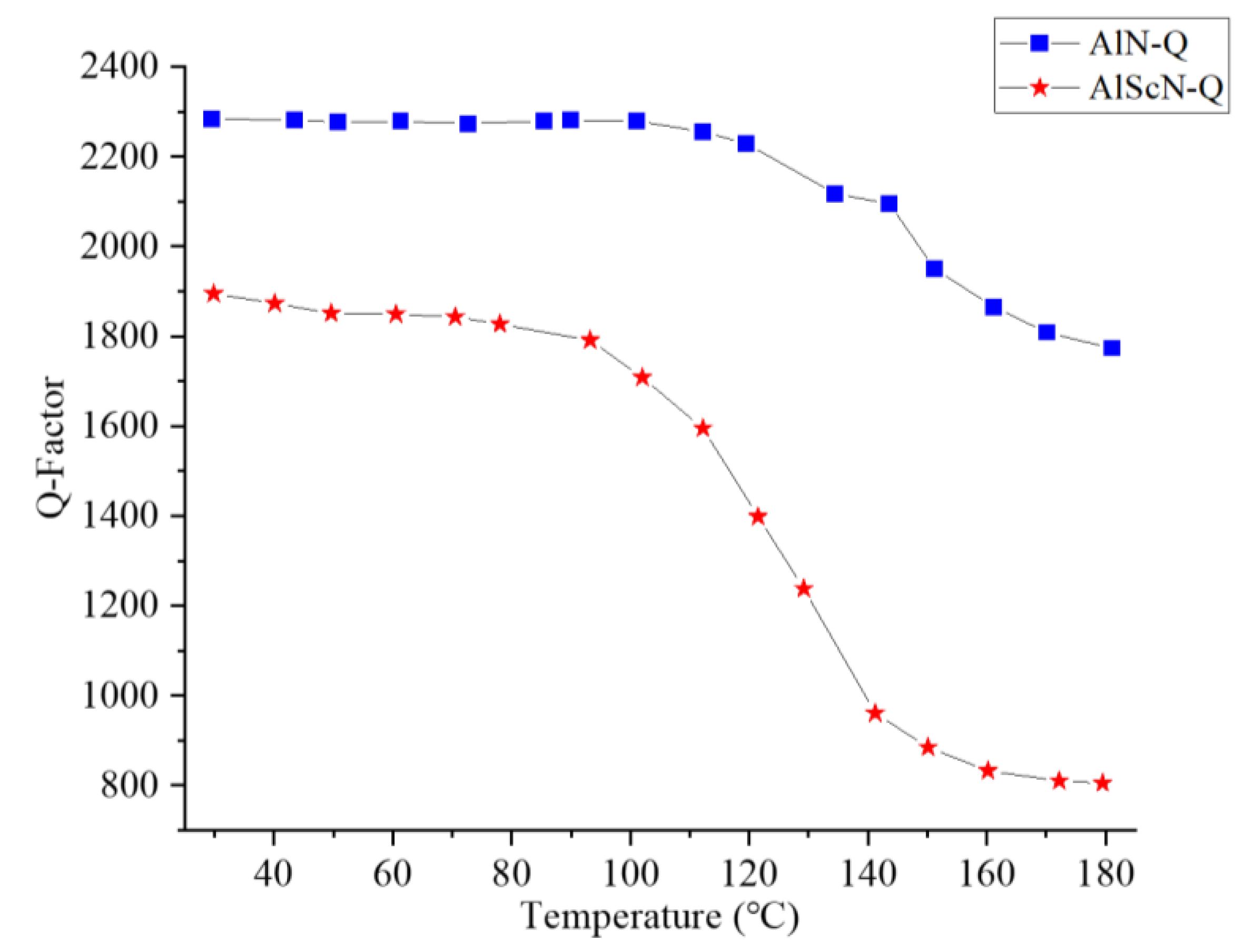

3.4. Quality Factor Q

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jiao, C.; Wang, C.; Wang, M.; Pan, J.; Gao, C.; Wang, Q. Finite Element Analysis Model of Electronic Skin Based on Surface Acoustic Wave Sensor. Nanomaterials 2023, 13, 465. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Chiang, H.; Dong, N. Power-Line Partial Discharge Recognition with Hilbert–Huang Transform Features. Energies 2022, 15, 6521. [Google Scholar] [CrossRef]

- Meer, R.; Khan, Y.; Wani, N.R.; Al-Arainy, A.A. The Estimation of Lightning Impulses Superimposed onto Pre-Stressed DC Breakdown Voltages Using the Leader Propagation Method. Energies 2022, 15, 1708. [Google Scholar] [CrossRef]

- Suo, C.; Zhao, J.; Wu, X.; Xu, Z.; Zhang, W.; He, M. Partial Discharge Detection Technology for Switchgear Based on Near-Field Detection. Electronics 2023, 12, 336. [Google Scholar] [CrossRef]

- Bulst, W.-E.; Fischerauer, G.; Reindl, L. State of the art in wireless sensing with surface acoustic waves. IEEE Trans. Ind. Electron. 2001, 48, 265–271. [Google Scholar] [CrossRef]

- Wilson, W.C.; Malocha, D.C.; Kozlovski, N.; Gallagher, D.R.; Fisher, B.; Pavlina, J.; Saldanha, N.; Puccio, D.; Atkinson, G.M. Orthogonal Frequency Coded SAW Sensors for Aerospace SHM Applications. IEEE Sens. J. 2009, 9, 1546–1556. [Google Scholar] [CrossRef]

- Wang, W.; Xue, X.; Huang, Y.; Liu, X. A Novel Wireless and Temperature-Compensated SAW Vibration Sensor. Sensors 2014, 14, 20702–20712. [Google Scholar] [CrossRef] [PubMed]

- Shu, L.; Peng, B.; Yang, Z.; Wang, R.; Deng, S.; Liu, X. High-Temperature SAW Wireless Strain Sensor with Langasite. Sensors 2015, 15, 28531–28542. [Google Scholar] [CrossRef] [PubMed]

- Weng, H.; Duan, F.L.; Xie, Z.; Liu, S.; Ji, Z.; Zhang, Y. LiNbO3-Based SAW Sensors Capable to Measure up to 1100 °C High Temperature. IEEE Sens. J. 2020, 20, 12679–12683. [Google Scholar] [CrossRef]

- Zhgoon, S.; Shvetsov, A.; Ancev, I.; Bogoslovsky, S.; Sapozhnikov, G.; Trokhimets, K.; Derkach, M. SAW temperature sensor on Quartz. IEEE Trans. Ultrason. Ferroelect. Freq. Contr. 2015, 62, 1066–1075. [Google Scholar] [CrossRef] [PubMed]

- Maskay, A.; Ayes, A.; Lad, R.J.; Pereira da Cunha, M. Stability of Pt/Al2O3-based electrode langasite SAW sensors with Al2O3 capping layer and yttria-stabilized zirconia sensing layer. In Proceedings of the 2017 IEEE International Ultrasonics Symposium (IUS), Washington, DC, USA, 6–9 September 2017; pp. 1–4. [Google Scholar]

- Fan, S.; Wang, W.; Li, X.; Jia, Y.; Sun, Y.; Liu, M. Optimization of AIN Composite Structure Based Surface Acoustic Wave Device for Potential Sensing at Extremely High Temperature. Sensors 2020, 20, 4160. [Google Scholar] [CrossRef] [PubMed]

- Naumenko, N.; Nicolay, P. AlN/Pt/LN structure for SAW sensors capable of operating at high temperature. Appl. Phys. Lett. 2017, 111, 073507. [Google Scholar] [CrossRef]

- Deger, C.; Born, E.; Angerer, H.; Ambacher, O.; Stutzmann, M.; Hornsteiner, J.; Riha, E.; Fischerauer, G. Sound velocity of AlxGa1−xN thin films obtained by surface acoustic-wave measurements. Appl. Phys. Lett. 1998, 72, 2400–2402. [Google Scholar] [CrossRef]

- Nguyen, N.T. Micromachined flow sensors—A review. Flow Meas. Instrum. 1997, 8, 7–16. [Google Scholar] [CrossRef]

- Tominaga, T.; Takayanagi, S.; Yanagitani, T. c-Axis-Tilted ScAlN Film on Silicon Substrate for Surface Acoustic Wave Device. In Proceedings of the 2021 IEEE International Ultrasonics Symposium (IUS), Xi’an, China, 11 September 2021; pp. 1–4. [Google Scholar]

- Suzuki, M.; Kakio, S. Theoretical Analysis and Design of Longitudinal Leaky SAW Device Consisting of ScA1N Film/Piezoelectric Single Crystal Substrate. In Proceedings of the 2018 IEEE International Ultrasonics Symposium (IUS), Kobe, Japan, 22 October 2018; pp. 1–9. [Google Scholar]

- Li, Y.; Ma, L.; Zhang, D.; Liu, X. FEM simulation of SAW temperature sensor based on Al/AlN/Si structure. In Proceedings of the 2017 Chinese Automation Congress (CAC), Jinan, China, 20–22 October 2017; pp. 6717–6720. [Google Scholar]

- Reindl, L.; Shrena, I.; Kenshil, S.; Peter, R. Wireless measurement of temperature using surface acoustic waves sensors. In Proceedings of the IEEE International Frequency Control Sympposium and PDA Exhibition Jointly with the 17th European Frequency and Time Forum, Tampa, FL, USA, 4–8 May 2003; pp. 935–941. [Google Scholar]

- Liu, W.; Tan, B.; Gong, Y. SAW temperature sensors system for smart electric grid. In Proceedings of the 2010 IEEE International Ultrasonics Symposium, San Diego, CA, USA, 11–14 October 2010; pp. 756–759. [Google Scholar]

- Feil, N.M.; Kurz, N.; Urban, D.F.; Altayara, A.; Christian, B.; Ding, A.; Zukauskaite, A.; Ambacher, O. Finite Element Analysis of SAW Propagation Characteristics in c-plane (0001) and a-plane (11–20) AlScN Thin Films. In Proceedings of the 2019 IEEE International Ultrasonics Symposium (IUS), Glasgow, UK, 6–9 October 2019; pp. 2588–2591. [Google Scholar]

| Material | Temperature-Sensing Characteristic | Advantages | Disadvantages |

|---|---|---|---|

| AlN/AlScN |

|

| Film-growing technology is complex. |

| Quartz material |

| Good linearity. |

|

| LiNbO3 | High sensitivity at lower temperatures. | High electromechanical coupling coefficient. | The temperature stability is poor. |

| LGS |

| High-temperature field is widely used. |

|

| Material | AlN | AlScN | Si | Mo | |

|---|---|---|---|---|---|

| Density (kg/m3) | 3260 | 2614 | 2320 | 10,200 | |

| Elastic constants (GPa) | 410 | 328 | - | - | |

| 137 | 149 | - | - | ||

| 99 | 111 | - | - | ||

| - | - | - | - | ||

| 389 | 311 | - | - | ||

| 125 | 100 | - | - | ||

| Piezoelectric constants (C/m2) | −0.48 | −0.38 | - | - | |

| −0.58 | −0.69 | - | - | ||

| 1.55 | 1.86 | - | - | ||

| Dielectric constant (10−11 F/m) | 9 | 10.8 | 4.5 | 11.7 | |

| 11 | 13.2 | - | - | ||

| Thermal expansion coefficient (1/°C × 10−6) | 4.5 | 4.5 | 2.6 | 4.8 | |

| Dielectric loss (×10−3) | 2 | ||||

| Mechanical loss (×10−3) | 4 | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, H.; Zhang, L.; Zhou, Z.; Lou, L. Temperature Performance Study of SAW Sensors Based on AlN and AlScN. Micromachines 2023, 14, 1065. https://doi.org/10.3390/mi14051065

Wang H, Zhang L, Zhou Z, Lou L. Temperature Performance Study of SAW Sensors Based on AlN and AlScN. Micromachines. 2023; 14(5):1065. https://doi.org/10.3390/mi14051065

Chicago/Turabian StyleWang, Hui, Linwei Zhang, Zhixin Zhou, and Liang Lou. 2023. "Temperature Performance Study of SAW Sensors Based on AlN and AlScN" Micromachines 14, no. 5: 1065. https://doi.org/10.3390/mi14051065

APA StyleWang, H., Zhang, L., Zhou, Z., & Lou, L. (2023). Temperature Performance Study of SAW Sensors Based on AlN and AlScN. Micromachines, 14(5), 1065. https://doi.org/10.3390/mi14051065