Design and Fabrication of a MEMS Bandpass Filter with Different Center Frequency of 8.5–12 GHz

Abstract

1. Introduction

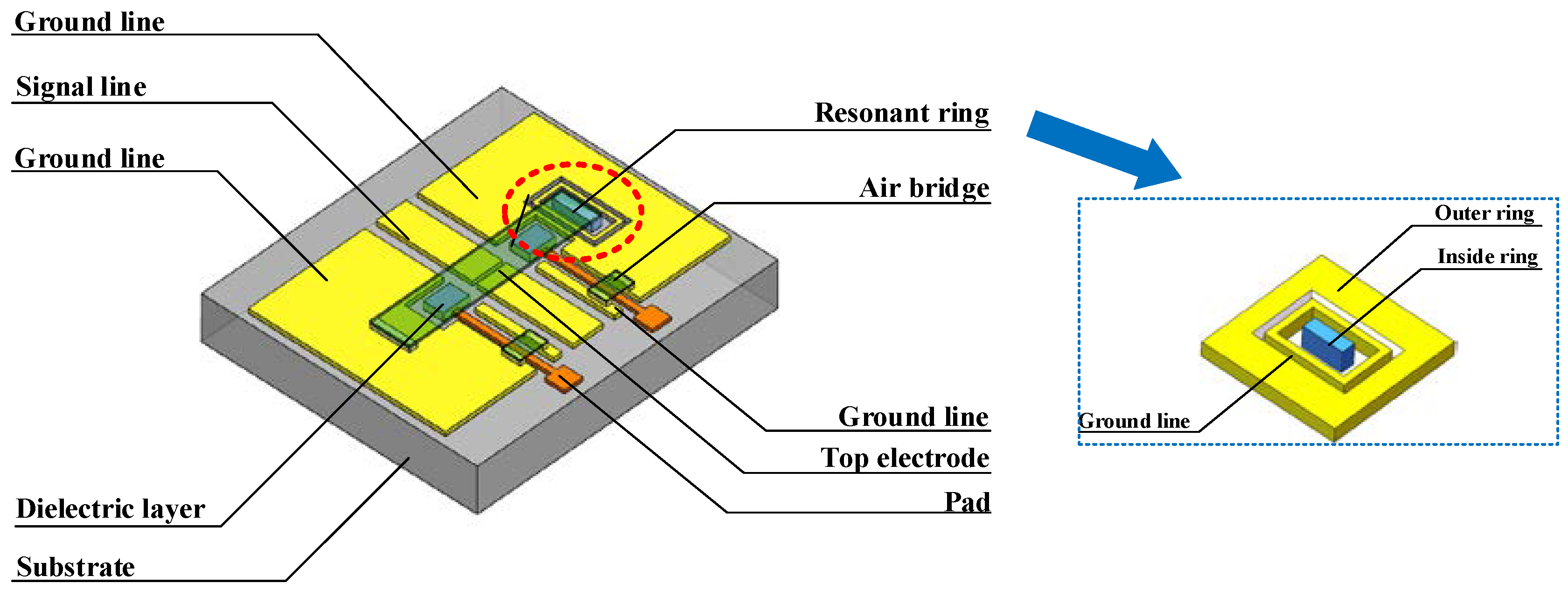

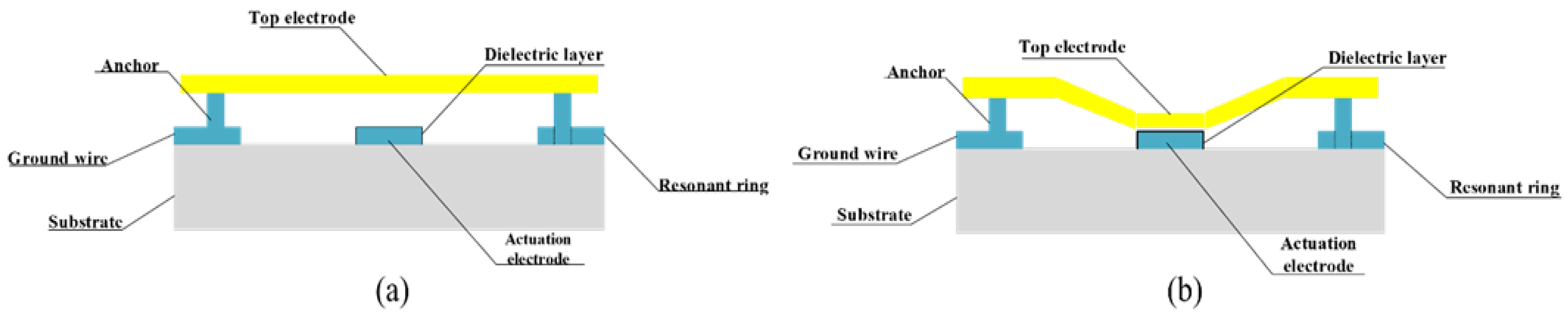

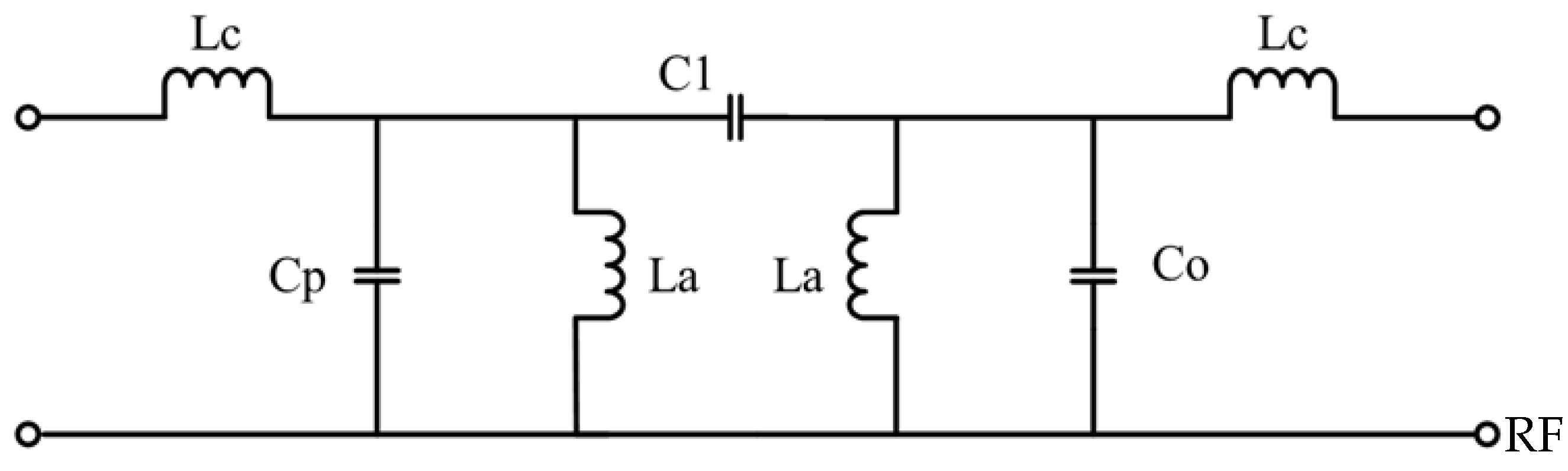

2. Design and Simulation of RF MEMS Filter

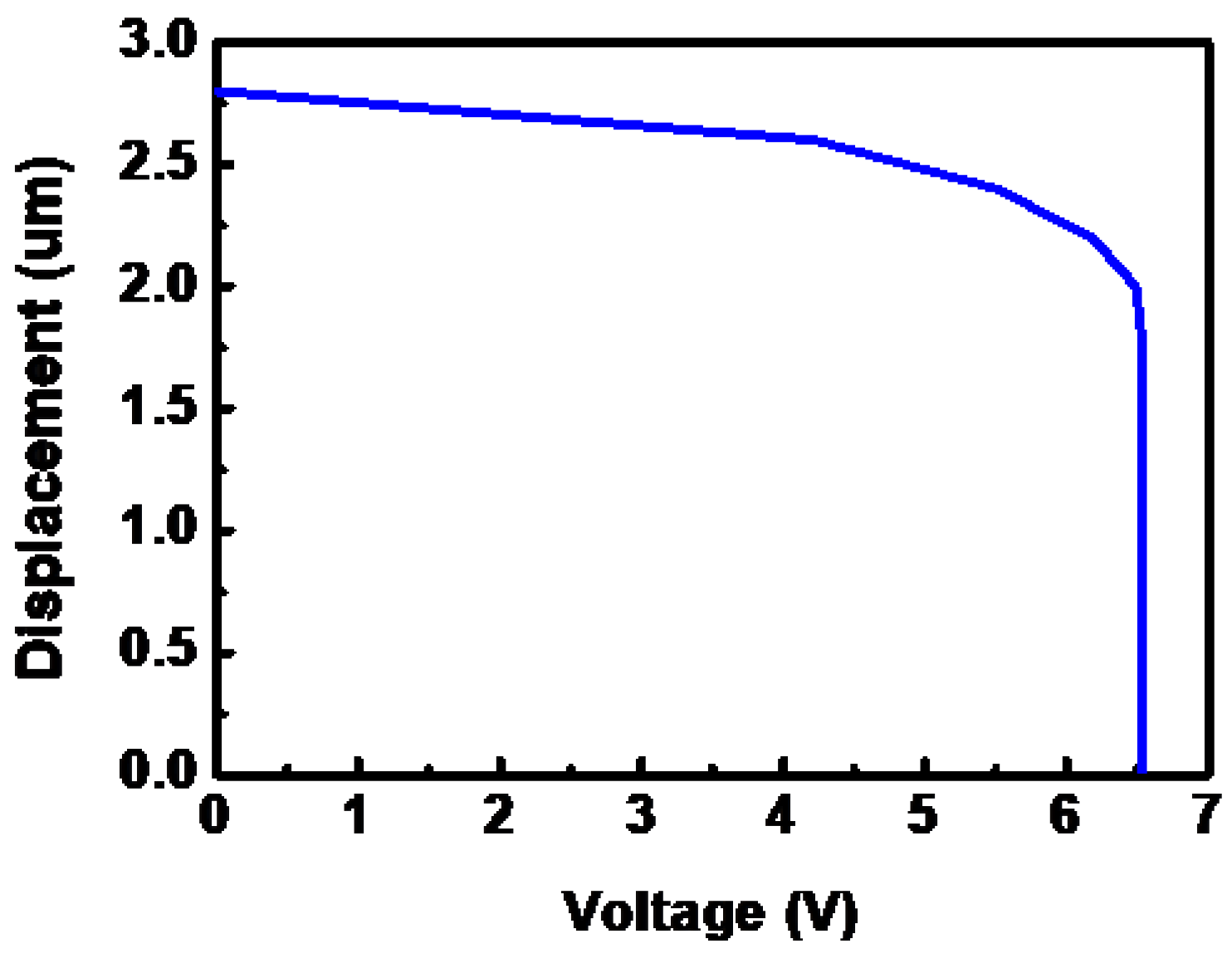

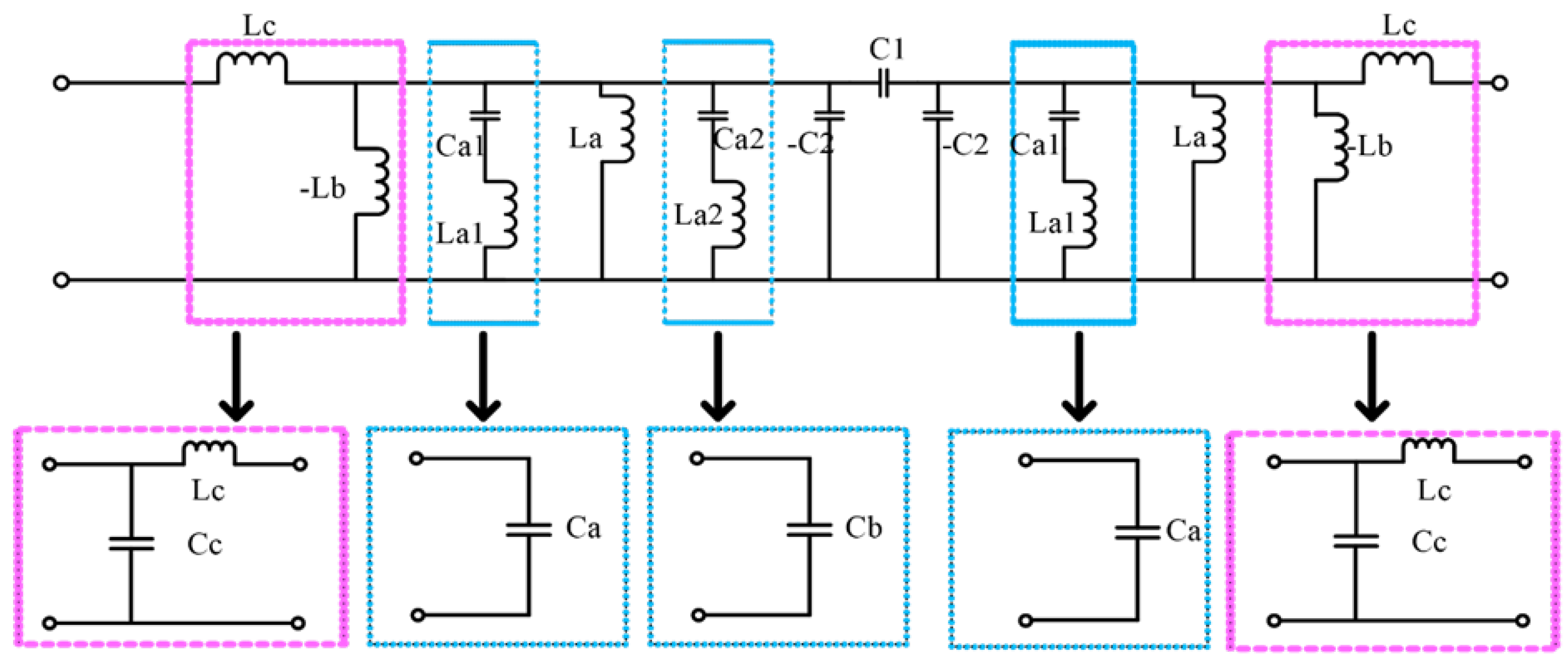

2.1. Theory

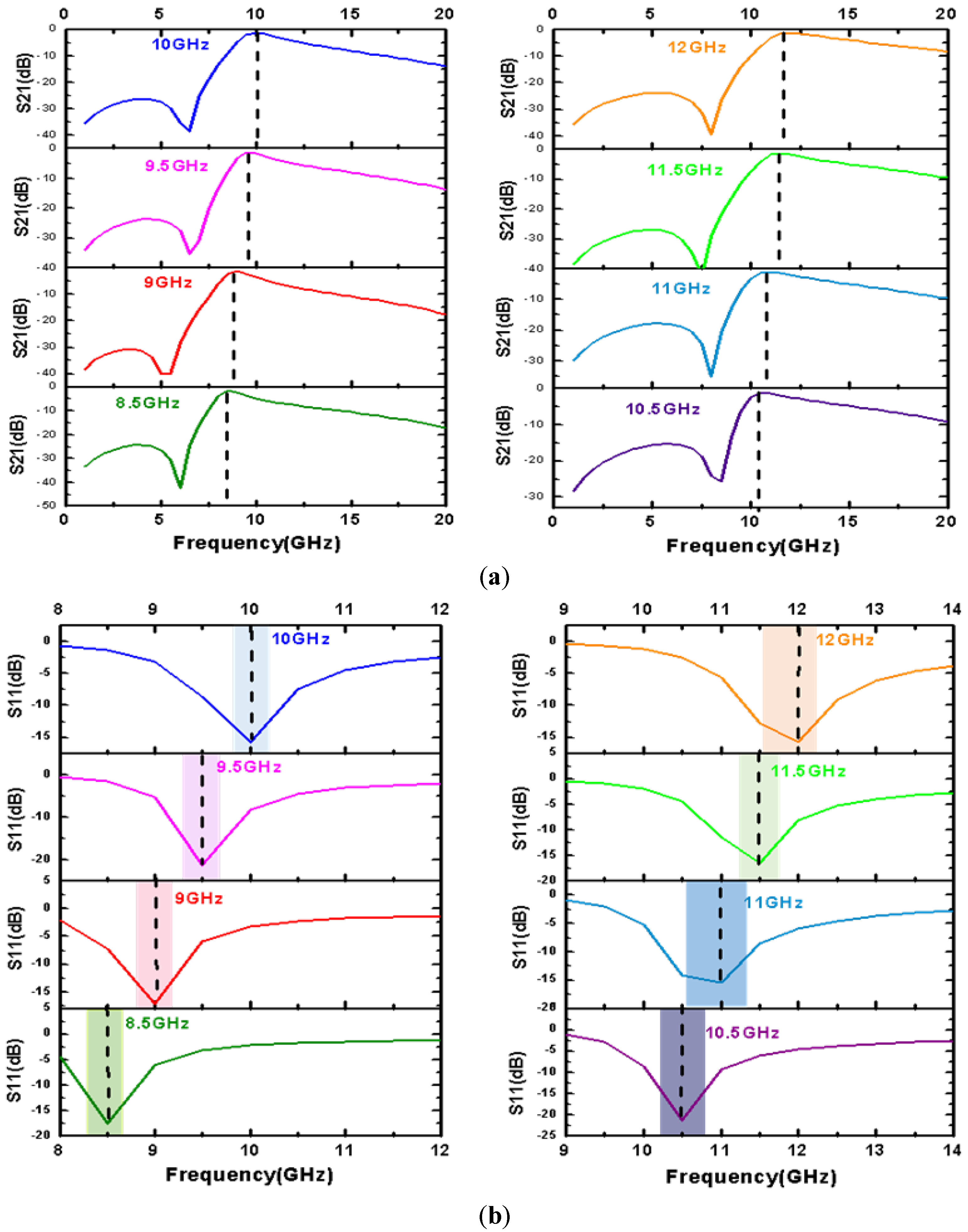

2.2. Microwave Performance

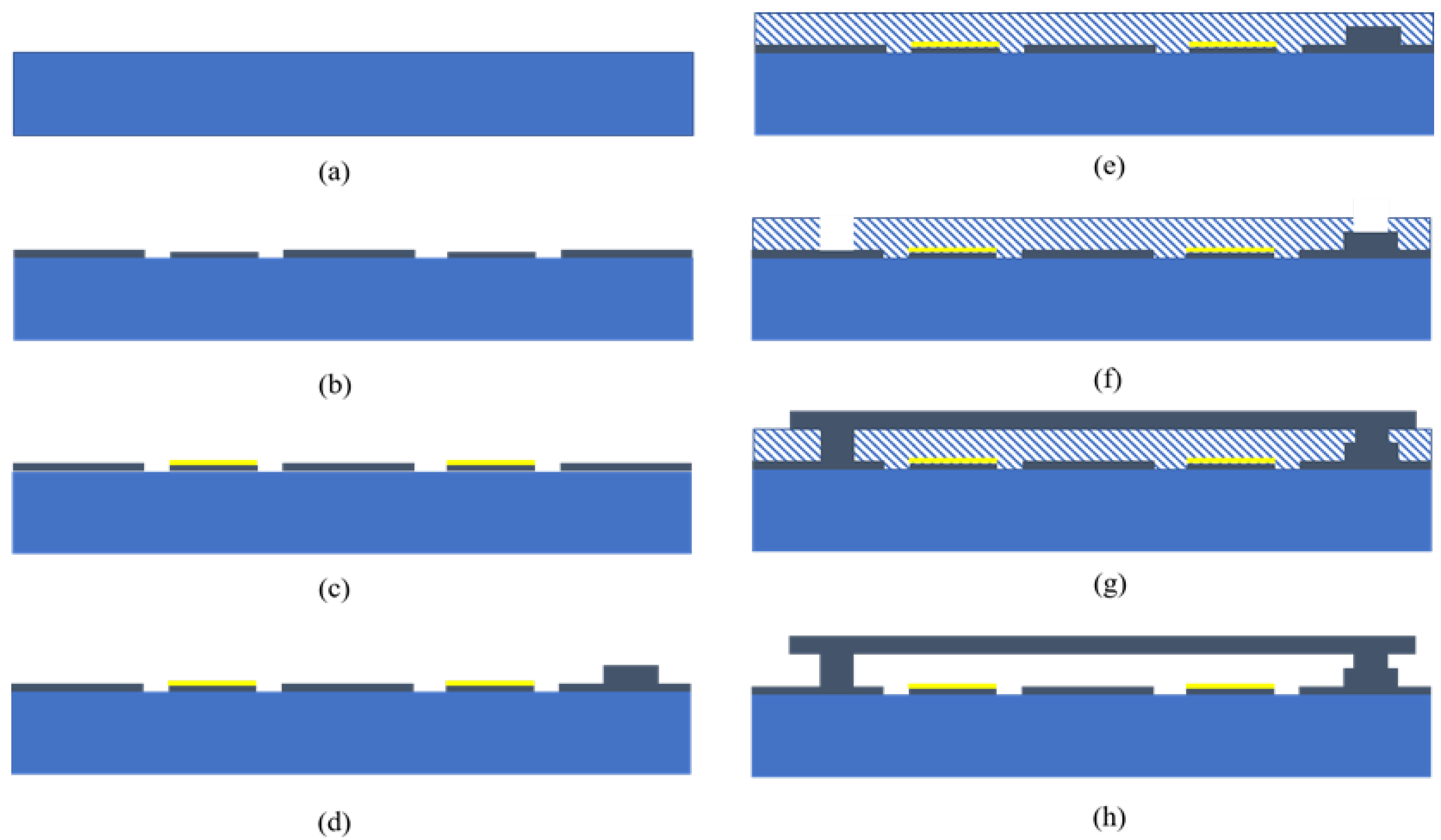

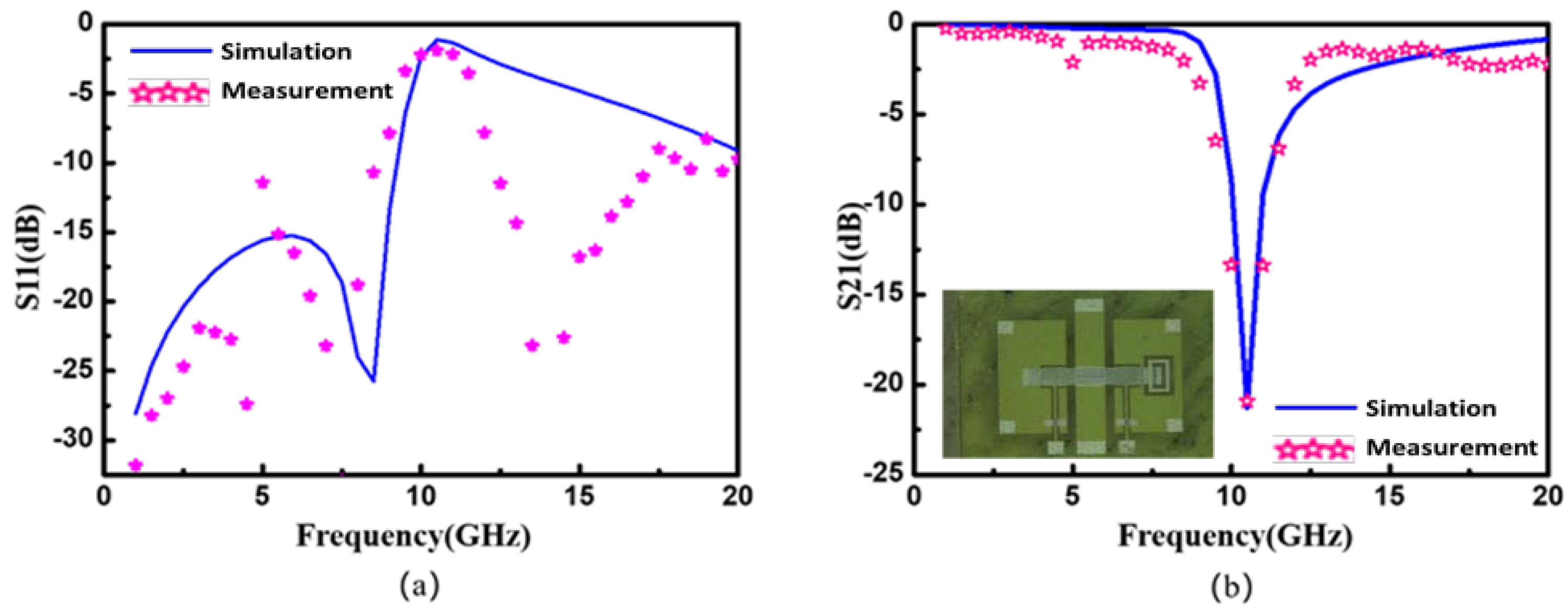

3. Fabrication and Measurement of the Filter

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Capmany, J.; Domenech, D.; Muñoz, P. Silicon graphene reconfigurable CROWS and SCISSORS. IEEE Photonics J. 2015, 7, 1–9. [Google Scholar] [CrossRef]

- Spencer, D.T.; Bauters, J.F.; Heck, M.J.; Bowers, J.E. Integrated waveguide coupled Si3N4 resonators in the ultrahigh-Q regime. Optica 2014, 1, 153–157. [Google Scholar] [CrossRef]

- Liu, K.; Jin, N.; Cheng, H.; Chauhan, N.; Puckett, M.W.; Nelson, K.D.; Behunin, R.O.; Rakich, P.T.; Blumenthal, D.J. Ultralow 0.034 dB/m loss wafer-scale integrated photonics realizing 720 million Q and 380 μW threshold Brillouin lasing. Opt. Lett. 2022, 47, 1855–1858. [Google Scholar] [CrossRef] [PubMed]

- Ciminelli, C.; Dell’Olio, F.; Brunetti, G.; Conteduca, D.; Armenise, M.N. New microwave photonic filter based on a ring resonator including a photonic crystal structure. In Proceedings of the 2017 19th International Conference on Transparent Optical Networks (ICTON), Girona, Spain, 2–6 July 2017; pp. 1–4. [Google Scholar]

- Brunetti, G.; Sasanelli, N.; Armenise, M.N.; Ciminelli, C. High performance and tunable optical pump-rejection filter for quantum photonic systems. Opt. Laser Technol. 2021, 139, 106978. [Google Scholar] [CrossRef]

- Ciminelli, C.; Innone, F.; Brunetti, G.; Conteduca, D.; Dell’Olio, F.; Tatoli, T.; Armenise, M.N. Rigorous model for the design of ultra-high Q-factor resonant cavities. In Proceedings of the 2016 18th International Conference on Transparent Optical Networks (ICTON), Trento, Italy, 10–14 July 2016; pp. 1–4. [Google Scholar]

- Mirebrahimi, S.M.; Dousti, M.; Afrang, S. MEMS tunable filters based on DGS and waveguide structures: A literature review. Analog Integr. Circuits Signal Process. 2021, 108, 141–164. [Google Scholar] [CrossRef]

- Teymoori, M.M.; Dousti, M.; Afrang, S. A Compact Low-Loss 6-bit DMTL Phase Shifter Using a Novel Three-State Unit Cell. Circuits Syst. Signal Process. 2022, 41, 4210–4237. [Google Scholar] [CrossRef]

- Luo, J.; Shi, K.; Gao, S. Compact multiband bandpass filters based on parallel coupled split structure multimode resonators. Electron. Lett. 2022, 59, e12684. [Google Scholar] [CrossRef]

- Mirebrahimi, S.M.; Dousti, M.; Afrang, S. High-quality coplanar waveguide tunable band-stop filter using defected ground structure and comb-line resonator with radio frequency microelectromechanical system varactors. Int. J. Circuit Theory Appl. 2020, 48, 1436–1449. [Google Scholar] [CrossRef]

- Rebeiz, G.M.; Entesari, K.; Reines, I.C.; Park, S.-J.; El-Tanani, M.A.; Grichener, A.; Brown, A.R. Tuning in to RF MEMS. IEEE Microw. Mag. 2009, 10, 55–72. [Google Scholar] [CrossRef]

- Chaubey, M.K.; Bhadauria, A. Rf mems based tunable bandpass filter for x-band applications. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Rajasthan, India, 14–16 October 2017; p. 012030. [Google Scholar]

- Tsai, J.-C.; Yin, C.-Y.; Sun, C.-W.; Wu, M.C. Analysis of the interchannel response in a MEMS 1 × N2 wavelength-selective switch. Appl. Opt. 2007, 46, 3227–3232. [Google Scholar] [CrossRef]

- Zohur, A.; Mopidevi, H.; Rodrigo, D.; Unlu, M.; Jofre, L.; Cetiner, B.A. RF MEMS reconfigurable two-band antenna. IEEE Antennas Wirel. Propag. Lett. 2013, 12, 72–75. [Google Scholar] [CrossRef]

- Ghodsian, B.; Bogdanoff, P.; Hyman, D. Wideband DC-contact MEMS series switch. Micro Nano Lett. 2008, 3, 66–69. [Google Scholar] [CrossRef]

- Rocha, L.A.; Dias, R.; Cretu, E.; Mol, L.; Wolffenbuttel, R. Auto-calibration of capacitive MEMS accelerometers based on pull-in voltage. Microsyst. Technol. 2011, 17, 429–436. [Google Scholar] [CrossRef]

- Dai, C.-L.; Chen, J.-H. Low voltage actuated RF micromechanical switches fabricated using CMOS-MEMS technique. Microsyst. Technol. 2006, 12, 1143–1151. [Google Scholar] [CrossRef]

- Sun, J.; Li, Z.; Zhu, J.; Yu, Y.; Jiang, L. Design of DC-contact RF MEMS switch with temperature stability. AIP Adv. 2015, 5, 041313. [Google Scholar] [CrossRef]

- Mabrouk, M.; Boujemaa, M.A.; Choubani, F. Flexible Engineering Tool for Radiofrequency Parameter Identification of RF-MEMS BAW Filters. ETRI J. 2016, 38, 988–995. [Google Scholar] [CrossRef]

- Pal, J.; Zhu, Y.; Lu, J.; Dao, D.V.; Khan, F. RF MEMS switches for smart antennas. Microsyst. Technol. 2015, 21, 487–495. [Google Scholar] [CrossRef]

- Bansal, D.; Kumar, A.; Sharma, A.; Rangra, K. Design of compact and wide bandwidth SPDT with anti-stiction torsional RF MEMS series capacitive switch. Microsyst. Technol. 2015, 21, 1047–1052. [Google Scholar] [CrossRef]

- Pacheco, S.; Nguyen, C.T.; Katehi, L.P. Micromechanical electrostatic K-band switches. In Proceedings of the 1998 IEEE MTT-S International Microwave Symposium Digest (Cat. No. 98CH36192), Baltimore, MD, USA, 7–12 June 1998; pp. 1569–1572. [Google Scholar]

- Pillans, B.; Kleber, J.; Goldsmith, C.; Eberly, M. RF power handling of capacitive RF MEMS devices. In Proceedings of the 2002 IEEE MTT-S International Microwave Symposium Digest (Cat. No. 02CH37278), Seattle, WA, USA, 2–7 June 2002; pp. 329–332. [Google Scholar]

- Entesari, K.; Rebeiz, G.M. A differential 4-bit 6.5-10-GHz RF MEMS tunable filter. IEEE Trans. Microw. Theory Tech. 2005, 53, 1103–1110. [Google Scholar] [CrossRef]

- Alazemi, A.J.; Rebeiz, G.M. A low-loss 1.4–2.1 GHz compact tunable three-pole filter with improved stopband rejection using RF-MEMS capacitors. In Proceedings of the 2016 IEEE MTT-S International Microwave Symposium (IMS), San Francisco, CA, USA, 22–27 May 2016; pp. 1–4. [Google Scholar]

- Zahn, M. Electromagnetic Field Theory: A Problem Solving Approach; John Wiley & Sons: New York, NY, USA, 1979. [Google Scholar]

- Zhang, N.; Deng, Z.; Shu, C.; Wang, H. Design and analysis of a tunable bandpass filter employing RF MEMS capacitors. IEEE Electron Device Lett. 2011, 32, 1460–1462. [Google Scholar] [CrossRef]

- Cheng, C.-C.; Rebeiz, G.M. A three-pole 1.2–2.6-GHz RF MEMS tunable notch filter with 40-dB rejection and bandwidth control. IEEE Trans. Microw. Theory Tech. 2012, 60, 2431–2438. [Google Scholar] [CrossRef]

- Pradhan, B.; Gupta, B. Ka-band tunable filter using metamaterials and RF MEMS varactors. J. Microelectromech. Syst. 2015, 24, 1453–1461. [Google Scholar] [CrossRef]

- Yang, Y.; Lu, R.; Gao, L.; Gong, S. A C-band lithium niobate MEMS filter with 10% fractional bandwidth for 5G front-ends. In Proceedings of the 2019 IEEE International Ultrasonics Symposium (IUS), Glasgow, UK, 6–9 October 2019; pp. 1981–1984. [Google Scholar]

- Dey, S.; Koul, S.K. Reliable, compact, and tunable MEMS bandpass filter using arrays of series and shunt bridges for 28-GHz 5G applications. IEEE Trans. Microw. Theory Tech. 2020, 69, 75–88. [Google Scholar] [CrossRef]

| Metal | Platinum | Aluminum | Gold | Tungsten | Copper |

|---|---|---|---|---|---|

| Resistivity (Ω·m) | 2.22 | 2.83 | 2.40 | 5.48 | 1.75 |

| No. | Center Frequency (GHz) | Width of Top Electrode (μm) | Insertion Loss (dB) (S21) | Return Loss (dB) (S11) | Stopband Rejection (dB) (S21) |

|---|---|---|---|---|---|

| 1 | 8.5 | 260 | −1.27 | −17.59 | −25.83 |

| 2 | 9 | 240 | −1.12 | −17.23 | −25.42 |

| 3 | 9.5 | 220 | −1.17 | −21.21 | −35.11 |

| 4 | 10 | 200 | −1.14 | −15.68 | −38.57 |

| 5 | 10.5 | 190 | −1.13 | −21.28 | −25.03 |

| 6 | 11 | 180 | −1.03 | −16.54 | −25.55 |

| 7 | 11.5 | 170 | −1.24 | −15.41 | −29.12 |

| 8 | 12 | 140 | −1.10 | −15.69 | −26.76 |

| Center Frequency (GHz) | Insertion Loss(dB) | Return Loss (dB) | Stopband Rejection (dB) | Drive Voltage (V) | |

|---|---|---|---|---|---|

| Simulation | 10.5 | −1.13 | −21.28 | −25.03 | 6.48 |

| Measurement | 10.5 | −1.12 | −21.3 | −28.3 | 5.80 |

| Ref. | Center Frequency | Insertion Loss | Stopband Rejection |

|---|---|---|---|

| 2012 [28] | 1.6/2.0 GHz | 0.8 dB | 40 dB |

| 2015 [29] | 35.32 GHz | - | 20.19 dB/18.29 dB |

| 2016 [25] | 1.15 GHz | 2 dB | 30 dB |

| 2018 [12] | 9.5 GHz | 1.2 dB | - |

| 2019 [30] | 4.5 GHz | 1.7 dB | |

| 2020 [31] | 27~29 GHz | 1.92 dB | 23.4 dB |

| This work | 8.5 GHz | 1. 12 dB | 28.3 dB |

| Our filter | 8/8.5/9/9.5/10/10.5/11/11.5/12 GHz | ≤1.86 dB | 30.5 dB |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.-F.; Cui, M.; Wu, D.-P. Design and Fabrication of a MEMS Bandpass Filter with Different Center Frequency of 8.5–12 GHz. Micromachines 2023, 14, 280. https://doi.org/10.3390/mi14020280

Zhang Y-F, Cui M, Wu D-P. Design and Fabrication of a MEMS Bandpass Filter with Different Center Frequency of 8.5–12 GHz. Micromachines. 2023; 14(2):280. https://doi.org/10.3390/mi14020280

Chicago/Turabian StyleZhang, Yi-Fei, Min Cui, and Dong-Ping Wu. 2023. "Design and Fabrication of a MEMS Bandpass Filter with Different Center Frequency of 8.5–12 GHz" Micromachines 14, no. 2: 280. https://doi.org/10.3390/mi14020280

APA StyleZhang, Y.-F., Cui, M., & Wu, D.-P. (2023). Design and Fabrication of a MEMS Bandpass Filter with Different Center Frequency of 8.5–12 GHz. Micromachines, 14(2), 280. https://doi.org/10.3390/mi14020280