Simulation Analysis of a Sandwich Cantilever Ultrasonic Motor for a Dexterous Prosthetic Hand

Abstract

:1. Introduction

- (1)

- Configuration design: Starting from the structural analysis of the prosthetic hand with a connecting rod, the shortcomings and deficiencies of the current motor drive are found. Considering the influence of the traditional motor on the structural limitations, a new ultrasonic motor is designed to optimize the performance of the prosthetic hand with a connecting rod, so as to ensure the flexibility, accuracy, fast response, and power density of the prosthetic hand.

- (2)

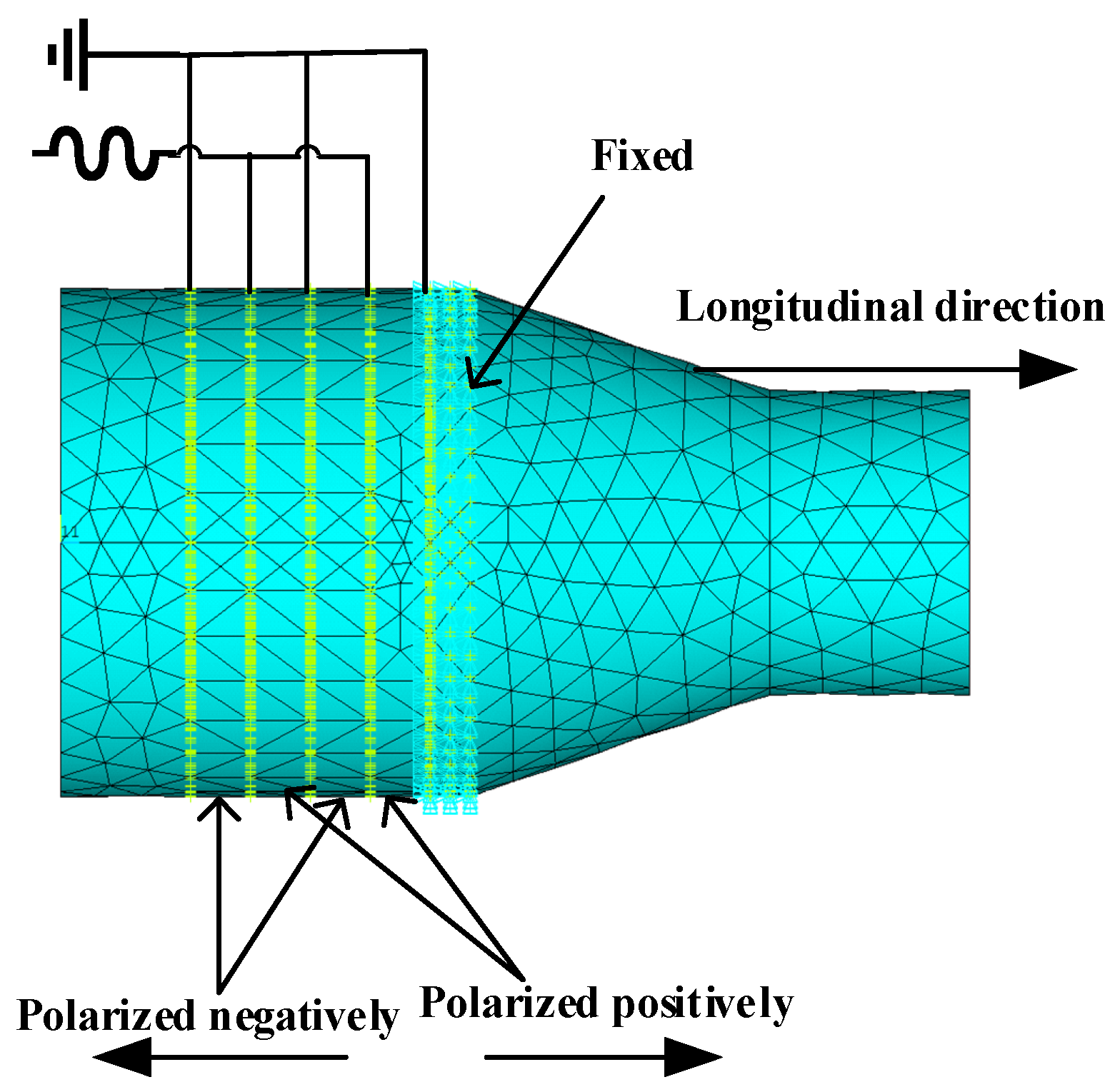

- Parameter simulation: We selected the longitudinal vibration piezoelectric metal composite method to design the vibrator, design and simulate the longitudinal vibration system, establish its basic design distribution and structural size, establish a finite element model for the vibrator system, analyze and determine the modal longitudinal vibration frequency, and determine the harmonic response amplitude and maximum displacement of the transient driving the foot surface.

- (3)

- Structural finalization: The fixing method of the vibration system is determined. Under the action of sinusoidal voltage, the motion of the ultrasonic vibrator is calculated to meet the input shaft speed required by the prosthetic hand, and the overall structure of the ultrasonic motor is determined, which makes the application of the ultrasonic motor in the prosthetic hand with a connecting rod possible. This will also be an attempt to explore the application of ultrasonic motors in the direction of prosthetic robots, while sufficiently preparing theoretically for the production of prosthetic drives.

2. Materials and Methods

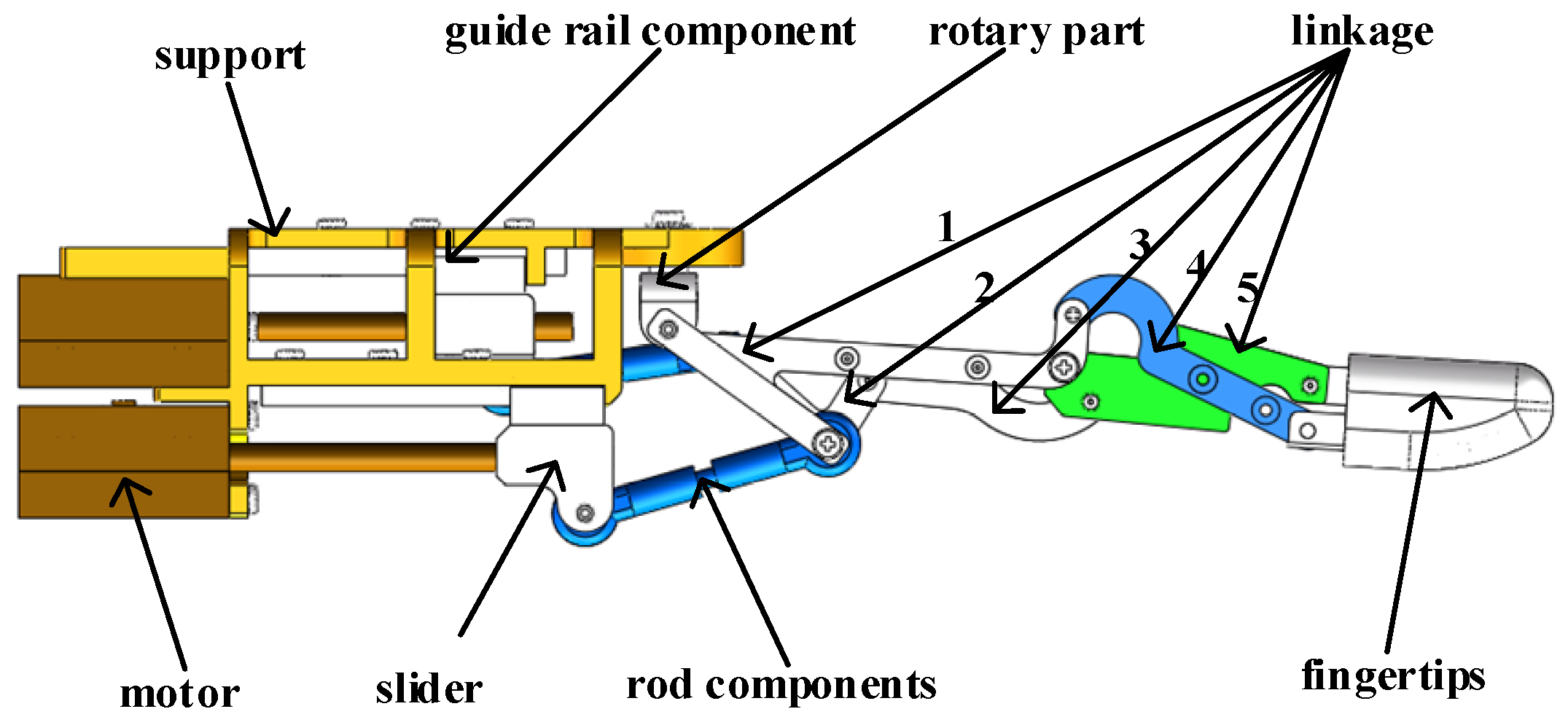

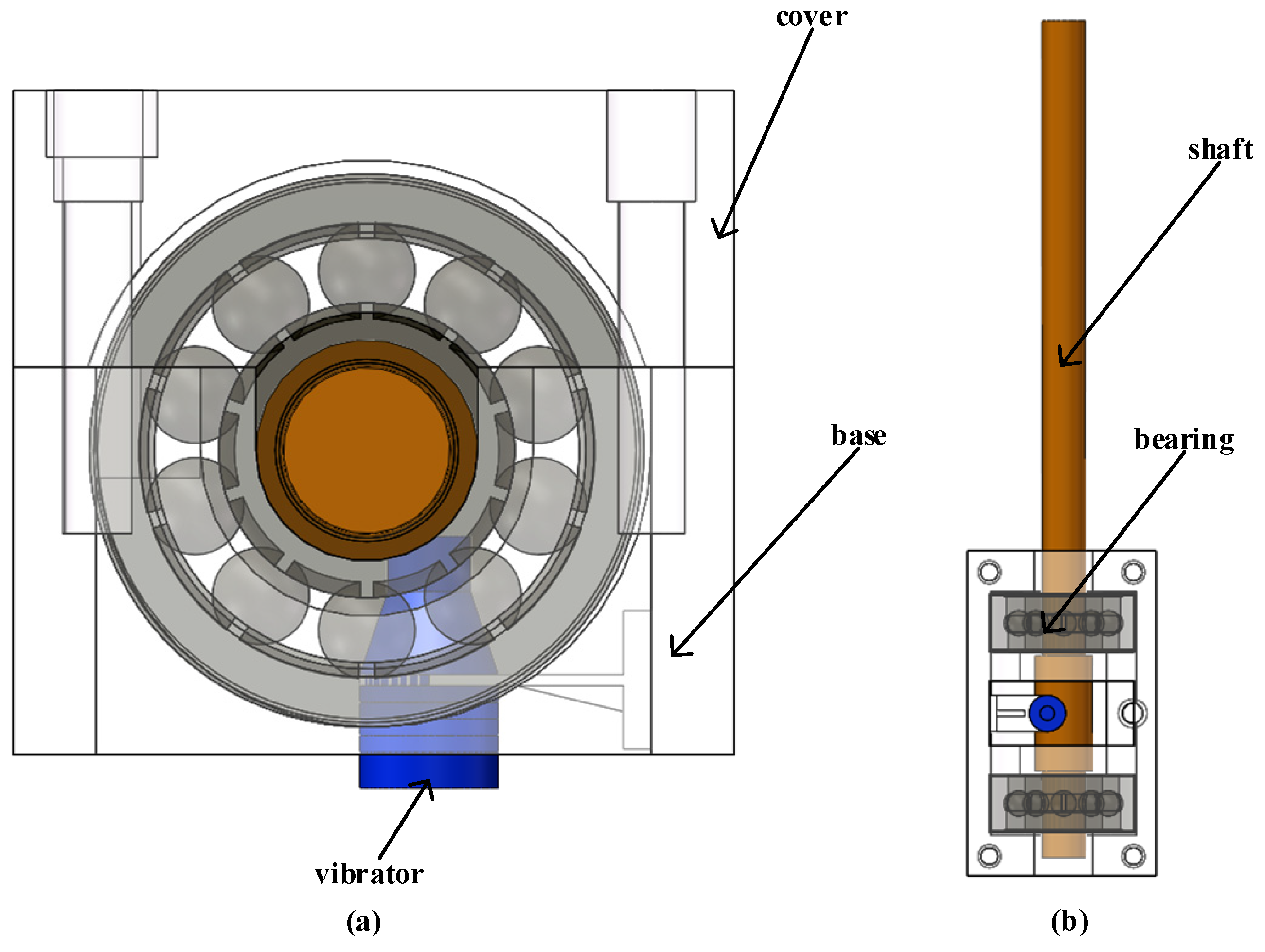

2.1. Design of Prosthetic Hand and Motor Structure

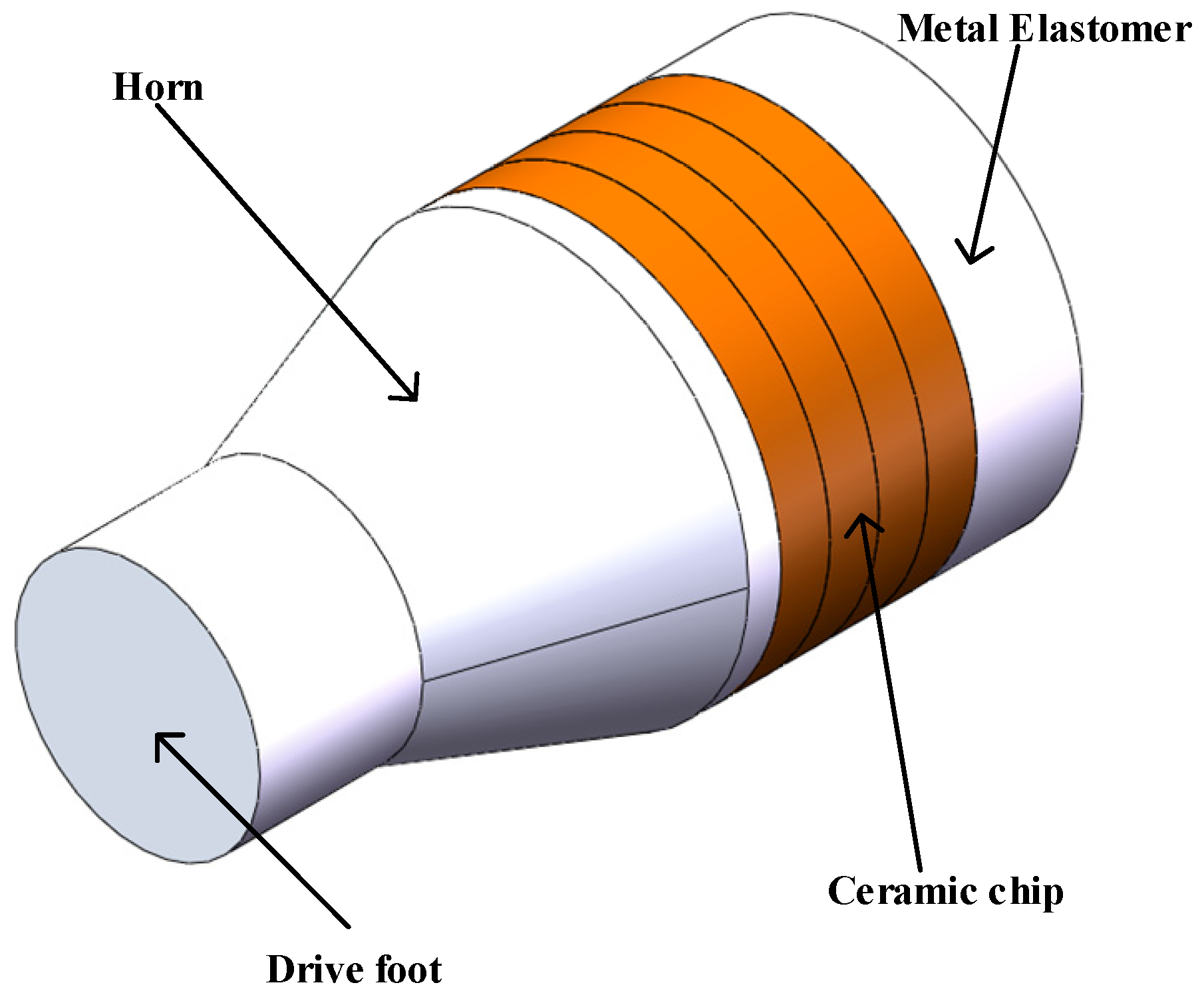

2.2. Structural Design of Longitudinal Vibration System

2.3. Resonant Frequency Equation

- Vi—Vibration velocity parameters of rods at the end surface;

- Fi—Force parameters of rods at the end surface;

- —transfer matrix.

- —wave number, , is the angular frequency of ultrasonic vibration, i = 1, 2, 3;

- —length of each rod, i = 1, 2, 3;

- —Equivalent impedance, , is the material density, is the longitudinal propagation velocity of ultrasonic waves;

- is the cross-sectional area, i = 1, 2, 3.

- —wave number, , (i = 4, 5);

- is the angular frequency of ultrasonic vibration, (i = 4, 5);

- —length of each rod, (i = 4, 5);

- —Section reduction rate, , (j = 4);

- —Taper factor, , (j = 4);

- —Equivalent impedance, , is the material density, is the longitudinal propagation velocity of ultrasonic waves;

- is the cross-sectional area, i = 4, 5.

2.4. Structure Size

- —The total cross-sectional area of the connecting section between the rear end cover and the hard aluminum alloy, , is the cross-sectional area of the rear end cap, is the cross-sectional area of duralumin;

- —The total cross-sectional area of the connecting section between the piezoelectric ceramic sheet and the hard aluminum alloy, , is the cross-sectional area of the piezoelectric ceramic sheet.

3. Results and Discussion

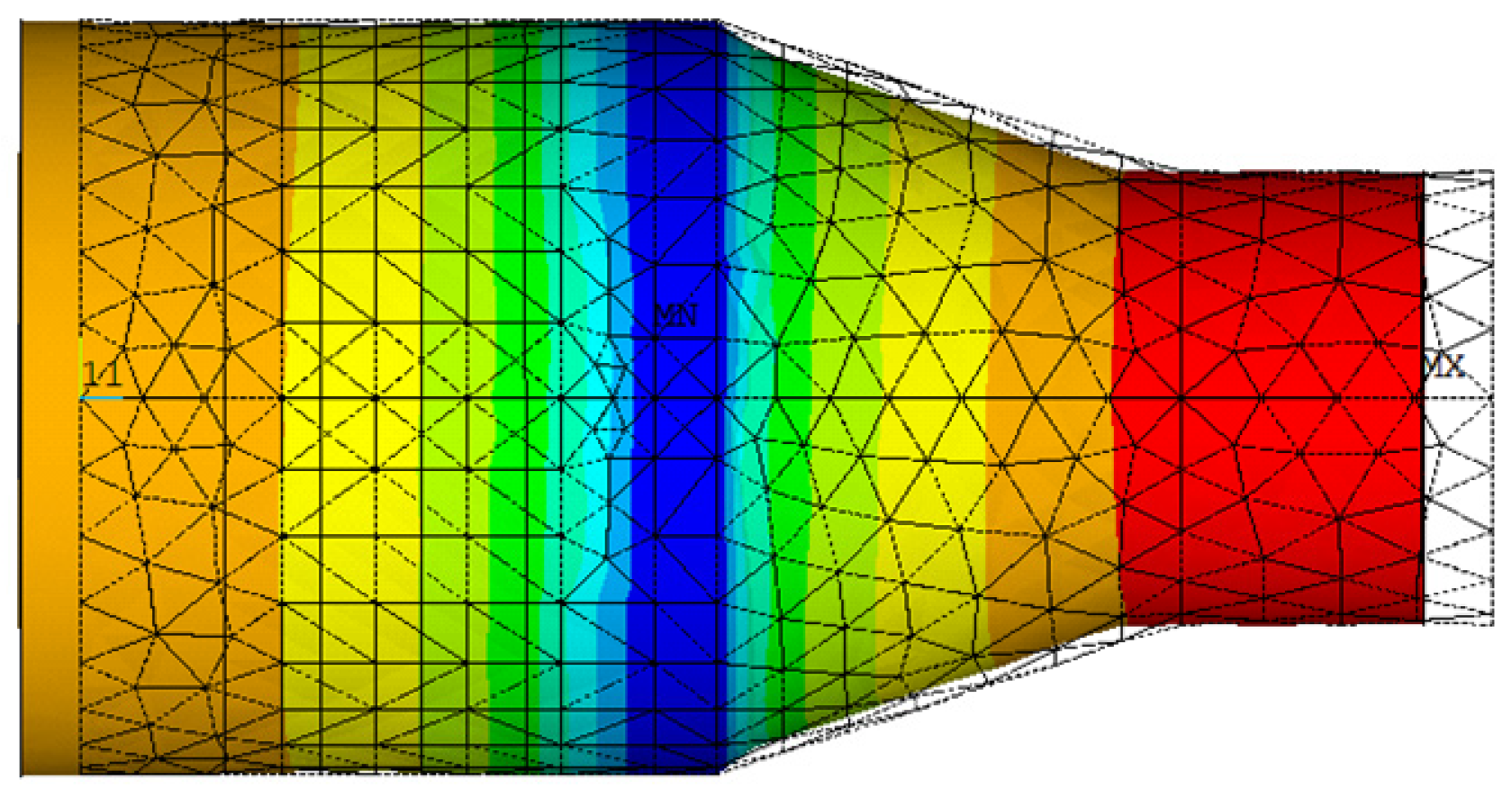

3.1. Simulation Analysis of Vibrator

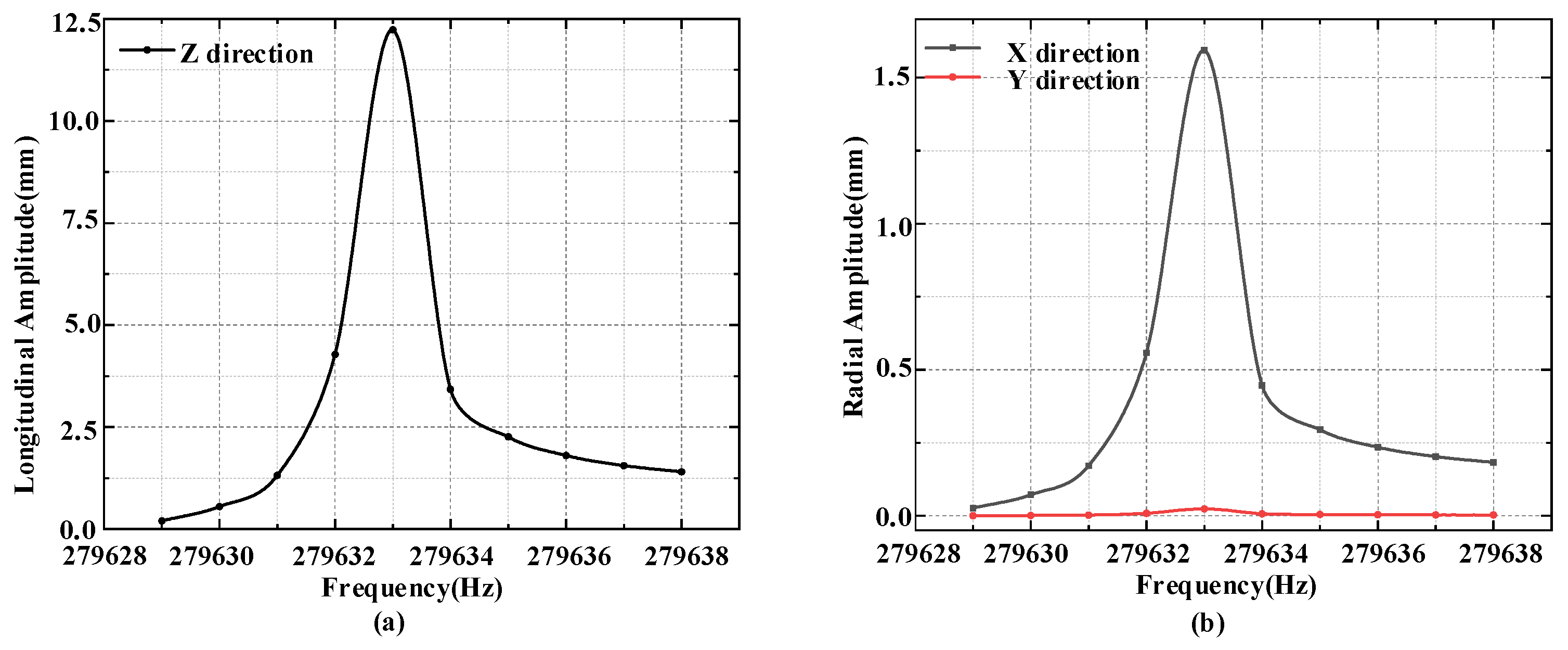

3.2. Modal Analysis and Harmonic Analysis

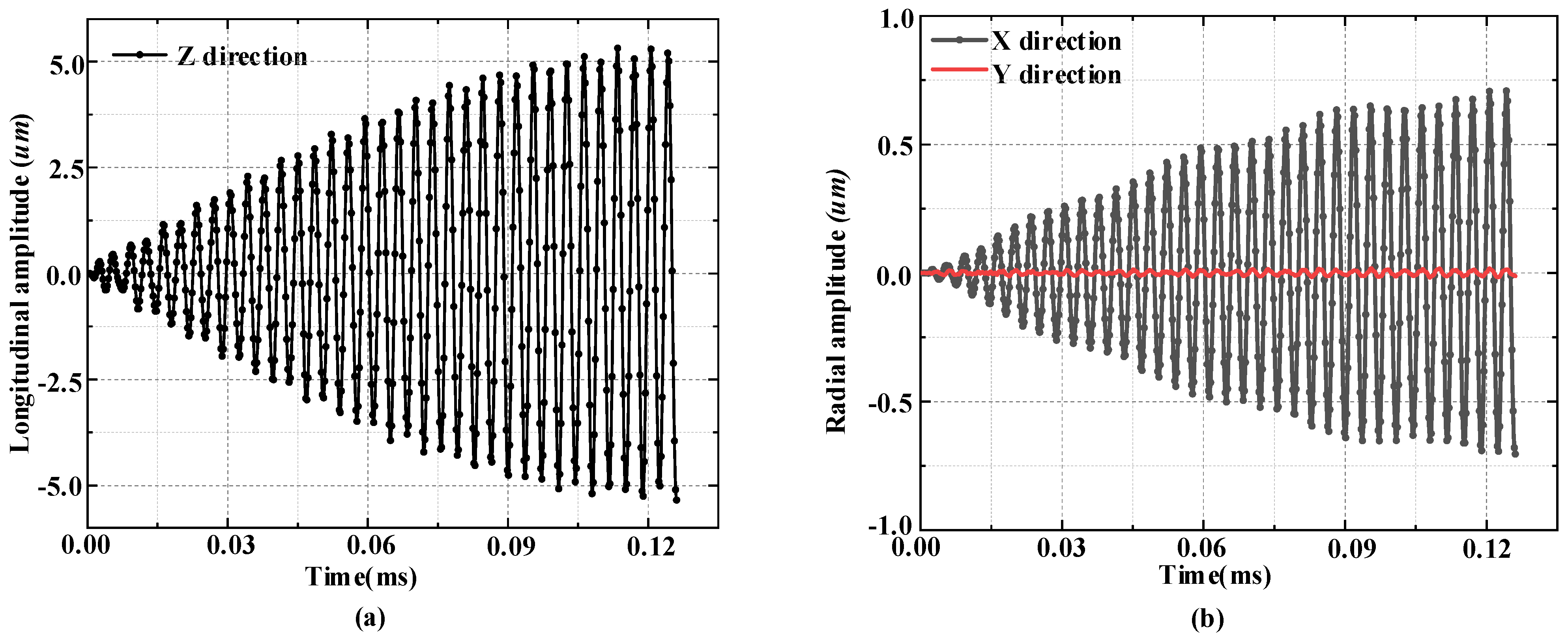

3.3. Transient Analysis and Output Shaft Speed

3.4. Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Niu, C.M.; Luo, Q.; Chou, C.H.; Liu, J.; Hao, M.; Lan, N. Neuromorphic Model of Reflex for Realtime Human-Like Compliant Control of Prosthetic Hand. Ann. Biomed. Eng. 2021, 49, 673–688. [Google Scholar] [CrossRef] [PubMed]

- Ryu, W.; Choi, Y.; Choi, Y.J.; Lee, Y.G.; Lee, S. Development of an Anthropomorphic Prosthetic Hand with Underactuated Mechanism. Appl. Sci. 2020, 10, 4384. [Google Scholar] [CrossRef]

- Kashef, S.R.; Amini, S.; Akbarzadeh, A. Robotic hand: A review on linkage-driven finger mechanisms of prosthetic hands and evaluation of the performance criteria. Mech. Mach. Theory 2020, 145, 103677. [Google Scholar] [CrossRef]

- Simons, M.F.; Digumarti, K.M.; Le, N.H.; Chen, H.-Y.; Carreira, S.C.; Zaghloul, N.S.S.; Diteesawat, R.S.; Garrad, M.; Conn, A.T.; Kent, C.; et al. B:Ionic Glove: A Soft Smart Wearable Sensory Feedback Device for Upper Limb Robotic Prostheses. IEEE Robot. Autom. Lett. 2021, 6, 3311–3316. [Google Scholar] [CrossRef]

- Rahiminejad, E.; Parvizi-Fard, A.; Iskarous, M.M.; Thakor, N.V.; Amiri, M. A Biomimetic Circuit for Electronic Skin with Application in Hand Prosthesis. IEEE Trans. Neural Syst. Rehabil. Eng. 2021, 29, 2333–2344. [Google Scholar] [CrossRef]

- Lu, H.; Zou, Z.; Wu, X.; Shi, C.; Liu, Y.; Xiao, J. Biomimetic Prosthetic Hand Enabled by Liquid Crystal Elastomer Tendons. Micromachines 2021, 12, 736. [Google Scholar] [CrossRef] [PubMed]

- Kwon, H.-C.; Cho, D.-H.; Kim, K.-H. Underactuated Three-Finger Robot Hand with Human-Like Flexion. Int. J. Precis. Eng. Manuf. 2021, 22, 791–798. [Google Scholar] [CrossRef]

- Johansen, D.; Popovic, D.B.; Dosen, S.; Struijk, L. Hybrid Tongue—Myoelectric Control Improves Functional Use of a Robotic Hand Prosthesis. IEEE Trans. Biomed. Eng. 2021, 68, 2011–2020. [Google Scholar] [CrossRef]

- Gao, G.; Shahmohammadi, M.; Gerez, L.; Kontoudis, G.; Liarokapis, M. On Differential Mechanisms for Underactuated, Lightweight, Adaptive Prosthetic Hands. Front. Neurorobot. 2021, 15, 702031. [Google Scholar] [CrossRef]

- Cuellar, J.S.; Plettenburg, D.; Zadpoor, A.A.; Breedveld, P.; Smit, G. Design of a 3D-printed hand prosthesis featuring articulated bio-inspired fingers. Proc. Inst. Mech. Eng. Part H J. Eng. Med. 2021, 235, 336–345. [Google Scholar] [CrossRef]

- Liu, S.; Van, M.; Chen, Z.; Angeles, J.; Chen, C. A novel prosthetic finger design with high load-carrying capacity. Mech. Mach. Theory 2021, 156, 104121. [Google Scholar] [CrossRef]

- Yoder, Z.; Kellaris, N.; Chase-Markopoulou, C.; Ricken, D.; Mitchell, S.K.; Emmett, M.B.; Weir, R.F.F.; Segil, J.; Keplinger, C. Design of a High-Speed Prosthetic Finger Driven by Peano-HASEL Actuators. Front. Robot. AI 2020, 7, 586216. [Google Scholar] [CrossRef]

- Ryu, W.; Choi, Y.; Choi, Y.J.; Lee, S. Development of a Lightweight Prosthetic Hand for Patients with Amputated Fingers. Appl. Sci. 2020, 10, 3536. [Google Scholar] [CrossRef]

- Liow, L.; Clark, A.B.; Rojas, N. OLYMPIC: A Modular, Tendon-Driven Prosthetic Hand with Novel Finger and Wrist Coupling Mechanisms. IEEE Robot. Autom. Lett. 2020, 5, 299–306. [Google Scholar] [CrossRef]

- Vertongen, J.; Kamper, D.G.; Smit, G.; Vallery, H. Mechanical Aspects of Robot Hands, Active Hand Orthoses, and Prostheses: A Comparative Review. IEEE/ASME Trans. Mechatron. 2021, 26, 955–965. [Google Scholar] [CrossRef]

- Dunai, L.; Novak, M.; Garcia Espert, C. Human Hand Anatomy-Based Prosthetic Hand. Sensors 2020, 21, 137. [Google Scholar] [CrossRef] [PubMed]

- Blana, D.; van den Bogert, A.J.; Murray, W.M.; Ganguly, A.; Krasoulis, A.; Nazarpour, K.; Chadwick, E.K. Model-based control of individual finger movements for prosthetic hand function. IEEE Trans. Neural Syst. Rehabil. Eng. 2020, 28, 612–620. [Google Scholar] [CrossRef]

- Weiner, P.; Neef, C.; Shibata, Y.; Nakamura, Y.; Asfour, T. An Embedded, Multi-Modal Sensor System for Scalable Robotic and Prosthetic Hand Fingers. Sensors 2019, 20, 101. [Google Scholar] [CrossRef]

- Barontini, F.; Catalano, M.G.; Grioli, G.; Bianchi, M.; Bicchi, A. Wearable Integrated Soft Haptics in a Prosthetic Socket. IEEE Robot. Autom. Lett. 2021, 6, 1785–1792. [Google Scholar] [CrossRef]

- Chen, T.-R.; Zhao, X.-W.; Ma, G.-C.; Tao, B.; Yin, Z.-P. Design of 3D-Printed Cable Driven Humanoid Hand Based on Bidirectional Elastomeric Passive Transmission. Chin. J. Mech. Eng. 2020, 34, 76. [Google Scholar] [CrossRef]

- Lan, N.; Hao, M.; Niu, C.M.; Cui, H.; Wang, Y.; Zhang, T.; Fang, P.; Chou, C.H. Next-Generation Prosthetic Hand: From Biomimetic to Biorealistic. Research 2021, 2021, 4675326. [Google Scholar] [CrossRef] [PubMed]

- Coskun, M.; Yildirim, O.; Demir, Y.; Acharya, U.R. Efficient deep neural network model for classification of grasp types using sEMG signals. J. Ambient. Intell. Humaniz. Comput. 2021, 13, 4437–4450. [Google Scholar] [CrossRef]

- Connan, M.; Sierotowicz, M.; Henze, B.; Porges, O.; Albu-Schaffer, A.; Roa, M.A.; Castellini, C. Learning to teleoperate an upper-limb assistive humanoid robot for bimanual daily-living tasks. Biomed. Phys. Eng. Express 2021, 8, 015022. [Google Scholar] [CrossRef] [PubMed]

- Mashimo, T.; Urakubo, T.; Shimizu, Y. Micro Geared Ultrasonic Motor. IEEE/ASME Trans. Mechatron. 2018, 23, 781–787. [Google Scholar] [CrossRef]

- Liu, Y.; Shi, S.; Wang, D.; Chen, W.; Xu, D. Research on the thermal characteristics of bending hybrid piezoelectric actuators under different exciting methods. Ceram. Int. 2017, 43, S15–S20. [Google Scholar] [CrossRef]

- Ryndzionek, R.; Sienkiewicz, L. A review of recent advances in the single- and multi-degree-of-freedom ultrasonic piezoelectric motors. Ultrasonics 2021, 116, 106471. [Google Scholar] [CrossRef] [PubMed]

- Xu, D.; Zhang, X.; Zhao, L.; Yu, S. A Novel Rotary Ultrasonic Motor Using the Longitudinal Vibration Mode. IEEE Access 2019, 7, 135650–135655. [Google Scholar] [CrossRef]

- Liu, Y.; Yan, J.; Wang, L.; Chen, W. A Two-DOF Ultrasonic Motor Using a Longitudinal–Bending Hybrid Sandwich Transducer. IEEE Trans. Ind. Electron. 2019, 66, 3041–3050. [Google Scholar] [CrossRef]

- Chiang, E.T.K.; Mashimo, T. Comparison study of bending and three-wave vibration modes for micro ultrasonic motors. Sens. Actuators A Phys. 2021, 329, 112801. [Google Scholar] [CrossRef]

- Li, H.; Tian, X.; Shen, Z.; Li, K.; Liu, Y. A low-speed linear stage based on vibration trajectory control of a bending hybrid piezoelectric ultrasonic motor. Mech. Syst. Signal Process. 2019, 132, 523–534. [Google Scholar] [CrossRef]

- Wu, J.; Mizuno, Y.; Nakamura, K. A Rotary Ultrasonic Motor Operating in Torsional/Bending Modes with High Torque Density and High Power Density. IEEE Trans. Ind. Electron. 2021, 68, 6109–6120. [Google Scholar] [CrossRef]

- Yin, Z.; Dai, C.; Cao, Z.; Li, W.; Chen, Z.; Li, C. Modal analysis and moving performance of a single-mode linear ultrasonic motor. Ultrasonics 2020, 108, 106216. [Google Scholar] [CrossRef] [PubMed]

- Ting, Y.; Lin, H.-P.; Sung, Y.-K.; Yu, C.-H. Design a composite piezoelectric motor using face-shear and longitudinal resonance vibration. Sens. Actuators A Phys. 2019, 290, 62–70. [Google Scholar] [CrossRef]

- Li, J.; Liu, S.; Zhou, N.; Yu, A.; Cui, Y.; Chen, P. A traveling wave ultrasonic motor with a metal/polymer-matrix material compound stator. Smart Mater. Struct. 2018, 27, 015027. [Google Scholar] [CrossRef]

- Yang, X.; Liu, Y.; Chen, W.; Liu, J. A cylindrical traveling wave ultrasonic motor using bonded-type composite beam. Ultrasonics 2016, 65, 277–281. [Google Scholar] [CrossRef] [PubMed]

- Yang, X.; Liu, Y.; Chen, W.; Zhao, X. New Excitation Method for Sandwich Transducer Using Bending Composite Vibrations: Modeling, Simulation, and Experimental Evaluation. IEEE Trans. Ind. Electron. 2018, 65, 4889–4896. [Google Scholar] [CrossRef]

- Nguyen, V.P.; Dhyan, S.B.; Mai, V.; Han, B.S.; Chow, W.T. Bioinspiration and Biomimetic Art in Robotic Grippers. Micromachines 2023, 14, 1772. [Google Scholar] [CrossRef]

- Goh, G.L.; Goh, G.D.; Nguyen, V.P.; Toh, W.; Lee, S.; Li, X.; Sunil, B.D.; Lim, J.Y.; Li, Z.; Sinha, A.K.; et al. A 3D Printing-Enabled Artificially Innervated Smart Soft Gripper with Variable Joint Stiffness. Adv. Mater. Technol. 2023, 2301426. [Google Scholar] [CrossRef]

- Min, S.; Yi, S. Development of cable-driven anthropomorphic robot hand. IEEE Robot. Autom. Lett. 2021, 6, 1176–1183. [Google Scholar] [CrossRef]

- Nikafrooz, N.; Leonessa, A. A single-actuated, cable-driven, and self-contained robotic hand designed for adaptive grasps. Robotics 2021, 10, 109. [Google Scholar] [CrossRef]

- Ruehl, S.W.; Parlitz, C.; Heppner, G.; Hermann, A.; Roennau, A.; Dillmann, R. Experimental evaluation of the schunk 5-finger gripping hand for grasping tasks. In Proceedings of the 2014 IEEE International Conference on Robotics and Biomimetics (ROBIO 2014), Bali, Indonesia, 5–10 December 2014; IEEE: Piscataway, NJ, USA, 2014; pp. 2465–2470. [Google Scholar]

| Material | Density | Wave Velocity |

|---|---|---|

| 2Cr13 | ||

| PZT-8 | ||

| 7A04 |

| r (mm) | R (mm) | L1 (mm) | L2 (mm) | L3 (mm) | L4 (mm) | L5 (mm) |

|---|---|---|---|---|---|---|

| 0.75 | 1.25 | 0.65 | 1.2 | 0.2 | 1.5 | 1 |

| Order | 1 | 2 | 3 | 4 | 5 | 6 |

|---|---|---|---|---|---|---|

| Frequency/Hz | 147,319 | 153,129 | 185,826 | 187,821 | 261,215 | 279,633 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, K.; Lu, J.; Yang, H. Simulation Analysis of a Sandwich Cantilever Ultrasonic Motor for a Dexterous Prosthetic Hand. Micromachines 2023, 14, 2150. https://doi.org/10.3390/mi14122150

Guo K, Lu J, Yang H. Simulation Analysis of a Sandwich Cantilever Ultrasonic Motor for a Dexterous Prosthetic Hand. Micromachines. 2023; 14(12):2150. https://doi.org/10.3390/mi14122150

Chicago/Turabian StyleGuo, Kai, Jingxin Lu, and Hongbo Yang. 2023. "Simulation Analysis of a Sandwich Cantilever Ultrasonic Motor for a Dexterous Prosthetic Hand" Micromachines 14, no. 12: 2150. https://doi.org/10.3390/mi14122150

APA StyleGuo, K., Lu, J., & Yang, H. (2023). Simulation Analysis of a Sandwich Cantilever Ultrasonic Motor for a Dexterous Prosthetic Hand. Micromachines, 14(12), 2150. https://doi.org/10.3390/mi14122150