Boosting Evaporative Cooling Performance with Microporous Aerogel

Abstract

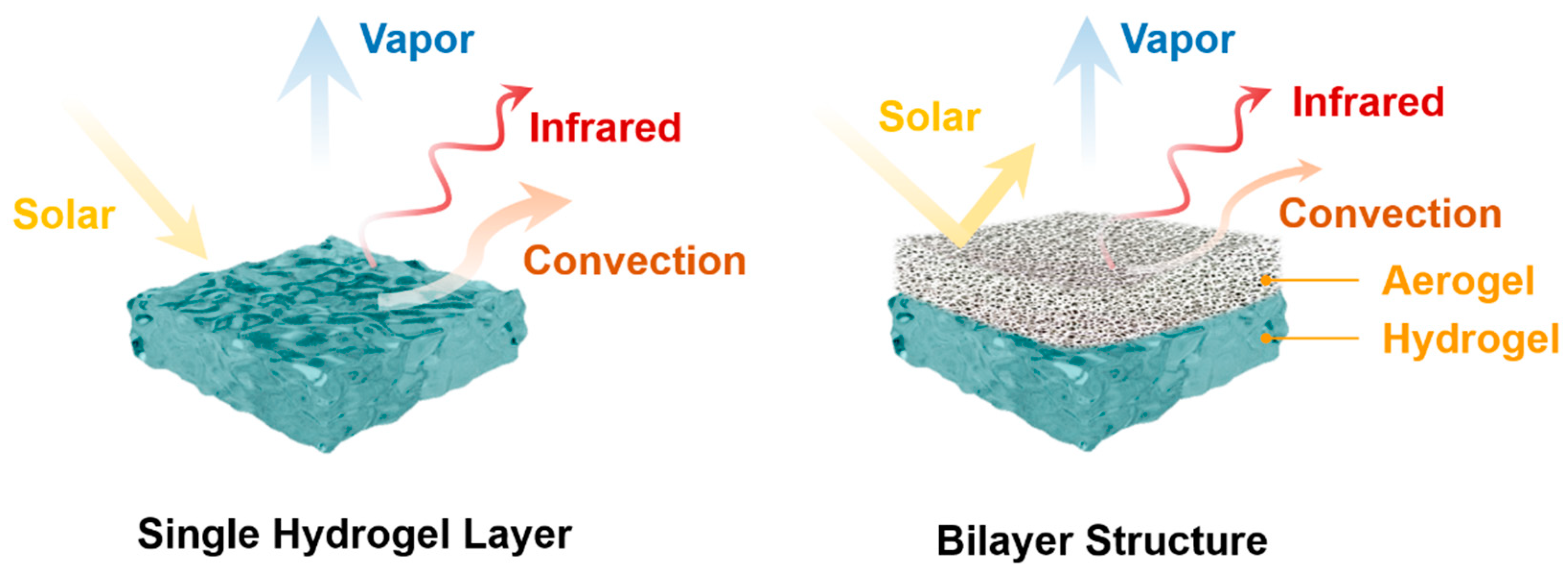

1. Introduction

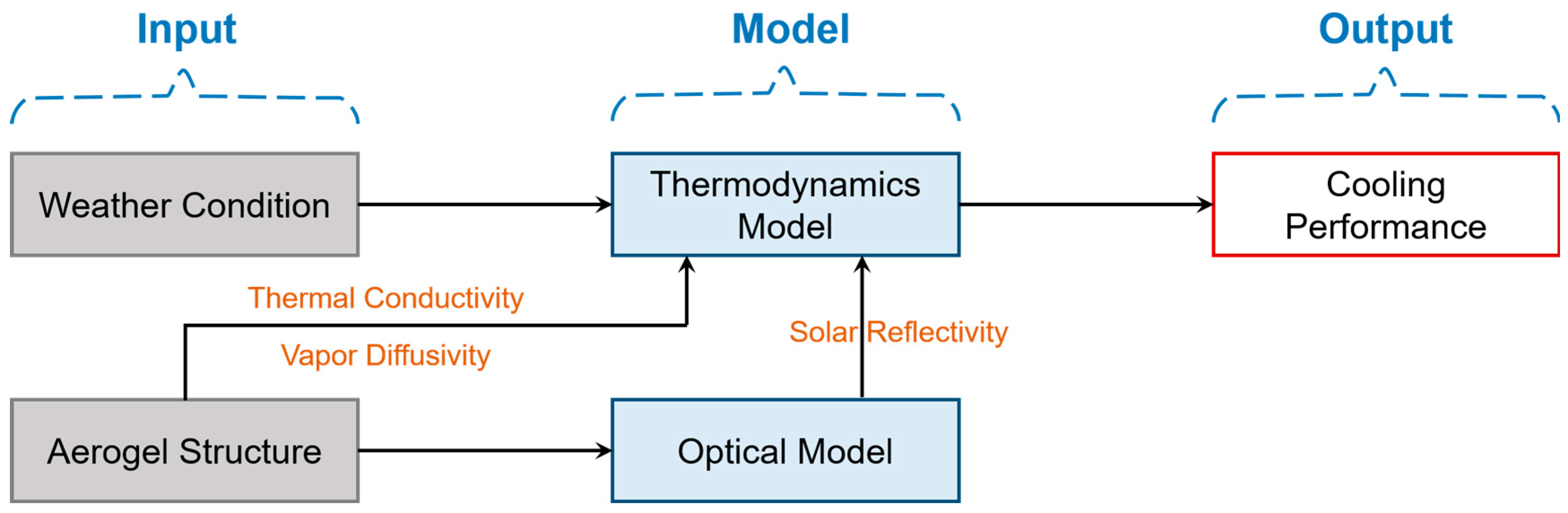

2. Methodology

2.1. Optical Model

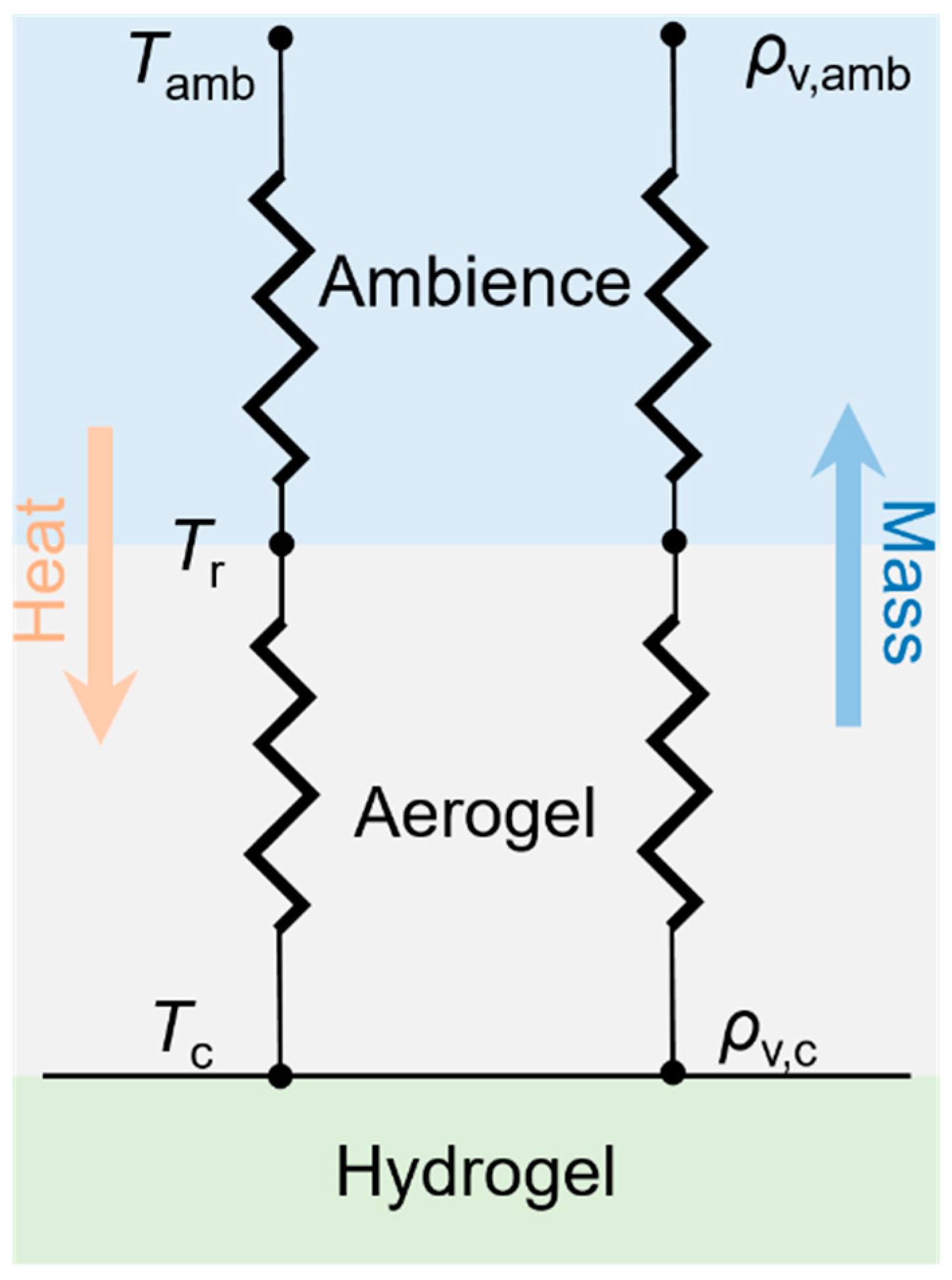

2.2. Thermodynamics Model

3. Results

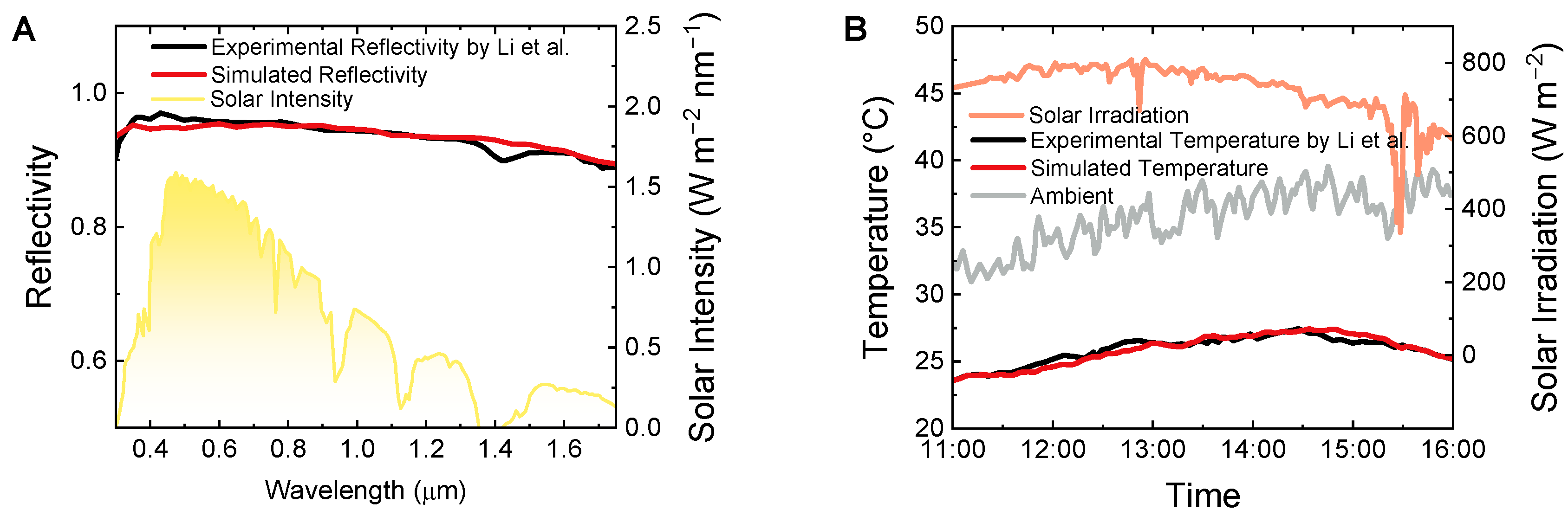

3.1. Model Validation

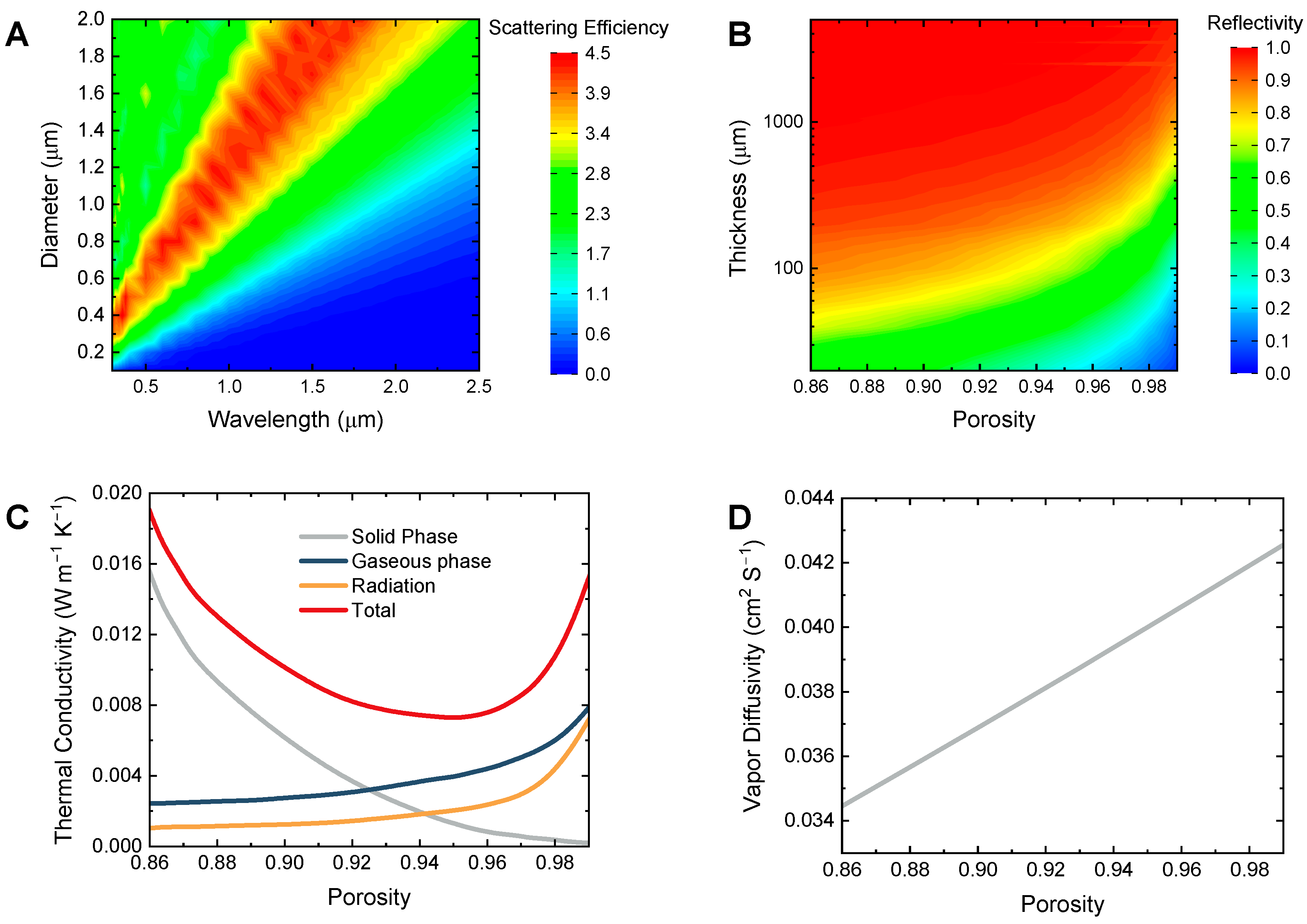

3.2. Aerogel Properties

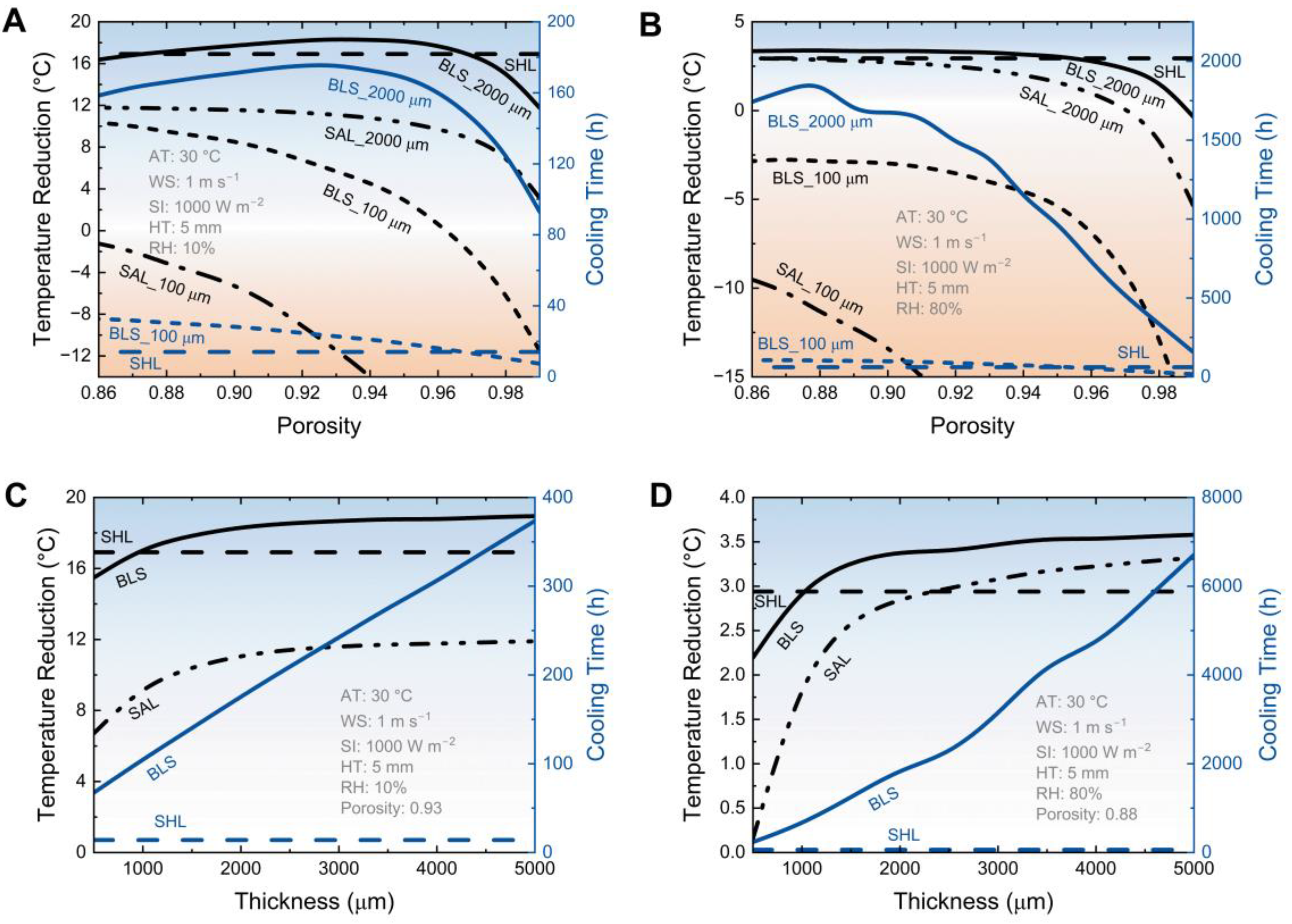

3.3. The Effect of Aerogel Structure Parameters on Cooling Performance

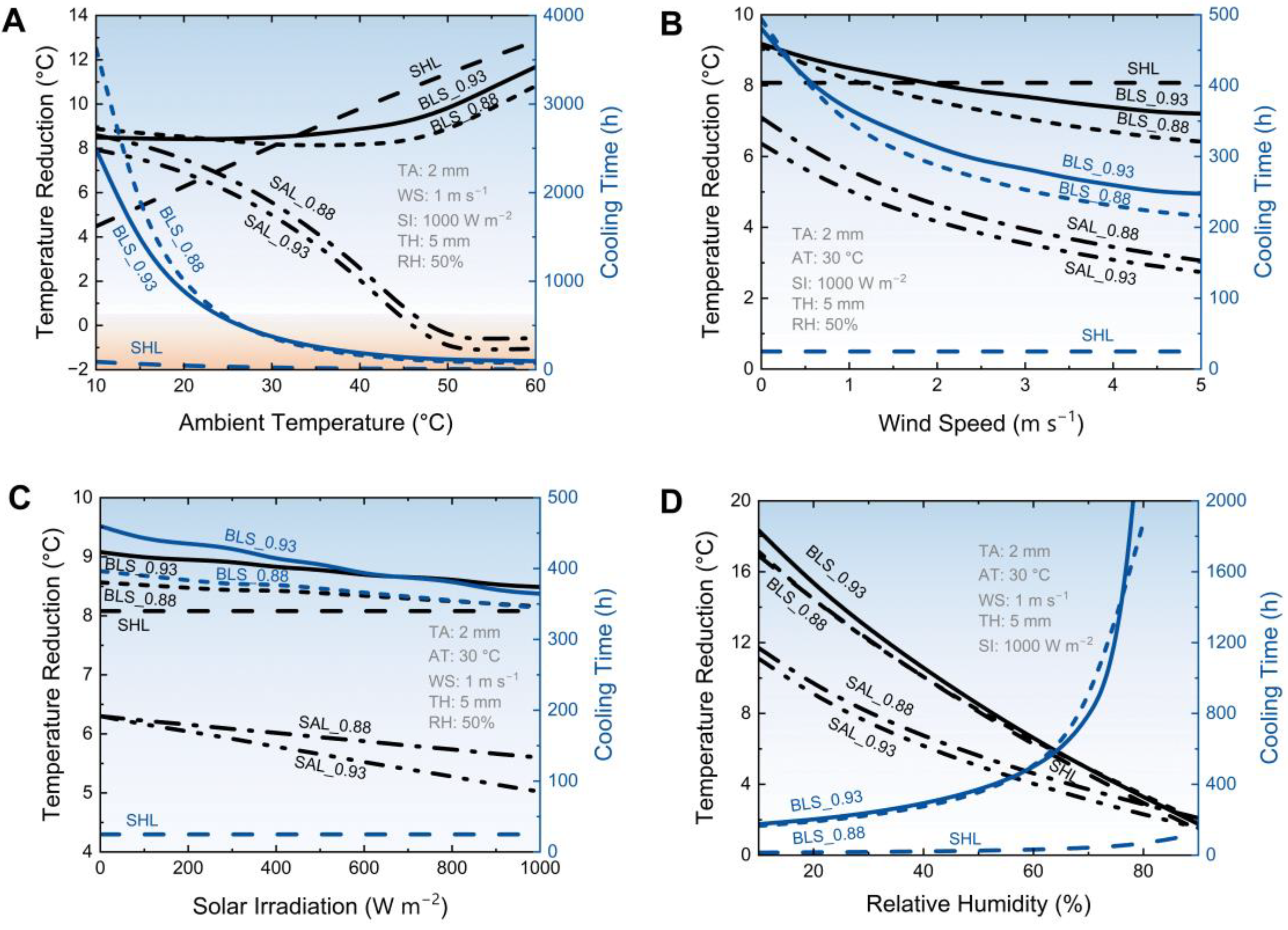

3.4. The Effect of Weather Conditions on Cooling Performance

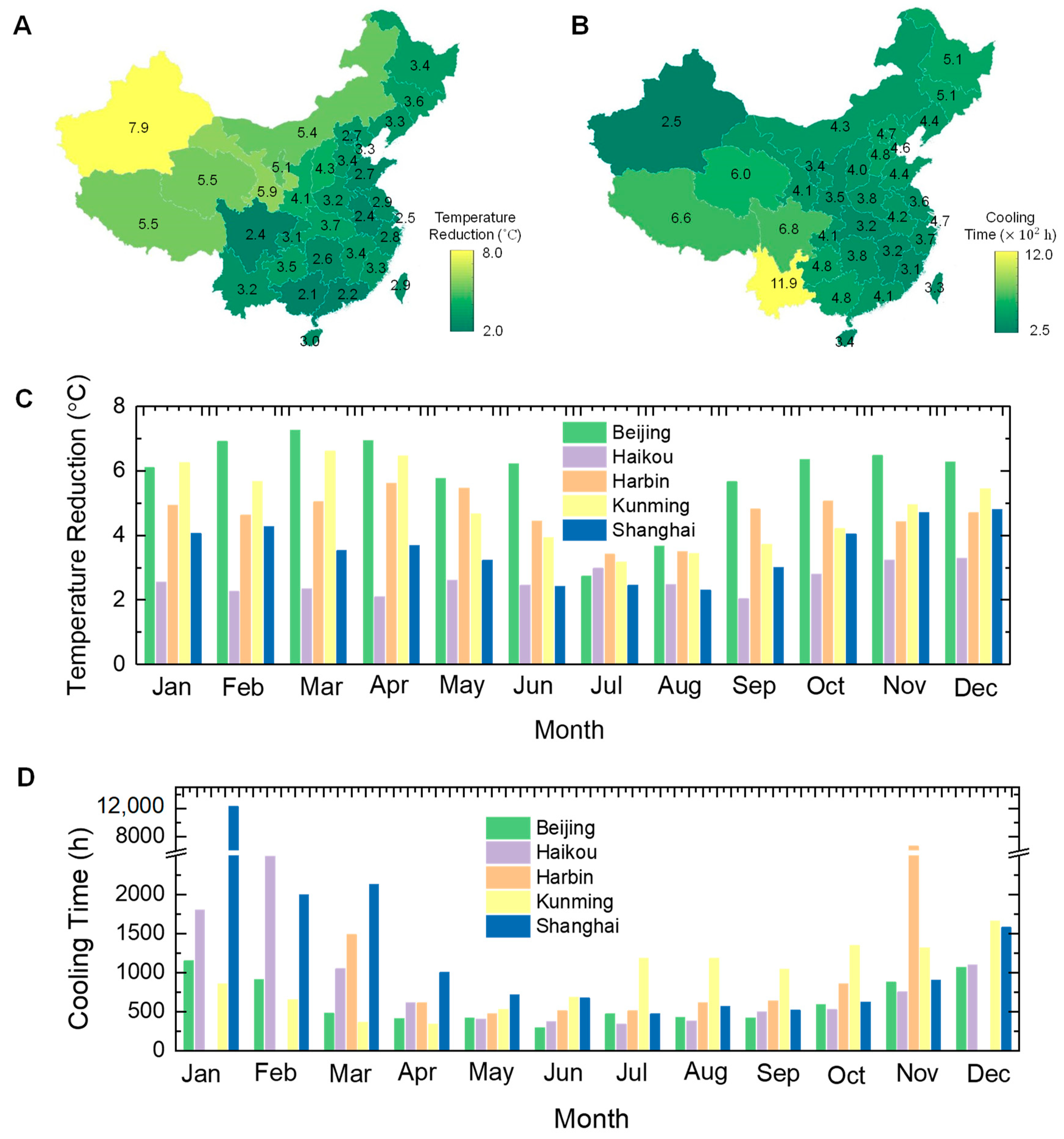

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Glossary

| Nomenclature | |

| Mie coefficients | |

| diameter of the fiber, m | |

| porosity | |

| asymmetry factor | |

| non-radiative heat coefficient, W m−2 K−1 | |

| enthalpy of vapor, kJ kg−1 | |

| the spectral radiance of a black body, W | |

| solar illumination, W m−2 | |

| thermal conductivity, W m−1 K−1 | |

| absorbed IR radiation, W m−2 | |

| non-radiation heat transfer, W m−2 | |

| evaporative cooling power, W m−2 | |

| net passive cooling power, W m−2 | |

| emitted IR radiation, W m−2 | |

| radiative cooling power, W m−2 | |

| solar intensity absorbed by radiative paints, W m−2 | |

| scattering efficiency | |

| mass transfer resistance, s m−1 | |

| cooling temperature, K | |

| thickness, m | |

| size parameter | |

| Greek symbols | |

| spectral and angular solar absorptivity | |

| length of incident wave, m | |

| density of the hydrogel layer, kg m−3 | |

| vapor mass density, g kg−1 | |

| scattering coefficient of the fiber coma | |

| spectral and angular emissivity in the infrared region | |

| cooling time, h | |

| solid angel for scattering | |

| water mass fraction of the hydrogel | |

| Superscripts and subscripts | |

| aer | aerogel |

| amb | ambient |

| atm | atmospheric |

| ext | external |

| g | gaseous phase |

| h | hydrogel |

| r | radiation |

| s | solid phase |

References

- Zhu, B.; Li, W.; Zhang, Q.; Li, D.; Liu, X.; Wang, Y.; Xu, N.; Wu, Z.; Li, J.; Li, X.; et al. Subambient Daytime Radiative Cooling Textile Based on Nanoprocessed Silk. Nat. Nanotechnol. 2021, 16, 1342–1348. [Google Scholar] [CrossRef]

- Ji, Y.; Sun, Y.; Javed, M.; Xiao, Y.; Li, X.; Jin, K.; Cai, Z.; Xu, B. Skin Inspired Thermoresponsive Polymer for Constructing Self-Cooling System. Energy Convers. Manag. 2022, 254, 115251. [Google Scholar] [CrossRef]

- Pu, S.; Fu, J.; Liao, Y.; Ge, L.; Zhou, Y.; Zhang, S.; Zhao, S.; Liu, X.; Hu, X.; Liu, K.; et al. Promoting Energy Efficiency via a Self-Adaptive Evaporative Cooling Hydrogel. Adv. Mater. 2020, 32, e1907307. [Google Scholar] [CrossRef]

- Xu, L.; Sun, D.; Tian, Y.; Sun, L.; Fan, T.; Zhu, Z. Combined Effects of Radiative and Evaporative Cooling on Fruit Preservation under Solar Radiation: Sunburn Resistance and Temperature Stabilization. ACS Appl. Mater. Interfaces 2022, 14, 45788–45799. [Google Scholar] [CrossRef]

- Zhang, X.; Yang, W.; Shao, Z.; Li, Y.; Su, Y.; Zhang, Q.; Hou, C.; Wang, H. A Moisture-Wicking Passive Radiative Cooling Hierarchical Metafabric. ACS Nano 2022, 16, 2188–2197. [Google Scholar] [CrossRef] [PubMed]

- Miao, D.; Cheng, N.; Wang, X.; Yu, J.; Ding, B. Integration of Janus Wettability and Heat Conduction in Hierarchically Designed Textiles for All-Day Personal Radiative Cooling. Nano Lett. 2022, 22, 680–687. [Google Scholar] [CrossRef] [PubMed]

- Tu, Y.; Wang, R.; Zhang, Y.; Wang, J. Progress and Expectation of Atmospheric Water Harvesting. Joule 2018, 2, 1452–1475. [Google Scholar] [CrossRef]

- Yin, X.; Yang, R.; Tan, G.; Fan, S. Terrestrial Radiative Cooling: Using the Cold Universe as a Renewable and Sustainable Energy Source. Science 2020, 791, 786–791. [Google Scholar] [CrossRef]

- Zhao, D.; Aili, A.; Zhai, Y.; Xu, S.; Tan, G.; Yin, X.; Yang, R. Radiative Sky Cooling: Fundamental Principles, Materials, and Applications. Appl. Phys. Rev. 2019, 6, 021306. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, J.; Tang, H.; Zhou, Z.; Zhang, D.; Ye, L.; Zhao, D. Recent Advances in the Development of Radiative Sky Cooling Inspired from Solar Thermal Harvesting. Nano Energy 2021, 81, 105611. [Google Scholar] [CrossRef]

- Raman, A.P.; Anoma, M.A.; Zhu, L.; Rephaeli, E.; Fan, S. Passive Radiative Cooling below Ambient Air Temperature under Direct Sunlight. Nature 2014, 515, 540–544. [Google Scholar] [CrossRef]

- Tang, H.; Zhou, Z.; Jiao, S.; Zhang, Y.; Li, S.; Zhang, D.; Zhang, J. Radiative Cooling of Solar Cells with Scalable and High-Performance Nanoporous Anodic Aluminum Oxide. Sol. Energy Mater. Sol. Cells 2022, 235, 111498. [Google Scholar] [CrossRef]

- Zhu, L.; Raman, A.P.; Fan, S. Radiative Cooling of Solar Absorbers Using a Visibly Transparent Photonic Crystal Thermal Blackbody. Proc. Natl. Acad. Sci. USA 2015, 112, 12282–12287. [Google Scholar] [CrossRef] [PubMed]

- Zhai, Y.; Ma, Y.; David, S.N.; Zhao, D.; Lou, R.; Tan, G.; Yang, R.; Yin, X. Scalable-Manufactured Randomized Glass-Polymer Hybrid Metamaterial for Daytime Radiative Cooling. Science 2017, 355, 1062–1066. [Google Scholar] [CrossRef] [PubMed]

- Tang, H.; Li, S.; Zhang, Y.; Na, Y.; Sun, C.; Zhao, D. Radiative Cooling Performance and Life-Cycle Assessment of a Scalable MgO Paint for Building Applications. J. Clean. Prod. 2022, 380, 135035. [Google Scholar] [CrossRef]

- Xue, X.; Qiu, M.; Li, Y.; Zhang, Q.M.; Li, S.; Yang, Z.; Feng, C.; Zhang, W.; Dai, J.G.; Lei, D.; et al. Creating an Eco-Friendly Building Coating with Smart Subambient Radiative Cooling. Adv. Mater. 2020, 32, 1906751. [Google Scholar] [CrossRef]

- Mandal, J.; Fu, Y.; Overvig, A.C.; Jia, M.; Sun, K.; Shi, N.N.; Zhou, H.; Xiao, X.; Yu, N.; Yang, Y. Hierarchically Porous Polymer Coatings for Highly Efficient Passive Daytime Radiative Cooling. Science 2018, 362, 315–319. [Google Scholar] [CrossRef]

- Li, T.; Zhai, Y.; He, S.; Gan, W.; Wei, Z.; Heidarinejad, M.; Dalgo, D.; Mi, R.; Zhao, X.; Song, J.; et al. A Radiative Cooling Structural Material. Science 2019, 364, 760–763. [Google Scholar] [CrossRef]

- Liu, J.; Tang, H.; Jiang, C.; Wu, S.; Ye, L.; Zhao, D.; Zhou, Z. Micro-Nano Porous Structure for Efficient Daytime Radiative Sky Cooling. Adv. Funct. Mater. 2022, 32, 2206962. [Google Scholar] [CrossRef]

- Leroy, A.; Bhatia, B.; Kelsall, C.C.; Castillejo-Cuberos, A.; Di Capua, M.H.; Zhao, L.; Zhang, L.; Guzman, A.M.; Wang, E.N. High-Performance Subambient Radiative Cooling Enabled by Optically Selective and Thermally Insulating Polyethylene Aerogel. Sci. Adv. 2019, 5, 2206962. [Google Scholar] [CrossRef]

- Li, T.; Sun, H.; Yang, M.; Zhang, C.; Lv, S.; Li, B.; Chen, L.; Sun, D. All-Ceramic, Compressible and Scalable Nanofibrous Aerogels for Subambient Daytime Radiative Cooling. Chem. Eng. J. 2023, 452, 139518. [Google Scholar] [CrossRef]

- Feng, C.; Yang, P.; Liu, H.; Mao, M.; Liu, Y.; Xue, T.; Fu, J.; Cheng, T.; Hu, X.; Jin, H.; et al. Bilayer Porous Polymer for Efficient Passive Building Cooling. Nano Energy 2021, 85, 105971. [Google Scholar] [CrossRef]

- Sun, Y.; Ji, Y.; Javed, M.; Li, X.; Fan, Z.; Wang, Y.; Cai, Z.; Xu, B. Preparation of Passive Daytime Cooling Fabric with the Synergistic Effect of Radiative Cooling and Evaporative Cooling. Adv. Mater. Technol. 2022, 7, 2100803. [Google Scholar] [CrossRef]

- Li, J.; Wang, X.; Liang, D.; Xu, N.; Zhu, B.; Li, W.; Yao, P.; Jiang, Y.; Min, X.; Huang, Z.; et al. A Tandem Radiative / Evaporative Cooler for Weather-Insensitive and High-Performance Daytime Passive Cooling. Sci. Adv. 2022, 8, eabq0411. [Google Scholar] [CrossRef] [PubMed]

- Lu, Z.; Strobach, E.; Chen, N.; Ferralis, N.; Grossman, J.C. Passive Sub-Ambient Cooling from a Transparent Evaporation-Insulation Bilayer. Joule 2020, 4, 2693–2701. [Google Scholar] [CrossRef]

- Zhang, J.; Zhou, Z.; Tang, H.; Xing, J.; Quan, J.; Liu, J.; Yu, J.; Hu, M. Mechanically Robust and Spectrally Selective Convection Shield for Daytime Subambient Radiative Cooling. ACS Appl. Mater. Interfaces 2021, 13, 14132–14140. [Google Scholar] [CrossRef] [PubMed]

- Modest, M.F. Chapter 12—Radiative Properties of Particulate Media. In Radiative Heat Transfer, 3rd ed.; Academic Press: Cambridge, MA, USA, 2013; pp. 387–439. [Google Scholar] [CrossRef]

- Zhao, D.; Aili, A.; Zhai, Y.; Tan, G.; Zhao, D.; Aili, A.; Zhai, Y.; Lu, J.; Kidd, D.; Tan, G.; et al. Subambient Cooling of Water: Toward Real-World Applications of Daytime Radiative Cooling. Joule 2019, 3, 111–123. [Google Scholar] [CrossRef]

- Lamanna, J.M.; Kandlikar, S.G. Determination of Effective Water Vapor Diffusion Coefficient in Pemfc Gas Diffusion Layers. Int. J. Hydrog. Energy 2011, 36, 5021–5029. [Google Scholar] [CrossRef]

- Hrubesh, L.W.; Pekala, R.W. Thermal Properties of Organic and Inorganic Aerogels. J. Mater. Res. 1994, 9, 731–738. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tang, H.; Guo, C.; Xu, Q.; Zhao, D. Boosting Evaporative Cooling Performance with Microporous Aerogel. Micromachines 2023, 14, 219. https://doi.org/10.3390/mi14010219

Tang H, Guo C, Xu Q, Zhao D. Boosting Evaporative Cooling Performance with Microporous Aerogel. Micromachines. 2023; 14(1):219. https://doi.org/10.3390/mi14010219

Chicago/Turabian StyleTang, Huajie, Chenyue Guo, Qihao Xu, and Dongliang Zhao. 2023. "Boosting Evaporative Cooling Performance with Microporous Aerogel" Micromachines 14, no. 1: 219. https://doi.org/10.3390/mi14010219

APA StyleTang, H., Guo, C., Xu, Q., & Zhao, D. (2023). Boosting Evaporative Cooling Performance with Microporous Aerogel. Micromachines, 14(1), 219. https://doi.org/10.3390/mi14010219