1. Introduction

Nowadays, magnesium (Mg) and Mg-based alloys play a very interesting role in the field of biomaterials [

1]. As one of the essential elements for the regulatory functions of the human body [

2,

3], the use of magnesium for biomedical devices is therefore desirable. Due to its absorbable nature in biological fluids, the biocompatibility of its corrosion products and its low toxicity, this material represents an optimal candidate for several applications, especially where an implantable device is required to perform its function for a limited period of time and a short-term integrity is necessary [

4,

5]. The corrosion inside body fluids allows the device to disappear completely once it is no longer useful avoiding removal surgeries [

6,

7].

In this specific context, a Mg-based drug delivery device for the treatment of age-related macular degeneration (AMD), currently treated with monthly injections of anti-vascular endothelial growth factors (anti-VEGF) drugs in the posterior chamber of the eye [

8], might be a solution to be proposed. The high frequency of injections not only causes various complications, such as endophthalmitis, but also leads patients, caregivers and physicians to bear a high overall care burden. This fact can be significant and can lead to non-compliance or complete discontinuation of treatment [

9]. With this novel application, the main goal is to avoid these issues by reducing the number of injections while achieving the same results. The behaviour of the device was investigated in previous studies by means of a numerical model for a critical evaluation of the effective shear stress field induced by ocular fluid dynamics on its free external surfaces. This approach showed the possibility of achieving uniform controlled corrosion of the device [

10,

11,

12].

Currently, the manufacturing technology suitable for the prototyping of this innovative Mg-based drug delivery system needs to be investigated. In particular, the critical aspect in its realisation is closely linked to the presence of cavities, which provide the drug housing with a very high depth-to-diameter ratio.

In the field of manufacturing, a wide range of possible technologies and machining strategies to transform biocompatible materials into biomedical implants can be found. In particular, two methods can be defined: conventional and unconventional. The first includes milling, turning and drilling, while the second includes abrasive water jet machining (AWJM), ultrasonic machining (USM), ion beam machining (IBM), laser beam machining (LBM), electric discharge machining (EDM) and electron beam machining (EBM) [

13]. Among these technologies, mechanical microdrilling has the advantage of achieving good geometrical quality and at the same time good productivity. For this reason, this specific study focused on micromechanical cutting methods. These are commonly used to obtain the final shape of magnesium-based devices, but very few studies can be found in the literature [

14,

15]. Moreover, in microscale machining, a number of issues that are fundamentally different from those of macroscale machining emerge. These affect the basic mechanisms of the process. The consequences lead to changes in the chip formation process, cutting forces, vibrations and process stability, as well as the resulting machined surface [

16].

One of the biggest obstacles in this field is the minimum chip thickness effect. When working in the micro area, the chip volume decreases, leading to an uncut chip thickness

that can be compared to the size of the tool radius

. The relationship between these two factors determines the material cutting mechanism. It can be observed in the literature that if the uncut chip thickness

is less than a critical value called minimum chip thickness

dependent on the cutting edge geometry, depth of cut, feed rate and target material, chip formation will not be present. In fact, what happens is that the workpiece material is subjected to ploughing due to elastic-plastic deformation [

16,

17,

18].

Another aspect to consider, especially in deep microdrilling, is the proper evacuation of chips. Indeed, when holes with a high depth-to-diameter ratio have to be drilled, the amount of chip formed during the process is high. Therefore, if chips are not removed correctly, they can clog the flute, bringing to high values of forces on the drill, which in turn raises the temperature. These phenomena reduce hole quality and accelerate tool wear and breakage [

19]. To overcome this problem, peck drilling is often used. In fact, this strategy is a commonly used method to minimise problems related to excessive cutting forces and torque in deep microdrilling [

20,

21]. It consists of drilling the microhole with an intermittent feed, so that the micro drill alternates phases in which it cuts (peck phases), and phases in which it does not cut the material at all.

There are numerous studies in the literature concerning the drilling process, but there are few cases in which the micromachining of pure magnesium and its alloys is considered.

Some experimental micromilling tests were conducted to investigate the micromachinability of Mg

5Sn

4Zn alloy (TZ54) as a biomedical material compared to pure Mg [

14]. By studying the variation in cutting forces, surface quality, and burr width, appropriate cutting parameters were defined. It has been observed that the surface quality decreases and burr formation increases with a feed per tooth lower than the minimum chip thickness. Furthermore, an experimental study was conducted on the micro drilling mechanisms of a Mg metal matrix composite and pure Mg. The influence of drilling parameters such as rotational speed and feed rate on the morphology of the hole surface was studied [

15]. The results showed that smaller feed and rotation speeds are used in microdrilling to achieve lower burr heights. In this particular study, the minimum chip thickness for Mg has been measured equal to 1.7 μm.

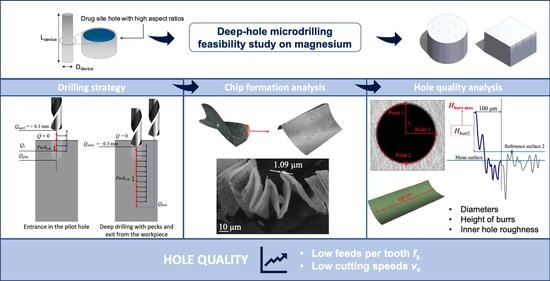

In this paper, the mechanisms of deep-hole microdrilling of pure Mg were experimentally studied in order to find a suitable setup for a novel intraocular drug delivery device prototyping. For this reason, a feasibility study of deep-hole microdrilling of pure magnesium was conducted in order to understand the suitability of this technology for the future manufacture of the device. Microdrilling tests were performed with 0.20 mm and 0.35 mm microdrills, compatible with the device cross-sectional dimensions using a full factorial design in which cutting speed and feed were varied over two levels. Chip formation for low feed values down to 1 μm was investigated to confirm the choice of working cutting parameters. Therefore, entrance diameters and burr height were examined. Moreover, the surface roughness of the inner hole wall was measured.

2. Materials and Methods

Microdrilling tests were carried out on four circular pure magnesium specimens (diameter

D = 20 mm, thickness

th = 10 mm).

Table 1 shows the material properties. Hardness was measured using a microhardness tester (FM-810, FUTURE-TECH CORP., Kawasaki, Japan), while density was measured using an analytical balance (MC-1 Analytic AC210P, Sartorius AG, Göttingen, Germany) with a density determination kit (YDK 01, Sartorius AG, Germany).

When the thickness of the uncut chip is of the same order of magnitude as the grain size of the material, the workpiece material can no longer be assumed to be homogeneous and isotropic [

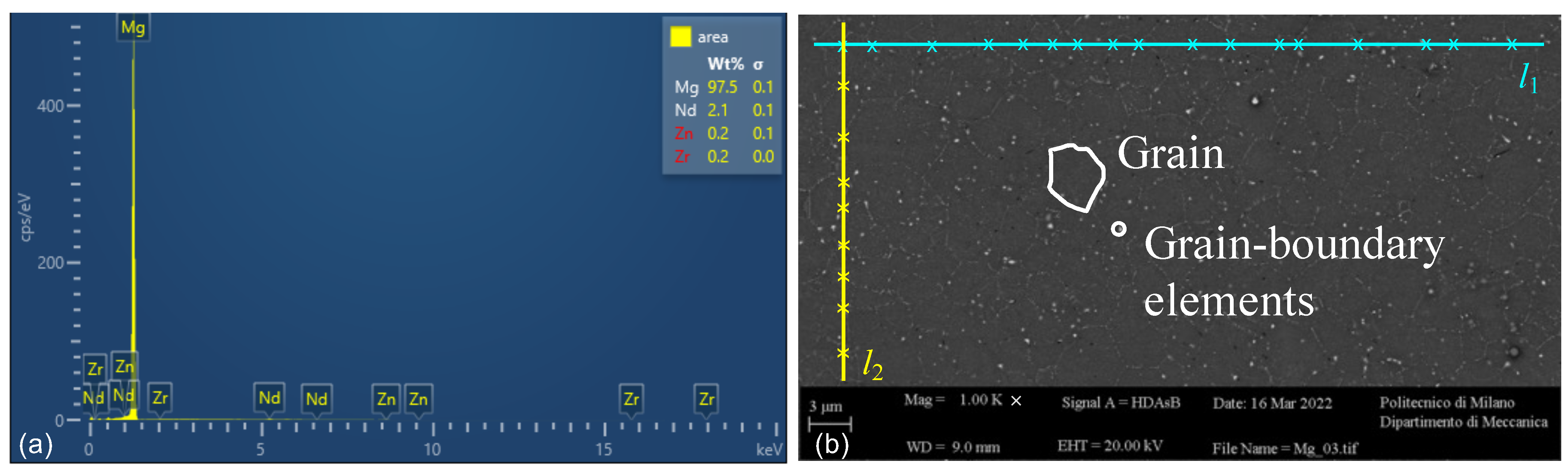

22]. For this reason, a metallographic analysis of the bulk material was performed before the tests using a field emission scanning electron microscope (FE-SEMs, ZEISS Sigma 500 Gemini, Carl Zeiss, Oberkochen, Germany). In

Figure 1 the composition of the material and the grain boundaries are shown. White spots can be observed: these are grain-boundary elements as neodymium and zinc. These analyses revealed that the material, previously studied for biomedical applications associated with magnesium [

23,

24], contains very low amounts of alloying elements. This makes such material suitable for the present application, therefore it will conventionally be treated as pure Mg.

Three horizontal lines of length

= 55 μm and three vertical lines of length

= 35 μm were drawn on the micrograph (see

Figure 1b) in order to measure the average size of the grain

. Dividing

and

by the number of intersections with the grain boundaries, 6 values of

were obtained. The average grain size of the workpiece material was evaluated as 3 μm (

= 0.27 μm).

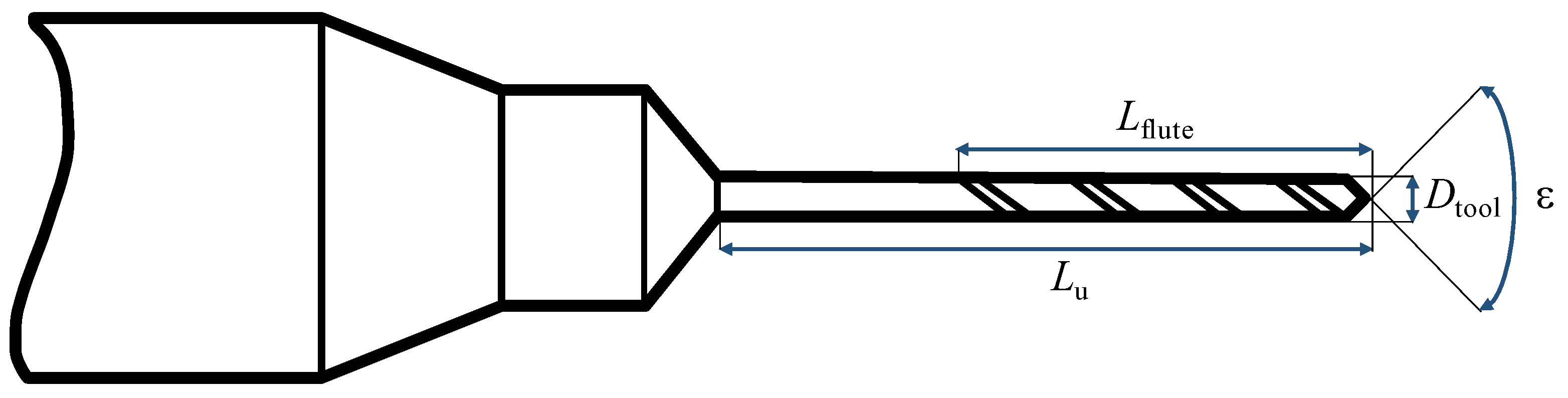

2.1. Cutting Tools and Drilling Strategy

A 0.20 mm (Custom, Louis Belét, Vendlincourt, Switzerland) and a 0.35 mm (2.CD. 080035.IN, Mikron Tool, Agno, Switzerland) coated microtwist drills with two cutting edges were used for the experimental campaign (see

Figure 2 and

Table 2). The radius of the cutting edges

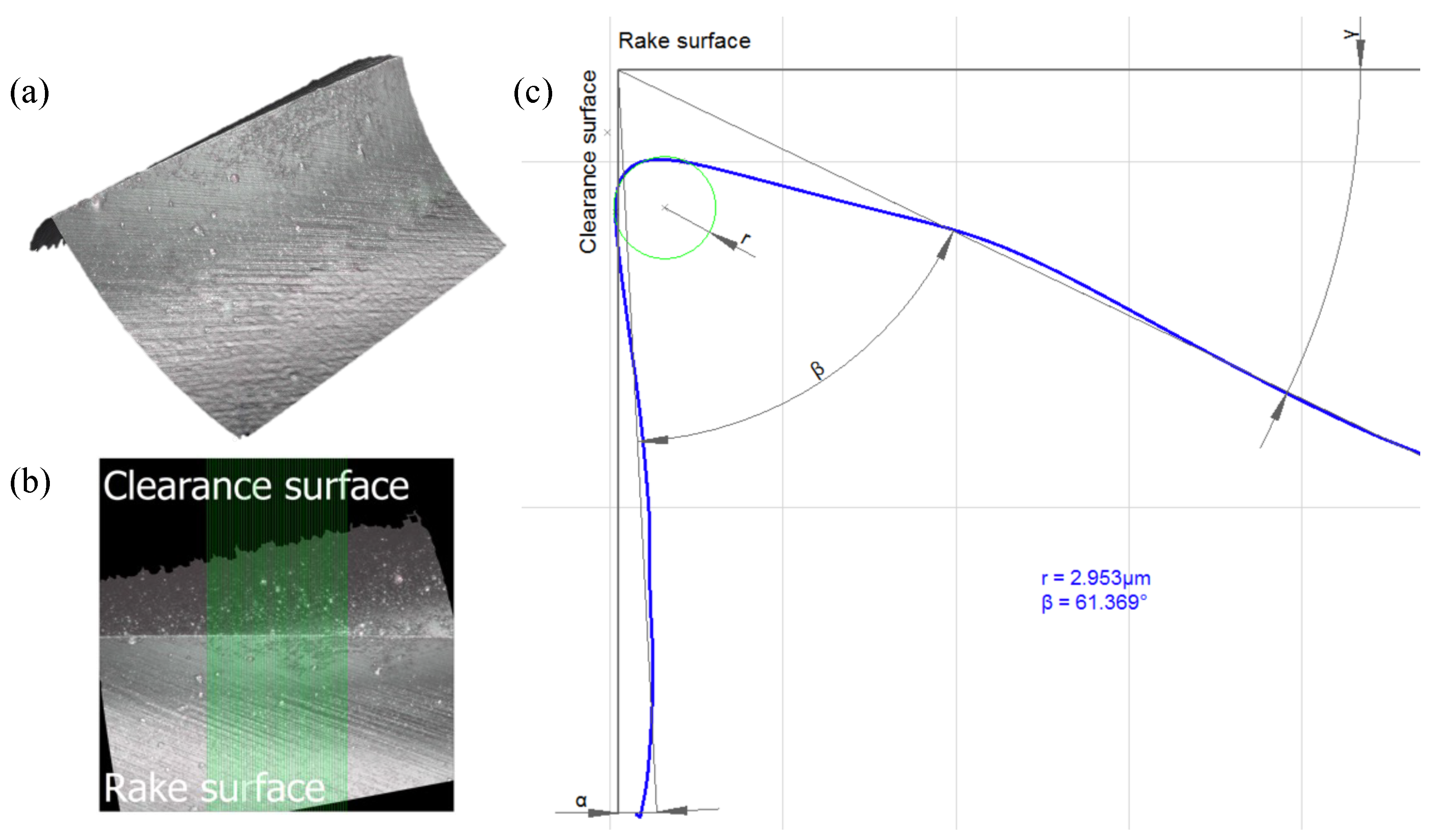

for both the microdrills was measured using the 3D microscope Alicona InfiniteFocus G5plus (Bruker Alicona, Graz, Austria). This value was measured using the appropriate EdgeMasterModule, which directly quotes the geometrical features of the tool (see

Figure 3). The software algorithm, with default settings considers 50% of the length of the acquired cutting edge, and measures 800 equidistant profiles (green band in

Figure 3b). This means that

, which corresponds to the radius of the circle that best fits the points of the profile, is averaged over 800 profiles.

The Kern EVO high-precision machining center was used for the experimental campaign. Its spindle can rotate at speeds ranging from 500 to 50,000 rpm and can provide a maximum power of 6.4 kW. The machine accuracy on the workpiece is declared to be ±2.0 μm.

A centering operation was performed in order to achieve a better stability of the microdrill during the deep-drilling operation. In this case a Louis Belét (342d0.21,

Dpilot0.21 = 0.21 mm) and a MikronTool (2.PFS.035.1,

Dpilot0.35 = 0.35 mm) pilot drills were used to obtain a pilot hole depth

Qpilot. It was preferred to use a pilot drill with a diameter 0.01 mm larger than the 0.20 mm microdrill in order to prevent tool breakage due to runout effects. The parameters

= 23 m/min –

= 5 μm and

= 50 m/min –

= 5 μm were used for the 0.21 mm and 0.35 mm pilot holes, respectively. Then, a deep drilling strategy with partial retraction of the tool was performed.

Figure 4a,b explain the adopted solution. The tool in step (a) enters the pilot hole using the peck drilling strategy, in which at each peck rises to the rising point

outside the workpiece, until it reaches the safety depth

. The value of

was chosen in order to get the tool into the pilot hole as far as possible, but without colliding with the surface of the bottom of the pilot hole, and thus avoid tool breakage. This quote represents the point at which the entrance into the pilot hole ends to start deep drilling, and its value changes depending on the pilot hole. In fact, 0.20 mm and 0.35 mm holes have pilot holes with different depths, so consequently

also changes. Specifically,

is equal to −0.48 mm and −0.57 mm for the 0.20 mm and 0.35 mm holes respectively. Subsequently, in step (b) the tool rises to

inside the workpiece in order to achieve a better tool stability during pecking, from which the actual deep-drilling begins: at each peck the tool goes to the rising point

until the final depth of the hole

is obtained.

The used cutting conditions are reported in

Table 3. The strategy was carefully chosen to promote heat dissipation, avoid chip adhesion and facilitate chip evacuation. Infact, the cooling lubricant Blasogrind HC5 was used during the drilling operations in order to prevent all the issues generally encountered in deep microdrilling [

25]. The lubricant was supplied during machining with a very slight flow in order not to deflect the tool, as shown in

Figure 4c.

Moreover, in this experimental study the peck values were chosen in order to break the chip frequently, and thus reduce its length for better evacuation. This technique, with the rising of the tool in these holes with high aspect ratios, contributed greatly to the success of the hole and to prevent the drill from breaking.

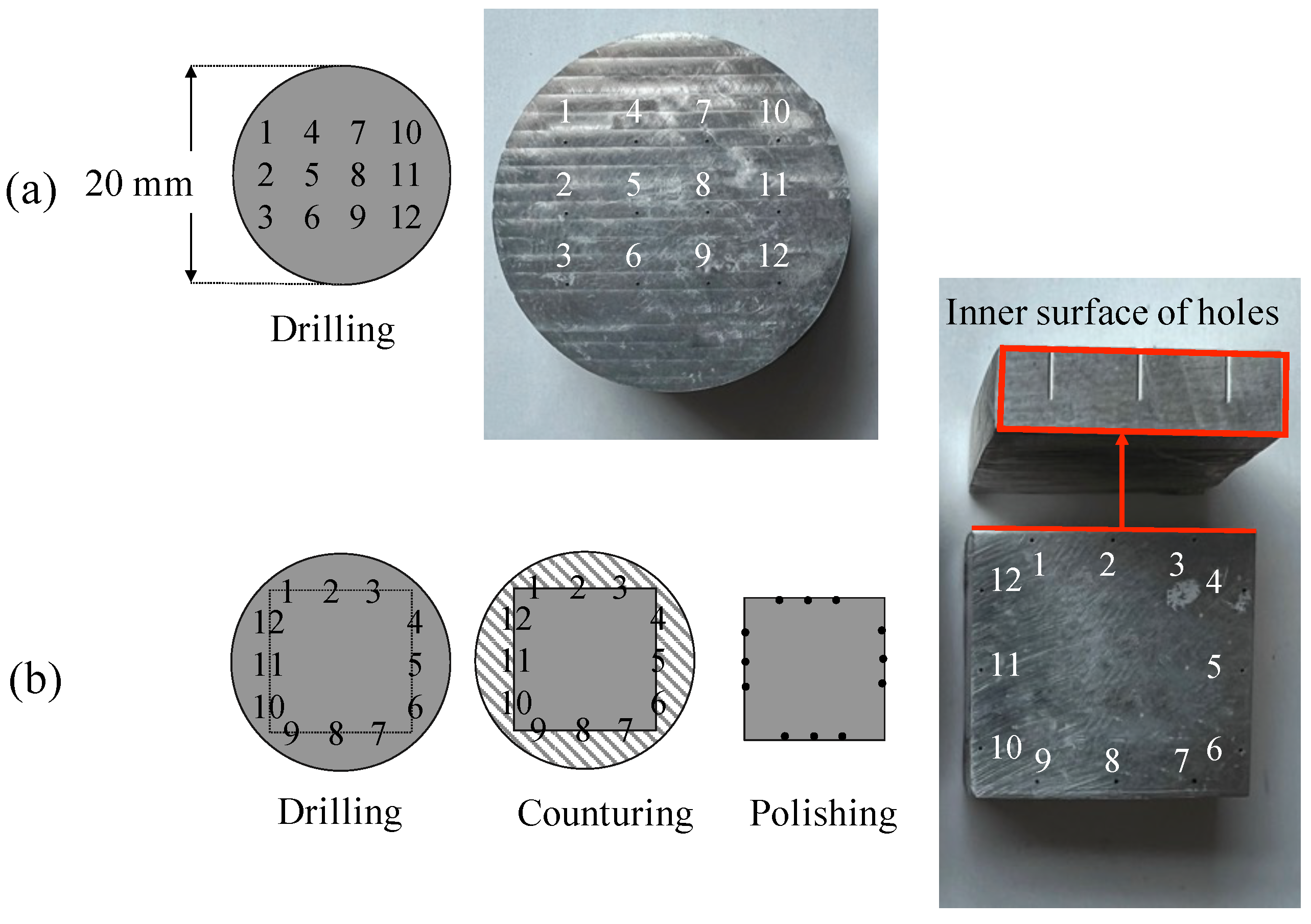

In this experimental campaign, two Mg samples were drilled for both 0.2 mm and 0.35 mm holes: one for measuring diameters and burr height, the other for measuring the internal roughness of the holes (see

Figure 5). A 2

2 factorial design with 3 replicates (12 holes) was selected for the experimentation, thus varying the

and

factors on 2 levels (see

Table 4). The range of values for feeds and cutting speeds were selected in agreement with the manufacturers of the respective tools. For these measurements, an Alicona InfiniteFocus G4 (Bruker Alicona, Austria) was implied.

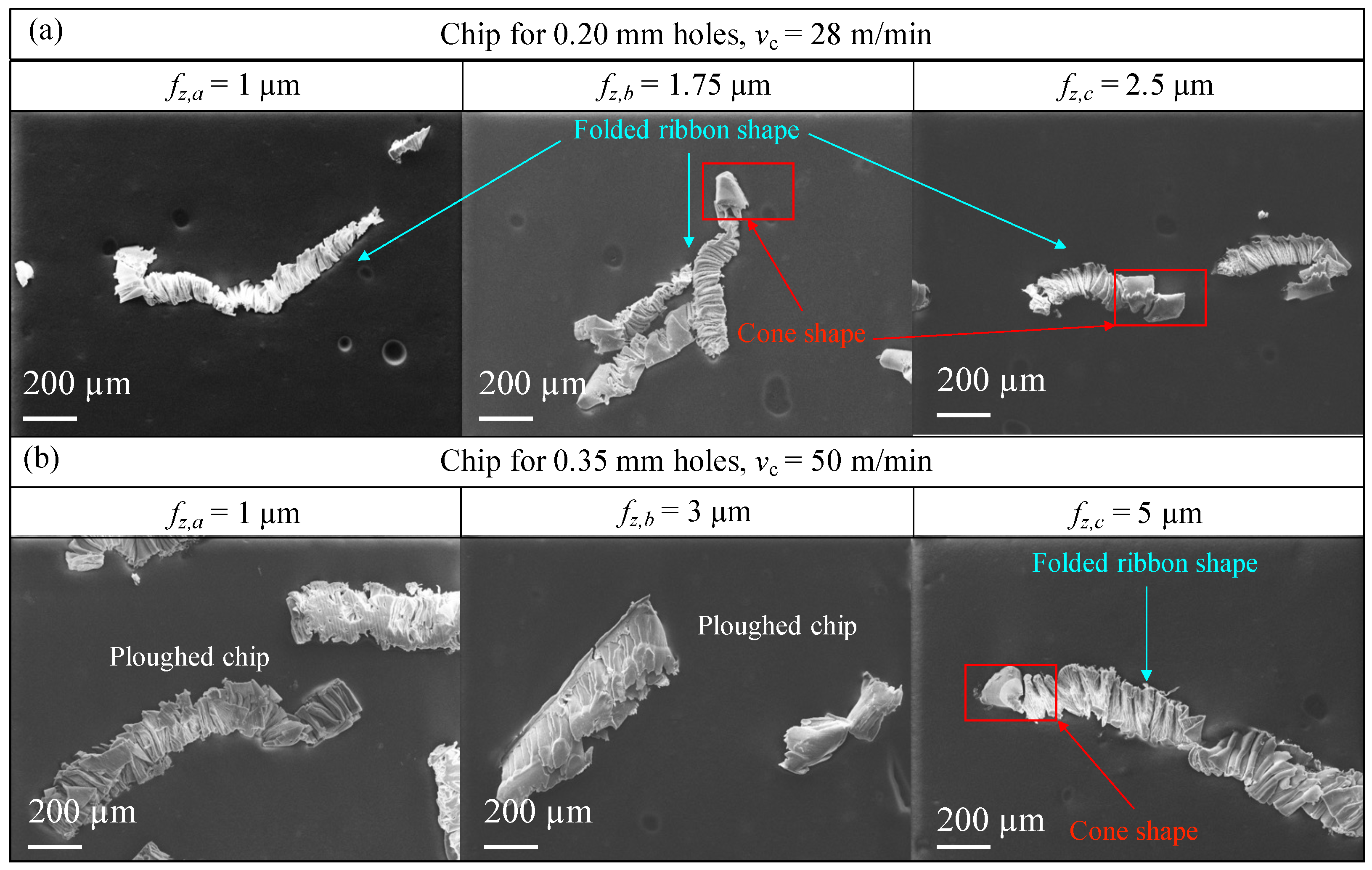

2.2. Chip Analysis

The cutting parameters were chosen according to the range recommended by the respective manufacturers. In addition, a qualitative chip analysis was performed to be sure to work in cutting and not ploughing conditions.

If

is assumed to be between 20–40% of the cutting edge radius for Mg as in the case of aluminum alloys [

26,

27,

28],

assumes a maximum value equal to 1.81 μm and 1.18 μm for the 0.35 mm and 0.20 mm holes respectively, considering the value of

in

Table 2. The chip thickness for the 0.35 mm and 0.20 mm drills

and

can be determined using Equation (

1).

Substituting

and ϵ into the Equation (

1) with the values given in

Table 2 and

Table 4, a value of

greater than

is always obtained:

= 2.17 μm for = 2.5 μm

= 4.33 μm for = 5 μm.

= 4.53 μm for = 5 μm

= 13.59 μm for = 15 μm

As a result, it can be stated that the material removal should take place through shearing and not ploughing of the target material.

In order to verify this condition, tests were performed to observe the chip formation as the feed rate decreased to 1 μm. Then, 3 holes were drilled at different

values, as shown in the

Table 5, for the 0.20 mm and 0.35 mm drill. In this case, the cutting speed was kept fixed, since it should not play a significant role in chip breakage [

29].

The holes were drilled following the strategy described above (

Figure 4 and

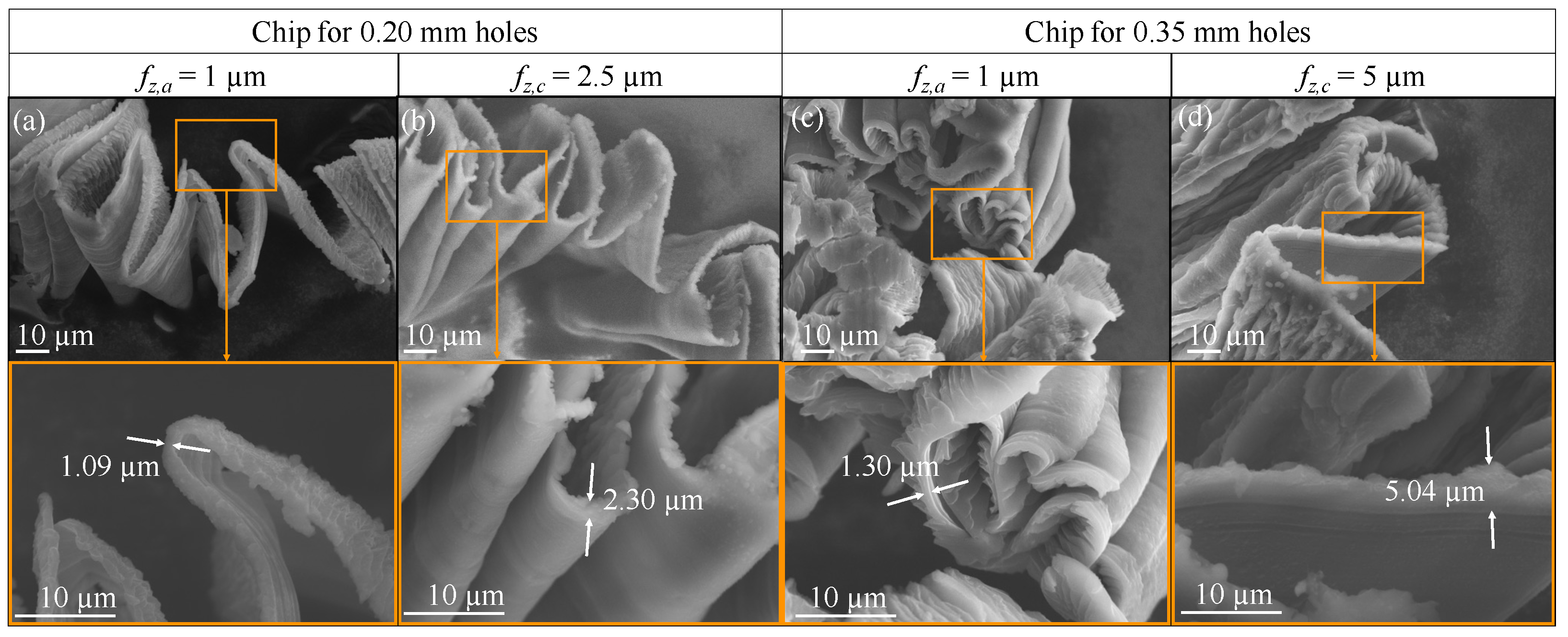

Table 3), changing only the hole depth, which was kept at 2 mm. In addition, no lubricant was used, in order to be able to collect the chips more easily. Then, the collected chip morphology was observed with the scanning electron microscope ZEISS EVO 50 (Carl Zeiss, Oberkochen, Germany). The chip thickness was measured with the software ImageJ for

and

and compared with the calculated theoretical values

using the Equation (

1) (see

Table 6).

2.3. Hole Quality

For the study of hole quality, data on maximum burr height, hole entry diameter and internal roughness were collected for each hole.

2.3.1. Burr Height Measurement

BS EN ISO 8785:1999 [

30] was followed for the burr height measurement. With the Alicona software, using the ’ProfileFormMeasurement’ function, a line was drawn through the centre of the hole, as shown in

Figure 6a. This allowed the profile shape of the hole belonging to the section plane passing through the axis of the hole to be obtained (

Figure 6b. Initially, the main surface was defined. Then, for each side of the profile, the reference surface was also set, parallel to the main surface and passing through the maximum peak considered 100 μm away from the highest point of the burr. In this way the burr height for each side was measured as the distance between the corresponding reference surface and the maximum peak of the burr itself. For each hole, two values of burr height

and

were taken and the greater of the two was considered and named

. The distances between the peaks and the reference surfaces were measured using the ‘Height Step–Maximum distance’ tool. This tool allows the distance measurement mode, with which the areas that define the reference level and the measurement level can be set, thus obtaining the height step (maximum distance).

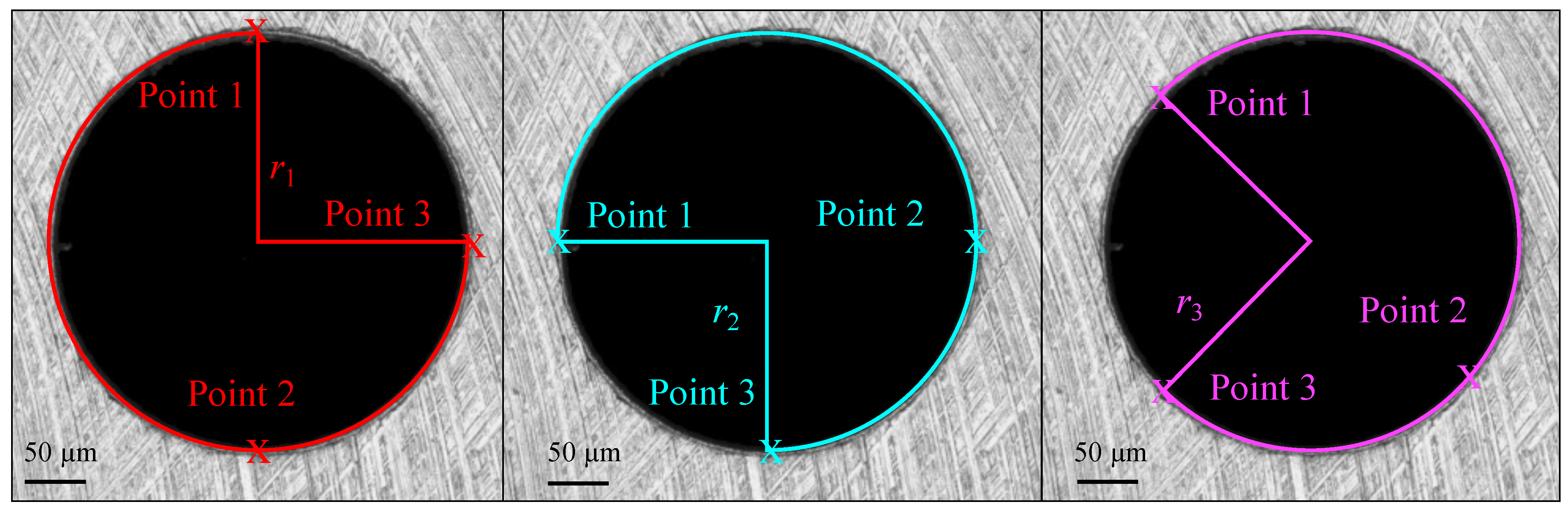

2.3.2. Diameter Measurements

The diameter of the holes was measured by using the Alicona software, with a manual drawing tool in the 2DImageMeasurements. By selecting three points on the circumference of the holes, a circle that exactly intersects the three points was drawn. This function returns the radius of that circle. For each hole, the best-fitting 3-point circle has been drawn three times in order to obtain a mean value for each radius. The points were selected as shown in

Figure 7.

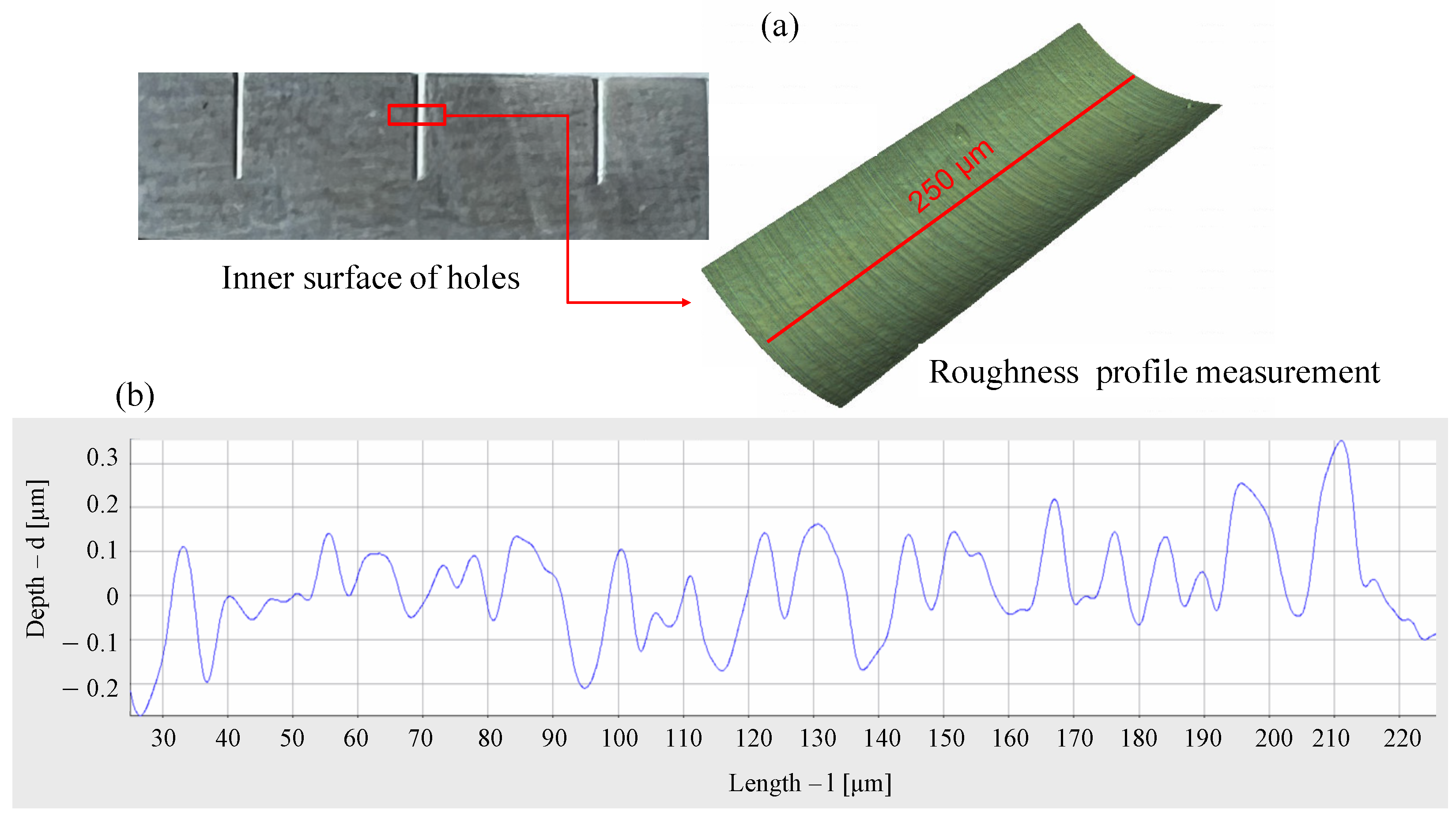

2.3.3. Roughness Measurements

A second microdrilling operation was performed in order to measure the roughness of the inner surface of the holes as a relevant factor to assess the corrosion rate of Mg-based implants that is expected to increase at lower surface quality [

31]. Therefore, as a biodegradable medical metallic material, the surface roughness of magnesium is very important for its service life. In this case, the microholes were drilled in the same run order with the same strategy as the previous tests (see

Table 2,

Table 3,

Table 4 and

Figure 4). The holes were arranged to create a square on the surface as shown in

Figure 5b. To remove excess material and expose the surface of the holes, the cylindrical specimen was milled using a contour cycle. In this way, the mill passed along the sides of the square tangentially to the diameter of the holes so that they were not completely exposed. Then, with a 800 mesh SiC paper, the extra material was removed manually from the side faces of the specimens (see

Figure 8a). Due to the fact that the contouring operation slightly damaged some areas of the inside of the hole, the inner surfaces were not captured in their full length but only in a defect-free central area with a maximum length of 300 μm with a 100× magnification. The average roughness profile

has been obtained by drawing a line along the axis of the hole with the Alicona software as shown in

Figure 8a, which is a detail taken from

Figure 5b. Therefore, the roughness profile lengths were kept equal to 250 μm for the 0.20 mm and 0.35 mm holes. The cut off wavelength was kept equal to 800 μm. An example of the obtained roughness profile is shown in

Figure 8b.

4. Discussion

Micromechanical cutting methods are commonly used to obtain the final shape of the magnesium-based medical devices, but very few studies can be found in literature describing their objective and repeatable application [

14,

15]. Furthermore, deep-hole microdrilling is very challenging for pure magnesium, especially for high aspect ratios.

The work reported here was focused on testing different cutting conditions, with the purpose to understand the suitability of microdrilling for the future manufacture of a Mg-based intraocular drug delivery device for AMD treatment, or other Mg-based biomedical devices. This preliminary study was performed with 0.20 mm and 0.35 mm microdrills, using a full factorial design in which cutting speed and feed were varied over two levels. The use of pecks in this microdrilling process proved to be very advantageous for obtaining holes with a high /.

The chip analysis confirmed how the chip removal process took place regularly producing a deformed chip thickness higher than the undeformed one, as usual, even if these cutting conditions should have been under the minimum chip thickness and so in a region where the chip should not have been properly formed. The reported results show how the chips are ploughed but it was still possible to form chips, suggesting that the minimum chip thickness could be lower than predicted. Moreover, for a feed per tooth equal to 1 μm, the drilling process is still capable to form a chip, even if it is not optimal. In fact, when is as low as 1 μm, the chip not only packs into folded structures, but in some cases appears ploughed. This phenomenon indicates that microdrilling must be performed for higher feed values, so as not to cause excessive tool wear or even tool breakage due to chip clogging. In any case, the simple fact that the chip is formed at 1 μm of feed per tooth seems to point out as the minimum chip thickness for pure magnesium is lower than expected, which means lower than the aluminium one. On the other hand, the measurement of chip thickness, for feeds of 2.5 μm and 5 μm for the 0.20 mm and 0.35 mm holes respectively, confirmed the correct choice of cutting parameters for the drilling, as the measured is slightly higher than the uncut chip thickness.

Furthermore, in a proper microdrilling process, the chip should break up into short segments and not remain on the tool body [

29]. This optimal condition is only achieved with higher feeds. As it is not possibile to achieve the feeds able to naturally break the chip in this study in order not to produce excessive forces, it was verified how the chip forms in the studied parameters range and then peck drilling strategy was selected for the chip breaking purpose.

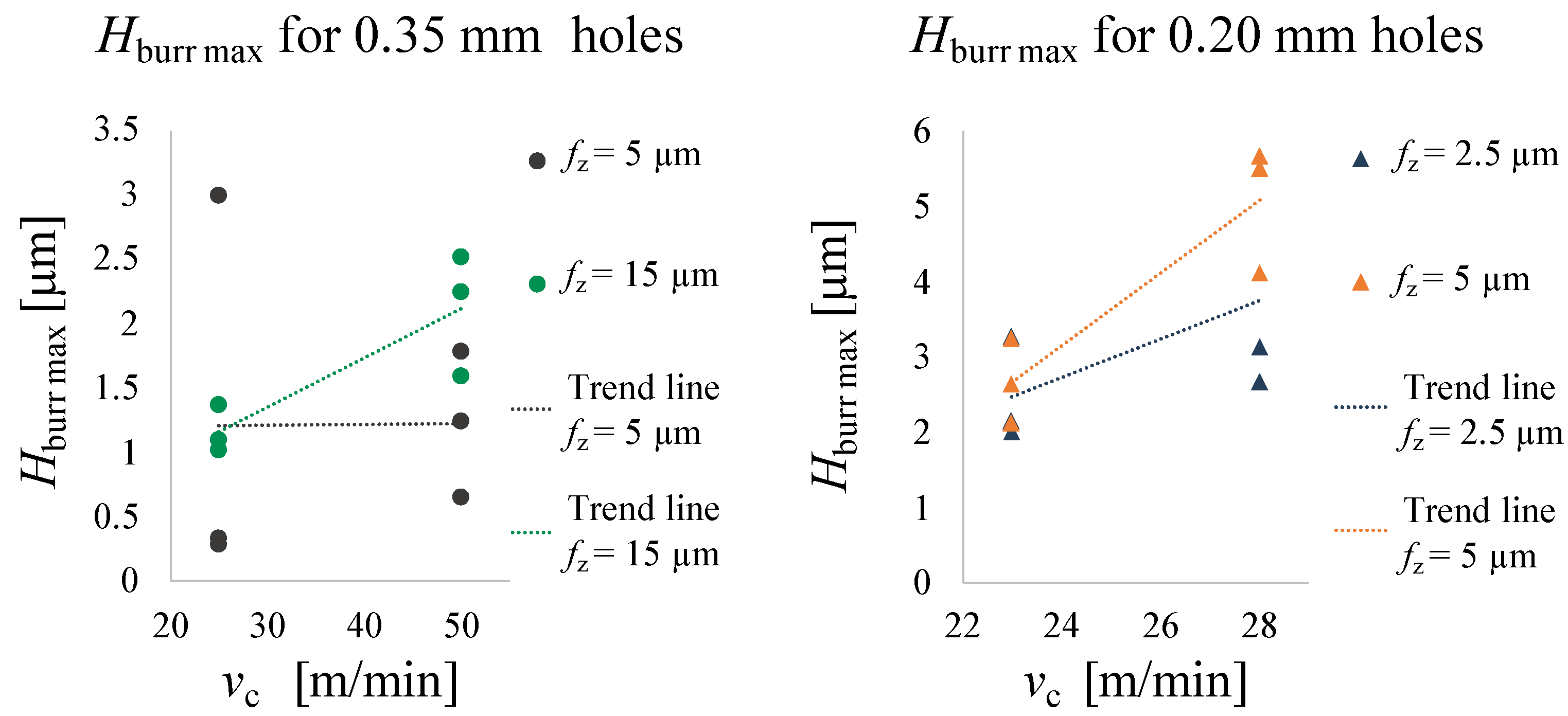

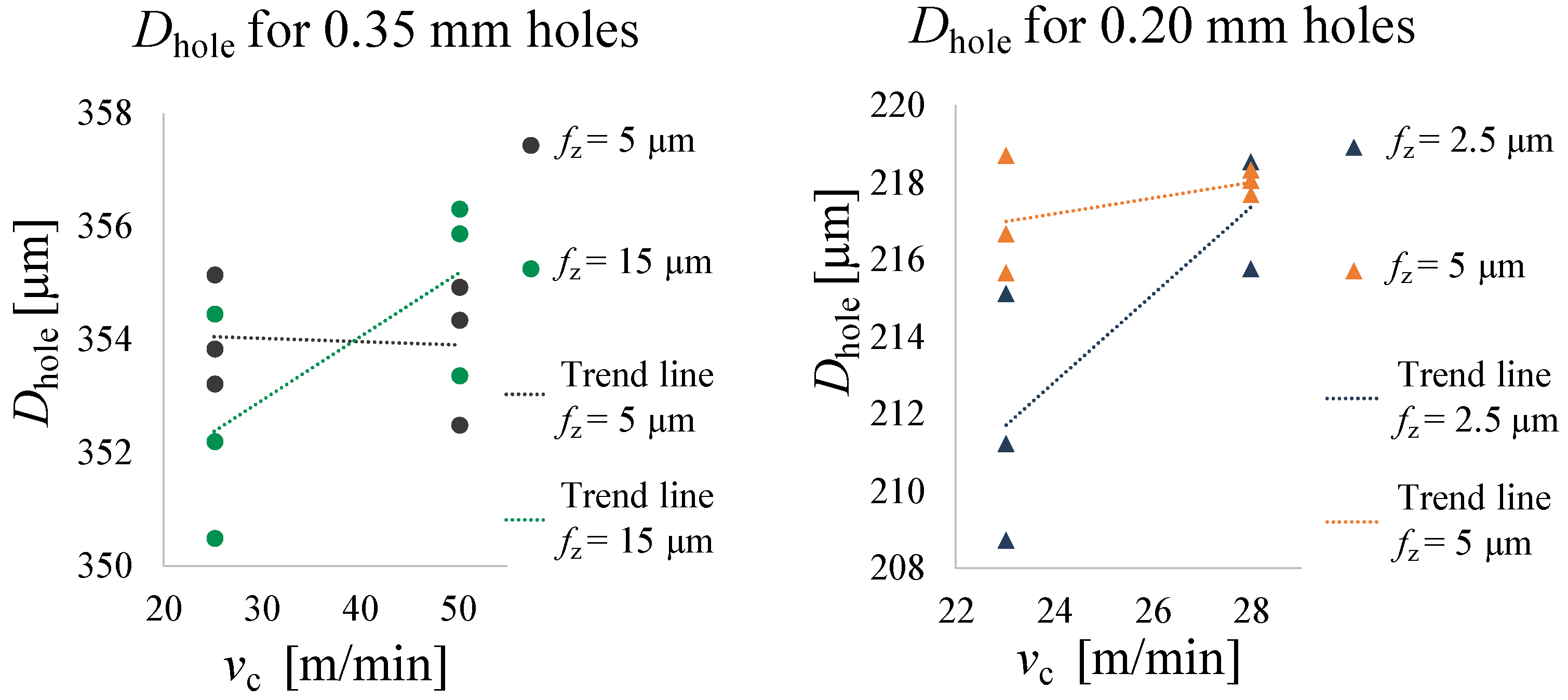

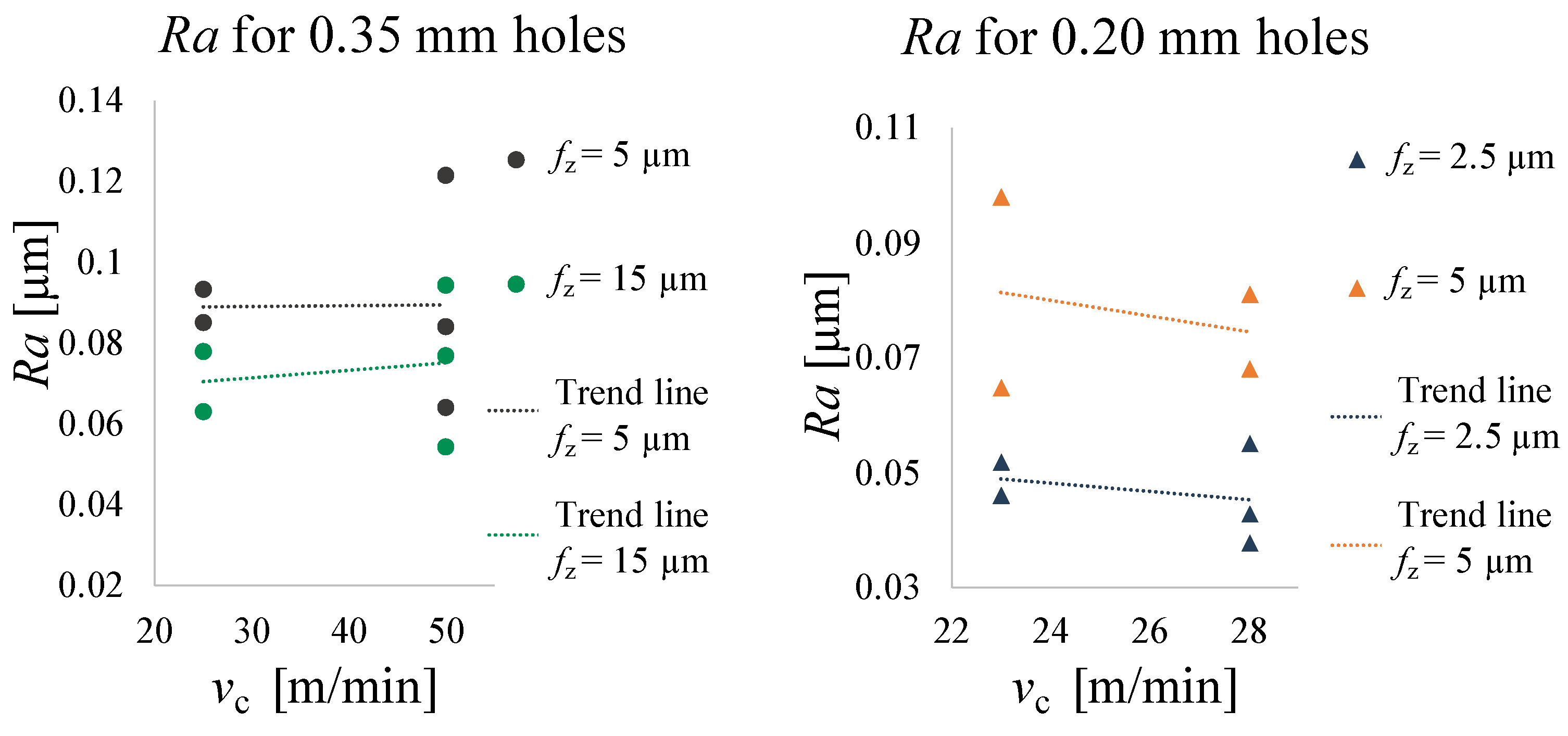

The results of microdrilling experiments showed that the maximum burr height of magnesium is influenced by the cutting speed for the 0.20 mm holes. In fact, increases with higher cutting speeds, probably due to the thermal effect that plasticizes the material. Being an unavoidable process during drilling, the formation of burrs must be minimised: the removal of burrs involves similar issues respect to conventional drilling, but their small size makes them difficult to observe, measure and remove. In light of this, the results have proved that low cutting speed values result in lower burr height and thus better micro-hole quality for magnesium. In addition, this working parameter also affects the entrance diameter. This can probably be attributed to the runout of the tool, which may increase due to the high speeds, thus increasing the size of the flying diameter of the tool entering the hole. For this reason it is necessary to work at low cutting speeds during prototype development to remain within tolerances.

Furthermore, the outcomes related to the 0.20 mm holes showed that the cutting parameter

determines the quality of the hole in terms of entry diameter and internal roughness. These results are in agreement with the literature. As reported in the state of the art, the feed is the most influential parameter in mechanical cutting methods. As the feed increases, the cutting forces increase [

15,

32]. In the present work, hole entrance diameters are larger than the nominal tool diameters, and their values increase as

increases. This phenomenon can therefore lead to greater deformation of the tool for the buckling effect, which in turn causes greater tool diameters. The same happens for

of the inner surface of the holes, which, as is common knowledge, assumes higher values with increasing

for purely geometric causes.

In addition, a study about the influence of the material microstructure on the machining characteristics of copper in microturning showed that when the feed is equal to the grain size, the roughness of the machined surface is lower [

33]. The results obtained in the present study about microdrilling, in fact, show that the roughness

for 0.20 mm holes is lower for a

= 2.5 μm (closer to grain size

= 3 μm than for 5 μm), as the cutting occurs largely at the grain boundaries.

Nevertheless, the 0.35 mm drilling tests did not show any relevant results on the effect of process parameters. This could be attributed to the fact that a wider range of and should be used to observe significant differences.