Optimization of Microchannels and Application of Basic Activation Functions of Deep Neural Network for Accuracy Analysis of Microfluidic Parameter Data

Abstract

:1. Introduction

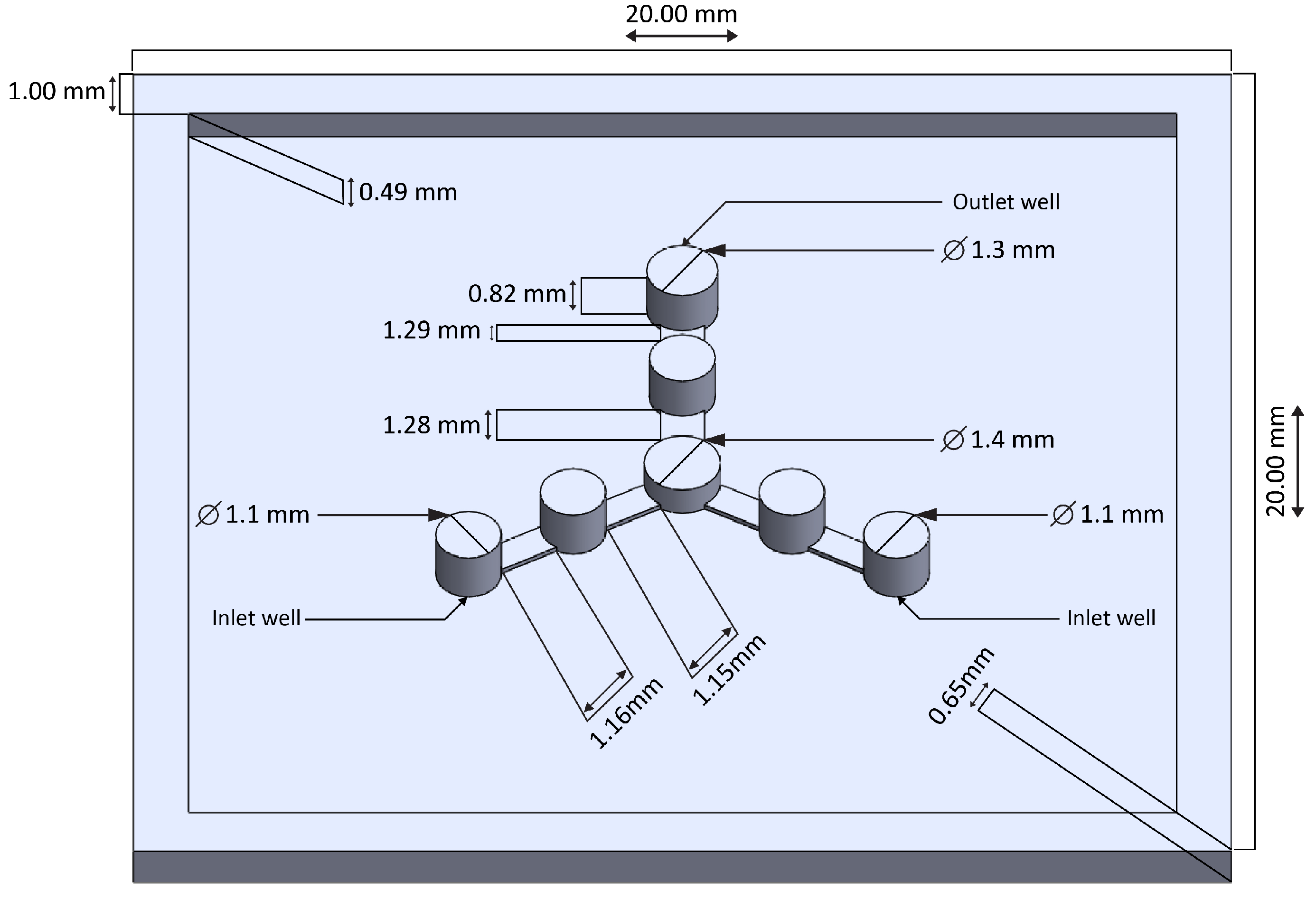

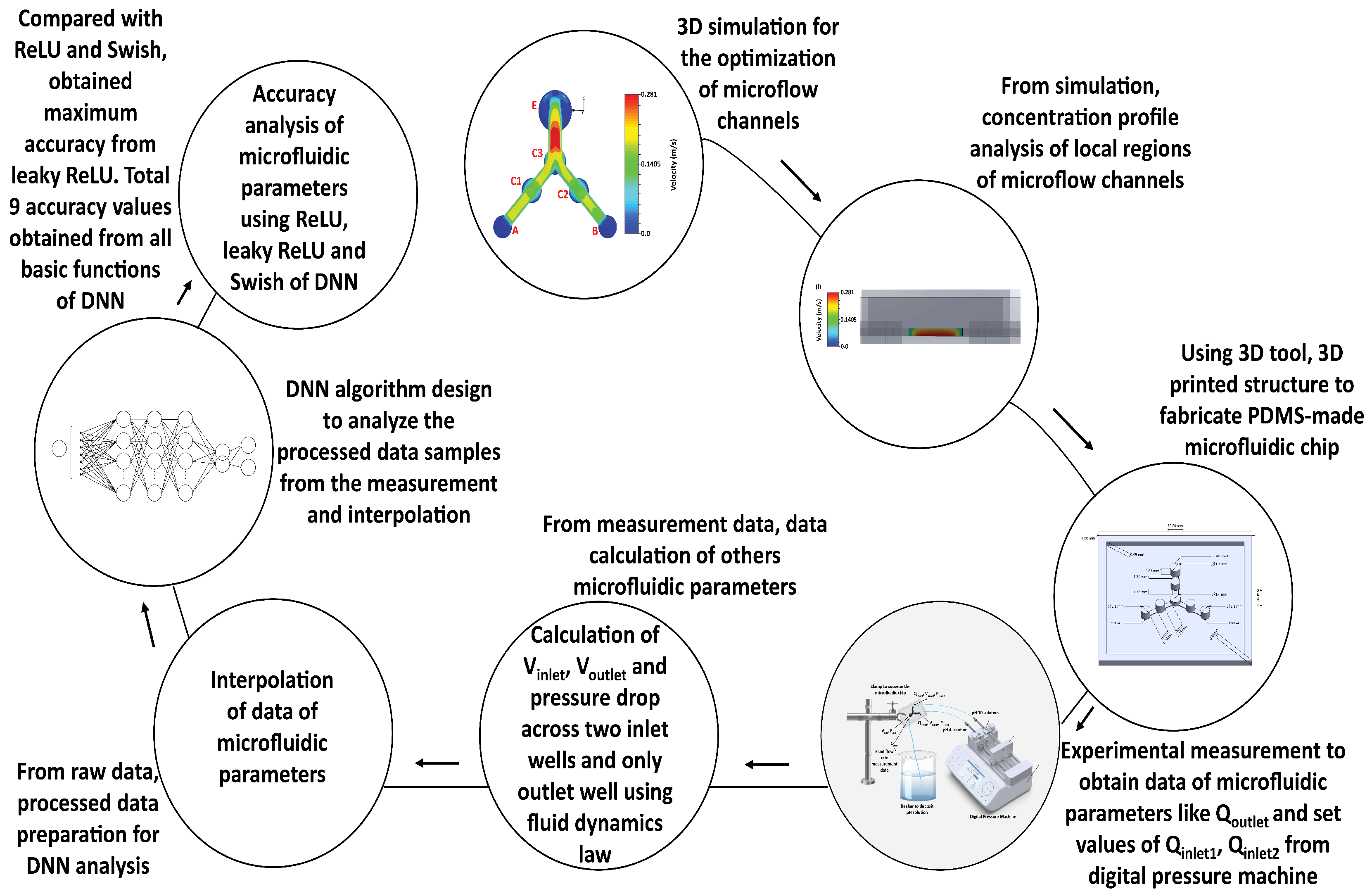

2. Materials and Methods

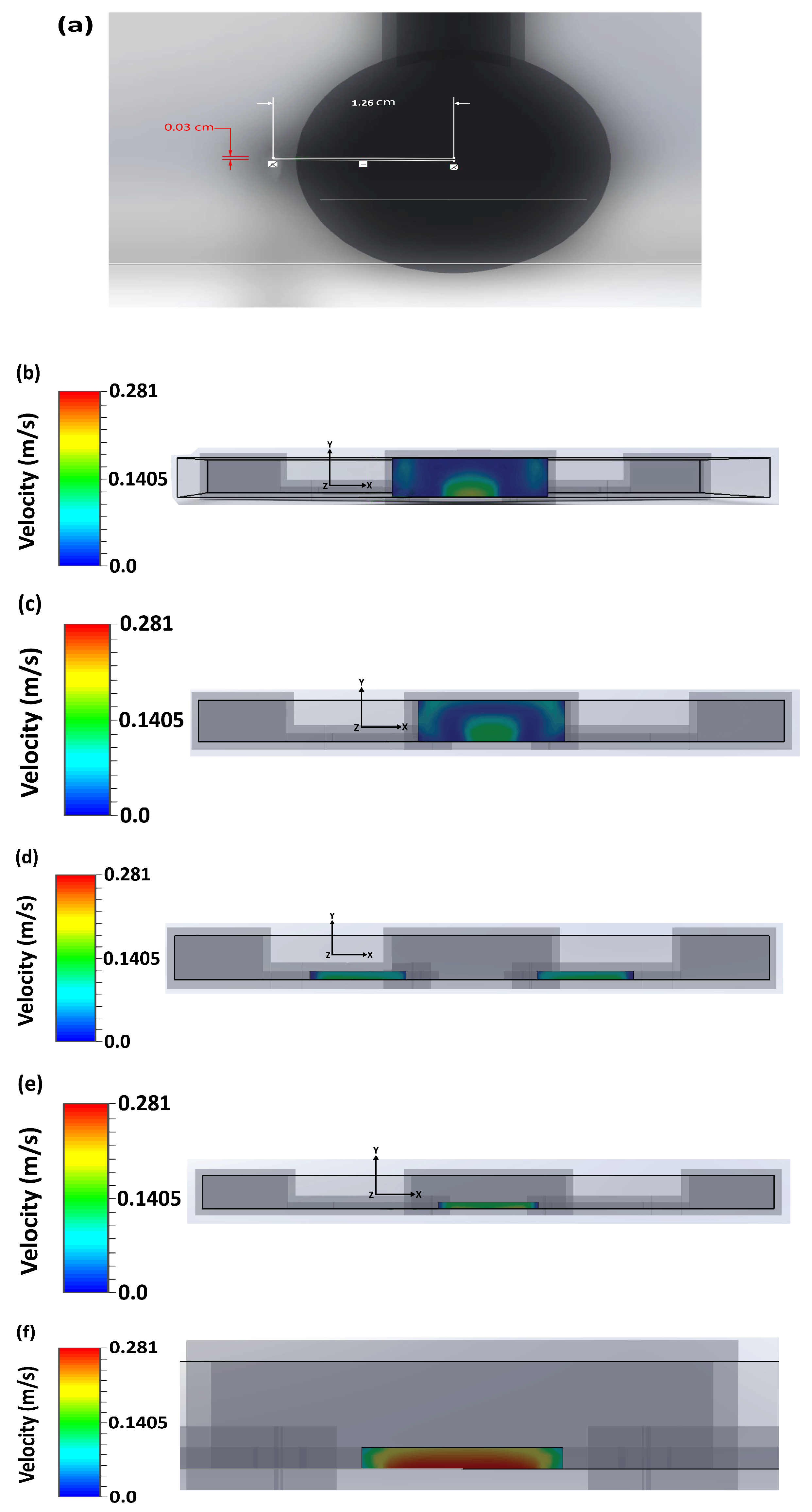

2.1. Simulation for Microfluidic Channel Optimization

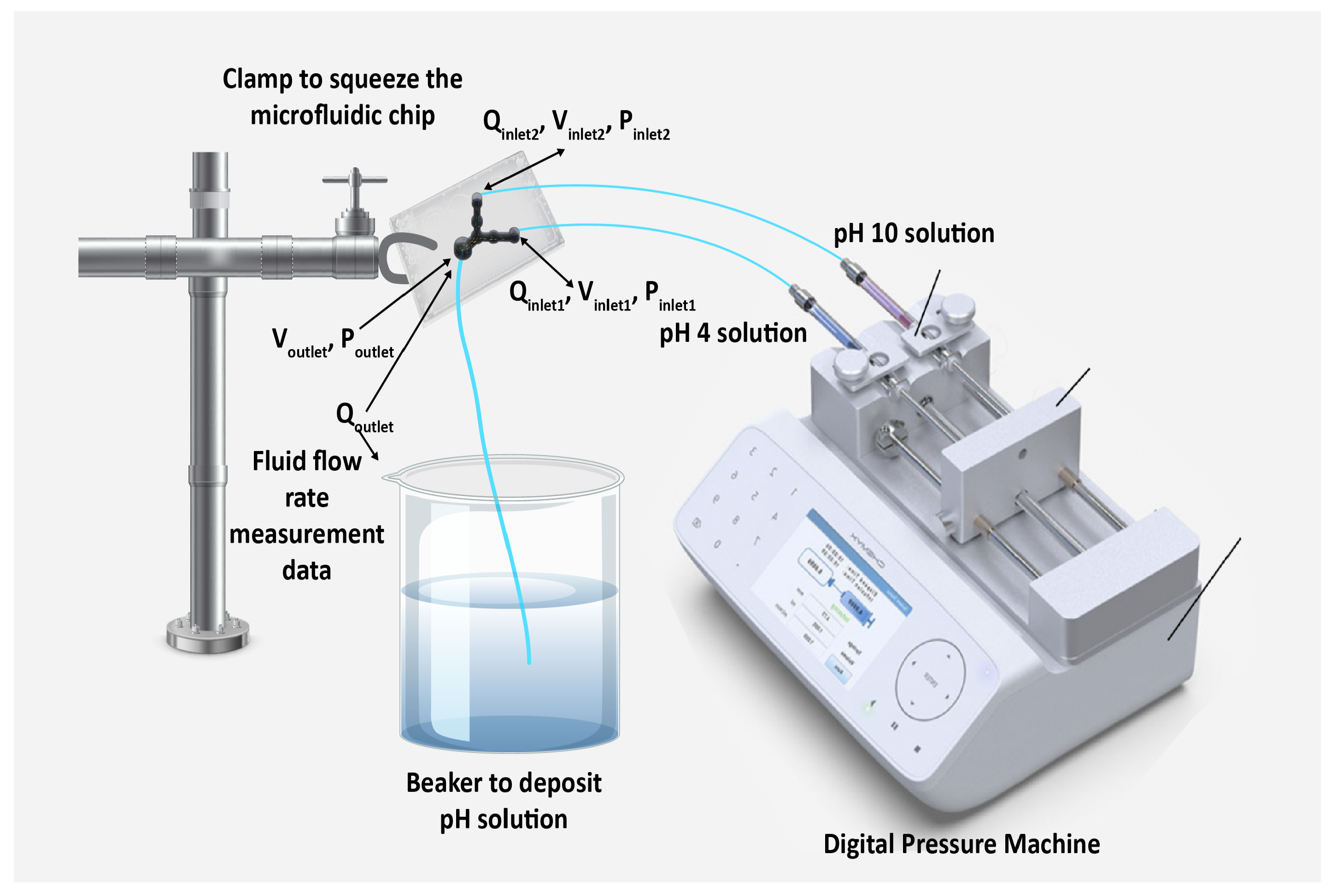

2.2. Fabrication of Microfluidic Chip and Experiments for Data Measurements

2.3. Dense Layers of ReLU, Swish, and Leaky ReLU of DL Model

2.3.1. Prediction of Possible Inputs

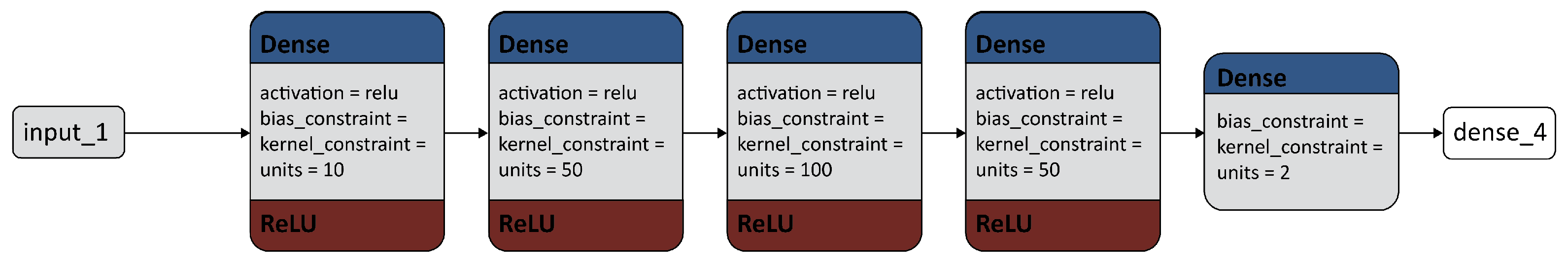

2.3.2. Establishment of Deep Neural Network Model

- The first layer, called the input layer, has an input shape to set an input size of 5 that matches the training data.

- Next, weights of the output shape of dense layers of 10, 50, 100, and 50 of the ReLU activation function are updated (Figure 3).

- In another DL model, weights of the output shape of dense layers of 10, 25, 50, 100, 100, 50, 25, and 10 of the ReLU, Swish, and Leaky ReLU activation functions are updated (Figure 4).

- Finally, the output layer has a weight update of two units of the ReLU dense layers.

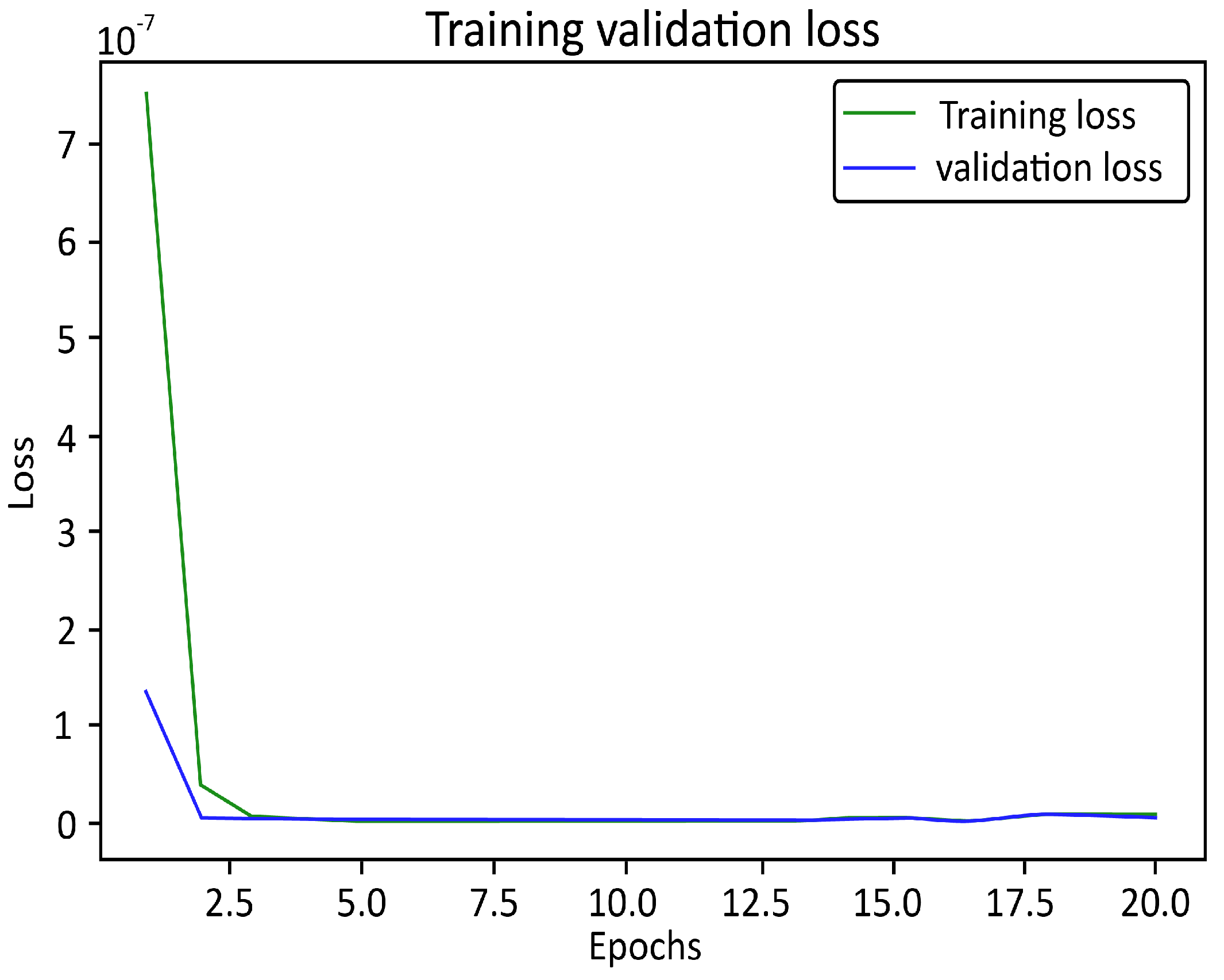

2.3.3. Training of Model

3. Results

3.1. Concentration Profiles of Different Microflow Regions Revealed from Simulations

3.2. Dense Layers of ReLU, Swish, and Leaky ReLU Functions to Test Training Data Accuracy with Applied k-fold Cross-Validation

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ReLU | Rectified Linear Unit |

| Leaky ReLU | Leaky Rectified Linear Unit |

| DL | Deep Learning |

| ML | Machine Learning |

| DNN | Deep Neural Network |

| PDMS | Polydimethylsiloxane |

References

- Galan, E.A.; Zhao, H.; Wang, X.; Dai, Q.; Huck, W.T.S.; Ma, S. Intelligent Microfluidics: The Convergence of Machine Learning and Microfluidics in Materials Science and Biomedicine. Matter 2020, 3, 1893–1922. [Google Scholar] [CrossRef]

- Squires, T.M.; Quake, S.R. Microfluidics: Fluid physics at the nanoliter scale. Rev. Mod. Phys. 2005, 77, 977–1026. [Google Scholar] [CrossRef] [Green Version]

- Hashemzadeh, H.; Shojaeilangari, S.; Allahverdi, A.; Rothbauer, M.; Ertl, P.; Manesh, H.N. D combined microfluidic deep learning approach for lung cancer cell high throughput screening toward automatic cancer screening applications. Sci Rep. 2021, 11, 9804. [Google Scholar] [CrossRef] [PubMed]

- Riordon, J.; Sovilj, D.; Sanner, S.; Sinton, D.; Young, E.W. Deep learning with microfluidics for biotechnology. Trends Biotechnol. 2019, 37, 310. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Chen, J.; Bai, H.; Wang, H.; Hao, S.; Ding, Y.; Peng, B.; Zhang, J.; Li, L.; Huang, W. An Overview of Organs-on-Chips Based on Deep Learning. Research 2022, 2022, 9869518. [Google Scholar] [CrossRef] [PubMed]

- Gao, H.; Yan, C.; Wu, W.; Li, J. Application of microfluidic chip technology in food safety sensing. Sensors 2020, 20, 1792. [Google Scholar] [CrossRef] [Green Version]

- Tiancheng, X.; Jiang, R.; Fu, Y.Q.; Jin, N. Automated blood cell detection and counting via deep learning for microfluidic point-of-care medical devices. In IOP Conference Series: Materials Science and Engineering, Beijing, China, 1–3 August 2019, AIAAT 2019; IOP Publishing: Bristol, UK, 2019; Volume 646, p. 012048. [Google Scholar]

- Dungchai, W.; Chailapakul, O.; Henry, C.S. Electrochemical detection for paper-based microfluidics. Anal. Chem. 2009, 81, 5821–5826. [Google Scholar] [CrossRef]

- Funke, M.; Buchenauer, A.; Schnakenberg, U.; Mokwa, W.; Diederichs, S.; Mertens, A.; Büchs, J. Microfluidic biolector—Microfluidic bioprocess control in microtiter plates. Biotechnol. Bioeng. 2010, 107, 497. [Google Scholar] [CrossRef]

- Ahmed, F.; Yoshida, Y.; Wang, J.; Sakai, K.; Kiwa, T. Design and validation of microfluidic parameters of a microfluidic chip using fluid dynamics. AIP Adv. 2021, 11, 075224. [Google Scholar] [CrossRef]

- Dincau, B.; Dressaire, E.; Sauret, A. Pulsatile Flow in Microfluidic Systems. Small 2020, 16, 1904032. [Google Scholar] [CrossRef]

- Ahmed, F.; Mahana, A.; Taniizumi, K.; Wang, J.; Sakai, K.; Kiwa, T. Terahertz imaging technique for monitoring the flow of buffer solutions at different pH values through a microfluidic chip. Jpn. J. Appl. Phys. 2021, 60, 027003. [Google Scholar] [CrossRef]

- Witkowski, D.; Kubicki, W.; Dziuban, J.A.; Jašíková, D.; Karczemska, A. Micro-particle image velocimetry for imaging flows in passive microfluidic mixers. Metrol. Meas. Systm. 2018, 25, 441–450. [Google Scholar]

- Abe, T.; Oh-hara, S.; Ukita, Y. Adoption of reinforcement learning for the intelligent control of a microfluidic peristaltic pump. Biomicrofluidics 2021, 15, 034101. [Google Scholar] [CrossRef] [PubMed]

- Honrado, C.; McGrath, J.S.; Reale, R.; Bisegna, P.; Swami, N.S.; Caselli, F. DA neural network approach for real-time particle/cell characterization in microfluidic impedance cytometry. Anal. Bioanal. Chem. 2020, 412, 3835–3845. [Google Scholar] [CrossRef]

- Lee, X.Y.; Balu, A.; Stoecklein, D.; Ganapathysubramanian, B.; Sarkar, S. A case study of deep reinforcement learning for engineering design: Application to microfluidic devices for flow sculpting. J. Mech. Des. 2019, 141, 111401-10. [Google Scholar] [CrossRef]

- Brunton, S.L.; Noack, B.R.; Koumoutsakos, P. Machine Learning for Fluid Mechanics. Annu. Rev. Fluid Mech. 2020, 52, 477–508. [Google Scholar] [CrossRef] [Green Version]

- Lashkaripour, A.; Rodriguez, C.; Mehdipour, N.; Mardian, R.; McIntyre, D.; Ortiz, L.; Campbell, J.; Densmore, D. Machine learning enables design automation of microfluidic flow-focusing droplet generation. Nat. Commun. 2021, 12, 25. [Google Scholar] [CrossRef]

- Wang, J.; Rodgers, V.G.J.; Brisk, P.; Grover, W.H. Instantaneous simulation of fluids and particles in complex microfluidic devices. PLoS ONE 2017, 12, e0189429. [Google Scholar] [CrossRef] [Green Version]

- Zheng, J.; Cole, T.; Zhang, Y.; Kim, J.; Tang, S.-Y. Exploiting machine learning for bestowing intelligence to microfluidics. Biosens. Bioelectron. 2021, 194, 113666. [Google Scholar] [CrossRef]

- Nair, V.; Hinton, G.E. Rectified linear units improve restricted boltzmann machines. In Proceedings of the 27th International Conference on Machine Learning (ICML-10), Haifa, Israel, 21–24 June 2010; pp. 807–814. [Google Scholar]

- Javid, A.M.; Das, S.; Skoglund, M.; Chatterjee, S. A ReLU Dense Layer to Improve the Performance of Neural Networks. In Proceedings of the ICASSP 2021—2021 IEEE International Conference on Acoustics, Speech and Signal Processing (ICASSP), Toronto, ON, Canada, 6–11 June 2021; pp. 2810–2814. [Google Scholar]

- Jinsakul, N.; Tsai, C.F.; Tsai, C.E.; Wu, P. Enhancement of deep learning in image classification performance using xception with the swish activation function for colorectal polyp preliminary screening. Mathematics 2019, 7, 1170. [Google Scholar] [CrossRef] [Green Version]

- Mercioni, M.A.; Holban, S. P-swish: Activation function with learnable parameters based on swish activation function in deep learning. In Proceedings of the 2020 International Symposium on Electronics and Telecommunications (ISETC), Timisoara, Romania, 5–6 November 2020; IEEE: Piscataway, NJ, USA, 2020. [Google Scholar]

- Mastromichalakis, S. ALReLU: A different approach on Leaky ReLU activation function to improve Neural Networks Performance. arXiv 2020, preprint. arXiv:2012.07564. [Google Scholar]

- Xu, J.; Li, Z.; Du, B.; Zhang, M.; Liu, J. Reluplex made more practical: Leaky ReLU. In Proceedings of the 2020 IEEE Symposium on Computers and Communications (ISCC), Rennes, France, 7–10 July 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 1–7. [Google Scholar]

- Wong, T.T.; Yeh, P.Y. Reliable accuracy estimates from k-fold cross validation. IEEE Trans. Knowl. Data Eng. 2019, 32, 1586–1594. [Google Scholar] [CrossRef]

- Jung, Y. Multiple predicting K-fold cross-validation for model selection. J. Nonparamet. Stat. 2018, 30.1, 197–215. [Google Scholar] [CrossRef]

- Anguita, D.; Ghelardoni, L.; Ghio, A.; Oneto, L.; Ridella, S. The ‘K’in K-fold cross validation. In Proceedings of the 20th European Symposium on Artificial Neural Networks, Computational Intelligence and Machine Learning (ESANN), Bruges, Belgium, 25–27 April 2012; pp. 441–446. [Google Scholar]

- Srivastava, N.; Hinton, G.; Krizhevsky, A.; Sutskever, I.; Salakhutdinov, R. Dropout: A simple way to prevent neural networks from overfitting. J. Mach. Learn. Res. 2014, 15, 1929–1958. [Google Scholar]

- Shaeke, S.; Liu, X. Overfitting mechanism and avoidance in deep neural networks. arXiv 2019, preprint. arXiv:1901.06566. [Google Scholar]

- Brownlee, J. Fix Overfitting with Regularization. In Better Deep Learning: Train Faster, Reduce Overfitting, and Make Better Predictions; Cheremskoy, A., Sanderson, M., Koshy, A., Eds.; Machine Learning Mastery: Melbourne, VIC, Australia, 2018; pp. 245–251. [Google Scholar]

- Google Colab. Available online: https://colab.research.google.com/drive/1lhBD_ojJ_E6S9ix0f9xTAkKdXUZKi3aD (accessed on 8 August 2022).

- Ramasubramanian, K.; Singh, A. Deep Learning Using Keras and Tensorflow; Apress: Berkeley, CA, USA, 2019; pp. 667–688. [Google Scholar]

- Joseph, F.J.J.; Nonsiri, S.; Monsakul, A. Keras and TensorFlow: A Hands-On Experience. In Advanced Deep Learning for Engineers and Scientists; Springer: Cham, Switzerland, 2021; pp. 85–111. [Google Scholar]

- Bergstra, J.; Yamins, D.; David, D. Cox: A Python Library for Optimizing the Hyperparameters of Machine Learning Algorithms. In Proceedings of the 12th Python in Science Conference, SCIPY, Austin, TX, USA, 24–29 June 2013; Volume 13, p. 20. [Google Scholar]

- Shivam, S.; Singh, T.N.; Singh, V.K.; Verma, A.K. Epoch determination for neural network by self-organized map (SOM). Comput. Geosci. 2010, 1, 199–206. [Google Scholar]

- Siddique, M.A.B.; Khan, M.M.; Arif, B.; Ashrafi, Z. Study and Observation of the Variations of Accuracies for Handwritten Digits Recognition with Various Hidden Layers and Epochs using Neural Network Algorithm. In Proceedings of the 2018 4th International Conference on Electrical Engineering and Information and Communication Technology (ICEEICT), IEEE, Dhaka, Bangladesh, 13–15 September 2018; IEEE: Piscataway, NJ, USA; pp. 118–123. [Google Scholar]

- Tomoumi, T. Dynamic batch size tuning based on stopping criterion for neural network training. Neurocomputing 2021, 429, 1–11. [Google Scholar]

- Smith, S.L.; Kindermans, P.-J.; Ying, C.; Le Quoc, V. Don’t Decay the Learning Rate, Increase the Batch Size. In 2018 Sixth International Conference on Learning Representations. arXiv 2018, preprint. arXiv:1711.00489. [Google Scholar]

| Defined Threshold Value | Basic Activation Functions | Average Accuracy (Model 1) | Average Accuracy (Model 2) | Average Accuracy (Model 3) |

|---|---|---|---|---|

| ReLU | 91.68% | 88.74% | 62.06% | |

| Leaky ReLU | 94.56% | 99.44% | 99.81% | |

| Swish | 86.80% | 94.62% | 51.25% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahmed, F.; Shimizu, M.; Wang, J.; Sakai, K.; Kiwa, T. Optimization of Microchannels and Application of Basic Activation Functions of Deep Neural Network for Accuracy Analysis of Microfluidic Parameter Data. Micromachines 2022, 13, 1352. https://doi.org/10.3390/mi13081352

Ahmed F, Shimizu M, Wang J, Sakai K, Kiwa T. Optimization of Microchannels and Application of Basic Activation Functions of Deep Neural Network for Accuracy Analysis of Microfluidic Parameter Data. Micromachines. 2022; 13(8):1352. https://doi.org/10.3390/mi13081352

Chicago/Turabian StyleAhmed, Feroz, Masashi Shimizu, Jin Wang, Kenji Sakai, and Toshihiko Kiwa. 2022. "Optimization of Microchannels and Application of Basic Activation Functions of Deep Neural Network for Accuracy Analysis of Microfluidic Parameter Data" Micromachines 13, no. 8: 1352. https://doi.org/10.3390/mi13081352

APA StyleAhmed, F., Shimizu, M., Wang, J., Sakai, K., & Kiwa, T. (2022). Optimization of Microchannels and Application of Basic Activation Functions of Deep Neural Network for Accuracy Analysis of Microfluidic Parameter Data. Micromachines, 13(8), 1352. https://doi.org/10.3390/mi13081352