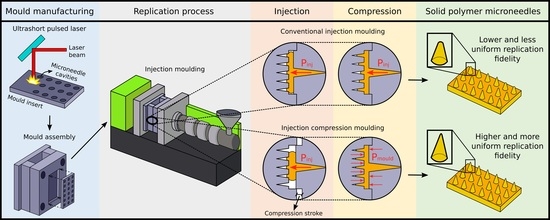

Comparing the Replication Fidelity of Solid Microneedles Using Injection Compression Moulding and Conventional Injection Moulding

Abstract

1. Introduction

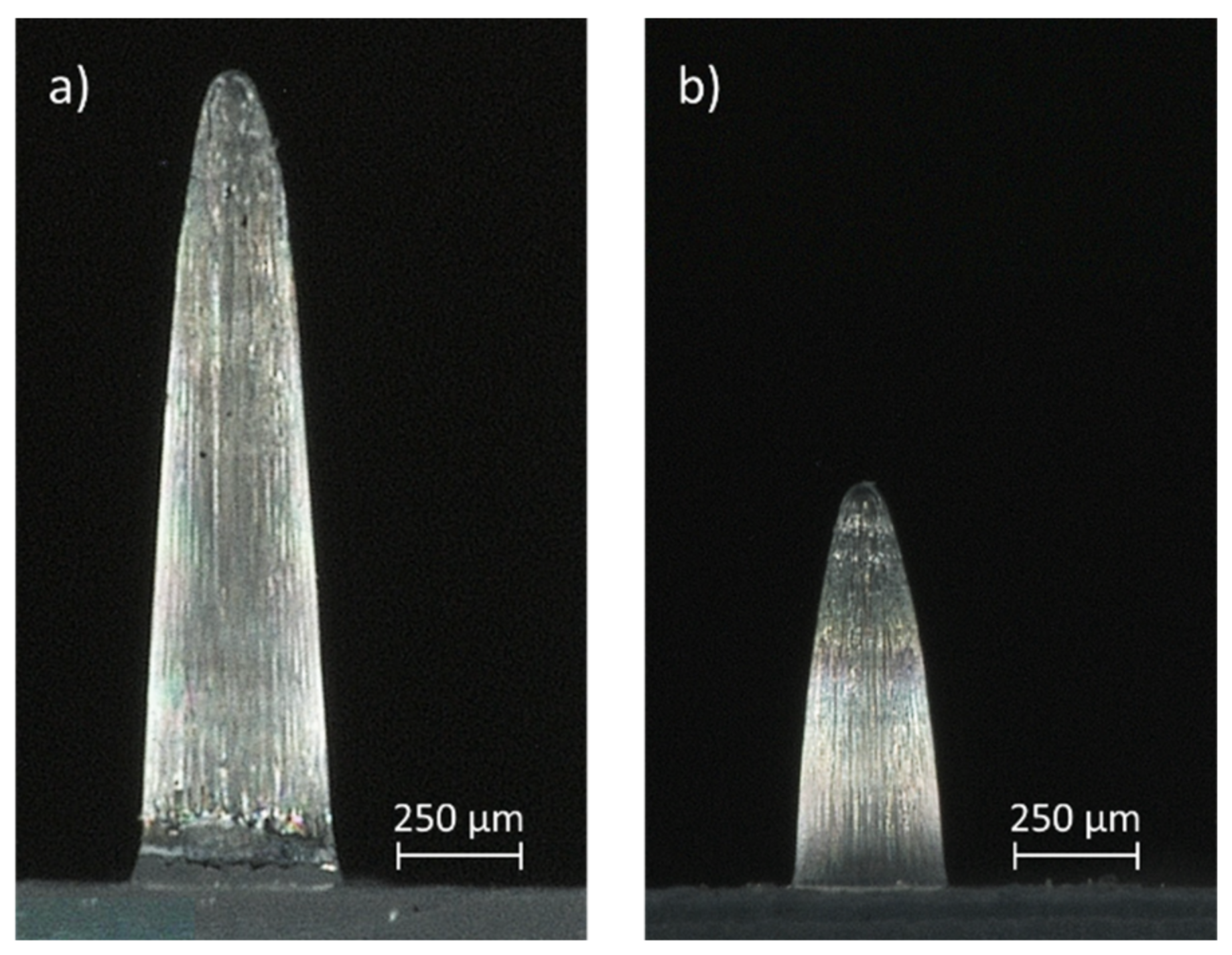

2. Materials and Methods

2.1. Thermoplastic and Mould Material

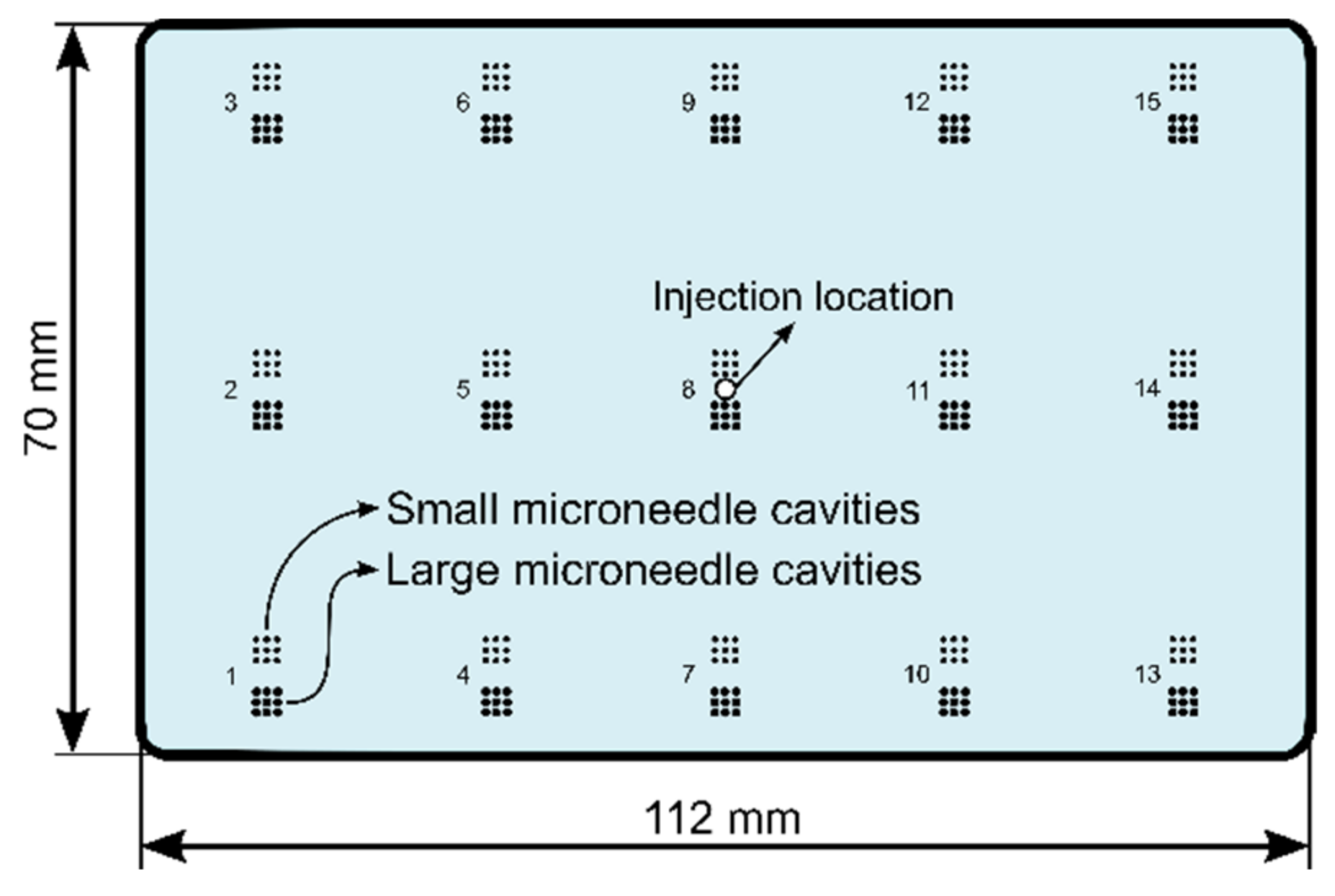

2.2. Mould Product Cavity and Laser Machining Experiments

2.3. Experimental Injection Moulding Set-Up

2.4. Two-Level Full Factorial Design

2.5. Topography Characterisation

2.6. Injection Moulding Simulations

3. Results and Discussion

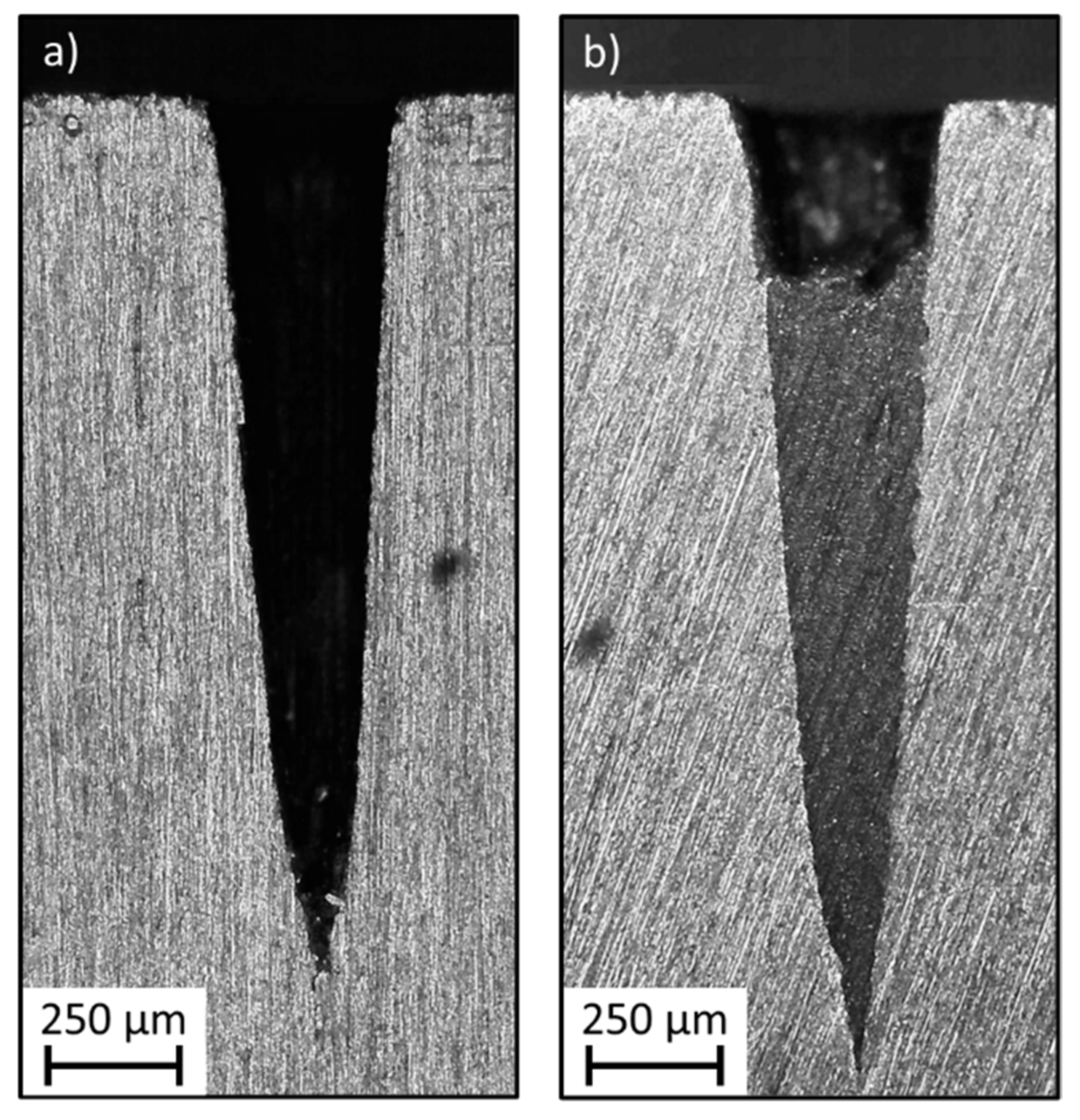

3.1. Geometry of the Ablated Microneedle Cavities

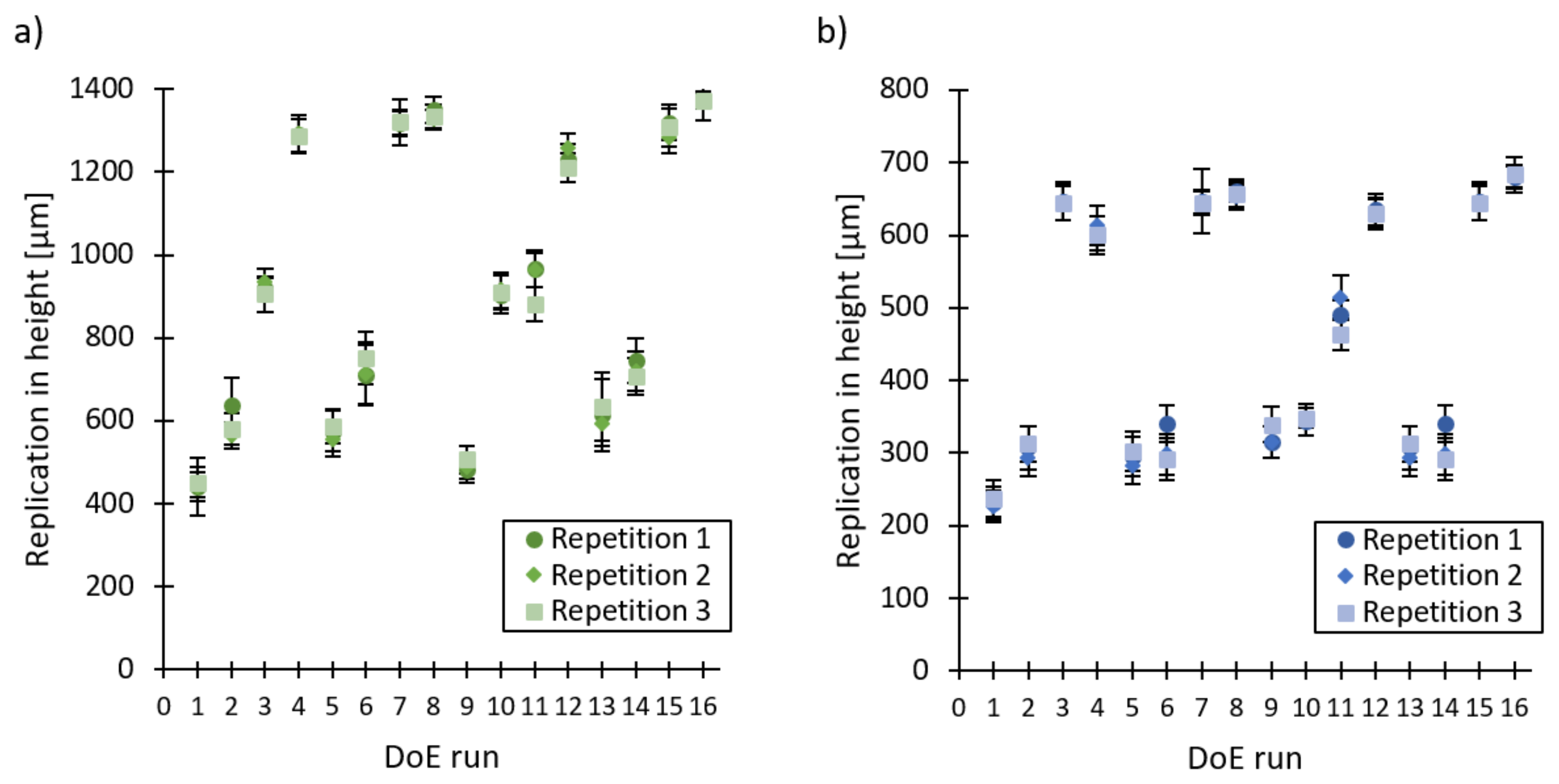

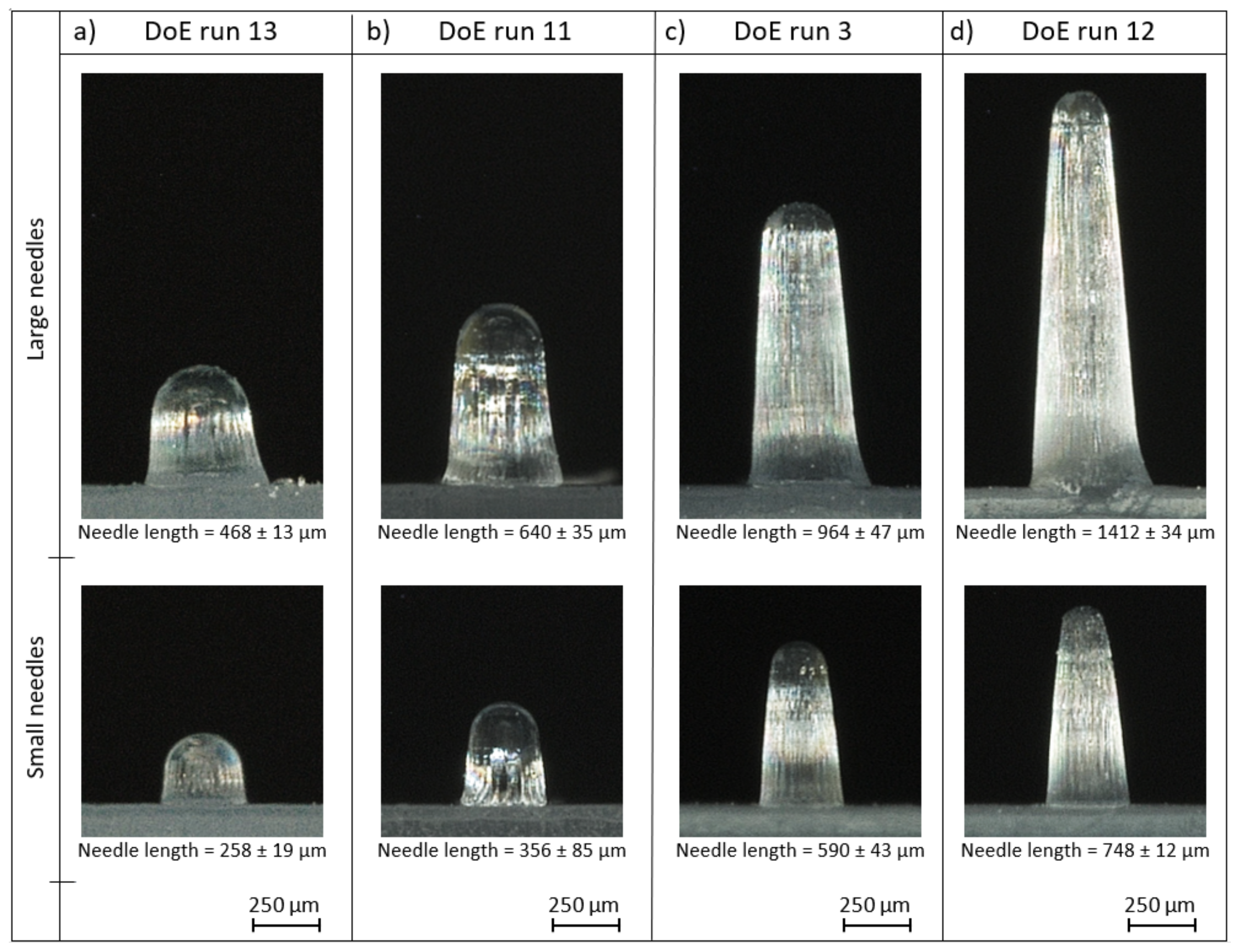

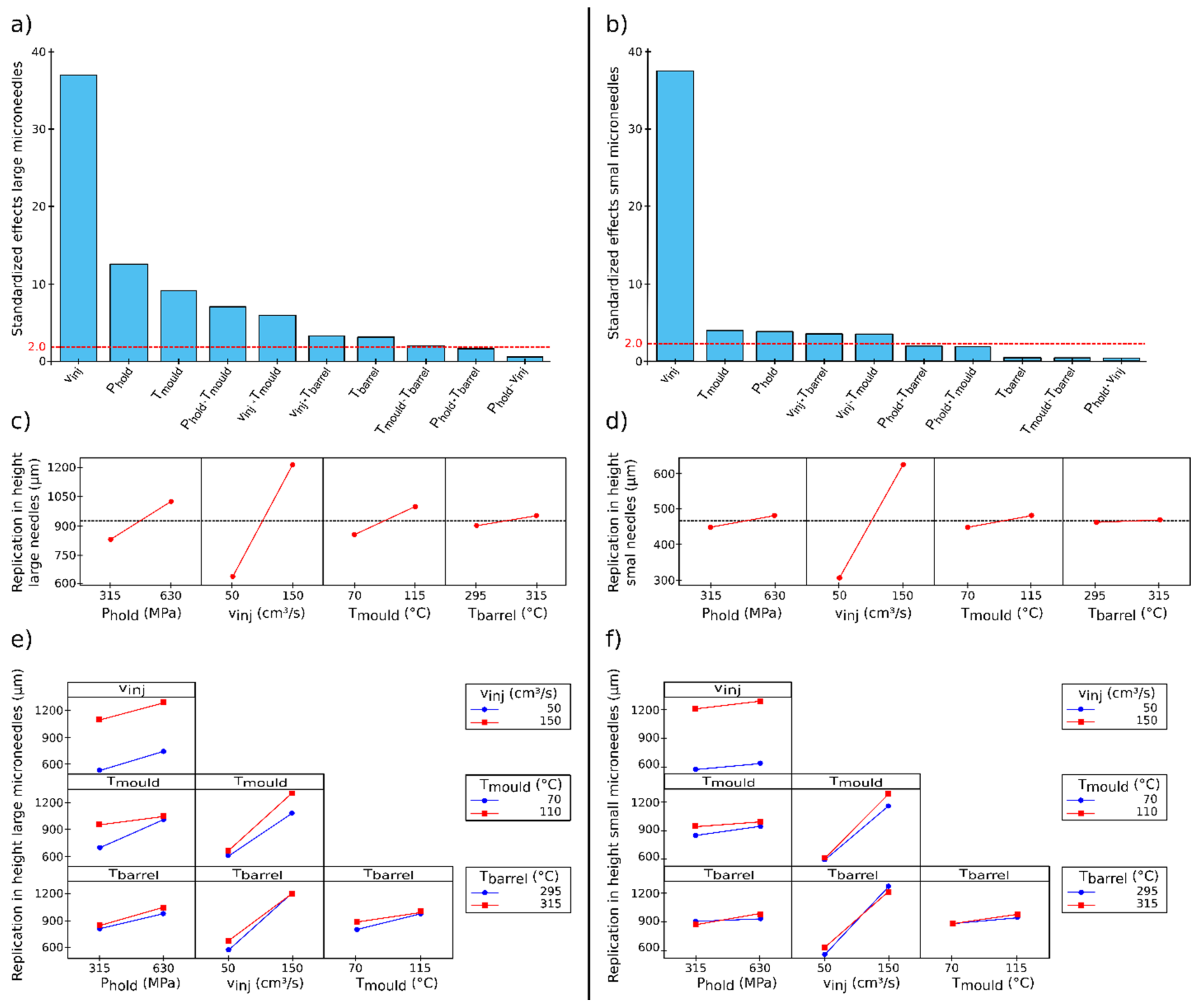

3.2. DoE to Define IM Parameters for a High Replication Fidelity

3.2.1. Volumetric Injection Rate

3.2.2. Holding Pressure

3.2.3. Mould Temperature

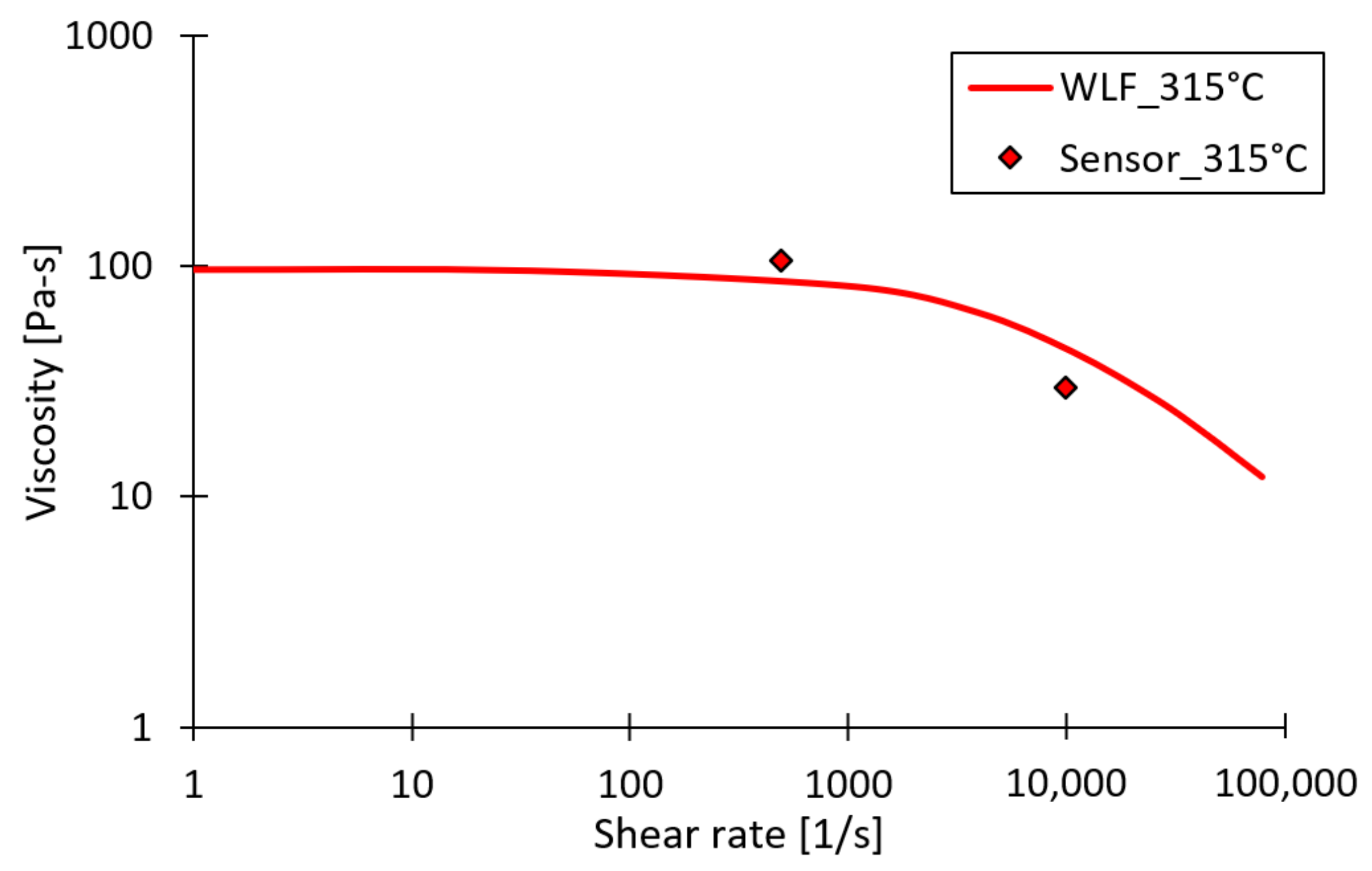

3.2.4. Melt Temperature

3.3. IM Using Parameters for an Optimal Replication Fidelity

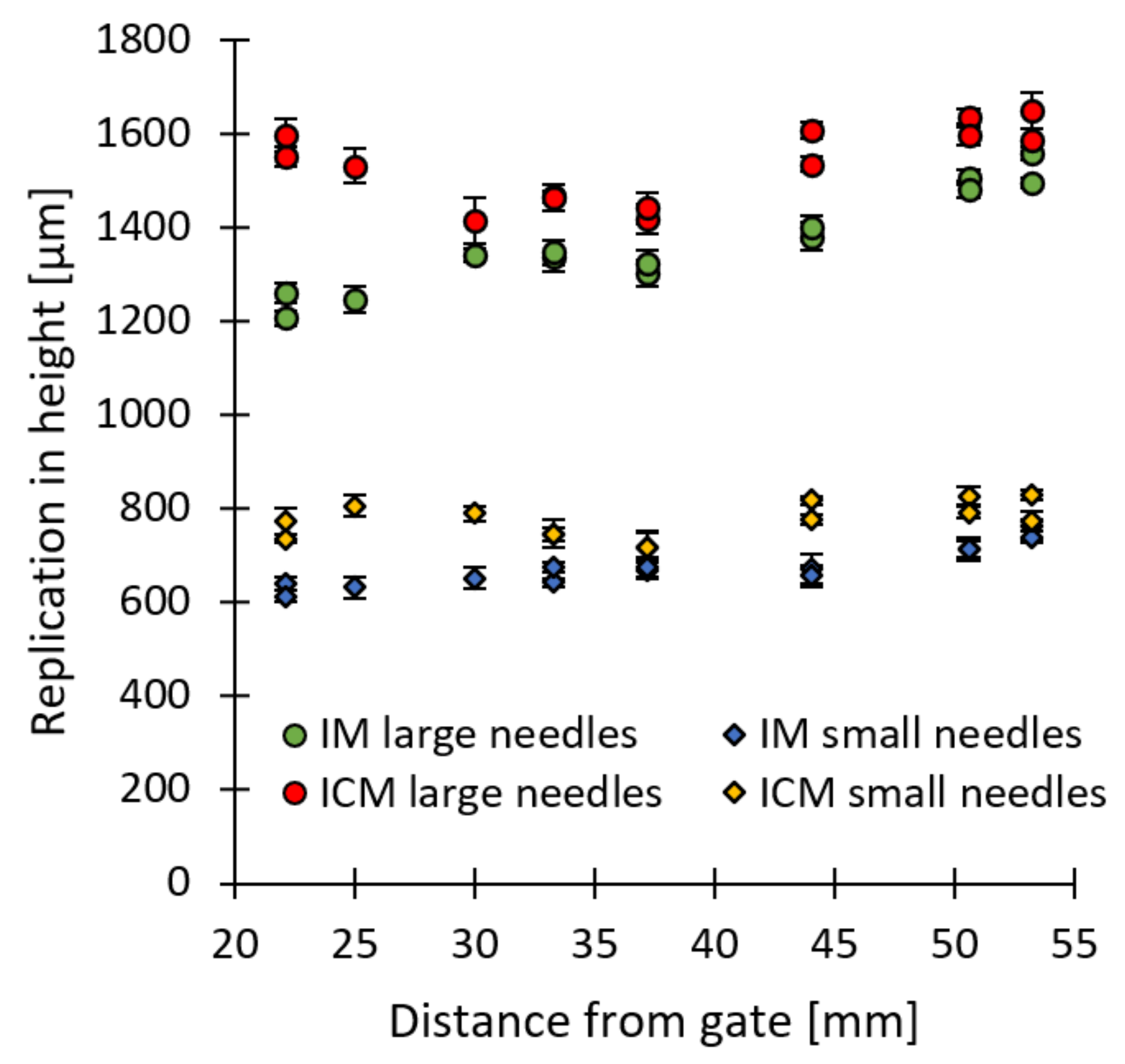

3.4. Injection Compression Moulding

3.5. Comparison between IM and ICM

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Maghsoudi, K.; Jafari, R.; Momen, G.; Farzaneh, M. Micro-Nanostructured Polymer Surfaces Using Injection Molding: A Review. Mater. Today Commun. 2017, 13, 126–143. [Google Scholar] [CrossRef]

- Nagarkar, R.; Singh, M.; Nguyen, H.X.; Jonnalagadda, S. A Review of Recent Advances in Microneedle Technology for Transdermal Drug Delivery. J. Drug Deliv. Sci. Technol. 2020, 59, 101923. [Google Scholar] [CrossRef]

- Evens, T.; Malek, O.; Castagne, S.; Seveno, D.; Van Bael, A. A Novel Method for Producing Solid Polymer Microneedles Using Laser Ablated Moulds in an Injection Moulding Process. Manuf. Lett. 2020, 24, 29–32. [Google Scholar] [CrossRef]

- Evens, T.; Van Hileghem, L.; Dal Dosso, F.; Lammertyn, J.; Malek, O.; Castagne, S.; Seveno, D.; Van Bael, A. Producing Hollow Polymer Microneedles Using Laser Ablated Molds in an Injection Molding Process. J. Micro Nano-Manuf. 2021, 9, 030902. [Google Scholar] [CrossRef]

- Evens, T.; Malek, O.; Castagne, S.; Seveno, D.; Van Bael, A. Controlling the Geometry of Laser Ablated Microneedle Cavities in Different Mould Materials and Assessing the Replication Fidelity within Polymer Injection Moulding. J. Manuf. Process. 2021, 62, 535–545. [Google Scholar] [CrossRef]

- Evens, T.; Castagne, S.; Seveno, D.; Van Bael, A. Predicting the Replication Fidelity of Injection Molded Solid Polymer Microneedles. Int. Polym. Process. 2022, 37, 237–254. [Google Scholar] [CrossRef]

- Larrañeta, E.; Lutton, R.E.M.; Woolfson, A.D.; Donnelly, R.F. Microneedle Arrays as Transdermal and Intradermal Drug Delivery Systems: Materials Science, Manufacture and Commercial Development. Mater. Sci. Eng. R Rep. 2016, 104, 1–32. [Google Scholar] [CrossRef]

- Zhang, N.; Chu, J.S.; Byrne, C.J.; Browne, D.J.; Gilchrist, M.D. Replication of Micro/Nano-Scale Features by Micro Injection Molding with a Bulk Metallic Glass Mold Insert. J. Micromech. Microeng. 2012, 22, 065019. [Google Scholar] [CrossRef]

- Baruffi, F.; Gülçür, M.; Calaon, M.; Romano, J.-M.; Penchev, P.; Dimov, S.; Whiteside, B.; Tosello, G. Correlating Nano-Scale Surface Replication Accuracy and Cavity Temperature in Micro-Injection Moulding Using in-Line Process Control and High-Speed Thermal Imaging. J. Manuf. Process. 2019, 47, 367–381. [Google Scholar] [CrossRef]

- Packianather, M.; Griffiths, C.; Kadir, W. Micro Injection Moulding Process Parameter Tuning. Procedia CIRP 2015, 33, 400–405. [Google Scholar] [CrossRef]

- Vera, J.; Brulez, A.-C.; Contraires, E.; Larochette, M.; Trannoy-Orban, N.; Pignon, M.; Mauclair, C.; Valette, S.; Benayoun, S. Factors Influencing Microinjection Molding Replication Quality. J. Micromech. Microeng. 2018, 28, 015004. [Google Scholar] [CrossRef]

- Sorgato, M.; Masato, D.; Lucchetta, G. Effect of Vacuum Venting and Mold Wettability on the Replication of Micro-Structured Surfaces. Microsyst. Technol. 2017, 23, 2543–2552. [Google Scholar] [CrossRef]

- Loaldi, D.; Quagliotti, D.; Calaon, M.; Parenti, P.; Annoni, M.; Tosello, G. Manufacturing Signatures of Injection Molding and Injection Compression Molding for Micro-Structured Polymer Fresnel Lens Production. Micromachines 2018, 9, 653. [Google Scholar] [CrossRef] [PubMed]

- Baruffi, F.; Calaon, M.; Tosello, G. Effects of Micro-Injection Moulding Process Parameters on Accuracy and Precision of Thermoplastic Elastomer Micro Rings. Precis. Eng. 2018, 51, 353–361. [Google Scholar] [CrossRef]

- Calaon, M.; Tosello, G.; Garnaes, J.; Hansen, H.N. Injection and Injection-Compression Moulding Replication Capability for the Production of Polymer Lab-on-a-Chip with Nano Structures. J. Micromech. Microeng. 2017, 27, 105001. [Google Scholar] [CrossRef]

- Sorgato, M.; Babenko, M.; Lucchetta, G.; Whiteside, B. Investigation of the Influence of Vacuum Venting on Mould Surface Temperature in Micro Injection Moulding. Int. J. Adv. Manuf. Technol. 2017, 88, 547–555. [Google Scholar] [CrossRef][Green Version]

- Zhang, N.; Zhang, H.; Stallard, C.; Fang, F.; Gilchrist, M.D. Replication Integrity of Micro Features Using Variotherm and Vacuum Assisted Microinjection Moulding. CIRP J. Manuf. Sci. Technol. 2018, 23, 20–38. [Google Scholar] [CrossRef]

- Theilade, U.A.; Hansen, H.N. Surface Microstructure Replication in Injection Molding. Int. J. Adv. Manuf. Technol. 2007, 33, 157–166. [Google Scholar] [CrossRef]

- Mnkknen, K.; Pakkanen, T.T.; Hietala, J.; Pkknen, E.J.; Pkknen, P.; Jskelinen, T.; Kaikuranta, T. Replication of Sub-Micron Features Using Amorphous Thermoplastics. Polym. Eng. Sci. 2002, 42, 1600–1608. [Google Scholar] [CrossRef]

- Lucchetta, G.; Sorgato, M.; Carmignato, S.; Savio, E. Investigating the Technological Limits of Micro-Injection Molding in Replicating High Aspect Ratio Micro-Structured Surfaces. CIRP Ann. 2014, 63, 521–524. [Google Scholar] [CrossRef]

- Masato, D.; Sorgato, M.; Lucchetta, G. Analysis of the Influence of Part Thickness on the Replication of Micro-Structured Surfaces by Injection Molding. Mater. Des. 2016, 95, 219–224. [Google Scholar] [CrossRef]

- Tosello, G.; Gava, A.; Hansen, H.N.; Lucchetta, G. Study of Process Parameters Effect on the Filling Phase of Micro-Injection Moulding Using Weld Lines as Flow Markers. Int. J. Adv. Manuf. Technol. 2010, 47, 81–97. [Google Scholar] [CrossRef]

- Rytka, C. Replication of Functional Polymeric Micro- and Nanostructures. Ph.D. Thesis, TU Dortmond, Dortmund, Germany, 2016; pp. 1–145. [Google Scholar]

- Loaldi, D.; Regi, F.; Baruffi, F.; Calaon, M.; Quagliotti, D.; Zhang, Y.; Tosello, G. Experimental Validation of Injection Molding Simulations of 3D Microparts and Microstructured Components Using Virtual Design of Experiments and Multi-Scale Modeling. Micromachines 2020, 11, 614. [Google Scholar] [CrossRef] [PubMed]

- Kamal, M.; Isayev, A.; Liu, S.-J. Injection Molding Technology and Fundamentals, 1st ed.; Carl Hanser Verlag: Munich, Germany, 2009; ISBN 978-3-446-41685-7. [Google Scholar]

- Hansen, H.N.; Hocken, R.J.; Tosello, G. Replication of Micro and Nano Surface Geometries. CIRP Ann. 2011, 60, 695–714. [Google Scholar] [CrossRef]

- Suzuki, H.; Takayama, T.; Ito, H. Replication Behavior for Micro Surface Features With High Aspect Ratio and Structure Development in Injection Compression Molding. Int. J. Mod. Phys. Conf. Ser. 2012, 6, 563–569. [Google Scholar] [CrossRef]

- Masato, D.; Sorgato, M.; Lucchetta, G. Characterization of the Micro Injection-Compression Molding Process for the Replication of High Aspect Ratio Micro-Structured Surfaces. Microsyst. Technol. 2017, 23, 3661–3670. [Google Scholar] [CrossRef]

- Roeder, M.; Drexler, M.; Rothermel, T.; Meissner, T.; Guenther, T.; Zimmermann, A. Injection Compression Molded Microlens Arrays for Hyperspectral Imaging. Micromachines 2018, 9, 355. [Google Scholar] [CrossRef]

- Metwally, K.; Barriere, T.; Khan-Malek, C. Replication of Micrometric and Sub-Micrometric Structured Surfaces Using Micro-Injection and Micro-Injection Compression Moulding. Int. J. Adv. Manuf. Technol. 2016, 83, 779–789. [Google Scholar] [CrossRef]

- Rytka, C.; Kristiansen, P.M.; Neyer, A. Iso- and Variothermal Injection Compression Moulding of Polymer Micro- and Nanostructures for Optical and Medical Applications. J. Micromech. Microeng. 2015, 25, 065008. [Google Scholar] [CrossRef]

- Nagato, K.; Hamaguchi, T.; Nakao, M. Injection Compression Molding of High-Aspect-Ratio Nanostructures. J. Vac. Sci. Technol. B Nanotechnol. Microelectron. Mater. Process. Meas. Phenom. 2011, 29, 06FG10. [Google Scholar] [CrossRef]

- Montgomery, D.; Runger, G.; Hubele, N. Engineering Statistics; John Wiley and Sons Inc.: New York, NY, USA, 2012; ISBN 0-471-17026-7. [Google Scholar]

- Hopmann, C.; Bobzin, K.; Brögelmann, T.; Orth, M.; Kruppe, N.; Naderi, M. Replication of Micro-Structured Injection Molds Using Physical Vapor Deposition Coating and Dynamic Laser Mold Tempering. J. Polym. Eng. 2018, 38, 315–322. [Google Scholar] [CrossRef]

- Tosello, G. Micro Injection Molding; Tosello, G., Ed.; Carl Hanser Verlag GmbH & Co. KG: München, Germany, 2018; ISBN 978-1-56990-653-8. [Google Scholar]

- Sha, B.; Dimov, S.; Griffiths, C.; Packianather, M.S. Investigation of Micro-Injection Moulding: Factors Affecting the Replication Quality. J. Mater. Process. Technol. 2007, 183, 284–296. [Google Scholar] [CrossRef]

- Liou, A.-C.; Chen, R.-H. Injection Molding of Polymer Micro- and Sub-Micron Structures with High-Aspect Ratios. Int. J. Adv. Manuf. Technol. 2006, 28, 1097–1103. [Google Scholar] [CrossRef]

- Park, S.H.; Lee, W.I.; Moon, S.N.; Yoo, Y.E.; Cho, Y.H. Injection Molding Micro Patterns with High Aspect Ratio Using a Polymeric Flexible Stamper. Express Polym. Lett. 2011, 5, 950–958. [Google Scholar] [CrossRef]

- Kim, S.H.; Jeong, J.H.; Youn, J.R. Nanopattern Insert Molding. Nanotechnology 2010, 21, 205302. [Google Scholar] [CrossRef]

- Despa, M.S.; Kelly, K.W.; Collier, J.R. Injection Molding of Polymeric LIGA HARMs. Microsyst. Technol. 1999, 6, 60–66. [Google Scholar] [CrossRef]

- Zhao, J.; Mayes, R.H.; Chen, G.; Chan, P.S.; Xiong, Z.J. Polymer Micromould Design and Micromoulding Process. Plast. Rubber Compos. 2003, 32, 240–247. [Google Scholar] [CrossRef]

- Yu, L.; Koh, C.G.; Lee, L.J.; Koelling, K.W.; Madou, M.J. Experimental Investigation and Numerical Simulation of Injection Molding with Micro-Features. Polym. Eng. Sci. 2002, 42, 871–888. [Google Scholar] [CrossRef]

- Lin, H.-Y.; Young, W.-B. Analysis of the Filling Capability to the Microstructures in Micro-Injection Molding. Appl. Math. Model. 2009, 33, 3746–3755. [Google Scholar] [CrossRef]

| DoE Run | Barrel Temperature [°C] | Mould Temperature [°C] | Volumetric Injection Rate [cm3/s] | Holding Pressure [MPa] |

|---|---|---|---|---|

| 1 | 295 | 70 | 50 | 31.5 |

| 2 | 295 | 70 | 50 | 63.0 |

| 3 | 295 | 70 | 150 | 31.5 |

| 4 | 295 | 70 | 150 | 63.0 |

| 5 | 295 | 115 | 50 | 31.5 |

| 6 | 295 | 115 | 50 | 63.0 |

| 7 | 295 | 115 | 150 | 31.5 |

| 8 | 295 | 115 | 150 | 63.0 |

| 9 | 315 | 70 | 50 | 31.5 |

| 10 | 315 | 70 | 50 | 63.0 |

| 11 | 315 | 70 | 150 | 31.5 |

| 12 | 315 | 70 | 150 | 63.0 |

| 13 | 315 | 115 | 50 | 31.5 |

| 14 | 315 | 115 | 50 | 63.0 |

| 15 | 315 | 115 | 150 | 31.5 |

| 16 | 315 | 115 | 150 | 63.0 |

| IM Simulation Parameters | PC |

|---|---|

| Barrel temperature [°C] | 315 |

| Volumetric injection rate [cm3/s] | 150 |

| Holding pressure [MPa] | 63 |

| Mould coolant temperature [°C] | 115 |

| HTC during filling stage [W/m2∙K] | 30,000 |

| HTC packing [W/m2∙K] | 2500 |

| HTC detached [W/m2∙K] | 1250 |

| Criterion for stopping calculation | 99.9999% |

| IM Parameters | PC |

|---|---|

| Barrel temperature [°C] | 315 |

| Volumetric injection rate [cm3/s] | 150 |

| Holding pressure [MPa] | 63 |

| Mould coolant temperature [°C] | 125 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Evens, T.; Castagne, S.; Seveno, D.; Van Bael, A. Comparing the Replication Fidelity of Solid Microneedles Using Injection Compression Moulding and Conventional Injection Moulding. Micromachines 2022, 13, 1280. https://doi.org/10.3390/mi13081280

Evens T, Castagne S, Seveno D, Van Bael A. Comparing the Replication Fidelity of Solid Microneedles Using Injection Compression Moulding and Conventional Injection Moulding. Micromachines. 2022; 13(8):1280. https://doi.org/10.3390/mi13081280

Chicago/Turabian StyleEvens, Tim, Sylvie Castagne, David Seveno, and Albert Van Bael. 2022. "Comparing the Replication Fidelity of Solid Microneedles Using Injection Compression Moulding and Conventional Injection Moulding" Micromachines 13, no. 8: 1280. https://doi.org/10.3390/mi13081280

APA StyleEvens, T., Castagne, S., Seveno, D., & Van Bael, A. (2022). Comparing the Replication Fidelity of Solid Microneedles Using Injection Compression Moulding and Conventional Injection Moulding. Micromachines, 13(8), 1280. https://doi.org/10.3390/mi13081280