Compact Integration of Hydrogen–Resistant a–InGaZnO and Poly–Si Thin–Film Transistors

Abstract

:1. Introduction

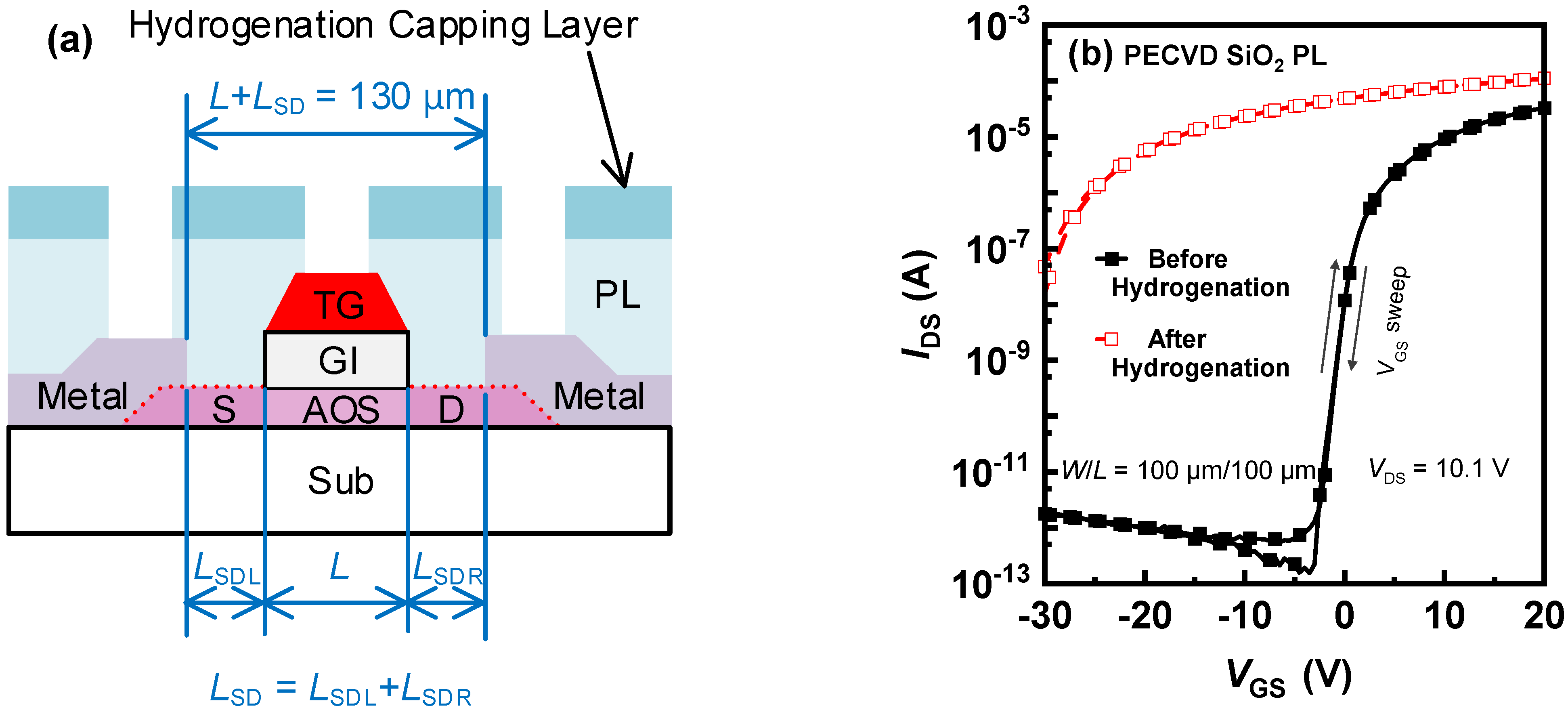

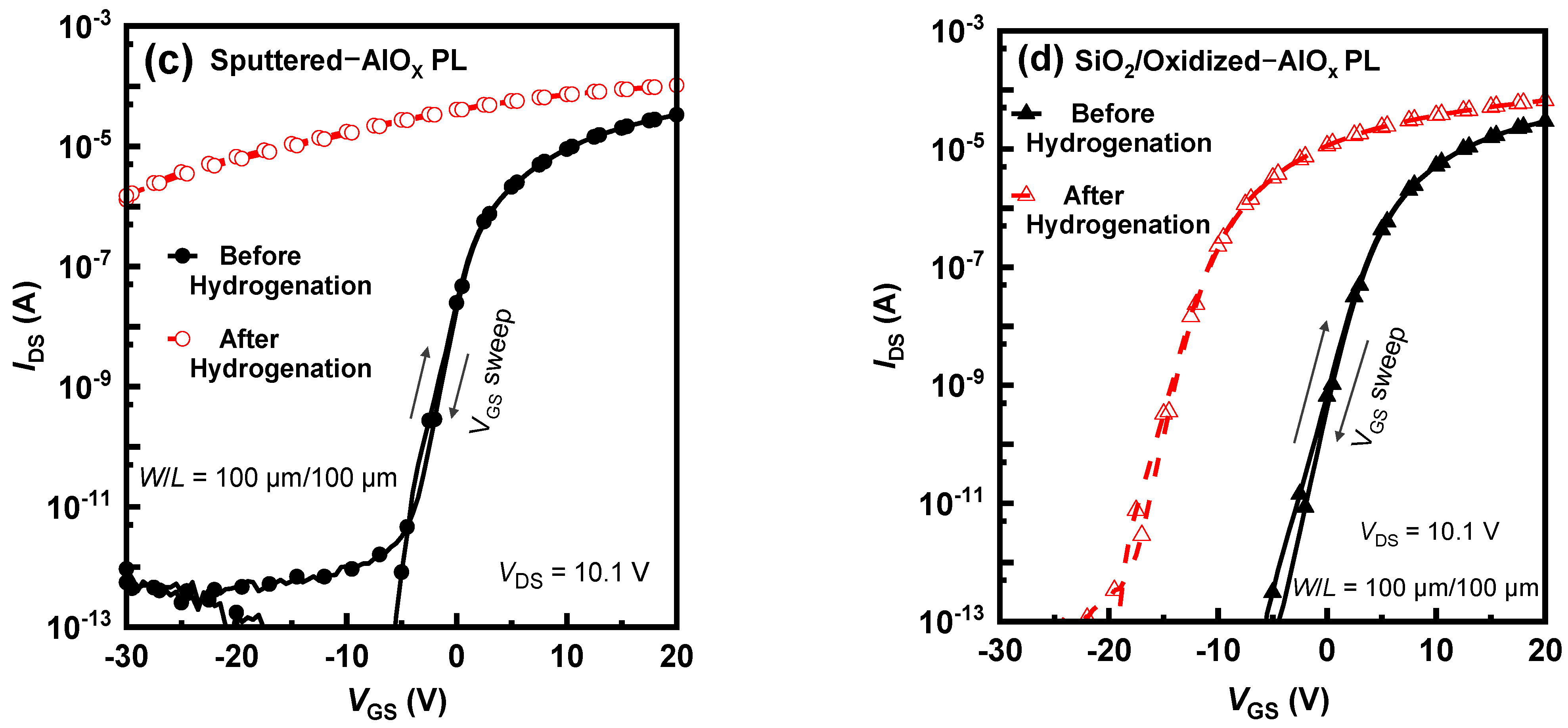

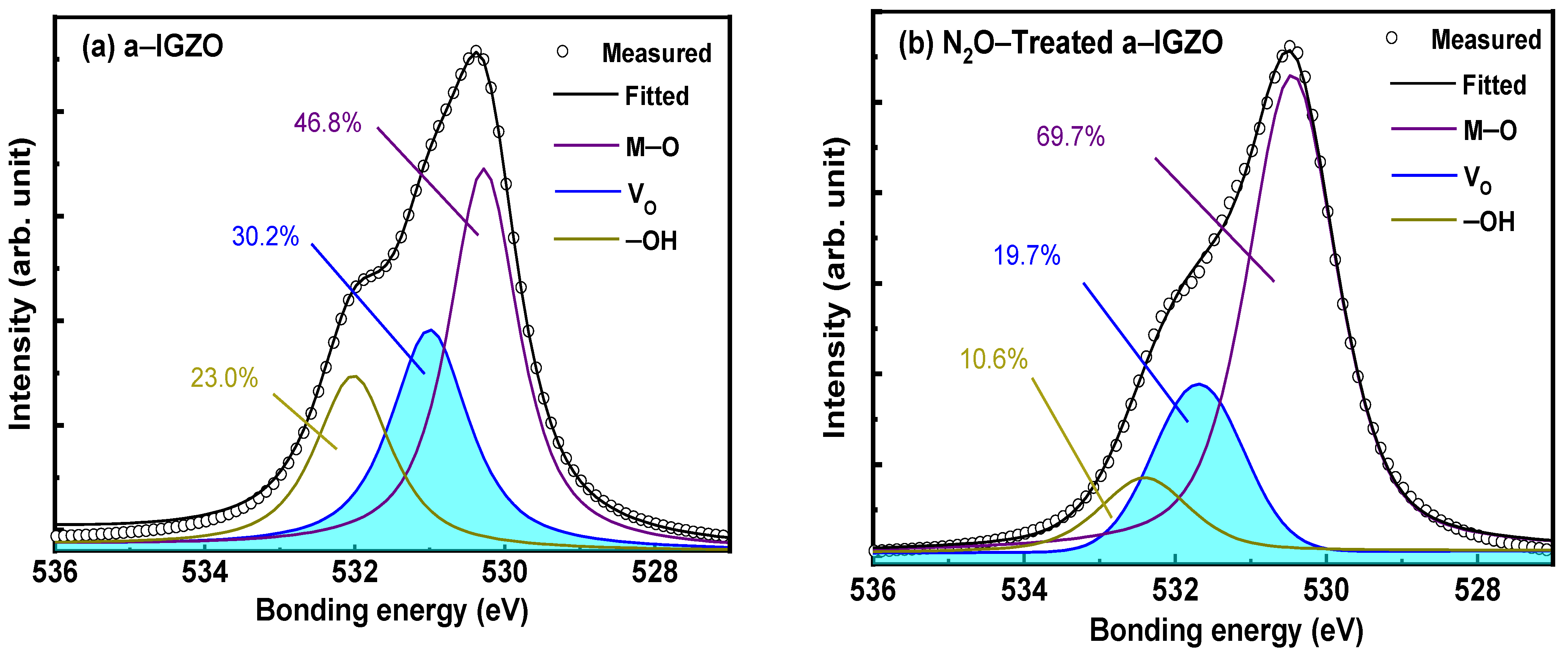

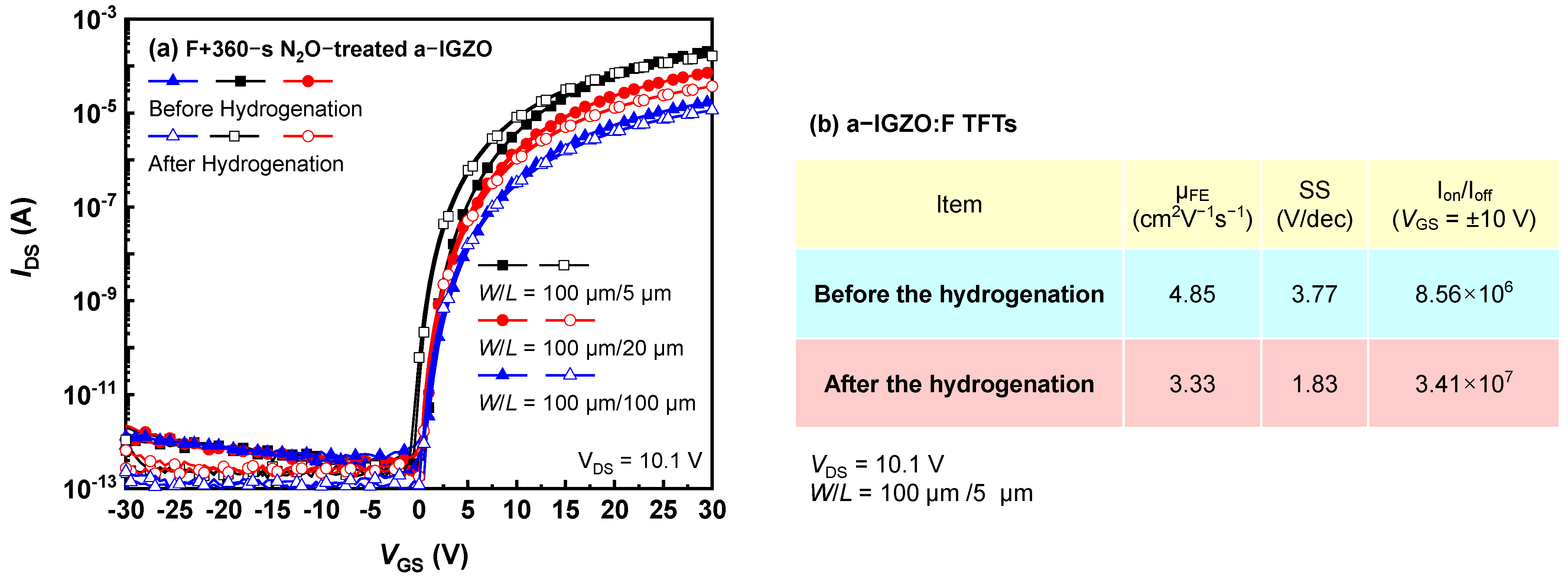

2. Development of Hydrogen–Resistant a–IGZO TFTs

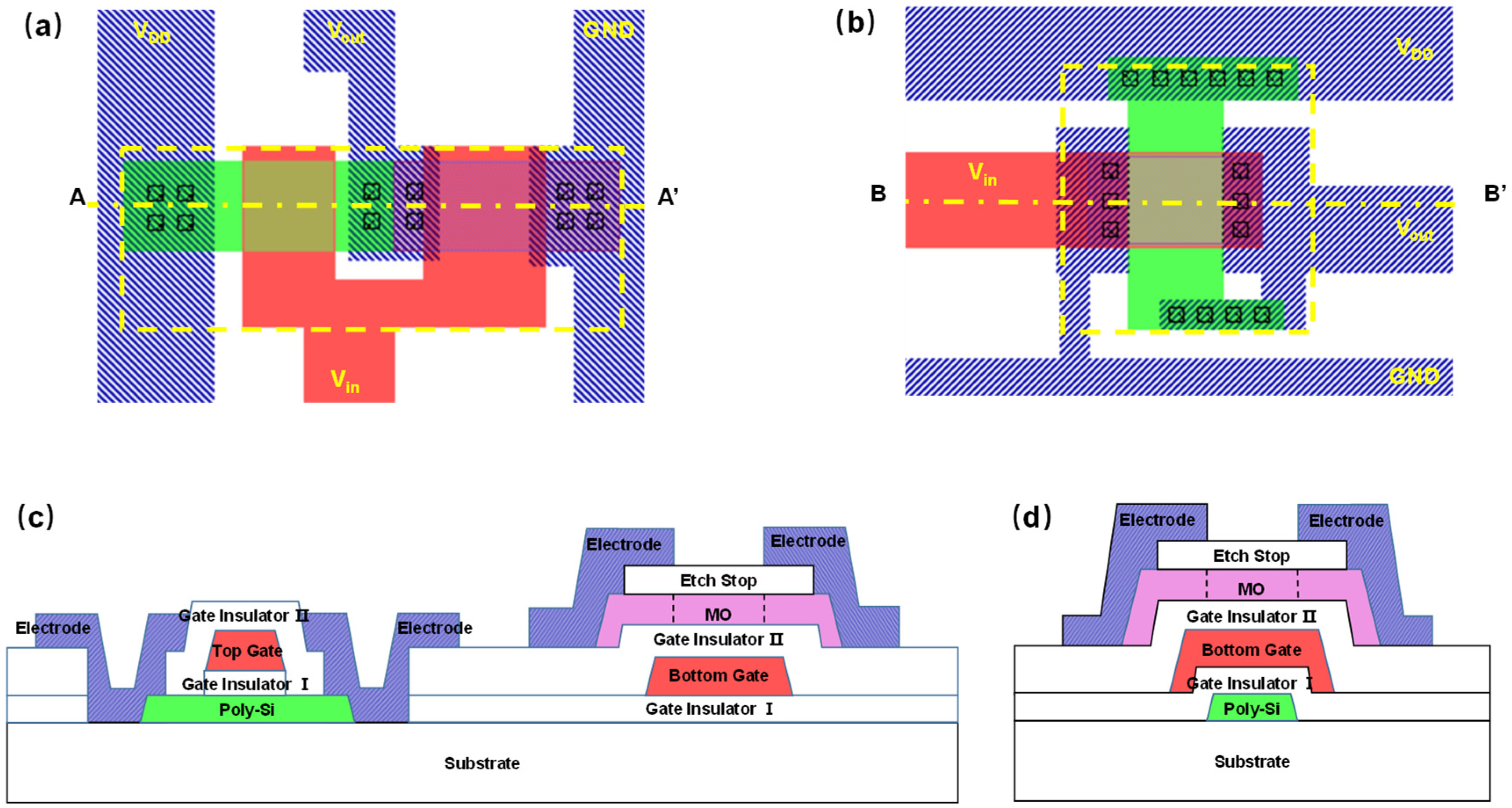

3. 3D Integration of IGZO and Poly–Si TFTs

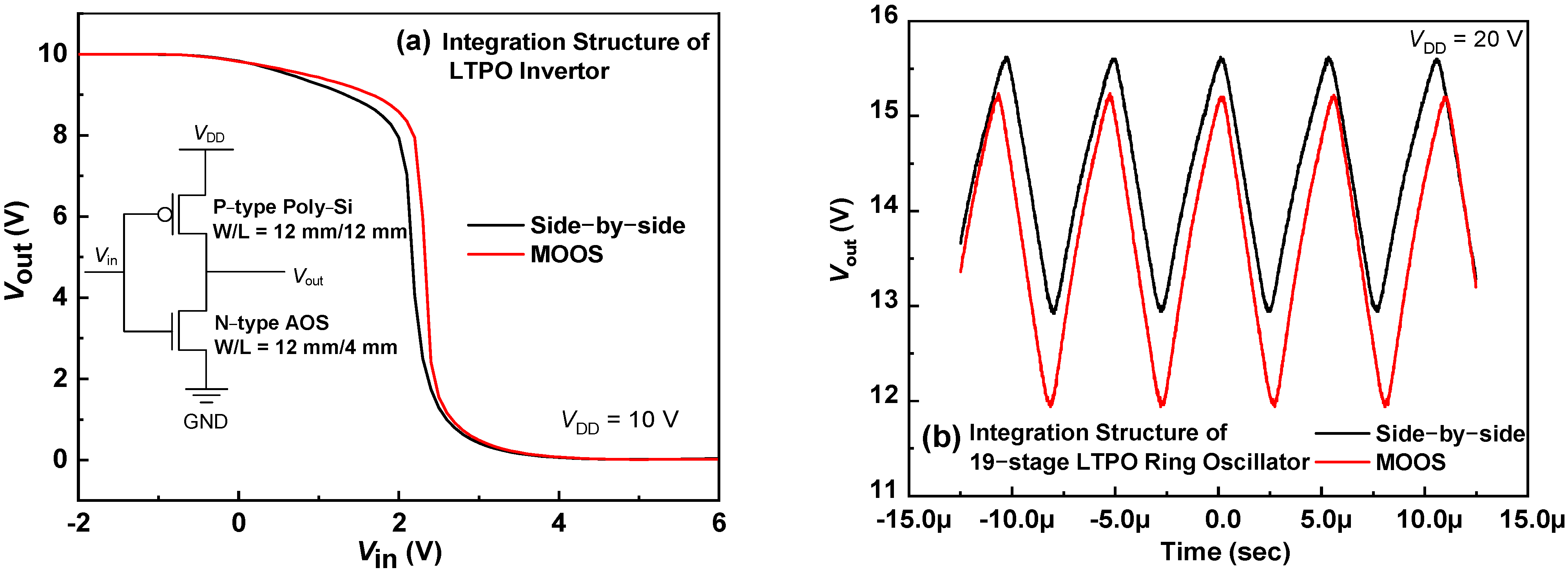

4. Results

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, D.; Furuta, M.; Tomai, S.; Yano, K. Understanding the Role of Temperature and Drain Current Stress in InSnZnO TFTs with Various Active Layer Thicknesses. Nanomaterials 2020, 10, 617. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, D.; Furuta, M.; Tomai, S.; Yano, K. Impact of Photo-Excitation on Leakage Current and Negative Bias Instability in InSnZnO Thickness-Varied Thin-Film Transistors. Nanomaterials 2020, 10, 1782. [Google Scholar] [CrossRef] [PubMed]

- Chortos, A.; Zhu, C.; Oh, J.Y.; Yan, X.; Pochorovski, I.; To, J.W.-F.; Liu, N.; Kraft, U.; Murmann, B.; Bao, Z. Investigating Limiting Factors in Stretchable All-Carbon Transistors for Reliable Stretchable Electronics. ACS Nano 2017, 11, 7925–7937. [Google Scholar] [CrossRef] [PubMed]

- Magari, Y.; Kataoka, T.; Yeh, W.; Furuta, M. High-mobility hydrogenated polycrystalline In2O3 (In2O3:H) thin-film transistors. Nat. Commun. 2022, 13, 1078. [Google Scholar] [CrossRef]

- Um, J.K.; Lee, S.; Jin, S.; Mativenga, M.; Oh, S.Y.; Lee, C.H.; Jang, J. High-Performance Homojunction a-IGZO TFTs With Selectively Defined Low-Resistive a-IGZO Source/Drain Electrodes. IEEE Trans. Electron Devices 2015, 62, 2212–2218. [Google Scholar] [CrossRef]

- Chang, S.C.; Hung, M.-C.; Yu, C.-H.; Chang, T.-K.; Roudbari, A.J.; Lin, S.-C.; Kim, K.-W.; Huang, C.-Y.; Lee, S.-H.; Chen, Y.-C. Liquid Crystal Displays with Oxide-Based Thin-Film Tran-sistors. Application No US-0228070, 27 March 2014. [Google Scholar]

- Seager, C.H.; Ginley, D.S. Passivation of grain boundaries in polycrystalline silicon. Appl. Phys. Lett. 1979, 34, 337–340. [Google Scholar] [CrossRef]

- Bang, J.; Matsuishi, S.; Hosono, H. Hydrogen anion and subgap states in amorphous In–Ga–Zn–O thin films for TFT applications. Appl. Phys. Lett. 2017, 110, 232105. [Google Scholar] [CrossRef] [Green Version]

- Abliz, A.; Gao, Q.; Wan, D.; Liu, X.; Xu, L.; Liu, C.; Jiang, C.; Li, X.; Chen, H.; Guo, T.; et al. Effects of Nitrogen and Hydrogen Codoping on the Electrical Performance and Reliability of InGaZnO Thin-Film Transistors. ACS Appl. Mater. Interfaces 2017, 9, 10798–10804. [Google Scholar] [CrossRef]

- Abliz, A. Effects of hydrogen plasma treatment on the electrical performances and reliability of InGaZnO thin-film transistors. J. Alloys Compd. 2020, 831, 154694. [Google Scholar] [CrossRef]

- Lv, N.; Lu, L.; Wang, Z.; Wang, H.; Zhang, D.; Wong, M.; Wang, M. Suppression of the Short-Channel Effect in Dehydrogenated Elevated-Metal Metal- Oxide (EMMO) Thin-Film Transistors. IEEE Trans. Electron Devices 2020, 67, 3001–3004. [Google Scholar] [CrossRef]

- Hanyu, Y.; Domen, K.; Nomura, K.; Hiramatsu, H.; Kumomi, H.; Hosono, H.; Kamiya, T. Hydrogen passivation of electron trap in amorphous In-Ga-Zn-O thin-film transistors. Appl. Phys. Lett. 2013, 103, 202114. [Google Scholar] [CrossRef]

- Chowdhury, D.H.; Mativenga, M.; Um, J.G.; Mruthyunjaya, R.K.; Heiler, G.N.; Tredwell, T.J.; Jang, J. Effect of SiO2 and SiO2/SiNx Passivation on the Stability of Amorphous Indium-Gallium Zinc-Oxide Thin-Film Transistors Under High Humidity. IEEE Trans. Electron Devices 2015, 62, 869–874. [Google Scholar] [CrossRef]

- Peng, H.; Chang, B.; Fu, H.; Yang, H.; Zhang, Y.; Zhou, X.; Lu, L.; Zhang, S. Top-Gate Amorphous Indium-Gallium-Zinc-OxideThin-Film Transistors with Magnesium Metallized Source/Drain Regions. IEEE Trans. Electron Devices 2020, 67, 1619–1624. [Google Scholar] [CrossRef]

- Lu, L.; Li, J.; Feng, Z.Q.; Kwok, H.S.; Wong, M. Elevated-Metal Metal-Oxide (EMMO) Thin-Film Transistor: Technology and Characteristics. IEEE Electron Device Lett. 2016, 37, 728–730. [Google Scholar] [CrossRef]

- Wang, S.; Shi, R.; Li, J.; Lu, L.; Xia, Z.; Kwok, H.S.; Wong, M. Resilience of Fluorinated Indium-Gallium-Zinc Oxide Thin-Film Transistor Against Hydrogen-Induced Degradation. IEEE Electron Device Lett. 2020, 41, 729–732. [Google Scholar] [CrossRef]

- Wang, S.; Li, J.; Shi, R.; Xia, Z.; Lu, L.; Kwok, H.S.; Wong, M. Fluorinated indium-gallium-zinc oxide thin-film transistor with reduced vulnerability to hydrogen-induced degradation. J. Soc. Inf. Disp. 2020, 28, 520–527. [Google Scholar] [CrossRef]

- Kim, D.-G.; Kim, J.-U.; Lee, J.-S.; Park, K.-S.; Chang, Y.-G.; Kim, M.-H.; Choi, D.-K. Negative threshold voltage shift in an a-IGZO thin film transistor under X-ray irradiation. RSC Adv. 2019, 9, 20865–20870. [Google Scholar] [CrossRef] [Green Version]

- Luo, C.; Yin, G.; Shu, Z.; Liu, G.; Ai, F. P-2: High-Performance LTPO TFT-LCD Using Metal as Hydrogen Barrier Layer. SID Symp. Dig. Tech. Pap. 2021, 52, 1063–1066. [Google Scholar] [CrossRef]

- Ide, K.; Nomura, K.; Hosono, H.; Kamiya, T. Electronic Defects in Amorphous Oxide Semiconductors: A Review. Phys. Status solidi (a) 2019, 216, 1800372. [Google Scholar] [CrossRef]

- Jeong, H.-Y.; Lee, B.-Y.; Lee, Y.-J.; Lee, J.-I.; Yang, M.-S.; Kang, I.-B.; Mativenga, M.; Jang, J. Coplanar amorphous-indium-gallium-zinc-oxide thin film transistor with He plasma treated heavily doped layer. Appl. Phys. Lett. 2014, 104, 022115. [Google Scholar] [CrossRef]

- Noh, H.Y.; Kim, J.; Kim, J.-S.; Lee, M.-J.; Lee, H.-J. Role of Hydrogen in Active Layer of Oxide-Semiconductor-Based Thin Film Transistors. Crystals 2019, 9, 75. [Google Scholar] [CrossRef] [Green Version]

- Knobelspies, S.; Takabayashi, A.; Daus, A.; Cantarella, G.; Münzenrieder, N.; Tröster, G. Improvement of contact resistance in flexible a-IGZO thin-film transistors by CF4/O2 plasma treatment. Solid-state Electron. 2018, 150, 23–27. [Google Scholar] [CrossRef]

- Park, J.; Kim, S.; Kim, C.; Kim, S.; Song, I.; Yin, H.; Kim, K.-K.; Lee, S.; Hong, K.; Lee, J.; et al. High-performance amorphous gallium indium zinc oxide thin-film transistors through N2O plasma passivation. Appl. Phys. Lett. 2008, 93, 733. [Google Scholar] [CrossRef]

- Guo, Y.; Zhu, L.; Li, Y.; Niu, W.; Zhang, X.; Ye, Z. Interaction of H and F atoms—Origin of the high conductive stability of hydrogen-incorporated F-doped ZnO thin films. Thin Solid Films 2015, 589, 85–89. [Google Scholar] [CrossRef]

- Sinatra, L.; Lutfullin, M.; Abbas, A.S.; Pan, J.; Bakr, O.M. P-203: Late News Poster: Novel Techniques for Highly Stable Luminescent Per-Ovskite Halide Quantum Dots; Society for Information Display: San Jose, CA, USA, 2018; pp. 1681–1684. [Google Scholar]

- Zhou, W.; Meng, Z.; Zhao, S.; Zhang, M.; Chen, R.; Wong, M.; Kwok, H.-S. Bridged-Grain Solid-Phase-Crystallized Polycrystalline-Silicon Thin-Film Transistors. IEEE Electron Device Lett. 2012, 33, 1414–1416. [Google Scholar] [CrossRef]

- Huang, T.-C.; Fukuda, K.; Lo, C.-M.; Yeh, Y.-H.; Sekitani, T.; Someya, T.; Cheng, K.-T. Pseudo-CMOS: A Design Style for Low-Cost and Robust Flexible Elec-tronics. IEEE Trans. Electron Devices 2010, 58, 141–150. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Zhou, Y.; Xia, Z.; Zhou, W.; Zhang, M.; Yeung, F.S.Y.; Wong, M.; Kwok, H.S.; Zhang, S.; Lu, L. Compact Integration of Hydrogen–Resistant a–InGaZnO and Poly–Si Thin–Film Transistors. Micromachines 2022, 13, 839. https://doi.org/10.3390/mi13060839

Wang Y, Zhou Y, Xia Z, Zhou W, Zhang M, Yeung FSY, Wong M, Kwok HS, Zhang S, Lu L. Compact Integration of Hydrogen–Resistant a–InGaZnO and Poly–Si Thin–Film Transistors. Micromachines. 2022; 13(6):839. https://doi.org/10.3390/mi13060839

Chicago/Turabian StyleWang, Yunping, Yuheng Zhou, Zhihe Xia, Wei Zhou, Meng Zhang, Fion Sze Yan Yeung, Man Wong, Hoi Sing Kwok, Shengdong Zhang, and Lei Lu. 2022. "Compact Integration of Hydrogen–Resistant a–InGaZnO and Poly–Si Thin–Film Transistors" Micromachines 13, no. 6: 839. https://doi.org/10.3390/mi13060839

APA StyleWang, Y., Zhou, Y., Xia, Z., Zhou, W., Zhang, M., Yeung, F. S. Y., Wong, M., Kwok, H. S., Zhang, S., & Lu, L. (2022). Compact Integration of Hydrogen–Resistant a–InGaZnO and Poly–Si Thin–Film Transistors. Micromachines, 13(6), 839. https://doi.org/10.3390/mi13060839