Quality Study and Numerical Simulation Analysis of Solid–Liquid Two-Phase Magnetic Fluid Polishing Seven-Order Variable-Diameter Pipe

Abstract

:1. Introduction

2. Theory and Method

2.1. Kelvin Force and Magnetic Viscosity Coefficient of Ferromagnetic Fluid

2.2. Basic Equations of Ferromagnetic Fluid

2.3. Method

3. Experimental Study on Polishing Seven-Order Variable-Diameter Pipe by SLTPMF

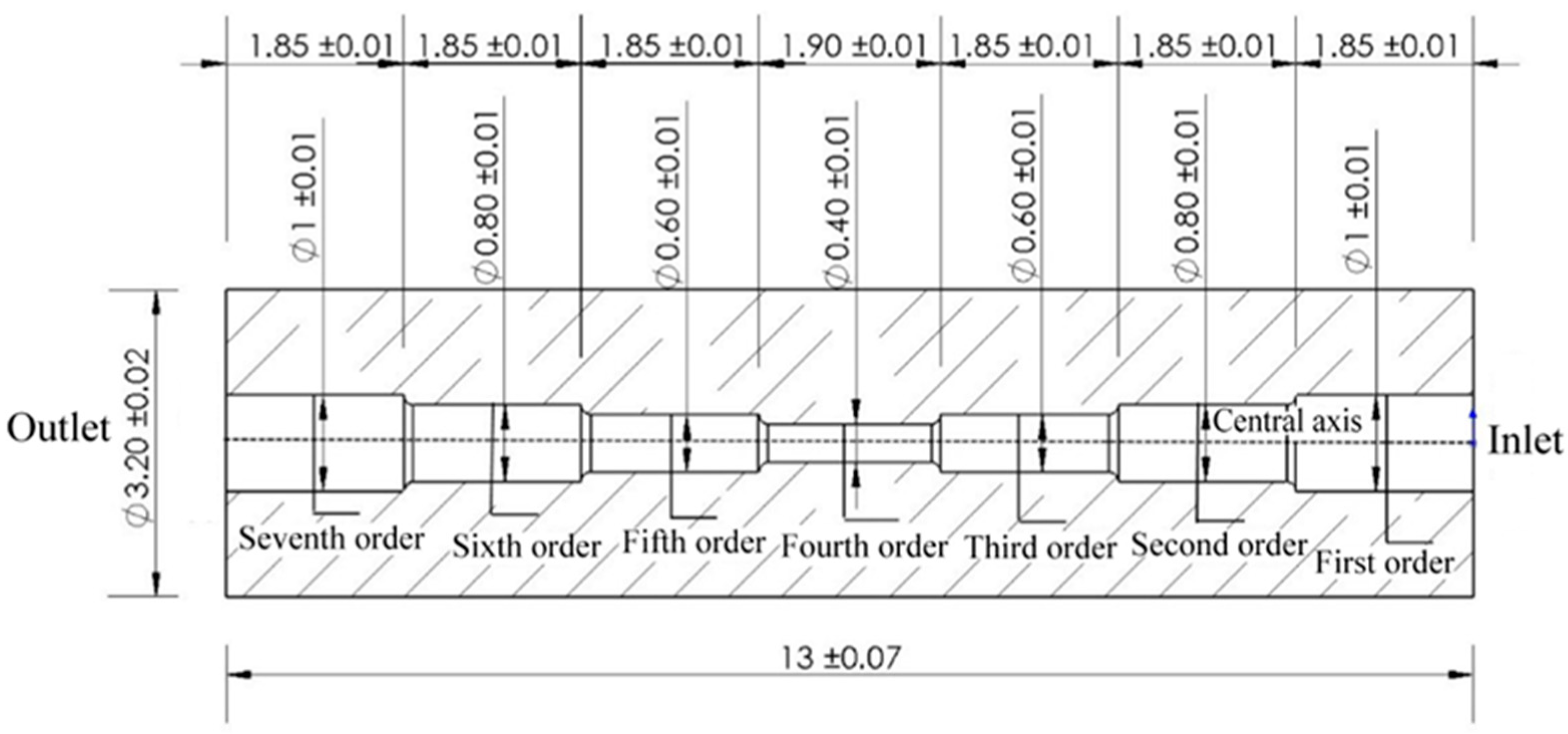

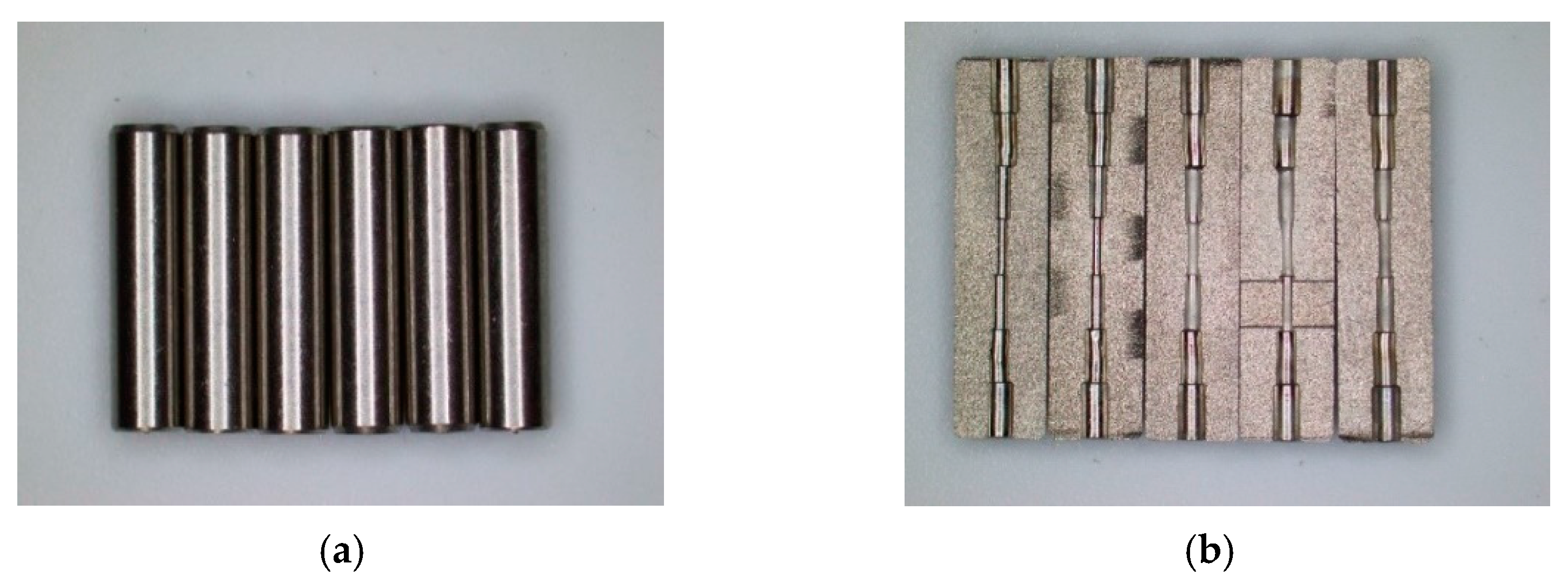

3.1. Selection of Workpieces

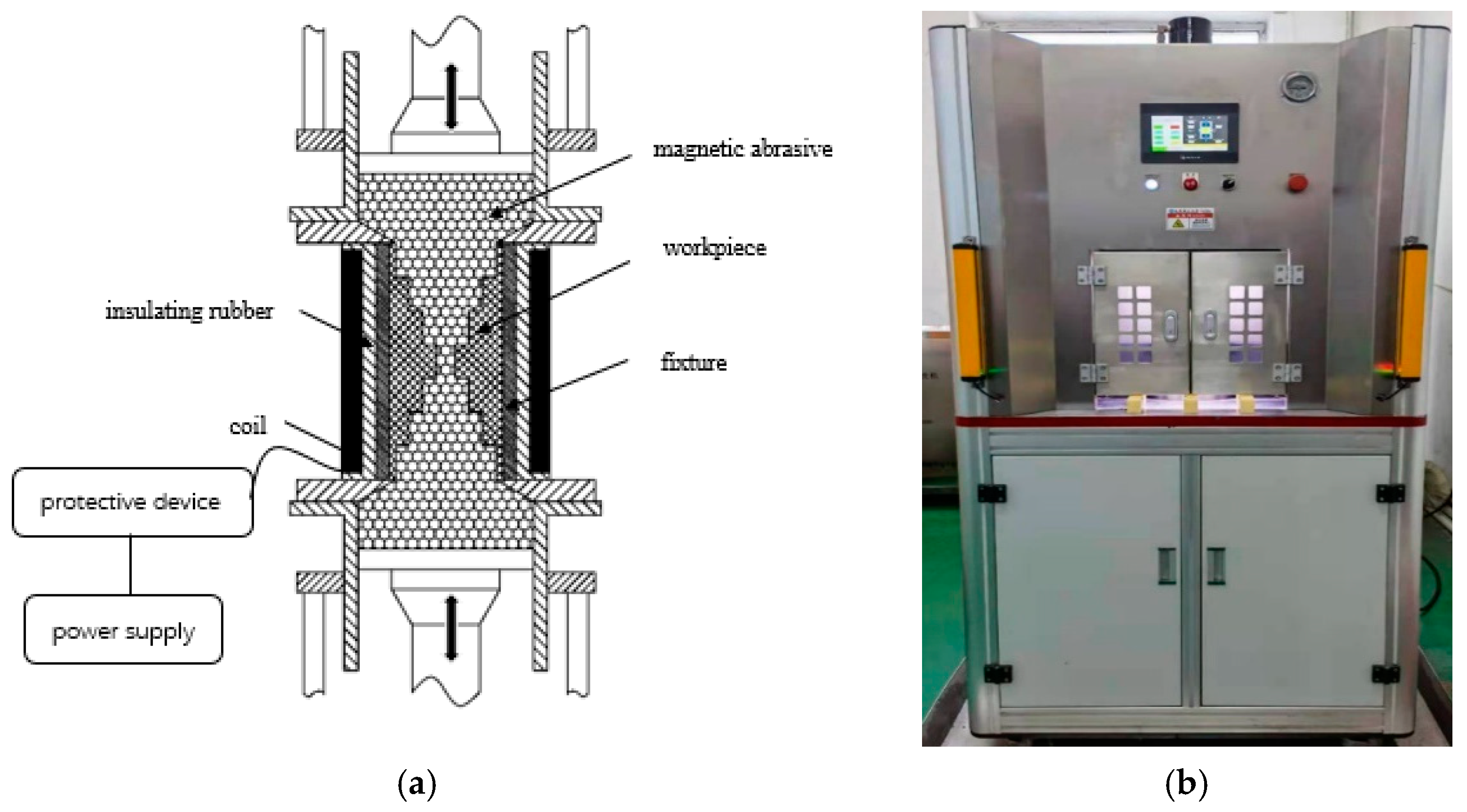

3.2. Experimental Design

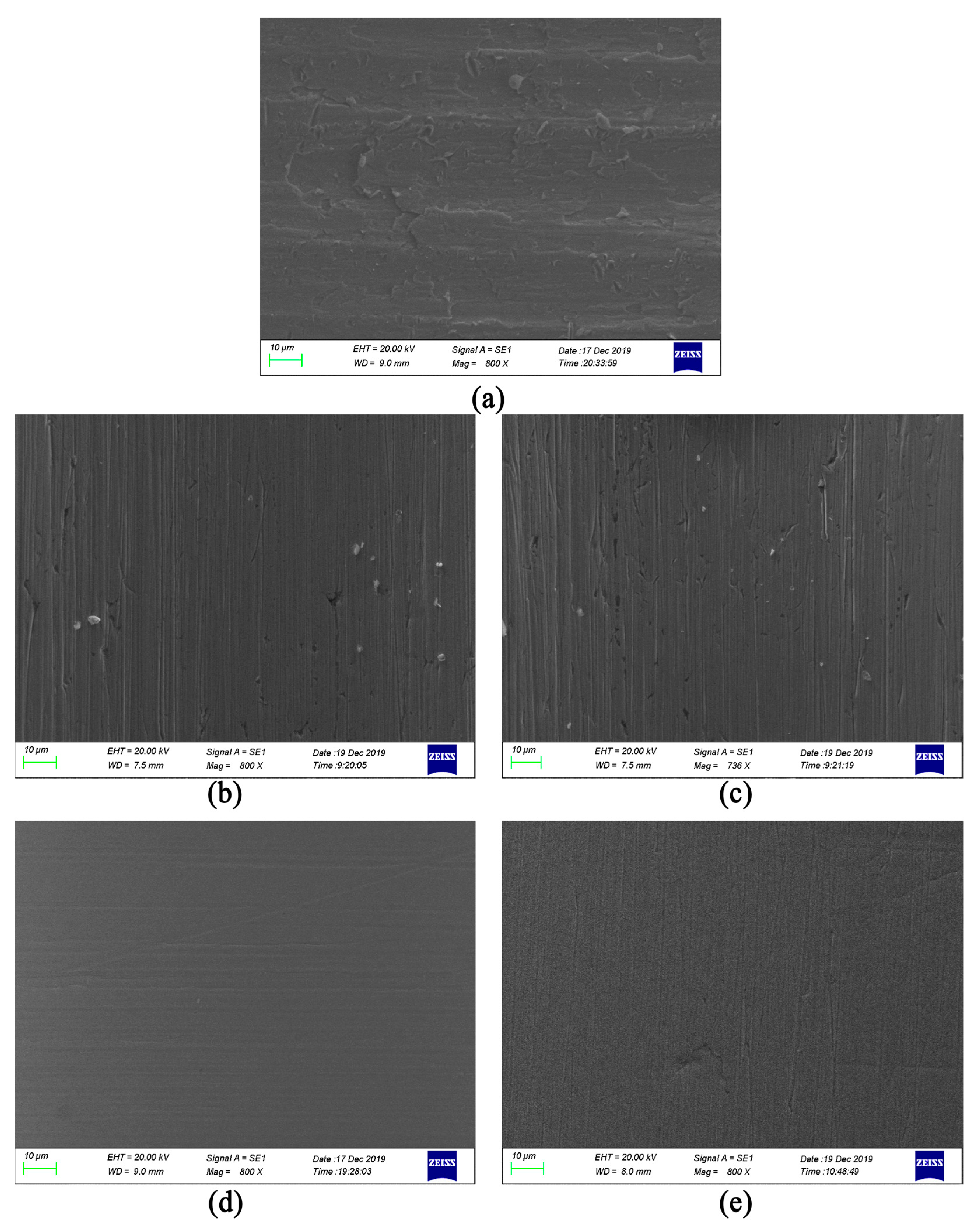

3.3. Surface Morphology Detection and Analysis

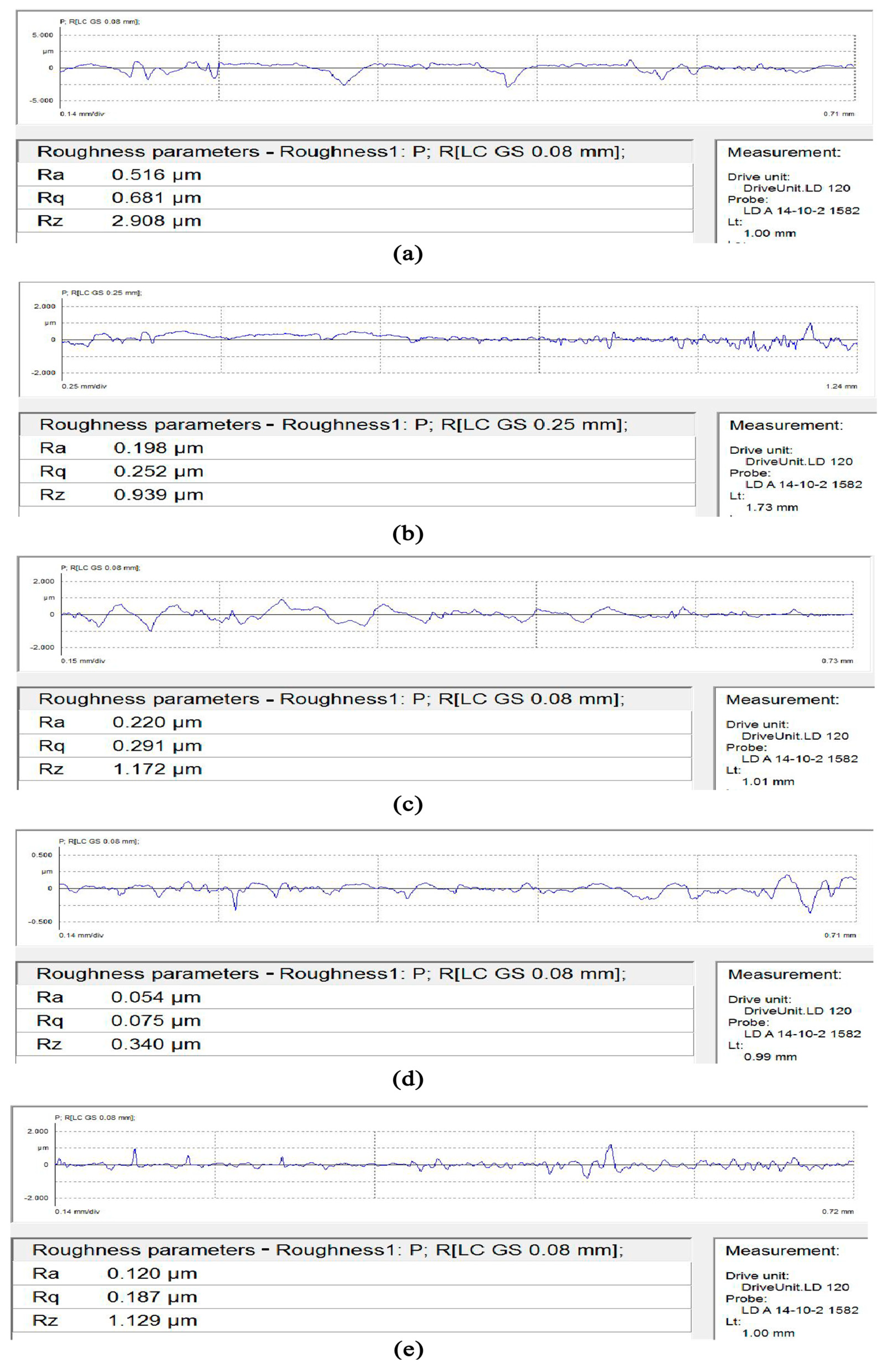

3.4. Surface Roughness Detection and Analysis

4. Numerical Simulation Analysis

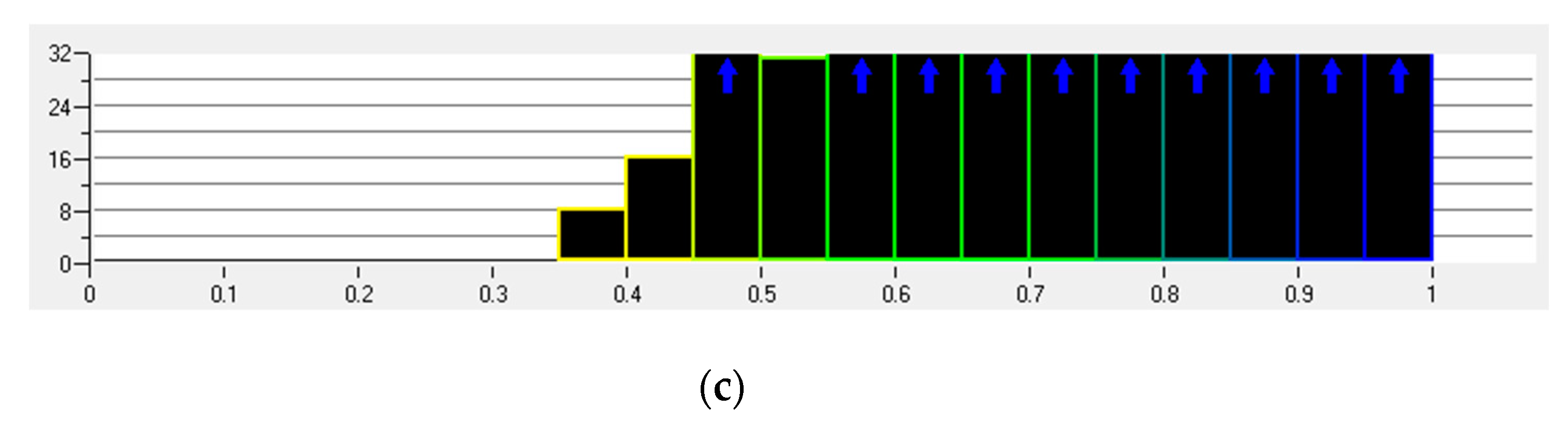

4.1. Model Building

4.2. Parameter Setting

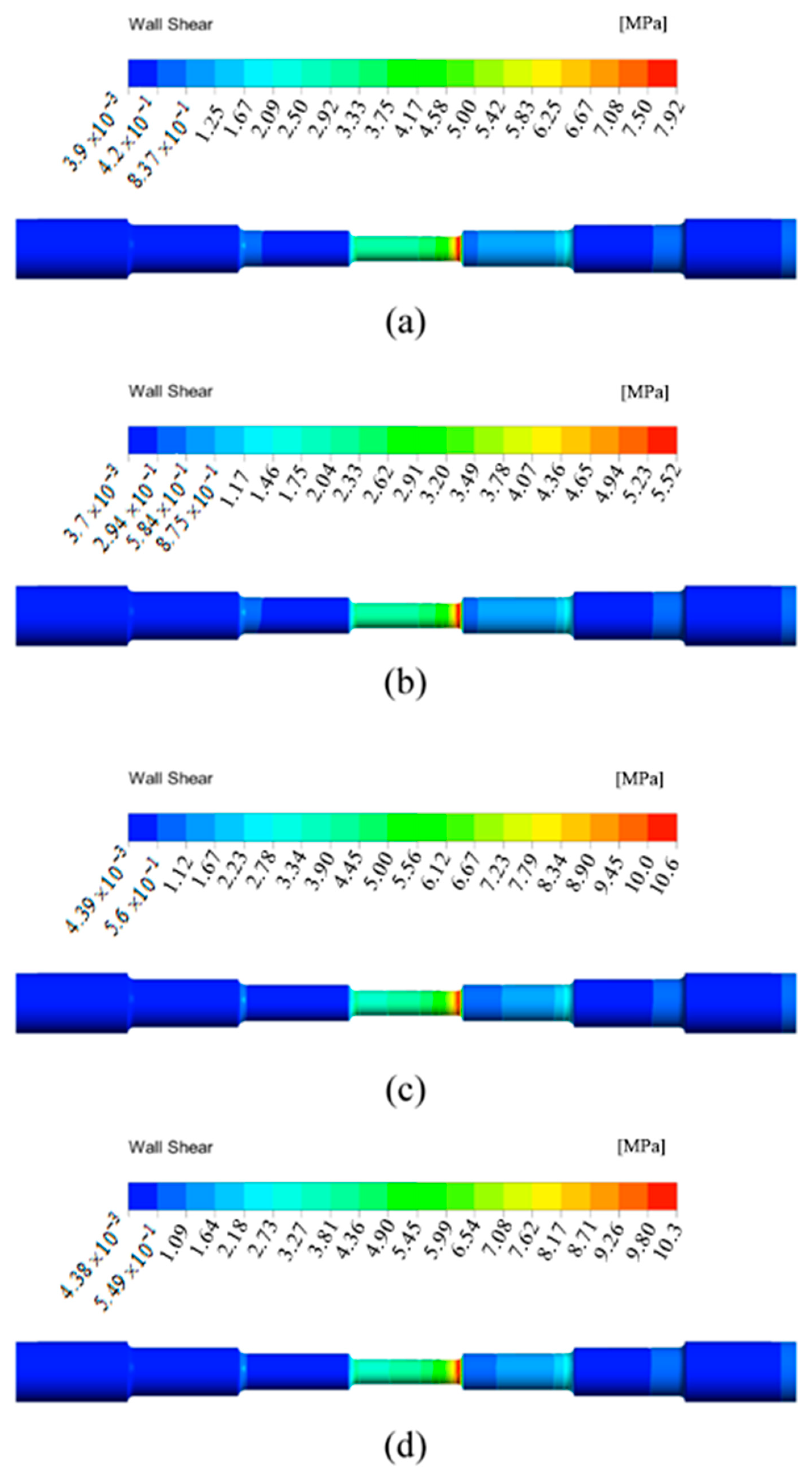

4.3. Simulation Result Analysis

5. Conclusions

- (1)

- The experimental results show that the optimal surface roughness is reduced by an order of magnitude, reaching Ra 0.054 μm. After polishing, the protrusions and burrs on the surface of the workpiece are eliminated, and the surface of the workpiece becomes smooth. SLTPMFP technology has reliability and superiority in improving the roughness of reducing pipe fittings.

- (2)

- The numerical simulation results show that the shear stress of the magnetic fluid on the workpiece under different parameter combinations affects the surface roughness of the workpiece. The greater the shear stress value, the lower the surface roughness of the workpiece. Due to the shear collision between the abrasive particles and the surface close to the wall, the speed and kinetic energy of the abrasive particles are reduced, and the polishing effect is weakened.

Author Contributions

Funding

Conflicts of Interest

References

- Li, J.; Zhang, H.; Wei, L.; Liu, Y.; Zhang, X.; Zhao, W. Quality prediction and discussion of an abrasive flow precision polishing baffle servo valve nozzle based on orthogonal experiments. JOM 2020, 72, 3236–3246. [Google Scholar] [CrossRef]

- Kim, K.J.; Kim, Y.G.; Kim, K.H. Deburring of offset hole intersection with abrasive flow machining. Trans. Korean Soc. Mech. Eng. A 2019, 43, 507–511. [Google Scholar] [CrossRef]

- Li, J.; Zhu, Z.; Hu, J.; Zhou, Z.; Zhang, X.; Zhao, W. Particle collision-based abrasive flow mechanisms in precision machining. Int. J. Adv. Manuf. Technol. 2020, 110, 1819–1831. [Google Scholar] [CrossRef]

- Munhoz, M.R.; Dias, L.G.; Breganon, R.; Ribeiro, F.S.; de Souza Gonçalves, J.F.; Hashimoto, E.M.; da Silva Júnior, C.E. Analysis of the surface roughness obtained by the abrasive flow machining process using an abrasive paste with oiticica oil. Int. J. Adv. Manuf. Technol. 2020, 106, 5061–5070. [Google Scholar] [CrossRef]

- Guo, J.; Song, C.; Fu, Y.; Au, K.H.; Kum, C.W.; Goh, M.H.; Ren, T.; Huang, R.; Sun, C.N. Internal surface quality enhancement of selective laser melted inconel 718 by abrasive flow machining. J. Manuf. Sci. E 2020, 142, 101003. [Google Scholar] [CrossRef]

- Khatekar, V.; Pawade, S. Analysis and modeling of surface characteristics in electrophoretic deposition–assisted internal polishing of AISI 304 steel. Int. J. Adv. Manuf. Technol. 2019, 104, 3083–3094. [Google Scholar] [CrossRef]

- Yuan, Q.; Huan, Q.; Wen, D. Numerical and experimental study on the spiral-rotating abrasive flow in polishing of the internal surface of 6061 aluminium alloy cylinder. Powder Technol. 2016, 302, 153–159. [Google Scholar] [CrossRef]

- Radkevich, M.; Kuzmichev, S. Technological Principles of Internal Surfaces Finishing by Forced Electrolytic-Plasma Polishing. Key Eng. Mater. 2019, 822, 634–639. [Google Scholar] [CrossRef]

- Tyagi, P.; Goulet, T.; Riso, C.; Stephenson, R.; Chuenprateep, N.; Schlitzer, J.; Benton, C.; Garcia-Moreno, F. Reducing the roughness of internal surface of an additive manufacturing produced 316 steel component by chempolishing and electropolishing. Addit. Manuf. 2019, 25, 32–38. [Google Scholar] [CrossRef] [Green Version]

- Qu, P.; Liu, W. Research on ultra-precision polisher for the internal surface of the elbow. Int. J. Electr. Eng. Educ. 2020, 0020720920940588. [Google Scholar] [CrossRef]

- Furumoto, T.; Ueda, T.; Amino, T.; Hosokawa, A. A study of internal face finishing of the cooling channel in injection mold with free abrasive grains. J. Mater. Process. Technol. 2011, 211, 1742–1748. [Google Scholar] [CrossRef]

- Barman, A.; Das, M. Design and fabrication of a novel polishing tool for finishing freeform surfaces in magnetic field assisted finishing (MFAF) process. Precis. Eng. 2017, 49, 61–68. [Google Scholar] [CrossRef]

- Song, W.; Peng, Z.; Li, P.; Shi, P.; Choi, S. Annular surface micromachining of titanium tubes using a magnetorheological polishing technique. Micromachines 2020, 11, 314. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Peng, Z.; Song, W.; Ye, C.; Shi, P.; Choi, S. Model establishment of surface roughness and experimental investigation on magnetorheological finishing for polishing the internal surface of titanium alloy tubes. J. Intell. Mater. 2021, 32, 1278–1289. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, H.; Kumar, A.; Jin, M. Experimental and theoretical study of internal finishing by a novel magnetically driven polishing tool. Int. J. Mach. Tools Manuf. 2020, 153, 103552. [Google Scholar] [CrossRef]

- Grover, V.; Singh, A. A novel magnetorheological honing process for nano-finishing of variable cylindrical internal surfaces. Mater. Manuf. Process. 2017, 32, 573–580. [Google Scholar] [CrossRef]

- Barman, A.; Das, M. Magnetic field assisted finishing process for super-finished Ti alloy implant and its 3D surface characterization. J. Micromanuf. 2018, 1, 154–169. [Google Scholar] [CrossRef]

- Huang, S.; Huang, J.; Hui, Z.; Li, M.; Ye, W. Wear calculation of sandblasting machine based on EDEM-FLUENT coupling. Int. J. Hydromechatron. 2018, 1, 447–459. [Google Scholar] [CrossRef]

- Kim, S.; Seo, J.; Lee, D.; Hong, D.; Kang, S.; Lee, M. Thermodynamic behaviors of magnetic-fluid in a thin channel with magnetic field and aspect ratio. Int. J. Precis. Eng. Manuf. 2014, 15, 1377–1382. [Google Scholar] [CrossRef]

- Parameswari, G.; Jain, V.K.; Ramkumar, J.; Nagdeve, L. Experimental investigations into nanofinishing of Ti6Al4V flat disc using magnetorheological finishing process. Int. J. Adv. Manuf. Technol. 2017, 100, 1055–1065. [Google Scholar] [CrossRef]

- Singh, P.; Singh, L.; Singh, S. Manufacturing and performance analysis of mechanically alloyed magnetic abrasives for magneto abrasive flow finishing. J. Manuf. Process. 2020, 50, 161–169. [Google Scholar] [CrossRef]

- Khan, D.A.; Jha, S. Synthesis of polishing fluid and novel approach for nanofinishing of copper using ball-end magnetorheological finishing process. Mater. Manuf. Process. 2017, 33, 1150–1159. [Google Scholar] [CrossRef]

- Ahmad Khan, D.; Jha, S. Selection of optimum polishing fluid composition for ball end magnetorheological finishing (BEMRF) of copper. Int. J. Adv. Manuf. Technol. 2017, 100, 1093–1103. [Google Scholar] [CrossRef]

- Murata, J.; Ueno, Y.; Yodogawa, K.; Sugiura, T. Polymer/CeO2–Fe3O4 multicomponent core–shell particles for high-efficiency magnetic-field-assisted polishing processes. Int. J. Mach. Tools Manuf. 2016, 101, 28–34. [Google Scholar] [CrossRef]

- Zhang, J.; Hu, J.; Wang, H.; Kumar, A.; Chaudhari, A. A novel magnetically driven polishing technique for internal surface finishing. Precis. Eng. 2018, 54, 222–232. [Google Scholar] [CrossRef]

- Guo, J.; Au, K.; Sun, C.; Goh, M.; Kum, C.; Liu, K.; Wei, J.; Suzuki, H.; Kang, R. Novel rotating-vibrating magnetic abrasive polishing method for double-layered internal surface finishing. J. Mater. Process. Technol. 2019, 264, 422–437. [Google Scholar] [CrossRef]

- Wang, C.; Cheung, C.; Ho, L.; Yung, K.; Kong, L. A novel magnetic field-assisted mass polishing of freeform surfaces. J. Mater. Process. Technol. 2020, 279, 116552. [Google Scholar] [CrossRef]

- Guo, J.; Wang, H.; Goh, M.; Liu, K. Investigation on surface integrity of rapidly solidified aluminum RSA 905 by magnetic field-assisted finishing. Micromachines 2018, 9, 146. [Google Scholar] [CrossRef] [Green Version]

- Wang, D.; Shinmura, T.; Yamaguchi, H. Study of magnetic field assisted mechanochemical polishing process for inner surface of Si3N4 ceramic components: Finishing characteristics under wet finishing using distilled water. Int. J. Mach. Tools Manuf. 2004, 44, 1547–1553. [Google Scholar] [CrossRef]

- Rosensweig, R. Directions in ferrohydrodynamics (invited). J. Appl. Phys. 1985, 57, 4259–4264. [Google Scholar] [CrossRef]

- Blums, E.; Mezulis, A.; Maiorov, M.; Kronkalns, G. Thermal diffusion of magnetic nanoparticles in ferrocolloids: Experiments on particle separation in vertical columns. J. Magn. Magn. Mater. 1997, 169, 220–228. [Google Scholar] [CrossRef]

- Shliomis, M. Magnetic fluids. Sov. Phys. Uspekhi 1974, 17, 427–458. [Google Scholar] [CrossRef]

- Li, J.; Wang, L.; Zhang, H.; Hu, J.; Zhang, X.; Zhao, W. Mechanism research and discussion of the quality of precision machining of a fifth-order variable-diameter pipe using abrasive flow. Stroj. Vestn. J. Mech. Eng. 2020, 66, 358–374. [Google Scholar] [CrossRef]

- Miao, C.; Shafrir, S.N.; Lambropoulos, J.C.; Mici, J.; Jacobs, S.D. Shear stress in magnetorheological finishing for glasses. Appl. Opt. 2009, 48, 2585–2594. [Google Scholar] [CrossRef]

- Li, W.; Li, X.; Yang, S.; Li, W. A newly developed media for magnetic abrasive finishing process: Material removal behavior and finishing performance. J. Mater. Process. Technol. 2018, 260, 20–29. [Google Scholar] [CrossRef]

- Kathiresan, S.; Mohan, B. Multi-objective optimization of magneto rheological abrasive flow nano finishing process on AISI stainless steel 316L. J. Nano Res. 2020, 63, 98–111. [Google Scholar] [CrossRef]

| Experiment Number | Inlet Velocity (m/s) | Voltage (V) | Abrasive Particle Size (μm) |

|---|---|---|---|

| Sample #1 | 30 | 15 | 500 |

| Sample #2 | 30 | 45 | 500 |

| Sample #3 | 50 | 45 | 500 |

| Sample #4 | 50 | 45 | 1200 |

| Experiment Number | Roughness (μm) |

|---|---|

| Original 0# | 0.516 |

| Sample 1# | 0.198 |

| Sample 2# | 0.220 |

| Sample 3# | 0.054 |

| Sample 4# | 0.120 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, J.; Gui, L.; Hou, W.; Sun, L.; Liu, Y.; Li, J. Quality Study and Numerical Simulation Analysis of Solid–Liquid Two-Phase Magnetic Fluid Polishing Seven-Order Variable-Diameter Pipe. Micromachines 2022, 13, 500. https://doi.org/10.3390/mi13040500

Guo J, Gui L, Hou W, Sun L, Liu Y, Li J. Quality Study and Numerical Simulation Analysis of Solid–Liquid Two-Phase Magnetic Fluid Polishing Seven-Order Variable-Diameter Pipe. Micromachines. 2022; 13(4):500. https://doi.org/10.3390/mi13040500

Chicago/Turabian StyleGuo, Jing, Lin Gui, Wei Hou, Liwei Sun, Yang Liu, and Junye Li. 2022. "Quality Study and Numerical Simulation Analysis of Solid–Liquid Two-Phase Magnetic Fluid Polishing Seven-Order Variable-Diameter Pipe" Micromachines 13, no. 4: 500. https://doi.org/10.3390/mi13040500

APA StyleGuo, J., Gui, L., Hou, W., Sun, L., Liu, Y., & Li, J. (2022). Quality Study and Numerical Simulation Analysis of Solid–Liquid Two-Phase Magnetic Fluid Polishing Seven-Order Variable-Diameter Pipe. Micromachines, 13(4), 500. https://doi.org/10.3390/mi13040500