Route to Cost-Effective Fabrication of Wafer-Scale Nanostructure through Self-Priming Nanoimprint

Abstract

1. Introduction

2. Materials and Methods

2.1. PDMS Mold Fabrication

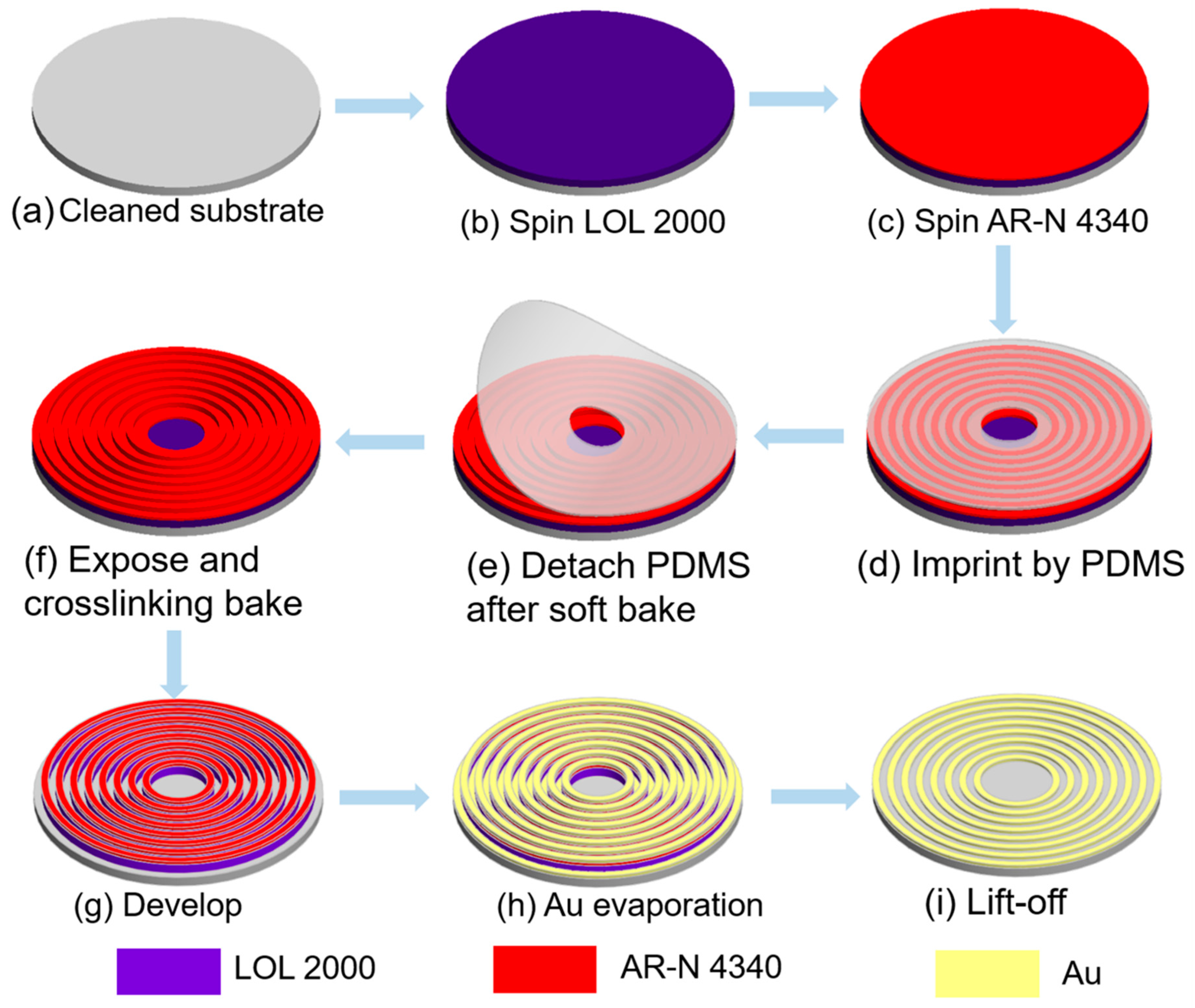

2.2. Double-Layer Self-Priming Lithography on Hard and Soft Substrates

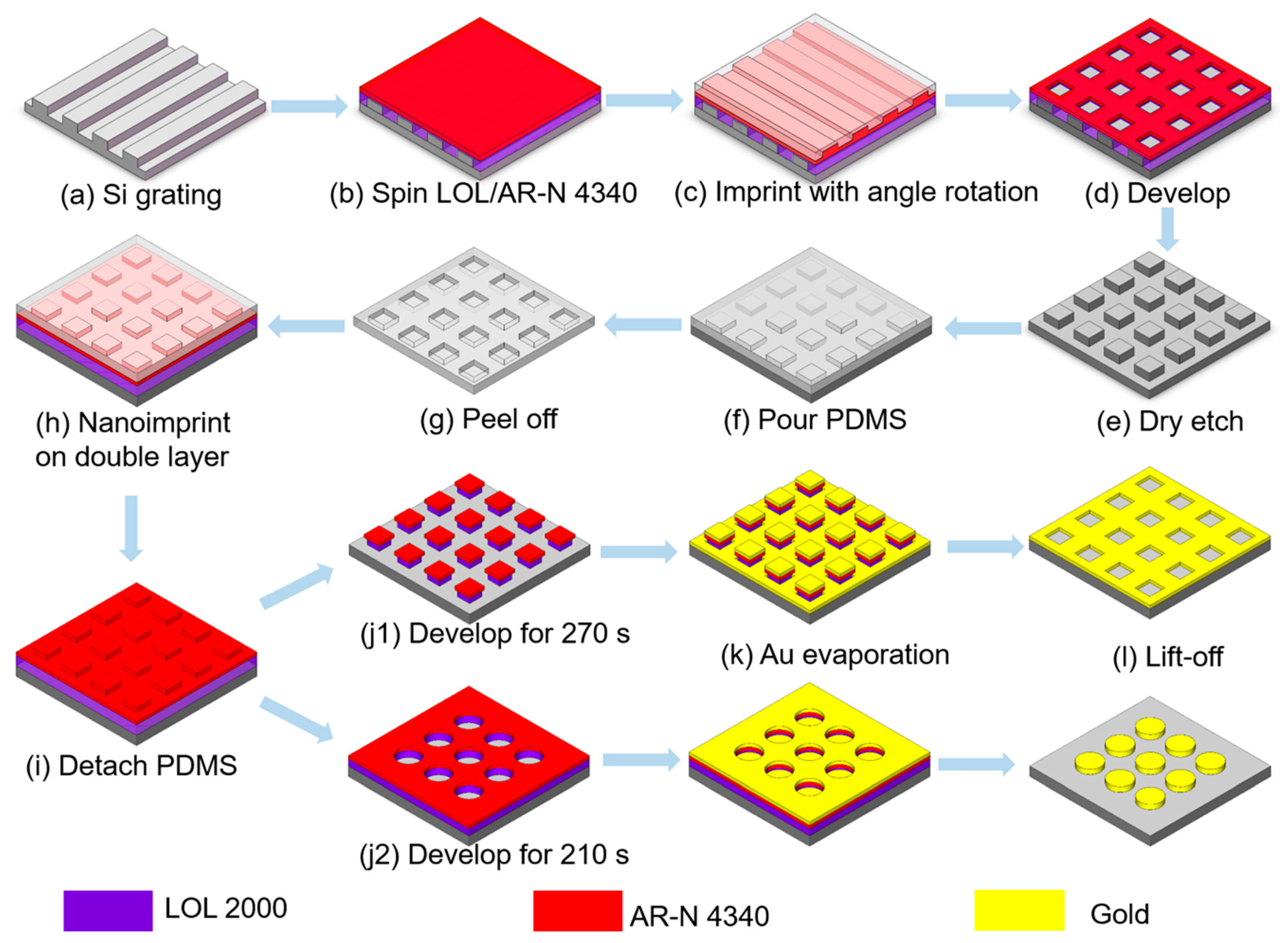

2.3. Gold Nanoparticle and Nanohole Arrays Fabrication

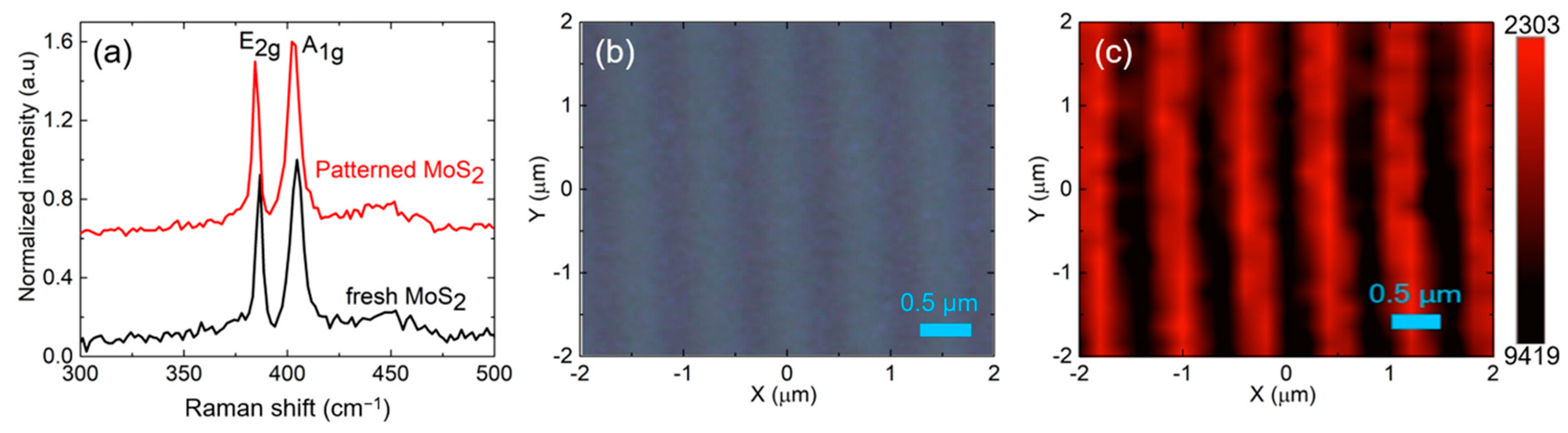

2.4. MoS2 Gratings Fabrication

2.5. Reflection Spectra Detection

2.6. Raman Characterizations

3. Results

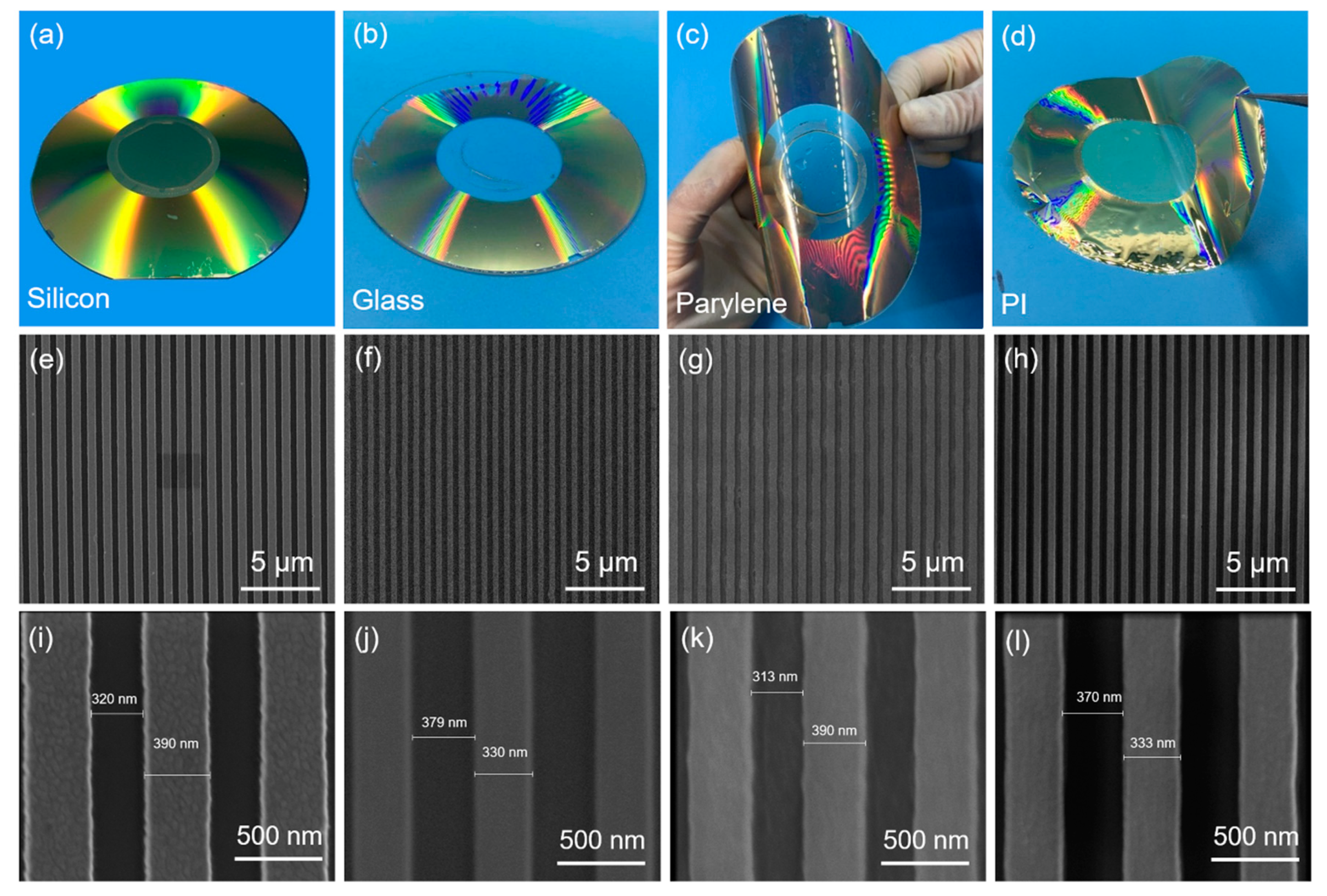

3.1. Gold Gratings Fabricated on Different Substrates

3.2. Characterization of Uniformity

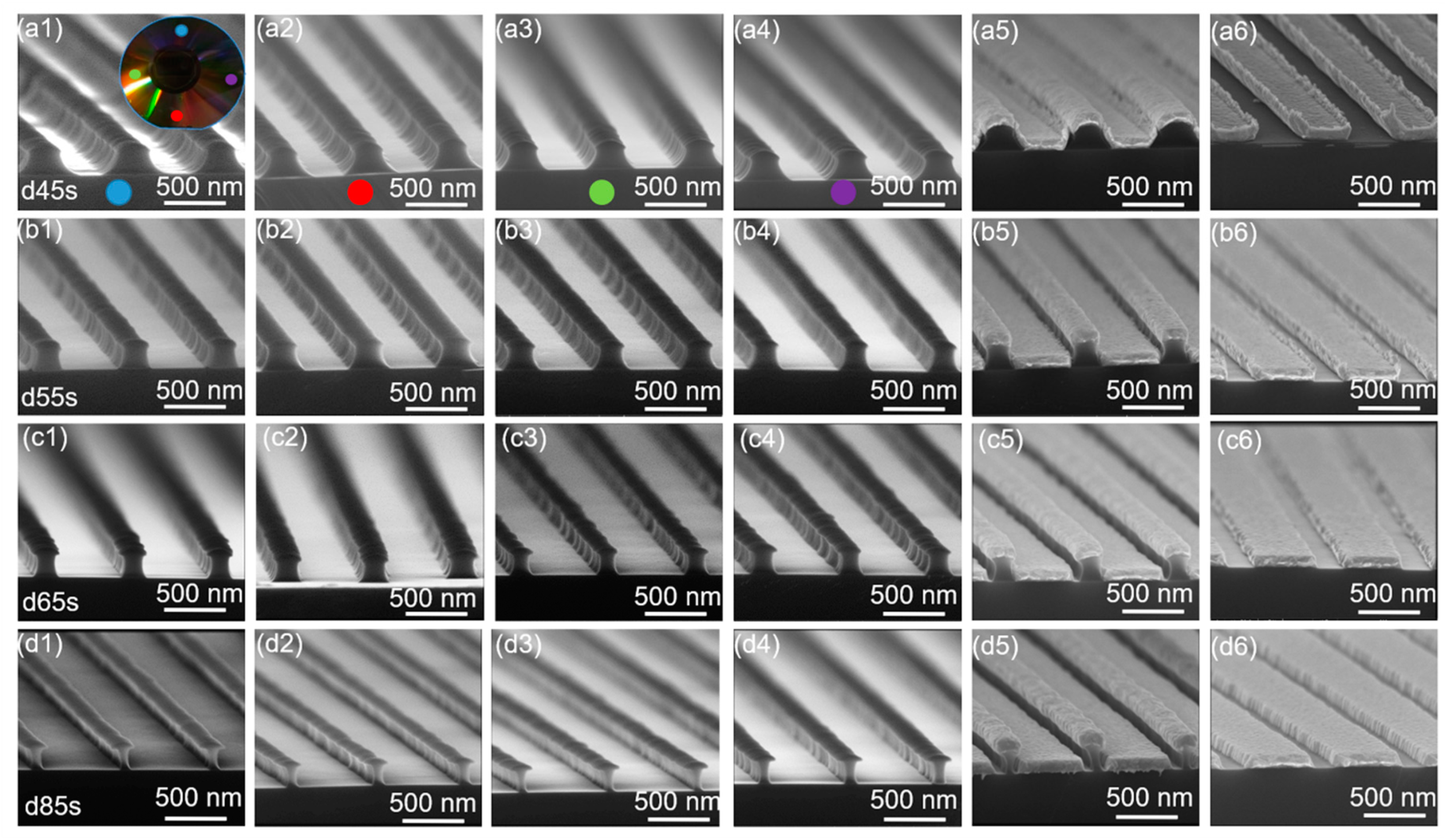

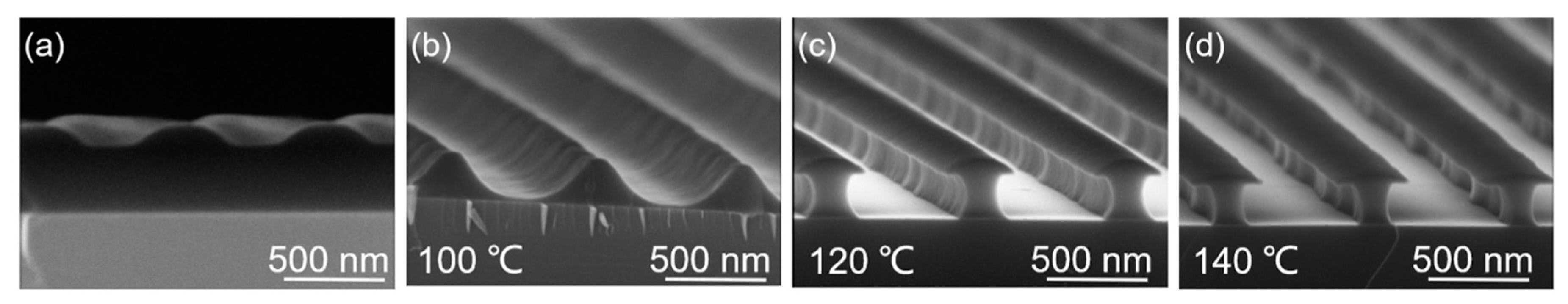

3.3. Effect of Crosslinking Bake Temperature

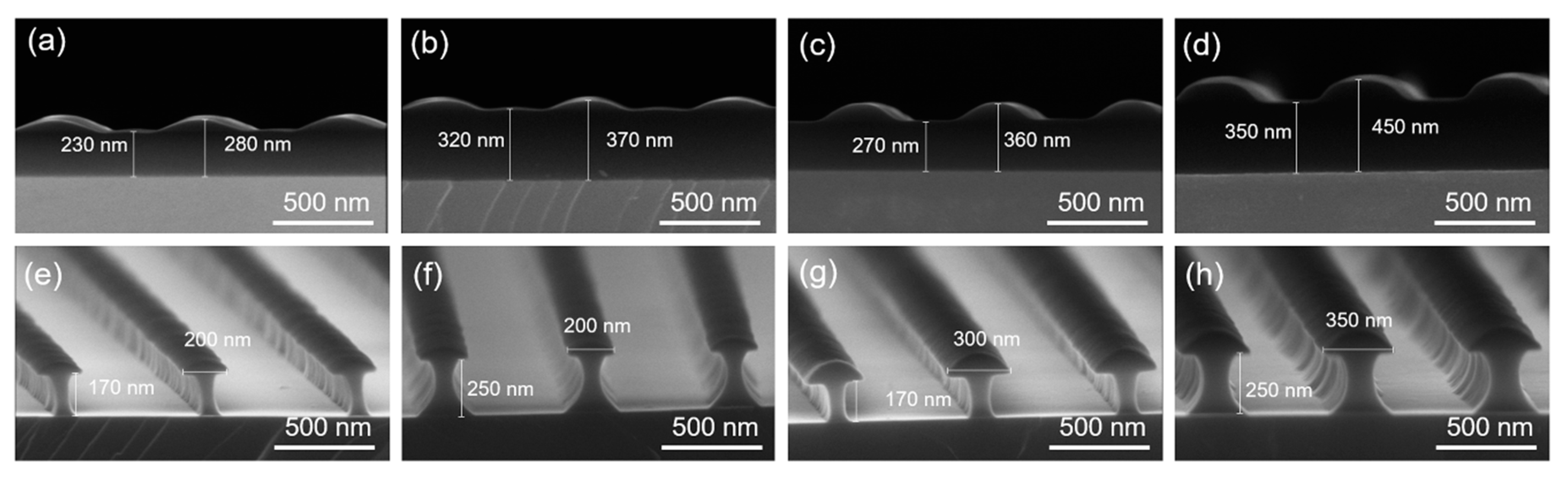

3.4. Effect of Photoresist Thickness

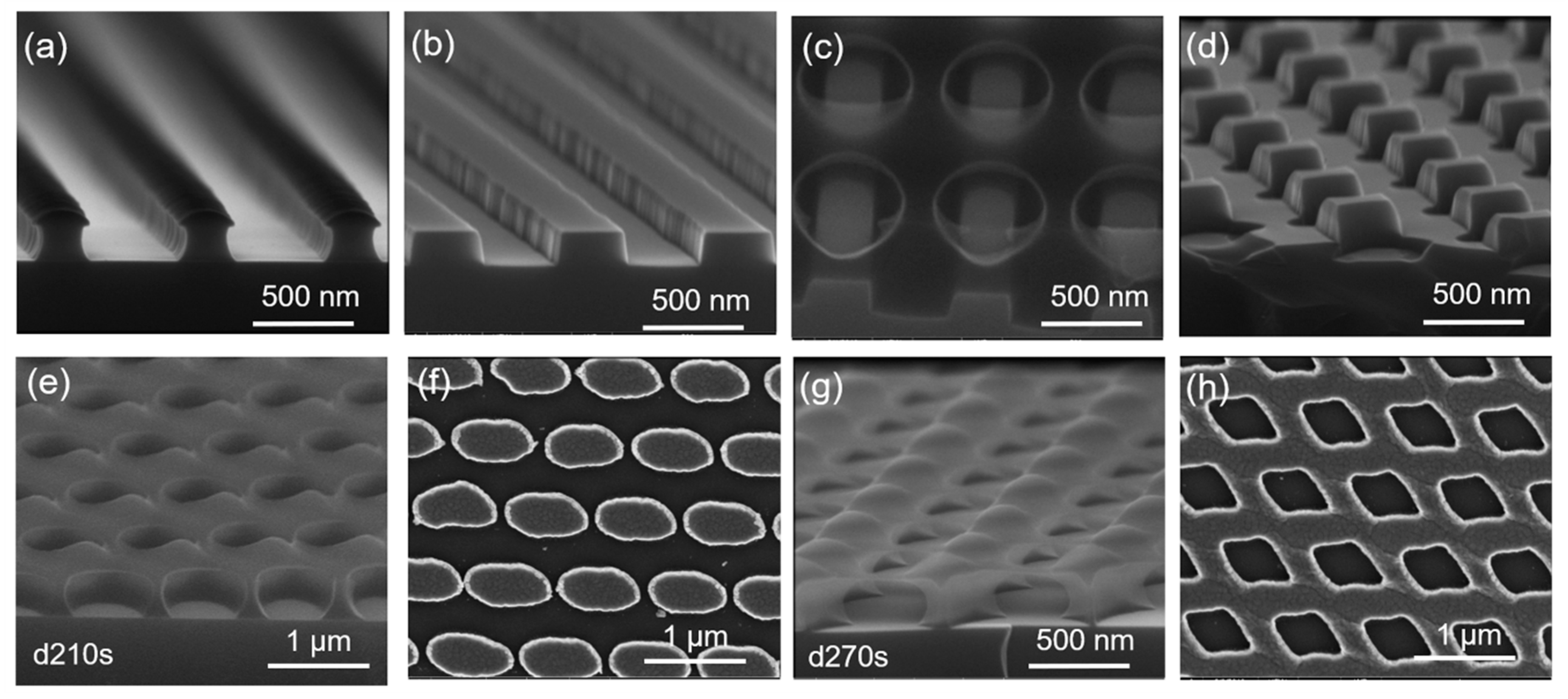

3.5. Gold Nanohole and Nanoparticle

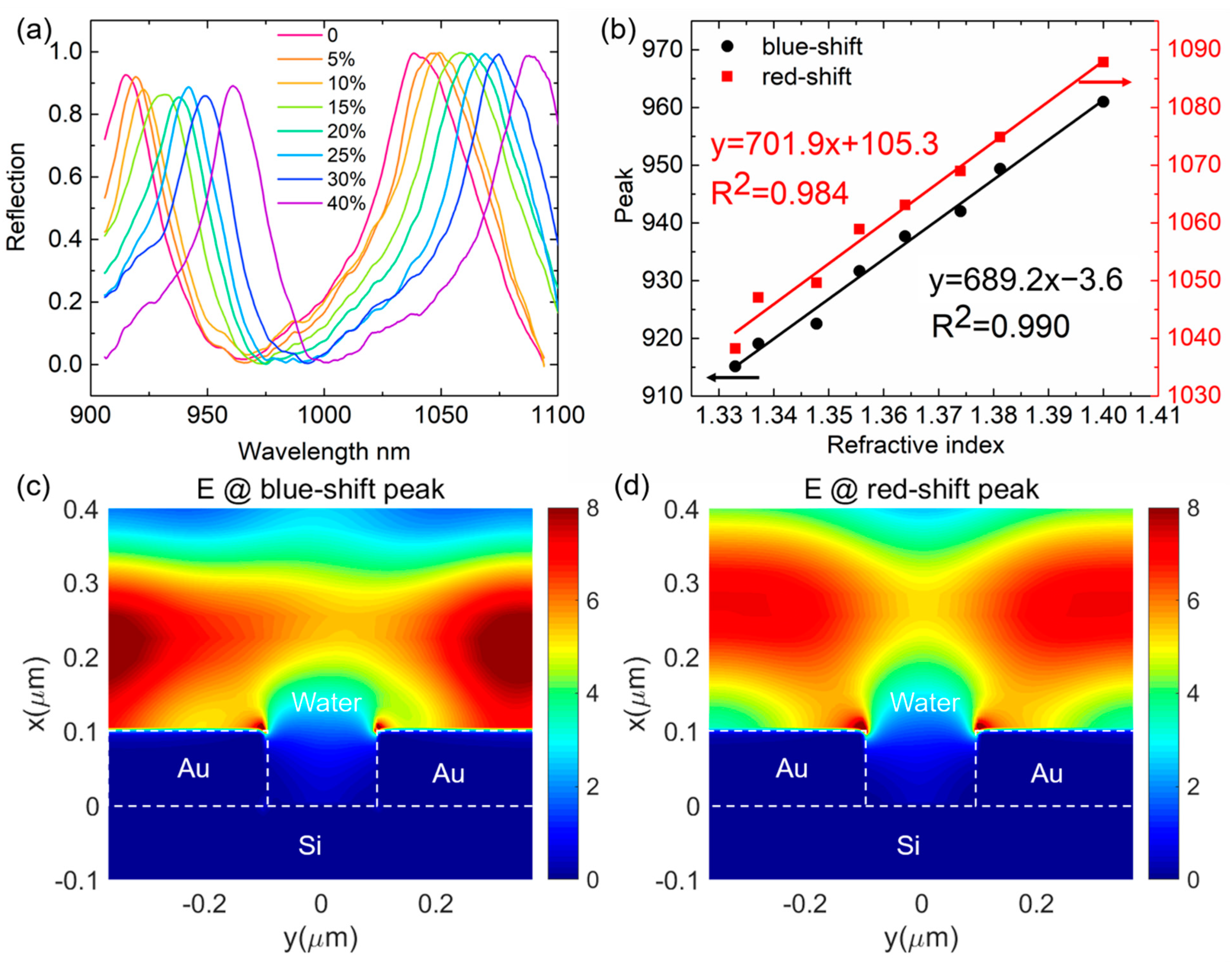

3.6. Refractive Index Sensor

3.7. MoS2 Nanogratings

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Zhang, Q.; Uchaker, E.; Candelaria, S.L.; Cao, G. Nanomaterials for energy conversion and storage. Chem. Soc. Rev. 2013, 42, 3127–3171. [Google Scholar] [CrossRef] [PubMed]

- Im, H.; Shao, H.; Park, Y.I.; Peterson, V.M.; Castro, C.M.; Weissleder, R.; Lee, H. Label-free detection and molecular profiling of exosomes with a nano-plasmonic sensor. Nat. Biotechnol. 2014, 32, 490–495. [Google Scholar] [CrossRef] [PubMed]

- Luo, X.; Tsai, D.; Gu, M.; Hong, M. Extraordinary optical fields in nanostructures: From sub-diffraction-limited optics to sensing and energy conversion. Chem. Soc. Rev. 2019, 48, 2458–2494. [Google Scholar] [CrossRef] [PubMed]

- Lee, H.K.; Lee, Y.H.; Koh, C.S.L.; Phan-Quang, G.C.; Han, X.; Lay, C.L.; Sim, H.Y.F.; Kao, Y.-C.; An, Q.; Ling, X.Y. Designing surface-enhanced Raman scattering (SERS) platforms beyond hotspot engineering: Emerging opportunities in analyte manipulations and hybrid materials. Chem. Soc. Rev. 2019, 48, 731–756. [Google Scholar] [CrossRef]

- Gonçalves, G.; Borme, J.; Bdkin, I.; González-Mayorga, A.; Irurueta, G.; Nogueira, H.I.S.; Serrano, M.C.; Alpuim, P.; Marques, P.A.A.P. Reductive nanometric patterning of graphene oxide paper using electron beam lithography. Carbon 2018, 129, 63–75. [Google Scholar] [CrossRef]

- Lewis, S.M.; Hunt, M.S.; DeRose, G.A.; Alty, H.R.; Li, J.; Wertheim, A.; De Rose, L.; Timco, G.A.; Scherer, A.; Yeates, S.G.; et al. Plasma-etched pattern transfer of sub-10 nm structures using a metal–organic resist and helium ion beam lithography. Nano Lett. 2019, 19, 6043–6048. [Google Scholar] [CrossRef]

- Horák, M.; Bukvišová, K.; Švarc, V.; Jaskowiec, J.; Křápek, V.; Šikola, T. Comparative study of plasmonic antennas fabricated by electron beam and focused ion beam lithography. Sci. Rep. 2018, 8, 9640. [Google Scholar] [CrossRef]

- Suh, K.Y.; Lee, H.H. Capillary Force Lithography: Large-area patterning, self-organization, and anisotropic dewetting. Adv. Funct. Mater. 2002, 12, 405–413. [Google Scholar] [CrossRef]

- Chou, S.Y.; Krauss, P.R.; Renstrom, P.J. Imprint lithography with 25-nanometer resolution. Science 1996, 272, 85–87. [Google Scholar] [CrossRef]

- Xia, Y.; Whitesides, G.M. Soft lithography. Annu. Rev. Mater. Sci. 1998, 28, 153–184. [Google Scholar] [CrossRef]

- Qin, D.; Xia, Y.; Whitesides, G.M. Soft lithography for micro- and nanoscale patterning. Nat. Protoc. 2010, 5, 491–502. [Google Scholar] [CrossRef] [PubMed]

- Lee, M.H.; Huntington, M.D.; Zhou, W.; Yang, J.-C.; Odom, T.W. Programmable soft lithography: Solvent-assisted nanoscale embossing. Nano Lett. 2011, 11, 311–315. [Google Scholar] [CrossRef] [PubMed]

- Henzie, J.; Lee, M.H.; Odom, T.W. Multiscale patterning of plasmonic metamaterials. Nat. Nanotech. 2007, 2, 549–554. [Google Scholar] [CrossRef] [PubMed]

- Suh, D.; Tak, H.; Choi, S.-j.; Kim, T.-i. Permeability- and Surface-Energy-Tunable Polyurethane Acrylate Molds for Capillary Force Lithography. ACS Appl. Mater. Interfaces 2015, 7, 23824–23830. [Google Scholar] [CrossRef]

- Liu, X.; Bhandaru, N.; Banik, M.; Wang, X.; Al-Enizi, A.M.; Karim, A.; Mukherjee, R. Capillary force lithography pattern-directed self-assembly (CFL-PDSA) of phase-separating polymer blend thin films. ACS Omega 2018, 3, 2161–2168. [Google Scholar] [CrossRef]

- Wang, J.; Min, G.; Song, Z.; Ni, X.; Zhou, W.; Zhan, J.; Zhang, Y.; Zhang, J.; Shi, L. Solvent-infiltration imprint lithography: A novel method to prepare large area poly(3-hexylthiophene) micro/nano-patterns. J. Mater. Chem. 2012, 22, 21154–21158. [Google Scholar] [CrossRef]

- Zhang, X.; Xu, Y.; Zhang, W.; Fu, X.; Hao, Z.; He, M.; Trefilov, D.; Ning, X.; Ge, H.; Chen, Y. Controllable subtractive nanoimprint lithography for precisely fabricating paclitaxel-loaded PLGA nanocylinders to enhance anticancer efficacy. ACS Appl. Mater. Interfaces 2020, 12, 14797–14805. [Google Scholar] [CrossRef]

- Hu, X.; Wang, H.; Zhai, C.; Ge, H.; Cui, Y. Fabrication of metallic patterns on highly curved substrates via nanoimprint lithography in association with an etch-in process. J. Mater. Chem. C 2016, 4, 11104–11109. [Google Scholar] [CrossRef]

- Li, Y.; Choi, J.; Sun, Z.; Russell, T.P.; Carter, K.R. Fabrication of sub-20 nm patterns using dopamine chemistry in self-aligned double patterning. Nanoscale 2018, 10, 20779–20784. [Google Scholar] [CrossRef]

- Rommel, M.; Nilsson, B.; Jedrasik, P.; Bonanni, V.; Dmitriev, A.; Weis, J. Sub-10nm resolution after lift-off using HSQ/PMMA double layer resist. Microelectron. Eng. 2013, 110, 123–125. [Google Scholar] [CrossRef]

- Sung, S.; Kim, C.-H.; Lee, J.; Jung, J.-Y.; Jeong, J.-H.; Choi, J.-H.; Lee, E.-S. Advanced metal lift-offs and nanoimprint for plasmonic metal patterns. Int. J. Precis. Eng. Manuf.-Green Tech. 2014, 1, 25–30. [Google Scholar] [CrossRef][Green Version]

- Kwon, B.S.; Zhang, W.; Li, Z.; Krishnan, K.M. Direct release of sombrero-shaped magnetite nanoparticles via nanoimprint lithography. Adv. Mater. Interfaces 2015, 2, 1400511. [Google Scholar] [CrossRef]

- Wang, S.; Shi, Q.; Chai, J.; Cheng, K.; Du, Z. Double layer lift-off nanofabrication controlled gaps of nanoelectrodes with sub-100 nm by nanoimprint lithography. Nanotechnology 2015, 26, 185301. [Google Scholar] [CrossRef] [PubMed]

- Bhandaru, N.; Roy, S.; Harikrishnan, G.; Mukherjee, R. Lithographic tuning of polymeric thin film surfaces by stress relaxation. ACS Macro Lett. 2013, 2, 195–200. [Google Scholar] [CrossRef]

- Shi, S.; Lu, N.; Lu, Y.; Wang, Y.; Qi, D.; Xu, H.; Chi, L. Fabrication of periodic metal nanowires with microscale mold by nanoimprint lithography. ACS Appl. Mater. Interfaces 2011, 3, 4174–4179. [Google Scholar] [CrossRef]

- Odom, T.W.; Love, J.C.; Wolfe, D.B.; Paul, K.E.; Whitesides, G.M. Improved pattern transfer in soft lithography using composite stamps. Langmuir 2002, 18, 5314–5320. [Google Scholar] [CrossRef]

- Lin, L.; Bidstrup, S.A. Processing effects on optical anisotropy in spin-coated polyimide films. J. Appl. Polym. Sci. 1993, 49, 1277–1289. [Google Scholar] [CrossRef]

- Staufert, S.; Gutzwiller, P.; Mushtaq, F.; Hierold, C. Surface nanostructuring of Ti6Al4 V surfaces for parylene-C coatings with ultradurable adhesion. ACS Appl. Nano Mater. 2018, 1, 1586–1594. [Google Scholar] [CrossRef]

- Gao, H.; Henzie, J.; Lee, M.H.; Odom, T.W. Screening plasmonic materials using pyramidal gratings. Proc. Natl. Acad. Sci. USA 2008, 105, 20146–20151. [Google Scholar] [CrossRef]

- Kothari, R.; Beaulieu, M.R.; Hendricks, N.R.; Li, S.; Watkins, J.J. Direct patterning of robust one-dimensional, two-dimensional, and three-dimensional crystalline metal oxide nanostructures using imprint lithography and nanoparticle dispersion inks. Chem. Mater. 2017, 29, 3908–3918. [Google Scholar] [CrossRef]

- Suh, K.Y.; Kim, P.; Lee, H.H. Capillary kinetics of thin polymer films in permeable microcavities. Appl. Phys. Lett. 2004, 85, 4019–4021. [Google Scholar] [CrossRef]

- Yoo, D.; Nguyen, N.-C.; Martin-Moreno, L.; Mohr, D.A.; Carretero-Palacios, S.; Shaver, J.; Peraire, J.; Ebbesen, T.W.; Oh, S.-H. High-throughput fabrication of resonant metamaterials with ultrasmall coaxial apertures via atomic layer lithography. Nano Lett. 2016, 16, 2040–2046. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Gu, C.; Li, J. Sub-5 nm metal nanogaps: Physical properties, fabrication methods, and device applications. Small 2019, 15, 1804177. [Google Scholar] [CrossRef] [PubMed]

- Suresh, V.; Ding, L.; Chew, A.B.; Yap, F.L. Fabrication of large-area flexible SERS substrates by nanoimprint lithography. ACS Appl. Nano Mater. 2018, 1, 886–893. [Google Scholar] [CrossRef]

- Hwang, S.H.; Zhao, Z.-J.; Jeon, S.; Kang, H.; Ahn, J.; Jeong, J.H. Repeatable and metal-independent nanotransfer printing based on metal oxidation for plasmonic color filters. Nanoscale 2019, 11, 11128–11137. [Google Scholar] [CrossRef]

- Silvestri, D.; Sonato, A.; Ruffato, G.; Meneghello, A.; Antognoli, A.; Cretaio, E.; Dettin, M.; Zamuner, A.; Casarin, E.; Zacco, G.; et al. A peptide nucleic acid label-free biosensor for Mycobacterium tuberculosis DNA detection via azimuthally controlled grating-coupled SPR. Anal. Methods 2015, 7, 4173–4180. [Google Scholar] [CrossRef]

- Wang, Y.; Sun, C.; Li, H.; Gong, Q.; Chen, J. Self-reference plasmonic sensors based on double Fano resonances. Nanoscale 2017, 9, 11085–11092. [Google Scholar] [CrossRef]

- Lee, K.-L.; Hung, C.-Y.; Pan, M.-Y.; Wu, T.-Y.; Yang, S.-Y.; Wei, P.-K. Dual Sensing Arrays for surface plasmon resonance (SPR) and surface-enhanced Raman scattering (SERS) based on nanowire/nanorod hybrid nanostructures. Adv. Mater. Interfaces 2018, 5, 1801064. [Google Scholar] [CrossRef]

- Menghrajani, K.S.; Nash, G.R.; Barnes, W.L. Vibrational strong coupling with surface plasmons and the presence of surface Plasmon Stop Bands. ACS Photonics 2019, 6, 2110–2116. [Google Scholar] [CrossRef]

- Wu, F.; Liu, L.; Feng, L.; Xu, D.; Lu, N. Improving the sensing performance of double gold gratings by oblique incident light. Nanoscale 2015, 7, 13026–13032. [Google Scholar] [CrossRef]

- Iqbal, T.; Afsheen, S. One Dimensional plasmonic grating: High sensitive biosensor. Plasmonics 2017, 12, 19–25. [Google Scholar] [CrossRef]

- Lee, C.; Yan, H.; Brus, L.E.; Heinz, T.F.; Hone, J.; Ryu, S. Anomalous lattice vibrations of single- and few-layer MoS2. ACS Nano 2010, 4, 2695–2700. [Google Scholar] [CrossRef] [PubMed]

- Zhao, J.; Yu, H.; Chen, W.; Yang, R.; Zhu, J.; Liao, M.; Shi, D.; Zhang, G. Patterned peeling 2D MoS2 off the substrate. ACS Appl. Mater. Interfaces 2016, 8, 16546–16550. [Google Scholar] [CrossRef] [PubMed]

- Zuo, P.; Jiang, L.; Li, X.; Tian, M.; Xu, C.; Yuan, Y.; Ran, P.; Li, B.; Lu, Y. Maskless micro/nanopatterning and bipolar electrical rectification of MoS2 flakes through femtosecond laser direct writing. ACS Appl. Mater. Interfaces 2019, 11, 39334–39341. [Google Scholar] [CrossRef]

- Hong, Q.; Chen, X.; Zhang, J.; Zhu, Z.; Qin, S.; Yuan, X. Remarkably high-Q resonant nanostructures based on atomically thin two-dimensional materials. Nanoscale 2019, 11, 23149–23155. [Google Scholar] [CrossRef]

- Islam, M.A.; Kim, J.H.; Ko, T.-J.; Noh, C.; Nehate, S.; Kaium, M.G.; Ko, M.; Fox, D.; Zhai, L.; Cho, C.-H.; et al. Three dimensionally-ordered 2D MoS2 vertical layers integrated on flexible substrates with stretch-tunable functionality and improved sensing capability. Nanoscale 2018, 10, 17525–17533. [Google Scholar] [CrossRef]

- Liu, R.; Liao, B.; Guo, X.; Hu, D.; Hu, H.; Du, L.; Yu, H.; Zhang, G.; Yang, X.; Dai, Q. Study of graphene plasmons in graphene–MoS2 heterostructures for optoelectronic integrated devices. Nanoscale 2017, 9, 208–215. [Google Scholar] [CrossRef]

| The spin-speed of AR-N-4340 | 6000 rpm | 3000 rpm | 2000 rpm |

| The thickness of AR-N-4340 | 62 nm | 80 nm | 105 nm |

| The nanoimprint height difference (NHD) before development | 50 nm | 90 nm | 100 nm |

| The width of top photoresist (w1) after development | 200 nm | 300 nm | 350 nm |

| Concentration of tetramethylammonium hydroxide (TMAH) | 1.2% | 1.6% | 1.6% |

| Imprint Material | Imprint Condition | Curing Process | Transfer Structure | Structure | Resolution | Reference |

|---|---|---|---|---|---|---|

| AR-N-4340 | Self-priming | heat | lift-off | grating, particle, hole | 165 nm | this work |

| PS/Polymethyl methacrylate (PMMA) blend film | 4 kPa; 180 °C | cool | no | grating | 400 nm | Ref. [15] |

| PC sheet | 50 bar; 160 °C | cool | Evaporation without lift-off | nanocone | 100 nm | Ref. [34] |

| ultraviolet (UV)-curable resin | With pressure | UV-curing | template stripping | grating | 100 nm | Ref. [35] |

| UV resist | no | UV-curing | dry etch | nanodot | 60 nm | Ref. [17] |

| poly(methyl methacrylate) | 300 psi; 140 °C | cool | no | grating | 13 nm | Ref. [19] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Su, Y.; Geng, Z.; Fang, W.; Lv, X.; Wang, S.; Ma, Z.; Pei, W. Route to Cost-Effective Fabrication of Wafer-Scale Nanostructure through Self-Priming Nanoimprint. Micromachines 2021, 12, 121. https://doi.org/10.3390/mi12020121

Su Y, Geng Z, Fang W, Lv X, Wang S, Ma Z, Pei W. Route to Cost-Effective Fabrication of Wafer-Scale Nanostructure through Self-Priming Nanoimprint. Micromachines. 2021; 12(2):121. https://doi.org/10.3390/mi12020121

Chicago/Turabian StyleSu, Yue, Zhaoxin Geng, Weihao Fang, Xiaoqing Lv, Shicai Wang, Zhengtai Ma, and Weihua Pei. 2021. "Route to Cost-Effective Fabrication of Wafer-Scale Nanostructure through Self-Priming Nanoimprint" Micromachines 12, no. 2: 121. https://doi.org/10.3390/mi12020121

APA StyleSu, Y., Geng, Z., Fang, W., Lv, X., Wang, S., Ma, Z., & Pei, W. (2021). Route to Cost-Effective Fabrication of Wafer-Scale Nanostructure through Self-Priming Nanoimprint. Micromachines, 12(2), 121. https://doi.org/10.3390/mi12020121