Modeling and Simulation of the Surface Generation Mechanism of a Novel Low-Pressure Lapping Technology

Abstract

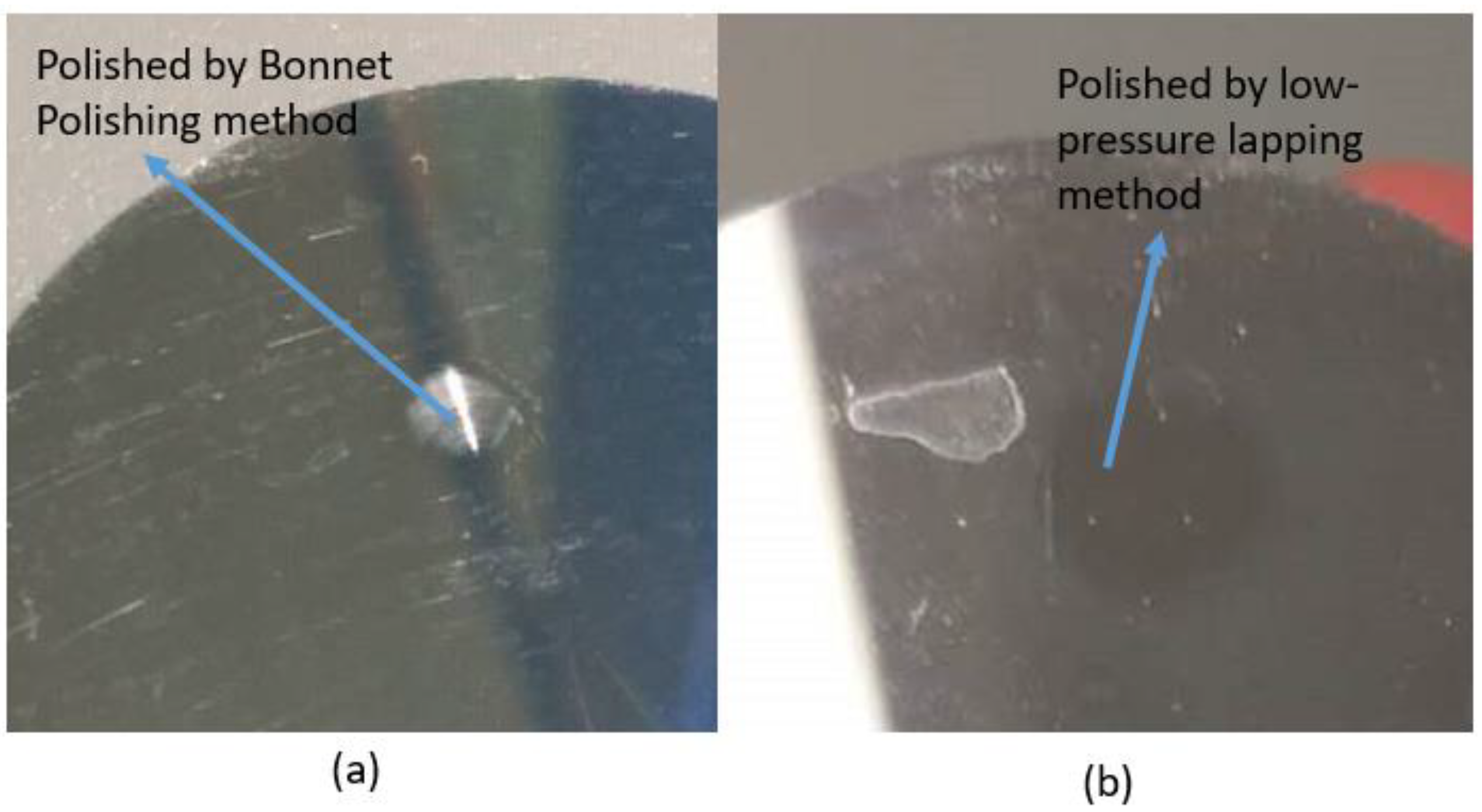

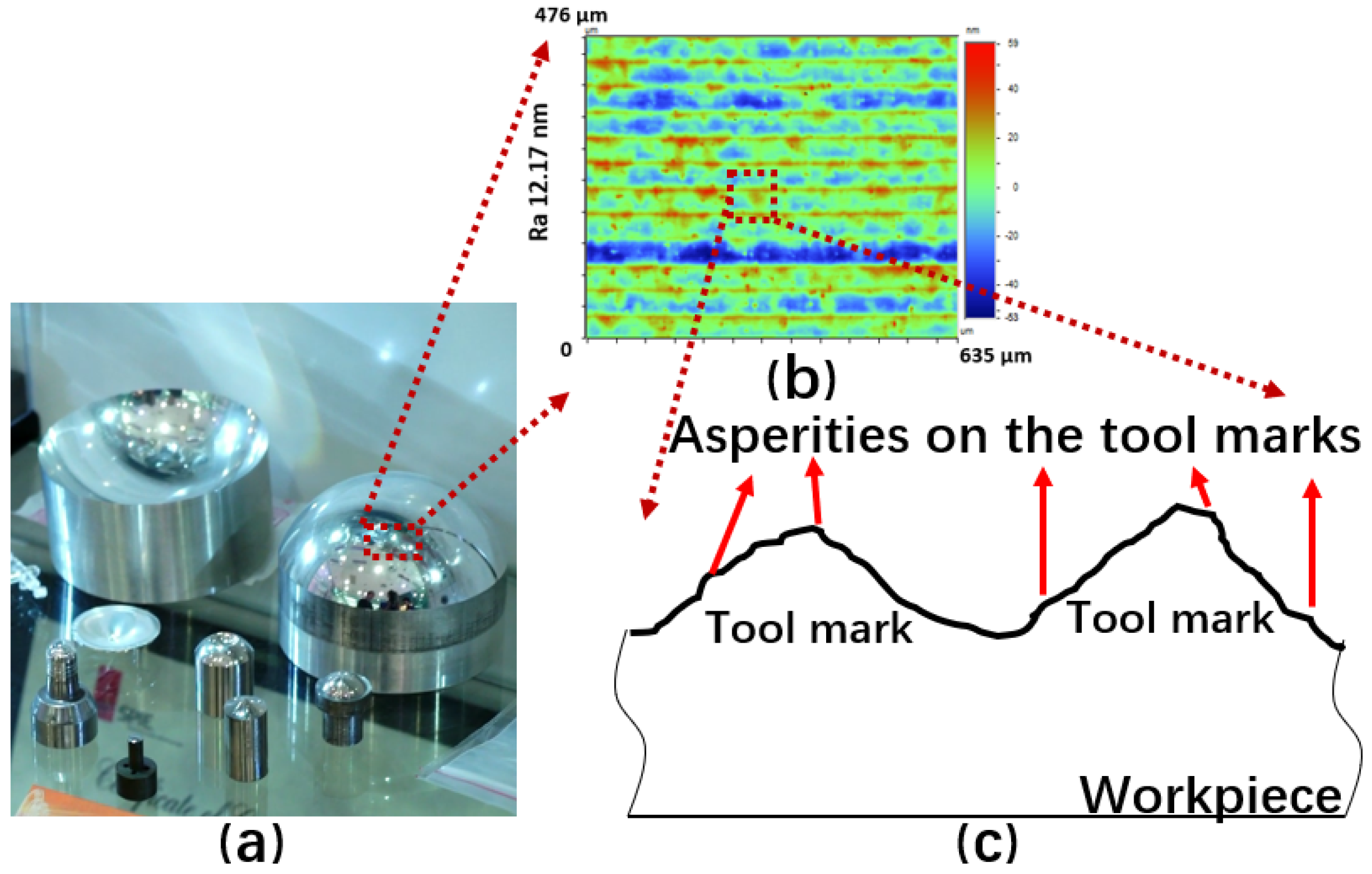

:1. Introduction

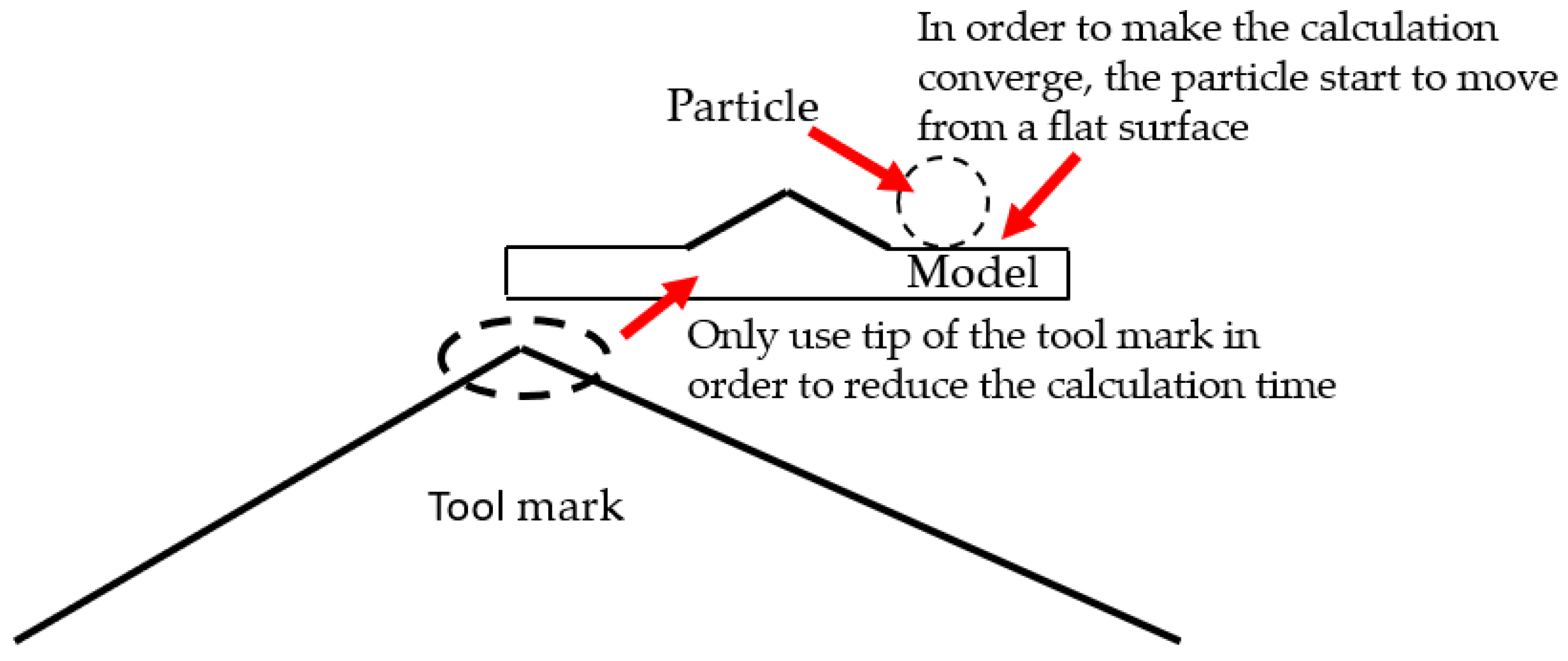

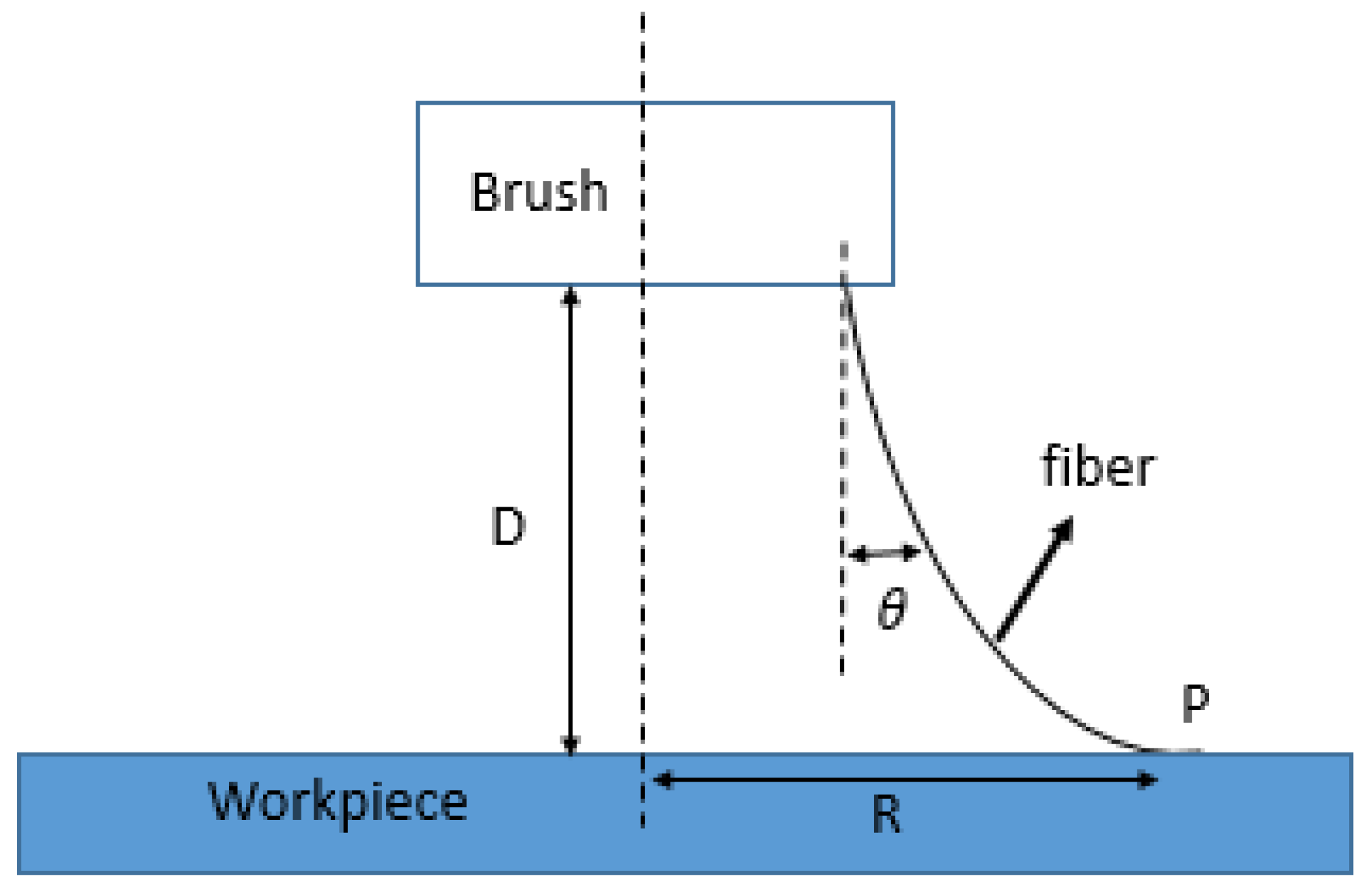

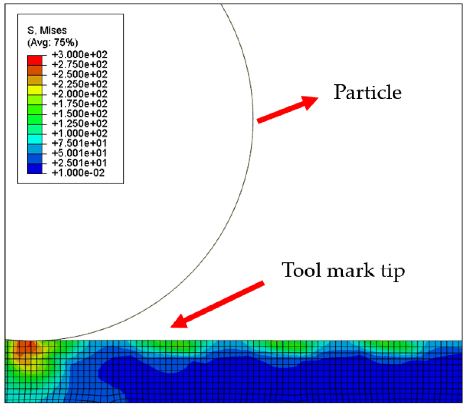

2. Modeling Processes

2.1. Parameter Setting

2.2. Software Setting

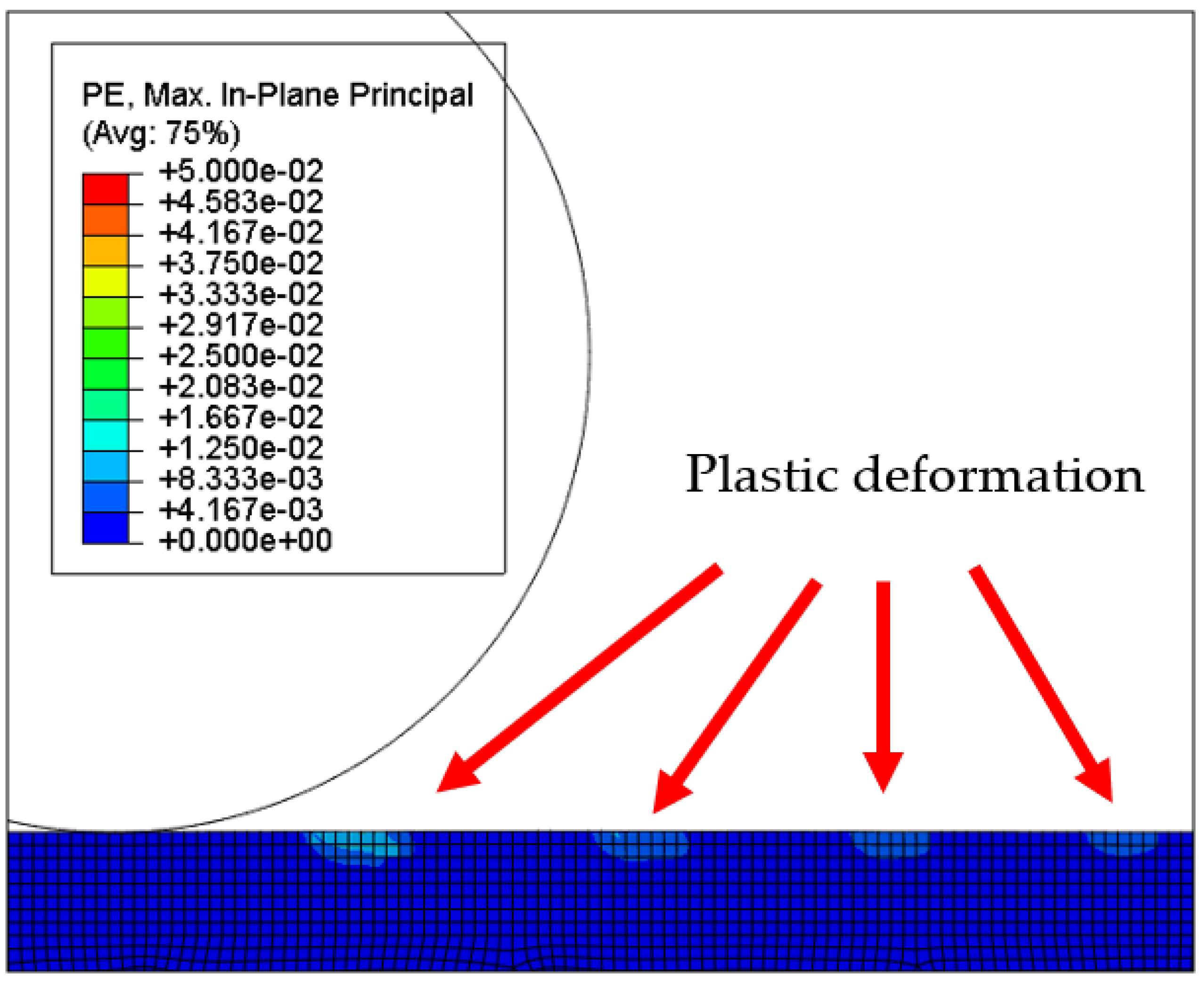

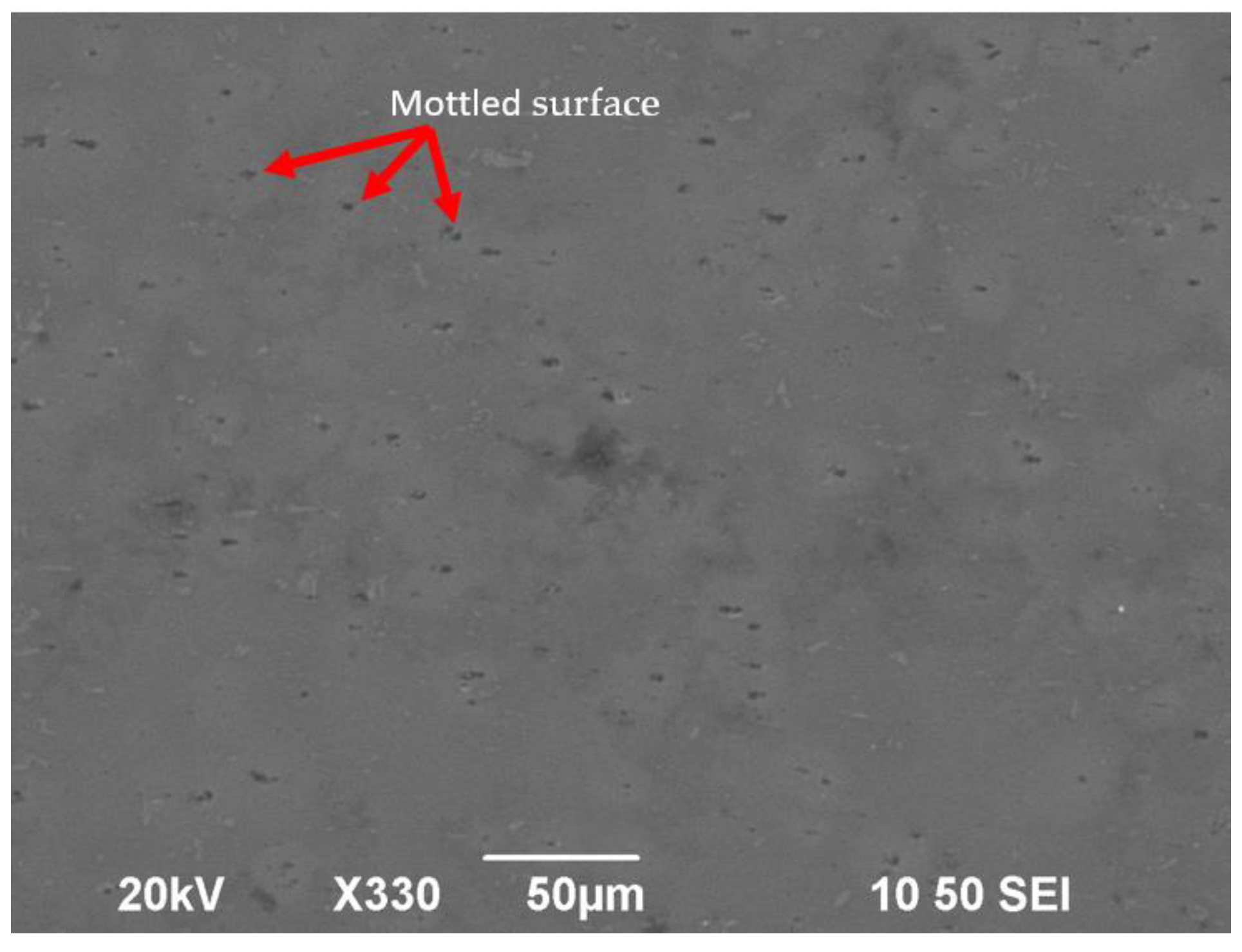

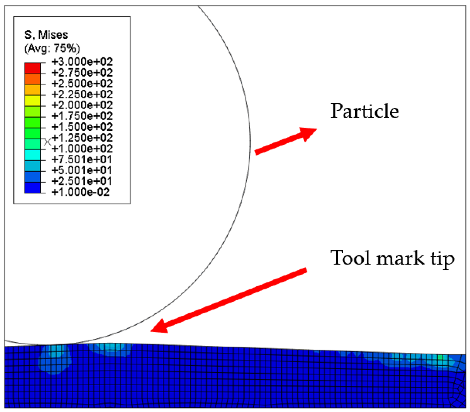

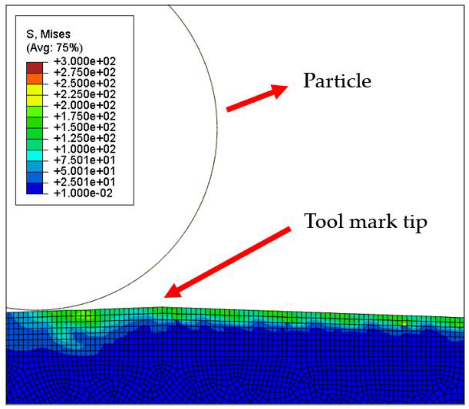

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Yu, N.H.; Chan, C.Y.; Li, L.H.; Lee, W.B. Spectral analysis of surface roughness features of a lapped ultraprecision single-point diamond machined surface. Int. J. Adv. Manuf. Technol. 2016, 88, 1407–1415. [Google Scholar] [CrossRef]

- Bartels, P.H.; Samuels, L.E. Metallographic Polishing by Mechanical Methods. Trans. Am. Microsc. Soc. 1972, 91, 248. [Google Scholar] [CrossRef]

- Kral, E.R.; Komvopoulos, K.; Bogy, D.B. Elastic-Plastic Finite Element Analysis of Repeated Indentation of a Half-Space by a Rigid Sphere. J. Appl. Mech. 1993, 60, 829–841. [Google Scholar] [CrossRef]

- Kogut, L.; Etsion, I. Elastic-Plastic Contact Analysis of a Sphere and a Rigid Flat. J. Appl. Mech. 2002, 69, 657–662. [Google Scholar] [CrossRef] [Green Version]

- Greenwood, J.A.; Williamson, J.B.P. Contact of nominally flat surfaces. Proc. R. Soc. London. Ser. A Math. Phys. Sci. 1966, 295, 300–319. [Google Scholar] [CrossRef]

- Chang, W.-R.; Etsion, I.; Bogy, D.B. An Elastic-Plastic Model for the Contact of Rough Surfaces. J. Tribol. 1987, 109, 257–263. [Google Scholar] [CrossRef]

- Tabor, D. The Hardness of Metals; Clarendon Press: Oxford, UK, 1951; pp. 213–219. [Google Scholar]

- Jackson, R.L.; Green, I. A Finite Element Study of Elasto-Plastic Hemispherical Contact Against a Rigid Flat. J. Tribol. 2005, 127, 343–354. [Google Scholar] [CrossRef] [Green Version]

- Kadin, Y.; Kligerman, Y.; Etsion, I. Multiple Loading-Unloading of an Elastic-Plastic Spherical Contact. In Proceedings of the World Tribology Congress III, Washington, DC, USA, 12–16 September 2005; pp. 215–216. [Google Scholar] [CrossRef] [Green Version]

- Peng, H.; Liu, Z.; Huang, F.; Ma, R. A study of elastic–plastic contact of statistical rough surfaces. Proc. Inst. Mech. Eng. Part J. Eng. Tribol. 2013, 227, 1076–1089. [Google Scholar] [CrossRef]

- Almuramady, N.; Borodich, F. Simulations of sliding adhesive contact between microgear teeth in silicon-based MEMS work in a vacuum environment. In Proceedings of the 25th UKACM Conference on Computational Mechanics, Birmingham, UK, 12–13 April 2017; pp. 38–41. [Google Scholar]

- Lee, Y.J.; Chaudhari, A.; Zhang, J.; Wang, H. Thermally Assisted Microcutting of Calcium Fluoride Single Crystals. In Simulation and Experiments of Material-Oriented Ultra-Precision Machining; Zhang, J., Guo, B., Zhang, J., Eds.; Springer: Berlin/Heidelberg, Germany, 2019; pp. 77–102. [Google Scholar]

- Schönemann, L.; Riemer, O. Thermo-mechanical tool setting mechanism for ultra-precision milling with multiple cutting edges. Precis. Eng. 2019, 55, 171–178. [Google Scholar] [CrossRef]

- Fish, J.; Oskay, C.; Fan, R.; Barsoum, R. Al 6061-T6-Elastomer Impact Simulations; Electronic Document; Rensselaer Polytechnic Institute: Troy, NY, USA, 2005. [Google Scholar]

- Qi, J.; Herron, J.R.; Sansalone, K.H.; Mars, W.V.; Du, Z.Z.; Snyman, M.; Surendranath, H. Validation of a Steady-State Transport Analysis for Rolling Treaded Tires. Tire Sci. Technol. 2007, 35, 183–208. [Google Scholar] [CrossRef]

- Oila, A.; Bull, S. Assessment of the factors influencing micropitting in rolling/sliding contacts. Wear 2005, 258, 1510–1524. [Google Scholar] [CrossRef]

- Verdu, C.; Adrien, J.; Buffière, J. Three-dimensional shape of the early stages of fatigue cracks nucleated in nodular cast iron. Mater. Sci. Eng. A 2008, 483-484, 402–405. [Google Scholar] [CrossRef]

- Terrin, A.; Dengo, C.; Meneghetti, G. Experimental analysis of contact fatigue damage in case hardened gears for off-highway axles. Eng. Fail. Anal. 2017, 76, 10–26. [Google Scholar] [CrossRef]

- Paulson, N.R.; Sadeghi, F.; Habchi, W. A coupled finite element EHL and continuum damage mechanics model for rolling contact fatigue. Tribol. Int. 2017, 107, 173–183. [Google Scholar] [CrossRef]

- Suresh, S. Fatigue of Materials; Cambridge University Press, Massachusetts Institute of Technology: Cambridge, MA, USA, 1998. [Google Scholar]

- Rahman, M.A.; Amrun, M.R.; Rahman, M.; Kumar, A.S. Variation of surface generation mechanisms in ultra-precision machining due to relative tool sharpness (RTS) and material properties. Int. J. Mach. Tools. Manuf. 2017, 115, 15–28. [Google Scholar] [CrossRef]

- Turley, D.M.; Samuels, L.E. The nature of mechanically polished surfaces of copper. Metallography 1981, 14, 275–294. [Google Scholar] [CrossRef]

- Chiffre, L.D. Extrusion cutting of brass strips. Int. J. Mach. Tool Des. Res. 1983, 23, 141–151. [Google Scholar] [CrossRef]

- Cai, S.L.; Chen, Y.; Ye, G.G.; Jiang, M.Q.; Wang, H.Y.; Dai, L.H. Characterization of the deformation field in large-strain extrusion machining. J. Mater. Process. Technol. 2015, 216, 48–58. [Google Scholar] [CrossRef]

- Lee, Y.J.; Kumar, A.S.; Wang, H. Beneficial stress of a coating on ductile-mode cutting of single-crystal brittle material. Int. J. Mach. Tools. Manuf. 2021, 168, 03787. [Google Scholar] [CrossRef]

| Fundamental Units | |

|---|---|

| Length | mm |

| Force | μN |

| Time | s |

| Mass | kg |

| Derived Units | |

| Pressure | MPa |

| Velocity | μm/s |

| Density | kg/μm3 |

| Young’s modulus | MPa |

| Yield stress | MPa |

| A | B | C | n | m | |||

|---|---|---|---|---|---|---|---|

| 289.6 MPa | 203.4 MPa | 0.011 | 0.35 | 1.34 | 1.0 s−1 | 925.37 K | 294.26 K |

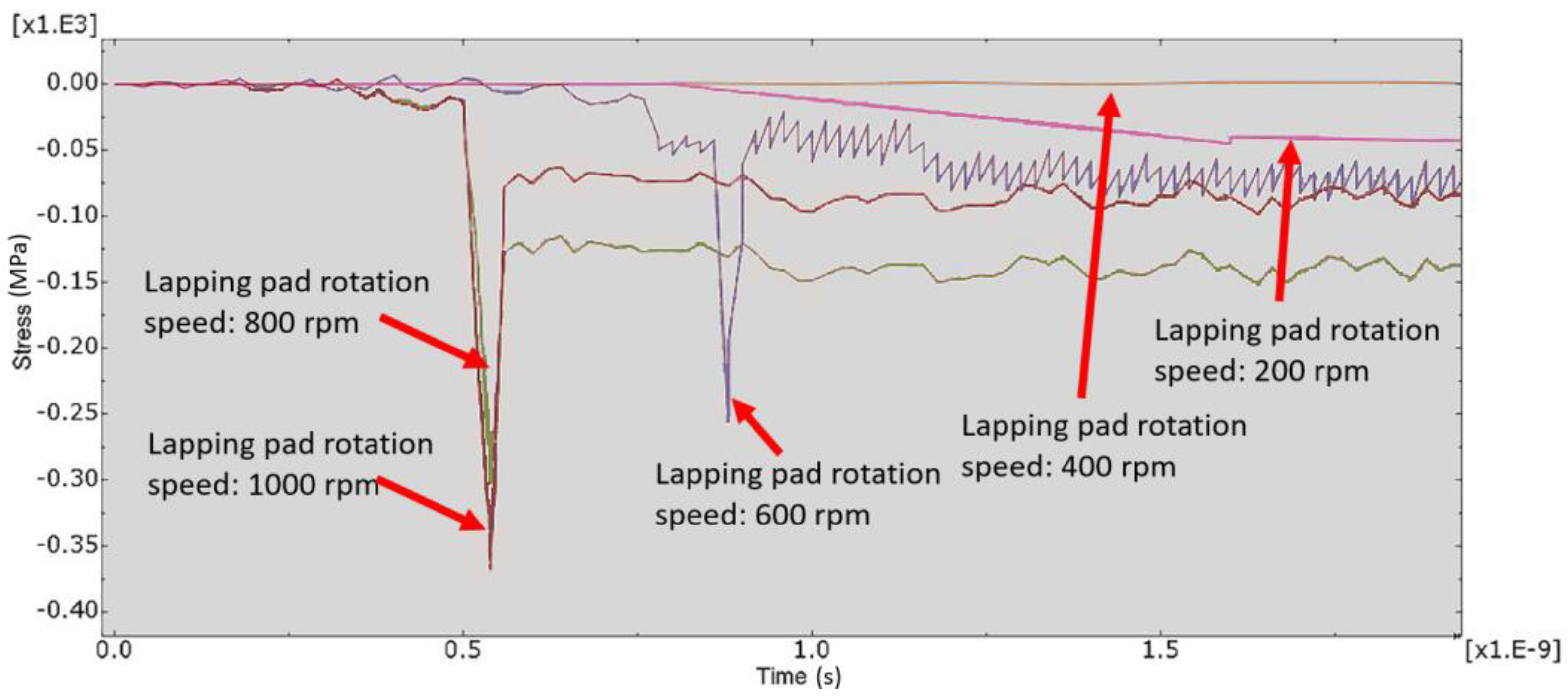

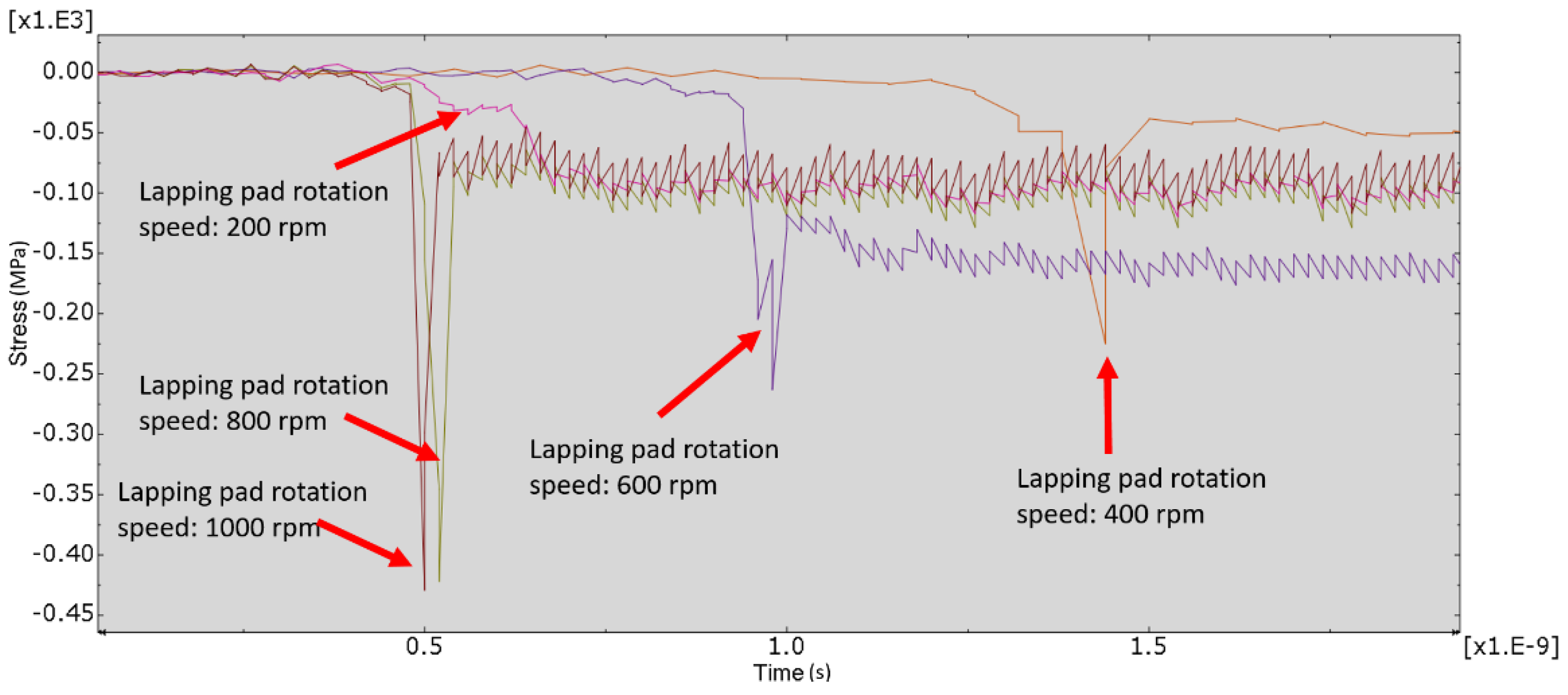

| 1 | Rotational speed: 200 rpm | 6.28 × 106 μm/s |

| 2 | Rotational speed: 400 rpm | 1.26 × 107 μm/s |

| 3 | Rotational speed: 600 rpm | 1.88 × 107 μm/s |

| 4 | Rotational speed: 800 rpm | 2.51 × 107 μm/s |

| 5 | Rotational speed: 1000 rpm | 3.14 ×107 μm/s |

| Tool Mark Height | Rotational Speed | Results |

|---|---|---|

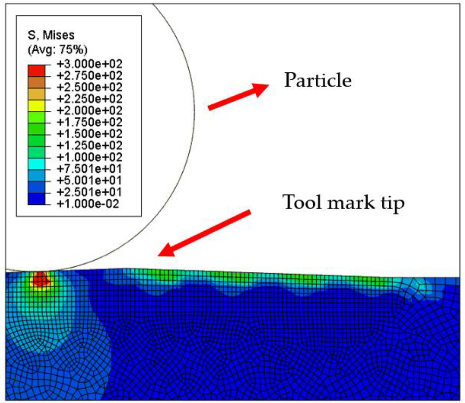

| (a) 1000 nm | 200 rpm |  |

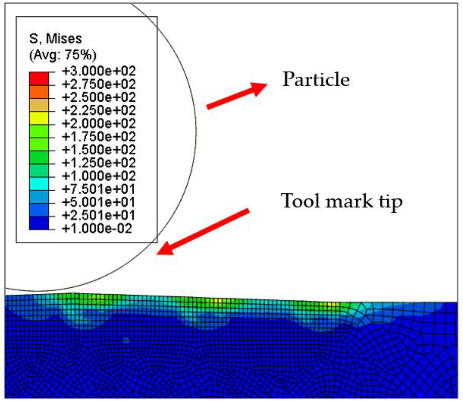

| (b) 1000 nm | 400 rpm |  |

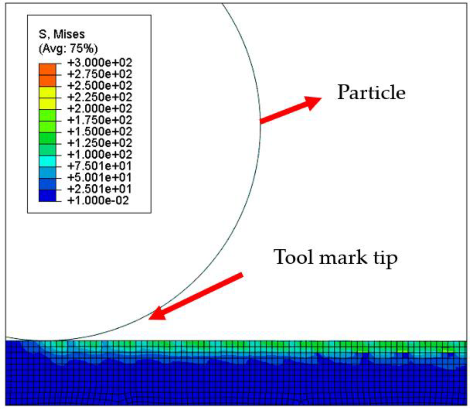

| (c) 1000 nm | 600 rpm |  |

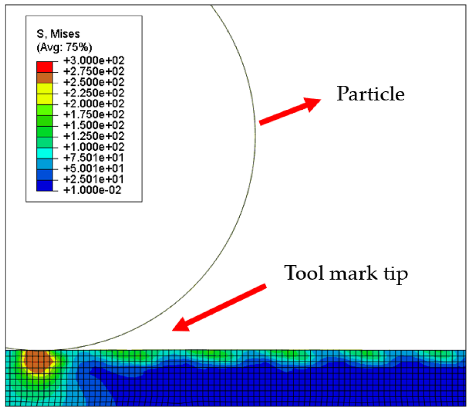

| (d) 1000 nm | 800 rpm |  |

| (e) 1000 nm | 1000 rpm |  |

| Tool Mark Height | Rotational Speed | Results |

|---|---|---|

| (a) 20 nm | 200 rpm |  |

| (b) 20 nm | 400 rpm |  |

| (c) 20 nm | 600 rpm |  |

| (d) 20 nm | 800 rpm |  |

| (e) 20 nm | 1000 rpm |  |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, N.; Li, L.; Kee, C.-s. Modeling and Simulation of the Surface Generation Mechanism of a Novel Low-Pressure Lapping Technology. Micromachines 2021, 12, 1510. https://doi.org/10.3390/mi12121510

Yu N, Li L, Kee C-s. Modeling and Simulation of the Surface Generation Mechanism of a Novel Low-Pressure Lapping Technology. Micromachines. 2021; 12(12):1510. https://doi.org/10.3390/mi12121510

Chicago/Turabian StyleYu, Ninghui, Lihua Li, and Chea-su Kee. 2021. "Modeling and Simulation of the Surface Generation Mechanism of a Novel Low-Pressure Lapping Technology" Micromachines 12, no. 12: 1510. https://doi.org/10.3390/mi12121510

APA StyleYu, N., Li, L., & Kee, C.-s. (2021). Modeling and Simulation of the Surface Generation Mechanism of a Novel Low-Pressure Lapping Technology. Micromachines, 12(12), 1510. https://doi.org/10.3390/mi12121510