Annular Surface Micromachining of Titanium Tubes Using a Magnetorheological Polishing Technique

Abstract

1. Introduction

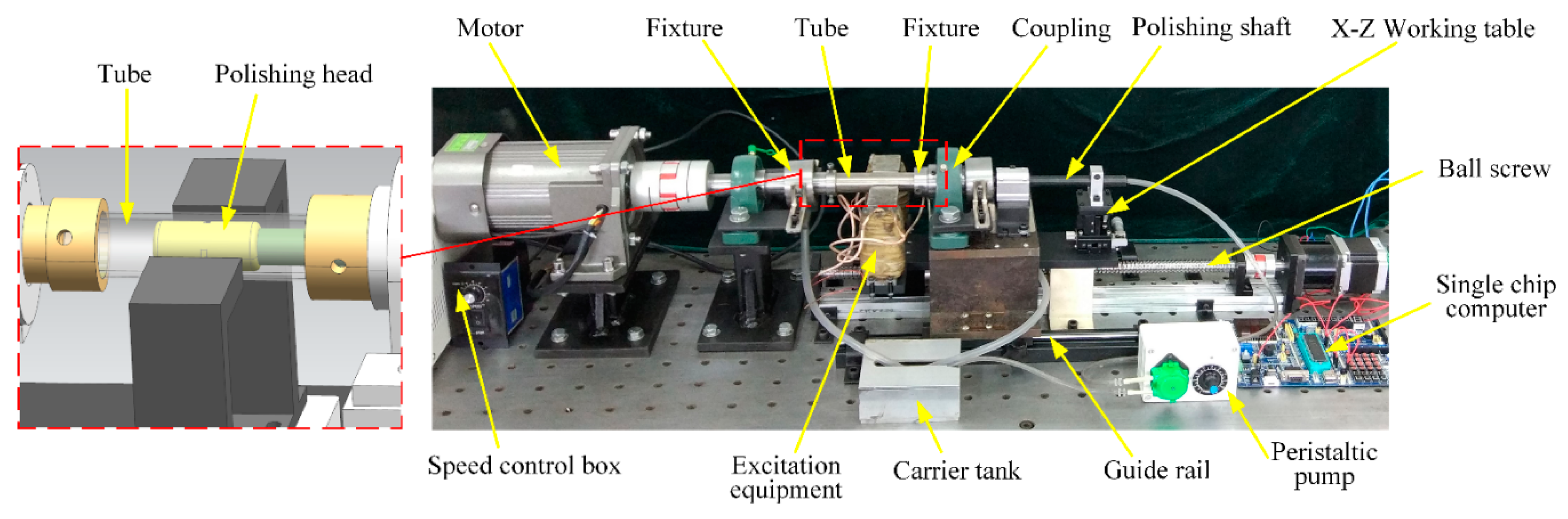

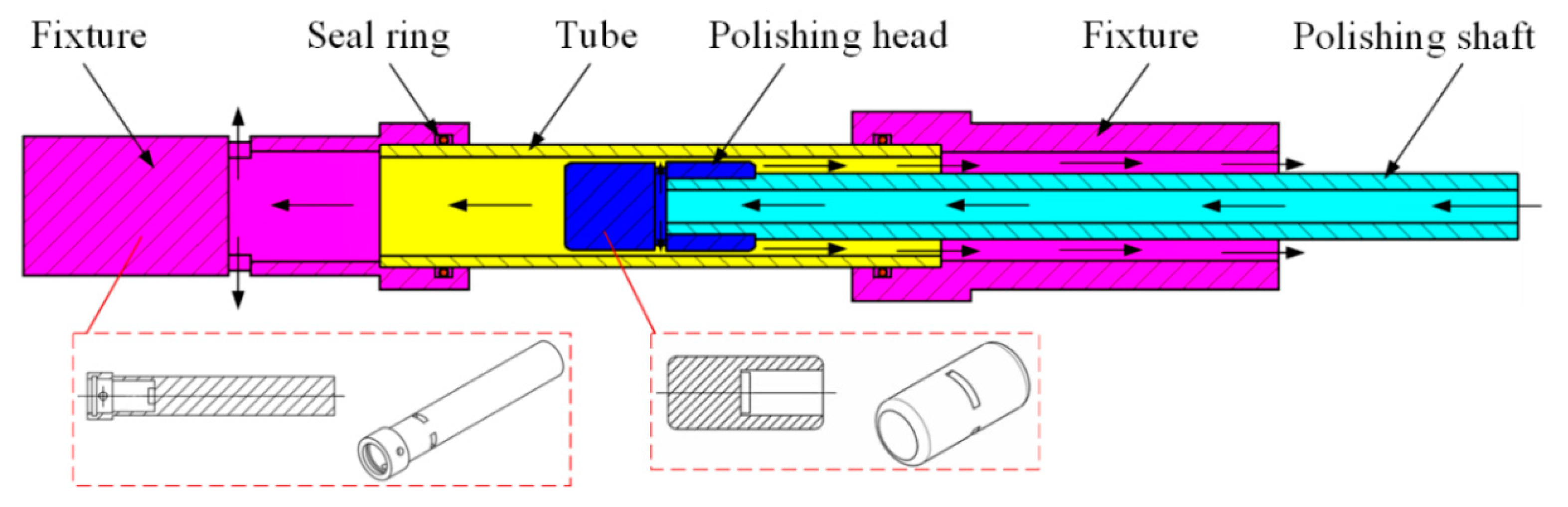

2. Design of the MR Polishing Apparatus

2.1. MR Polishing Apparatus

- The structure is compact and easy to install.

- Recycling of MR polishing fluid is realized to maximize the material utilization.

- The polished tube is allowed to rotate at high speed.

- Reciprocating linear motion of polishing head is an indispensable function, which should be considered into the design of MR polishing apparatus.

- The movement speed of MR polishing device is controllable.

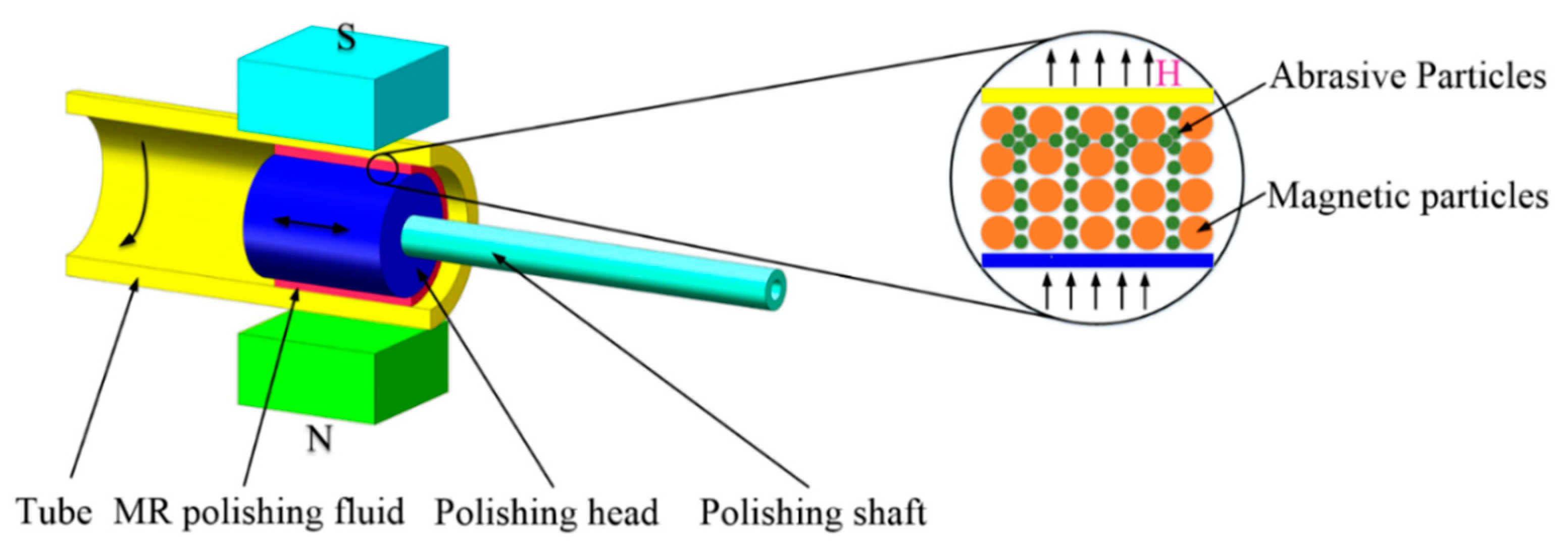

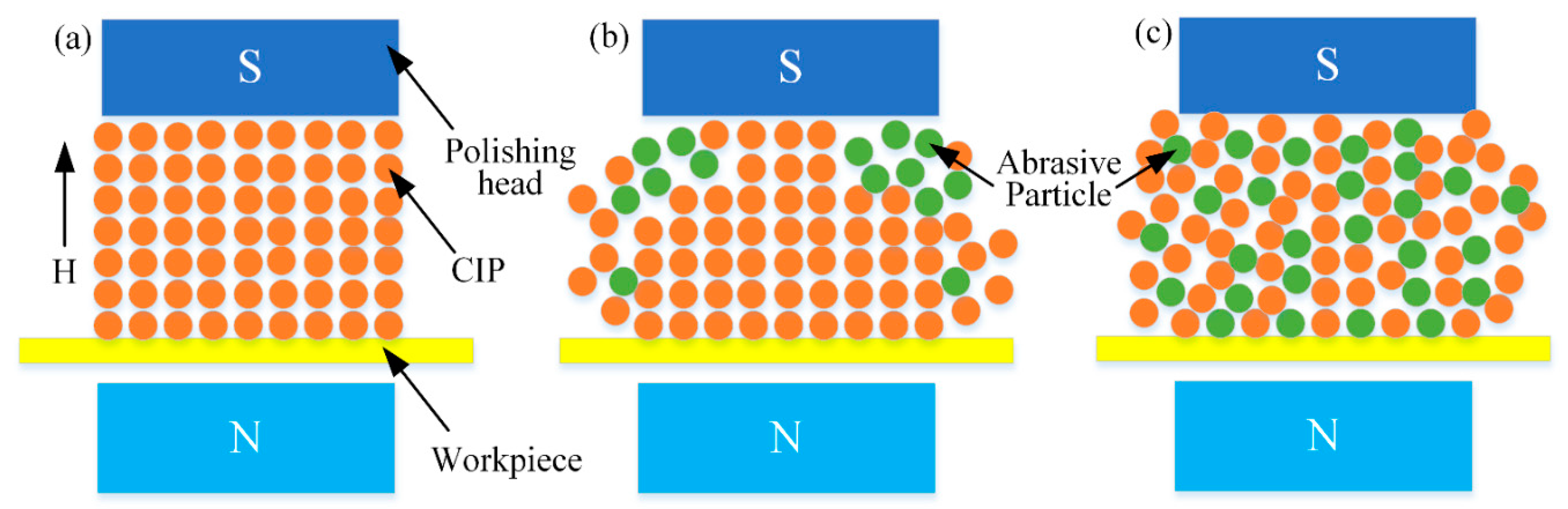

2.2. Polishing Mechanism

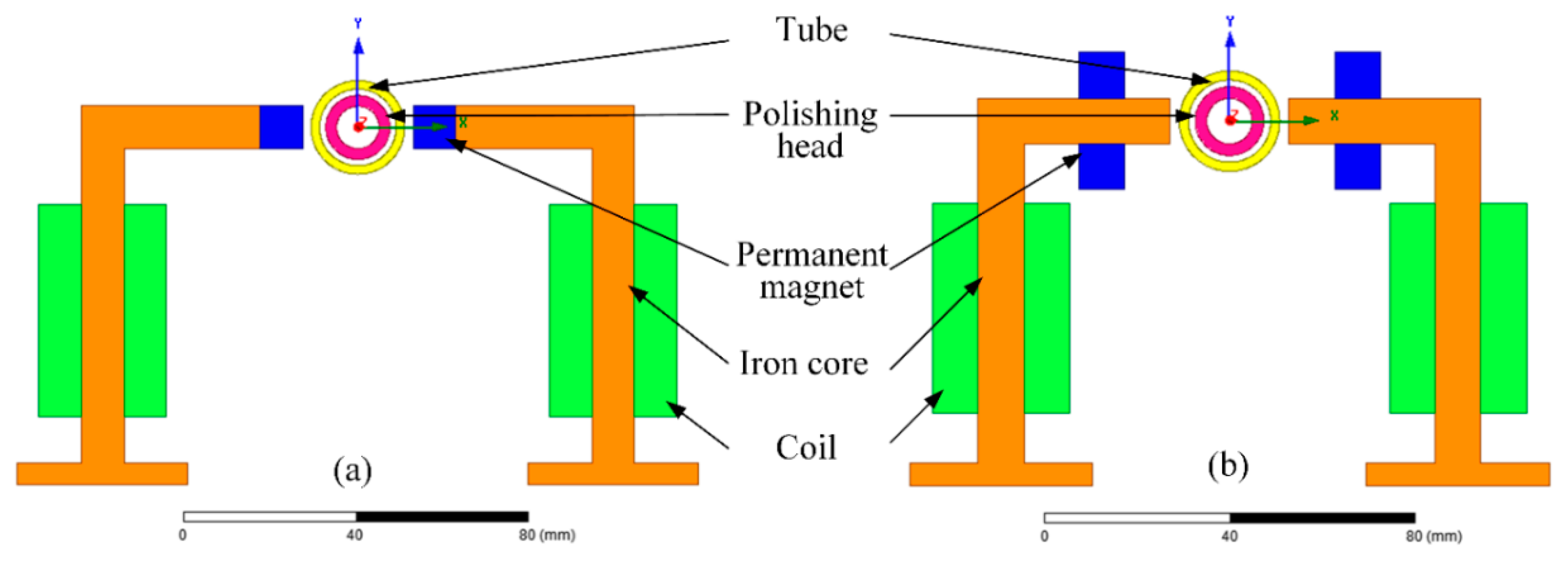

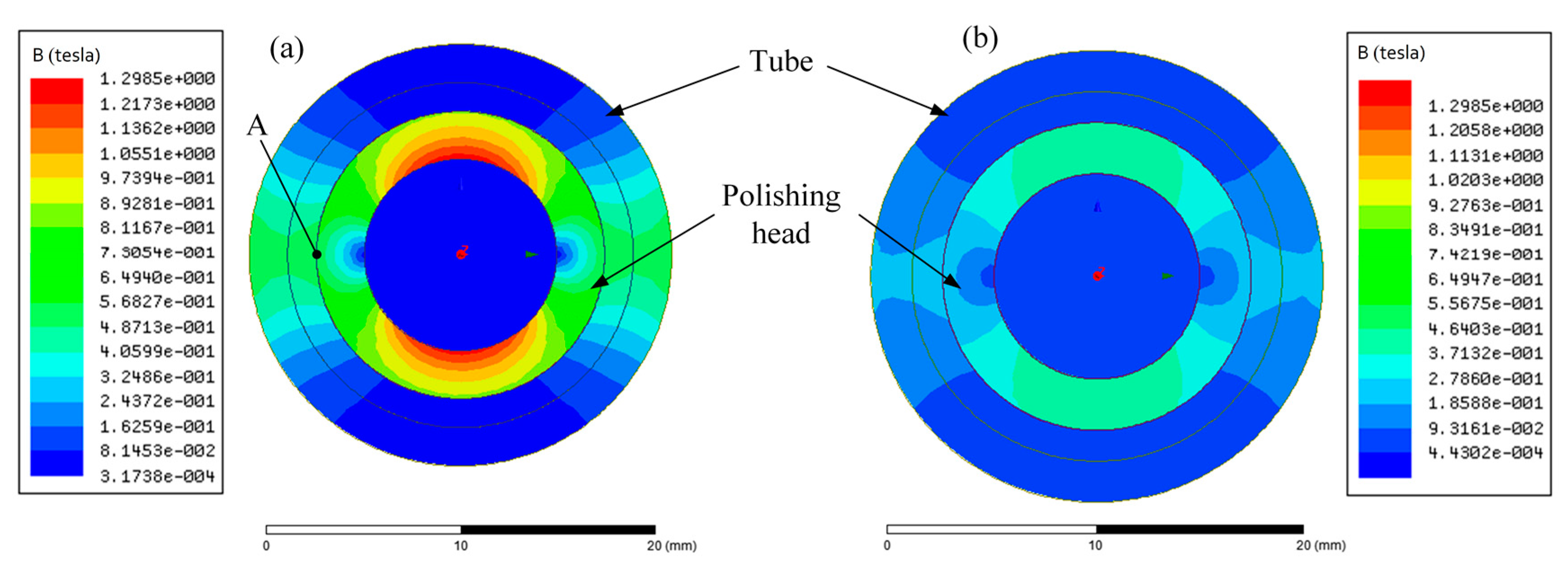

2.3. Design and Validation of the Excitation Equipment

3. Experimentation

3.1. Preparation of the MR Polishing Fluid

3.2. Polishing Settings

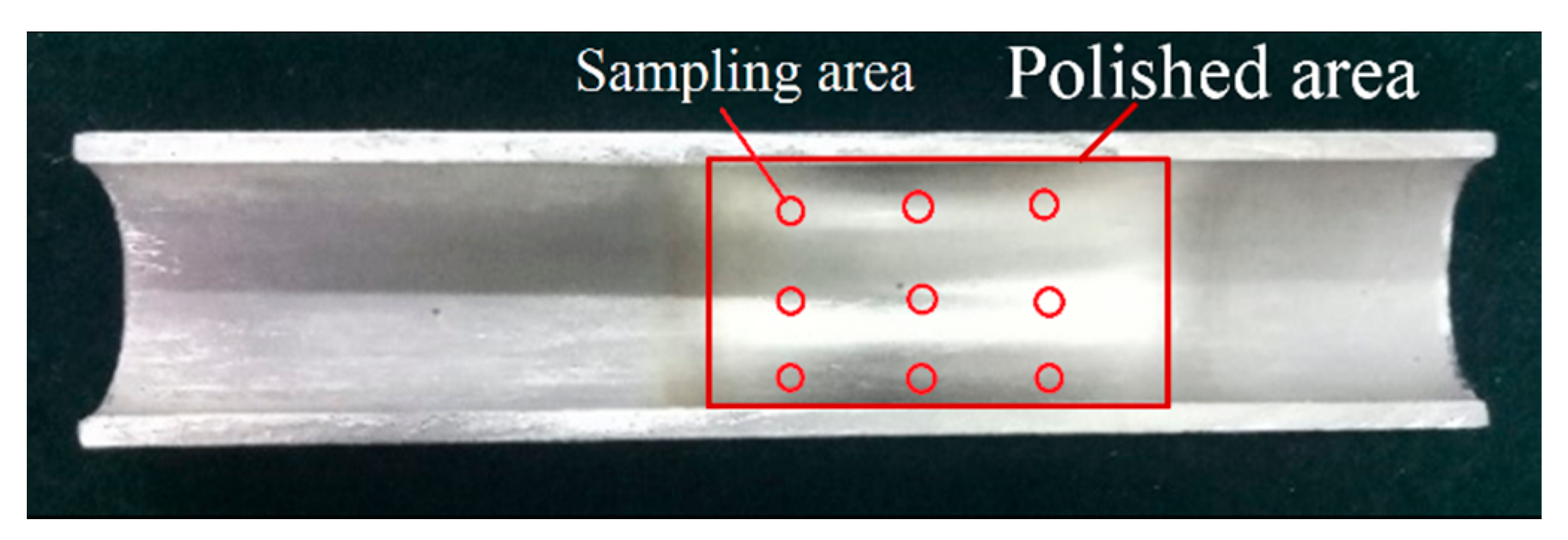

3.3. Measurement of Surface Roughness and Removed Mass

4. Results and Discussion

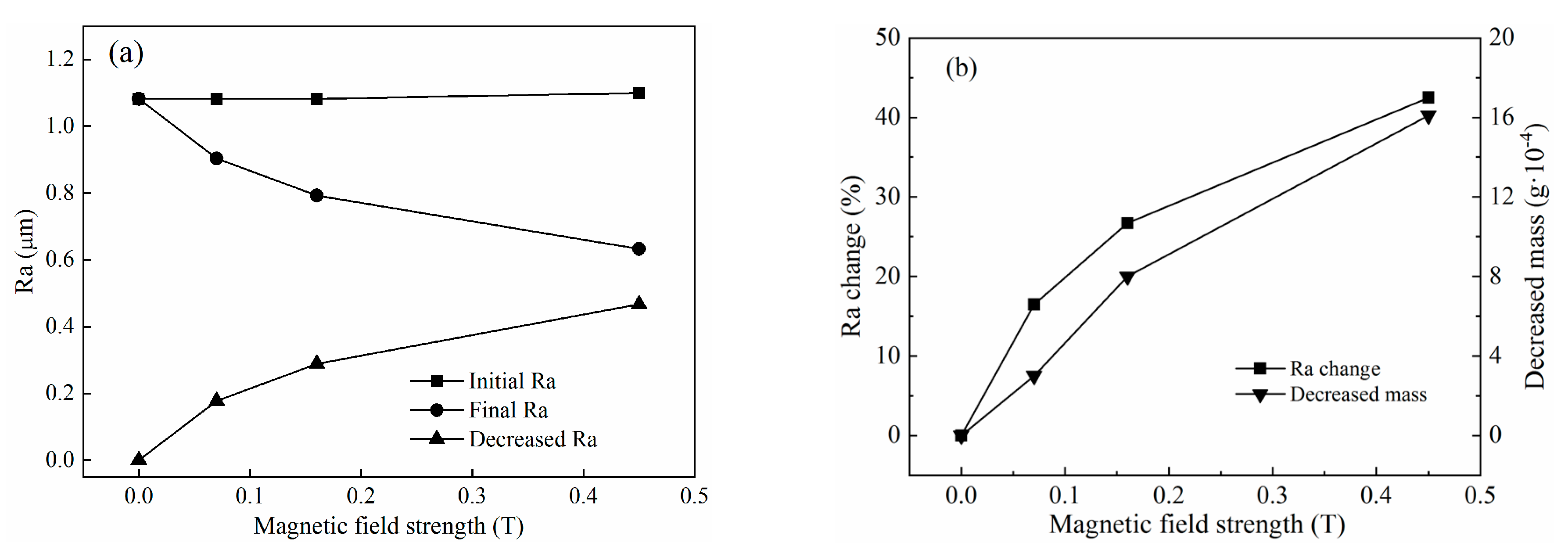

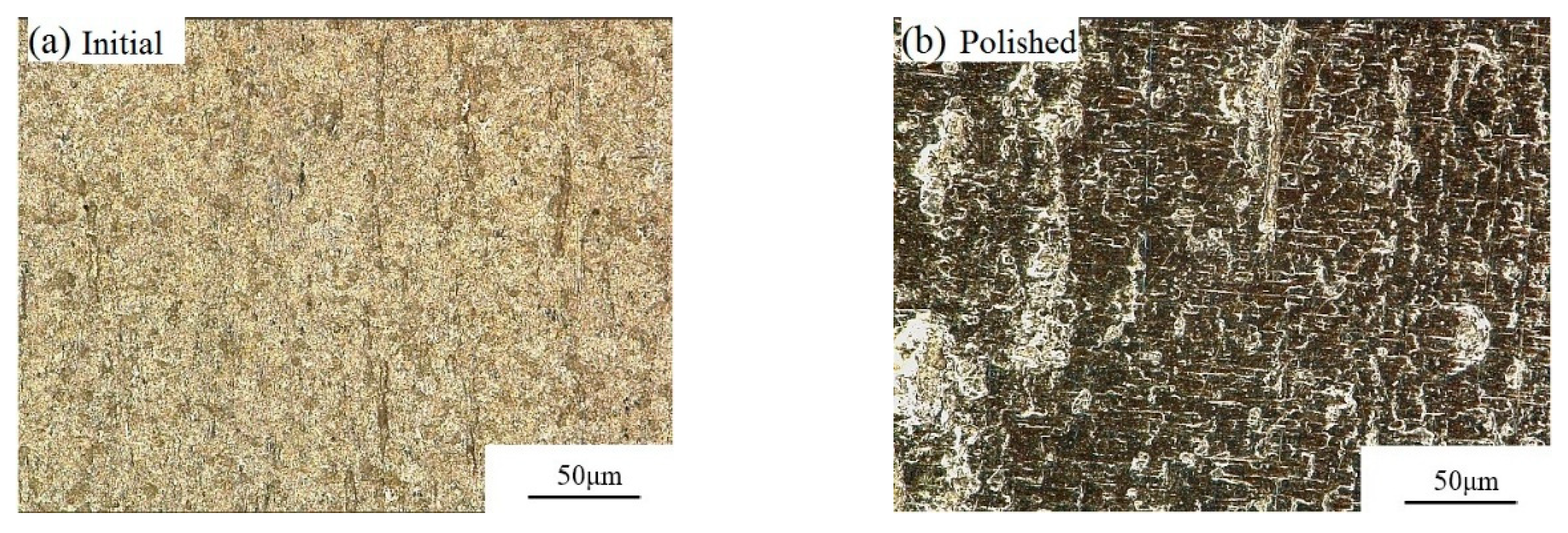

4.1. Effect of Compound Magnetic Field Strength on Surface Roughness

4.2. Effect of Rotation Speed on Surface Roughness

4.3. Effect of the Type of Abrasive Particle on Surface Roughness

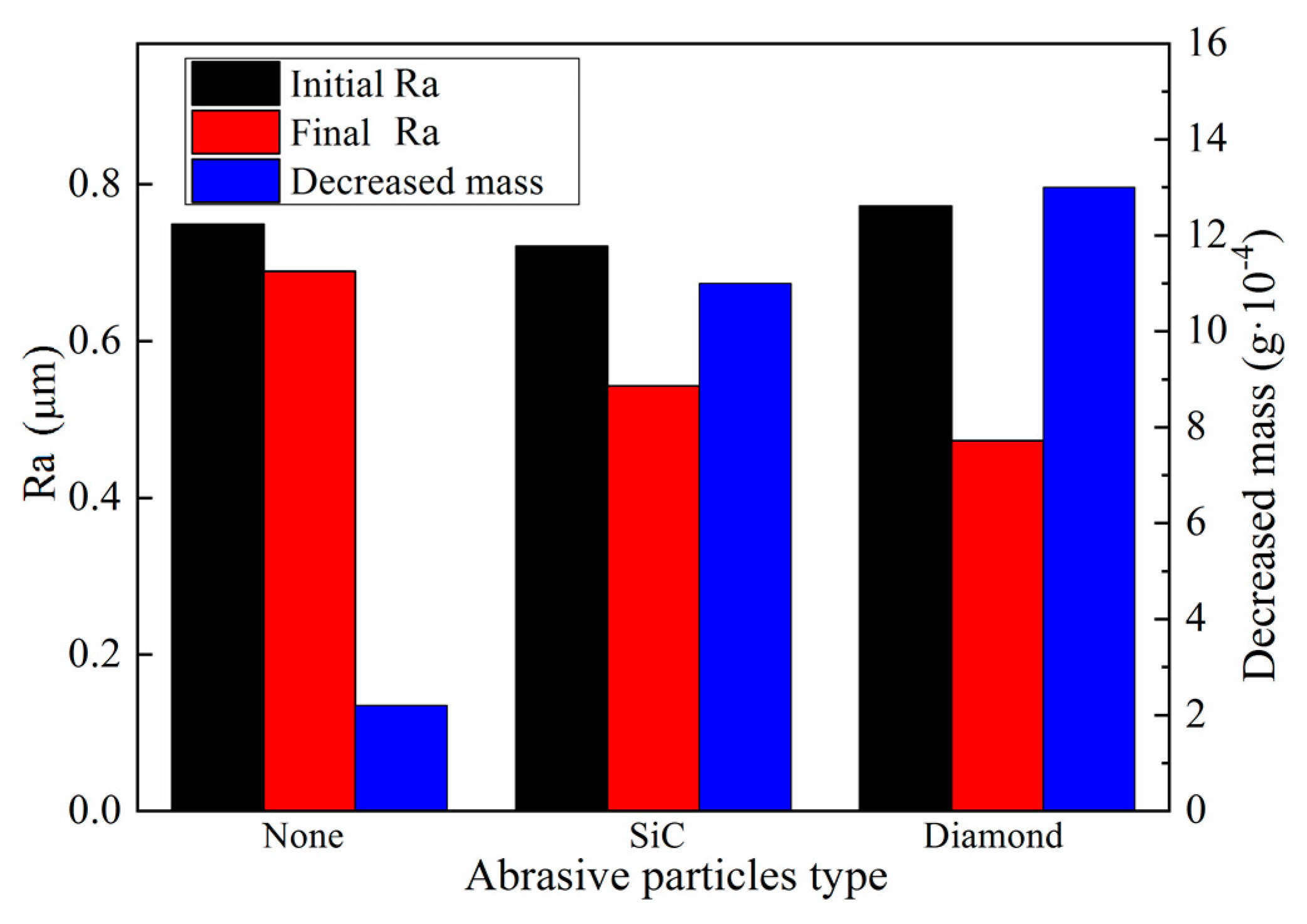

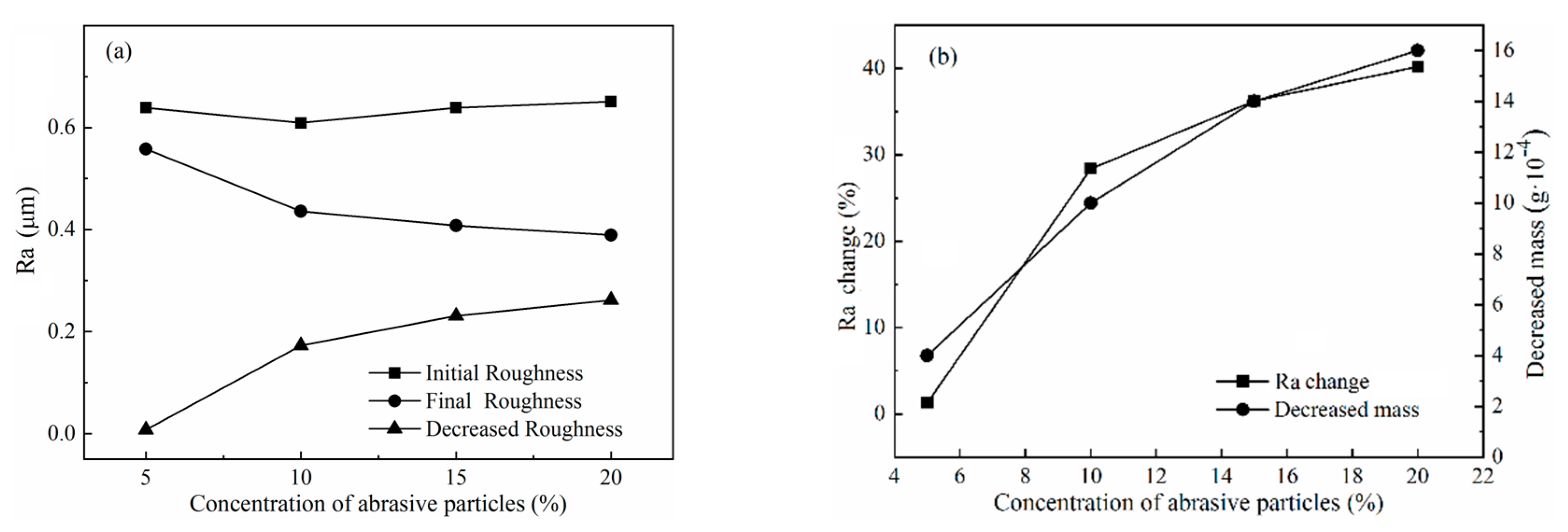

4.4. Effect of the Concentration of Abrasive Particles on Surface Roughness

5. Conclusions

- A novel MR polishing device under compound magnetic field was designed to achieve microlevel MR polishing of the titanium alloy tubes. The polishing process is realized by combining the rotation motion of the tube and the reciprocating linear motion of the polishing head. Before and after the experiment, the surface roughness Ra within polished area of workpiece was measured, and through the changing rule of surface roughness, the influence of the independent variable on the polishing effect was judged.

- Under a zero magnetic field, little variation of surface roughness and material mass was observed. Under an external magnetic field, the polished surface exhibited a significant improvement, particularly with higher magnetic field strengths. The initial surface roughness Ra decreased to 57.5% under a magnetic flux density of 0.45 T.

- Prior to the rotation speed reaching 700 rpm, the reduction of surface roughness and material mass tended to increase with an increase in rotation speed. However, high rotation speeds exceeding 700 rpm damaged the CIP chain structure and worsened the polishing performance, leading to a slowing down of the downward trend of final surface roughness Ra.

- When no abrasive particles were used in MR polishing, the abrasion caused by CIPs was far from the desired polishing effect. When SiC or diamond were added as abrasive particles to the MR polishing fluid, the polishing efficiency improved. Compared with SiC particles, diamond particles performed better in MR polishing: The surface roughness reduced by Ra 0.299 μm with diamond but only by Ra 0.178 μm with SiC.

- Low concentrations of abrasive particles led to a low polishing efficiency owing to the small number of abrasive particles in contact with the internal surface of the tube. Higher concentrations resulted in a greater number of abrasive particles available for the polishing process. From the analysis of surface roughness Ra obtained by polishing the workpiece with different concentration of polishing particles, 10% is the appropriate concentration of abrasive particles to make the best of materials and get a good polishing performance.

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| MR | Magnetorheological |

| CMP | Chemical–Mechanical Polishing |

| EDM | Electrical discharge Machining |

| ECH | Electrochemical Honing |

| MRAFF | Magnetorheological Abrasive Flow Finishing |

| R-MRAFF | Rotational–Magnetorheological Abrasive Flow Finishing |

| MRAH | Magnetorheological Abrasive Honing |

| CIPs | Carbonyl iron particles |

| dp | depth of indentation (m) |

| Rs | resistance force due to the shear action (N) |

| Fs | shear force (N) |

| σ | yield strength of machined material with a value of 895 MPa |

| Ap | cross-sectional area of indentation |

References

- Cui, C.X.; Hu, B.M.; Zhao, L.C.; Liu, S.J. Titanium alloy production technology, market prospects and industry development. Mater. Des. 2011, 32, 1684–1691. [Google Scholar] [CrossRef]

- Boujelbene, M. Investigation and modeling of the tangential cutting force of the Titanium alloy Ti-6Al-4V in the orthogonal turning process. Procedia Manuf. 2018, 20, 571–577. [Google Scholar] [CrossRef]

- Pervaiz, S.; Rashid, A.; Deiab, I.; Nicolescu, M. Influence of Tool Materials on Machinability of Titanium- and Nickel-Based Alloys: A Review. Mater. Manuf. Process. 2014, 29, 219–252. [Google Scholar] [CrossRef]

- Fan, Z.H.; Tian, Y.B.; Liu, Z.Q.; Shi, C.; Zhao, Y.Q. Investigation of a novel finishing tool in magnetic field assisted finishing fortitanium alloy Ti-6Al-4V. J. Manuf. Process. 2019, 43, 74–82. [Google Scholar] [CrossRef]

- Zhang, Z.Y.; Shi, Z.F.; Du, Y.F.; Yu, Z.J.; Guo, L.C.; Guo, D.M. A novel approach of chemical mechanical polishing for a titanium alloy using an environment-friendly slurry. Appl. Surf. Sci. 2018, 427, 409–415. [Google Scholar] [CrossRef]

- Khan, M.A.R.; Rahman, M.M. Surface finish characteristics of titanium alloy in a non conventional technique. Mater. Today Proc. 2017, 4, 9352–9355. [Google Scholar] [CrossRef]

- Ma, C.P.; Guan, Y.C.; Zhou, W. Laser polishing of additive manufactured Ti alloys. Opt. Lasers Eng. 2017, 93, 171–177. [Google Scholar] [CrossRef]

- Rao, P.S.; Jain, P.K.; Dwivedi, D.K. Optimization of Key Process Parameters on Electro Chemical Honing (ECH) of External Cylindrical Surfaces of Titanium alloy Ti 6Al 4V. Mater. Today Proc. 2017, 4, 2279–2289. [Google Scholar] [CrossRef]

- Sidpara, A.; Jain, V.K. Analysis of forces on the freeform surface in magnetorheological fluid based finishing process. Int. J. Mach. Tools Manuf. 2013, 69, 1–10. [Google Scholar] [CrossRef]

- Nie, M.; Cao, J.G.; Li, J.Y.; Fu, M.H. Magnet arrangements in a magnetic field generator for magnetorheological finishing. Int. J. Mech. Sci. 2019, 10508, 161–162. [Google Scholar] [CrossRef]

- Grover, V.; Singh, A.K. Modelling of surface roughness in a new magnetorheological honing process for internal finishing of cylindrical workpieces. Int. J. Mech. Sci. 2018, 144, 679–695. [Google Scholar] [CrossRef]

- Hong, S.W.; Yoon, J.Y.; Kim, S.H.; Lee, S.H.; Lee, S.K.; Kim, Y.R.; Park, Y.J.; Kim, G.W.; Choi, S.B. 3D-printed soft structure of polyurethane and magnetorheological fluid: A proof-of-concept investigation of its stiffness tunability. Micromachines 2019, 10, 655. [Google Scholar] [CrossRef] [PubMed]

- Sidpara, A.; Jain, V.K. Experimental investigations into forces during magnetorheological fluid based finishing process. Int. J. Mach. Tools Manuf. 2011, 51, 358–362. [Google Scholar] [CrossRef]

- Yin, X.C.; Guo, S.X.; Song, Y. Magnetorheological Fluids Actuated Haptic-Based Teleoperated Catheter Operating System. Micromachines 2018, 9, 465. [Google Scholar] [CrossRef] [PubMed]

- Saraswathamma, K.; Jha, S.; Rao, P.V. Experimental investigation into Ball end Magnetorheological Finishing of silicon. Precis. Eng. 2015, 42, 218–223. [Google Scholar] [CrossRef]

- Barman, A.; Das, M. Design and fabrication of a novel polishing tool for finishing freeform surfaces in magnetic field assisted finishing (MFAF) process. Precis. Eng. 2017, 49, 61–68. [Google Scholar] [CrossRef]

- Singh, A.K.; Jha, S.; Pandey, P.M. Nanofinishing of a typical 3D ferromagnetic workpiece using ball end magnetorheological finishing process. Int. J. Mach. Tools Manuf. 2012, 63, 21–31. [Google Scholar] [CrossRef]

- Fu, J.; Bai, J.F.; Lai, J.J.; Li, P.D.; Yu, M.; Lam, H.K. Adaptive fuzzy control of a magnetorheological elastomer vibration isolation system with time-varying sinusoidal excitations. J. Sound Vib. 2019, 456, 386–406. [Google Scholar] [CrossRef]

- Jha, S.; Jain, V.K. Design and development of the magnetorheological abrasive flow finishing (MRAFF) process. Int. J. Mach. Tools Manuf. 2004, 44, 1019–1029. [Google Scholar] [CrossRef]

- Song, W.L.; Li, H.L.; Ma, J.T.; Hu, Z.C.; Shi, P. Experimental investigation of the magnetorheological polishing process with roller. Ind. Lubr. Tribol. 2018, 70, 1060–1065. [Google Scholar] [CrossRef]

- Das, M.; Jain, V.K.; Ghoshdastidar, P.S. Nanofinishing of flat workpieces using rotational–magnetorheological abrasive flow finishing (R-MRAFF) process. Int. J. Adv. Manuf. Technol. 2012, 62, 405–420. [Google Scholar] [CrossRef]

- Bolat, F.C.; Sivrioglu, S. Active Control of a Small-Scale Wind Turbine Blade Containing Magnetorheological Fluid. Micromachines 2018, 9, 80. [Google Scholar] [CrossRef] [PubMed]

- Yamaguchi, H.; Kang, J.; Hashimoto, F. Metastable austenitic stainless steel tool for magnetic abrasive finishing. CIRP Ann. 2011, 60, 339–342. [Google Scholar] [CrossRef]

- Paswan, S.K.; Bedi, T.S.; Singh, A.K. Modeling and simulation of surface roughness in magnetorheological fluid based honing process. Wear 2017, 376, 1207–1221. [Google Scholar] [CrossRef]

- Zhang, J.; Hu, J.L.; Wang, H.; Kumar, A.S.; Chaudhari, A. A novel magnetically driven polishing technique for internal surface finishing. Precis. Eng. 2018, 54, 222–232. [Google Scholar] [CrossRef]

- Wang, Y.Q.; Yin, S.H.; Huang, H.; Chen, F.J.; Deng, G.J. Magnetorheological polishing using a permanent magnetic yoke with straight air gap for ultra-smooth surface planarization. Precis. Eng. 2015, 40, 309–317. [Google Scholar] [CrossRef]

- Das, M.; Jain, V.K.; Ghoshdastidar, P.S. A 2D CFD simulation of MR polishing medium in magnetic field-assisted finishing process using electromagnet. Int. J. Adv. Manuf. Technol. 2015, 76, 173–187. [Google Scholar] [CrossRef]

- Das, M.; Jain, V.K.; Ghoshdastidar, P.S. Fluid flow analysis of magnetorheological abrasive flow finishing (MRAFF) process. Int. J. Mach. Tools Manuf. 2008, 48, 415–426. [Google Scholar] [CrossRef]

- Barman, A.; Das, M. Nano-finishing of bio-titanium alloy to generate different surface morphologies by changing magnetorheological polishing fluid compositions. Precis. Eng. 2018, 51, 145–152. [Google Scholar] [CrossRef]

- Xiu, S.C.; Wang, R.S.; Sun, B.W.; Ma, L.; Song, W.L. Preparation and experiment of magnetorheological polishing fluid in reciprocating magnetorheological polishing process. J. Intell. Mater. Syst. Struct. 2018, 29, 125–136. [Google Scholar] [CrossRef]

| Constituents of MR Polishing Fluid | Concentration (%) | Size |

|---|---|---|

| CIPs | 30 | Φ18 μm |

| Abrasive particles (SiC) | 0–20 | Φ 25 μm |

| Abrasive particles (Diamond) | 0–20 | Φ 20 μm |

| Glycerol | 8 | |

| Deionized water | 42–62 |

| Parameter | Values |

|---|---|

| Titanium-alloy tubes | 22 mm × 18 mm × 100 m |

| Polishing gap | 1.5 mm |

| Reciprocating stroke | 10 mm |

| Reciprocating linear speed | 8 cycles per minute |

| Reciprocating linear cycles | 675 |

| Feeding speed | 3 mm/s |

| Test No. | Magnetic Flux Density (T) | Rotation Speed (rpm) | Type of Abrasive Particles | Concentration of Abrasive Particles (%) |

|---|---|---|---|---|

| 1 | 0 | 560 | diamond | 10 |

| 0.07 | 560 | diamond | 10 | |

| 0.16 | 560 | diamond | 10 | |

| 0.45 | 560 | diamond | 10 | |

| 2 | 0.45 | 420 | diamond | 10 |

| 0.45 | 560 | diamond | 10 | |

| 0.45 | 700 | diamond | 10 | |

| 0.45 | 840 | diamond | 10 | |

| 3 | 0.45 | 560 | no abrasive particles | 10 |

| 0.45 | 560 | SiC | 10 | |

| 0.45 | 560 | diamond | 10 | |

| 4 | 0.45 | 560 | diamond | 5 |

| 0.45 | 560 | diamond | 10 | |

| 0.45 | 560 | diamond | 15 | |

| 0.45 | 560 | diamond | 20 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, W.; Peng, Z.; Li, P.; Shi, P.; Choi, S.-B. Annular Surface Micromachining of Titanium Tubes Using a Magnetorheological Polishing Technique. Micromachines 2020, 11, 314. https://doi.org/10.3390/mi11030314

Song W, Peng Z, Li P, Shi P, Choi S-B. Annular Surface Micromachining of Titanium Tubes Using a Magnetorheological Polishing Technique. Micromachines. 2020; 11(3):314. https://doi.org/10.3390/mi11030314

Chicago/Turabian StyleSong, Wanli, Zhen Peng, Peifan Li, Pei Shi, and Seung-Bok Choi. 2020. "Annular Surface Micromachining of Titanium Tubes Using a Magnetorheological Polishing Technique" Micromachines 11, no. 3: 314. https://doi.org/10.3390/mi11030314

APA StyleSong, W., Peng, Z., Li, P., Shi, P., & Choi, S.-B. (2020). Annular Surface Micromachining of Titanium Tubes Using a Magnetorheological Polishing Technique. Micromachines, 11(3), 314. https://doi.org/10.3390/mi11030314