Atomistic Simulation Study of Nanoparticle Effect on Nano-Cutting Mechanisms of Single-Crystalline Materials

Abstract

1. Introduction

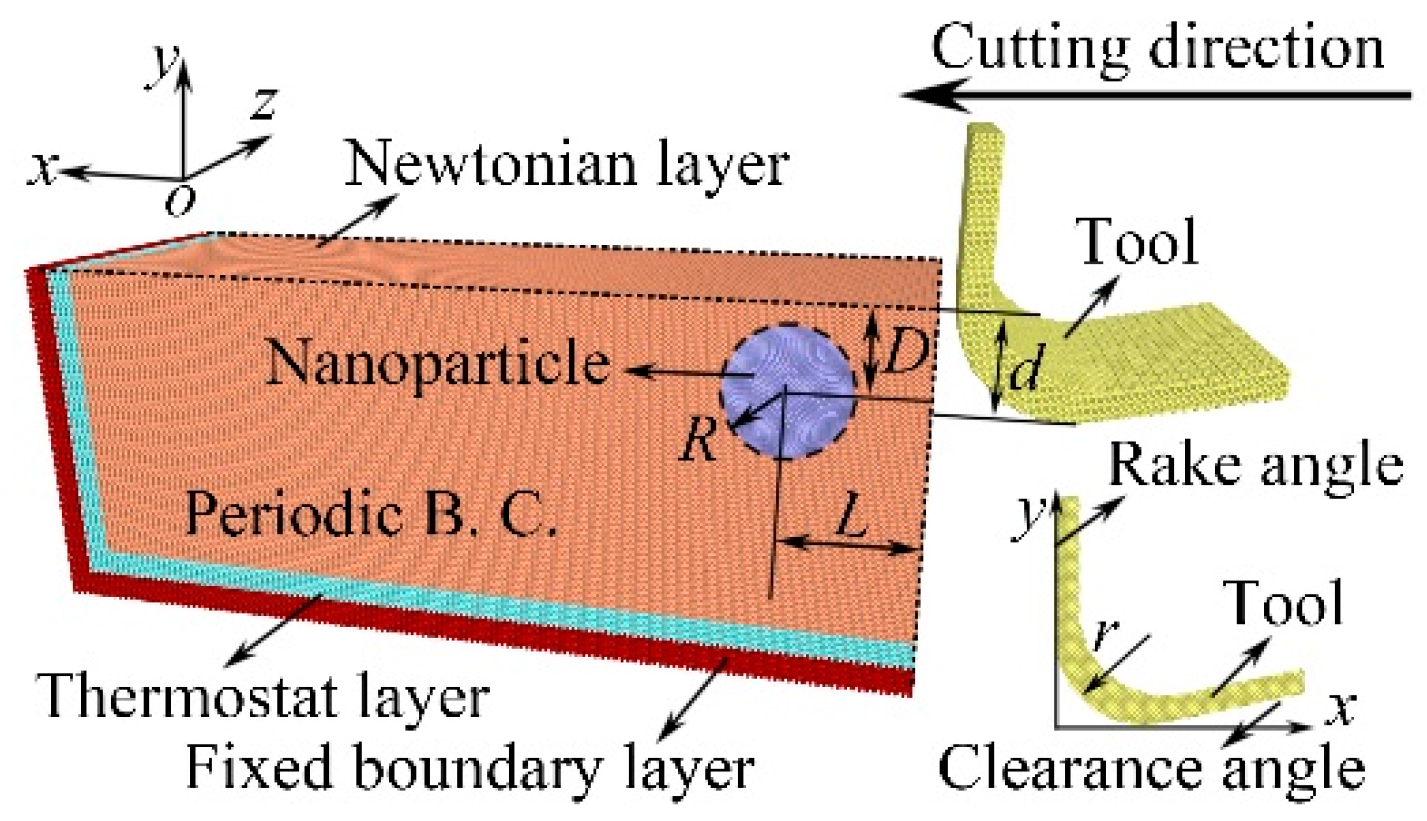

2. Simulation Methods

3. Results and Discussions

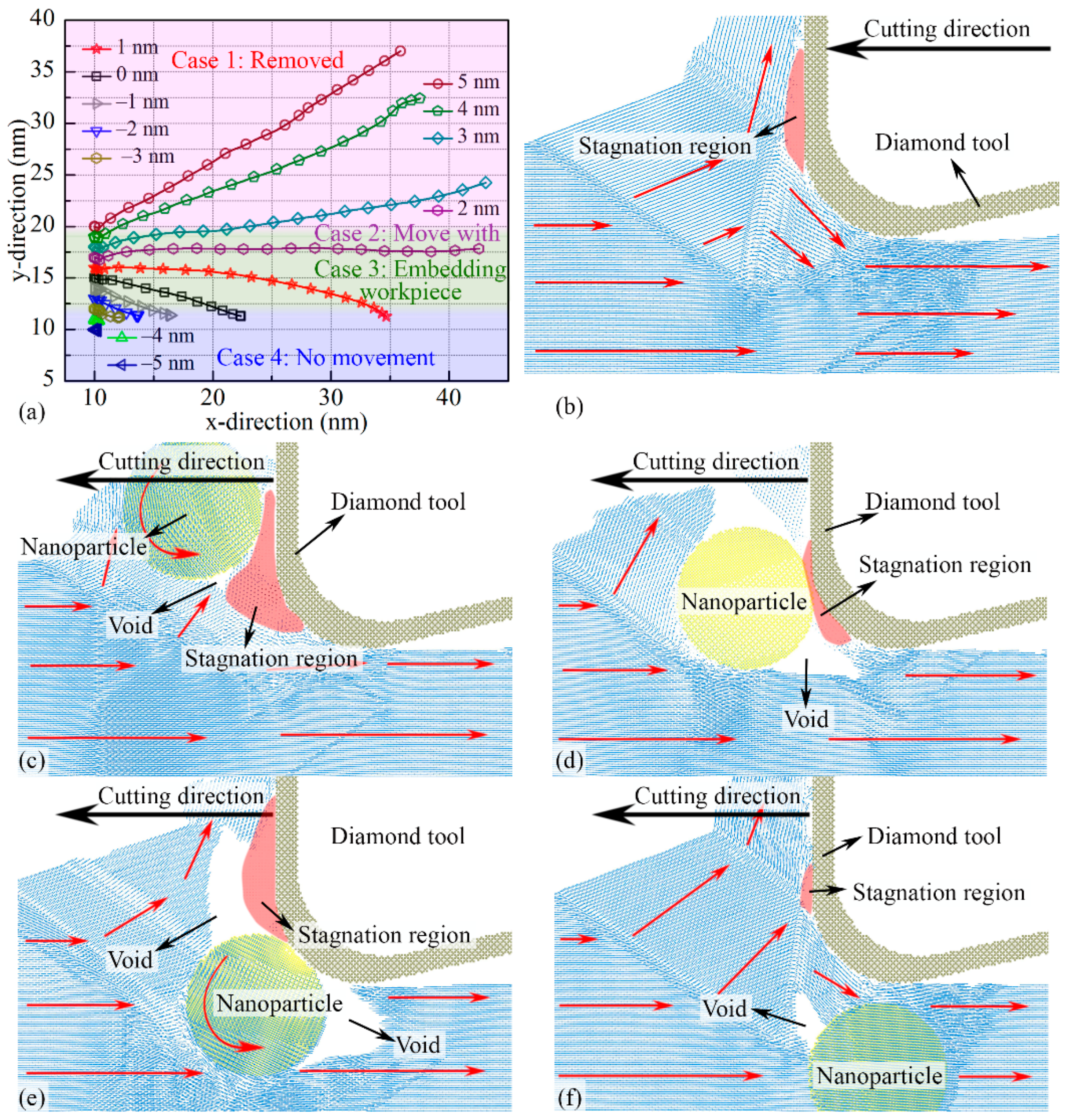

3.1. Mechanical Response

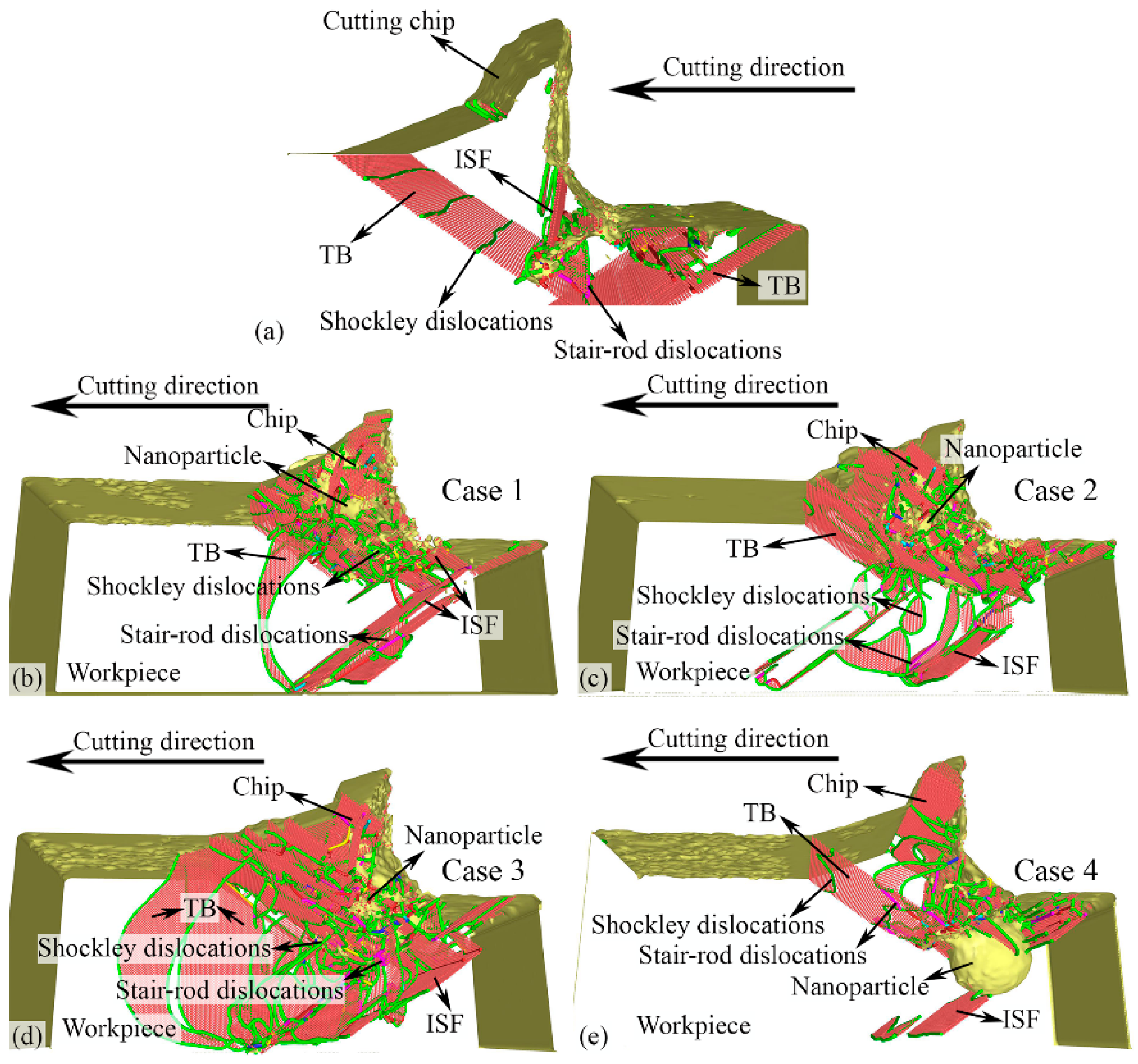

3.2. Plastic Deformation Mechanism

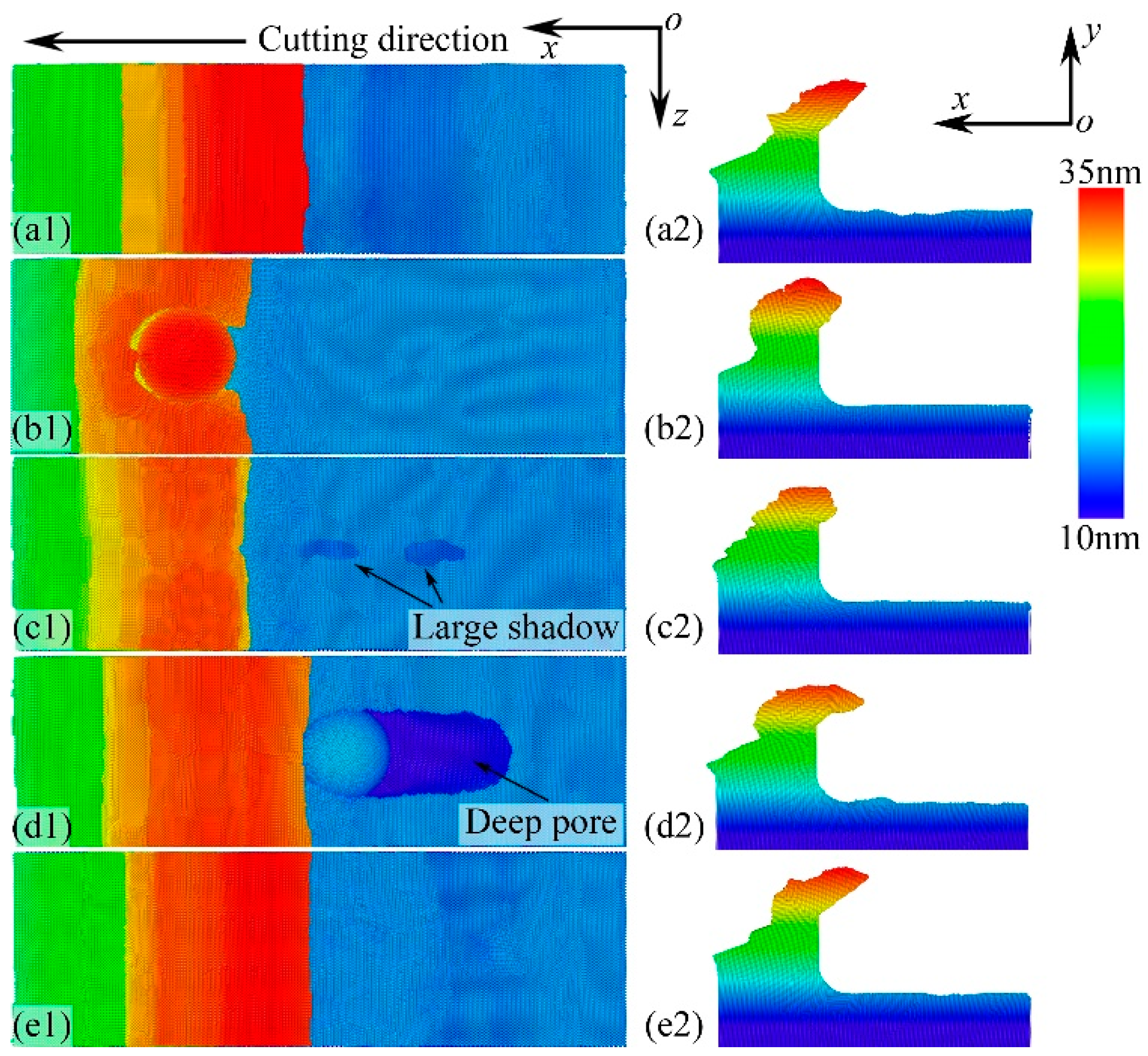

3.3. Machined Surface Quality

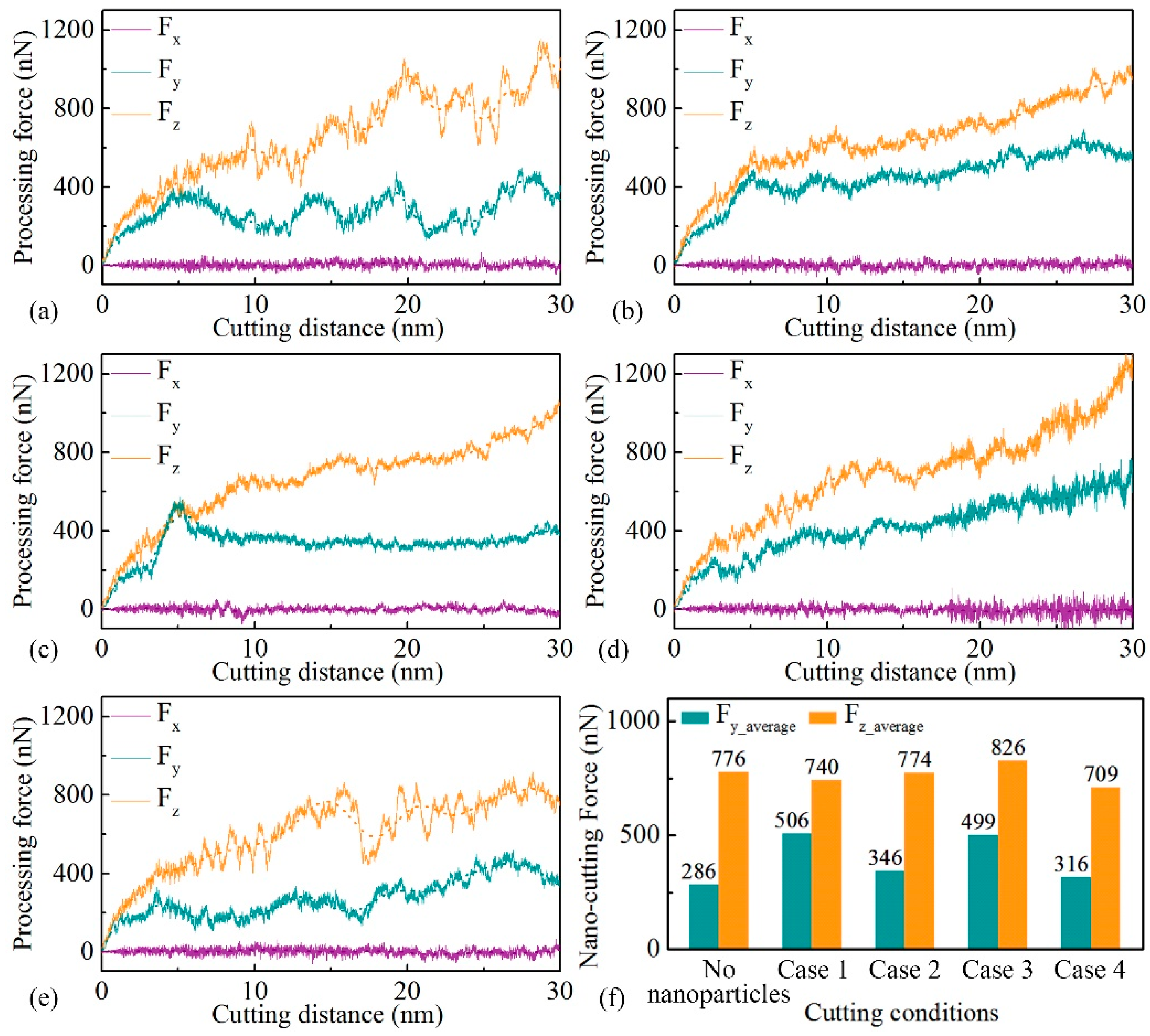

3.4. Processing Force

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Chavoshi, S.Z.; Luo, X. Hybrid micro-machining processes: A review. Precis. Eng. 2015, 41, 1–23. [Google Scholar] [CrossRef]

- Rossi, C.; Zhang, K.; Esteve, D.; Alphonse, P.; Tailhades, P.; Vahlas, C. Nanoenergetic materials for mems: A review. J. Microelectromech. Sys. 2007, 16, 919–931. [Google Scholar] [CrossRef]

- Roncaglia, A.; Ferri, M. Thermoelectric materials in mems and nems: A review. Sci. Adv. Mater. 2011, 3, 401–419. [Google Scholar] [CrossRef]

- Uddin, M.S.; Seah, K.; Li, X.; Rahman, M.; Liu, K. Effect of crystallographic orientation on wear of diamond tools for nano-scale ductile cutting of silicon. Wear 2004, 257, 751–759. [Google Scholar] [CrossRef]

- Tauhiduzzaman, M.; Veldhuis, S. Effect of material microstructure and tool geometry on surface generation in single point diamond turning. Precis. Eng. 2014, 38, 481–491. [Google Scholar] [CrossRef]

- Chandra, S.; Samal, M.; Chavan, V.; Raghunathan, S. Void growth in single crystal copper-an atomistic modeling and statistical analysis study. Philos. Mag. 2018, 98, 577–604. [Google Scholar] [CrossRef]

- Li, J.; Fang, Q.; Liu, B.; Liu, Y. The effects of pore and second-phase particle on the mechanical properties of machining copper matrix from molecular dynamic simulation. Appl. Surf. Sci. 2016, 384, 419–431. [Google Scholar] [CrossRef]

- Mohanty, S.; Routara, B.C. A review on machining of metal matrix composites using nanoparticle mixed dielectric in electro-discharge machining. Inter. J. Automot. Mech. Eng. 2016, 13, 3518–3539. [Google Scholar] [CrossRef]

- Ding, X.; Jarfors, A.; Lim, G.; Shaw, K.; Liu, Y.; Tang, L. A study of the cutting performance of poly-crystalline oxygen free copper with single crystalline diamond micro-tools. Precis. Eng. 2012, 36, 141–152. [Google Scholar] [CrossRef]

- Sreejith, P.; Ngoi, B. Material removal mechanisms in precision machining of new materials. Int. J. Mach. Tool. Manuf. 2001, 41, 1831–1843. [Google Scholar] [CrossRef]

- Zhu, Y.; Kishawy, H. Influence of alumina particles on the mechanics of machining metal matrix composites. Int. J. Mach. Tool. Manuf. 2005, 45, 389–398. [Google Scholar] [CrossRef]

- Choi, Y.; Liu, C.R. Performance of nano/micro cbn particle coated tools in superfinish hard machining. Int. J. Mach. Tool. Manuf. 2009, 49, 683–689. [Google Scholar] [CrossRef]

- Reddy, N.S.K.; Kwang-Sup, S.; Yang, M. Experimental study of surface integrity during end milling of al/sic particulate metal–matrix composites. J. Mater. Process. Technol. 2008, 201, 574–579. [Google Scholar] [CrossRef]

- Wang, T.; Xie, L.; Wang, X.; Jiao, L.; Shen, J.; Xu, H.; Nie, F. Surface integrity of high speed milling of al/sic/65p aluminum matrix composites. Procedia CIRP 2013, 8, 475–480. [Google Scholar] [CrossRef]

- Ge, Y.; Xu, J.; Yang, H.; Luo, S.; Fu, Y. Workpiece surface quality when ultraprecision turning of sicp/al composites. J. Mater. Process. Technol. 2008, 203, 166–175. [Google Scholar] [CrossRef]

- Ding, X.; Butler, D.; Lim, G.; Cheng, C.; Shaw, K.; Liu, K.; Fong, W.; Zheng, H. Machining with micro-size single crystalline diamond tools fabricated by a focused ion beam. J. Micromech. Microeng. 2009, 19, 025005. [Google Scholar] [CrossRef]

- Xu, F.; Fang, F.; Zhang, X. Side flow effect on surface generation in nano cutting. Nanoscale Res. Letter. 2017, 12, 359. [Google Scholar] [CrossRef]

- Casals, O.; Ocenasek, J.; Alcala, J. Crystal plasticity finite element simulations of pyramidal indentation in copper single crystals. Acta Mater. 2007, 55, 55–68. [Google Scholar] [CrossRef]

- Ding, F.; Luo, X.; Zhong, W.; Chang, W. Design of a new fast tool positioning system and systematic study on its positioning stability. Int. J. Mach. Tool. Manuf. 2019, 142, 54–65. [Google Scholar] [CrossRef]

- Zhang, R.F.; Wang, J.; Beyerlein, I.J.; Germann, T.C. Dislocation nucleation mechanisms from fcc/bcc incoherent interfaces. Scr. Mater. 2011, 65, 1022–1025. [Google Scholar] [CrossRef]

- Sansoz, F.; Stevenson, K.D. Relationship between hardness and dislocation processes in a nanocrystalline metal at the atomic scale. Phys. Rev. B Condens. Matter Mater. Phys. 2011, 83, 224101. [Google Scholar] [CrossRef]

- Wang, F.; Huang, P.; Xu, K. Strain rate sensitivity of nanoindentation creep in polycrystalline al film on silicon substrate. Surf. Coat. Technol. 2007, 201, 5216–5218. [Google Scholar] [CrossRef]

- Zhang, F.; Liu, Z.; Zhou, J.Q. Molecular dynamics simulation of micromechanical deformations in polycrystalline copper with bimodal structures. Mater. Letter. 2016, 183, 261–264. [Google Scholar] [CrossRef]

- Li, J.; Guo, J.W.; Luo, H.; Fang, Q.H.; Wu, H.; Zhang, L.C.; Liu, Y.W. Study of nanoindentation mechanical response of nanocrystalline structures using molecular dynamics simulations. Appl. Surf. Sci. 2016, 364, 190–200. [Google Scholar] [CrossRef]

- Huang, C.C.; Chiang, T.C.; Fang, T.H. Grain size effect on indentation of nanocrystalline copper. Appl. Surf. Sci. 2015, 353, 494–498. [Google Scholar] [CrossRef]

- Tahiri, A.; Idiri, M.; Hasnaoui, A.; Boubeker, B. Nano-indentation of nanocrystalline tungsten—A molecular dynamic simulation. Res. Rev. J. Mater. Sci. 2018, 6, 23–28. [Google Scholar]

- Gao, Y.; Ruestes, C.J.; Tramontina, D.R.; Urbassek, H.M. Comparative simulation study of the structure of the plastic zone produced by nanoindentation. J. Mechan. Phys. Solid. 2015, 75, 58–75. [Google Scholar] [CrossRef]

- Yuan, Z.; Lee, W.; Yao, Y.; Zhou, M. Effect of crystallographic orientation on cutting forces and surface quality in diamond cutting of single crystal. CIRP Ann. 1994, 43, 39–42. [Google Scholar] [CrossRef]

- Zhang, L.; Zhao, H.; Dai, L.; Yang, Y.; Du, X.; Tang, P.; Zhang, L. Molecular dynamics simulation of deformation accumulation in repeated nanometric cutting on single-crystal copper. Rsc Adv. 2015, 5, 12678–12685. [Google Scholar] [CrossRef]

- Zhang, J.J.; Sun, T.; Hartmaier, A.; Yan, Y.D. Atomistic simulation of the influence of nanomachining-induced deformation on subsequent nanoindentation. Comput. Mater. Sci. 2012, 59, 14–21. [Google Scholar] [CrossRef]

- Tunc, L.T.; Budak, E. Effect of cutting conditions and tool geometry on process damping in machining. Int. J. Mach. Tool. Manuf. 2012, 57, 10–19. [Google Scholar]

- Tucker, G.J.; Foiles, S.M. Quantifying the influence of twin boundaries on the deformation of nanocrystalline copper using atomistic simulations. Int. J. Plast. 2015, 65, 191–205. [Google Scholar] [CrossRef]

- Goel, S.; Kovalchenko, A.; Stukowski, A.; Cross, G. Influence of microstructure on the cutting behaviour of silicon. Acta Mater. 2016, 105, 464–478. [Google Scholar] [CrossRef]

- Foiles, S.M.; Baskes, M.I.; Daw, M.S. Erratum: Embedded-atom-method functions for the fcc metals cu, ag, au, ni, pd, pt, and their alloys. Phys. Rev. B Condens. Matter Mater. Phys. 1986, 33, 7983. [Google Scholar] [CrossRef] [PubMed]

- Daw, M.S.; Foiles, S.M.; Baskes, M.I. The embedded-atom method: A review of theory and applications. Mater. Sci. Rep. 1993, 9, 251–310. [Google Scholar] [CrossRef]

- Sha, Z.D.; Branicio, P.S.; Pei, Q.X.; Sorkin, V.; Zhang, Y.W. A modified tersoff potential for pure and hydrogenated diamond-like carbon. Comput. Mater. Sci. 2013, 67, 146–150. [Google Scholar] [CrossRef]

- Pei, Q.X.; Lu, C.; Fang, F.Z.; Wu, H. Nanometric cutting of copper: A molecular dynamics study. Comput. Mater. Sci. 2006, 37, 434–441. [Google Scholar] [CrossRef]

- Sharma, A.; Datta, D.; Balasubramaniam, R. An investigation of tool and hard particle interaction in nanoscale cutting of copper beryllium. Comput. Mater. Sci. 2018, 145, 208–223. [Google Scholar] [CrossRef]

- Wang, Q.; Bai, Q.; Chen, J.; Sun, Y.; Guo, Y.; Liang, Y. Subsurface defects structural evolution in nano-cutting of single crystal copper. Appl. Surf. Sci. 2015, 355, 38–46. [Google Scholar] [CrossRef]

- Wang, Q.; Bai, Q.; Chen, J.; Guo, Y.; Xie, W. Stress-induced formation mechanism of stacking fault tetrahedra in nano-cutting of single crystal copper. Appl. Surf. Sci. 2015, 355, 1153–1160. [Google Scholar] [CrossRef]

- Plimpton, S. Fast parallel algorithms for short-range molecular dynamics. J. Comput. Phys. 1995, 117, 1–19. [Google Scholar] [CrossRef]

- Stukowski, A.; Albe, K. Extracting dislocations and non-dislocation crystal defects from atomistic simulation data. Model. Simul. Mater. Sci. Eng. 2010, 18, 085001. [Google Scholar] [CrossRef]

- Voyiadjis, G.Z.; Yaghoobi, M. Size and strain rate effects in metallic samples of confined volumes: Dislocation length distribution. Scr. Mater. 2017, 130, 182–186. [Google Scholar] [CrossRef]

- Stukowski, A.; Bulatov, V.V.; Arsenlis, A. Automated identification and indexing of dislocations in crystal interfaces. Model. Simul. Mater. Sci. Eng. 2012, 20, 085007. [Google Scholar] [CrossRef]

- Xiao, G.; He, Y.; Geng, Y.; Yan, Y.; Ren, M. Molecular dynamics and experimental study on comparison between static and dynamic ploughing lithography of single crystal copper. Appl. Surf. Sci. 2019, 463, 96–104. [Google Scholar] [CrossRef]

- Zhang, J.; Shuai, M.; Zheng, H.; Li, Y.; Jin, M.; Sun, T. Atomistic and experimental investigation of the effect of depth of cut on diamond cutting of Cerium. Micromachines 2018, 9, 26. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Sun, Y.; Yan, Y.; Liang, Y.; Dong, S. Molecular dynamics simulation of subsurface deformed layers in AFM-based nanometric cutting process. Appl. Surf. Sci. 2008, 254, 4774–4779. [Google Scholar] [CrossRef]

- Yaghoobi, M.; Voyiadjis, G.Z. Microstructural investigation of the hardening mechanism in fcc crystals during high rate deformations. Comput. Mater. Sci. 2017, 138, 10–15. [Google Scholar] [CrossRef]

- Voyiadjis, G.Z.; Shojaei, A.; Mozaffari, N. Strain gradient plasticity for amorphous and crystalline polymers with application to micro-and nanoscale deformation analysis. Polymer 2014, 55, 4182–4198. [Google Scholar] [CrossRef]

- Chavoshi, S.Z.; Xu, S.; Luo, X. Dislocation-mediated plasticity in silicon during nanometric cutting: A molecular dynamics simulation study. Mater. Sci. Semicond. Process. 2016, 51, 60–70. [Google Scholar] [CrossRef]

- Xiang, Y.; Srolovitz, D.J.; Cheng, L.T.; Weinan, E. Level set simulations of dislocation-particle bypass mechanisms. Acta Mater. 2004, 52, 1745–1760. [Google Scholar] [CrossRef]

- Guo, Y.B.; Xu, T.; Li, M. Atomistic calculation of internal stress in nanoscale polycrystalline materials. Philos. Mag. 2012, 92, 3064–3083. [Google Scholar] [CrossRef]

- Chavoshi, S.Z.; Luo, X. Molecular dynamics simulation study of deformation mechanisms in 3c–sic during nanometric cutting at elevated temperatures. Mater. Sci. Eng. A 2016, 654, 400–417. [Google Scholar] [CrossRef]

- Robson, J. The effect of internal stresses due to precipitates on twin growth in magnesium. Acta Mater. 2016, 121, 277–287. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, P.; Zhang, Q.; Guo, Y.; Liu, H.; Deng, Z. Atomistic Simulation Study of Nanoparticle Effect on Nano-Cutting Mechanisms of Single-Crystalline Materials. Micromachines 2020, 11, 265. https://doi.org/10.3390/mi11030265

Zhao P, Zhang Q, Guo Y, Liu H, Deng Z. Atomistic Simulation Study of Nanoparticle Effect on Nano-Cutting Mechanisms of Single-Crystalline Materials. Micromachines. 2020; 11(3):265. https://doi.org/10.3390/mi11030265

Chicago/Turabian StyleZhao, Pengyue, Qi Zhang, Yongbo Guo, Huan Liu, and Zongquan Deng. 2020. "Atomistic Simulation Study of Nanoparticle Effect on Nano-Cutting Mechanisms of Single-Crystalline Materials" Micromachines 11, no. 3: 265. https://doi.org/10.3390/mi11030265

APA StyleZhao, P., Zhang, Q., Guo, Y., Liu, H., & Deng, Z. (2020). Atomistic Simulation Study of Nanoparticle Effect on Nano-Cutting Mechanisms of Single-Crystalline Materials. Micromachines, 11(3), 265. https://doi.org/10.3390/mi11030265