WEDM of Copper for the Fabrication of Large Surface-Area Micro-Channels: A Prerequisite for the High Heat-Transfer Rate

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

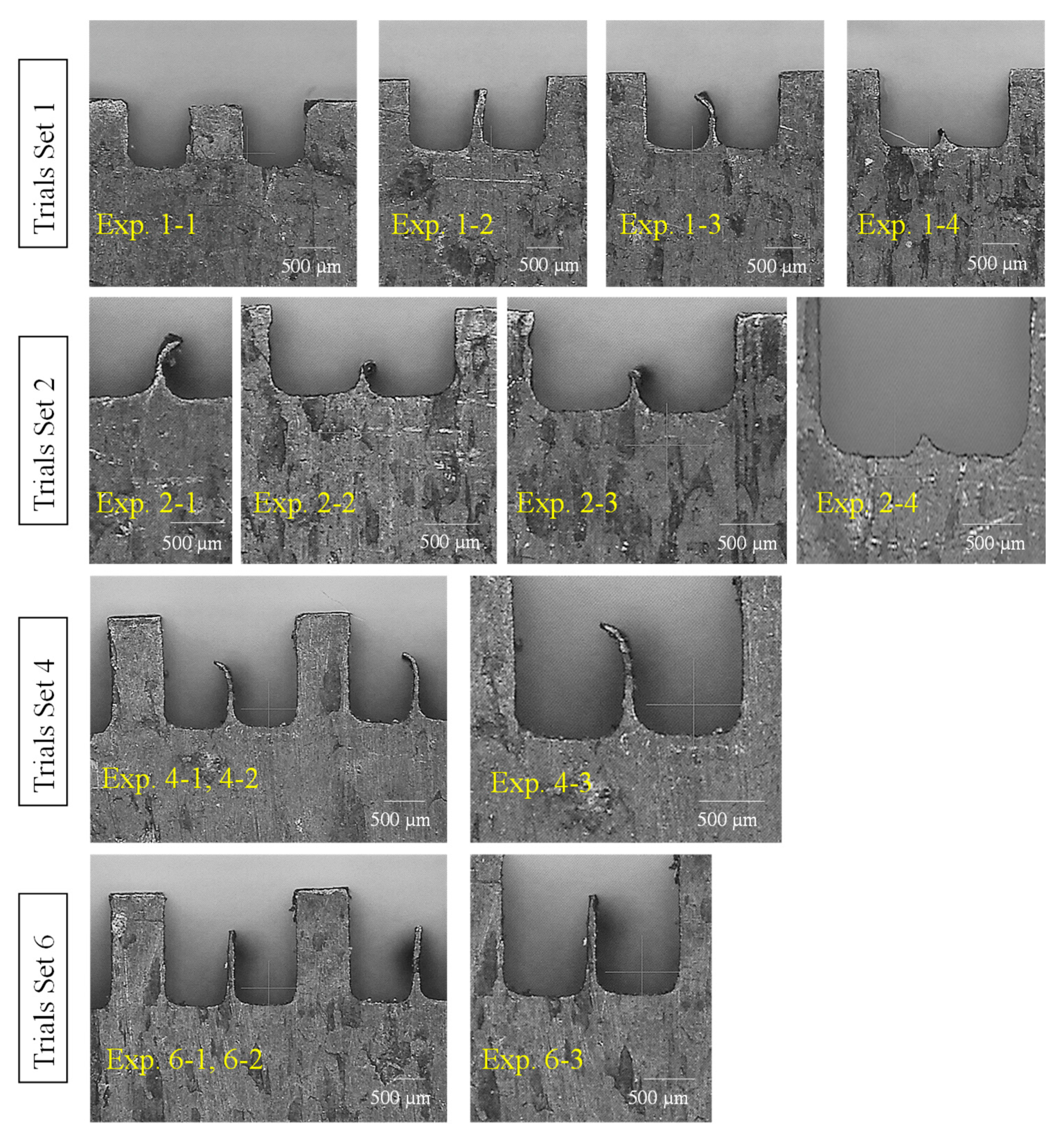

3.1. Trial Experimentation (Phase-1)

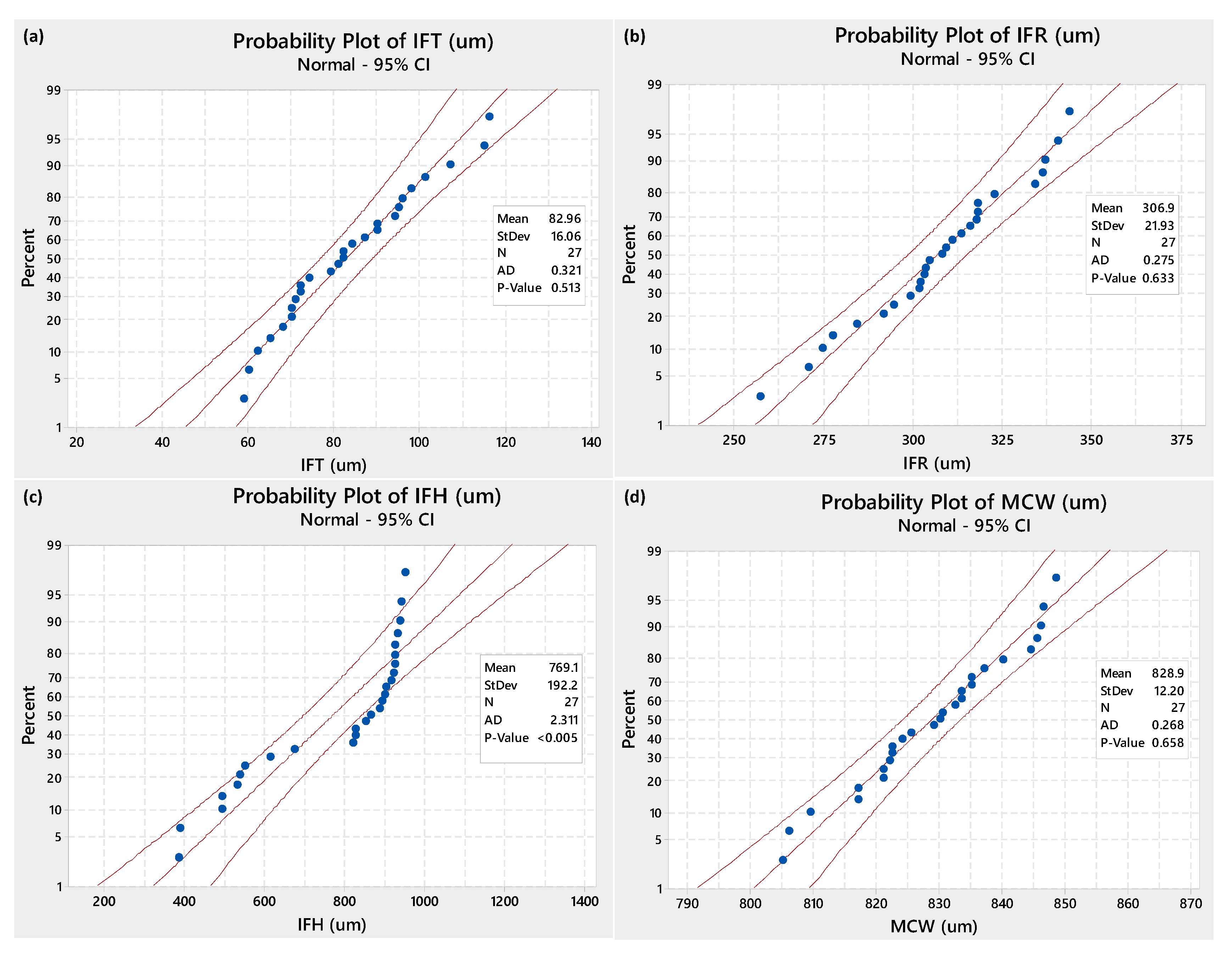

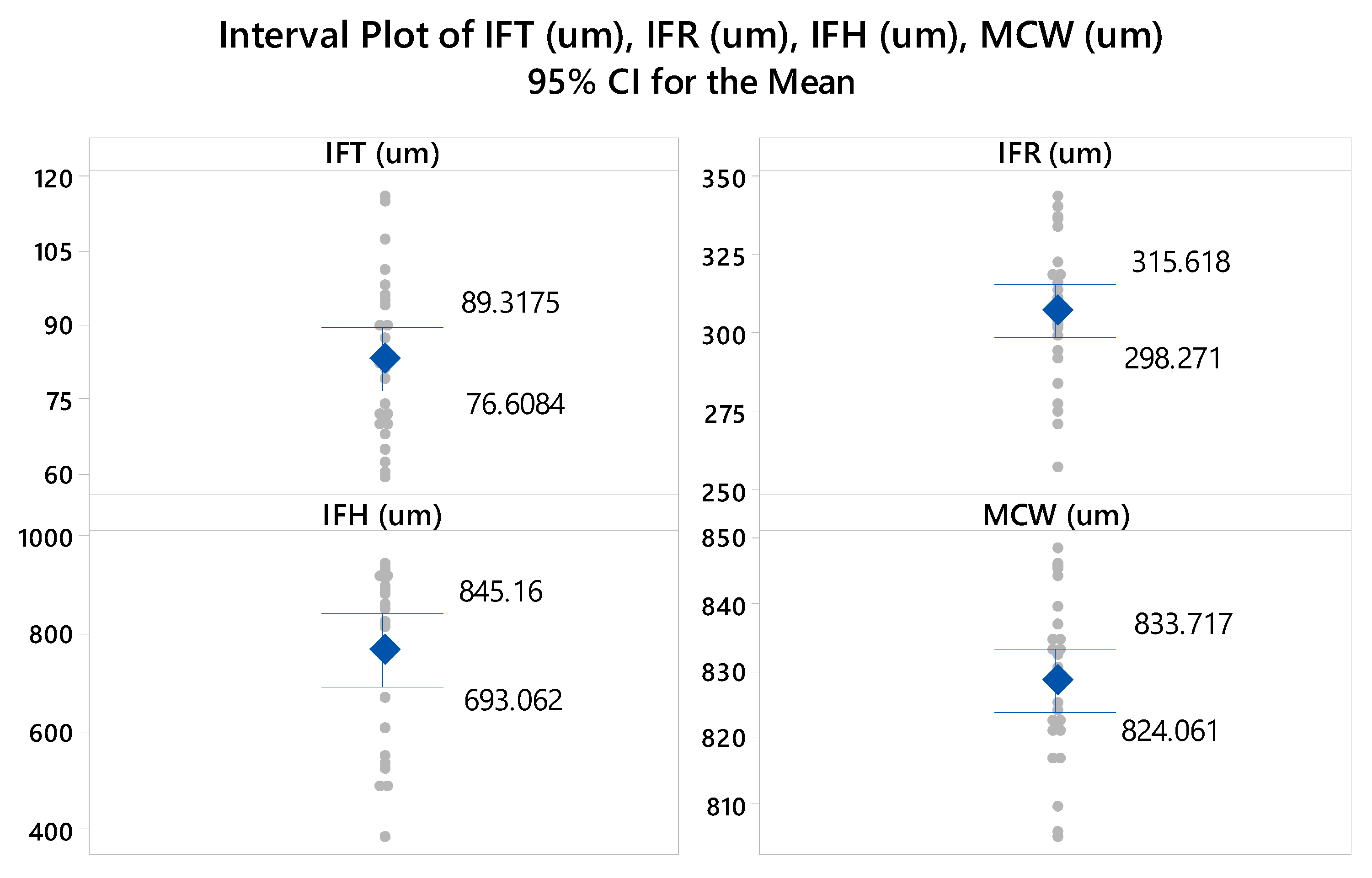

3.2. Mature Experimentation under Taguchi L27 (Phase-2)

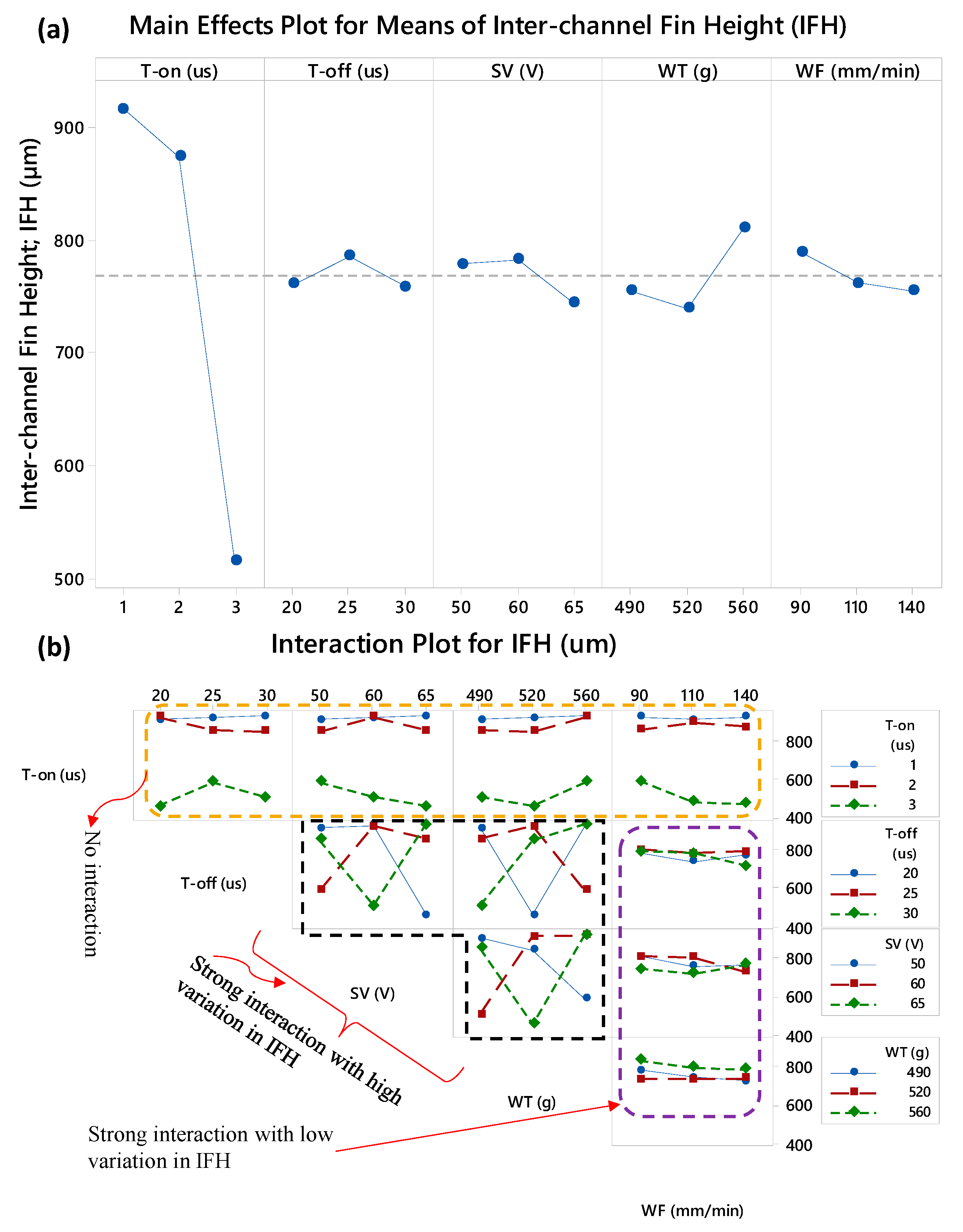

3.3. Parametric Effects and Signal-to-Noise Ratio Analysis

3.3.1. Analysis of Interchannels Fin Thickness (IFT)

3.3.2. Analysis of Interchannels Fin Height (IFH)

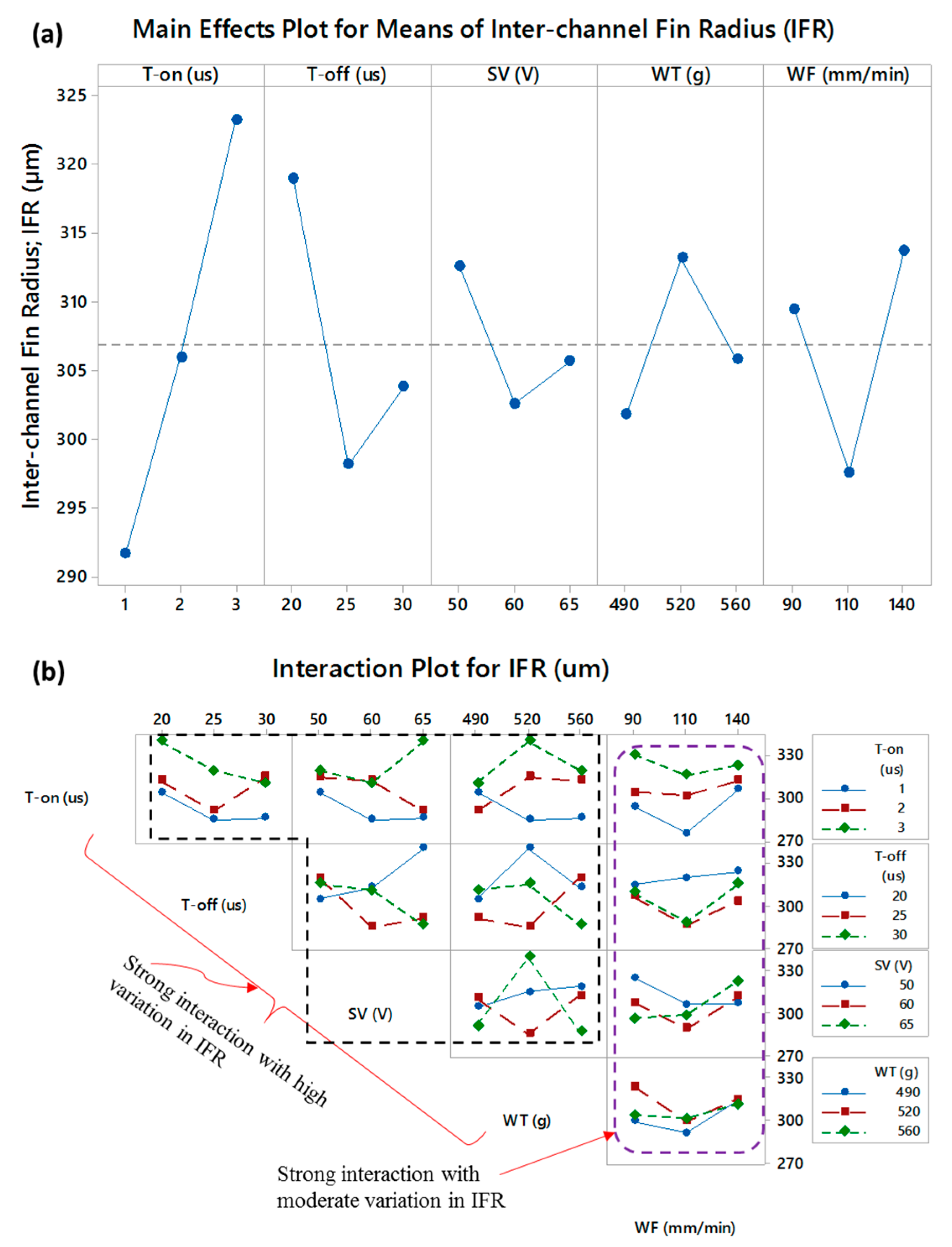

3.3.3. Analysis of Interchannels Fin Radius (IFR)

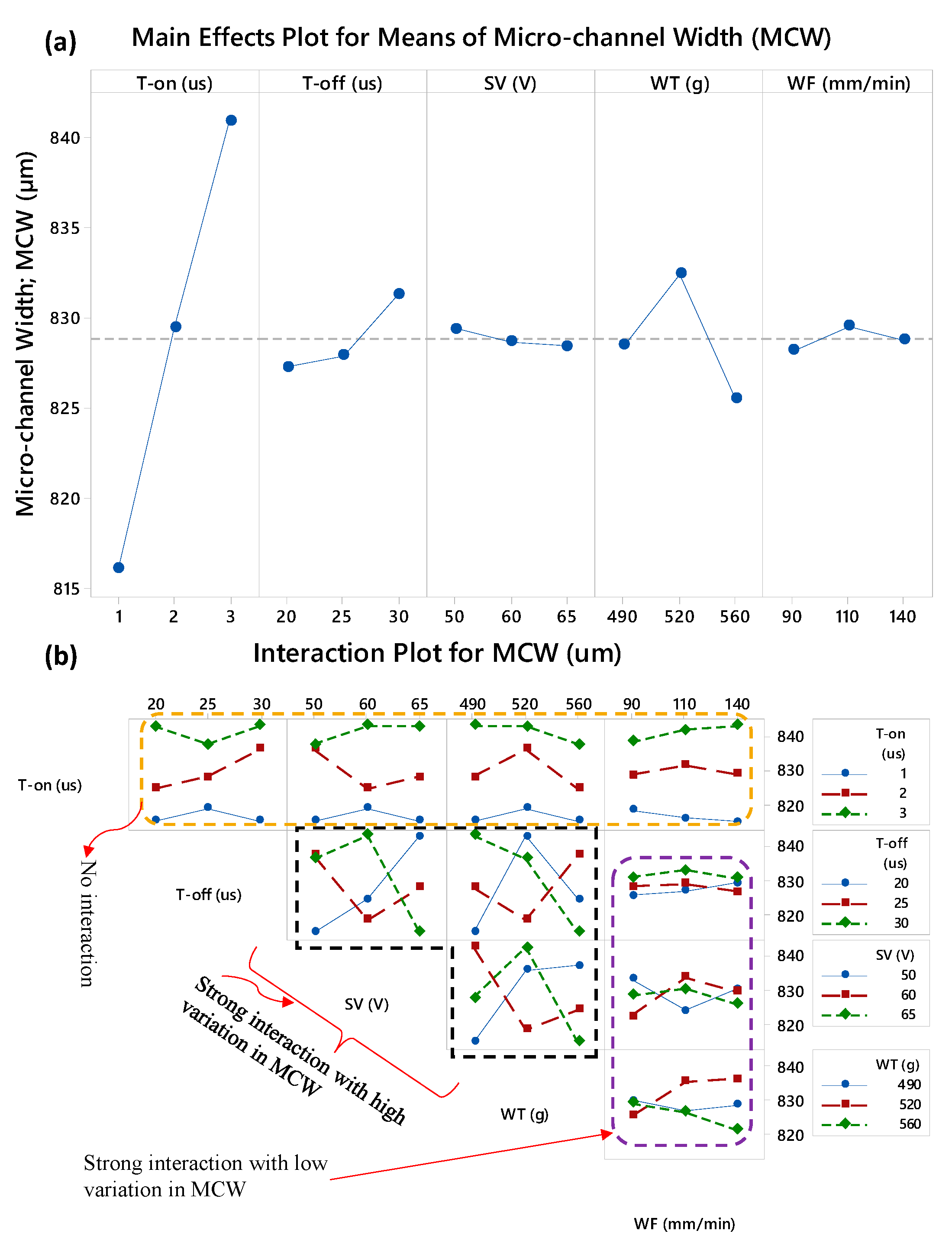

3.3.4. Analysis of Micro-Channels Width (MCW)

3.4. Correlation Analysis of Micro-Channels Attriutes

4. Conclusions

- i.

- Among the other attributes of the micro-channels, the inter-channels fin thickness (IFT) and the inter-channels fin height (IFH) are more sensitive to the WEDM parameters. The width of the micro-channel (MCW) and the inter-channels fin radius (IFR) can be controlled easily because of having ample space (1000 µm) for the wire to travel along the width of the channels.

- ii.

- The shape of the fin remains intact at the bottom end, whereas the top end of the fin gets damaged due to the pressure of plasma plume and the excessive heat dissipation over the less available material at the fin tip. Therefore, four configurations of inter-channels fins are observed.

- (a)

- No formation of the inter-channels fin or small spikes (fin broken at the top end);

- (b)

- Straight fins with moderate deflection (left-sided bend) at the top end;

- (c)

- Straight fins with aggressive deflection (left-sided curly bend) at the top end;

- (d)

- Straight fins with no/slight deflection at the top end.

- iii.

- As per the statistical analysis and S/N ratio analysis the pulse on-time (T-on), among the set of five WEDM process parameters, is always found to be the most significant and contributing factor for each of the four attributes of the micro-channels (IFT, IFH, IFR, and MCW). WT and T-off are also observed to have a noticeable effect on most of the micro-channel’s features. SV and WF revealed minimal effects.

- iv.

- The lower level of the pulse on-time (1 µs), the middle level of the pulse off-time (25 µs), and a higher level of the wire tension (560 g) can produce the micro-channels having competitive machining results (straight fins with no distortion) in terms of IFT, IFH, and IFR. However, if the prime concern is to produce the channels with greater width then the high pulse on-time is the most appropriate choice.

- v.

- To get the larger surface area (maximum number of micro-channels per unit area), the inter-channels fin thickness (IFT), fin radius (IFR), and micro-channel width (MCW) should have minimum dimensions, whereas the inter-channels fin height (IFH) should be at its maximum value with respect to the planned dimensions. The micro-channels in which the fins are straight with no deflection at the top end, the minimum values of IFT, IFR and MCW are observed to be 81 µm, 257 µm, and 805 µm, respectively. The maximum value of the inter-channels fin height (IFH), among the results of the straight fin with no deflection, is found to be 939 µm. The multi-objective optimization is expected to be performed in future work which can lead to having more control over the features of micro-channels.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Saranya, S.; Sankar, A.R. Fabrication of precise microchannels using a side-insulated tool in a spark assisted chemical engraving process. Mater. Manuf. Process. 2018, 33, 1422–1428. [Google Scholar] [CrossRef]

- Tang, W.; Liu, H.; Zhu, L.; Shi, J.; Li, Z.; Xiang, N.; Yang, J. Fabrication of Different Microchannels by Adjusting the Extrusion Parameters for Sacrificial Molds. Micromachines 2019, 10, 544. [Google Scholar] [CrossRef] [PubMed]

- Hakamada, M.; Asao, Y.; Kuromura, T.; Chen, Y.; Kusuda, H.; Mabuchi, M. Fabrication of copper microchannels by the spacer method. Scr. Mater. 2007, 56, 781–783. [Google Scholar] [CrossRef]

- Jayaramu, P.; Gedupudi, S.; Das, S.K. Influence of heating surface characteristics on flow boiling in a copper microchannel: Experimental investigation and assessment of correlations. Int. J. Heat Mass Transf. 2019, 128, 290–318. [Google Scholar] [CrossRef]

- Zhou, F.; Ling, W.; Zhou, W.; Qiu, Q.; Chu, X. Heat transfer characteristics of Cu-based microchannel heat exchanger fabricated by multi-blade milling process. Int. J. Therm. Sci. 2019, 138, 559–575. [Google Scholar] [CrossRef]

- Qin, J.; Ji, J.; Huang, W.; Qin, H.; Modjinou, M.; Li, G. Experimental Study of a Novel Direct-Expansion Variable Frequency Finned Solar/Air-Assisted Heat Pump Water Heater. Available online: https://www.hindawi.com/journals/ijp/2018/5986463/ (accessed on 13 November 2019).

- Kussul, E.; Makeyev, O.; Baidyk, T.; Olvera, O. Design of Ericsson Heat Engine with Micro Channel Recuperator. Available online: https://www.hindawi.com/journals/isrn/2012/613642/ (accessed on 13 November 2019).

- Shah, R.K.; Sekuli, D.P. Fundamentals of Heat Exchanger Design; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2003; ISBN 978-0-470-17260-5. [Google Scholar]

- Lee, D.; Chen, Y.T.; Bai, T.Y. A study of flows in tangentially crossing micro-channels. Microfluid. Nanofluid. 2009, 7, 169–179. [Google Scholar] [CrossRef]

- De Loos, S.R.A.; van der Schaaf, J.; Tiggelaar, R.M.; Nijhuis, T.A.; de Croon, M.H.J.M.; Schouten, J.C. Gas–liquid dynamics at low Reynolds numbers in pillared rectangular micro channels. Microfluid. Nanofluid. 2010, 9, 131–144. [Google Scholar] [CrossRef]

- Clyne, T.W.; Golosnoy, I.O.; Tan, J.C.; Markaki, A.E. Porous materials for thermal management under extreme conditions. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2006, 364, 125–146. [Google Scholar] [CrossRef]

- Fugmann, H.; Laurenz, E.; Schnabel, L. Wire Structure Heat Exchangers—New Designs for Efficient Heat Transfer. Energies 2017, 10, 1341. [Google Scholar] [CrossRef]

- Akbari, O.A.; Toghraie, D.; Karimipour, A. Numerical simulation of heat transfer and turbulent flow of water nanofluids copper oxide in rectangular microchannel with semi-attached rib. Adv. Mech. Eng. 2016, 8. [Google Scholar] [CrossRef]

- Wang, R.; Wang, J.; Yuan, W. Analysis and Optimization of a Microchannel Heat Sink with V-Ribs Using Nanofluids for Micro Solar Cells. Micromachines 2019, 10, 620. [Google Scholar] [CrossRef] [PubMed]

- Fu, B.R.; Chung, S.Y.; Lin, W.J.; Wang, L.; Pan, C. Critical heat flux enhancement of HFE-7100 flow boiling in a minichannel heat sink with saw-tooth structures. Adv. Mech. Eng. 2017, 9. [Google Scholar] [CrossRef]

- Prakash, S.; Kumar, S. Fabrication of microchannels: A review. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2015, 229, 1273–1288. [Google Scholar] [CrossRef]

- He, Z.; Li, D.; Cao, L.; Tang, Y. Fabrication and Characterization of Cross-Connected Microchannel Porous Mesh Plates (CCMPMPs) by Multi-Cutter Milling. Mater. Manuf. Process. 2015, 30, 256–262. [Google Scholar] [CrossRef]

- Ghoshal, B.; Bhattacharyya, B. Micro electrochemical sinking and milling method for generation of micro features. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2013, 227, 1651–1663. [Google Scholar] [CrossRef]

- Agrawal, D.; Kamble, D. Optimization of photochemical machining process parameters for manufacturing microfluidic channel. Mater. Manuf. Process. 2019, 34, 1–7. [Google Scholar] [CrossRef]

- Patil, D.H.; Mudigonda, S. The Effect of the Rolling Direction, Temperature, and Etching Time on the Photochemical Machining of Monel 400 Microchannels. Available online: https://www.hindawi.com/journals/amse/2016/6751305/ (accessed on 13 November 2019).

- Darwish, S.; Ahmed, N.; Alahmari, A.M.; Mufti, N.A. A study of micro-channel size and spatter dispersion for laser beam micro-milling. Mater. Manuf. Process. 2017, 32, 171–184. [Google Scholar] [CrossRef]

- Duong, T.H.; Kim, H.C.; Lee, D.Y.; Lee, S.W.; Park, E.S.; Je, T.J. A theoretical deformation prediction of micro channels in ultra-precision machining. Int. J. Precis. Eng. Manuf. 2013, 14, 173–181. [Google Scholar] [CrossRef]

- Huang, J.; Deng, Y.; Yi, P.; Peng, L. Experimental and numerical investigation on thin sheet metal roll forming process of micro channels with high aspect ratio. Int. J. Adv. Manuf. Technol. 2019, 100, 117–129. [Google Scholar] [CrossRef]

- Abyar, H.; Abdullah, A.; Akbarzadeh, A. Prediction Algorithm for WEDM Arced Path Errors Based on Spark Variable Gap and Nonuniform Spark Distribution Models. J. Manuf. Sci. Eng. 2019, 141. [Google Scholar] [CrossRef]

- Kirwin, R.M.; Mahbub, M.D.; Jahan, M.P. Investigating the effect of wire feed rate and wire tension on the corner and profile accuracies during wire-EDM of TI-6AL-4V. In Proceedings of the ASME 2018 13th International Manufacturing Science and Engineering Conference (MSEC 2018), College Station, TX, USA, 18–22 June 2018. [Google Scholar]

- Karthikeyan, G.; Sambhav, K.; Ramkumar, J.; Dhamodaran, S. Simulation and experimental realization of μ-channels using a μED-milling process. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2011, 225, 2206–2219. [Google Scholar] [CrossRef]

- Gupta, K.; Jain, N.K. Deviations in geometry of miniature gears fabricated by wire electrical discharge machining. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition, San Diego, CA, USA, 15–21 November 2013. [Google Scholar]

- Liao, Q.; Zhou, C.; Lu, Y.; Wu, X.; Chen, F.; Lou, Y. Efficient and Precise Micro-Injection Molding of Micro-Structured Polymer Parts Using Micro-Machined Mold Core by WEDM. Polymers 2019, 11, 1591. [Google Scholar] [CrossRef]

- Miller, S.F.; Kao, C.C.; Shih, A.J.; Qu, J. Investigation of wire electrical discharge machining of thin cross-sections and compliant mechanisms. Int. J. Mach. Tools Manuf. 2005, 45, 1717–1725. [Google Scholar] [CrossRef]

- Gupta, K.; Jain, N.K. On Micro-Geometry of Miniature Gears Manufactured by Wire Electrical Discharge Machining. Mater. Manuf. Process. 2013, 28, 1153–1159. [Google Scholar] [CrossRef]

- Ali, M.Y.; Mohammad, A.S. Experimental Study of Conventional Wire Electrical Discharge Machining for Microfabrication. Mater. Manuf. Process. 2008, 23, 641–645. [Google Scholar] [CrossRef]

- Malapati, M.; Bhattacharyya, B. Investigation into Electrochemical Micromachining Process during Micro-Channel Generation. Mater. Manuf. Process. 2011, 26, 1019–1027. [Google Scholar] [CrossRef]

- Zhou, W.; Deng, W.; Lu, L.; Zhang, J.; Qin, L.; Ma, S.; Tang, Y. Laser micro-milling of microchannel on copper sheet as catalyst support used in microreactor for hydrogen production. Int. J. Hydrogen Energy 2014, 39, 4884–4894. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, Z.; Huang, H.; Huang, Y.; Zhang, G.; Li, W.; Liu, C. Study on thermal deformation behavior and microstructural characteristics of wire electrical discharge machining thin-walled components. J. Manuf. Process. 2018, 31, 9–19. [Google Scholar] [CrossRef]

- Karidkar, S.S.; Dabade, U.A. Finite Element Modeling and Simulation of Inconel 718 Using WEDM; American Society of Mechanical Engineers Digital Collection; American Society of Mechanical Engineers: New York, NY, USA, 2017. [Google Scholar]

- Zhang, Y.M.; Zhang, Z.; Zhang, G.J.; Li, W.Y. Reduction of Energy Consumption and Thermal Deformation in WEDM by Magnetic Field Assisted Technology. Int. J. Precis. Eng. Manuf. Green Technol. 2019, 7, 391–404. [Google Scholar] [CrossRef]

- Darwish, S.M.H.; Ahmed, N.; Al-Ahmari, A.M. Laser Beam Micro-Milling of Micro-Channels in Aerospace Alloys; Springer: Berlin/Heidelberg, Germany, 2017; ISBN 978-981-10-3602-6. [Google Scholar]

- Abdo, B.M.A.; Ahmed, N.; El-Tamimi, A.M.; Anwar, S.; Alkhalefah, H.; Nasr, E.A. Laser beam machining of zirconia ceramic: An investigation of micro-machining geometry and surface roughness. J. Mech. Sci. Technol. 2019, 33, 1817–1831. [Google Scholar] [CrossRef]

| Property | Unit | Value |

|---|---|---|

| Density | g/cm3 | 8.96 |

| Hardness | HV | 110 |

| Electrical resistivity | Ωm | 16.78 |

| Thermal conductivity | W/mK | 401 |

| Melting point | °C | 1085 |

| No | Variable Name | Unit | Levels | ||

|---|---|---|---|---|---|

| 1 | 2 | 3 | |||

| 1 | Pulse On-time | µs | 1 | 2 | 3 |

| 2 | Pulse Off-time | µs | 20 | 25 | 30 |

| 3 | Spark Voltage | V | 55 | 60 | 65 |

| 4 | Wire Tension | g | 490 | 520 | 560 |

| 5 | Wire feed rate | mm/min | 90 | 110 | 140 |

| Runs | Exp. # | Wire Electrical Discharge Machining (WEDM) Parameters | Designed Inter-Channels Fin Thickness; IFT (µm) | Actual Inter-Channels Fin Thickness; IFT (µm) | Remarks |

|---|---|---|---|---|---|

| Trials Set 1: Inter-channel wall thickness ranging from 1000 to 250 µm (an increment of 250 µm) | |||||

| 1 | 1-1 | T-on = 2 µs, T-off = 25 µs, SV = 60 V, WT = 520 g, WF = 110 mm/min | 1000 | 1354 | Existence of inter-channel fin with noticeable thickness |

| 2 | 1-2 | 750 | 816 | ||

| 3 | 1-3 | 500 | 358 | ||

| 4 | 1-4 | 250 | - | Inter-channel wall gets broken | |

| Trials Set 2: Inter-channel wall thickness ranging from 500 to 300 µm (an increment of 50 µm) | |||||

| 5 | 2-1 | T-on = 2 µs, T-off = 25 µs, SV = 60 V, WT = 520 g, WF = 110 mm/min | 500 | 358 | Existence of inter-channel fin with noticeable thickness |

| 6 | 2-2 | 450 | 239 | ||

| 7 | 2-3 | 400 | 179 | ||

| 8 | 2-4 | 350 | - | No existence of inter-channel fin | |

| 9 | 2-5 | 300 | - | ||

| Trials Set 3: Inter-channel wall thickness ranging from 400 to 360 µm (an increment of 10 µm) | |||||

| 10 | 3-1 | T-on = 2 µs, T-off = 25 µs, SV = 60 V, WT = 520 g, WF = 110 mm/min | 400 | 179 | |

| 11 | 3-2 | 390 | - | No existence of inter-channel fin | |

| 12 | 3-3 | 380 | - | ||

| 13 | 3-4 | 370 | - | ||

| 14 | 3-5 | 360 | - | ||

| Trials Set 4: Inter-channel wall with constant thickness of 400 µm (confirmatory runs) | |||||

| 15 | 4-1 | T-on = 2 µs, T-off = 25 µs, SV = 60 V, WT = 520 g, WF = 110 mm/min | 400 | Measurements were not performed. Only CMM-based observations were captured | Inter-channel fin having a bend at the tip |

| 16 | 4-2 | 400 | |||

| 17 | 4-3 | 400 | |||

| 18 | 4-4 | 400 | |||

| 19 | 4-5 | 400 | |||

| Trials Set 5: Inter-channel wall with constant thickness of 400 µm (confirmatory runs) | |||||

| 20 | 5-1 | T-on = 3 µs, T-off = 30 µs, SV = 65 V, WT = 560 g, WF = 140 mm/min | 400 | - | No existence of inter-channel fin |

| 21 | 5-2 | 400 | - | ||

| 22 | 5-3 | 400 | - | ||

| 23 | 5-4 | 400 | - | ||

| 24 | 5-5 | 400 | - | ||

| Trials Set 6: Inter-channel wall with constant thickness of 400 µm (confirmatory runs) | |||||

| 25 | 6-1 | T-on = 1 µs, T-off = 20 µs, SV = 55 V, WT = 490 g, WF = 90 mm/min | 400 | Measurements were not performed. Only CMM-based observations were captured | Straight inter-channel fins were obtained. |

| 26 | 6-2 | 400 | |||

| 27 | 6-3 | 400 | |||

| 28 | 6-4 | 400 | |||

| 29 | 6-5 | 400 | |||

| Run | WEDM Parameters | Responses (Micro-Channels’ Attributes) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| T-on (µs) | T-off (µs) | SV (V) | WT (g) | WF (mm/min) | IFT (µm) | IFR (µm) | IFH (µm) | MCW (µm) | |

| 1 | 1 | 20 | 50 | 490 | 90 | 95 | 304.5 | 936 | 822.5 |

| 2 | 1 | 20 | 50 | 490 | 110 | 115 | 299 | 863 | 805 |

| 3 | 1 | 20 | 50 | 490 | 140 | 90 | 309 | 921 | 817 |

| 4 | 1 | 25 | 60 | 520 | 90 | 107 | 303 | 902 | 809.5 |

| 5 | 1 | 25 | 60 | 520 | 110 | 98 | 257 | 939 | 825.5 |

| 6 | 1 | 25 | 60 | 520 | 140 | 81 | 294.5 | 915 | 821 |

| 7 | 1 | 30 | 65 | 560 | 90 | 94 | 274.5 | 923 | 822 |

| 8 | 1 | 30 | 65 | 560 | 110 | 84 | 270.5 | 922 | 817 |

| 9 | 1 | 30 | 65 | 560 | 140 | 116 | 313.5 | 929 | 806 |

| 10 | 2 | 20 | 60 | 560 | 90 | 101 | 301.5 | 923 | 821 |

| 11 | 2 | 20 | 60 | 560 | 110 | 62 | 318 | 949 | 830 |

| 12 | 2 | 20 | 60 | 560 | 140 | 79 | 318 | 897 | 822.5 |

| 13 | 2 | 25 | 65 | 490 | 90 | 72 | 277.5 | 819 | 830.5 |

| 14 | 2 | 25 | 65 | 490 | 110 | 87 | 284 | 851 | 829 |

| 15 | 2 | 25 | 65 | 490 | 140 | 96 | 311 | 890 | 824 |

| 16 | 2 | 30 | 50 | 520 | 90 | 70 | 334 | 826 | 833.5 |

| 17 | 2 | 30 | 50 | 520 | 110 | 70 | 302 | 886 | 835 |

| 18 | 2 | 30 | 50 | 520 | 140 | 65 | 308 | 825 | 840 |

| 19 | 3 | 20 | 65 | 520 | 90 | 82 | 336 | 491 | 833.5 |

| 20 | 3 | 20 | 65 | 520 | 110 | 72 | 340.5 | 387 | 846 |

| 21 | 3 | 20 | 65 | 520 | 140 | 59 | 343.5 | 491 | 848.5 |

| 22 | 3 | 25 | 50 | 560 | 90 | 74 | 337 | 673 | 844.5 |

| 23 | 3 | 25 | 50 | 560 | 110 | 82 | 316 | 536 | 832.5 |

| 24 | 3 | 25 | 50 | 560 | 140 | 90 | 303.5 | 550 | 835 |

| 25 | 3 | 30 | 60 | 490 | 90 | 71 | 317.5 | 611 | 837 |

| 26 | 3 | 30 | 60 | 490 | 110 | 68 | 291.5 | 528 | 846.5 |

| 27 | 3 | 30 | 60 | 490 | 140 | 60 | 322.5 | 383 | 845.5 |

| Responses | N | Min. | Max. | Mean | StDev |

|---|---|---|---|---|---|

| IFT (µm) | 27 | 59 | 116 | 82.96 | 16.06 |

| IFR (µm) | 27 | 257 | 343.5 | 306.9 | 21.93 |

| IFH (µm) | 27 | 383 | 949 | 769.1 | 192.20 |

| MCW (µm) | 27 | 805 | 848.5 | 828.9 | 12.20 |

| Level | T-on (µs) | T-off (µs) | SV (V) | WT (g) | WF (mm/min) |

|---|---|---|---|---|---|

| 1 | 39.74 | 38.29 | 38.30 | 38.30 | 38.49 |

| 2 | 37.73 | 38.77 | 37.97 | 37.72 | 38.13 |

| 3 | 37.20 | 37.62 | 38.41 | 38.65 | 38.05 |

| Delta | 2.54 | 1.15 | 0.44 | 0.93 | 0.44 |

| Rank | 1 | 2 | 5 | 3 | 4 |

| Level | T-On (µs) | T-Off (µs) | SV (V) | WT (g) | WF (mm/min) |

|---|---|---|---|---|---|

| 1 | 59.24 | 57.19 | 57.67 | 57.24 | 57.76 |

| 2 | 58.82 | 57.73 | 57.50 | 56.98 | 57.26 |

| 3 | 54.13 | 57.27 | 57.02 | 57.98 | 57.17 |

| Delta | 5.11 | 0.54 | 0.64 | 1.00 | 0.59 |

| Rank | 1 | 5 | 3 | 2 | 4 |

| Level | T-on (µs) | T-off (µs) | SV (V) | WT (g) | WF (mm/min) |

|---|---|---|---|---|---|

| 1 | −49.28 | −50.06 | −49.89 | −49.59 | −49.79 |

| 2 | −49.70 | −49.47 | −49.60 | −49.88 | −49.44 |

| 3 | −50.18 | −49.63 | −49.67 | −49.69 | −49.92 |

| Delta | 0.89 | 0.60 | 0.29 | 0.30 | 0.48 |

| Rank | 1 | 2 | 5 | 4 | 3 |

| Level | T-On (µs) | T-Off (µs) | SV (V) | WT (g) | WF (mm/min) |

|---|---|---|---|---|---|

| 1 | 58.24 | 58.35 | 58.37 | 58.37 | 58.36 |

| 2 | 58.38 | 58.36 | 58.37 | 58.41 | 58.38 |

| 3 | 58.50 | 58.40 | 58.36 | 58.33 | 58.37 |

| Delta | 0.26 | 0.04 | 0.01 | 0.07 | 0.01 |

| Rank | 1 | 3 | 5 | 2 | 4 |

| Response | p-Value | Significance | Coefficient | Relationship | |

|---|---|---|---|---|---|

| Strength | Direction | ||||

| Correlation of micro-channels’ features with pulse on-time (T-on) | |||||

| IFT | 0.000 | Significant | −0.639 | Moderately strong | -ve |

| IFR | 0.001 | - | 0.596 | Moderately strong | +ve |

| IFH | 0.000 | - | −0.866 | Strong | -ve |

| MCW | 0.000 | - | 0.847 | Strong | +ve |

| Correlation of micro-channels’ features with pulse off-time (T-off) | |||||

| IFT | 0.414 | Insignificant | −0.164 | Very weak | -ve |

| IFR | 0.147 | - | −0.287 | Weak | -ve |

| IFH | 0.976 | - | −0.006 | Zero | NA |

| MCW | 0.492 | - | 0.138 | Very weak | +ve |

| Correlation of micro-channels’ features with servo voltage (SV) | |||||

| IFT | 0.950 | - | 0.013 | Zero | NA |

| IFR | 0.439 | - | −0.155 | Very weak | -ve |

| IFH | 0.751 | - | −0.064 | Zero | NA |

| MCW | 0.868 | - | −0.033 | - | - |

| Correlation of micro-channels’ features with wire tension (WT) | |||||

| IFT | 0.628 | - | 0.098 | Zero | NA |

| IFR | 0.771 | - | 0.059 | - | - |

| IFH | 0.522 | - | 0.129 | Very weak | +ve |

| MCW | 0.559 | - | −0.118 | - | -ve |

| Correlation of micro-channels’ features with wire feed rate (WF) | |||||

| IFT | 0.689 | - | −0.081 | Zero | NA |

| IFR | 0.569 | - | 0.155 | Very weak | +ve |

| IFH | 0.731 | - | 0.069 | Zero | NA |

| MCW | 0.938 | - | 0.016 | - | - |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahmed, N.; Mughal, M.P.; Shoaib, W.; Farhan Raza, S.; Alahmari, A.M. WEDM of Copper for the Fabrication of Large Surface-Area Micro-Channels: A Prerequisite for the High Heat-Transfer Rate. Micromachines 2020, 11, 173. https://doi.org/10.3390/mi11020173

Ahmed N, Mughal MP, Shoaib W, Farhan Raza S, Alahmari AM. WEDM of Copper for the Fabrication of Large Surface-Area Micro-Channels: A Prerequisite for the High Heat-Transfer Rate. Micromachines. 2020; 11(2):173. https://doi.org/10.3390/mi11020173

Chicago/Turabian StyleAhmed, Naveed, Mohammad Pervez Mughal, Waqar Shoaib, Syed Farhan Raza, and Abdulrhman M. Alahmari. 2020. "WEDM of Copper for the Fabrication of Large Surface-Area Micro-Channels: A Prerequisite for the High Heat-Transfer Rate" Micromachines 11, no. 2: 173. https://doi.org/10.3390/mi11020173

APA StyleAhmed, N., Mughal, M. P., Shoaib, W., Farhan Raza, S., & Alahmari, A. M. (2020). WEDM of Copper for the Fabrication of Large Surface-Area Micro-Channels: A Prerequisite for the High Heat-Transfer Rate. Micromachines, 11(2), 173. https://doi.org/10.3390/mi11020173