Characterization of Soft Tooling Photopolymers and Processes for Micromixing Devices with Variable Cross-Section

Abstract

:1. Introduction

2. Materials and Methods

2.1. Soft Tooling Material Process Screening

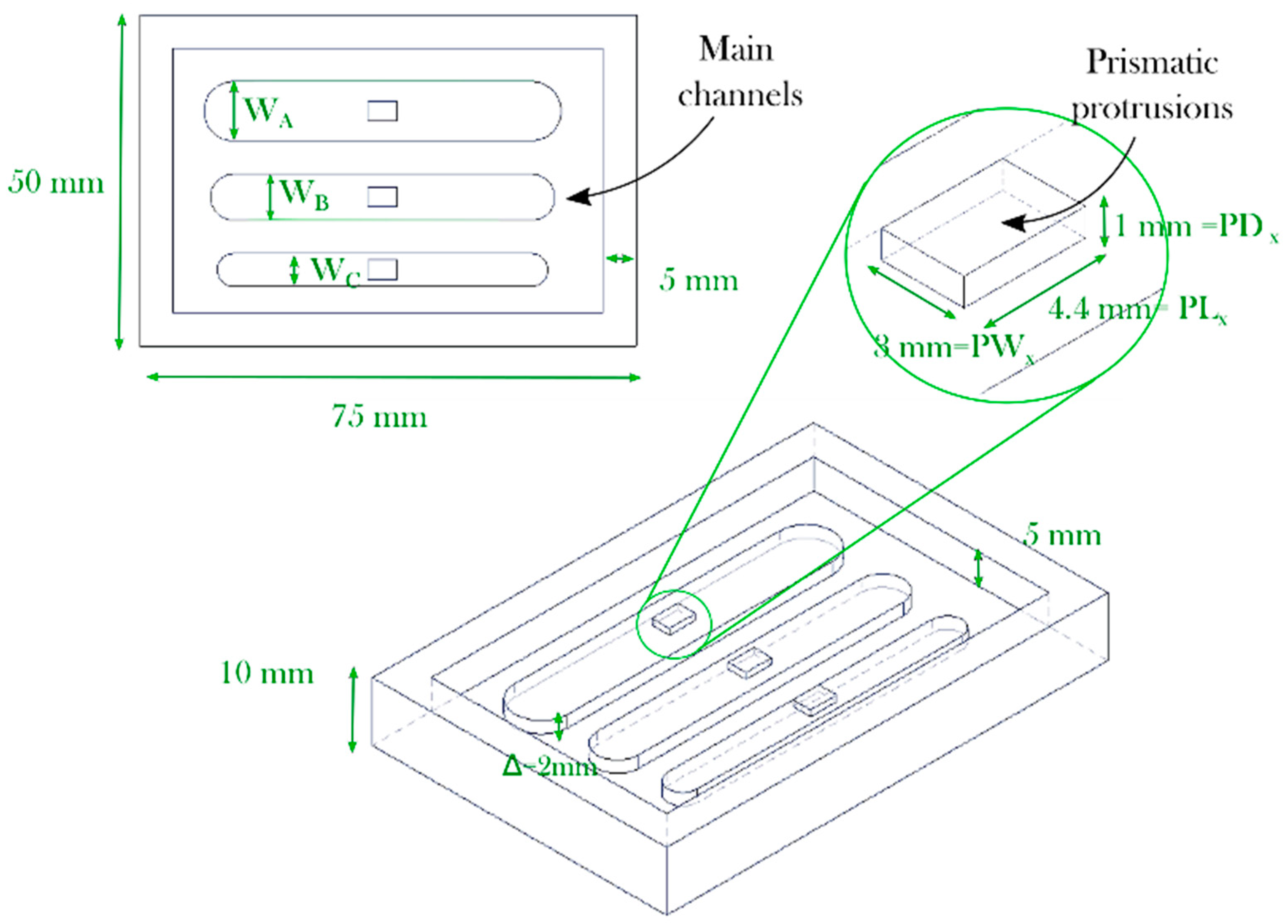

2.1.1. Screening Mold Geometry

2.1.2. Qualitative Assessment

2.1.3. Screening Mold Metrology

2.1.4. Aluminum Mold Manufactured Using a Conventional Subtractive Methodology

2.2. Additive Manufacturing Processes and Materials

2.3. Microdevice Polydimethylsiloxane (PDMS) Casting

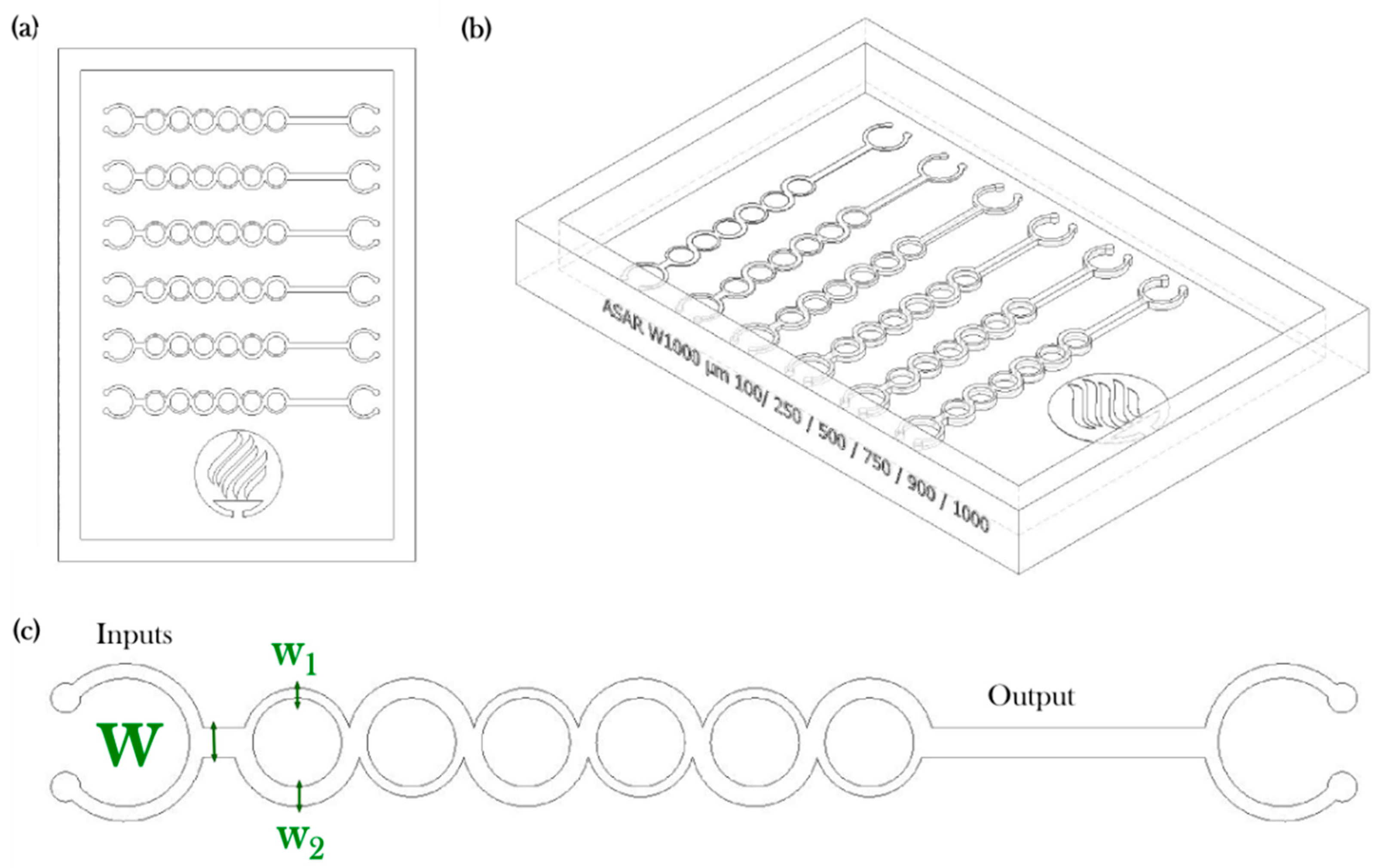

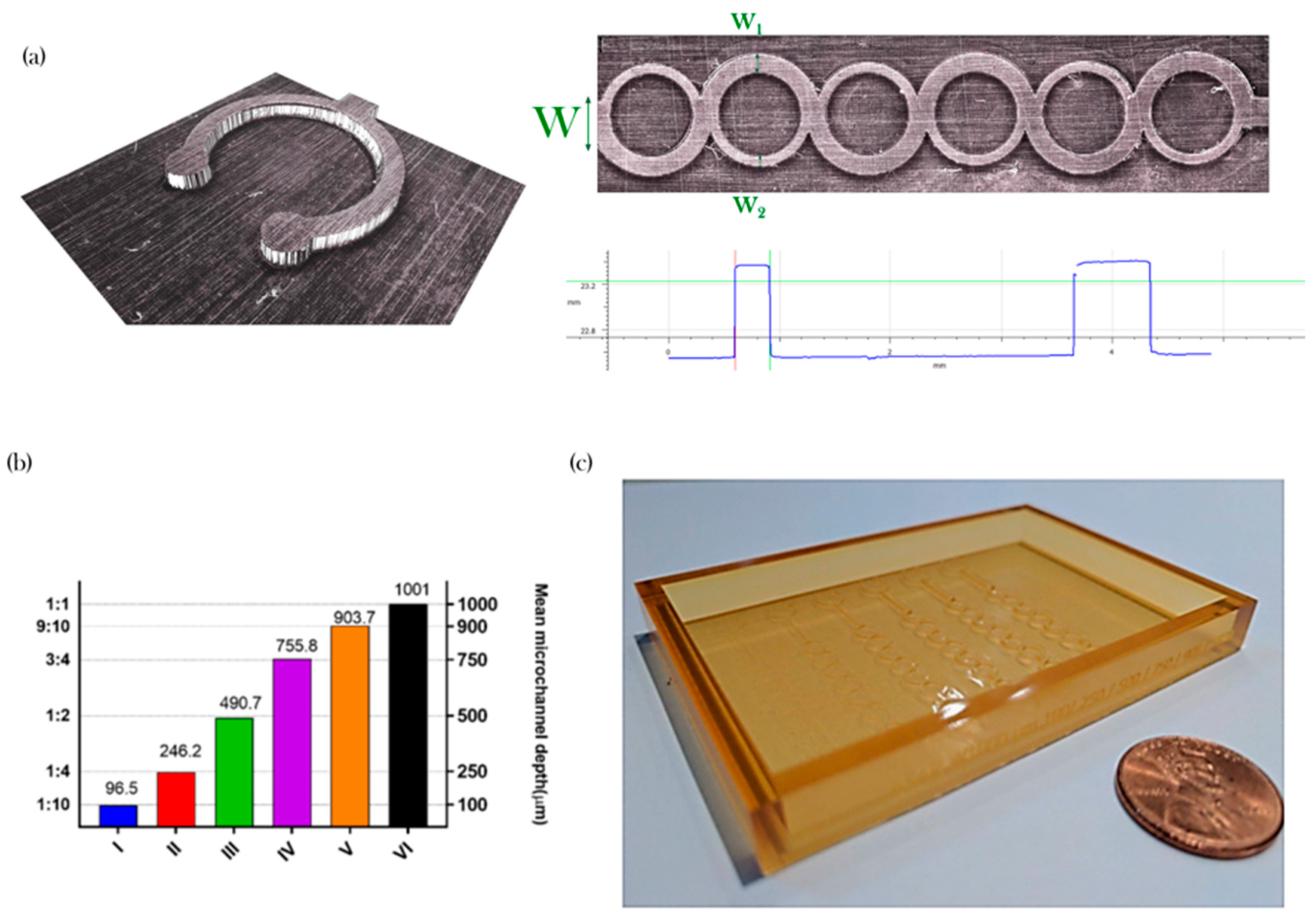

2.4. Case study: ASAR Micromixer Array

2.4.1. Micromixing Mold Geometry

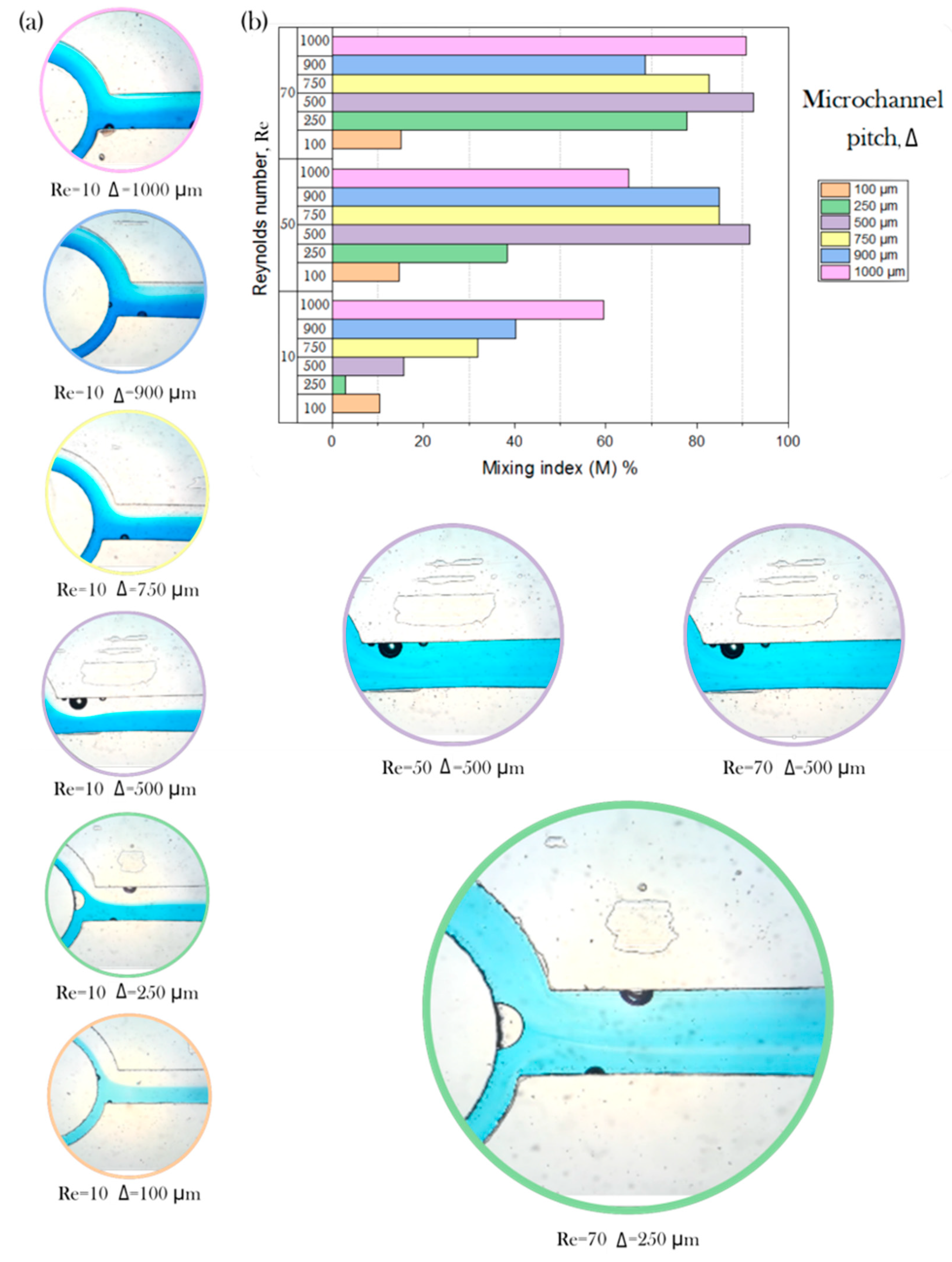

2.4.2. Micromixing Performance Evaluation

2.4.3. Micromixing Experimental Setup

3. Results

3.1. Qualitative Assessment of Screened Materials

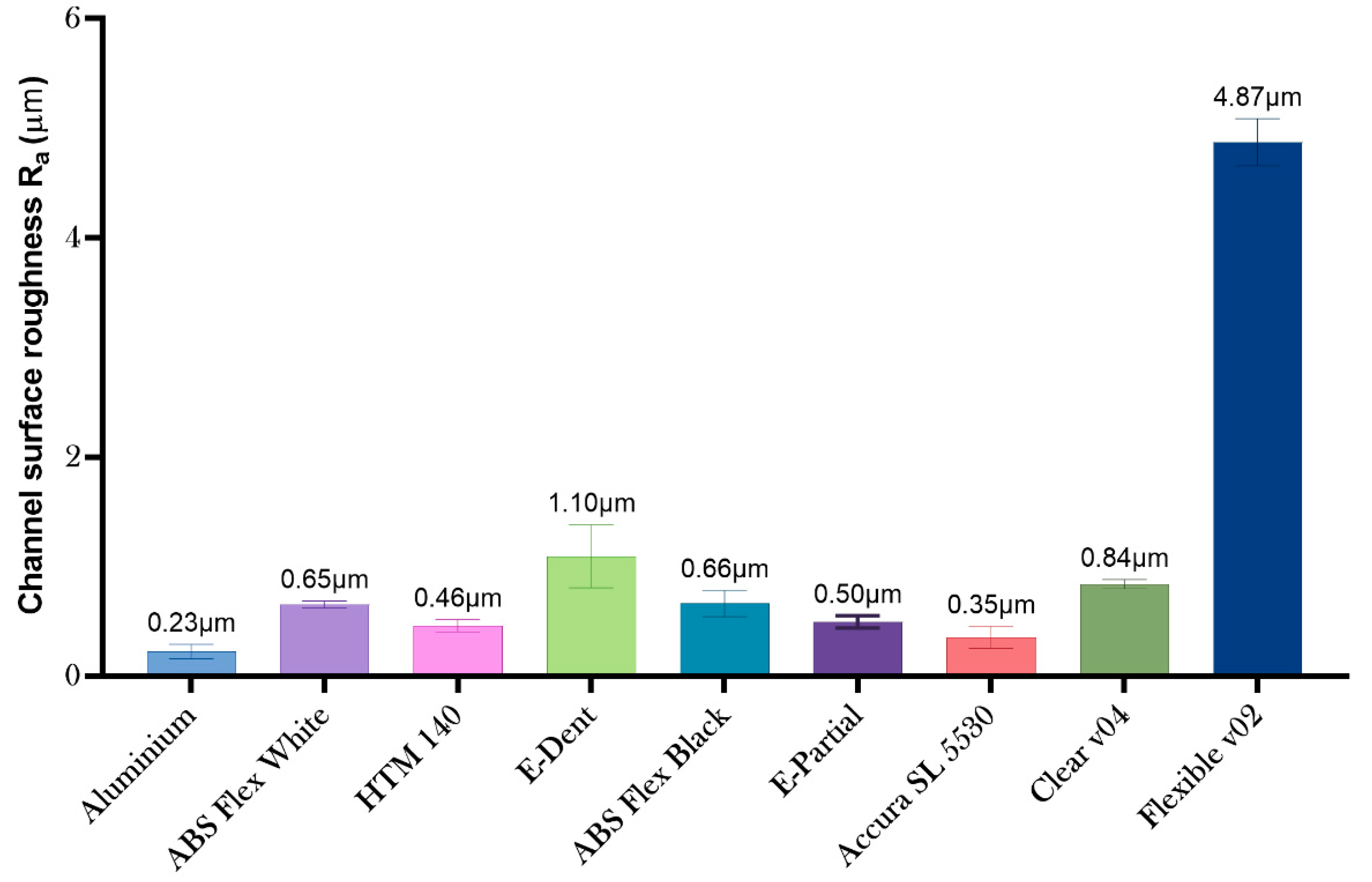

3.2. Dimensional and Surface Metrology of Photopolymers and AM Processes

3.3. Case Study: Asymmetric Split-and-Recombine (ASAR) Microdevice Surface Metrology

3.4. Micromixing Performance

3.5. Learned Lessons and Future Work

- It is possible to produce different versions of the same device on a single mold with a single demolding step. Other possible layouts include different devices on a single molding step or an array of a single device.

- Device identifier: engraving symbols on the device can be implemented for identifying the mold among different variations.

- Other potential futures were prospected for future work, as removable wall(s) that could ease the remotion of the PDMS and the capability to dispose placeholders for inlet or outlet pins as part of the mold.

4. Conclusions

- The rapid or soft tooling approach was screened for eight (8) different photopolymers as a viable option for developing complex micromixing devices.

- The experimental data provided valuable insights on acceptable manufacturing practices toward a new generation of devices.

- The novel design of the mold with variable depth was successfully implemented to test different regime conditions within the same device.

- Methodology for the production of an array of micromixers with a variable cross-section was successfully implemented.

- Multiple cross-sections on a single device could be implemented using stereolithography. Other device setups (an array of a single device or different type of devices on a single mold) could be implemented using the methodology presented in this work.

- Surface characterization showed an absolute deviational error within 10 micrometers.

- Stereolithography is a viable option for the development of complex three-dimensional molds for the development of micromixers, but it is necessary to consider the surface-to-surface interaction between the mold and the resin.

- Further studies are required to evaluate the effect of the geometrical features of the ASAR micromixer thoroughly.

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Gambhire, S.; Patel, N.; Gambhire, G.; Kale, S. A Review on Different Micromixers and its Micromixing within Microchannel. Int. J. Curr. Eng. Technol. 2016, 4. [Google Scholar] [CrossRef]

- Su, Y.; Chen, G.; Yuan, Q. Ideal micromixing performance in packed microchannels. Chem. Eng. Sci. 2011, 66, 2912–2919. [Google Scholar] [CrossRef]

- Chung, C.K.; Shih, T.R. Effect of geometry on fluid mixing of the rhombic micromixers. Microfluid. Nanofluidics 2008, 4, 419–425. [Google Scholar] [CrossRef]

- Hossain, S.; Kim, K.-Y. Mixing Analysis of Passive Micromixer with Unbalanced Three-Split Rhombic Sub-Channels. Micromachines 2014, 5, 913–928. [Google Scholar] [CrossRef]

- Hong, C.-C.; Choi, J.-W.; Ahn, C.H. A Novel In-Plane Passive Micromixer Using Coanda Effect. In Micro Total Analysis Systems 2001; Ramsey, J.M., van den Berg, A., Eds.; Springer: Dordrecht, The Netherlands, 2001; pp. 31–33. ISBN 978-94-010-3893-5. [Google Scholar]

- Hong, C.-C.; Choi, J.-W.; Ahn, C.H. A novel in-plane passive microfluidic mixer with modified Tesla structures. Lab. Chip 2004, 4, 109–113. [Google Scholar] [CrossRef] [PubMed]

- Hossain, S.; Ansari, M.A.; Husain, A.; Kim, K.-Y. Analysis and optimization of a micromixer with a modified Tesla structure. Chem. Eng. J. 2010, 158, 305–314. [Google Scholar] [CrossRef]

- Sudarsan, A.P.; Ugaz, V.M. Fluid mixing in planar spiral microchannels. Lab. Chip 2006, 6, 74–82. [Google Scholar] [CrossRef] [PubMed]

- Ansari, M.A.; Kim, K.-Y.; Anwar, K.; Kim, S.M. A novel passive micromixer based on unbalanced splits and collisions of fluid streams. J. Micromech. Microeng. 2010, 20, 055007. [Google Scholar] [CrossRef] [Green Version]

- Ansari, M.A.; Kim, K.-Y. Mixing performance of unbalanced split and recombine micomixers with circular and rhombic sub-channels. Chem. Eng. J. 2010, 162, 760–767. [Google Scholar] [CrossRef]

- Gidde, R.R.; Pawar, P.M.; Ronge, B.P.; Misal, N.D.; Kapurkar, R.B.; Parkhe, A.K. Evaluation of the mixing performance in a planar passive micromixer with circular and square mixing chambers. Microsyst. Technol. 2018, 24, 2599–2610. [Google Scholar] [CrossRef]

- Bazaz, S.R.; Warkiani, M.E.; Mehrizi, A.A.; Ghorbani, S.; Vasilescu, S.; Asadnia, M. A hybrid micromixer with planar mixing units. RSC Adv. 2018. [Google Scholar] [CrossRef] [Green Version]

- Nimafar, M.; Viktorov, V.; Martinelli, M. Experimental comparative mixing performance of passive micromixers with H-shaped sub-channels. Chem. Eng. Sci. 2012, 76, 37–44. [Google Scholar] [CrossRef]

- Feng, X.; Ren, Y.; Jiang, H. An effective splitting-and-recombination micromixer with self-rotated contact surface for wide {Reynolds} number range applications. Biomicrofluidics 2013, 7. [Google Scholar] [CrossRef] [Green Version]

- SadAbadi, H.; Packirisamy, M.; Wüthrich, R. High performance cascaded PDMS micromixer based on split-and-recombination flows for lab-on-a-chip applications. RSC Adv. 2013, 3, 7296–7305. [Google Scholar] [CrossRef]

- Jian Chen, J.; Ren Lai, Y.; Tang Tsai, R.; Der Lin, J.; Yang Wu, C. Crosswise ridge micromixers with split and recombination helical flows. Chem. Eng. Sci. 2011, 66, 2164–2176. [Google Scholar] [CrossRef]

- Chenouard, N.; Smal, I.; de Chaumont, F.; Maška, M.; Sbalzarini, I.F.; Gong, Y.; Cardinale, J.; Carthel, C.; Coraluppi, S.; Winter, M.; et al. Objective comparison of particle tracking methods. Nat. Methods 2014, 11, 281–289. [Google Scholar] [CrossRef] [Green Version]

- Gidde, R.R.; Pawar, P.M. Flow feature and mixing performance analysis of {RB}-{TSAR} and {EB}-{TSAR} micromixers. Microsyst. Technol. 2020, 26, 517–530. [Google Scholar] [CrossRef]

- Raza, W.; Kim, K.-Y. Unbalanced Split and Recombine Micromixer with Three-Dimensional Steps. Ind. Eng. Chem. Res. 2020, 59, 3744–3756. [Google Scholar] [CrossRef]

- Li, J.; Xia, G.; Li, Y. Numerical and experimental analyses of planar asymmetric split-and-recombine micromixer with dislocation sub-channels. J. Chem. Technol. Biotechnol. 2013, 88, 1757–1765. [Google Scholar] [CrossRef]

- Chen, X.; Shen, J. Numerical analysis of mixing behaviors of two types of {E}-shape micromixers. Int. J. Heat Mass Transf. 2017, 106, 593–600. [Google Scholar] [CrossRef]

- He, M.; Li, W.; Zhang, M.; Zhang, J. Numerical investigation on the efficient mixing of overbridged split-and-recombine micromixer at low {Reynolds} number. Microsyst. Technol. 2019, 25, 3447–3461. [Google Scholar] [CrossRef]

- Guckenberger, D.J.; De Groot, T.E.; Wan, A.M.D.; Beebe, D.J.; Young, E.W.K. Micromilling: A method for ultra-rapid prototyping of plastic microfluidic devices. Lab. Chip 2015. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Clark, J.; Kaufman, M.; Fodor, P.S. Mixing Enhancement in Serpentine Micromixers with a Non-Rectangular Cross-Section. Micromachines 2018, 9, 107. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Clark, J.A.; Butt, T.A.; Mahajan, G.; Kothapalli, C.R.; Kaufman, M.; Fodor, P.S. Performance and implementation of centrifugal serpentine micromixers with non-rectangular cross-section. J. Micromechanics Microengineering 2019, 29, 075012. [Google Scholar] [CrossRef]

- Au, A.K.; Huynh, W.; Horowitz, L.F.; Folch, A. {3D}-{Printed} {Microfluidics}. Angew. Chemie Int. Ed. 2016, 55, 3862–3881. [Google Scholar] [CrossRef]

- Chen, C.; Mehl, B.T.; Munshi, A.S.; Townsend, A.D.; Spence, D.M.; Martin, R.S. 3D-printed microfluidic devices: Fabrication, advantages and limitations—A mini review. Anal. Methods 2016, 8, 6005–6012. [Google Scholar] [CrossRef]

- Waheed, S.; Cabot, J.M.; Macdonald, N.P.; Lewis, T.; Guijt, R.M.; Paull, B.; Breadmore, M.C. {3D} printed microfluidic devices: Enablers and barriers. Lab. Chip 2016, 16, 1993–2013. [Google Scholar] [CrossRef] [Green Version]

- Shallan, A.I.; Smejkal, P.; Corban, M.; Guijt, R.M.; Breadmore, M.C. Cost-effective three-dimensional printing of visibly transparent microchips within minutes. Anal. Chem. 2014, 86, 3124–3130. [Google Scholar] [CrossRef]

- Carrière, P. On a three-dimensional implementation of the baker’s transformation. Phys. Fluids 2007, 19, 118110. [Google Scholar] [CrossRef] [Green Version]

- Robles-Linares, J.; Ramírez-Cedillo, E.; Siller, H.; Rodríguez, C.; Martínez-López, J.; Robles-Linares, J.A.; Ramírez-Cedillo, E.; Siller, H.R.; Rodríguez, C.A.; Martínez-López, J.I. Parametric Modeling of Biomimetic Cortical Bone Microstructure for Additive Manufacturing. Materials 2019, 12, 913. [Google Scholar] [CrossRef] [Green Version]

- Rajaguru, J.; Duke, M.; Au, C.K. Development of rapid tooling by rapid prototyping technology and electroless nickel plating for low-volume production of plastic parts. Int. J. Adv. Manuf. Technol. 2015, 78, 31–40. [Google Scholar] [CrossRef]

- Levy, G.N.; Schindel, R.; Kruth, J.P. Rapid manufacturing and rapid tooling with layer manufacturing (LM) technologies, state of the art and future perspectives. CIRP Ann. 2003, 52, 589–609. [Google Scholar] [CrossRef]

- Udroiu, R.; Braga, I.C. Polyjet Technology Applications for Rapid Tooling; EDP Sciences: Ulis, France, 2017; Volume 112. [Google Scholar]

- Charmet, J.; Rodrigues, R.; Yildirim, E.; Challa, P.K.; Roberts, B.; Dallmann, R.; Whulanza, Y. Low-Cost microfabrication tool box. Micromachines 2020, 11, 135. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Au, A.K.; Lee, W.; Folch, A. Mail-order microfluidics: Evaluation of stereolithography for the production of microfluidic devices. Lab. Chip 2014, 14, 1294–1301. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Martínez-López, J.I.; Mendoza-Buenrostro, C.; Retana, P.C.; Betancourt, H.; Vazquez, E.; Siller, H.R.; Rodriguez, C.A. Manufacturing and Test of Split and Recombine Micromixers with a Variable Cross-Section. ECS Meet. Abstr. 2018, MA2018-02, 1303. [Google Scholar] [CrossRef]

- Vangunten, M.T.; Walker, U.J.; Do, H.G.; Knust, K.N. 3D-Printed Microfluidics for Hands-On Undergraduate Laboratory Experiments. J. Chem. Educ. 2020, 97, 178–183. [Google Scholar] [CrossRef]

- Nielsen, J.B.; Hanson, R.L.; Almughamsi, H.M.; Pang, C.; Fish, T.R.; Woolley, A.T. Microfluidics: Innovations in materials and their fabrication and functionalization. Anal. Chem. 2020, 92, 150–168. [Google Scholar] [CrossRef]

- Kotz, F.; Risch, P.; Helmer, D.; Rapp, B.E. High-Performance Materials for 3D Printing in Chemical Synthesis Applications. Adv. Mater. 2019, 31, 1805982. [Google Scholar] [CrossRef]

- Castiaux, A.D.; Pinger, C.W.; Hayter, E.A.; Bunn, M.E.; Martin, R.S.; Spence, D.M. PolyJet 3D-Printed Enclosed Microfluidic Channels without Photocurable Supports. Anal. Chem. 2019. [Google Scholar] [CrossRef]

- Protolabs Manufacturing. Available online: http://www.protolabs.com (accessed on 9 September 2020).

- Martínez-López, J.I.; Mojica, M.; Rodríguez, C.A.; Siller, H.R. Xurography as a Rapid Fabrication Alternative for Point-of-Care Devices: Assessment of Passive Micromixers. Sensors 2016, 16, 705. [Google Scholar] [CrossRef] [Green Version]

- Martínez-López, J.I.; Betancourt, H.A.; García-López, E.; Rodriguez, C.A.; Siller, H.R. Rapid Fabrication of Disposable Micromixing Arrays Using Xurography and Laser Ablation. Micromachines 2017, 8, 144. [Google Scholar] [CrossRef] [Green Version]

- Mukhopadhyay, R. When PDMS isn’t the best. Anal. Chem. 2007, 79, 3249–3253. [Google Scholar] [CrossRef]

- Dangla, R.; Gallaire, F.; Baroud, C.N. Microchannel deformations due to solvent-induced PDMS swelling. Lab. Chip 2010, 10, 2972–2978. [Google Scholar] [CrossRef] [PubMed]

- Wolf, M.P.; Salieb-Beugelaar, G.B.; Hunziker, P. PDMS with designer functionalities—Properties, modifications strategies, and applications. Prog. Polym. Sci. 2018, 83, 97–134. [Google Scholar] [CrossRef]

- Leow, M.E.L.; Pho, R.W.H. RTV silicone elastomers in hand prosthetics: Properties, applications and techniques. Prosthet. Orthot. Int. 1999, 23, 169–173. [Google Scholar] [CrossRef] [Green Version]

- Schroettner, H.; Schmied, M.; Scherer, S. Comparison of 3D surface reconstruction data from certified depth standards obtained by SEM and an infinite focus measurement machine (IFM). In Microchimica Acta; Springer: Berlin/Heidelberg, Germany, 2006; Volume 155, pp. 279–284. [Google Scholar]

- Formlabs. Introducing the Form 3 and Form 3L. Available online: https://formlabs.com/blog/introducing-form-3-form-3l-low-force-stereolithography/ (accessed on 2 October 2020).

- Hossain, S.; Afzal, A.; Kim, K.Y. Shape Optimization of a Three-Dimensional Serpentine Split-and-Recombine Micromixer. Chem. Eng. Commun. 2017, 204, 548–556. [Google Scholar] [CrossRef]

- Raza, W.; Hossain, S.; Kim, K.Y. Effective mixing in a short serpentine split-and-recombination micromixer. Sensors Actuators B Chem. 2018, 258, 381–392. [Google Scholar] [CrossRef]

| Device Type | Array Elements | Microchannel Width (W) | SAR Subchannels (W1/W2) | Micromixer Pitch ∆ |

|---|---|---|---|---|

| Asymmetric split and recombine micromixer | 6 | 1000 µm | 667/333 µm | I = 100 µm, II = 250 µm, III = 500 µm, IV = 750 µm, V = 900 µm, VI = 1000 µm |

| Material | Manufacturing | Tensile Strength/Modulus (MPa) 1 | Observations during Casting |

|---|---|---|---|

| Aluminum 7075 | Micromilling | 276/ 68900 | Excellent surface quality, easy demolding |

| Clear V04 | SLA-LF | 65/2800 | Excellent surface quality, excellent demolding |

| Accura SL 5530 | SLA | 57-63/2854-3130 | Good surface quality |

| E-Partial | SLA-DLP | 129/3125 | Good surface quality |

| ABS Flex White | SLA-DLP | 65/1772 | Good surface quality |

| Flexible V02 | SLA-LF | 3.4/8.5 | Fair surface quality, easy demolding due flexibility |

| * E-Dent 400 | SLA-DLP | 85/2100 | Difficulties for demolding |

| * ABS Flex Black | SLA-DLP | 65/1772 | Difficulties for demolding |

| * HTM 140 | SLA-DLP | 115/3350 | PDMS reaction |

| Feature | Feature | Al | ABS Flex White | HTM 140 | E-Dent 400 | ABS Flex Black | Accura SL 5530 | Clear V04 | Flexible V02 |

|---|---|---|---|---|---|---|---|---|---|

| PD (mm) | Protrusion depth | 1.006 ± 0.002 | 1.014 ± 0.013 | 1.026 ± 0.003 | 0.943 ± 0.002 | 1.011 ± 0.009 | 0.890 ± 0.013 | 1.006 ± 0.011 | 0.993 ± 0.011 |

| PL (mm) | Protrusion length | 4.437 ± 0.002 | 4.207 ± 0.040 | 4.217 ± 0.052 | 4.512 ± 0.024 | 4.202 ± 0.019 | 4.450 ± 0.02 | 4.449 ± 0.041 | 4.504 ± 0.100 |

| PW (mm) | Protrusion width | 3.036 ± 0.002 | 2.890 ± 0.013 | 2.887 ± 0.036 | 3.032 ± 0.012 | 2.908 ± 0.006 | 3.11 ± 0.056 | 3.02 ± 0.009 | 3.083 ± 0.010 |

| Ra (µm) | Protrusion roughness | 0.262 ± 0.085 | 0.636 ± 0.002 | 0.526 ± 0.105 | 0.91 ± 0.170 | 0.394 ± 0.042 | 0.303 ± 0.036 | 0.807 ± 0.098 | 4.833 ± 0.164 |

| Feature | Feature | Al | ABS Flex White | HTM 140 | E-Dent 400 | ABS Flex Black | Accura SL 5530 | Clear V04 | Flexible V02 |

|---|---|---|---|---|---|---|---|---|---|

| WA (mm) | Channel width A | 5.038 | 4.484 | 4.758 | 5.001 | 4.819 | 5.035 | 9.056 | 9.098 |

| WB (mm) | Channel width B | 7.044 | 6.634 | 6.642 | 6.884 | 6.714 | 7.072 | 7.029 | 7.15 |

| WC | Channel width C | 9.035 | 8.574 | 8.552 | 8.796 | 8.642 | 9.104 | 5.07 | 5.056 |

| DABC (mm) | Channel depth | 1.996 ± 0.004 | 1.966 ± 0.015 | 2.004 ± 0.011 | 1.871 ± 0.008 | 1.954 ± 0.004 | 2.015 ± 0.005 | 2.009 ± 0.013 | 1.970 ± 0.010 |

| Ra (µm) | Channel Roughness | 0.225 ± 0.066 | 0.653 ± 0.032 | 0.460 ± 0.056 | 1.095 ± 0.288 | 0.664 ± 0.120 | 0.354 ± 0.10 | 0.839 ± 0.043 | 4.871 ± 0.214 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Martínez-López, J.I.; Betancourt Cervantes, H.A.; Cuevas Iturbe, L.D.; Vázquez, E.; Naula, E.A.; Martínez López, A.; Siller, H.R.; Mendoza-Buenrostro, C.; Rodríguez, C.A. Characterization of Soft Tooling Photopolymers and Processes for Micromixing Devices with Variable Cross-Section. Micromachines 2020, 11, 970. https://doi.org/10.3390/mi11110970

Martínez-López JI, Betancourt Cervantes HA, Cuevas Iturbe LD, Vázquez E, Naula EA, Martínez López A, Siller HR, Mendoza-Buenrostro C, Rodríguez CA. Characterization of Soft Tooling Photopolymers and Processes for Micromixing Devices with Variable Cross-Section. Micromachines. 2020; 11(11):970. https://doi.org/10.3390/mi11110970

Chicago/Turabian StyleMartínez-López, J. Israel, Héctor Andrés Betancourt Cervantes, Luis Donaldo Cuevas Iturbe, Elisa Vázquez, Edisson A. Naula, Alejandro Martínez López, Héctor R. Siller, Christian Mendoza-Buenrostro, and Ciro A. Rodríguez. 2020. "Characterization of Soft Tooling Photopolymers and Processes for Micromixing Devices with Variable Cross-Section" Micromachines 11, no. 11: 970. https://doi.org/10.3390/mi11110970

APA StyleMartínez-López, J. I., Betancourt Cervantes, H. A., Cuevas Iturbe, L. D., Vázquez, E., Naula, E. A., Martínez López, A., Siller, H. R., Mendoza-Buenrostro, C., & Rodríguez, C. A. (2020). Characterization of Soft Tooling Photopolymers and Processes for Micromixing Devices with Variable Cross-Section. Micromachines, 11(11), 970. https://doi.org/10.3390/mi11110970