Sustainability and Innovation in the Automotive Sector: A Structured Content Analysis

Abstract

:1. Introduction

2. Sustainability, Innovation and Automotive Sector

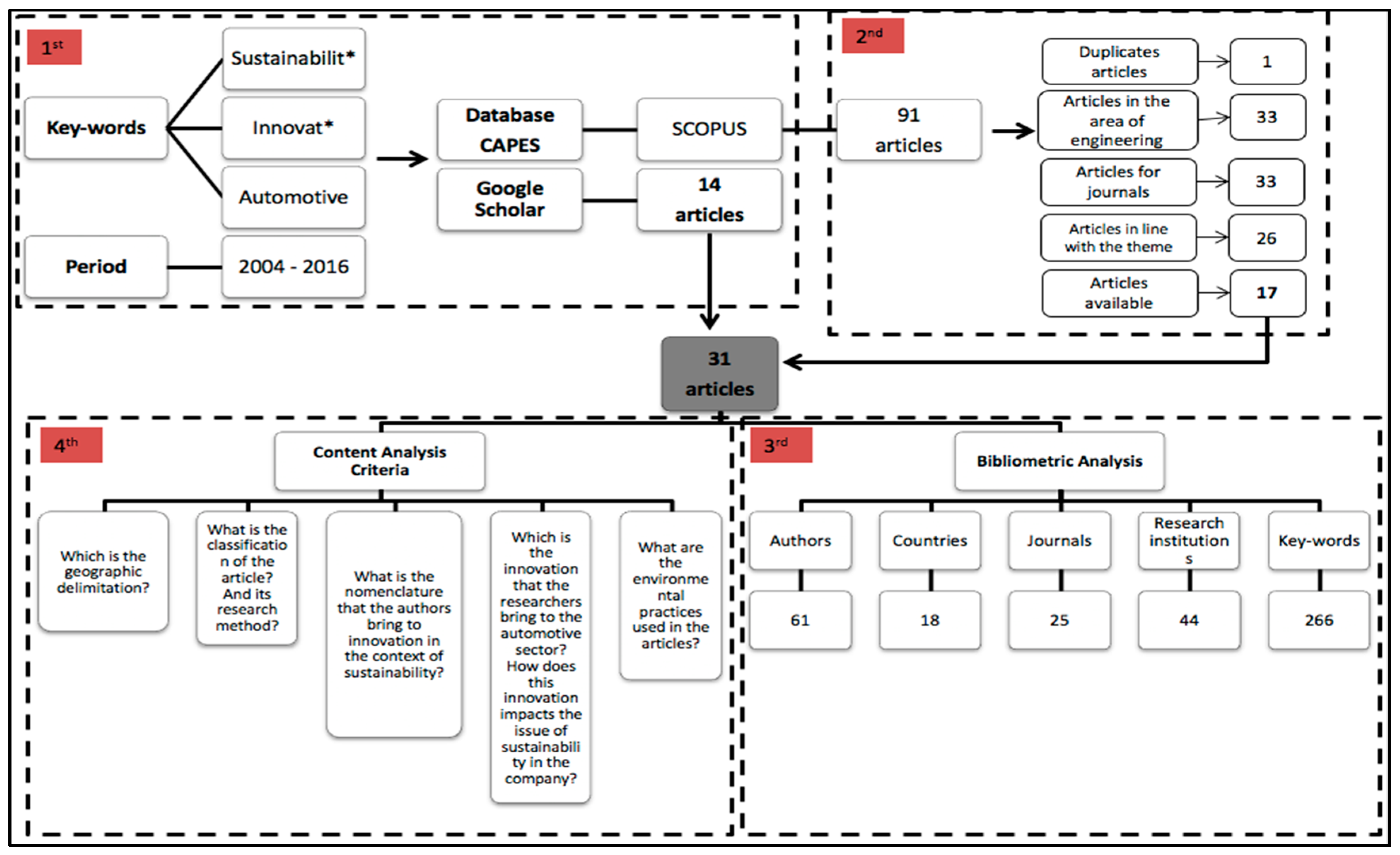

3. Method

- (i)

- Selection of database of raw articles, which, in turn, comprehends: selecting keywords, selecting databases, searching for articles and verifying the adherence of keywords;

- (ii)

- Filtering the raw articles database, which entails filtering the raw articles of the database by redundancy and filtering the raw articles of the database that are not repeated by the alignment with the title;

- (iii)

- Filtering the article database, pertaining to: determining the scientific recognition of articles, author identification;

- (iv)

- Filtering by alignment to the full article, concerning the full text of the articles.

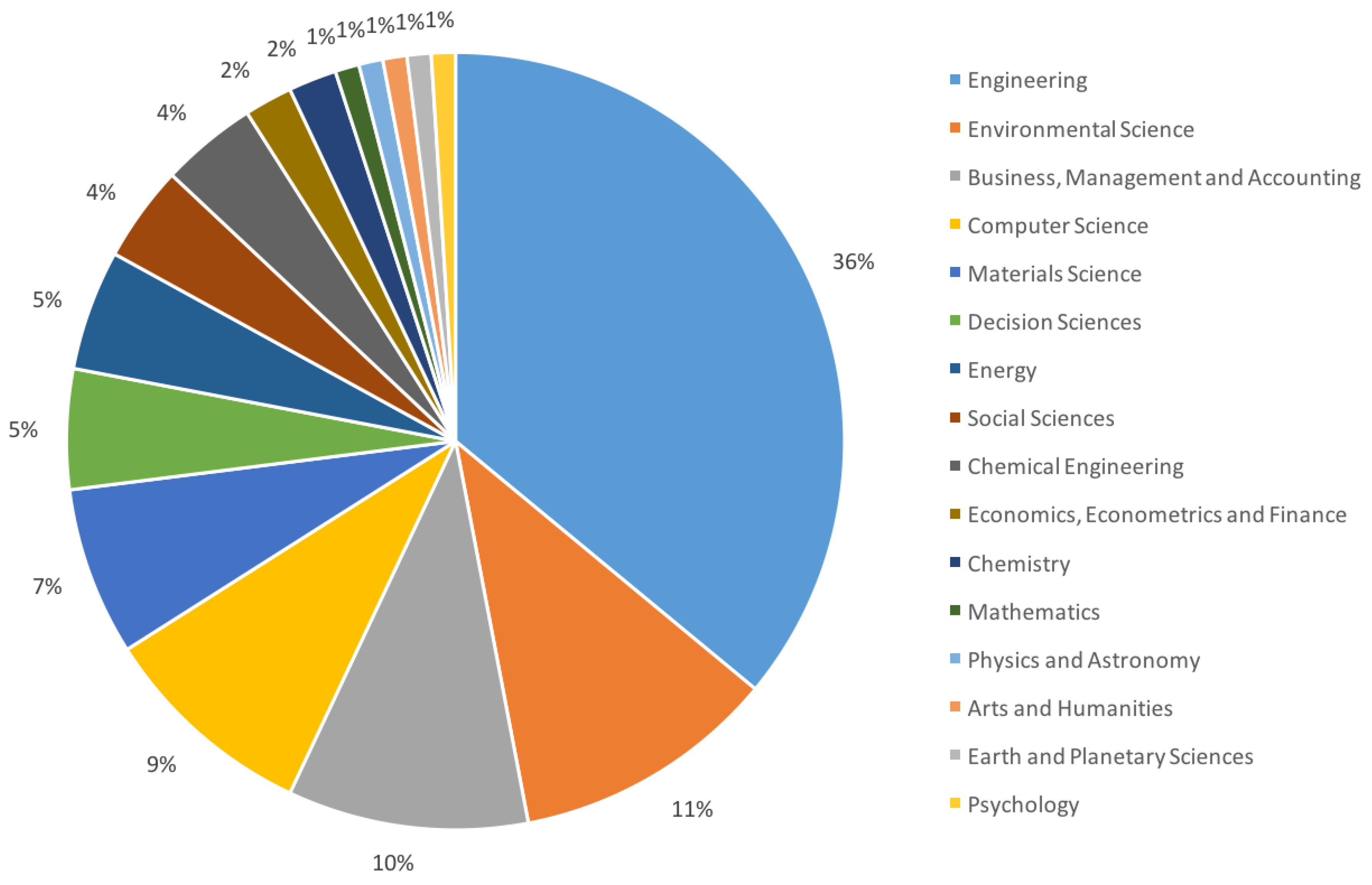

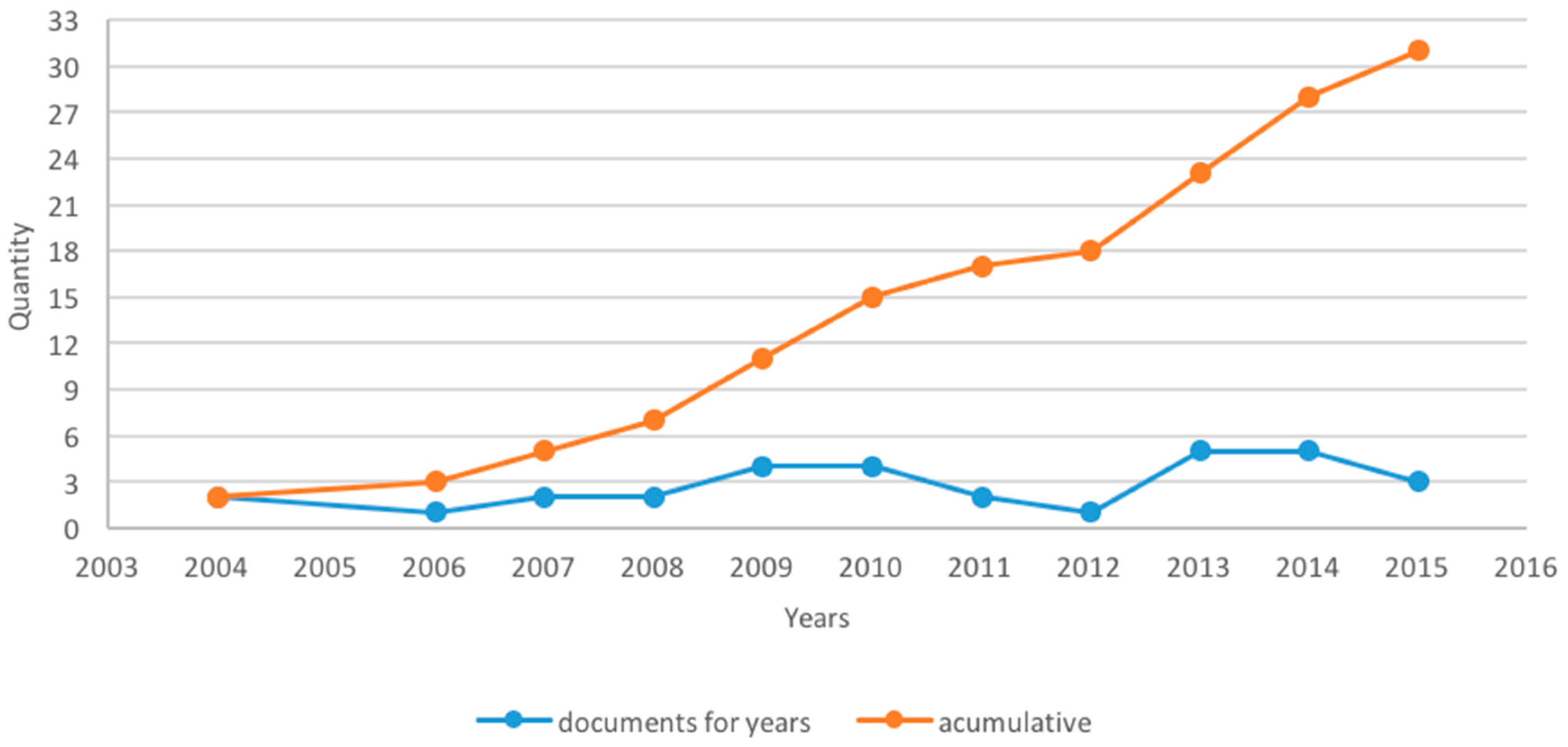

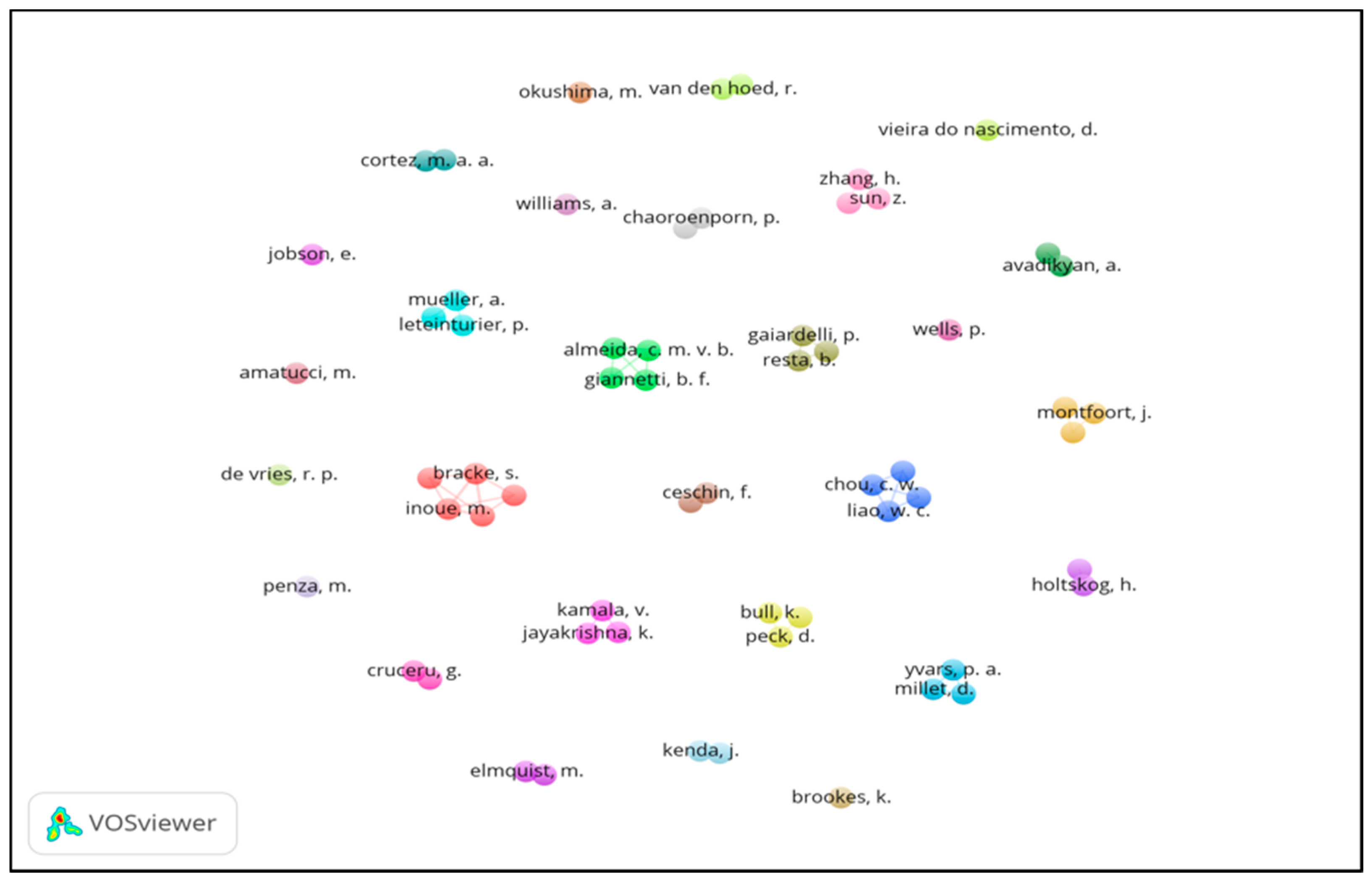

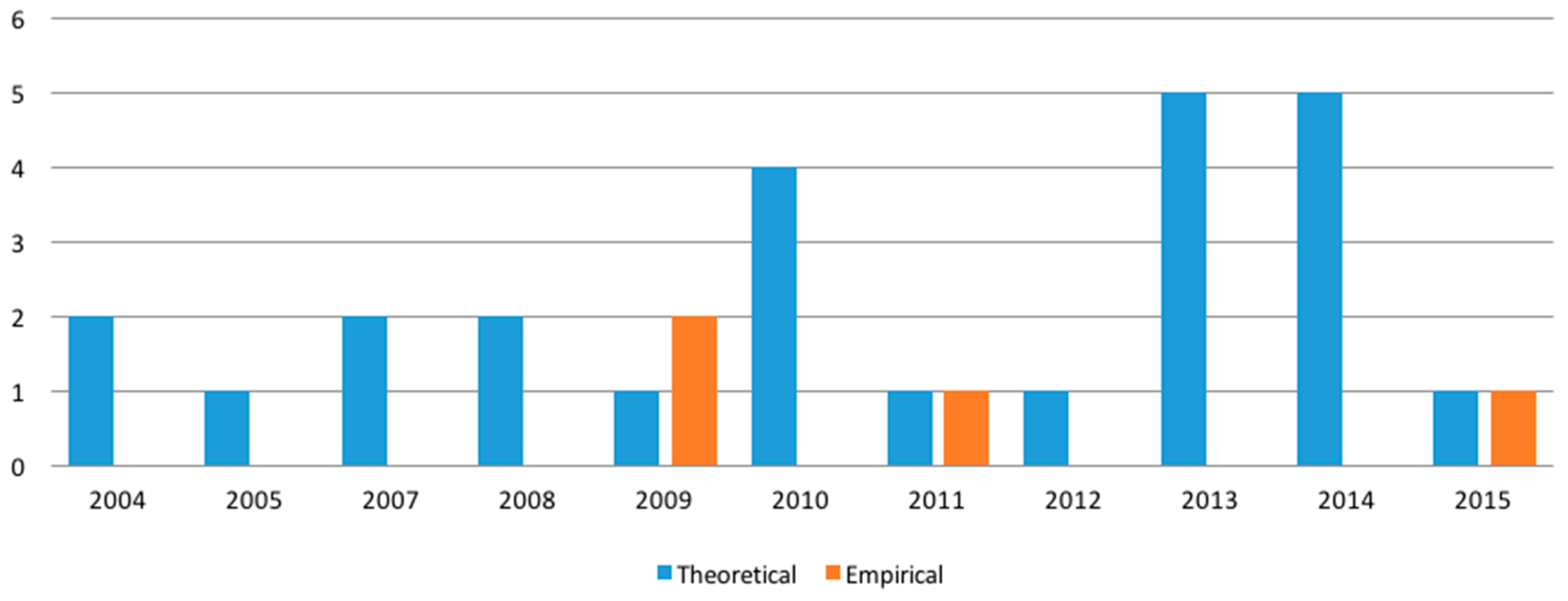

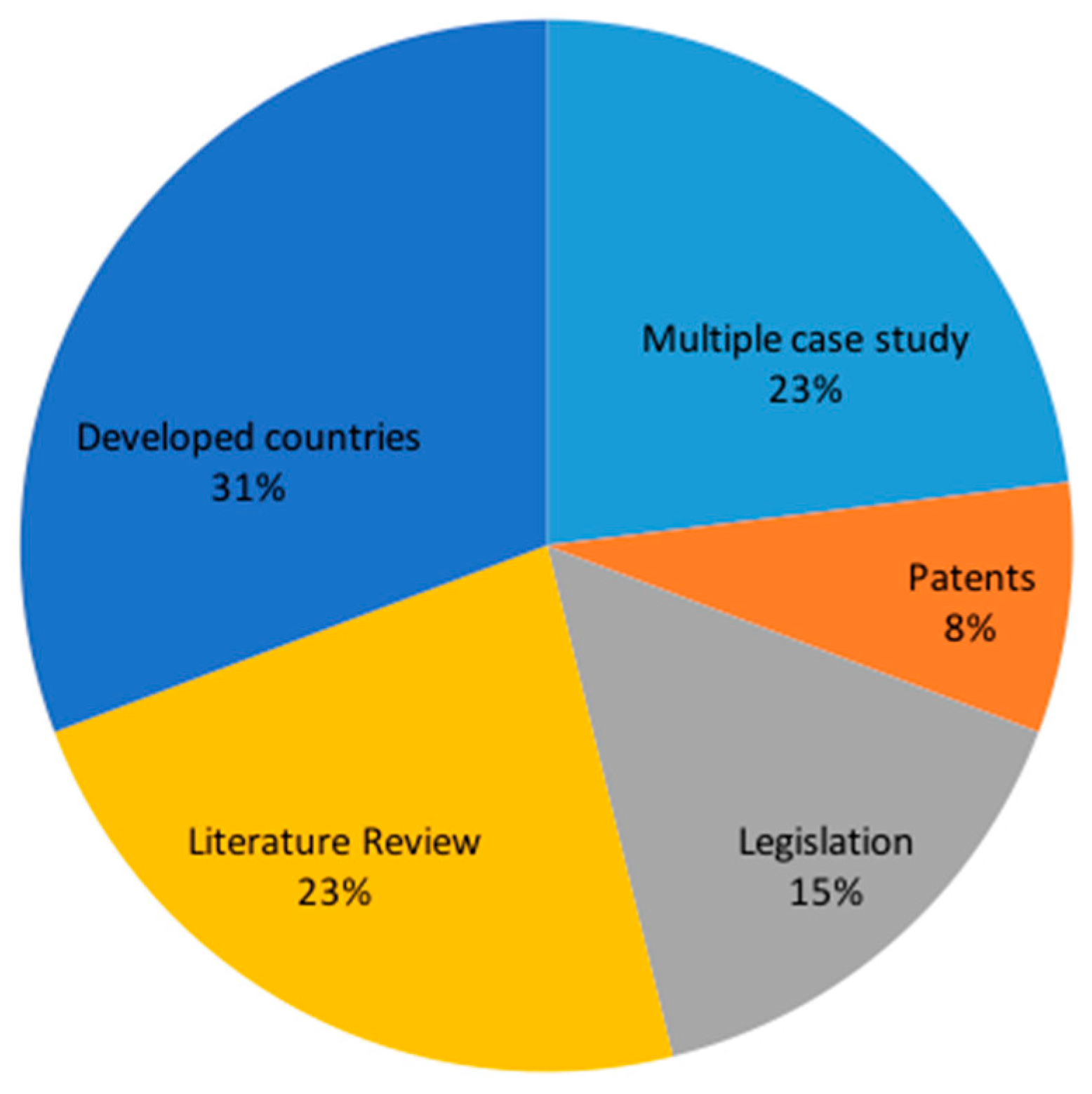

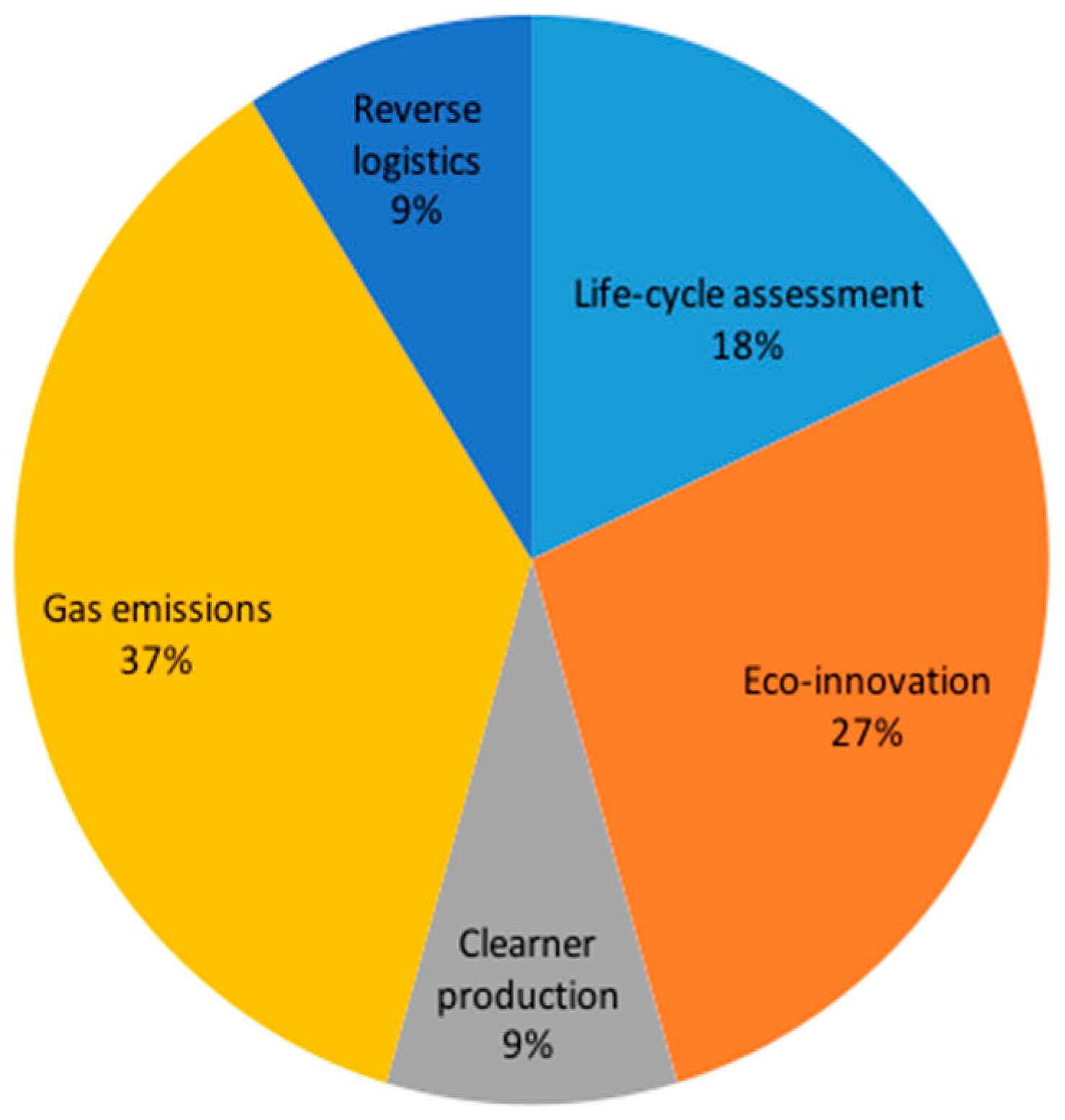

4. Results

- Future challenges in automotive emission control, by Jobson, E. [44]: The article deals with the global perspective on emissions by automotive vehicles, in future scenarios of energy production and consumption, the growing population and trade. Addressing, thus, the main technological and scientific challenges to NOx reduction.

- Institutional change in the automotive industry: Or how fuel cell technology is being institutionalized, by Van den Hoed, R. and Vergragt, P.J. [45]: The article addresses the need for change in the automotive industries, in order to attain sustainability, in relation to fuel cells. It tries to answer the following questions: Why is the industry adopting such technology? How is fuel cell technology in regards to the process of becoming institutionalized?

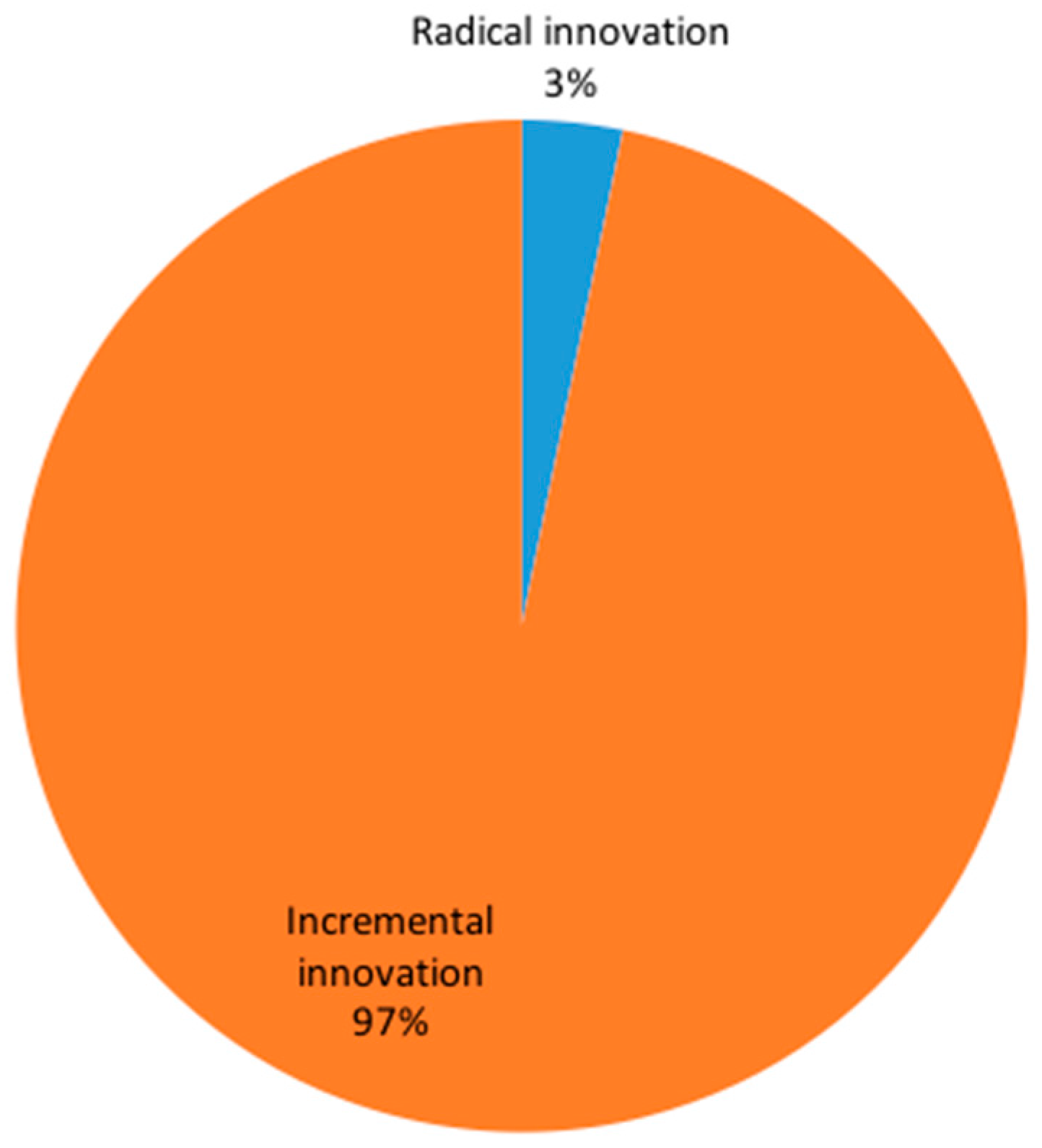

5. Discussion

- New entrants: New entrants such as entrepreneurs are less constrained by vested interests and developed routines, and are likely candidates to propose new practices. Apart from entrepreneurs, also powerful stakeholders from a different sector may take an interest in a radical technology; an example may be the investments of utilities in electric vehicle technology as part of their strategy to better utilize their installed capacity. New entries of entrepreneurs and other stakeholders not inhibited by typical constraints of established technologies are likely sources of radical practices.

- External shocks or crises: Shocks can be conceptualized as ‘occasional events’ that interrupt relative long periods of stability. Shocks are important mechanisms to lead to instability of the current practice. Shocks provide the occasion at which established practices are reflected upon, they provide uncertainty leading to unorthodox experiments, and create urgency for companies or sectors to develop (radical) alternatives.

- Performance of the new technology: The performance characteristics and learning curves of the technology itself, vis á vis the technology it replaces, form a third source of radical change. Although most radical technologies are costlier and may be more complex than the established technology, radical technology may demonstrate steep learning curves that feed expectations concerning long term benefits over established technologies. Radical technologies are more likely adopted if they provide superior performance characteristics over the established technology. Where radical technology is frequently treated as a black box in the innovation literature, it is argued here that performance characteristics form an essential element in the treatment of radical technological development.

- Market changes: Changing market demands may lead current practices or technologies to be challenged if performance limits are reached. Market changes may occur as a result of new options provided by new technologies (technology-induced), or can be a result of progressing demands for performance improvement. The former case stresses technology push mechanisms; the latter pulls, in which changes in market demand may induce experimenting with new, radical technologies, which in time may overturn the established technologies.

- Industry competition: Competition between/among members in an industrial sector may also be a key factor for radical change. Radical technologies may provide the opportunity to gain a competitive advantage; first movers may see a window of opportunity to increase their market share. Although this typically is the case for more incremental innovation, industry competition may also be a change factor in more radical innovations in order to gain benefits as a first mover.

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Appendix A

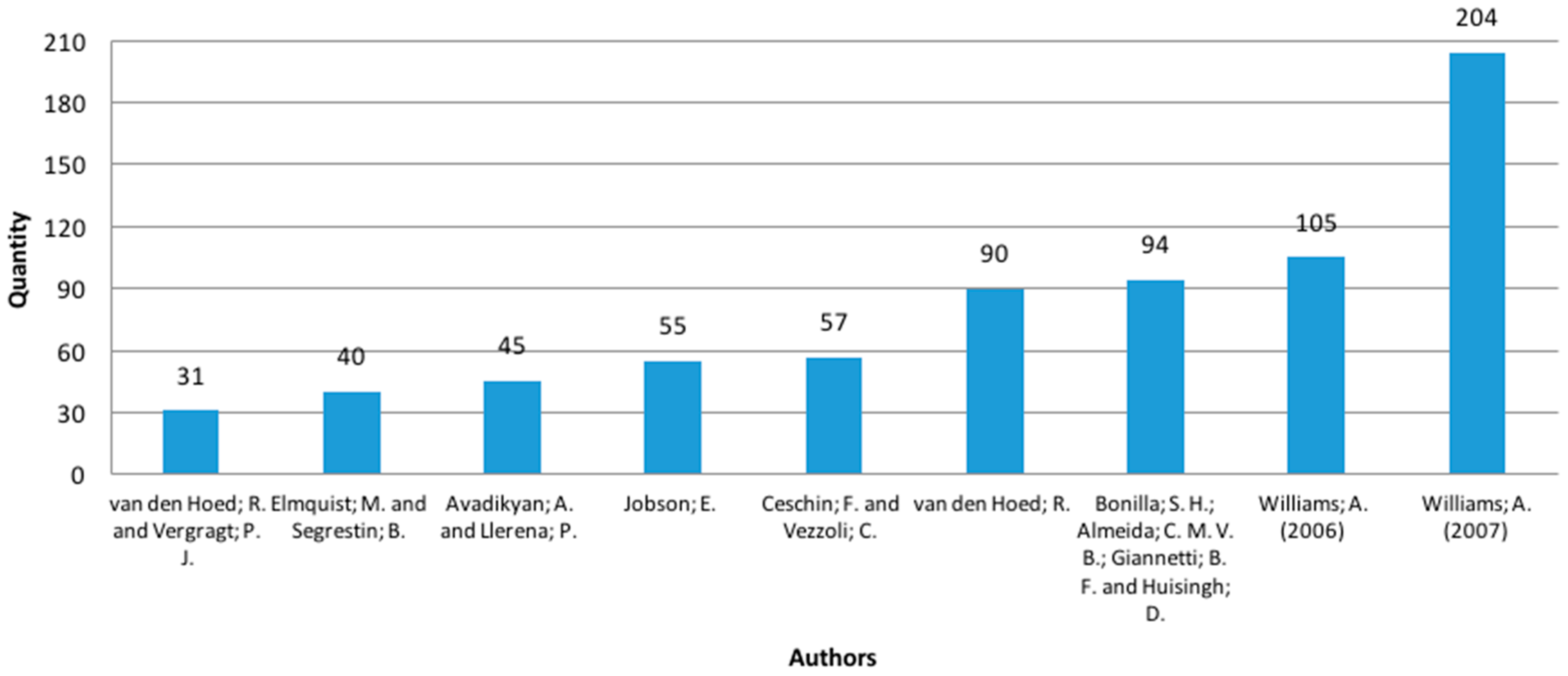

| Reference | Author | Year | Title | Citation |

|---|---|---|---|---|

| [45] | van den Hoed, R. and Vergragt, P.J. | 2004 | Institutional change in the automotive industry: Or how fuel cell technology is being institutionalised | 31 |

| [44] | Jobson, E. | 2004 | Future challenges in automotive emission control | 55 |

| [49] | Williams, A. | 2006 | Product-service systems in the automotive industry: The case of micro-factory retailing | 105 |

| [48] | Williams, A. | 2007 | Product service systems in the automobile industry: Contribution to system innovation? | 204 |

| [50] | van den Hoed, R. | 2007 | Sources of radical technological innovation: the emergence of fuel cell technology in the automotive industry | 90 |

| [64] | Ploss, R.; Mueller, A. and Leteinturier, P. | 2008 | Solving automotive challenges with electronics | 9 |

| [65] | De Vries, R.P. | 2008 | IC innovations in automotive | 1 |

| [57] | Resta, B.; Gaiardelli, P. and Pezzotta, G. | 2009 | Sustainability in the auto repair industry: A life cycle assessment application | 3 |

| [52] | Elmquist, M. and Segrestin, B. | 2009 | Sustainable development through innovative design: Lessons from the KCP method experimented with an automotive firm | 40 |

| [66] | Bull, K.; Hull, N. and Peck, D. | 2009 | Broadening industry perspectives of vehicle telematics application through virtual learning environments: EADIS: European automotive digital interaction studio | 0 |

| [67] | Ros, J.; Nagelhout, D. and Montfoort, J. | 2009 | New environmental policy for system innovation: Casus alternatives for fossil motor fuels | 19 |

| [68] | Cruceru, G. and Micuda, D. | 2010 | The european auto market under the impact of the financial crisis: Lessons to be learned | 0 |

| [55] | Ceschin, F. and Vezzoli, C. | 2010 | The role of public policy in stimulating radical environmental impact reduction in the automotive sector: The need to focus on product-service system innovation | 57 |

| [54] | Bonilla, S.H.; Almeida, C.M.V.B.; Giannetti, B.F. and Huisingh, D. | 2010 | The roles of cleaner production in the sustainable development of modern societies: An introduction to this special issue | 94 |

| [53] | Avadikyan, A. and Llerena, P. | 2010 | A real options reasoning approach to hybrid vehicle investments | 45 |

| [69] | Brookes, K. | 2011 | Unique values win PM design awards | 0 |

| [70] | Cortez, M.A.A. and Cudia, C.P. | 2011 | The virtuous cycles between environmental innovations and financial performance: Case study of japanese automotive and electronics companies | 9 |

| [71] | Millet, D.; Yvars, P.A. and Tonnelier, P. | 2012 | A method for identifying the worst recycling case: Application on a range of vehicles in the automotive sector | 20 |

| [72] | Wang; Y.; Zhang; H. and Sun; Z. | 2013 | Optimal control of the transient emissions and the fuel efficiency of a diesel hybrid electric vehicle | 10 |

| [73] | Holtskog, H. and Ringen, G. | 2013 | Opportunities in the wake of crisis | 5 |

| [47] | Bracke, S.; Michalski, J.; Inoue, M. and Yamada, T. | 2013 | CDMF-RELSUS concept: Reliable products are sustainable products—Influences on product design; manufacturing and use phase | 4 |

| [74] | Wells, P. | 2013 | Sustainable business models and the automotive industry: A commentary | 27 |

| [75] | Intarakumnerd, P. and Chaoroenporn, P. | 2013 | The roles of intermediaries and the development of their capabilities in sectoral innovation systems: A case study of Thailand | 9 |

| [76] | Vieira do Nascimento, D.M. | 2014 | The Brazilian experience of flex-fuel vehicles technology: Towards low carbon mobility | 0 |

| [77] | Pusavec, F. and Kenda, J. | 2014 | The transition to a clean; dry; and energy efficient polishing process: An innovative upgrade of abrasive flow machining for simultaneous generation of micro-geometry and polishing in the tooling industry | 16 |

| [78] | Penza, M. | 2014 | COST Action TD1105: New sensing technologies for environmental sustainability in smart cities | 5 |

| [46] | Bracke, S.; Inoue, M.; Ulutas, B. and Yamada, T. | 2014 | CDMF-RELSUS concept: Reliable and Sustainable products—Influences on design; manufacturing; layout integration and use phase | 4 |

| [79] | Vinodh, S.; Kamala, V. and Jayakrishna, K. | 2014 | Integration of ECQFD; TRIZ; and AHP for innovative and sustainable product development | 21 |

| [80] | Okushima, M. | 2015 | Simulating social influences on sustainable mobility shifts for heterogeneous agents | 3 |

| [56] | Chou, C.W.; Liao, W.C.; Wu, S. and Wee, H.M. | 2015 | The role of technical innovation and sustainability on energy consumption: A case study on the Taiwanese automobile industry | 1 |

| [81] | Amatucci, M. | 2015 | The world that chose the machine: An evolutionary view of the technological race in the history of the automobile | 7 |

Appendix B

| Author | Quantity | Author | Quantity |

|---|---|---|---|

| Yamada, T. | 2 | Montfoort, J. | 1 |

| Williams, A. | 2 | Millet, D. | 1 |

| van den Hoed, R. | 2 | Micuda, D. | 1 |

| Inoue, M. | 2 | Michalski, J. | 1 |

| Bracke, S. | 2 | Llerena, P. | 1 |

| Zhang, H. | 1 | Liao, W.C. | 1 |

| Yvars, P. A. | 1 | Leteinturier, P. | 1 |

| Wu, S. | 1 | Kenda, J. | 1 |

| Wells, P. | 1 | Kamala, V. | 1 |

| Wee, H. M. | 1 | Jobson, E. | 1 |

| Wang, Y. | 1 | Jayakrishna, K. | 1 |

| Vinodh, S. | 1 | Intarakumnerd, P. | 1 |

| Vieira do Nascimento, D.M. | 1 | Hull, N. | 1 |

| Vezzoli, C. | 1 | Huisingh, D. | 1 |

| Vergragt, P.J. | 1 | Holtskog, H. | 1 |

| Ulutas, B. | 1 | Giannetti, B.F. | 1 |

| Tonnelier, P. | 1 | Gaiardelli, P. | 1 |

| Sun, Z. | 1 | Elmquist, M. | 1 |

| Segrestin, B. | 1 | De Vries, R.P. | 1 |

| Ros, J. | 1 | Cudia, C.P. | 1 |

| Ringen, G. | 1 | Cruceru, G. | 1 |

| Resta, B. | 1 | Cortez, M.A.A. | 1 |

| Pusavec, F. | 1 | Chou, C.W. | 1 |

| Ploss, R. | 1 | Chaoroenporn, P. | 1 |

| Pezzotta, G. | 1 | Ceschin, F. | 1 |

| Penza, M. | 1 | Bull, K. | 1 |

| Peck, D. | 1 | Brookes, K. | 1 |

| Okushima, M. | 1 | Bonilla, S.H. | 1 |

| Nagelhout, D. | 1 | Avadikyan, A. | 1 |

| Mueller, A. | 1 | Amatucci, M. | 1 |

| Almeida, C.M.V.B. | 1 |

Appendix C

| Journals | Quantity of Articles |

|---|---|

| Journal of Cleaner Production | 5 |

| International Journal of Automotive Technology and Management | 3 |

| Transportation | 1 |

| Topics in Catalysis | 1 |

| Technological Forecasting and Social Change | 1 |

| Resources, Conservation and Recycling | 1 |

| Proceedings of the Institution of Mechanical Engineers, Part D: Journal of Automobile Engineering | 1 |

| Procedia CIRP | 1 |

| Metal Powder Report | 1 |

| International Journal of Sustainable Manufacturing | 1 |

| International Journal of Product Lifecycle Management | 1 |

| International Conference on Risk Management, Assessment and Mitigation, RIMA ’10 | 1 |

| IIMB Management Review | 1 |

| Greener Management International | 1 |

| Energies | 1 |

| Asian Journal of Technology Innovation | 1 |

| Applied Mathematical Modelling | 1 |

| Applied Energy | 1 |

| Academy of Accounting and Financial Studies Journal | 1 |

| 46th CIRP Conference on Manufacturing Systems, CIRP CMS 2013 | 1 |

| 20th International Conference on Urban Transport and the Environment, UT 2014 | 1 |

| 2008 International Symposium on VLSI Technology, Systems and Applications, VLSITSA | 1 |

| 2008 9th International Conference on SolidState and IntegratedCircuit Technology, ICSICT 2008 | 1 |

| 16th World Congress on Intelligent Transport Systems and Services, ITS 2009 | 1 |

| 13th IEEE SENSORS Conference, SENSORS 2014 | 1 |

References

- Belz, F.M.; Schmidt-Riediger, B. Marketing strategies in the age of sustainable development: Evidence from the food industry. Bus. Strategy Environ. 2010, 19, 401–416. [Google Scholar] [CrossRef]

- Fang, K.; Uhan, N.; Zhao, F.; Sutherland, J.W. A new approach to scheduling in manufacturing for power consumption and carbon footprint reduction. J. Manuf. Syst. 2011, 30, 234–240. [Google Scholar] [CrossRef]

- Farias, A.S.; Costa, D.S.; Freitas, L.S.; Cândido, G.A. Utilização de eco-inovação no processo de manufatura de cerâmica vermelha. RAI Rev. Adm. Inov. 2012, 9, 154–174. [Google Scholar] [CrossRef]

- Christensen, T.B. Modularised eco-innovation in the auto industry. J. Clean. Prod. 2011, 19, 212–220. [Google Scholar] [CrossRef]

- CUSTÓDIO, A.L.D.M.; RENATO, M. Guia Para Elaboração de Balanço Social e Relatório de Sustentabilidade 2007; Instituto Ethos: São Paulo, Brazil, 2007. [Google Scholar]

- Humphrey, J.; Memedovic, O. The Global Automotive Industry Value Chain: What Prospects for Upgrading by Developing Countries. 2003. Available online: https://papers.ssrn.com/sol3/papers.cfm?abstract_id=424560 (accessed on 27 April 2017).

- Schulze, A.; MacDuffie, J.P.; Täube, F.A. Introduction: Knowledge generation and innovation diffusion in the global automotive industry—Change and stability during turbulent times. Ind. Corp. Chang. 2015, 24, 603–611. [Google Scholar] [CrossRef]

- Casotti, B.P.; Goldenstein, M. Panorama do Setor Automotivo: As Mudanças Estruturais da Indústria e as Perspectivas Para o Brasil; BNDES Setorial: Rio de Janeiro, Brazil, 2008; pp. 147–187. [Google Scholar]

- Barros, D.C.; Castro, B.H.R.D.; Vaz, L.F.H. Automotivo. In Panoramas Setoriais: Mudanças Climáticas; Banco Nacional de Desenvolvimento Econômico e Social: Rio de Janeiro, Brazil, 2016. [Google Scholar]

- Sturgeon, T.; Van Biesebroeck, J.; Gereffi, G. Value chains, networks and clusters: Reframing the global automotive industry. J. Econ. Geogr. 2008, 8, 297–321. [Google Scholar] [CrossRef]

- Bastin, C.; Szklo, A.; Rosa, L.P. Diffusion of new automotive technologies for improving energy efficiency in Brazil’s light vehicle fleet. Energy Policy 2010, 38, 3586–3597. [Google Scholar] [CrossRef]

- Berggren, C.; Magnusson, T. Reducing automotive emissions—The potentials of combustion engine technologies and the power of policy. Energy Policy 2012, 41, 636–643. [Google Scholar] [CrossRef]

- Liu, Y.; Kokko, A. Who does what in China’s new energy vehicle industry? Energy Policy 2013, 57, 21–29. [Google Scholar] [CrossRef]

- Gerrard, J.; Kandlikar, M. Is European end-of-life vehicle legislation living up to expectations? Assessing the impact of the ELV Directive on ‘green’innovation and vehicle recovery. J. Clean. Prod. 2007, 15, 17–27. [Google Scholar] [CrossRef]

- Associação Nacional dos Fabricantes de Veículos Automotores (ANFAVEA). Anuário da Indústria Automobilística Brasileira; ANFAVEA: São Paulo, Brazil, 2014. [Google Scholar]

- Carson, R. Silent Spring; Houghton Mifflin Harcourt: Boston, MA, USA, 2002. [Google Scholar]

- Schot, J.; Geels, F.W. Strategic niche management and sustainable innovation journeys: Theory, findings, research agenda, and policy. Technol. Anal. Strateg. Manag. 2008, 20, 537–554. [Google Scholar] [CrossRef]

- Organization for Economic Co-operation and Development (OECD). The Oslo Manual: Guidelines for Collecting and Interpreting Innovation Data, 3rd ed.; OECD Publishing: Paris, France, 2005; p. 166. [Google Scholar]

- Kemp, R.; Foxon, T. Typology of Eco-Innovation. Project Paper: Measuring Eco-Innovation. 2007; 1–24. [Google Scholar]

- Elkington, J. Canibais Com Garfo e Faca; Makron Books São Paulo: São Paulo, Brazil, 2001. [Google Scholar]

- Falk, J.; Ryan, C. Inventing a sustainable future: Australia and the challenge of eco-innovation. Futures 2007, 39, 215–229. [Google Scholar] [CrossRef]

- Carrillo, J.; González, P.d.R.; Könnölä, T. Eco-Innovation: When Sustainability and Competitiveness Shake Hands; Palgrave Macmillan: Basingstoke, UK, 2009. [Google Scholar]

- Cohen-Rosenthal, E. Making sense out of industrial ecology: A framework for analysis and action. J. Clean. Prod. 2004, 12, 1111–1123. [Google Scholar] [CrossRef]

- Tukker, A.; Butter, M. Governance of sustainable transitions: About the 4 (0) ways to change the world. J. Clean. Prod. 2007, 15, 94–103. [Google Scholar] [CrossRef]

- Smith, K. Measuring innovation. In The Oxford Handbook of Innovation; Oxford University Press: NewYork, NY, USA, 2005. [Google Scholar]

- Nill, J.; Kemp, R. Evolutionary approaches for sustainable innovation policies: From niche to paradigm? Res. Policy 2009, 38, 668–680. [Google Scholar] [CrossRef]

- Pujari, D. Eco-innovation and new product development: Understanding the influences on market performance. Technovation 2006, 26, 76–85. [Google Scholar] [CrossRef]

- Carrillo-Hermosilla, J.; del Río, P.; Könnölä, T. Diversity of eco-innovations: Reflections from selected case studies. J. Clean. Prod. 2010, 18, 1073–1083. [Google Scholar] [CrossRef]

- Horbach, J.; Rammer, C.; Rennings, K. Determinants of eco-innovations by type of environmental impact—The role of regulatory push/pull, technology push and market pull. Ecol. Econ. 2012, 78, 112–122. [Google Scholar] [CrossRef]

- Senhoras, E.; Dias, J.M. Tendências da Indústria Automotiva Brasileira: Um Estudo do Caso FIAT. Available online: https://www.researchgate.net/publication/237801184_TENDENCIAS_DA_INDUSTRIA_AUTOMOTIVA_BRASILEIRA_UM_ESTUDO_DO_CASO_FIAT (accessed on 27 April 2017).

- Kotler, P.; Keller, K.L. Administração de Marketing; Prentice Hall: São Paulo, Brazil, 2006. [Google Scholar]

- Cusumano, M.A.; Nobeoka, K. Strategy, structure and performance in product development: Observations from the auto industry. Res. Policy 1992, 21, 265–293. [Google Scholar] [CrossRef]

- Hamel, G.; Prahalad, C.K. Corporate imagination and expeditionary marketing. Harv. Bus. Rev. 1990, 69, 81–92. [Google Scholar]

- AUTODATA. Terreno Fértil—Setor Automotivo Intensifica Programas e Práticas em Busca de Sustentabilidade, 262nd ed.; AUTODATA: Maidenhead, UK, 2011. [Google Scholar]

- Gil, A.C. Como Elaborar Projetos de Pesquisa; Atlas: São Paulo, Brazil, 2005. [Google Scholar]

- Ensslin, S.R.; Ensslin, L.; Lacerda, R.T.d.O.; Souza, V.H.A.d. Disclosure of the State of the Art of Performance Evaluation Applied to Project Management. Am. J. Ind. Bus. Manag. 2014, 4, 677. [Google Scholar] [CrossRef]

- Uriona Maldonado, M.; Silva Santos, J.L.; Santos, R.N.M. Inovação e Conhecimento Organizacional: Um mapeamento bibliométrico das publicações cientificas até 2009. In Proceedings of the XXXIV Encontro ANPAD, Rio de Janeiro, Brazil, 25–29 September 2010. [Google Scholar]

- Bardin, L. Análise de Conteúdo/Laurence Bardin; Tradução Luís Antero Reto, Augusto Pinheiro: São Paulo, Brazil, 2011; p. 70. [Google Scholar]

- Herbert, T.L. EndNote 5 for windows. J. Chem. Inf. Comput. Sci. 2002, 42, 134–135. [Google Scholar] [CrossRef] [PubMed]

- Van Eck, N.J.; Waltman, L. Software survey: VOSviewer, a computer program for bibliometric mapping. Scientometrics 2010, 84, 523–538. [Google Scholar] [CrossRef] [PubMed]

- Afonso, M.H.F.; de Souza, J.V.; Ensslin, S.R.; Ensslin, L. Como construir conhecimento sobre o tema de pesquisa? Aplicação do processo ProKnow-C na busca de literatura sobre avaliação do desenvolvimento sustentável. Rev. Gest. Soc. Ambient. 2012, 5, 47–62. [Google Scholar] [CrossRef]

- Creswell, J.W. Projeto de pesquisa métodos qualitativo, quantitativo e misto. 2010. Available online: http://bases.bireme.br/cgi-bin/wxislind.exe/iah/online/?IsisScript=iah/iah.xis&src=google&base=LILACS&lang=p&nextAction=lnk&exprSearch=695513&indexSearch=ID (accessed on 27 April 2017).

- Lacerda, R.T.O.; Ensslin, L.; Ensslin, S.R. Uma análise bibliométrica da literatura sobre estratégia e avaliação de desempenho. Gest. Prod. 2012, 19, 59–78. [Google Scholar] [CrossRef]

- Jobson, E. Future challenges in automotive emission control. Top. Catal. 2004, 28, 191–199. [Google Scholar] [CrossRef]

- Van den Hoed, R.; Vergragt, P.J. Institutional change in the automotive industry: Or how fuel cell technology is being institutionalised. Greener Manag. Int. 2004, 47, 45–61. [Google Scholar] [CrossRef]

- Bracke, S.; Inoue, M.; Ulutas, B.; Tamada, T. CDMF-RELSUS concept: Reliable and sustainable products—Influences on design, manufacturing, layout integration and use phase. In Procedia CIRP; Elsevier: Amsterdam, The Netherlands, 2014. [Google Scholar]

- Bracke, S.; Michalski, J.; Inoue, M.; Yamada, T. CDMF-RELSUS concept: Reliable products are sustainable products—Influences on product design, manufacturing and use phase. Int. J. Sustain. Manuf. 2013, 3, 57–73. [Google Scholar] [CrossRef]

- Williams, A. Product service systems in the automobile industry: Contribution to system innovation? J. Clean. Prod. 2007, 15, 1093–1103. [Google Scholar] [CrossRef]

- Williams, A. Product-service systems in the automotive industry: The case of micro-factory retailing. J. Clean. Prod. 2006, 14, 172–184. [Google Scholar] [CrossRef]

- Van den Hoed, R. Sources of radical technological innovation: The emergence of fuel cell technology in the automotive industry. J. Clean. Prod. 2007, 15, 1014–1021. [Google Scholar] [CrossRef]

- Mingers, J.; Leydesdorff, L. A review of theory and practice in scientometrics. Eur. J. Oper. Res. 2015, 246, 1–19. [Google Scholar] [CrossRef]

- Elmquist, M.; Segrestin, B. Sustainable development through innovative design: Lessons from the KCP method experimented with an automotive firm. Int. J. Automot. Technol. Manag. 2009, 9, 229–244. [Google Scholar] [CrossRef]

- Avadikyan, A.; Llerena, P. A real options reasoning approach to hybrid vehicle investments. Technol. Forecast. Soc. Chang. 2010, 77, 649–661. [Google Scholar] [CrossRef]

- Bonilla, S.H.; Almeida, C.M.V.B.; Giannetti, B.F.; Huisingh, D. The roles of cleaner production in the sustainable development of modern societies: an introduction to this special issue. J. Clean. Prod. 2010, 18, 1–5. [Google Scholar] [CrossRef]

- Ceschin, F.; Vezzoli, C. The role of public policy in stimulating radical environmental impact reduction in the automotive sector: The need to focus on product-service system innovation. Int. J. Automot.Technol. Manag. 2010, 10, 321–341. [Google Scholar] [CrossRef]

- Chou, C.W.; Liao, W.C.; Wu, S.; Wee, H.-M. The role of technical innovation and sustainability on energy consumption: A case study on the Taiwanese automobile industry. Energies 2015, 8, 6627–6640. [Google Scholar] [CrossRef]

- Resta, B.; Gaiardelli, P.; Pezzotta, G. Sustainability in the auto repair industry: A life cycle assessment application. Int. J. Prod. Lifecycle Manag. 2009, 4, 146–165. [Google Scholar] [CrossRef]

- Vaz, C.R.; Grabot, B.; Maldonado, M.U.; Selig, P.M. Some reasons to implement reverse logistics in companies. Int. J. Environ. Technol. Manag. 2013, 16, 467–479. [Google Scholar] [CrossRef]

- Zapata, C.; Nieuwenhuis, P. Exploring innovation in the automotive industry: New technologies for cleaner cars. J. Clean. Prod. 2010, 18, 14–20. [Google Scholar] [CrossRef]

- Tushman, M.L.; Anderson, P. Technological discontinuities and organizational environments. Adm. Sci. Q. 1986, 31, 439–465. [Google Scholar] [CrossRef]

- Utterback, J.M.; Abernathy, W.J. A dynamic model of process and product innovation. Omega 1975, 3, 639–656. [Google Scholar] [CrossRef]

- Moreira, H.M.; Giometti, A.B.d.R. Protocolo de Quioto e as possibilidades de inserção do Brasil no Mecanismo de Desenvolvimento Limpo por meio de projetos em energia limpa. Contexto Int. 2008, 9–47. [Google Scholar] [CrossRef]

- Brasil, P.d.R. Estratégicos da Presidência da República; Núcleo de Assuntos Estratégicos da Presidência da República, Secretaria de Comunicação de Governo e Gestão Estratégica: Brasília, Brazil, 2005; pp. 115–303. [Google Scholar]

- Ploss, R.; Mueller, A.; Leteinturier, P. Solving automotive challenges with electronics. In Proceedings of the 2008 International Symposium on VLSI Technology, Systems and Applications, VLSI-TSA, Hsinchu, Taiwan, 21–23 April 2008. [Google Scholar]

- De Vries, R.P. IC innovations in automotive. In Proceedings of the 2008 9th International Conference on Solid-State and Integrated-Circuit Technology, ICSICT 2008, Beijing, China, 20–23 October 2008. [Google Scholar]

- Bull, K.; Hull, N.; Peck, D. Broadening industry perspectives of vehicle telematics application through virtual learning environments: EADIS: European automotive digital interaction studio. In Proceedings of the 16th World Congress on Intelligent Transport Systems and Services, ITS 2009, Stockholm, Sweden, 21–25 September 2009. [Google Scholar]

- Ros, J.; Nagelhout, D.; Montfoort, J. New environmental policy for system innovation: Casus alternatives for fossil motor fuels. Appl. Energy 2009, 86, 243–250. [Google Scholar] [CrossRef]

- Cruceru, G.; Micuda, D. The european auto market under the impact of the financial crisis: Lessons to be learned. In Proceedings of the International Conference on Risk Management, Assessment and Mitigation, RIMA ’10, Bucharest, Romania, 11 April 2010. [Google Scholar]

- Brookes, K. Unique values win PM design awards. Met. Powder Rep. 2011, 66, 18–20. [Google Scholar] [CrossRef]

- Cortez, M.A.A.; Cudia, C.P. The virtuous cycles between environmental innovations and financial performance: Case study of japanese automotive and electronics companies. Acad. Account. Financ. Stud. J. 2011, 15 (Suppl. 2), 31–44. [Google Scholar]

- Millet, D.; Yvars, P.A.; Tonnelier, P. A method for identifying the worst recycling case: Application on a range of vehicles in the automotive sector. Resour. Conserv. Recycl. 2012, 68, 1–13. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, H.; Sun, Z. Optimal control of the transient emissions and the fuel efficiency of a diesel hybrid electric vehicle. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2013, 227, 1546–1561. [Google Scholar] [CrossRef]

- Holtskog, H.; Ringen, G. Opportunities in the wake of crisis. In Proceedings of the 46th CIRP Conference on Manufacturing Systems, CIRP CMS 2013, Setubal, Portugal, 29–31 May 2013. [Google Scholar]

- Wells, P. Sustainable business models and the automotive industry: A commentary. IIMB Manag. Rev. 2013, 25, 228–239. [Google Scholar] [CrossRef]

- Intarakumnerd, P.; Chaoroenporn, P. The roles of intermediaries and the development of their capabilities in sectoral innovation systems: A case study of Thailand. Asian J. Technol. Innov. 2013, 21 (Suppl. 2), 99–114. [Google Scholar] [CrossRef]

- Vieira do Nascimento, D.M. The Brazilian experience of flex-fuel vehicles technology: Towards low carbon mobility. In Proceedings of the 20th International Conference on Urban Transport and the Environment, UT 2014, Algarve, Portugal, 28–30 May 2014. [Google Scholar]

- Pusavec, F.; Kenda, J. The transition to a clean, dry, and energy efficient polishing process: An innovative upgrade of abrasive flow machining for simultaneous generation of micro-geometry and polishing in the tooling industry. J. Clean. Prod. 2014, 76, 180–189. [Google Scholar] [CrossRef]

- Penza, M. COST Action TD1105: New Sensing Technologies for Environmental Sustainability in Smart Cities. Available online: http://www.cluster-essc.eu/events/Bruxelles/01-PRESENTATIONS/01-ESSC_PRESENTATIONS_Brussels/05_ESSC_PreparatoryWorkshop_Brussels_Penza.pdf (accessed on 27 April 2017).

- Vinodh, S.; Kamala, V.; Jayakrishna, K. Integration of ECQFD, TRIZ, and AHP for innovative and sustainable product development. Appl. Math. Model. 2014, 38, 2758–2770. [Google Scholar] [CrossRef]

- Okushima, M. Simulating social influences on sustainable mobility shifts for heterogeneous agents. Transportation 2015, 42, 827–855. [Google Scholar] [CrossRef]

- Amatucci, M. The world that chose the machine: An evolutionary view of the technological race in the history of the automobile. Int. J. Automot. Technol. Manag. 2015, 15, 43–62. [Google Scholar] [CrossRef]

| Clusters | Author | Research Institutions | Country | Research Area |

|---|---|---|---|---|

| Red | Michalski, J. | University Wuppertal | Germany | Risk Management Quality methods Reliability |

| Bracke, S. | University Wuppertal | Germany | Risk Management Quality methods Reliability | |

| Inoue, M. | Meiji University | Japan | Product development Sustainability System engineering Design support system | |

| Ulutas, B. | Eskisehir Osmangazi University | Turkey | Industrial Engineering Manufacturing Heuristics | |

| Yamada, T. | University of Electro-Communications | Japan | Closed-loop Low-carbon supply chains Remanufacturing | |

| Green | Almeida, C.M.V.B. | Universidade Paulista | Brazil | Sustainable Cleaner Production Environmental Accounting |

| Bonilla, S.F. | Universidade Paulista | Brazil | Sustainable Development | |

| Giannetti, B.F. | Universidade Paulista | Brazil | Susteinable Indicator Cleaner Production Eco-Technology | |

| Huisingh, D. | Institute for a Secure and Sustainable Environment University of Tennesse | U.S.A | Sustainable Societies | |

| Blue | Wee, H.M | Chung Yuan Christian University | Taiwan | Production Engineering management |

| Chou, C.W. | National Taiwan University of Science and Technology | Taiwan | Production Engineering management | |

| Liau, W.C. | National Taiwan University of Science and Technology | Taiwan | Production Engineering management | |

| Wu, S. | Vigor Management Technology Group | China | System analysis |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vaz, C.R.; Rauen, T.R.S.; Lezana, Á.G.R. Sustainability and Innovation in the Automotive Sector: A Structured Content Analysis. Sustainability 2017, 9, 880. https://doi.org/10.3390/su9060880

Vaz CR, Rauen TRS, Lezana ÁGR. Sustainability and Innovation in the Automotive Sector: A Structured Content Analysis. Sustainability. 2017; 9(6):880. https://doi.org/10.3390/su9060880

Chicago/Turabian StyleVaz, Caroline Rodrigues, Tania Regina Shoeninger Rauen, and Álvaro Guillermo Rojas Lezana. 2017. "Sustainability and Innovation in the Automotive Sector: A Structured Content Analysis" Sustainability 9, no. 6: 880. https://doi.org/10.3390/su9060880

APA StyleVaz, C. R., Rauen, T. R. S., & Lezana, Á. G. R. (2017). Sustainability and Innovation in the Automotive Sector: A Structured Content Analysis. Sustainability, 9(6), 880. https://doi.org/10.3390/su9060880