Product Family Approach in E-Waste Management: A Conceptual Framework for Circular Economy

Abstract

:1. Introduction

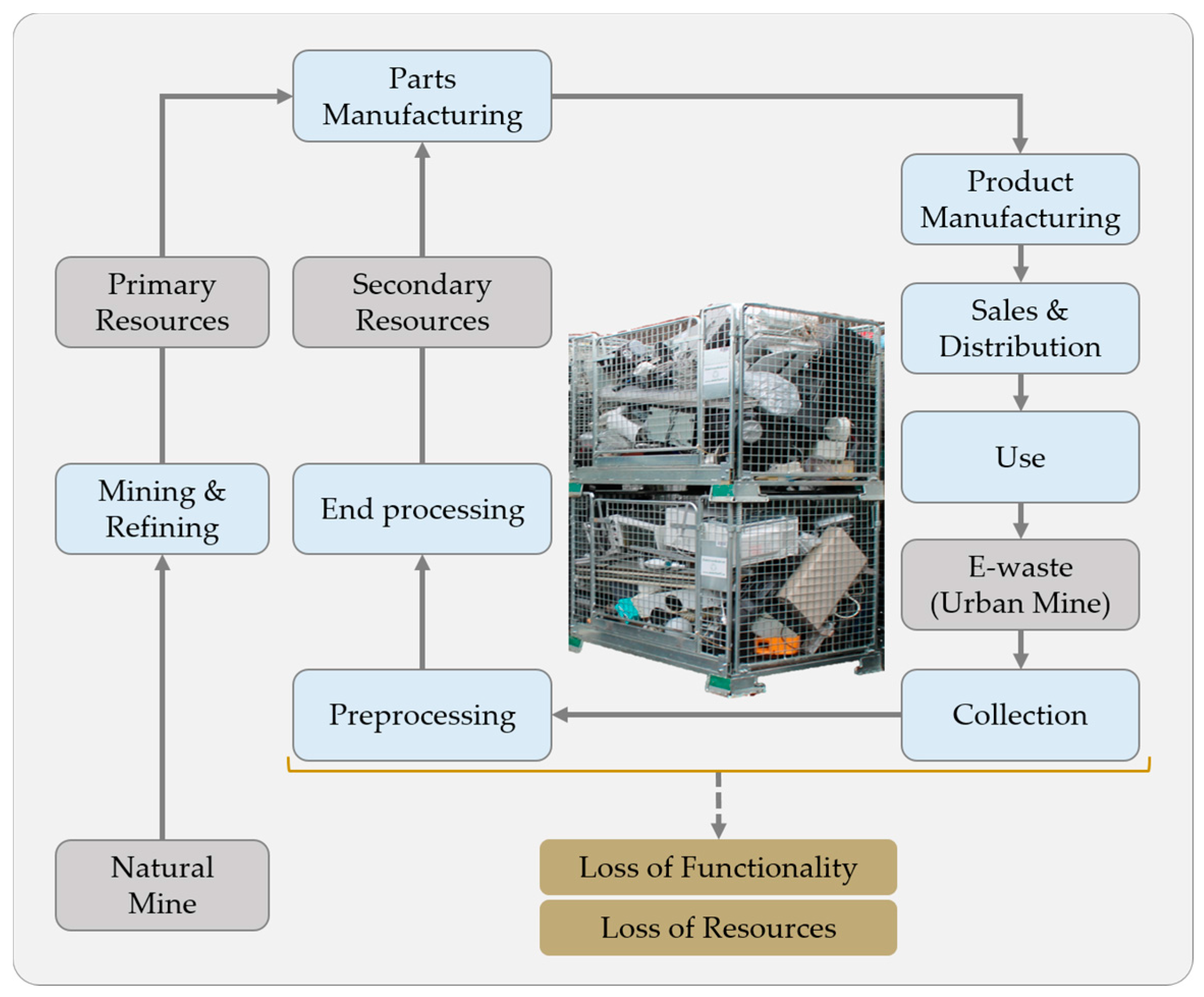

1.1. Background

1.2. Product Family Approach

1.3. Objectives

- provide a comprehensive diagnosis of the existing e-management system,

- define the key features of e-products and EoL management systems upon which product families can be defined and exemplify the approach using a variety of product types, and finally

- identify the success factors for the implementation of a framework based on product family.

2. Methodology

- (a)

- the quantities of e-products and e-waste, their management systems, and the relevant organizational and legislative provisions [12],

- (b)

- (c)

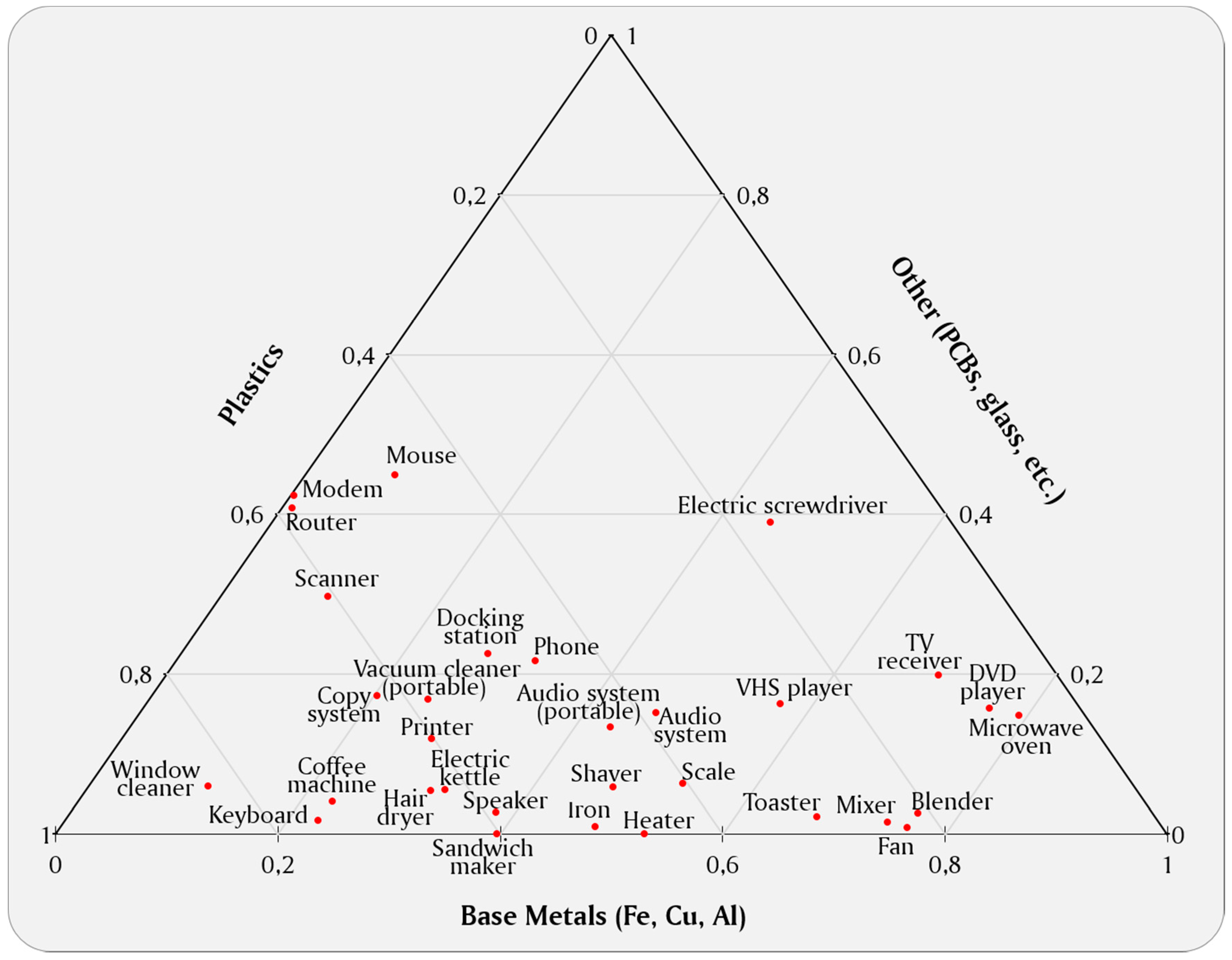

- the characteristics of EoL products (material composition, component composition, and design features) and economic assessment in order to compare possible EoL options (reuse, refurbishment, and recycling) [15],

- (d)

- the users’ perception of possible EoL scenarios for e-products [16], and finally

- (e)

- the role of information exchange for an integrated product lifecycle management of e-products [17].

3. Challenges in the Current E-Waste Management System

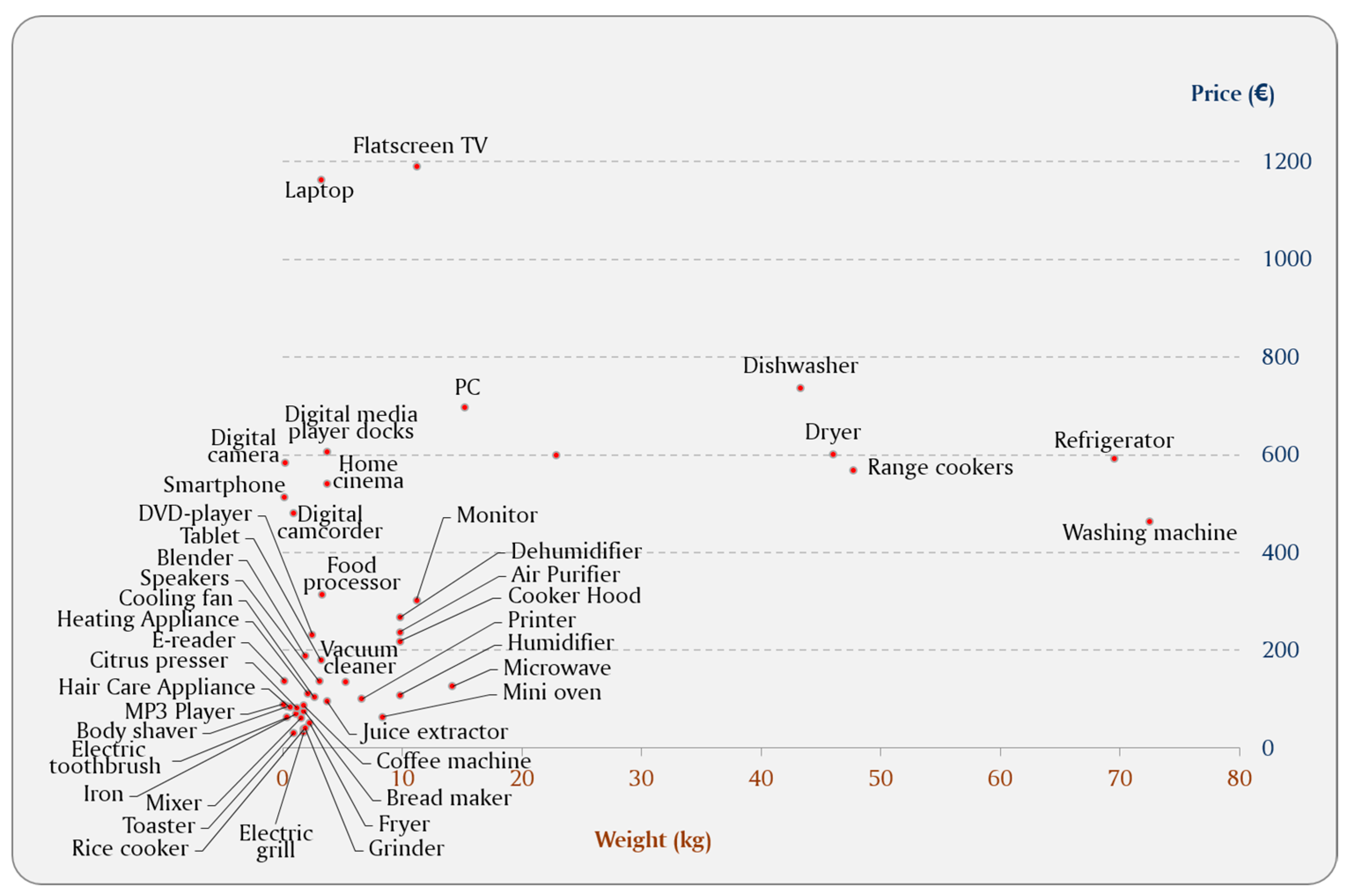

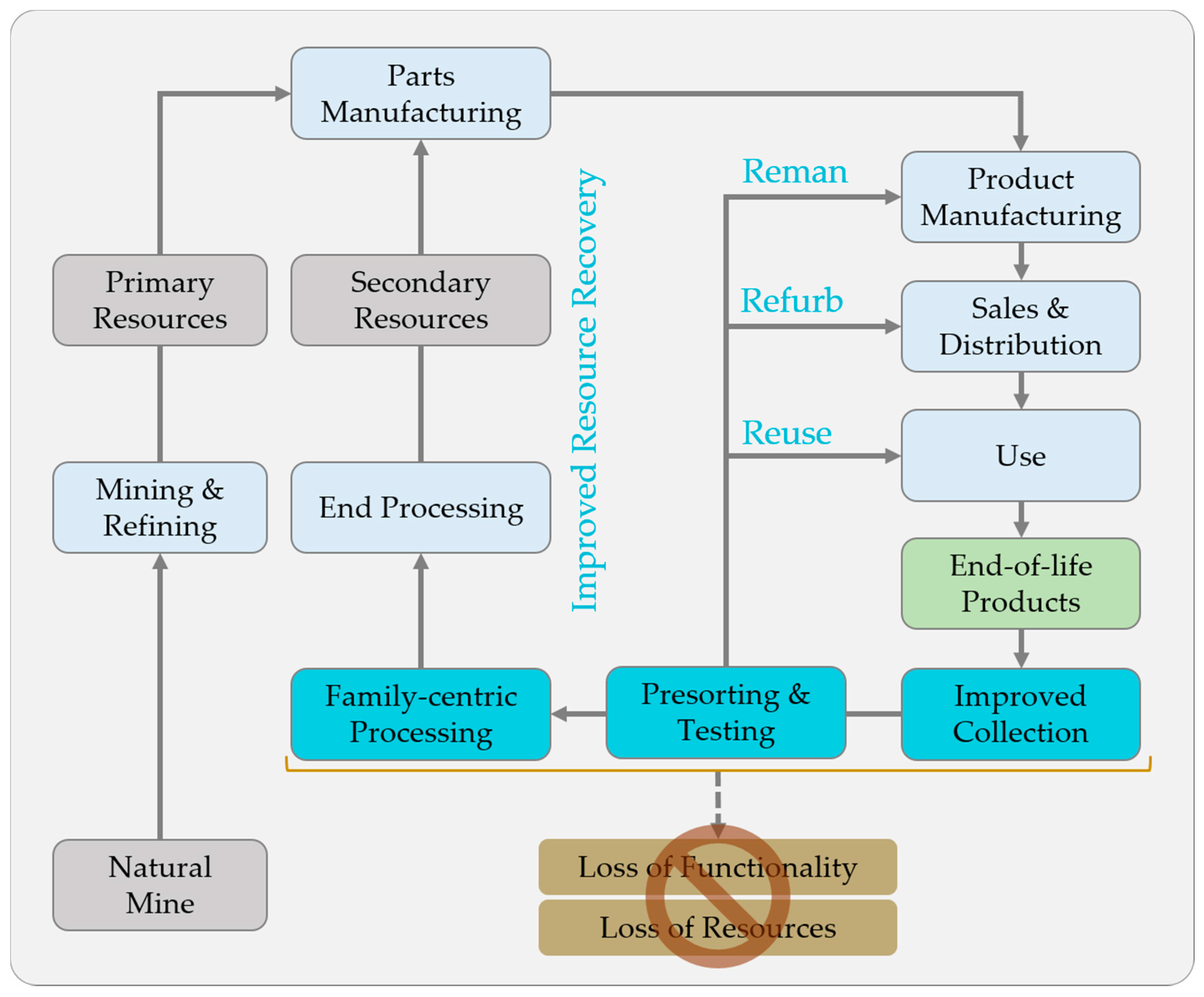

4. PFA in E-Waste Management

5. A Framework for CE

5.1. Improved Collection Systems

5.2. Presorting and Testing Platform

5.3. Family-Centric Processing

6. Concluding Remarks

Acknowledgments

Author Contributions

Conflicts of Interest

References

- European Commission Communication. COM (2015) 614/2: Closing the Loop–an EU Action Plan for the Circular Economy; European Commission Communication: Brussels, Belgium, 2015. [Google Scholar]

- Ellen MacArthur Foundation. Towards the Circular Economy (Vol. 1): Economic and Business Rationale for an Accelerated Transition. 2013. Available online: https://www.ellenmacarthurfoundation.org/assets/downloads/publications/Ellen-MacArthur-Foundation-Towards-the-Circular-Economy-vol.1.pdf (accessed on 7 May 2017).

- Sauvé, S.; Bernard, S.; Sloan, P. Environmental sciences, sustainable development and circular economy: Alternative concepts for trans-disciplinary research. Environ. Dev. 2016, 17, 48–56. [Google Scholar] [CrossRef]

- Bocken, N.M.P.; de Pauw, I.; Bakker, C.; van der Grinten, B. Product design and business model strategies for a circular economy. J. Ind. Prod. Eng. 2016, 33, 308–320. [Google Scholar] [CrossRef]

- Ford, P.; Santos, E.; Ferrão, P.; Margarido, F.; Van Vliet, K.J.; Olivetti, E. Utilizing Economic Value, Resource Availability, and Environmental Impact Metrics to Improve the WEEE and Battery Directives and Promote Alignment with the European Commission Circular Economy Strategy. In REWAS 2016: Towards Materials Resource Sustainability; Kirchain, R.E., Blanpain, B., Meskers, C., Olivetti, E., Apelian, D., Howarter, J., Kvithyld, A., Mishra, B., Neelameggham, N.R., Spangenberger, J., Eds.; Springer International Publishing: Cham, Switzerlands, 2016; pp. 289–295. [Google Scholar]

- Simpson, T.W.; Siddique, Z.; Jiao, J.R. Platform-Based Product Family Development. In Product Platform and Product Family Design: Methods and Applications; Simpson, T.W., Siddique, Z., Jiao, J.R., Eds.; Springer: Boston, MA, USA, 2006; pp. 1–15. [Google Scholar]

- Jiao, J.; Simpson, T.W.; Siddique, Z. Product family design and platform-based product development: A state-of-the-art review. J. Intell. Manuf. 2007, 18, 5–29. [Google Scholar] [CrossRef]

- Halman, J.I.M.; Hofer, A.P.; van Vuuren, W. Platform-Driven Development of Product Families. In Product Platform and Product Family Design: Methods and Applications; Simpson, T.W., Siddique, Z., Jiao, J.R., Eds.; Springer: Boston, MA, USA, 2006; pp. 27–47. [Google Scholar]

- Kim, S.; Moon, S.K. Sustainable platform identification for product family design. J. Clean. Prod. 2017, 143, 567–581. [Google Scholar] [CrossRef]

- Kwak, M.; Kim, H.M. Assessing product family design from an end-of-life perspective. Eng. Optim. 2011, 43, 233–255. [Google Scholar] [CrossRef]

- Kwak, M. Planning Demand- and Legislation-Driven Remanufacturing for a Product Family: A Model for Maximizing Economic and Environmental Potential. Ind. Eng. Manag. Syst. 2015, 14, 159–174. [Google Scholar] [CrossRef]

- Parajuly, K.; Habib, K.; Liu, G. Waste electrical and electronic equipment (WEEE) in Denmark: Flows, quantities and management. Resour. Conserv. Recycl. 2016. [Google Scholar] [CrossRef]

- Habib, K.; Parajuly, K.; Wenzel, H. Tracking the Flow of Resources in Electronic Waste—The Case of End-of-Life Computer Hard Disk Drives. Environ. Sci. Technol. 2015, 49, 12441–12449. [Google Scholar] [CrossRef] [PubMed]

- Parajuly, K.; Habib, K.; Cimpan, C.; Liu, G.; Wenzel, H. End-of-life resource recovery from emerging electronic products—A case study of robotic vacuum cleaners. J. Clean. Prod. 2016, 137, 652–666. [Google Scholar] [CrossRef]

- Parajuly, K.; Wenzel, H. Potential for circular economy in household WEEE management. J. Clean. Prod. 2017, 151, 272–285. [Google Scholar] [CrossRef]

- Atlason, R.S.; Giacalone, D.; Parajuly, K. Product design in the circular economy: Users’ perception of end-of-life scenarios for electrical and electronic appliances. Sustainability 2017, in press. [Google Scholar]

- Parajuly, K.; Wenzel, H. Circular economy in WEEE management: Information basis for resource recovery and design for end-of-life. Resour. Conserv. Recycl. 2017, in press. [Google Scholar]

- Mayers, K.; Peagam, R.; France, C.; Basson, L.; Clift, R. Redesigning the Camel. J. Ind. Ecol. 2011, 15, 4–8. [Google Scholar] [CrossRef]

- European Parliament Directive. 2012/19/EU of the European Parliament and of the Council of 4 July 2012 on Waste Electrical and Electronic Equipment (WEEE) (Recast). Available online: http://eur-lex.europa.eu/legal-content/EN/TXT/?uri=celex:32012L0019 (accessed on 7 May 2017).

- UNEP. UNEP Metal Recycling: Opportunities, Infrastructure, A Report of the Working Group on the Global Metal Flows to the International Resource Panel. Available online: http://apps.unep.org/publications/index.php?option=com_pmtdata&task=download&file=-Metal%20Recycling%20Opportunities,%20Limits,%20Infrastructure-2013Metal_recycling.pdf (accessed on 7 May 2017).

- Friege, H.; Oberdorfer, M.; Gunther, M. Optimising waste from electric and electronic equipment collection systems: A comparison of approaches in European countries. Waste Manag. Res. 2015, 33, 223–231. [Google Scholar] [CrossRef] [PubMed]

- Feng, W.; Huisman, J.; Balde, K.; Stevels, A. A systematic and compatible classification of WEEE. In Proceedings of the Electronics Goes Green 2012+ (EGG), Berlin, Germany, 9–12 September 2012; pp. 1–6. [Google Scholar]

- European Parliament Directive. 2002/96/EU of the European Parliament and of the Council of 27 January 2003 on Waste Electrical and Electronic Equipment (WEEE). Available online: http://eur-lex.europa.eu/legal-content/EN/ALL/?uri=CELEX:32002L0096 (accessed on 7 May 2017).

- DPA-System. WEEE, BAT, and ELV Statistics Denmark 2014; Danish Producer Responsibility System: Copenhagen, Denmark, 2015. [Google Scholar]

- Chiodo, J.; Boks, C. Assessment of end-of-life strategies with active disassembly using smart materials. J. Sustain. Prod. Des. 2002, 2, 69–82. [Google Scholar] [CrossRef]

- Chancerel, P.; Rotter, S. Recycling-oriented characterization of small waste electrical and electronic equipment. Waste Manag. 2009, 29, 2336–2352. [Google Scholar] [CrossRef] [PubMed]

- Oguchi, M.; Murakami, S.; Sakanakura, H.; Kida, A.; Kameya, T. A preliminary categorization of end-of-life electrical and electronic equipment as secondary metal resources. Waste Manag. 2011, 31, 2150–2160. [Google Scholar] [CrossRef] [PubMed]

- Parajuly, K.; Thapa, K.B.; Cimpan, C.; Wenzel, H. Electronic waste and informal recycling in Kathmandu, Nepal: Challenges and opportunities. J. Mater. Cycles Waste Manag. 2017. [Google Scholar] [CrossRef]

- UNEP. UNEP Fostering and Communicating Sustainable Lifestyles: Principles and Emerging Practices. Available online: http://wedocs.unep.org/handle/20.500.11822/17016 (accessed on 7 May 2017).

- Wang, R.; Xu, Z. Recycling of non-metallic fractions from waste electrical and electronic equipment (WEEE): A review. Waste Manag. 2014, 34, 1455–1469. [Google Scholar] [CrossRef] [PubMed]

- Stahel, W.R. The circular economy. Nature 2016, 531, 435. [Google Scholar] [CrossRef] [PubMed]

- Peeters, J.R.; Vanegas, P.; Dewulf, W.; Duflou, J.R. Economic and environmental evaluation of design for active disassembly. J. Clean. Prod. 2017, 140, 1182–1193. [Google Scholar] [CrossRef]

| Categories & Fractions Based On | Types * | To Support |

|---|---|---|

| Size, functionality, use of products [23] | 10 | Documentation & EoL treatment of e-products |

| EoL processing infrastructure [19] | 6 | |

| EoL treatment options [24] | 5 | Collection and material recovery |

| Functionality [22] | 58 | Documentation and EoL management |

| Material composition [25] | 4 | Active disassembly |

| Mechanical properties & chemical composition [26] | - | Product design and recycling processes |

| Metal content and EoL quantities [27] | 6 | EoL management |

| Product Type | Potentially Reusable Components | Components Suited More for Material Recovery | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Universal Components | Common Components | Plastic-Rich | Metal-Rich | High-Value | Special Components | ||||||

| Power Cables | Switches | Electromotors & Transformors | Displays | Casings & Body Frames | Casings & Body Frames | Other | PCBs | Other | Batteries | Other | |

| Audio System | * | * | * | * | * | * | * | ||||

| Blender | * | * | * | * | * | ||||||

| Coffee machine | * | * | * | * | |||||||

| Copy System | * | * | * | * | |||||||

| Docking Station | * | * | * | * | |||||||

| DVD-Player | * | * | * | * | * | ||||||

| Electric Kettle | * | * | * | * | |||||||

| Electric Screwdriver | * | * | * | * | * | ||||||

| Fan | * | * | * | * | * | * | |||||

| Hair Dryer | * | * | * | * | * | ||||||

| Hair Trimmer | * | * | * | * | * | ||||||

| Heater | * | * | * | * | |||||||

| Iron | * | * | * | ||||||||

| Keyboard | * | * | * | ||||||||

| Microwave Oven | * | * | * | * | * | * | * | ||||

| Mixer | * | * | * | * | * | * | |||||

| Modem | * | * | * | ||||||||

| Mouse | * | * | |||||||||

| Personal Computer | * | * | * | * | * | ||||||

| Phone | * | * | * | * | |||||||

| Portable Cassette Player | * | * | * | * | * | * | * | ||||

| Portable Vacuum Cleaner | * | * | * | * | * | ||||||

| Printer | * | * | * | * | * | ||||||

| Router | * | * | * | ||||||||

| Sandwich maker/Grill | * | * | |||||||||

| Scale | * | * | * | * | * | ||||||

| Scanner | * | * | * | * | * | ||||||

| Shaver | * | * | * | * | * | * | |||||

| Speaker | * | * | * | ||||||||

| Toaster | * | * | * | ||||||||

| TV receiver | * | * | * | ||||||||

| VHS Player | * | * | * | * | * | * | * | ||||

| Window cleaner | * | * | * | ||||||||

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Parajuly, K.; Wenzel, H. Product Family Approach in E-Waste Management: A Conceptual Framework for Circular Economy. Sustainability 2017, 9, 768. https://doi.org/10.3390/su9050768

Parajuly K, Wenzel H. Product Family Approach in E-Waste Management: A Conceptual Framework for Circular Economy. Sustainability. 2017; 9(5):768. https://doi.org/10.3390/su9050768

Chicago/Turabian StyleParajuly, Keshav, and Henrik Wenzel. 2017. "Product Family Approach in E-Waste Management: A Conceptual Framework for Circular Economy" Sustainability 9, no. 5: 768. https://doi.org/10.3390/su9050768

APA StyleParajuly, K., & Wenzel, H. (2017). Product Family Approach in E-Waste Management: A Conceptual Framework for Circular Economy. Sustainability, 9(5), 768. https://doi.org/10.3390/su9050768