Business Engagement with Sustainable Water Resource Management through Water Footprint Accounting: The Case of the Barilla Company

Abstract

:1. Introduction

1.1. Background and Objectives

1.2. Methodology and Study Design

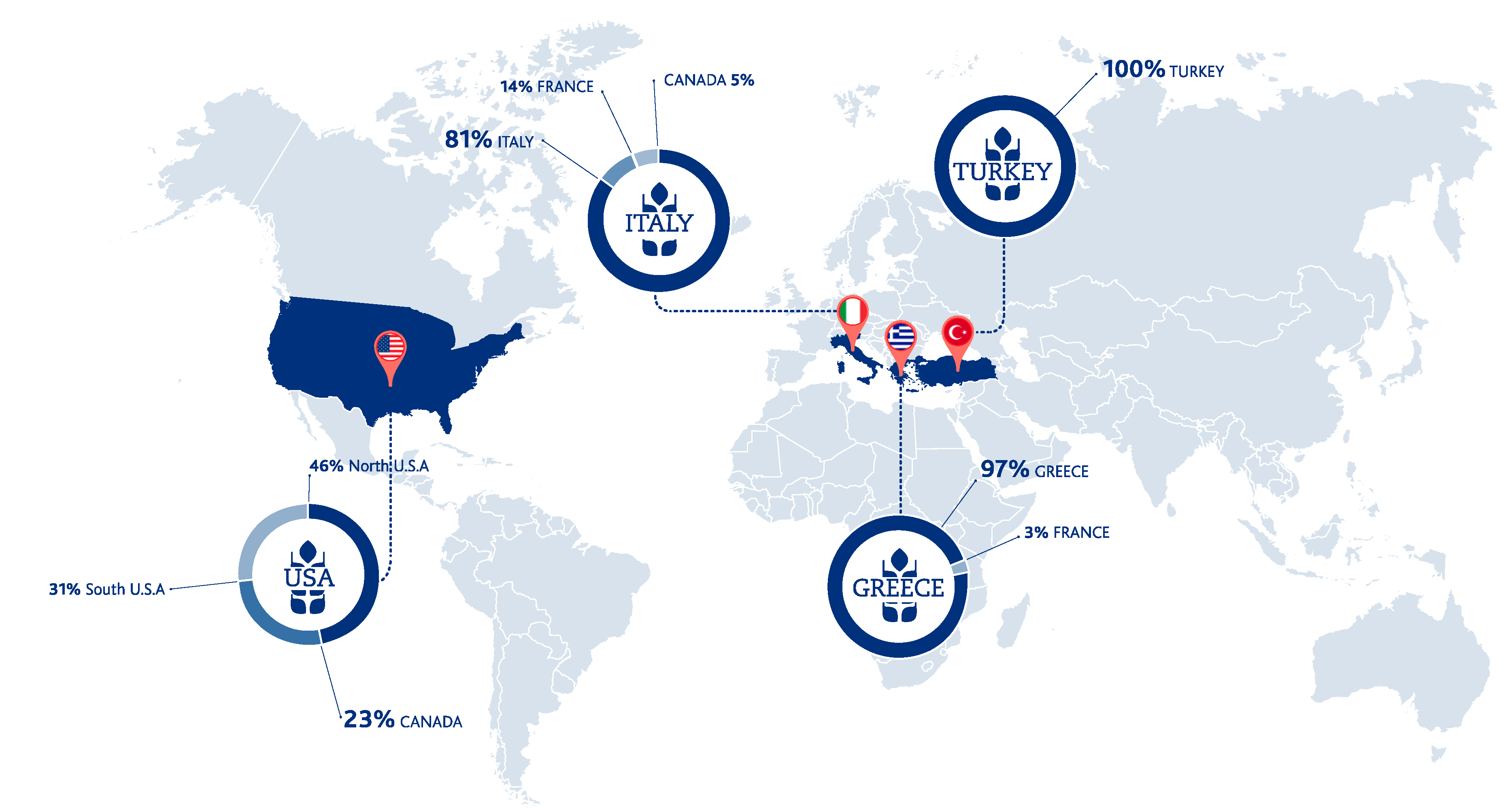

2. The Barilla Case

2.1. The Company

2.2. Corporate Social Responsibility and Engagement in Sustainable Water Resource Management

3. Barilla’s Sustainable Water Programs

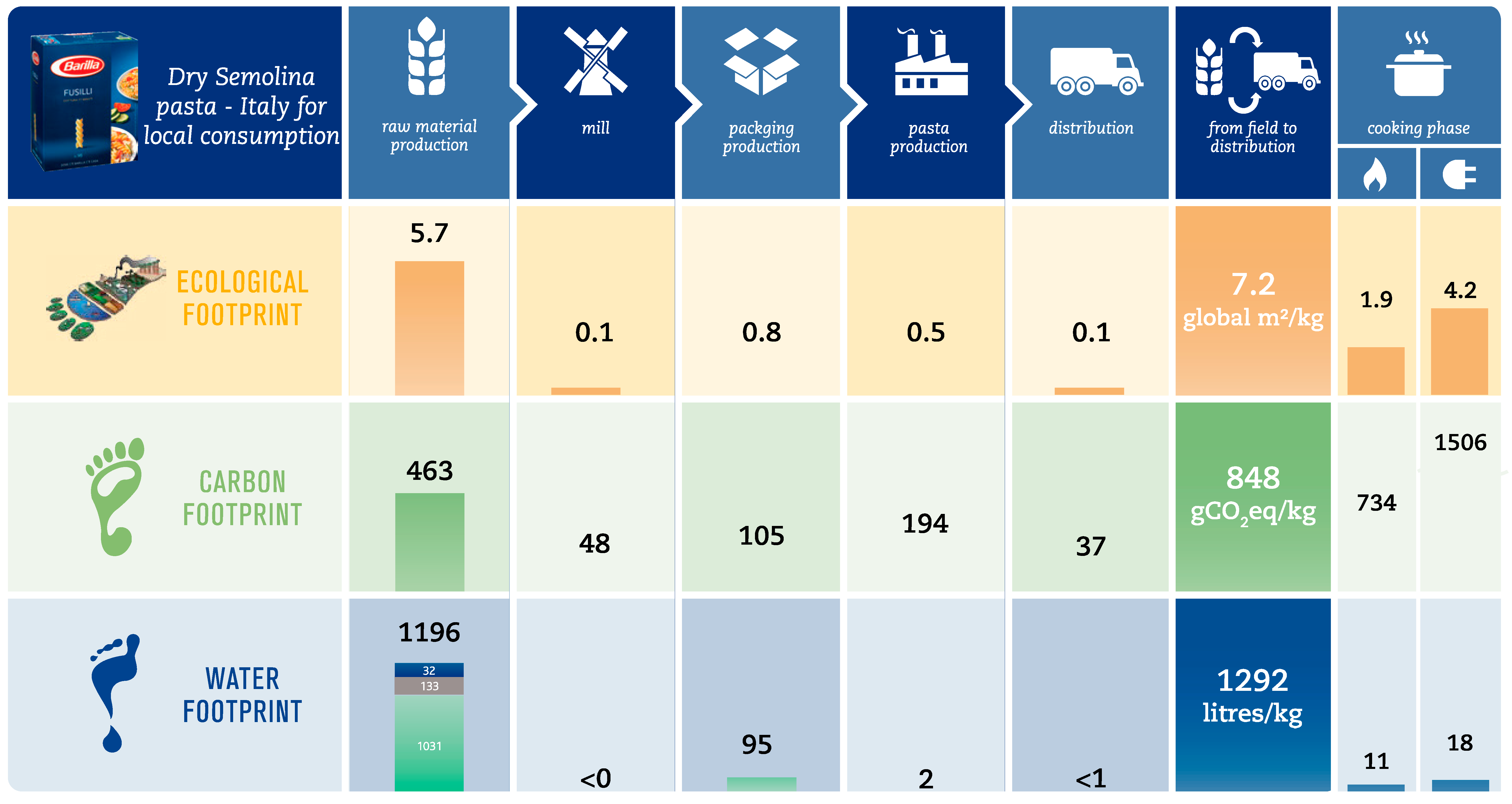

3.1. Environmental Products Declarations

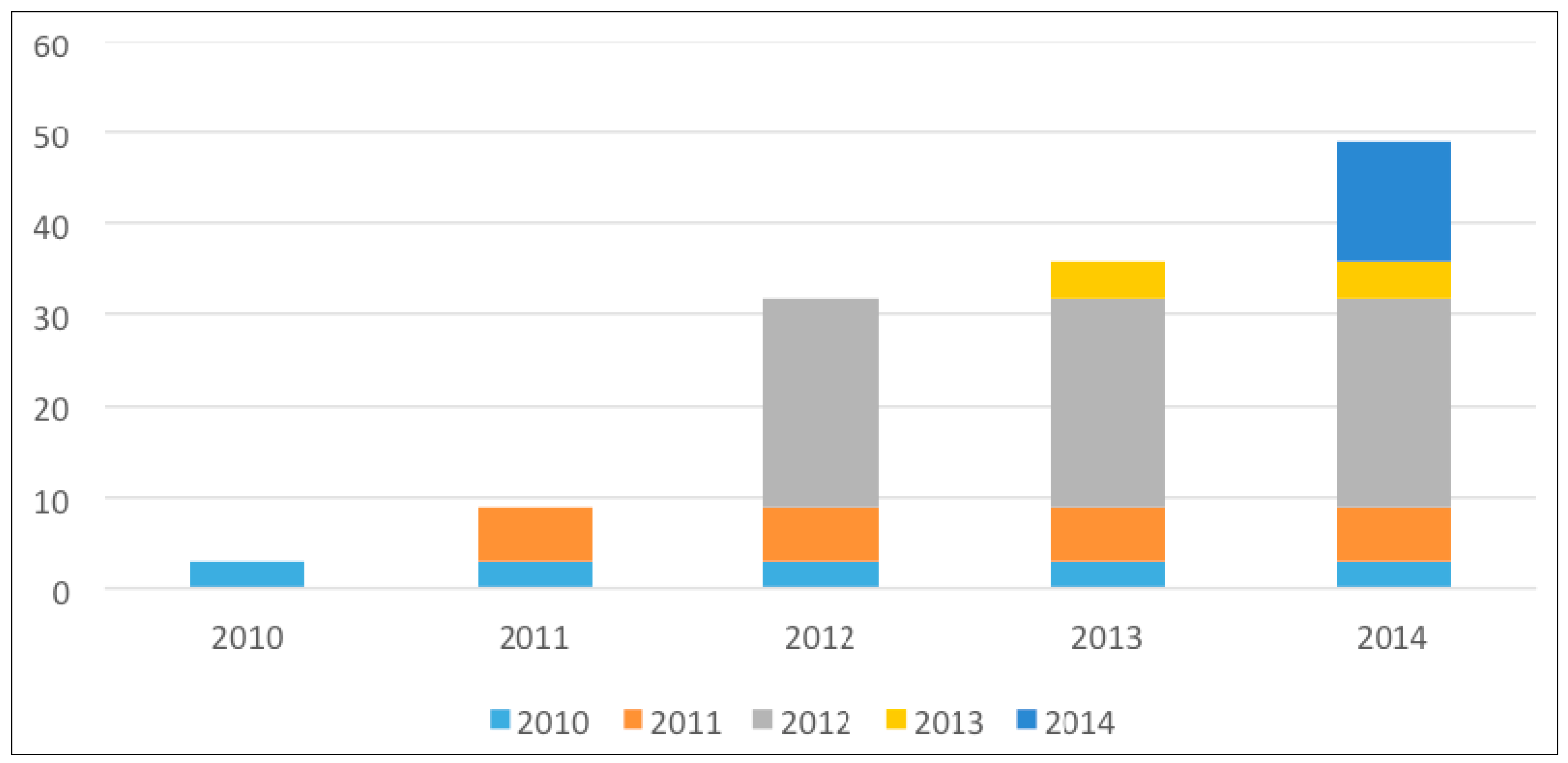

3.2. Water Footprint Reduction: The Aureo Wheat Programme

3.3. Other Initiatives

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Hoekstra, A.Y. The Water Footprint of Modern Consumer Society; Routledge: London, UK, 2013. [Google Scholar]

- FAO-AQUASTAT. Online database. Available online: http://www.fao.org/nr/water/aquastat/water_use/index.stm (accessed on 15 January 2015).

- World Water Assessment Programme. Message for business leaders. UN WWDR. Available online: http://www.unesco.org/new/fileadmin/MULTIMEDIA/HQ/SC/pdf/wwap_wwdr3_Messages_for_Business_Leaders.pdf (accessed on 10 January 2015).

- Ceres. Murky waters? Corporate reporting on water risks. A benchmarking study on 100 companies. Available online: http://www.ceres.org/resources/reports/corporate-reporting-on-water-risk-2010 (accessed on 11 January 2015).

- World Economic Forum. Global Risks 2015, 10th ed.; World Economic Forum: Cologny, Switzerland, 2015; Available online: http://www3.weforum.org/docs/WEF_Global_Risks_2015_Report15.pdf (accessed on 17 February 2015).

- Ridoutt, B.G.; Sanguansri, P.; Harper, G.S. Comparing carbon and water footprints for beef cattle production in Southern Australia. Sustainability 2011, 3, 2443–2455. [Google Scholar] [CrossRef]

- Hoekstra, A.Y.; Chapagain, A.K.; Aldaya, M.M.; Mekonnen, M.M. The Water Footprint Assessment Manual: Setting the Global Standard; Earthscan: London, UK, 2011. [Google Scholar]

- Aldaya, M.M.; Martinez-Santos, P.; Llamas, M.R. Incorporating the water footprint and virtual water into policy: Reflections from the Mancha Occidental Region, Spain. Water Resour. Manag. 2010, 24, 941–958. [Google Scholar] [CrossRef]

- Hoekstra, A.Y.; Mekonnen, M.M. The water footprint of humanity. Proc. Natl. Acad. Sci. USA 2012, 109, 3232–3237. [Google Scholar] [CrossRef] [PubMed]

- Mekonnen, M.M.; Hoekstra, A.Y.; Becht, R. Mitigating the water footprint of export cut flowers from the Lake Naivasha Basin, Kenya. Water Resour. Manag. 2012, 26, 3725–3742. [Google Scholar] [CrossRef]

- Hoekstra, A.Y.; Chapagain, A.K. Globalisation of Water: Sharing the Planet’s Freshwater Resources; Blackwell Publishing: Oxford, UK, 2008. [Google Scholar]

- Ridoutt, B.G.; Pfister, S. Towards an integrated family of footprint indicators. J. Ind. Ecol. 2013, 17, 337–339. [Google Scholar] [CrossRef]

- Wichelns, D. Do the virtual water and water footprint perspectives enhance policy discussions? Int. J. Water Resour. Dev. 2011, 27, 633–645. [Google Scholar]

- Chenoweth, J.; Hadjikakou, M.; Zoumides, C. Quantifying the human impact on water resources: A critical review of the water footprint concept. Hydrol. Earth Syst. Sci. 2014, 18, 2325–2342. [Google Scholar] [CrossRef]

- ISO 14 046, Briefing note. Available online: http://www.iso.org/iso/iso14046_briefing_note.pdf (accessed on 11 January 2015).

- Allan, J.A. Food-water security: Beyond water and the water sector. In Water Security: Principles, Perspectives, Practices; Lankford, B., Bakker, K., Zeitoun, M., Conway, D., Eds.; Earthscan: London, UK, 2013; pp. 321–335. [Google Scholar]

- Allan, J.A. The role of those who produce food and trade it in using and ‘trading’ embedded water: What are the impacts and who benefits. In Proceedings of the ESF Strategic Workshop on Accounting for Water Scarcity and Pollution in the Rules of International Trade, Amsterdam, The Netherlands, 25–26 November 2010; Hoekstra, A.Y., Aldaya, M.M., Avril, B., Eds.; UNESCO-IHE: Delft, The Netherlands, 2011. Available online: http://www.waterfootprint.org/Reports/Report54-Proceedings-ESF-Workshop-Water-Trade.pdf (accessed on 9 January 2015). [Google Scholar]

- Allan, J.A. Prioritising the processes beyond the water sector that will secure water for society—Farmers in political, economic, and social contexts and fair international trade. In Re-Thinking Water and Food Security: Fourth Marcelino Botin Foundation Water Workshop; Martinez-Cortina, L., Garrido, A., Lopez-Gunn, E., Eds.; CRC Press Taylor & Francis Group: Leiden, The Netherlands; Oxford, UK, 2010; Available online: http://www.rac.es/ficheros/doc/00725.pdf (accessed on 13 February 2015).

- Sojamo, S.; Larson, E.A. Investigating food and agribusiness corporations as global water security, management and governance agents: The case of Nestlé, Bunge and Cargill. Water Altern. 2012, 5, 619–635. [Google Scholar]

- World Water Assessment Programme. Water in a changing world. UN WWDR. Available online: http://www.unesco.org/new/en/natural-sciences/environment/water/wwap/wwdr/wwdr3-2009/ (accessed on 28 December 2014).

- Allan, J.A. IWRM IWRAM: A New Sanctioned Discourse? Occasional Paper 50; SOAS Water Issues Study Group: London, UK, 2003; pp. 1–27. [Google Scholar]

- Chapagain, A.K.; Orr, S. Water footprint of Nestlé’s ‘Bitesize Shredded Wheat’. A pilot study to account and analyse the water footprints of Bitesize Shredded Wheat in the context of water availability along its supply chain. Available online: http://temp.waterfootprint.org/Reports/Nestle-2010-Water-Footprint-Bitesize-Shredded-Wheat.pdf (accessed on 14 January 2015).

- SABMiller; GTZ; WWF. Water Futures: Working Together for a Secure Water Future; SABMiller: Woking, UK; WWF-UK: Godalming, UK, 2010. [Google Scholar]

- The Coca-Cola Company (TCCC); The Nature Conservancy (TNC). Product Water Footprint Assessments: Practical Application in Corporate Water Stewardship; TCCC: Atlanta, GA, USA; TNC: Arlington, VA, USA, 2010. [Google Scholar]

- Pepsi Co. Environmental Sustainability Report 2009/10: Path to Zero; Pepsi Co: London, UK, 2011. [Google Scholar]

- Unilever. Unilever: Our water footprint. Available online: http://www.unilever.com/sustainable-living/water/footprint/ (accessed on 11 January 2015).

- Daniel, M.A.; Sojamo, S. From risks to shared value? Corporate strategies in building a global water accounting and disclosure regime. Water Altern. 2012, 5, 636–657. [Google Scholar]

- WWF; SAAB Miller. Water Footprinting. Identifying & Addressing Water Risks in the Value Chain. Available online: http://www.sab.co.za/sablimited/action/media/downloadFile?media_fileid=918 (accessed on 23 December 2014).

- Environmental Product Declaration (EPD). General Programme Instructions for the International EPD System 2.01. Available online: http://www.environdec.com/Documents/GPI/General_programme_instructions_2_01_20130918.pdf (accessed on 17 February 2014).

- Ruini, L.F.; Marchelli, L.; Marino, M.; Filareto, A. Barilla EPD Process System to increase reliability, comparability and communicability of LCA studies. In Proceedings of the 8th International Conference on LCA in the Agri-Food Sector, Rennes, France, 2–4 October 2012; Available online: http://www.studiolce.it/Files/Pubblicazioni/2012/Barilla%20EPD%20Process%20System.pdf (accessed on 12 January 2015).

- Mekonnen, M.M.; Hoekstra, A.Y. The Green, Blue and Grey Water Footprint of Crops and Derived Crop Products; Value of Water Research Report Series No. 47; UNESCO-IHE: Delft, The Netherlands, 2010. [Google Scholar]

- Ecoivent database. Available online: http://www.ecoinvent.org/ (accessed on 10 March 2015).

- EPD. Durum Wheat Semolina Pasta. Available online: http://gryphon.environdec.com/data/files/6/7968/epd217en_rev5.pdf (accessed on 25 January 2015).

- Barilla Group. Good for you, good for the planet. Annual results. Available online: http://www.barillagroup.com/corporate/en/home/our-sustainable-model/sustainable-business-reports.html (accessed on 19 January 2015).

- Barilla Group. Good for you, good for the planet. Performance indicators. Available online: http://www.barillagroup.com/corporate/en/home/our-sustainable-model/sustainable-business-reports.html (accessed on 10 December 2014).

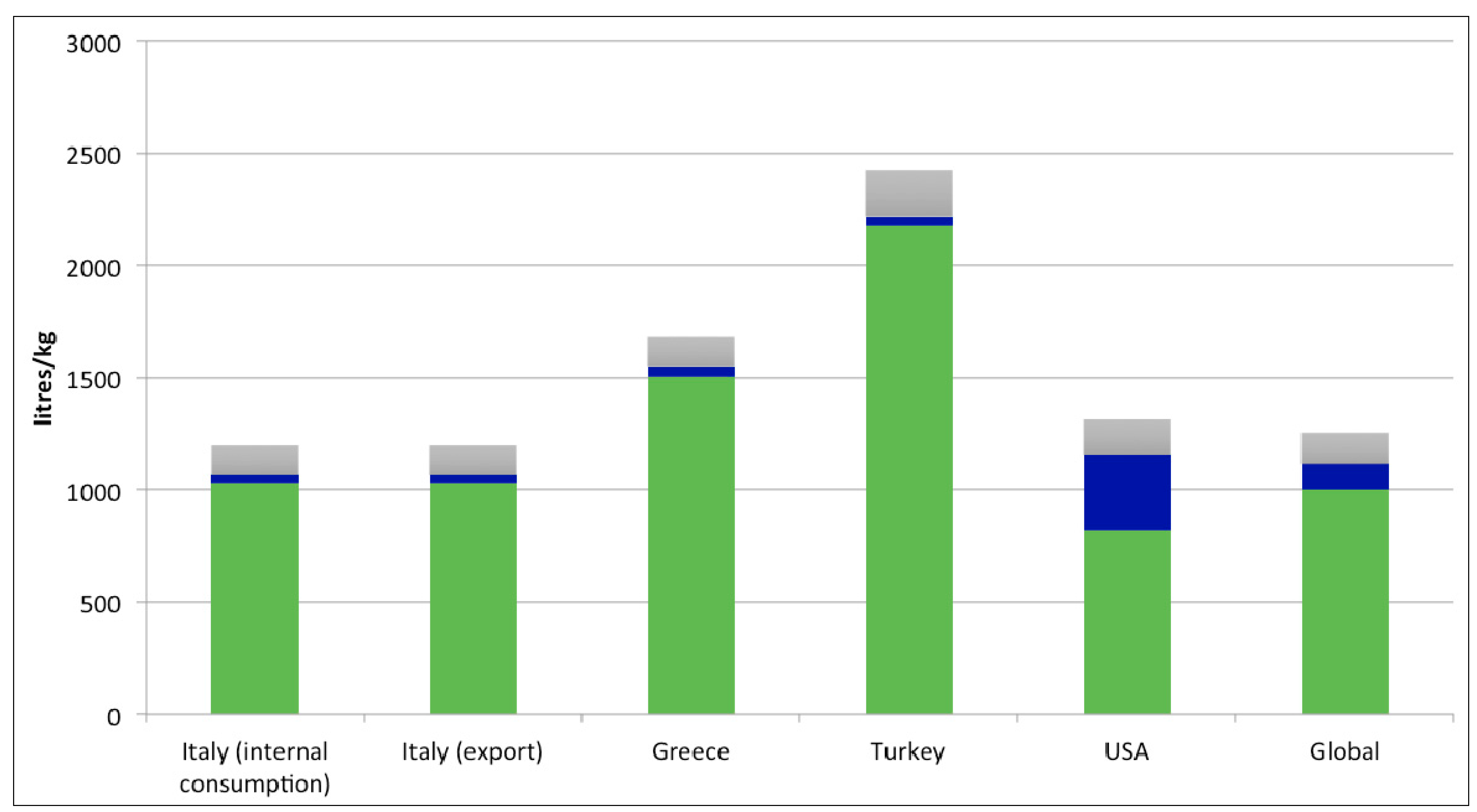

- Ruini, L.F.; Marino, M.; Pignatelli, S.; Laio, F.; Ridolfi, L. Water footprint of large-sized food company: The case of Barilla pasta production. Water Resour. Ind. 2013, 1–2, 7–24. [Google Scholar]

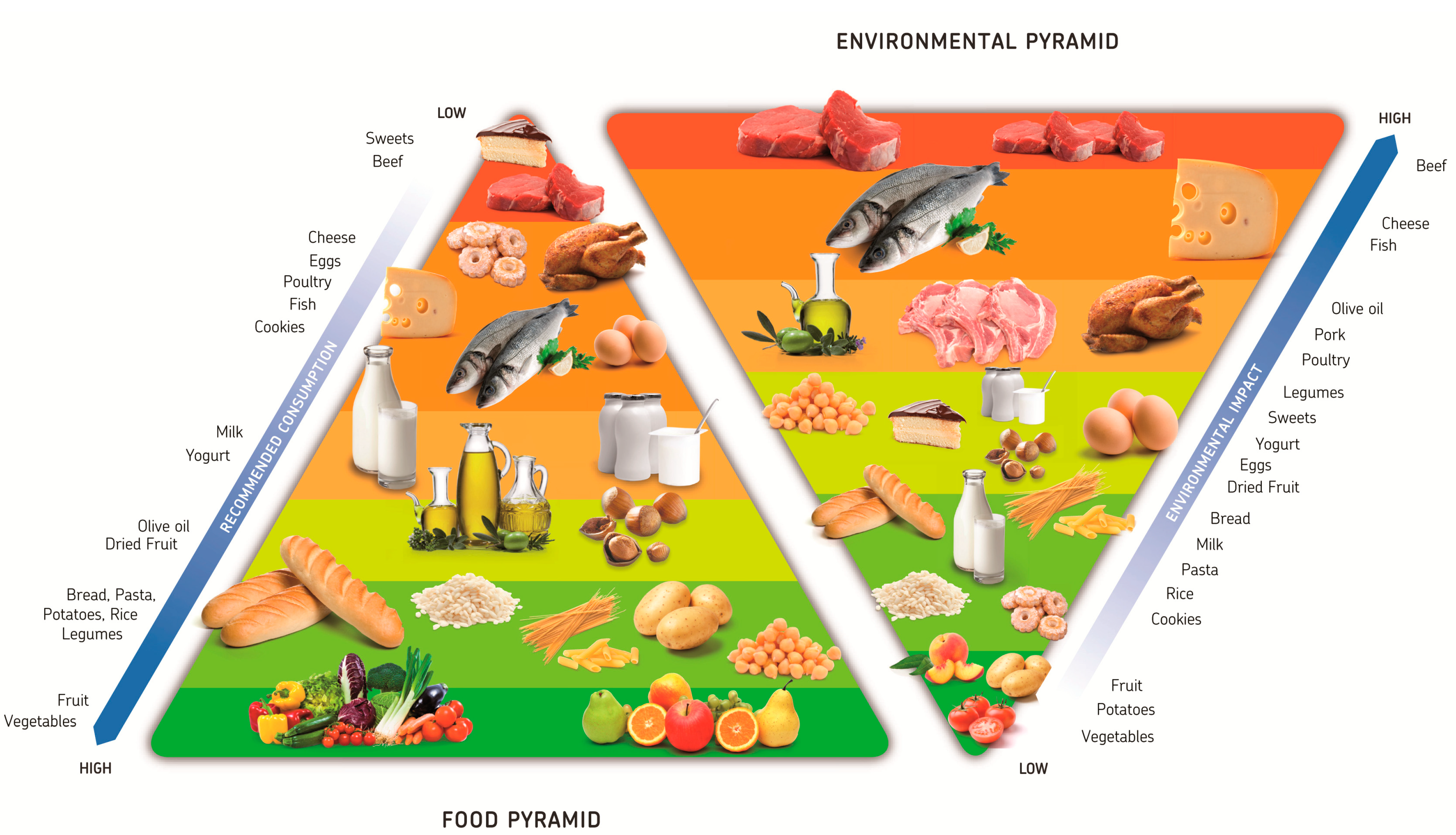

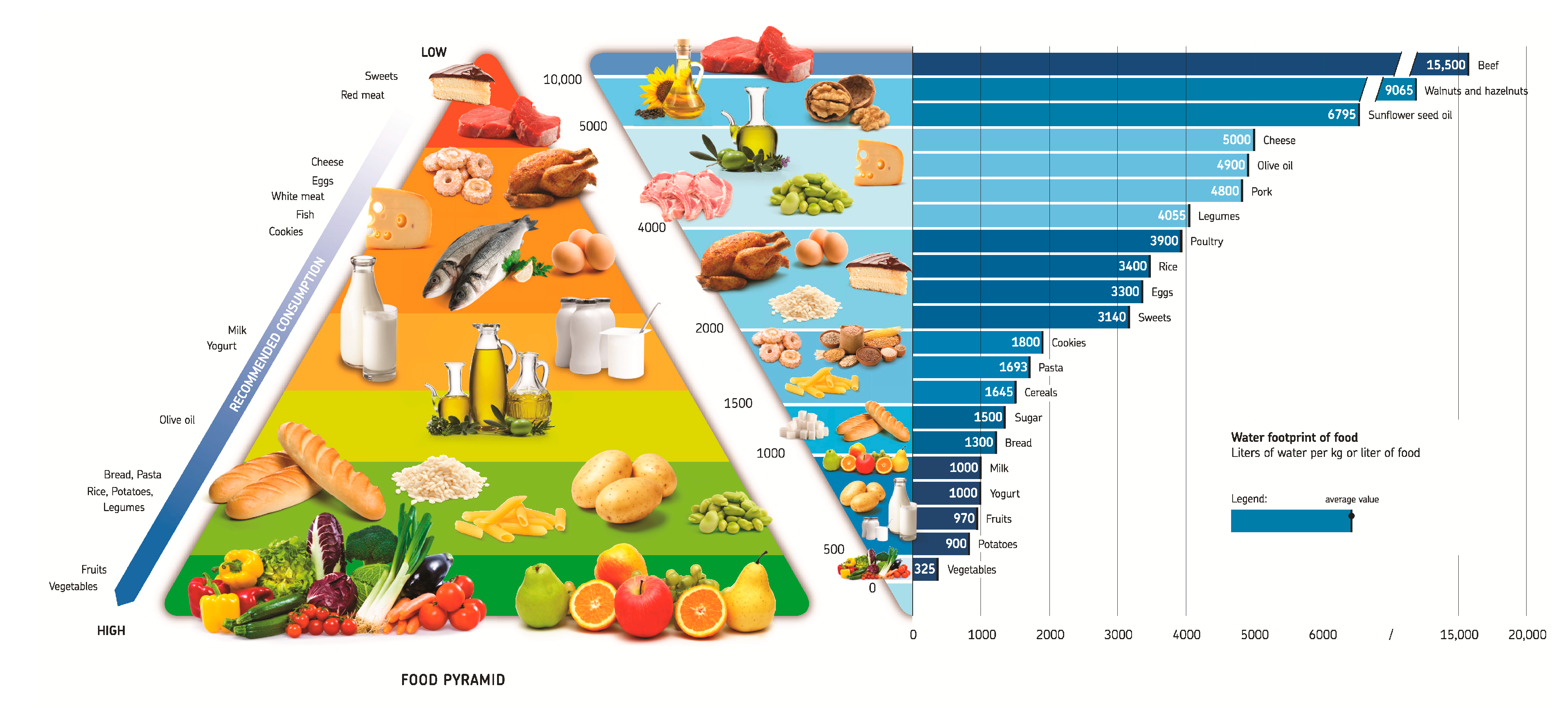

- BCFN. Double Pyramid 2014. Fifth edition: Diet and environmental impact. Available online: http://www.barillacfn.com/wp-content/uploads/2014/10/dp_divulgativo_ENG_DEF.pdf (accessed on 10 December 2014).

- BCFN. Water economy. Available online: http://www.barillacfn.com/wp-content/uploads/2012/07/watereconomy_bcfn2011.pdf (accessed on 10 December 2014).

- Aldaya, M.M.; Hoekstra, A.Y. The water needed for Italians to eat pasta and pizza. Agr. Syst. 2010, 103, 351–360. [Google Scholar] [CrossRef]

- Aldaya, M.M.; Allan, J.A.; Hoekstra, A.Y. Strategic importance of green water in international crop trade. Ecol. Econ. 2010, 69, 887–894. [Google Scholar] [CrossRef]

- Gilmont, M.; Antonelli, M. Analyse to optimise. Sustainable intensification of agricultural production through investment in integrated land and water management in Africa. In Handbook of Land and Water Grabs in Africa; Allan, J.A., Keulertz, M., Sojamo, S., Warner, J., Eds.; Routledge: Abingdon, UK, 2013; pp. 406–418. [Google Scholar]

- Yang, H.; Wang, L.; Abbaspour, K.C.; Zehnder, A.J.B. Virtual water trade: An assessment of water use efficiency in the international food trade. Hydrol. Earth Syst. Sci. 2006, 10, 443–454. [Google Scholar] [CrossRef]

- Zehnder, A.J.B.; Yang, H.; Schertenleib, R. Water issues: The need for actions at different levels. Aquat. Sci. 2003, 65, 1–20. [Google Scholar] [CrossRef]

- Frisvold, G.B.; Wilson, P.N.; Needham, R. Implications of federal farm policy and state regulation on agricultural water use. In Arizona Water Policy: Management Innovations in an Urbanizing, Arid Region; Colby, B.G., Jacobs, K.L., Eds.; Resources for the Future: Washington, DC, USA, 2010. [Google Scholar]

- Barilla Group. Handbook for Sustainable Cultivation of Quality Durum Wheat in Italy; Barilla Group: Parma, Italy, 2011. [Google Scholar]

- Ruini, L.; Ferrari, E.; Meriggi, P.; Marino, M.; Sessa, F. Increasing the sustainability of pasta production through a life cycle assessment approach. In Proceedings of the International Workshop Advances in Cleaner Production ‘Integrating Cleaner Production into Sustainability Strategy’, Sao Paulo, Brazil, 22–24 May 2013.

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Antonelli, M.; Ruini, L.F. Business Engagement with Sustainable Water Resource Management through Water Footprint Accounting: The Case of the Barilla Company. Sustainability 2015, 7, 6742-6758. https://doi.org/10.3390/su7066742

Antonelli M, Ruini LF. Business Engagement with Sustainable Water Resource Management through Water Footprint Accounting: The Case of the Barilla Company. Sustainability. 2015; 7(6):6742-6758. https://doi.org/10.3390/su7066742

Chicago/Turabian StyleAntonelli, Marta, and Luca Fernando Ruini. 2015. "Business Engagement with Sustainable Water Resource Management through Water Footprint Accounting: The Case of the Barilla Company" Sustainability 7, no. 6: 6742-6758. https://doi.org/10.3390/su7066742

APA StyleAntonelli, M., & Ruini, L. F. (2015). Business Engagement with Sustainable Water Resource Management through Water Footprint Accounting: The Case of the Barilla Company. Sustainability, 7(6), 6742-6758. https://doi.org/10.3390/su7066742