The Governance Logic of Green Technology Diffusion Under Ecological Civilization: The Case of Formaldehyde-Free Biomass Adhesive Industrialization

Abstract

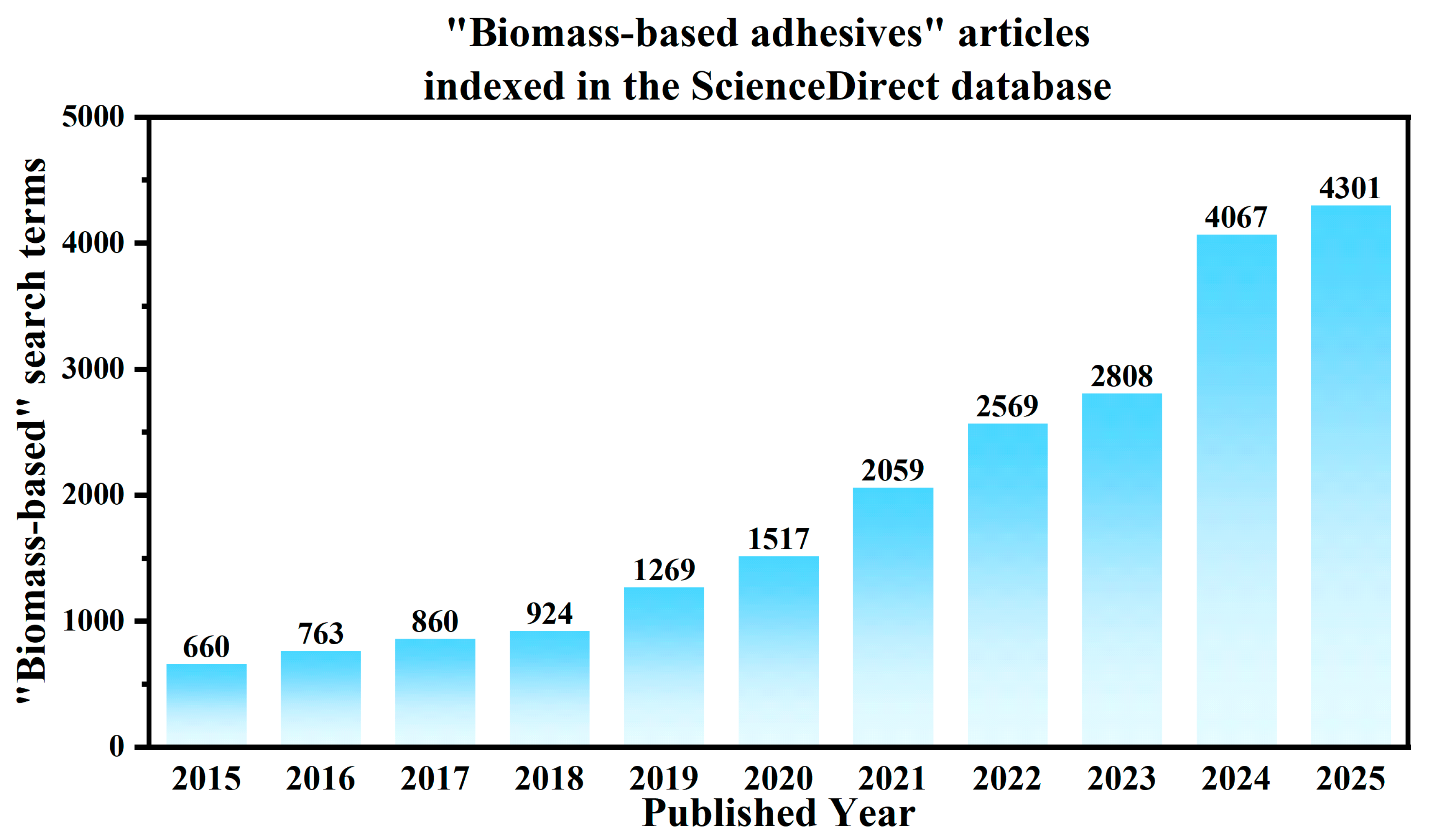

1. Introduction

2. Formaldehyde-Free Adhesive Technology Innovation and Ecological Benefits

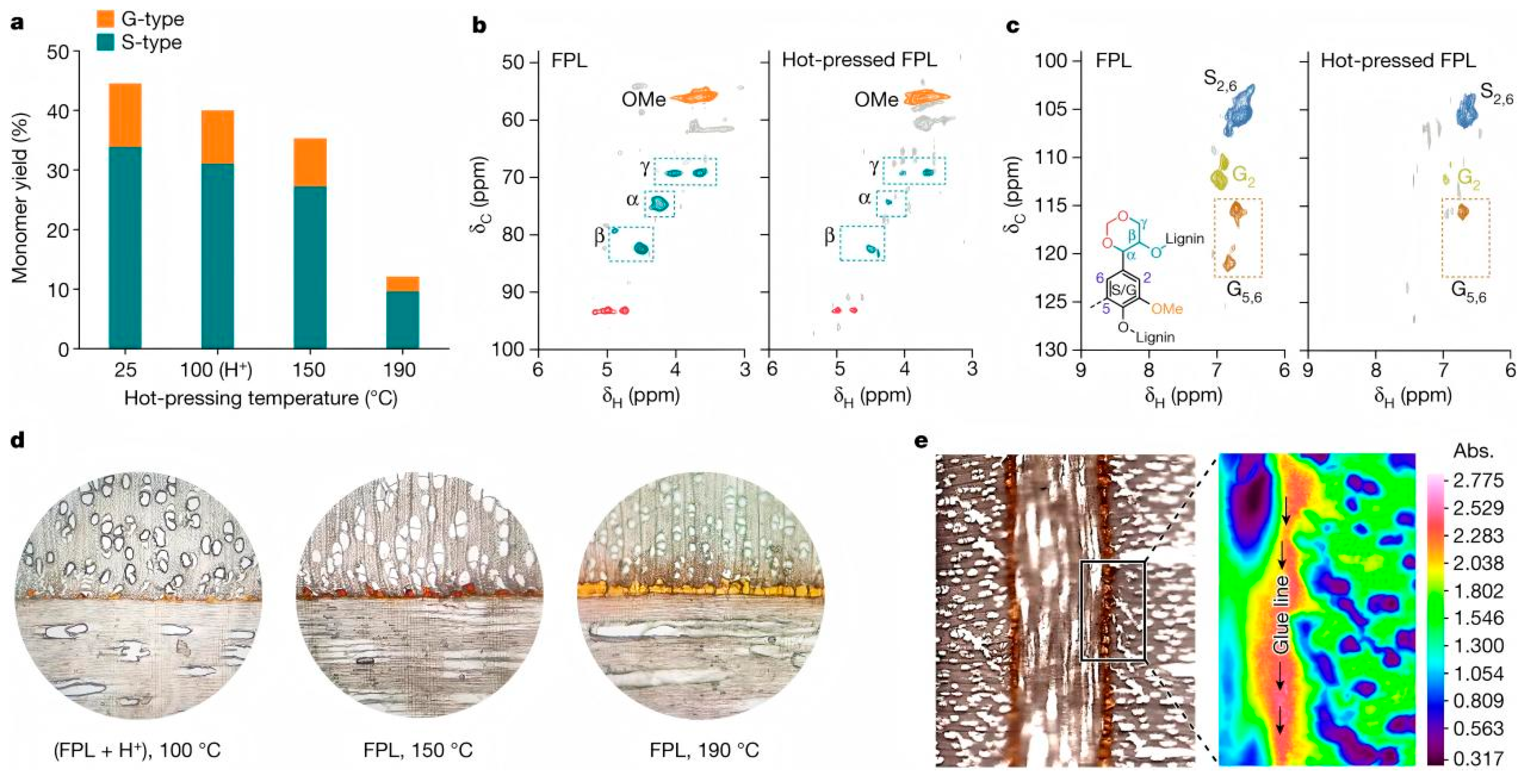

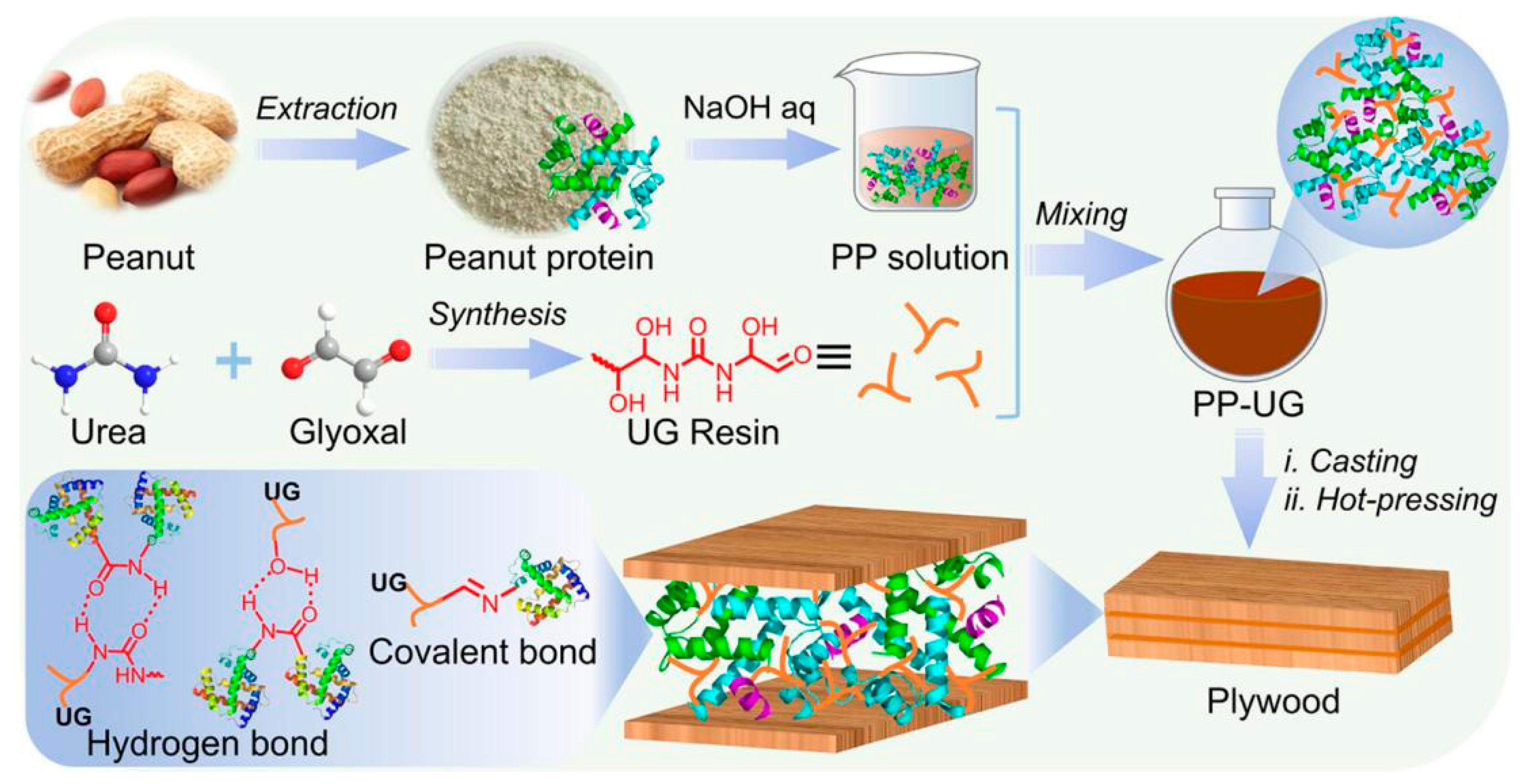

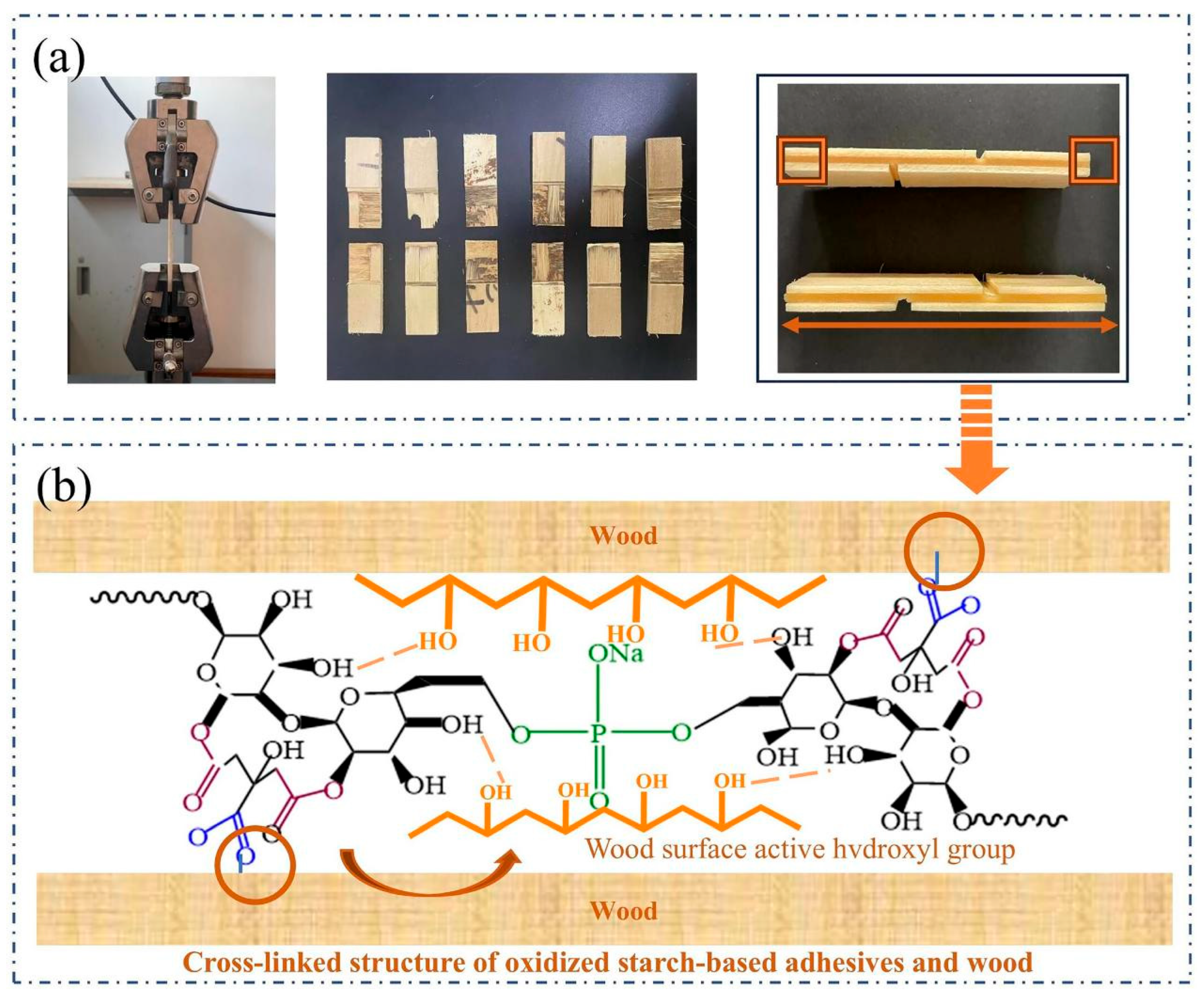

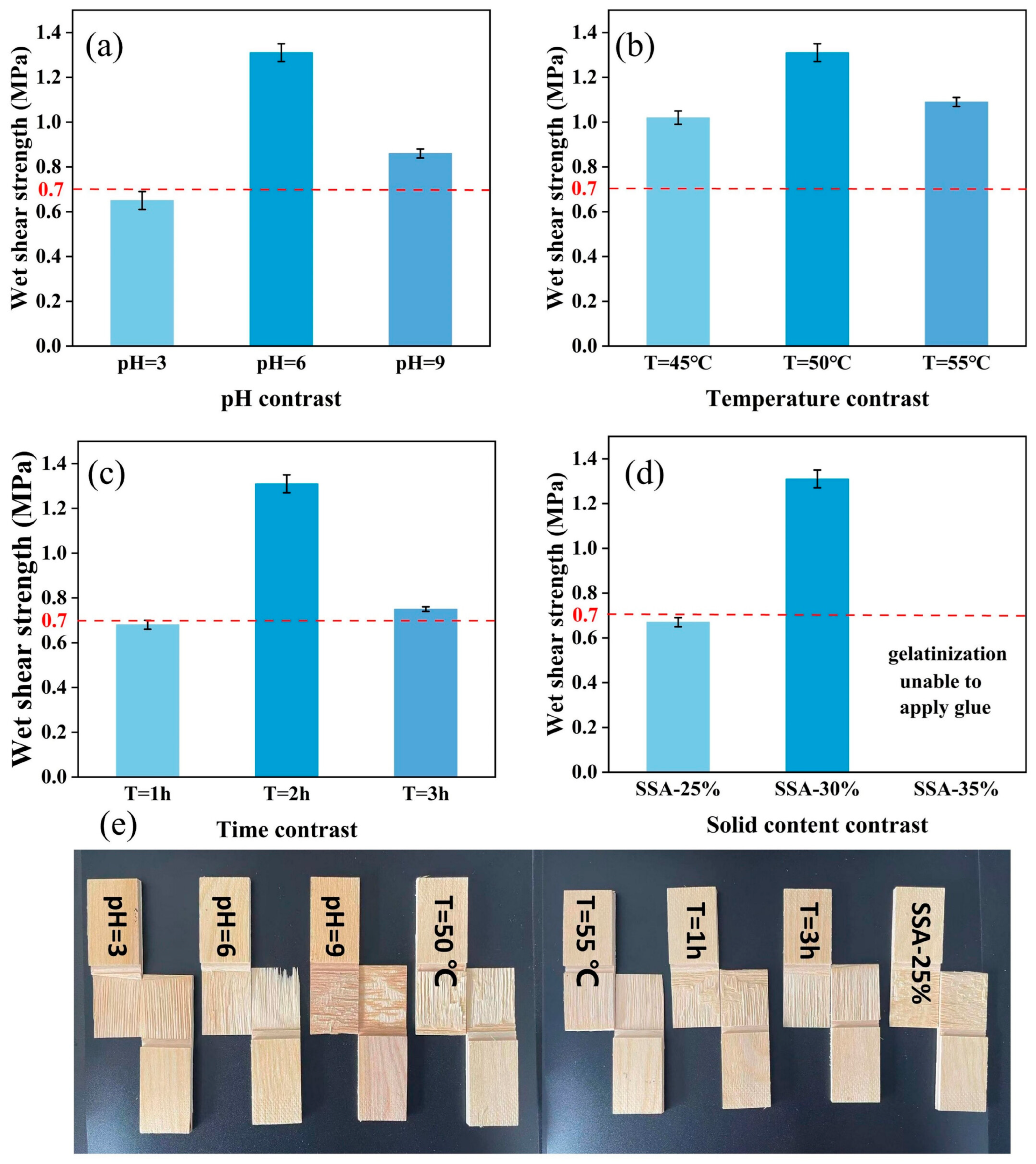

2.1. Technological Innovations in Formaldehyde-Free Adhesives

2.2. Evaluation of Ecological Benefits and Environmental Impacts

3. Ecological Civilization Policy Framework and Industrial Transformation

3.1. Overview of Ecological Civilization Policy Framework

3.2. The Guiding Role of Policy on Industrial Transformation

3.3. Challenges of Industrial Transformation

3.3.1. Existing Challenges

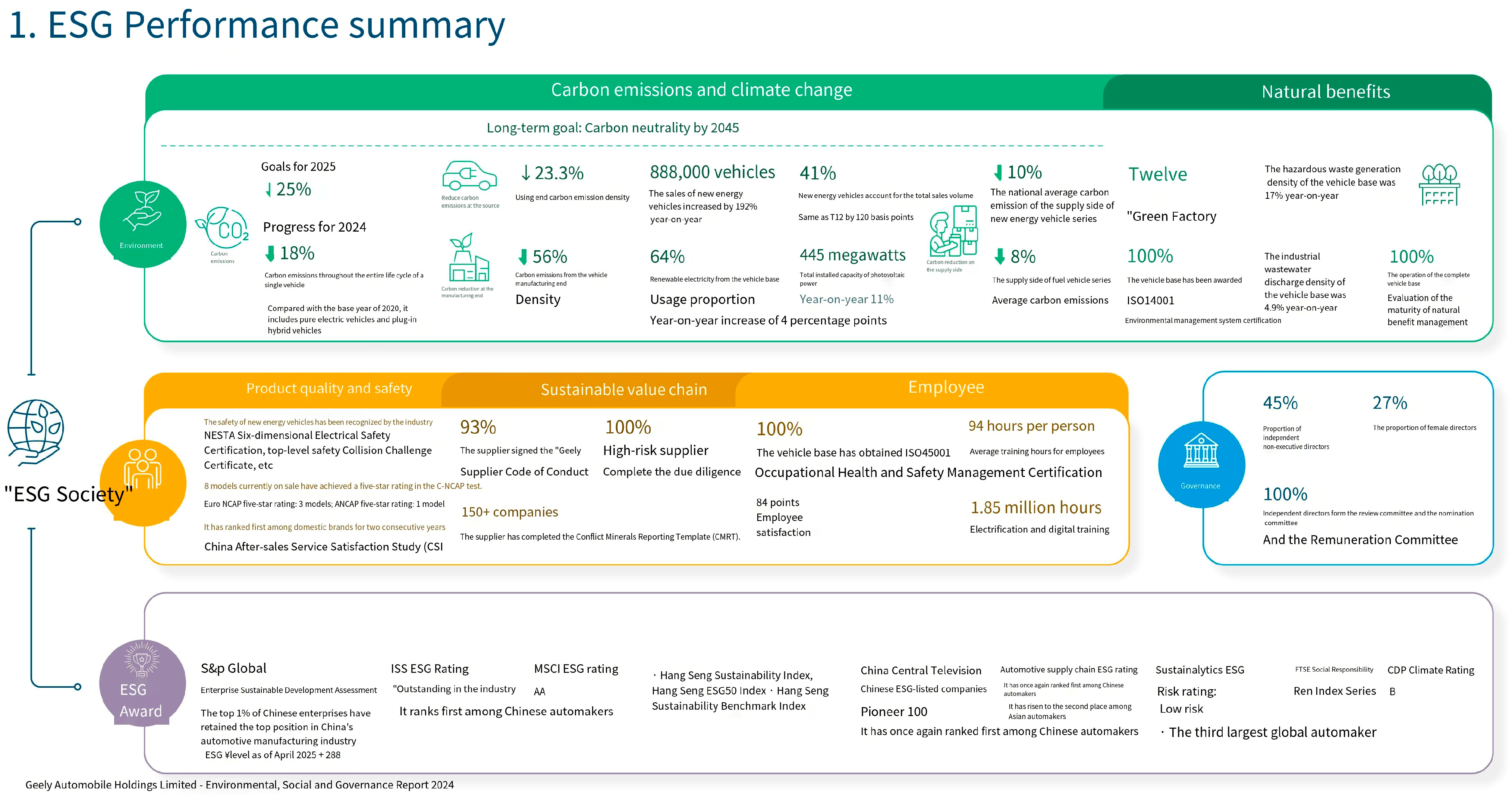

3.3.2. Transformation Case Analysis of Classic Industries

4. Socio-Economic Barriers and Comprehensive Policy Recommendations

4.1. Analysis of Socio-Economic Barriers and Development Bottlenecks

4.1.1. Regional and Industrial Development Contradictions

4.1.2. Short Board of Innovation System and Human Resources

4.1.3. Governance Structure and Policy Implementation Barriers

4.1.4. Distribution Mechanism and Sustainable Development Challenges

4.2. Systemic Policy Optimization Suggestions

4.2.1. Macro-Level: Building a Cross-Sectoral Synergistic and Incentive-Compatible Institutional Environment

- (1)

- Strengthen strategic planning and cross-sectoral synergistic mechanisms

- (2)

- Optimize innovation incentives and factor allocation policy

4.2.2. Meso-Level: Cultivate Deeply Integrated and Resilient Industrial Clusters and Innovation Ecology

- (1)

- Promote industrial clustering and digital transformation.

- (2)

- Build an innovation community for the deep integration of industry, academia, research and financial mediation.

4.2.3. Micro-Level: Innovating Grass-Roots Governance Mechanisms for Joint Construction and Shared Benefits

- (1)

- Deepening grass-roots governance and benefit linkage mechanisms

- (2)

- Promoting public participation and green consumption trends

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Barbu, M.C.; Tudor, E.M. State of the art of the Chinese forestry, wood industry and its markets. Wood Mater. Sci. Eng. 2022, 17, 1030–1039. [Google Scholar]

- Chang, M.; Shen, P.; Wang, L.; Ma, Q.; Jia, Z.; Hu, C.; Zhang, X. Research progress of eco-friendly plant-derived biomass-based wood adhesives: A review. Ind. Crops Prod. 2024, 222, 120093. [Google Scholar]

- Liu, N.R.; Fang, L.; Liu, W.; Kan, H.D.; Zhao, Z.H.; Deng, F.R.; Huang, C.; Zhao, B.; Zeng, X.A.; Sun, Y.X.; et al. Health effects of exposure to indoor formaldehyde in civil buildings: A systematic review and meta-analysis on the literature in the past 40 years. Build. Environ. 2023, 233, 110080. [Google Scholar] [CrossRef]

- Khoshakhlagh, A.H.; Mohammadzadeh, M.; Manafi, S.S.; Yousefian, F.; Gruszecka-Kosowska, A. Inhalational exposure to formaldehyde, carcinogenic, and non-carcinogenic risk assessment: A systematic review. Environ. Pollut. 2023, 331, 121854. [Google Scholar] [CrossRef] [PubMed]

- Tenorio-Alfonso, A.; Sánchez, M.C.; Franco, J.M. A Review of the Sustainable Approaches in the Production of Bio-based Polyurethanes and Their Applications in the Adhesive Field. J. Polym. Environ. 2020, 28, 749–774. [Google Scholar] [CrossRef]

- Calvez, I.; Garcia, R.; Koubaa, A.; Landry, V.; Cloutier, A. Recent Advances in Bio-Based Adhesives and Formaldehyde-Free Technologies for Wood-Based Panel Manufacturing. Curr. For. Rep. 2024, 10, 386–400. [Google Scholar]

- Zhu, Y.; Zhang, F.D.; Bian, R.H.; Zeng, G.D.; Li, J.J.; Lyu, Y.; Li, J.Z. Formaldehyde-free biomass adhesive based on industrial alkali lignin with high strength and toughness. Ind. Crops Prod. 2024, 222, 119525. [Google Scholar]

- Chen, X.; Sun, C.; Wang, Q.; Tan, H.; Zhang, Y. Preparation of glycidyl methacrylate grafted starch adhesive to apply in high-performance and environment-friendly plywood. Int. J. Biol. Macromol. 2022, 194, 954–961. [Google Scholar] [CrossRef]

- Huang, C.; Peng, Z.; Li, J.; Li, X.; Jiang, X.; Dong, Y. Unlocking the role of lignin for preparing the lignin-based wood adhesive: A review. Ind. Crops Prod. 2022, 187, 115388. [Google Scholar]

- Li, K.; Jin, S.; Zhou, Y.; Zhang, F.; Zeng, G.; Li, J.; Shi, S.Q.; Li, J. Bioinspired dual-crosslinking strategy for fabricating soy protein-based adhesives with excellent mechanical strength and antibacterial activity. Compos. Part B Eng. 2022, 240, 109987. [Google Scholar]

- GB/T 9846-2015; Plywood for General Use. General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China, China National Standardization Administration: Beijing, China, 2015.

- Chen, Y.X.; Zhu, H.S.; Gao, F.; Xiong, H.R.; Yang, H.; Xu, Z.X.; Duan, P.G.; Zheng, L.J.; Osman, S.M.; Luque, R. Green wood bio-adhesives from cellulose-derived bamboo powder hydrochars. Chem. Eng. J. 2024, 498, 155667. [Google Scholar] [CrossRef]

- Yang, Y.; Wu, H.; Zhang, J.; Wen, T.; Du, G.; Charrier, B.; Essawy, H.; Pizzi, A.; Wu, J.; Zhou, X.; et al. Soybean protein wood adhesive with enhanced water resistance and low environmental impact through lignin-protein hybridization. Ind. Crops Prod. 2025, 234, 121571. [Google Scholar]

- Zhu, Y.; Bian, R.; Yu, Y.; Li, J.; Li, C.; Lyu, Y.; Li, X.; Luo, J.; Li, J. Aminated alkali lignin nanoparticles enabled formaldehyde-free biomass wood adhesive with high strength, toughness, and mildew resistance. Chem. Eng. J. 2024, 494, 152914. [Google Scholar] [CrossRef]

- Mao, Y.; Zhang, S.; Wang, Y.; Pan, A.; Xu, B.; Zheng, G.; Zhang, X.; Xu, Y. Preparation of a multi-functional soy protein adhesive with toughness, mildew resistance and flame retardancy by constructing multi-bond cooperation. Int. J. Adhes. Adhes. 2025, 142, 104134. [Google Scholar] [CrossRef]

- Pan, S.; Kong, D.; Chen, H.; Gao, Q.; Li, J. Water-resistant and anti-mildew soy protein adhesive with network structures based on reversible boron-oxygen bonds and multiple hydrogen bonds. Ind. Crops Prod. 2024, 222, 119878. [Google Scholar] [CrossRef]

- Jin, T.; Huang, Y.; Yang, Y.; Liu, L.; Guo, H.; Zeng, H.; Xu, K.; Lei, H.; Du, G.; Zhang, L. Development of boiling water resistance starch-based wood adhesive via Schiff base crosslinking and air oxidation strategy. Colloids Surf. A Physicochem. Eng. Asp. 2024, 698, 134592. [Google Scholar]

- Chen, Y.; Rao, Y.; Liu, P.; Han, Z.; Xie, F. Facile fabrication of a starch-based wood adhesive showcasing water resistance, flame retardancy, and antibacterial properties via a dual crosslinking strategy. Int. J. Biol. Macromol. 2024, 282, 137180. [Google Scholar] [CrossRef]

- Kan, Z.; Huang, Y.; Wang, F.; Liu, L.; Wei, D.; Guo, H.; Chen, Y.; Xie, L.; Zhang, L.; Du, G. Low-temperature curing, flame-retardant and water-resistant modified cellulose-chitosan adhesive based on organic-inorganic hybridization. Int. J. Biol. Macromol. 2025, 329, 147835. [Google Scholar]

- Yang, G.X.; Gong, Z.G.; Luo, X.L.; Chen, L.H.; Shuai, L. Bonding wood with uncondensed lignins as adhesives. Nature 2023, 621, 511–515. [Google Scholar] [CrossRef]

- Ortner, N.; Fliedner, E.; Strüven, J.; Bornholdt, N.; Lange, I.; Ziegler, B.; Lehnen, R. Synthesis and characterization of lignin-carbonate prepolymers as formaldehyde-free wood adhesives. Ind. Crops Prod. 2025, 236, 121949. [Google Scholar]

- Ang, A.F.; Ashaari, Z.; Lee, S.H.; Md Tahir, P.; Halis, R. Lignin-based copolymer adhesives for composite wood panels—A review. Int. J. Adhes. Adhes. 2019, 95, 102408. [Google Scholar]

- Li, Z.; Du, X.T.; Pizzi, A.; Li, X.H.; Zhang, J.; Xia, Y.; Du, G.B.; Lu, Y.; Deng, S.D. Construction of Eco-Friendly and Water-Resistant Peanut Protein Wood Adhesive through Multiple Cross-Linking Strategies. ACS Sustain. Chem. Eng. 2025, 13, 3393–3405. [Google Scholar]

- Qu, Y.; Li, T.; Huang, X.G.; Liang, M.Z.; Qin, J.J.; Guo, Q.; Wang, Q. Developing multifunctional and environmental-friendly hot-pressed peanut meal protein adhesive based on peanut waste. Chem. Eng. J. 2023, 471, 144207. [Google Scholar]

- Zhao, H.Q.; Yao, W.R.; Liu, G.Y.; Chen, K.; Liu, M.Y.; Sun, C.; Tan, H.Y.; Shen, J.; Zhang, Y.H. A New Strategy for the Preparation of High-Strength Hydrophobic Aldehyde-Free Starch Adhesive. Polym. Adv. Technol. 2024, 35, e70000. [Google Scholar]

- Cao, H.; Kan, Z.; Feng, W.; Chen, Y.; Yao, J.; Wei, D.; Huang, Y.; Zhang, L.; Du, G.; Liu, L. Flame retardant modified starch adhesive made by crosslinking with phosphorus containing citrate based polyamines has excellent boiling water resistance. Carbohydr. Polym. 2025, 366, 123835. [Google Scholar] [CrossRef]

- La Torre, G.; Vitello, T.; Cocchiara, R.A.; Della Rocca, C. Relationship between formaldehyde exposure, respiratory irritant effects and cancers: A review of reviews. Public Health 2023, 218, 186–196. [Google Scholar] [CrossRef]

- Khoshakhlagh, A.H.; Mohammadzadeh, M.; Sicard, P.; Bamel, U. Human exposure to formaldehyde and health risk assessment: A 46-year systematic literature review. Environ. Geochem. Health 2024, 46, 206. [Google Scholar]

- Hu, S.; Chen, X.Q.; Ni, S.Z.; Wang, Z.J.; Fu, Y.J.; Qin, M.H.; Zhang, Y.C. Formaldehyde-Free, High-Bonding Performance, Fully Lignin-Based Adhesive Cross-Linked by Glutaraldehyde. Acs Appl. Polym. Mater. 2025, 7, 859–867. [Google Scholar]

- Chen, C.X.; Xu, C.; Zhai, J.X.; Zhao, C.W.; Ma, Y.H.; Yang, W.T. Low-Cost and Formaldehyde-Free Wood Adhesive Based on Water-Soluble Olefin-Maleamic Acid Copolymers. Ind. Eng. Chem. Res. 2023, 62, 20547–20555. [Google Scholar]

- de Paiva, E.M.; Mattos, A.L.A.; da Silva, G.S.; Canuto, K.M.; Alves, J.L.F.; de Brito, E.S. Valorizing cashew nutshell residue for sustainable lignocellulosic panels using a bio-based phenolic resin as a circular economy solution. Ind. Crops Prod. 2024, 212, 118379. [Google Scholar]

- Goncalves, D.; Bordado, J.M.; Marques, A.C.; dos Santos, R.G. Non-Formaldehyde, Bio-Based Adhesives for Use in Wood-Based Panel Manufacturing Industry—A Review. Polymers 2021, 13, 4086. [Google Scholar] [CrossRef]

- Arias, A.; González-García, S.; Feijoo, G.; Moreira, M.T. Environmental benefits of soy-based bio-adhesives as an alternative to formaldehyde-based options. Environ. Sci. Pollut. Res. 2021, 28, 29781–29794. [Google Scholar] [CrossRef]

- Yan, R.J.; Zhang, Q.Y.; Wu, D.; Hou, M.H.; Long, L.; Zhou, X.J.; Essawy, H.; Du, G.B.; Pizzi, A.; Xi, X.D. Preparation and analysis of environment-friendly and high- performance cellulose-based wood adhesive. Int. J. Biol. Macromol. 2025, 304, 140642. [Google Scholar] [CrossRef]

- Wang, H.Z.; Chen, G.L.; Zhang, S.F.; Zhang, W.; Wu, H.; Li, C.Z.; Xiao, Z.H. Camellia meal-based formaldehyde-free adhesive with self-crosslinking, and anti-mildew performance. Ind. Crops Prod. 2022, 176, 114280. [Google Scholar] [CrossRef]

- Gong, X.Y.; Liu, T.L.; Yu, S.S.; Meng, Y.; Lu, J.; Cheng, Y.; Wang, H.S. The preparation and performance of a novel lignin-based adhesive without formaldehyde. Ind. Crops Prod. 2020, 153, 112593. [Google Scholar] [CrossRef]

- Martin-Ortega, O.; Dehbi, F.; Nelson, V.; Pillay, R. Towards a Business, Human Rights and the Environment Framework. Sustainability 2022, 14, 6596. [Google Scholar] [CrossRef]

- Qin, Y.Y. Grassroots governance and social development: Theoretical and comparative legal aspects. Humanit. Soc. Sci. Commun. 2023, 10, 331. [Google Scholar] [CrossRef]

- Yang, Y.Z.; Wei, X.J.; Wei, J.; Gao, X. Industrial Structure Upgrading, Green Total Factor Productivity and Carbon Emissions. Sustainability 2022, 14, 1009. [Google Scholar] [CrossRef]

- Sasmoko, S.; Akhtar, M.Z.; Khan, H.u.R.; Sriyanto, S.; Jabor, M.K.; Rashid, A.; Zaman, K. How Do Industrial Ecology, Energy Efficiency, and Waste Recycling Technology (Circular Economy) Fit into China’s Plan to Protect the Environment? Up to Speed. Recycling 2022, 7, 83. [Google Scholar] [CrossRef]

- Zhou, H.; Wu, M.; He, S.; Peng, Z. Digitalization, Green Innovation, and Green Transformation of Energy Enterprises in China. Sustainability 2025, 17, 10619. [Google Scholar] [CrossRef]

- Wang, H.R.; Feng, T.T.; Kong, J.J.; Cui, M.L.; Xu, M. Grappling with the trade-offs of carbon emission trading and green certificate: Achieving carbon neutrality in China. J. Environ. Manag. 2024, 360, 121101. [Google Scholar] [CrossRef]

- Jermain, D.O.; Pilcher, R.C.; Ren, Z.J.; Berardi, E.J. Coal in the 21st century: Industry transformation and transition justice in the phaseout of coal-as-fuel and the phase-in of coal as multi-asset resource platforms. Energy Clim. Change 2024, 5, 100142. [Google Scholar]

- Xia, Y.; Li, M.; Zhang, J.; Cheol, C.M.; Kim, H.E. Competitiveness Analysis of Geely Automobile Group. Int. J. Adv. Cult. Technol. 2024, 12, 402–408. [Google Scholar]

- Geely Automobile Releases Its 2024 ESG Report: Has Achieved the Top Ranking in Multiple Authoritative Rating Lists, Demonstrating Its Strength and Shaping a New Global ESG Model. Available online: https://www.news.cn/auto/20250428/79d23729d2f44499af1794a0ca3e23d1/c.html (accessed on 1 July 2025).

- ISO 14001: 2015; Environmental Management Systems—Requirements with Guidance for Use. General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China, China National Standardization Administration: Beijing, China, 2015.

- Sofia: 2024 Annual Environmental, Social Responsibility and Corporate Governance Report. Available online: https://vip.stock.finance.sina.com.cn/corp/view/vCB_AllBulletinDetail.php?id=11042637 (accessed on 1 July 2025).

- A Post-90s Mother Uses KPC boards To Create an Eco-Friendly and Beautiful Home, Where Three Generations Live in Harmony and Joy. Available online: https://suofeiya.com/mcase/3562.html (accessed on 1 July 2025).

- Capello, R.; Cerisola, S. Towards a double bell theory of regional disparities. Ann. Reg. Sci. 2024, 73, 1701–1728. [Google Scholar] [CrossRef]

- Miao, P.; Zhang, X.Y.; Zhang, N. The complex impact of China’s science and technology talent policies on key core technologies R&D. PLoS ONE 2025, 20, e0324587. [Google Scholar]

- Xu, Y.; Zhu, J.; Tao, C.Q. The mechanism of technological potential energy driving Industry-University-Research institution collaborative innovation. Int. Entrep. Manag. J. 2021, 17, 1541–1567. [Google Scholar]

- Song, W.; Zhao, K. Navigating the innovation policy dilemma: How subnational governments balance expenditure competition pressures and long-term innovation goals. Heliyon 2024, 10, e34787. [Google Scholar] [CrossRef] [PubMed]

- Idrees, M.; Majeed, M.T. Income inequality, financial development, and ecological footprint: Fresh evidence from an asymmetric analysis. Environ. Sci. Pollut. Res. 2022, 29, 27924–27938. [Google Scholar] [CrossRef]

- Li, X.G. Research Progress on Green Adhesives for Engineered Wood Panels. J. Cent. South Univ. For. Technol. 2024, 44, 1–22. [Google Scholar]

- Shi, F.J. Research on Green Finance’s Role in Promoting the Development Path of Roadside Economy Industries: A Case Study of Gansu Province. Transp. Enterp. Manag. 2022, 37, 16–18. [Google Scholar]

- Wang, Y.H.; Zhan, X.Y. Patient Capital, Deep Integration of Industry-Academia-Research, and Corporate Independent Innovation: Empirical Evidence from Technology Achievement Transformation Guidance Funds. Contemp. Econ. Sci. 2025, 47, 31–45. [Google Scholar] [CrossRef]

- Li, Z. Research on Challenges and Countermeasures for Deep Integration of Industry-Academia-Research Development. Ind. Technol. Forum 2025, 24, 225–228. [Google Scholar]

- Zhang, H.L.; Yang, Q.L.; Huang, Y.B. Can Industry-Academia-Research Integration Empower High-Quality Economic Development? Empirical Evidence from Micro-Enterprise Innovation. Macroecon. Res. 2025, 106–122. [Google Scholar]

| Name | Raw Material | Dry Bonding Strength (MPa) | Wet Bonding Strength (MPa) | Special Characteristics |

|---|---|---|---|---|

| SM-OL1.5 | soy protein, lignin | 1.83 | 0.94 | low VOC emissions |

| ALN-50 | lignin | 1.51 | 1.15 | exceptional mold resistance |

| SPI/SA/Mg | soy protein | 1.91 | 0.96 | high refractoriness |

| SPI/TA 0.5/Borax 0.6 | soy protein | 2.37 | 1.12 | higher mold resistance |

| DAS-HBP-G | starch | 1.26 | 1.15 | lower curing temperature |

| Ost/Ita/Borax | starch | 5.34 | 1.22 | strong flame retardancy |

| HM-CS@BN | chitosan | 2.27 | 1.05 | high fire resistance |

| Types of Policy Tools | Specific Measures | Examples of Grassroots Implementation |

|---|---|---|

| Financial Subsidies | Funding Support for R&D and Industrialization | Township Government Provides Loan Guarantees for SMEs |

| Tax Incentives | Tax Reduction for Environmentally Friendly Enterprises | Village Committees Coordinate Local Enterprises to Apply |

| Standard Certifications | GB/T9846 Implementation | Community Involvement in Product Certification Training |

| Demonstration Projects | Green Parks | Pilot Workshops Established by Cooperation between Pools and Enterprises |

| Digital Advocacy | APP Product Traceability | Grassroots Organizations Promote Consumers Education |

| Main Challenges | Specific Manifestations | Corresponding Policy Suggestions |

|---|---|---|

| Cost Pressure | High raw material purification cost, high energy consumption in production process | 1. Provide financial subsidies for raw material collection and processing; 2. Support the development of low-energy production technology through R&D grants |

| Performance Stability | Insufficient water resistance, poor storage stability, uneven product quality | 1. Improve national standards for formaldehyde-free adhesives (supplement stability indicators); 2. Establish a product quality certification system |

| Policy Coordination | Disconnected policies among agriculture, industry, and environmental protection sectors | 1. Establish an inter-ministerial joint conference system; 2. Formulate regional differentiated policy packages |

| Market Acceptance | Low consumer awareness, resistance to green premium | 1. Carry out public education activities; 2. Include qualified products in green procurement catalogs |

| Innovation Transformation | Weak connection between laboratory results and industrial application | 1. Support the construction of pilot demonstration production lines; 2. Establish industry-university-research innovation alliances |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2026 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.

Share and Cite

Meng, X.; Wang, K.; Xu, J.; Shao, X.; Xu, W. The Governance Logic of Green Technology Diffusion Under Ecological Civilization: The Case of Formaldehyde-Free Biomass Adhesive Industrialization. Sustainability 2026, 18, 1477. https://doi.org/10.3390/su18031477

Meng X, Wang K, Xu J, Shao X, Xu W. The Governance Logic of Green Technology Diffusion Under Ecological Civilization: The Case of Formaldehyde-Free Biomass Adhesive Industrialization. Sustainability. 2026; 18(3):1477. https://doi.org/10.3390/su18031477

Chicago/Turabian StyleMeng, Xiaoke, Kaiqi Wang, Jintian Xu, Xiaoyang Shao, and Wei Xu. 2026. "The Governance Logic of Green Technology Diffusion Under Ecological Civilization: The Case of Formaldehyde-Free Biomass Adhesive Industrialization" Sustainability 18, no. 3: 1477. https://doi.org/10.3390/su18031477

APA StyleMeng, X., Wang, K., Xu, J., Shao, X., & Xu, W. (2026). The Governance Logic of Green Technology Diffusion Under Ecological Civilization: The Case of Formaldehyde-Free Biomass Adhesive Industrialization. Sustainability, 18(3), 1477. https://doi.org/10.3390/su18031477