1.1. Research Background

In recent decades, the impacts of climate change and the growing consumption of raw materials have heightened global awareness of the necessity to implement the concept of sustainable development on a worldwide scale. Architects and building designers play a crucial role in tackling climate change challenges, with the potential to greatly impact the environmental footprint of buildings, especially during the initial design phases [

1]. As the global environmental crisis intensifies, professionals across these fields are increasingly recognizing the need to reduce the ecological impact of their work. This shift is particularly critical in the context of the built environment, where construction activities and the operation of buildings contribute significantly to global greenhouse gas emissions and resource depletion. Historically, efforts of both policymakers and the construction industry have largely concentrated on minimizing operational impacts, mainly energy consumption, within buildings [

2]. Several policies and regulations have been established to enhance the energy efficiency of buildings. Initiatives like the EU Energy Performance of Buildings Directive (EPBD) [

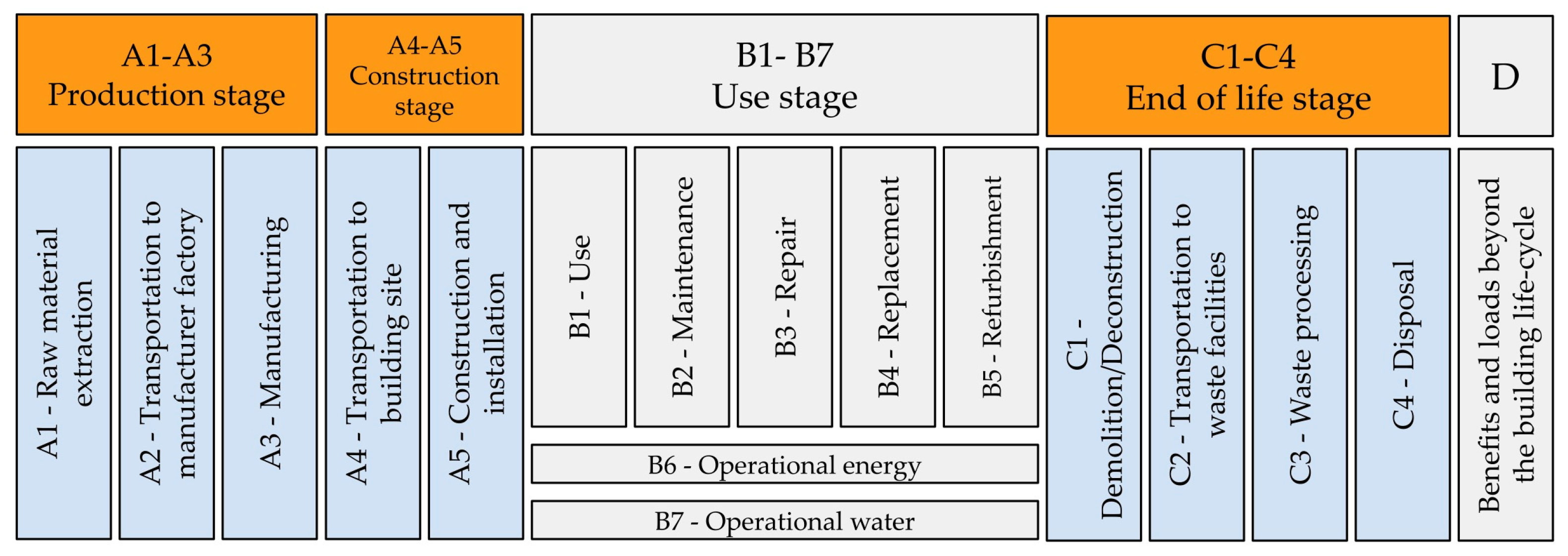

3] aim to promote efficient buildings by enforcing new standards for constructing nearly zero-energy buildings. With the aim of further mitigating greenhouse gas (GHG) emissions, it is now crucial to focus on other stages of the building life cycle, including the embodied impacts from manufacturing, transport, construction, upkeep, and end-of-life procedures [

4]. As operational carbon emissions lessen, the proportional contribution of embodied carbon will increase, constituting a greater portion of total emissions. Embodied carbon, which encompasses the aggregate emissions from all building materials, products, and construction activities, currently accounts for approximately 20% of the building sector’s total GHG emissions.

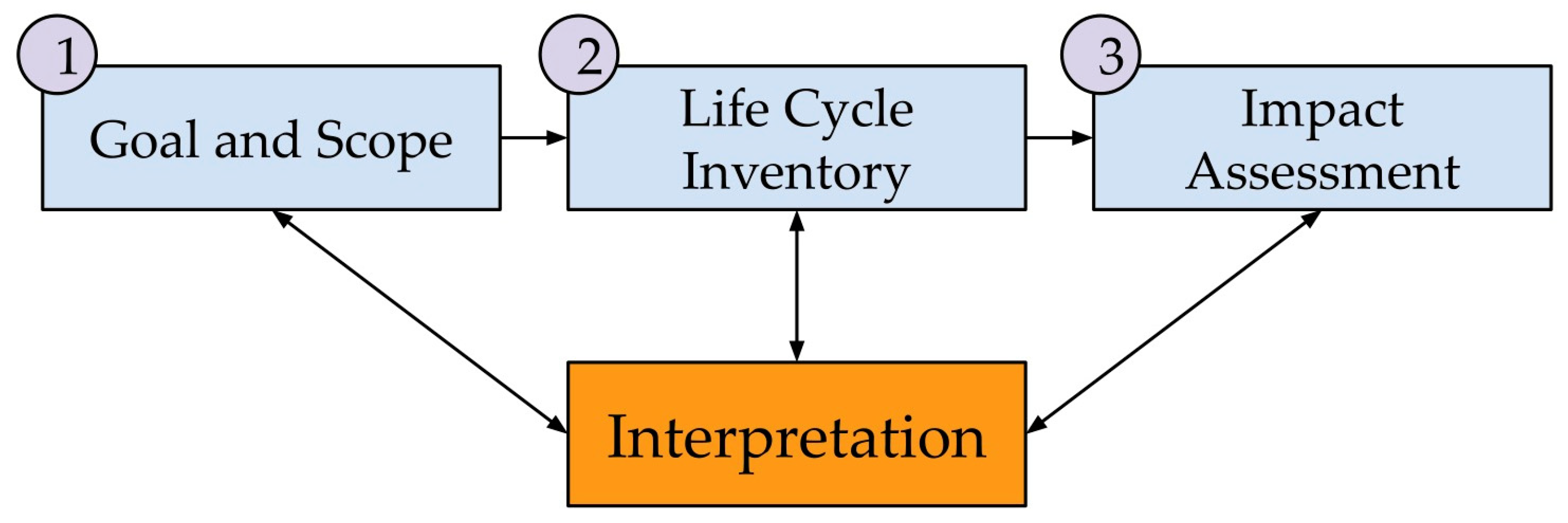

To support this shift, life cycle assessment (LCA) has emerged as a pivotal methodology for quantifying and understanding the environmental impacts associated with the construction and operation of buildings. First introduced by the ISO 14040 [

5] standard in the 90s and now governed by a regulatory framework composed of various standards (ISO at the international level and EN at the European level), LCA provides a comprehensive procedure for evaluating the full range of environmental consequences throughout a building’s life cycle—from material extraction and manufacturing to construction, operation, and eventual demolition or decommissioning. By offering insights into the environmental footprint of materials, construction processes, and the operational lifespan of buildings, LCA enables designers, engineers, and stakeholders to make informed decisions aimed at minimizing negative environmental impacts [

6].

Through the application of LCA, it is possible to identify the most sustainable materials, construction methods, and operational strategies that can significantly reduce a building’s carbon footprint. This methodology is crucial not only for assessing energy consumption and greenhouse gas emissions but also for evaluating other environmental factors, such as water use, waste generation, and resource depletion. As a result, LCA plays an increasingly vital role in the decision-making process, enabling architects and engineers to optimize their designs for both performance and sustainability. The ability to integrate LCA into the design process allows for the identification of trade-offs and opportunities for improvement, fostering more responsible and sustainable building practices that are aligned with the global goal of mitigating climate change.

As a result, the inclusion of LCA methodologies in architectural and engineering practices is vital for fostering environmentally responsible design outcomes. As awareness and urgency around climate change continue to rise, LCA will undoubtedly remain a central methodology for guiding the transition toward a more sustainable and low-carbon built environment.

In this context, building structural systems are acknowledged as significant sources of embodied carbon emissions. According to benchmarking research [

7], these systems are estimated to be responsible for approximately 24% of a building’s total life cycle embodied carbon emissions. Given their considerable share of a building’s overall environmental footprint, structural systems are a critical focus area for reducing embodied carbon in the construction industry. Strategies such as optimizing material efficiency, selecting low-carbon alternatives, and improving design methodologies can play a pivotal role in mitigating these emissions.

The authors have already examined the impact of structural systems on embodied carbon in previous studies. In their analysis of contemporary architectural trends, they highlighted how decorative spires influence the embodied carbon of tall buildings, despite contributing only 1% to the total [

8]. In 90-story buildings, these elements can increase the embodied carbon of structural systems by up to 14.2%, primarily due to the additional vertical and lateral loads they impose. This leads to a greater need for materials and an elevated embodied carbon cost linked to the increased vertical dimension (“vanity for height”). Additionally, their research has explored the role of cantilevers, which have become a defining characteristic of modern architecture. Driven by the pursuit of striking visual effects and the rise of ‘vanity architecture’, cantilevered structures enable dramatic overhangs and projecting volumes without visible supports. Their findings indicate that unbalanced cantilevers can lead to a 10% increase in embodied carbon compared to alternative designs that incorporate supporting columns [

9]. This study aligns with that same line of research, further investigating how structural design choices shape both architectural expression and environmental impact.

Certain buildings, such as gyms, swimming pools, cultural and recreational facilities, exhibition halls, auditoriums, and theaters, have always required long spans and open-plan layouts. However, the number of such structures being built is increasing, reflecting a growing preference for expansive, flexible spaces. Additionally, new building typologies are emerging, driven by advancements in construction technologies that enable even greater spatial versatility and structural innovation. The rapid growth of digital infrastructure, in fact, driven by advancements in artificial intelligence and the development of smart cities, has introduced new challenges and opportunities. This evolution emphasizes the need for buildings designed specifically to accommodate computer servers, known as data centers, which are integral to supporting these technological innovations. These data centers, often characterized by single-story structures with large open spaces on the ground floor, pose unique sustainability challenges [

10]. On the other hand, the growing demand for e-commerce is driving an increasing need for logistics centers. As online retail continues to expand, companies require larger and more advanced distribution hubs to handle inventory management, order fulfillment, and last-mile delivery more efficiently [

11]. Applying LCA to these buildings can help optimize their design for reduced environmental footprints [

12], addressing both their immediate construction impacts and their long-term operational efficiency. Moreover, applying LCA is strictly fundamental to making clients aware of the implications of long-span structures, ensuring informed decision-making. In this context, the role of architects and the construction industry becomes crucial in guiding this progress, promoting sustainable design choices, and balancing structural innovation with environmental responsibility.

Among the numerous design factors that influence the environmental performance of these buildings, the span length of structural elements plays a particularly significant role. Span length directly affects the choice and quantity of materials, the structural systems employed, and the associated construction methods [

13]. Longer spans often necessitate the use of high-performance materials or innovative construction techniques, which can result in higher embodied carbon emissions. Conversely, shorter spans might require additional supports or increased material use, which also carry environmental trade-offs. Understanding these nuances is essential for optimizing designs that align with sustainability goals.

1.2. The Open Plan as an Architectural Trend

To provide insights on span length, this article first explores its growth in architecture. Several architectural trends, such as cantilever and open-plan layouts, have driven this rise in structural spans and have become increasingly popular in recent decades. The open-plan concept in architecture refers to spatial configurations that minimize internal partitions to create flexible, multifunctional environments. Characterized by a column-free floor layout, this approach is particularly advantageous for spaces requiring adaptability and large, uninterrupted areas [

14]. It has been widely adopted in various building typologies, including offices, cultural facilities, and sports complexes, due to its ability to enhance spatial adaptability and foster social interaction [

15].

In contemporary practice, advancements in structural engineering have significantly facilitated the implementation of open-plan layouts by enabling the design of long-span structures that minimize the need for internal load-bearing partitions. These developments include the use of long-span steel trusses, arches, and space frames, which efficiently distribute loads across extensive spans, creating large, unobstructed interior spaces.

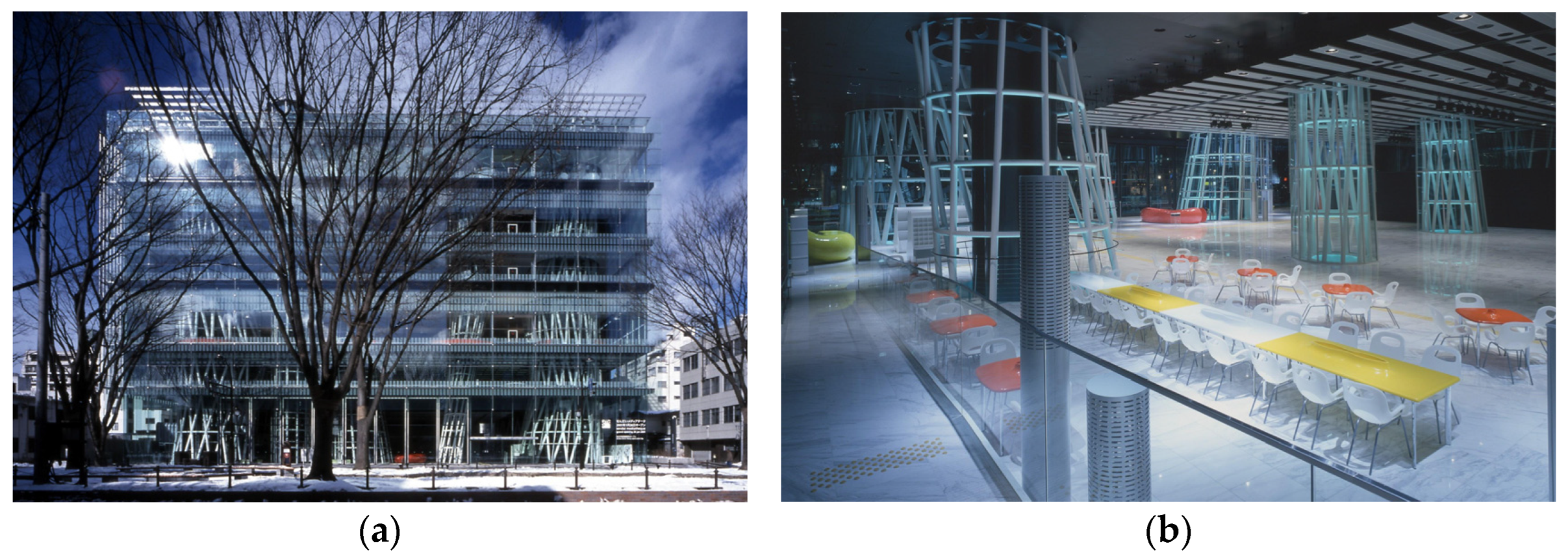

Notable examples include the Sendai Mediatheque (2001) by Toyo Ito (

Figure 1), which employs a system of irregularly arranged steel-tube columns to achieve structural openness (

Figure 1) and the Apple Park Headquarters (2017) by Foster + Partners, where extensive use of long-span structures supports a highly flexible, column-free interior

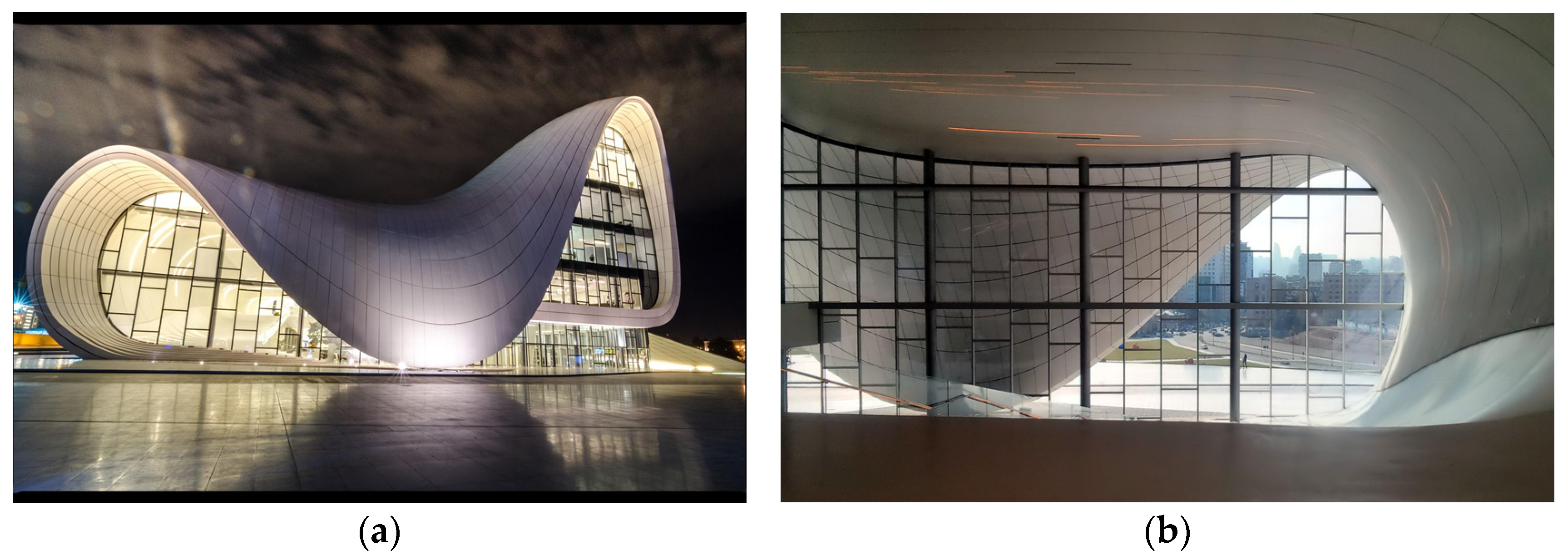

The Heydar Aliyev Center (2012) designed by Zaha Hadid Architects (

Figure 2), instead utilizes a complex shell structure to achieve fluid, uninterrupted interior spaces. Additionally, the selection of lightweight yet robust materials, such as high-strength steel and engineered wood products, has been crucial in managing loads and minimizing deflection in long-span designs [

16]. However, while open-plan configurations offer advantages in terms of flexibility and openness, they also pose challenges related to acoustics, privacy, and thermal zoning, necessitating strategic design interventions to balance openness with functional requirements [

17].

1.3. Literature Review on Environmental Performances

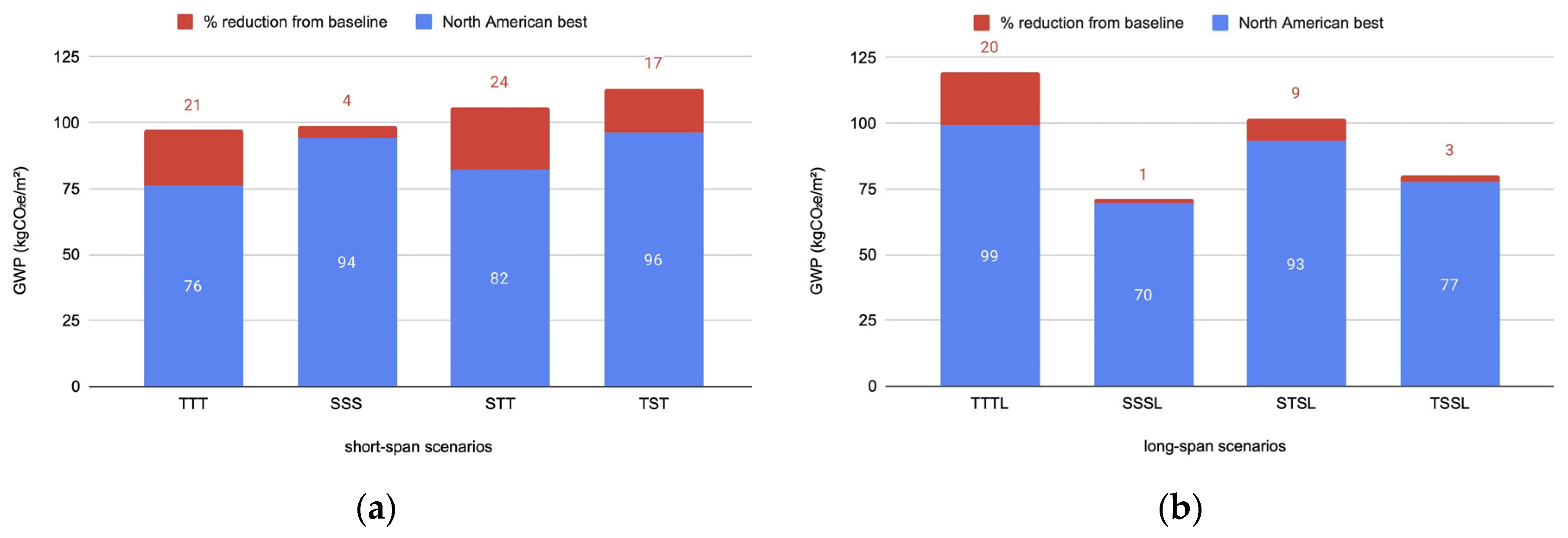

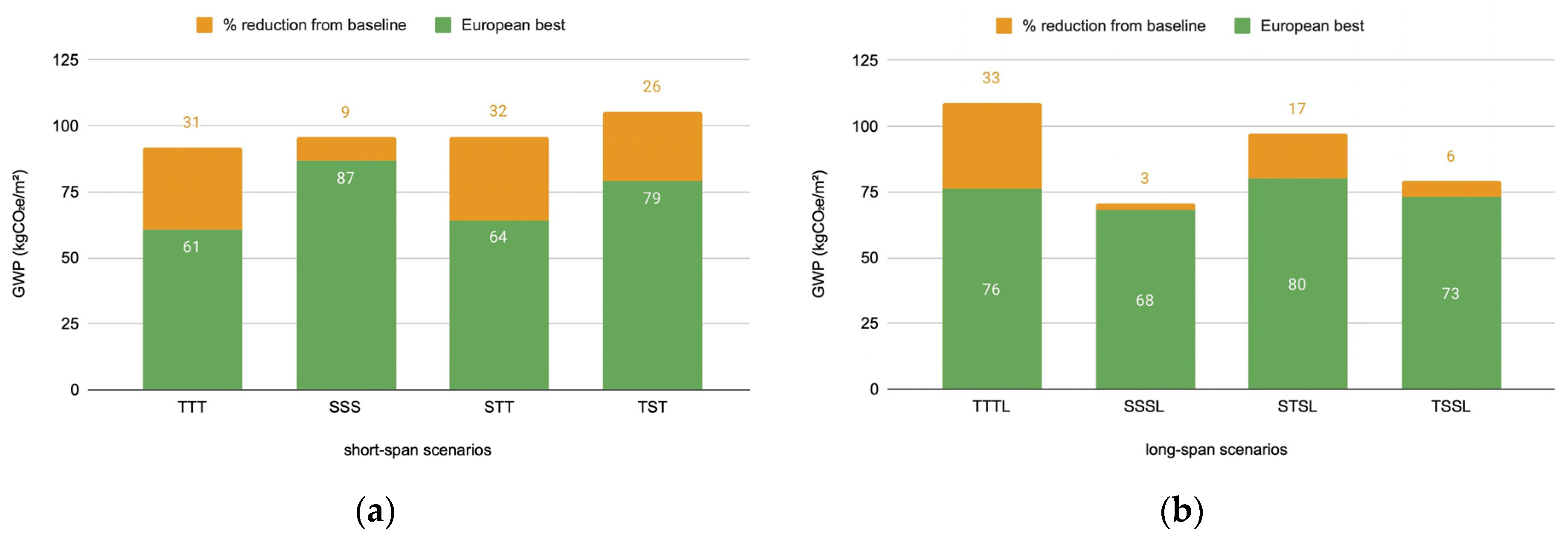

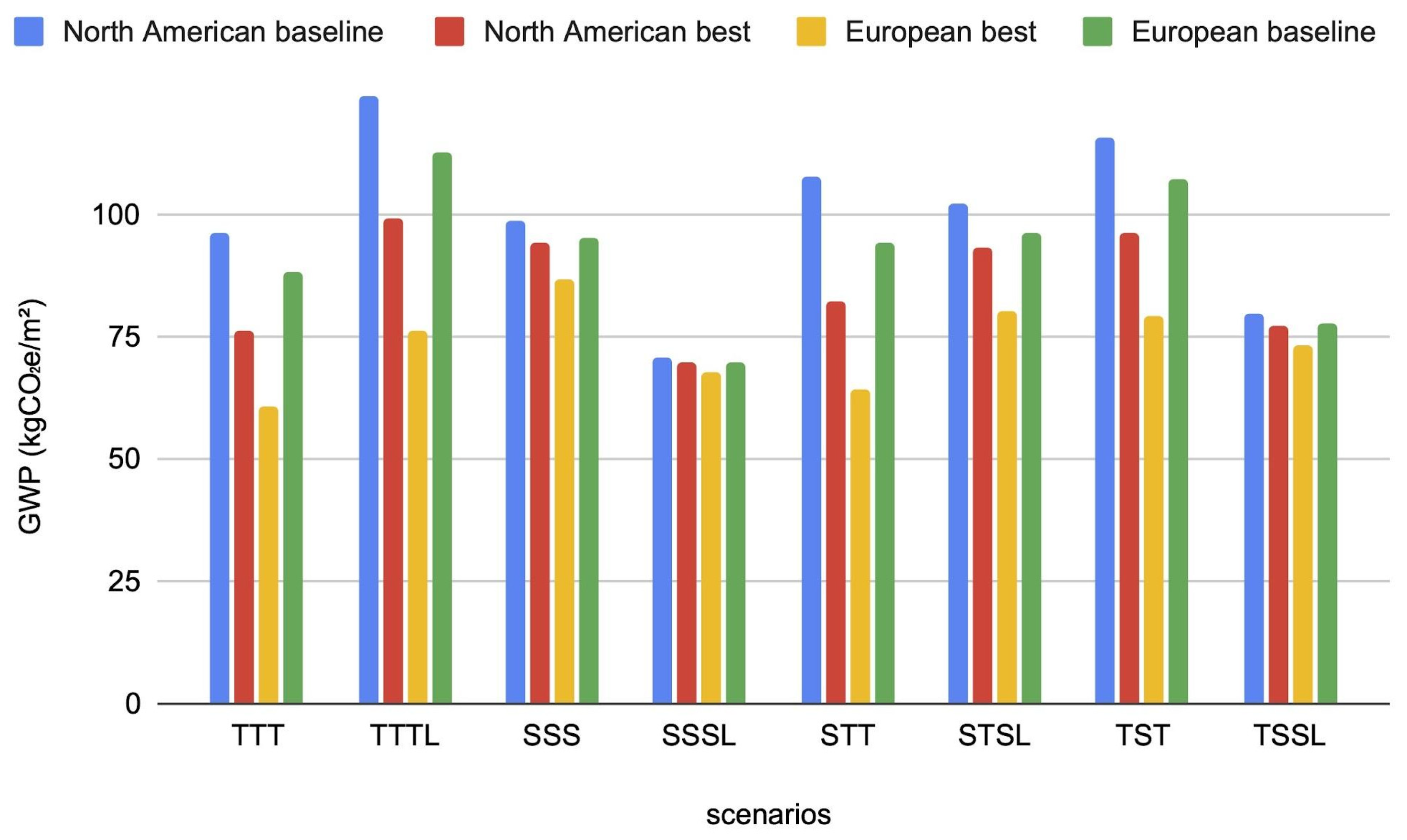

The present study builds on a previous work by the authors [

18], which analyzed the GWP impacts arising from a comparison of steel and timber alternatives for tall buildings, limiting its scope to the effect of height on the two options. A further review of the literature on span length reveals certain gaps. While numerous studies have examined the influence of materials [

19,

20], transportation [

21], and construction techniques [

22] on the environmental performance of buildings, the role of structural span length remains relatively underexplored—despite its critical impact on material consumption, structural efficiency, and spatial flexibility. Existing research has mostly addressed this variable in the context of bridge engineering [

23,

24], where span plays an explicit structural and environmental role. In building design, however, studies addressing this relationship are sparse and often fragmented.

Among the few notable contributions, Maxineasa et al. [

25] adopted a cradle-to-cradle perspective to compare GLT with conventional long-span beams, highlighting the lower environmental burden of timber. However, the focus of this work was limited to material comparison without fully isolating the effects of span length. Similarly, Van den Dobbelsteen et al. [

26] emphasized that increased spans may lead to disproportionately high impacts due to the need for more resource-intensive materials, though the study’s design context limited generalizability. Other works provide more qualitative insights, such as Sayhood and Mahmood’s [

27] analysis of the trade-offs between reducing spans to minimize slab material versus the added environmental cost of increased vertical supports—a tension that is rarely quantified. Trabucco et al. [

28] extended this by showing the growing environmental weight of horizontal structures in tall buildings, yet they stopped short of systematically linking span variation to life cycle impacts. Notably, other studies [

29,

30] have identified a span-dependent increase in embodied carbon, particularly with steel, but lack a cross-material or performance-normalized comparison. An Australian case study [

31] offers a rare, quantified result, revealing up to a 20.6% reduction in GWP per square meter based on span configuration, yet it remains an isolated case with limited replication.

These studies collectively suggest that span length has a measurable yet undertheorized impact on environmental performance. However, the lack of standardized metrics, cross-material comparisons, and reproducible methodologies limits broader conclusions.