Research on the HDPE Membrane Leakage Location Using the Electrode Power Supply Mode Outside a Landfill Site

Abstract

1. Introduction

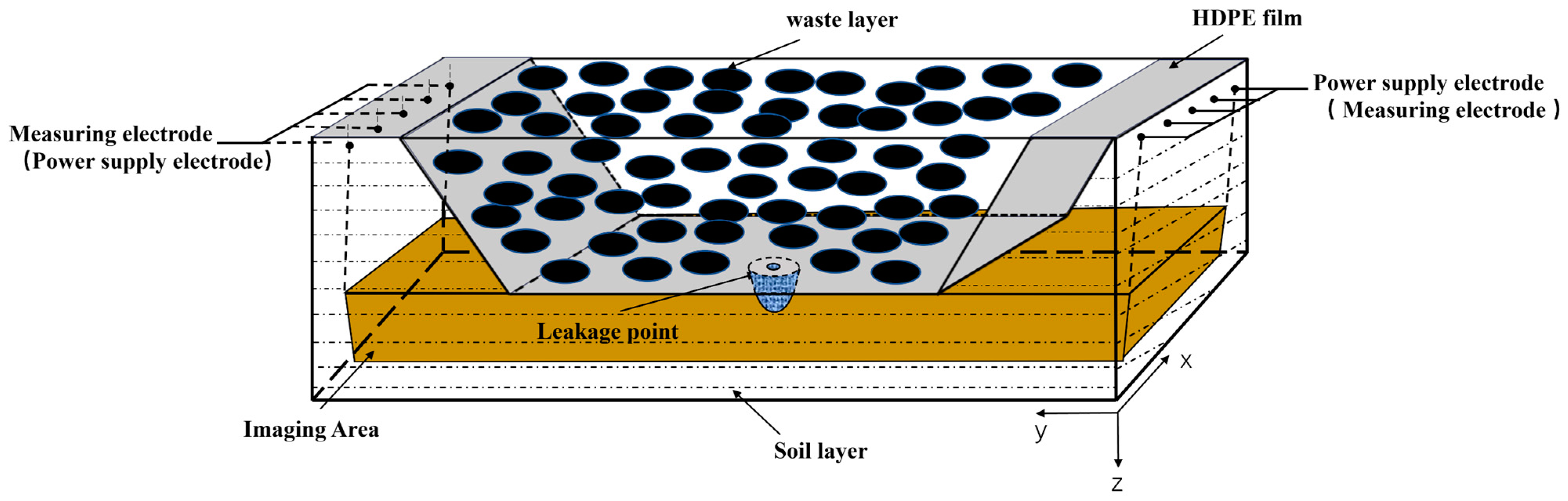

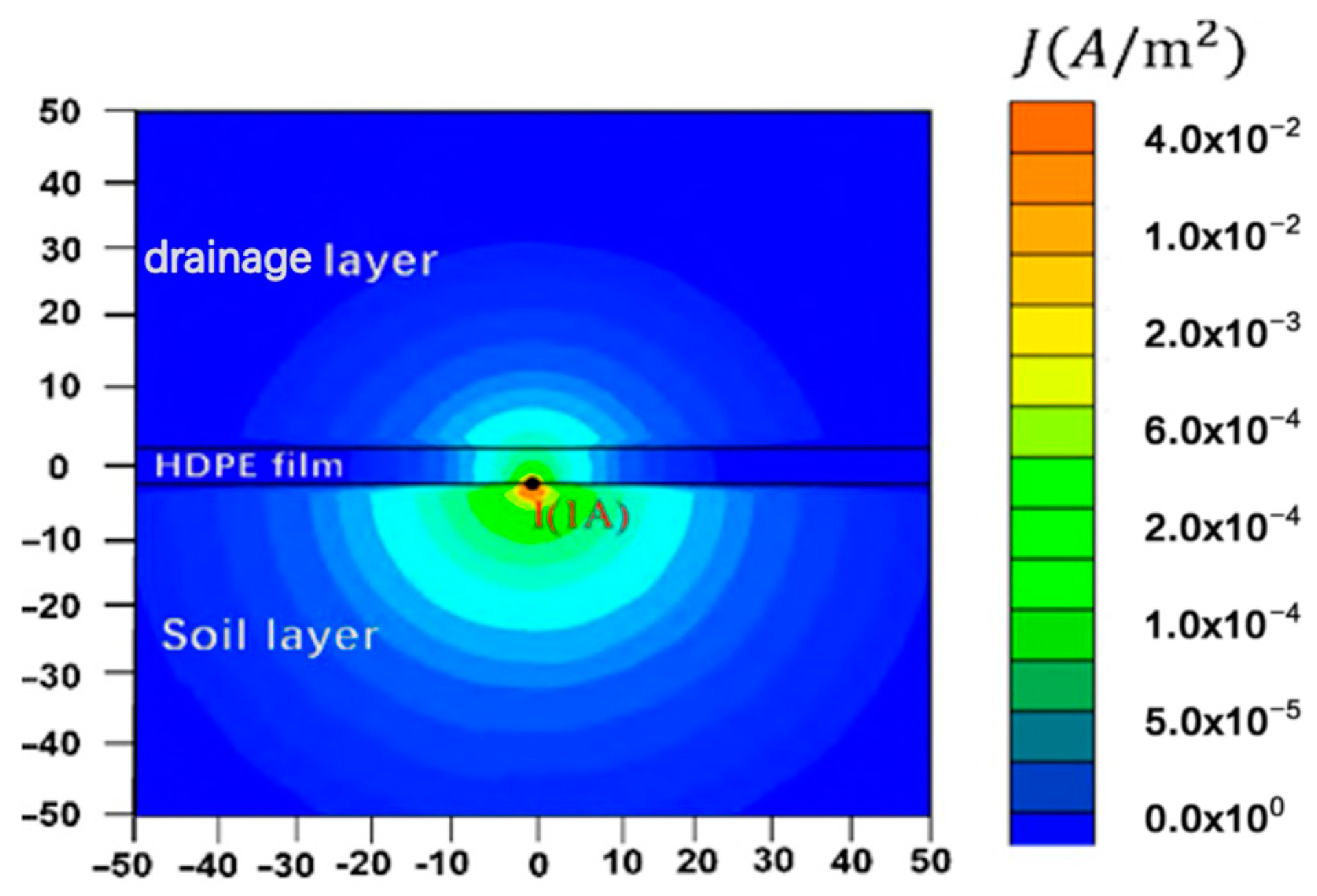

2. Principle of Detection

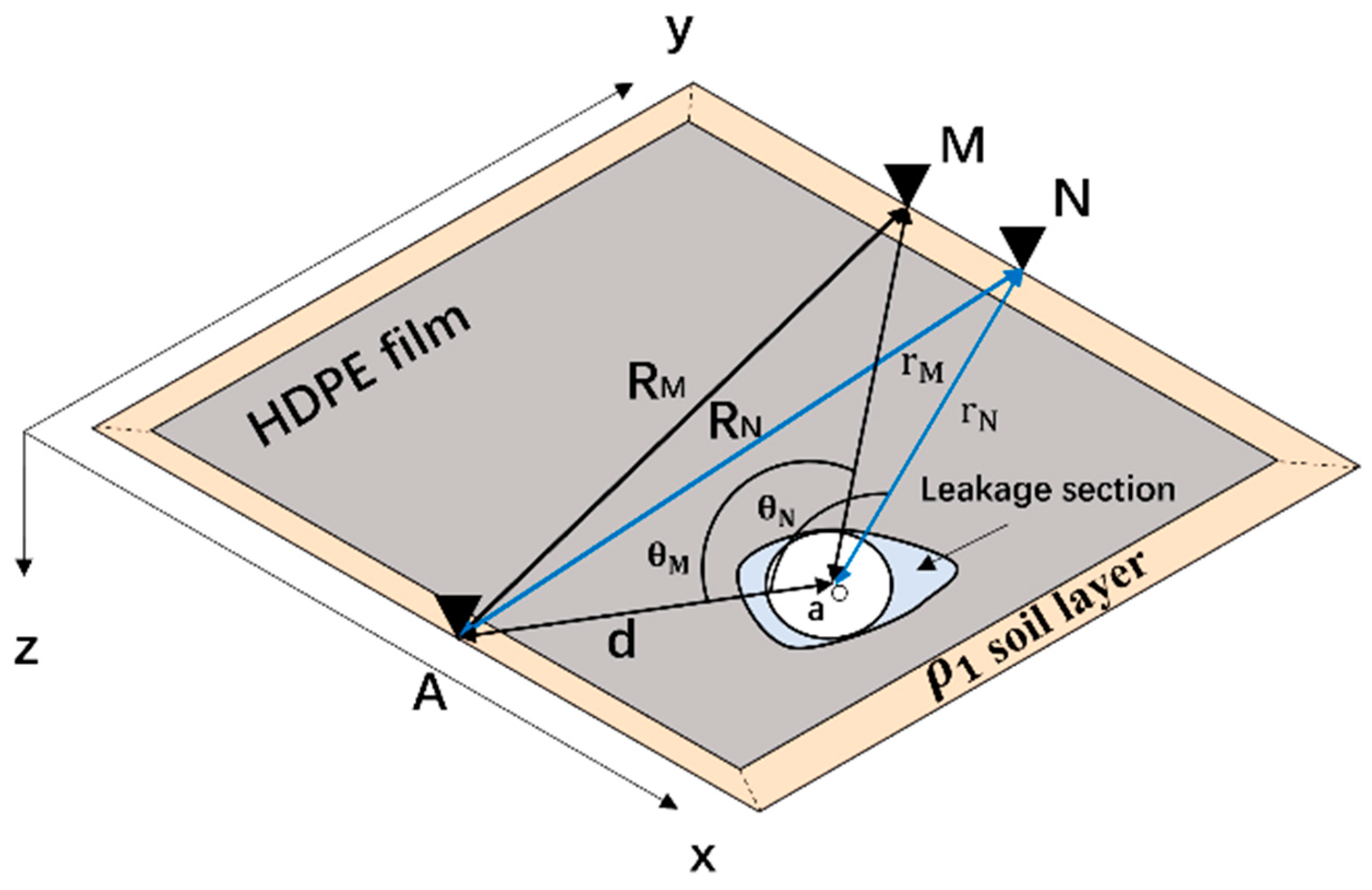

3. Potential Distribution Model Under the Membrane

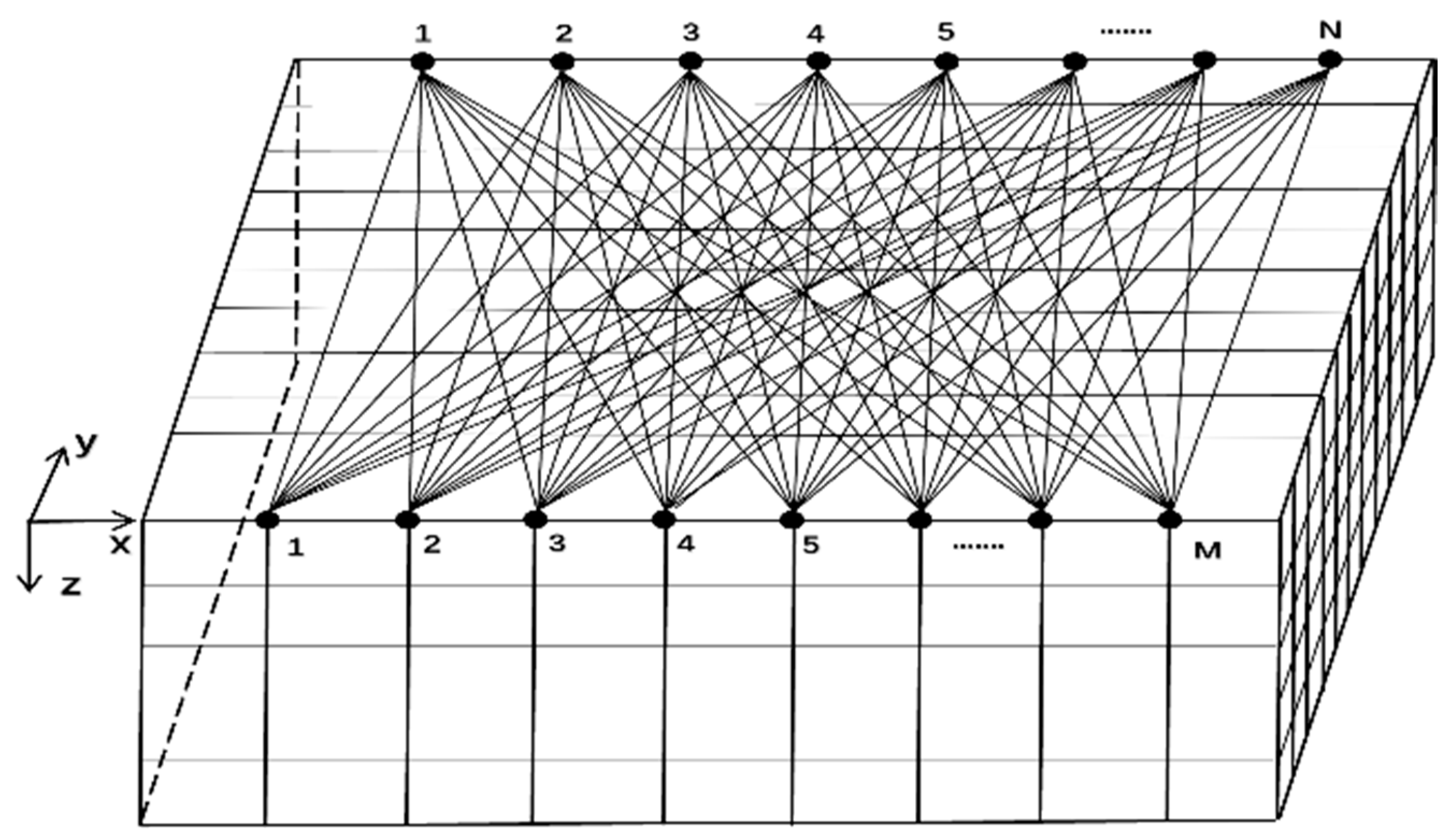

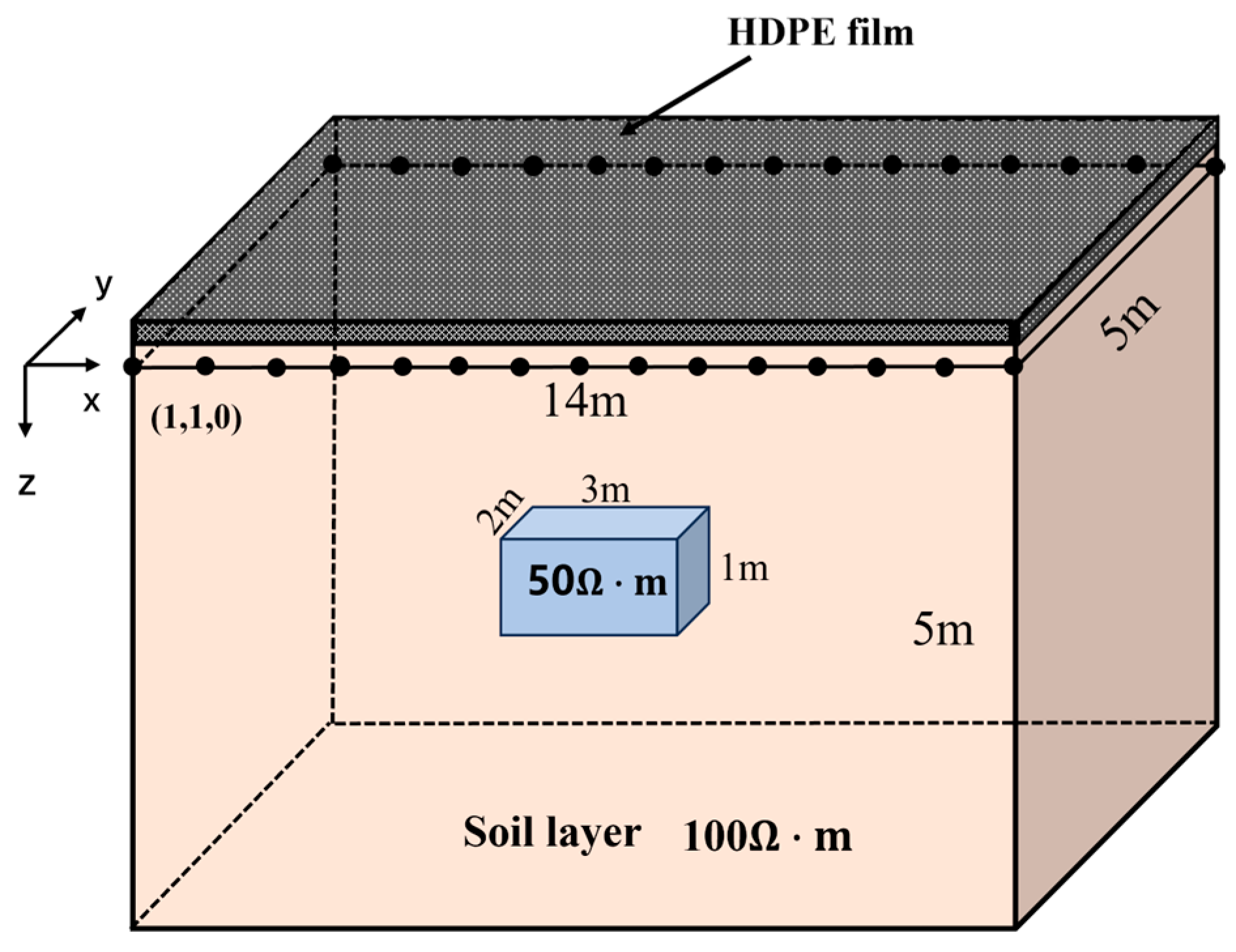

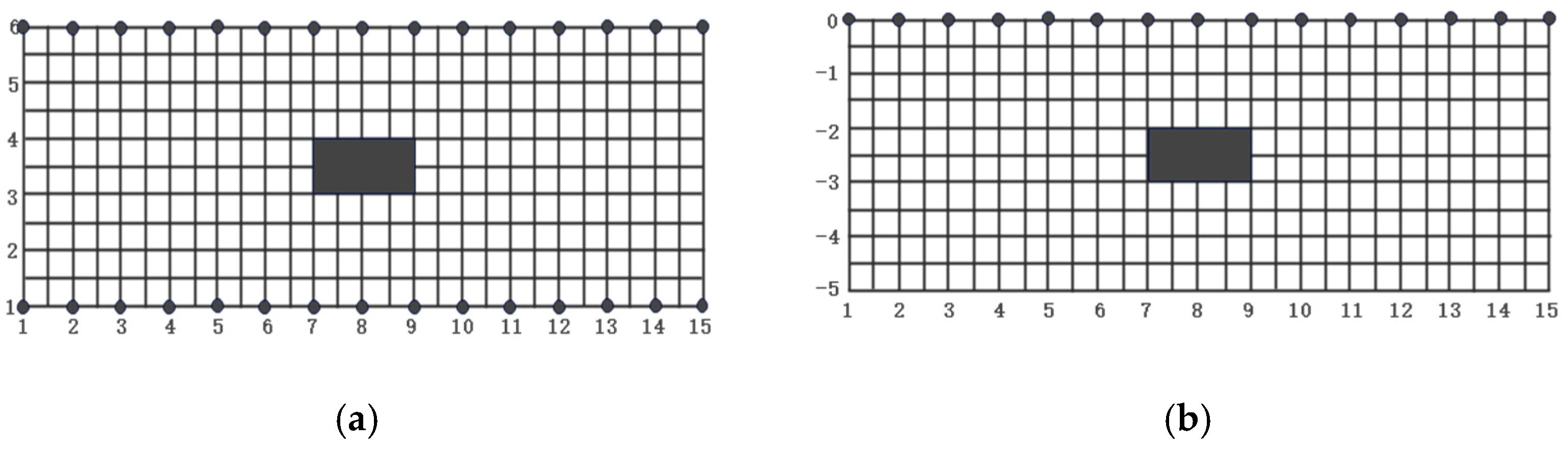

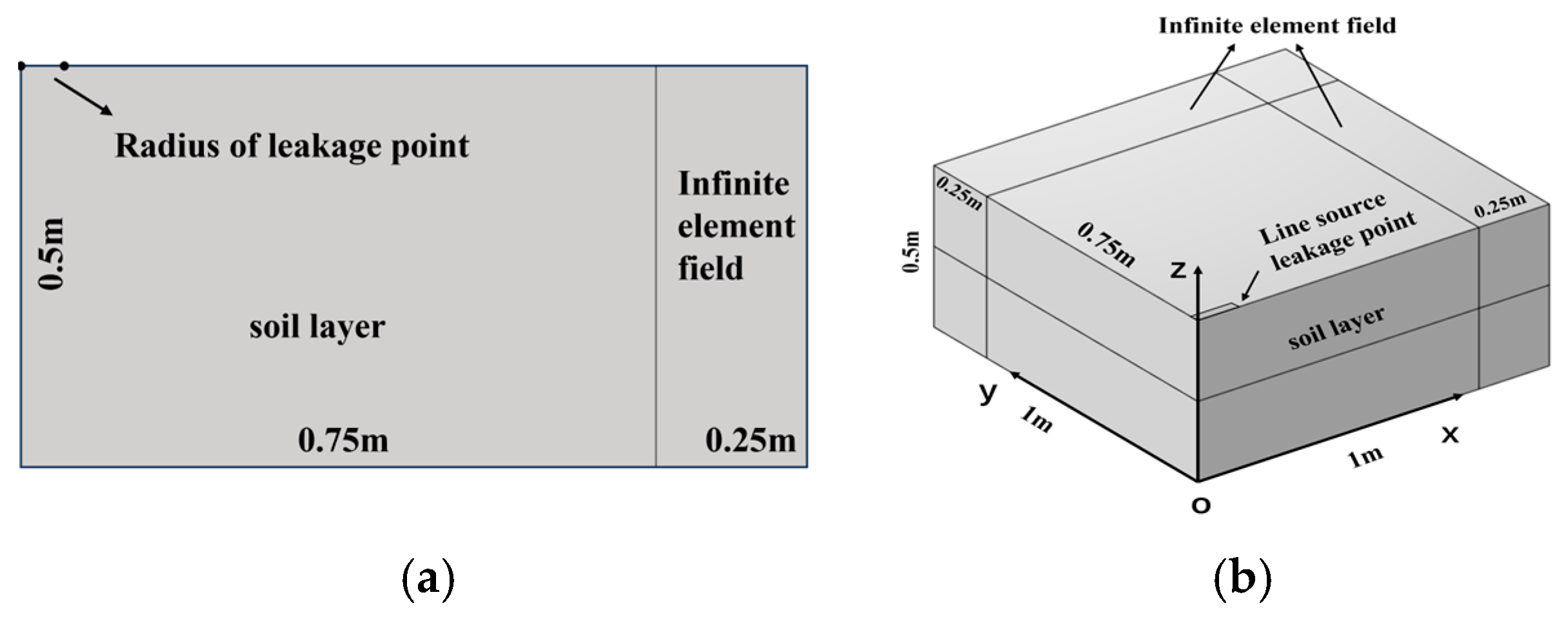

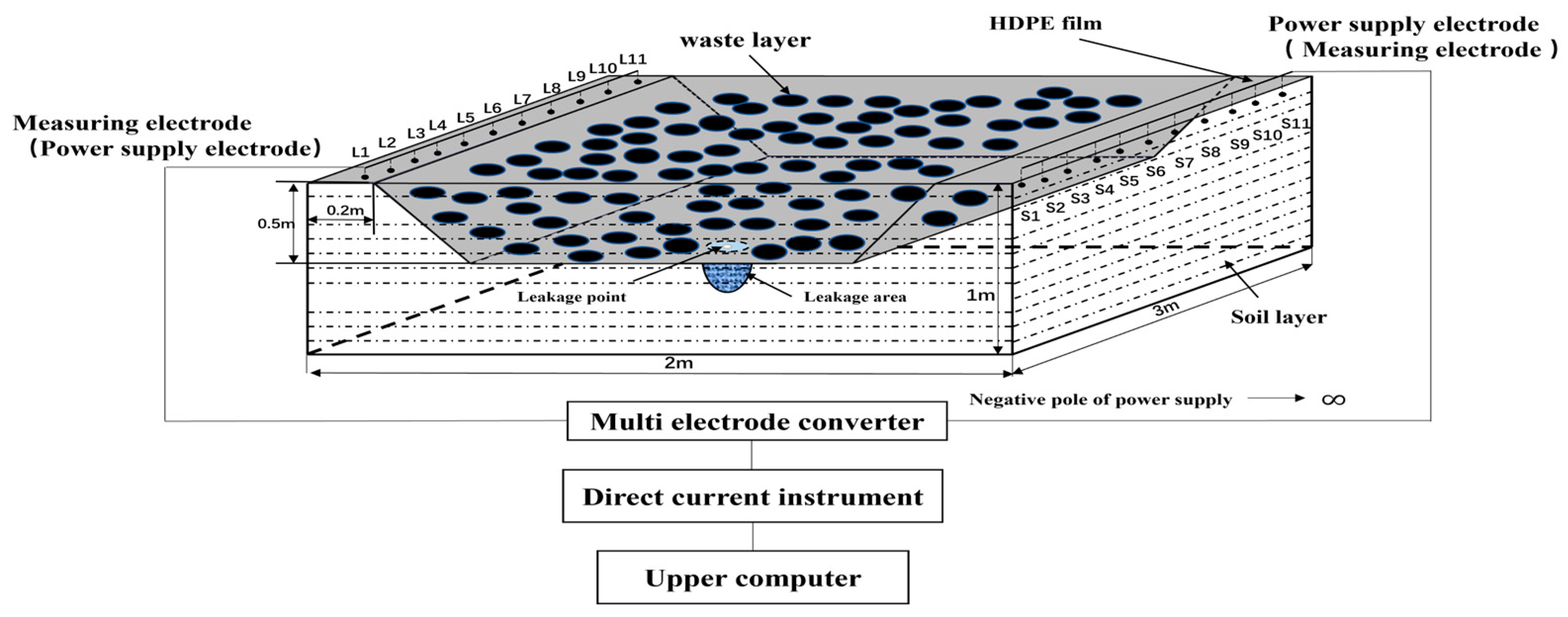

4. Establishment of HDPE Membrane Leakage Location Model

5. Parameter Fitting of HDPE Membrane Leakage Localization Model

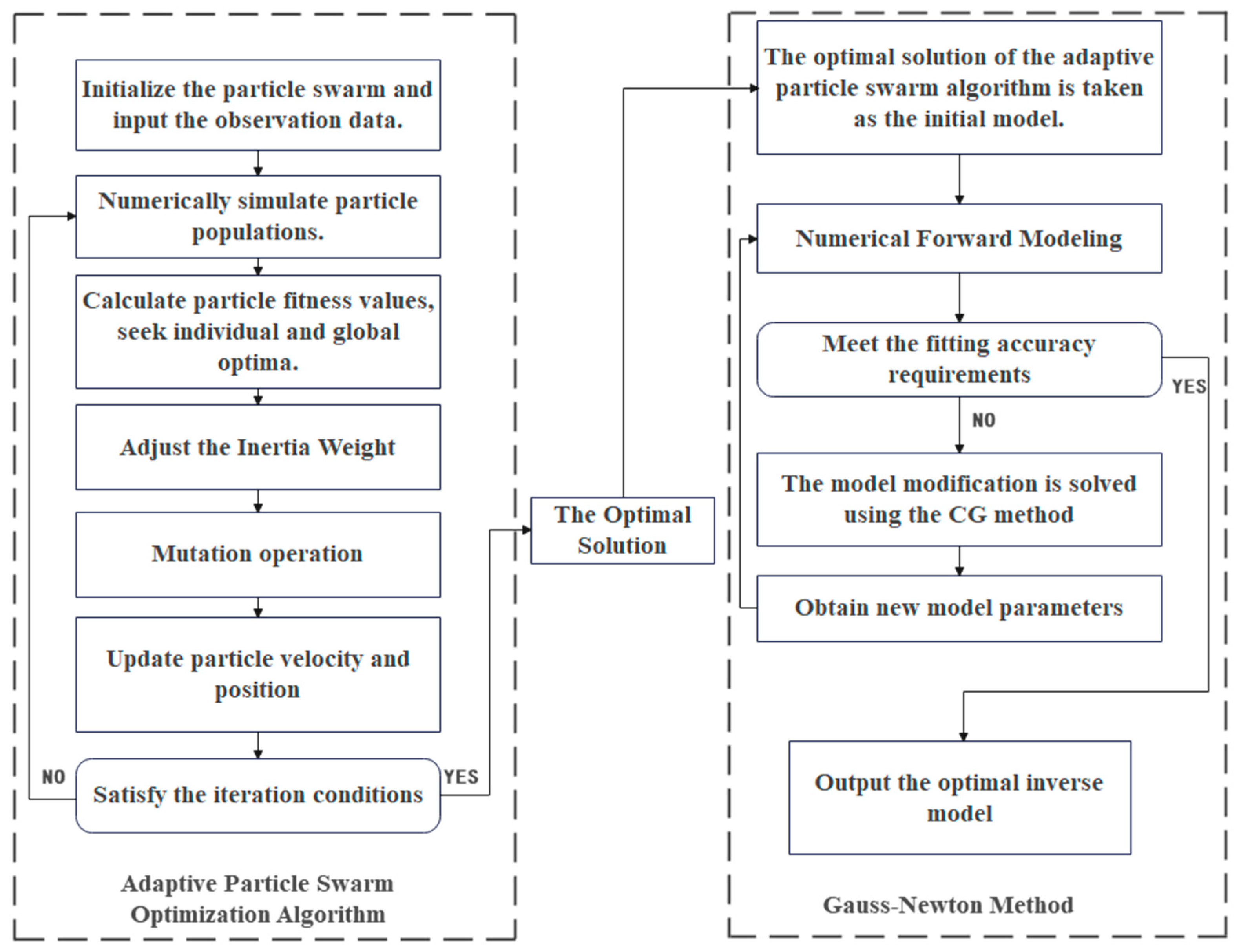

5.1. Improving the Gauss–Newton Method

5.2. The Adaptive Particle Swarm Optimization Algorithm Is Combined with the Gaussian–Newton Method to Fit Model Parameters

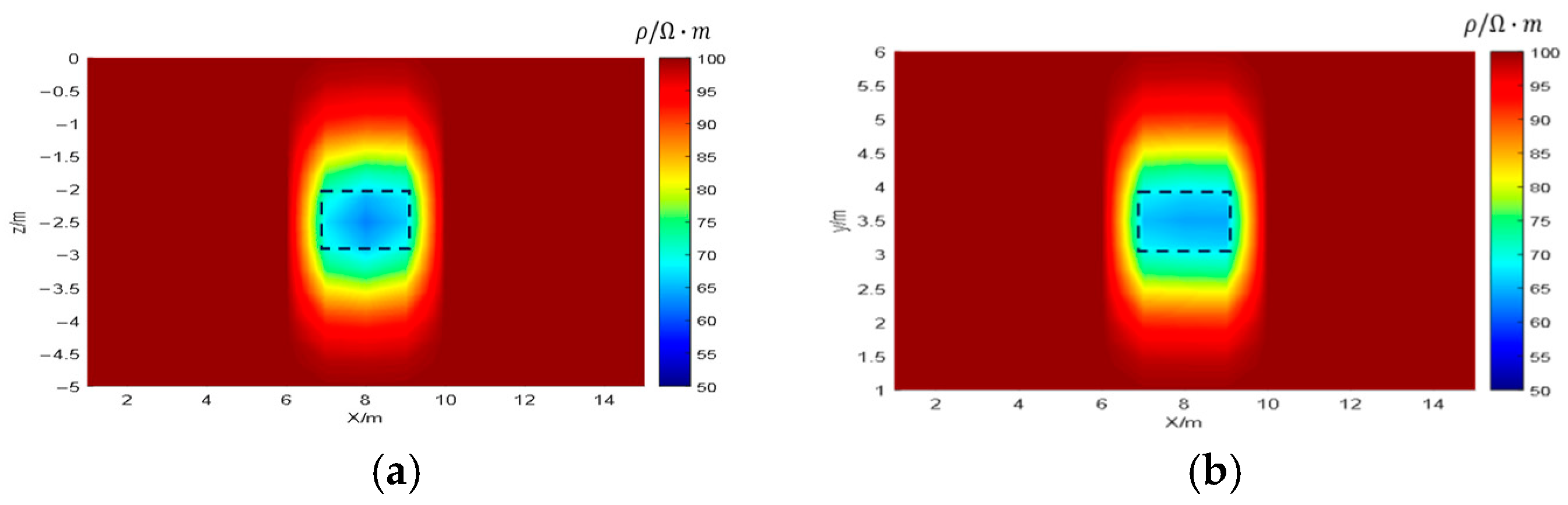

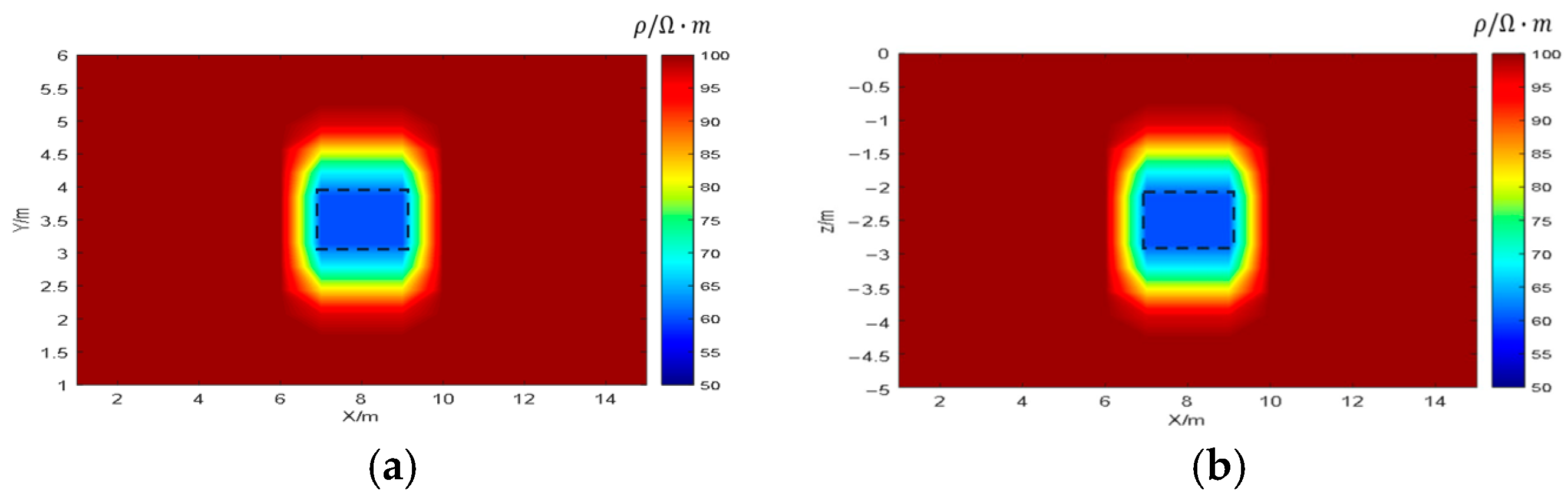

5.3. Verification of Homogeneous Medium Theory

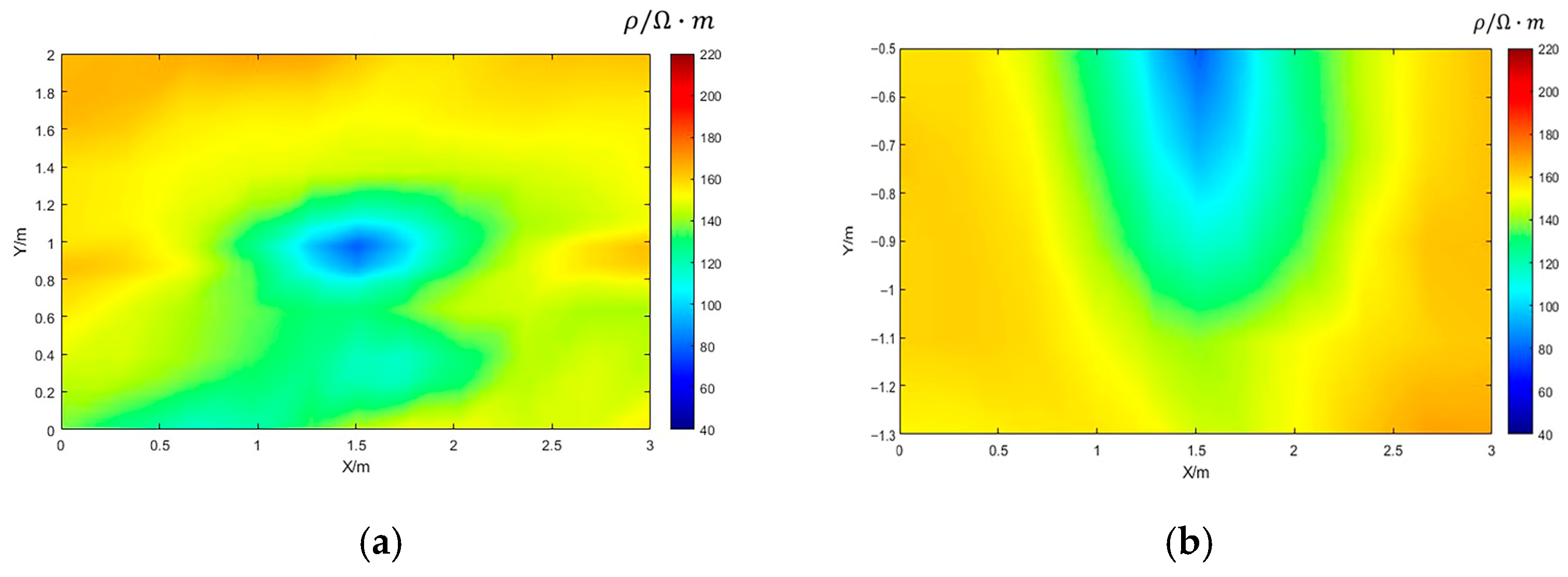

6. Simulation and Location Testing of Leachate Transport

6.1. The Shape of HDPE Membrane Leak Points and Simulation of Leachate Transport

6.2. Locating Experiment and Shape Recognition of HDPE Membrane Leak Points

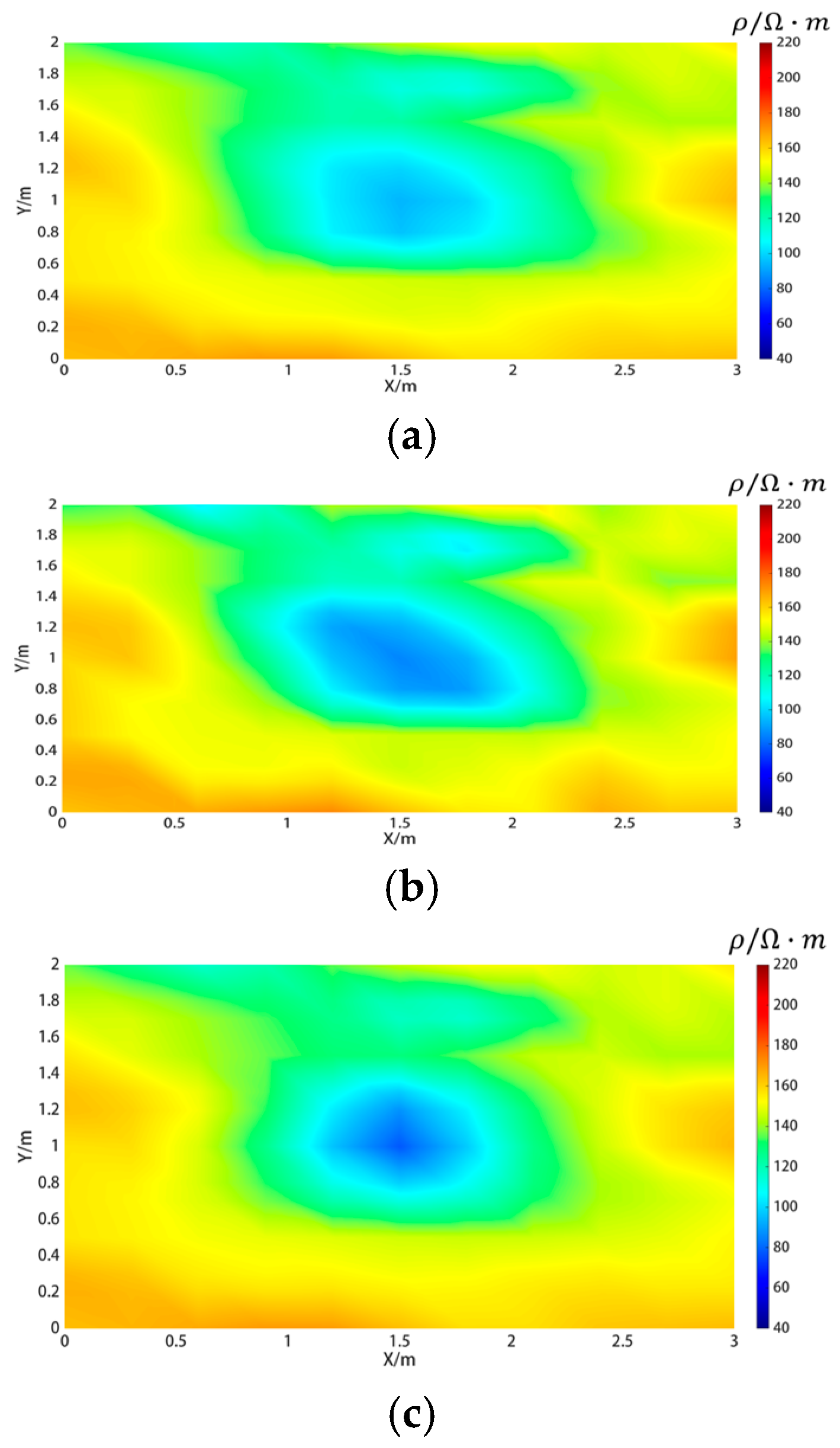

6.2.1. Leakage Point Location Experiment and Analysis

6.2.2. Identification and Analysis of Leak Point Shape Experimentation

6.2.3. Real-World Scenario Experiments

7. Conclusions

- The resistivity tomography inversion model based on the external-electrode power supply method does not require pre-burying sensors or embedded systems. It is applicable to old landfills without pre-existing monitoring facilities, thus overcoming the limitations of traditional methods that rely on pre-installed equipment. Moreover, since this method uses off-site electrodes for monitoring, compared with other methods, the monitoring devices are not corroded by leachate, which improves the sustainability of the landfill monitoring system;

- By combining the global search ability of APSO, where adaptive inertia weight and Cauchy mutation are used to avoid local optima, with the local fine-tuning optimization of the GN method, in which the conjugate gradient method is used to accelerate convergence, the inversion accuracy can be improved. Compared with single-algorithm methods, the hybrid algorithm significantly enhances the boundary recognition clarity in the low-resistivity anomaly region and reduces the reliance on the initial model;

- The maximum deviation between the inferred leakage location and the actual location is 10.1 cm, and the minimum is 6.4 cm, which meets the engineering requirements. The resistivity inversion area can effectively identify both simple point-source leakage points and line-source leakage points;

- This experiment can identify the shapes of simple point-source and line-source leakage points. However, it cannot recognize the shape of irregular leakage points. In the future, the algorithm should be further optimized to enhance the universality and accuracy of the method. Moreover, this method could potentially be developed into an automated monitoring system in the future, which would further improve the management efficiency of landfills and the environmental monitoring capabilities.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Daso, A.P.; Nevondo, V.; Okonkwo, O.J.; Malehase, T. Leachate Seepage from Landfill: A Source of Groundwater Mercury Contamination in South Africa. Water SA 2019, 45, 225–231. [Google Scholar] [CrossRef]

- Hassan, A.; Pariatamby, A.; Ossai, I.C.; Ahmed, A.; Muda, M.A.; Wen, T.Z.; Hamid, F.S. Bioaugmentation-Assisted Bioremediation and Kinetics Modelling of Heavy Metal-Polluted Landfill Soil. Int. J. Environ. Sci. Technol. 2022, 19, 6729–6754. [Google Scholar] [CrossRef]

- Al-Yaqout, A.; Hamoda, M.F. Long-Term Temporal Variations in Characteristics of Leachates from a Closed Landfill in an Arid Region. Water Air Soil Pollut. 2020, 231, 319. [Google Scholar] [CrossRef]

- Ayolabi, E.A.; Oluwatosin, L.B.; Ifekwuna, C.D. Integrated Geophysical and Physicochemical Assessment of Olushosun Sanitary Landfill Site, Southwest Nigeria. Arab. J. Geosci. 2015, 8, 4101–4115. [Google Scholar] [CrossRef]

- Ben Othmen, A.; Bouassida, M. Detecting Defects in Geomembranes of Landfill Liner Systems: Durable Electrical Method. Int. J. Geotech. Eng. 2013, 7, 130–135. [Google Scholar] [CrossRef]

- Vrijheid, M. Health Effects of Residence near Hazardous Waste Landfill Sites: A Review of Epidemiologic Literature. Environ. Health Perspect. 2000, 108, 101–112. [Google Scholar] [CrossRef] [PubMed]

- Pandey, L.M.S.; Shukla, S.K. An Insight into Waste Management in Australia with a Focus on Landfill Technology and Liner Leak Detection. J. Clean. Prod. 2019, 225, 1147–1154. [Google Scholar] [CrossRef]

- Nai, C.; Wang, Y.W.; Wang, Q.; Dong, L. Setup of High Voltage Direct Circuit Equivalent Circuit Model in Leakage Detection of Landfill. Environ. Sci. 2005, 26, 200–203. [Google Scholar] [CrossRef]

- Yang, P.; Jiang, T.; Li, Z.-C.; Yang, K.; Zhang, S.-H. Research Progress on Methods of Landfill Seepage Detection and Seepage Control. Environ. Eng. 2017, 35, 129–132+142. [Google Scholar] [CrossRef]

- Parra, J.O. Electrical Response of a Leak in a Geomembrane Liner. Geophysics 1988, 53, 1445–1452. [Google Scholar] [CrossRef]

- Chen, Y.; Yang, J.; Sun, H.; Wang, C. Research on Leakage Positioning of Solid Waste Landfill Based on Transmission Line Method. Environ. Eng. 2018, 36, 128–133+154. [Google Scholar] [CrossRef]

- Chen, Y.; Huang, X.; Sun, H.; Zhang, W. Impermeable Layer Leakage Detection using a Transmission Line Model. In Proceedings of the 2019 4th International Conference on Mechanical, Control and Computer Engineering (ICMCCE), Hohhot, China, 24–26 October 2019; pp. 780–7803. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, Z.; Nai, C.; Dong, L. Computer Simulation of Transmission Line Model for Landfill Leakage Location. Adv. Mater. Res. 2012, 466–467, 416–420. [Google Scholar] [CrossRef]

- Xie, X.; Xia, X.; Gao, Z. Optimal Arrangement of Structural Sensors in Landfill Based on Stress Wave Detection Technology. J. Sens. 2022, 2022, 7797856. [Google Scholar] [CrossRef]

- Konstantaki, L.A.; Ghose, R.; Draganov, D.; Heimovaara, T. Wet and Gassy Zones in a Municipal Landfill from P- and S-Wave Velocity Fields. Geophysics 2016, 81, EN75–EN86. [Google Scholar] [CrossRef]

- Chen, Y.; Sun, H.; Zhang, W.; Huang, X. Using Stress Wave Technology for Leakage Detection in a Landfill Impervious Layer. Environ. Sci. Pollut. Res. 2019, 26, 32050–32064. [Google Scholar] [CrossRef]

- Sweeney, J.J. Comparison of electrical resistivity methods for investigation of ground water conditions at a landfill site. Groundw. Monit. Remediat. 1984, 4, 52–59. [Google Scholar] [CrossRef]

- Binley, A.; Daily, W.; Ramirez, A. Detecting leaks from environmental barriers using electrical current imaging. J. Environ. Eng. Geophys. 1997, 2, 11–19. [Google Scholar] [CrossRef]

- Aristodemou, E.; Thomas-Betts, A. DC resistivity and induced polarization investigations at a waste disposal site and its environments. J. Appl. Geophys. 2000, 44, 275–302. [Google Scholar] [CrossRef]

- Binley, A.; Daily, W. The performance of electrical methods for assessing the integrity of geomembrane liners in landfill caps and waste storage ponds. Environ. Eng. Geophys. 2003, 8, 227–237. [Google Scholar] [CrossRef]

- Resurs, R. Resistivity-IP mapping for landfill applications. First Break 2010, 28, 40–45. [Google Scholar] [CrossRef]

- Abdulrahman, A.; Nawawi, M.; Saad, R.; Abu-Rizaiza, A.S.; Yusoff, M.S.; Khalil, A.E.; Ishola, K.S. Characterization of active and closed landfill sites using 2D resistivity/IP imaging: Case studies in Penang, Malaysia. Environ. Earth Sci. 2016, 75, 347. [Google Scholar] [CrossRef]

- Akintorinwa, O.J.; Okoro, O.V. Combined electrical resistivity method and multi-criteria GIS-based modeling for landfill site selection in the Southwestern Nigeria. Environ. Earth Sci. 2019, 78, 162. [Google Scholar] [CrossRef]

- Archie, G.E. The electrical resistivity log as an aid in determining some reservoir characteristics. Trans. AIME 1942, 146, 54–62. [Google Scholar] [CrossRef]

- Liu, Y.; Cai, H.; Hu, X.; Peng, R. 3D Forward Modeling and Analysis for Loop-Source Transient Electromagnetic Data Based on Finite-Volume Method in an Arbitrarily Anisotropy Earth. In Proceedings of the International Workshop on Gravity, Electrical & Magnetic Methods and Their Applications, Xi’an, China, 19–22 May 2019. [Google Scholar] [CrossRef]

- Sasaki, Y. 3-D resistivity inversion using the finite-element method. Geophysics 1994, 59, 1839–1848. [Google Scholar] [CrossRef]

- Loke, M.H.; Dahlin, T. A Comparison of the Gauss–Newton and Quasi-Newton Methods in Resistivity Imaging Inversion. J. Appl. Geophys. 2002, 49, 149–162. [Google Scholar] [CrossRef]

- Guo, L.; Wu, S.; Yang, B.; Dai, G. Three-Dimensional Direct Current Resistivity Finite Element Method Forward Modelling Based on Jacobi Preconditioned Conjugate Gradient Algorithm. J. Nanoelectron. Optoelectron. 2023, 18, 176–183. [Google Scholar] [CrossRef]

- Loke, M.H.; Barker, R.D. Practical Techniques for 3D Resistivity Surveys and Data Inversion. Geophys. Prospect. 1996, 44, 499–523. [Google Scholar] [CrossRef]

- Qin, G.; Xiao, X. Three-dimensional NLCG inversion by DC method based on unstructured grid. Chin. J. Eng. Geophys. 2024, 21, 473–483. [Google Scholar] [CrossRef]

- Liu, B.; Li, S.C.; Nie, L.C.; Wang, J.; Zhang, Q.S. 3D Resistivity Inversion Using an Improved Genetic Algorithm Based on Control Method of Mutation Direction. J. Appl. Geophys. 2012, 87, 1–8. [Google Scholar] [CrossRef]

- Pidlisecky, A.; Haber, E.; Knight, R. RESINVM3D: A 3D Resistivity Inversion Package. Geophysics 2007, 72, H1–H10. [Google Scholar] [CrossRef]

- Zhang, J.; Mackie, R.L.; Madden, T.R. 3-D Resistivity Forward Modeling and Inversion Using Conjugate Gradients. In SEG Technical Program Expanded Abstracts; Society of Exploration Geophysicists: Tulsa, OK, USA, 1994. [Google Scholar] [CrossRef]

- Zohdy, A.A.R. A New Method for the Automatic Interpretation of Schlumberger and Wenner Sounding Curves. Geophysics 1989, 54, 245–253. [Google Scholar] [CrossRef]

- Liu, B.; Li, S.; Li, S.; Nie, L.; Zhong, S.; Li, L.; Song, J.; Liu, Z. 3D electrical resistivity inversion with least-squares method based on inequality constraint and its computation efficiency optimization. Chin. J. Geophys. 2012, 55, 260–268. [Google Scholar] [CrossRef]

- Liu, B.; Liu, Z.Y.; Song, J.; Nie, L.C.; Wang, C.W.; Chen, L. Joint inversion method of 3D electrical resistivity detection based on inequality constraints. Chin. J. Geophys. 2017, 60, 820–832. [Google Scholar] [CrossRef]

- Zha, Y.; Yang, J.; Zeng, J.; Tso, C.H.; Zeng, W.; Shi, L. Review of Numerical Solution of Richardson–Richards Equation for Variably Saturated Flow in Soils. WIREs Water 2019, 6, e1364. [Google Scholar] [CrossRef]

- Faraj, I.S.; Abid, M.B. Water Movement through Soil under Drip Irrigation Using Different Hydraulic Soil Models. J. Eng. 2020, 26, 43–61. [Google Scholar] [CrossRef]

- Jafari, Z.; Matinkhah, S.; Mosaddeghi, M.R. Wetting Patterns in a Subsurface Irrigation System by Using Reservoirs of Different Permeabilities: Experimental and HYDRUS-2D/3D Modeling. Water Resour. Manag. 2022, 36, 5335–5352. [Google Scholar] [CrossRef]

- Cheng, H.; Liu, P.K.; Wang, Y.L.; Nai, C.X. Determination of dipole spacing in electrical landfill leakage detection. Adv. Mater. Res. 2011, 171, 171–174. [Google Scholar] [CrossRef]

- Guan, S.P.; Wang, Y.W.; Nai, C.X.; Dong, L. Comparison of Two Electrode Arrays for Liner Leakage Location at Landfills. In Proceedings of the 2009 4th IEEE Conference on Industrial Electronics and Applications, Xi’an, China, 25–27 May 2009. [Google Scholar] [CrossRef]

| Leak Spot | Estimate the Point-Source Leakage Center Coordinates/(cm) | Actual Point-Source Leakage Center Coordinates/(cm) | Deviation /(cm) |

|---|---|---|---|

| Leakage point 1 | (123.2, 114.3) | (130, 120) | 8.87 |

| Leakage point 2 | (142.4, 104.9) | (150, 100) | 9.04 |

| Leakage point 3 | (154.8, 86.6) | (160, 80) | 8.42 |

| Leakage point 4 | (166.5, 58.3) | (175, 50) | 12.61 |

| Leak Spot | Estimate the Point-Source Leakage Center Coordinates/(cm) | Actual Point-Source Leakage Center Coordinates/(cm) | Deviation /(cm) |

|---|---|---|---|

| Leakage point 1 | (124.2, 114.3) | (130, 120) | 8.13 |

| Leakage point 2 | (145.4, 106.9) | (150, 100) | 8.18 |

| Leakage point 3 | (151.9, 85.9) | (160, 80) | 10.02 |

| Leakage point 4 | (167.5, 58.3) | (175, 50) | 11.19 |

| Leak Spot | Estimate the Point-Source Leakage Center Coordinates/(cm) | Actual Point-Source Leakage Center Coordinates/(cm) | Deviation /(cm) |

|---|---|---|---|

| Leakage point 1 | (125.6, 115.3) | (130, 120) | 6.4 |

| Leakage point 2 | (145.1, 106.5) | (150, 100) | 8.1 |

| Leakage point 3 | (154.6, 84.6) | (160, 80) | 7.1 |

| Leakage point 4 | (168.2, 57.6) | (175, 50) | 10.1 |

| Leak Spot | Estimate the Point-Source Leakage Center Coordinates/(cm) | Actual Point-Source Leakage Center Coordinates/(cm) | Deviation /(cm) |

|---|---|---|---|

| T1 | (112.6, 92.3) | (120, 100) | 10.68 |

| (130.5, 94.5) | (140, 100) | 10.98 | |

| T2 | (143.6, 71.2) | (150, 80) | 10.89 |

| (166.7, 96.6) | (175,105) | 11.81 |

| Leak Spot | Estimate the Point-Source Leakage Center Coordinates/(cm) | Actual Point-Source Leakage Center Coordinates/(cm) | Deviation /(cm) |

|---|---|---|---|

| T1 | (113.8, 91.9) | (120, 100) | 10.20 |

| (131.7, 95.1) | (140, 100) | 9.64 | |

| T2 | (141.7, 72.8) | (150, 80) | 10.99 |

| (165.8, 96.9) | (175, 105) | 12.25 |

| Leak Spot | Estimate the Point-Source Leakage Center Coordinates/(cm) | Actual Point-Source Leakage Center Coordinates/(cm) | Deviation /(cm) |

|---|---|---|---|

| T1 | (116.6, 93) | (120, 100) | 7.78 |

| (133.3, 95.5) | (140, 100) | 8.07 | |

| T2 | (144.3, 75.0) | (150, 80) | 7.58 |

| (168.3, 100.3) | (175, 105) | 8.18 |

| Leakage Point Number | Actual the Leakage Point | Estimate the Leakage Point | Deviation d/(cm) |

|---|---|---|---|

| 1 | N 29°50.555′ E 117°41.585′ H131 m | N 29°50.554946′ E 117°41.584938′ H131 m | 10 |

| 2 | N 29°50.519′ E 117°41.642′ H126 m | N 29°50.51894717′ E 117°41.64193907′ H126 m | 9.8 |

| 3 | N 29°50.512′ E 117°41.644′ H126 m | N 29°50.51204474′ E 117°41.64405161′ H126 m | 8.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hao, W.; Chen, Y.; Jia, F.; Zhang, X. Research on the HDPE Membrane Leakage Location Using the Electrode Power Supply Mode Outside a Landfill Site. Sustainability 2025, 17, 4044. https://doi.org/10.3390/su17094044

Hao W, Chen Y, Jia F, Zhang X. Research on the HDPE Membrane Leakage Location Using the Electrode Power Supply Mode Outside a Landfill Site. Sustainability. 2025; 17(9):4044. https://doi.org/10.3390/su17094044

Chicago/Turabian StyleHao, Wei, Yayu Chen, Feixiang Jia, and Xu Zhang. 2025. "Research on the HDPE Membrane Leakage Location Using the Electrode Power Supply Mode Outside a Landfill Site" Sustainability 17, no. 9: 4044. https://doi.org/10.3390/su17094044

APA StyleHao, W., Chen, Y., Jia, F., & Zhang, X. (2025). Research on the HDPE Membrane Leakage Location Using the Electrode Power Supply Mode Outside a Landfill Site. Sustainability, 17(9), 4044. https://doi.org/10.3390/su17094044