Abstract

The construction industry continues to face significant challenges related to waste on construction sites, significantly impacting cost, timelines, and the quality of project outcomes. This study aims to identify contemporary sources of construction waste, assess their variability over time using data from 2016, 2021, and 2024, and evaluate strategies for their reduction. A mixed-methods approach was adopted, combining a literature review with a survey among Polish construction contractors. A total of 34 waste factors were assessed in terms of frequency and significance. Building Information Modelling (BIM) is recommended—based on both survey results and studies in the literature—as an effective strategy to optimise construction efficiency by reducing waste and supporting sustainability objectives. The analysis also shows increasing awareness and application of Lean Principles and BIM among contractors. By 2024, BIM use increased from 8% in 2016 to 63%, indicating broader recognition, although this recognition was still insufficient given the severity of reported waste. The findings revealed design errors as the most critical source of waste, alongside execution delays, quality defects, damages to completed works, and excessive workloads. Respondents also identified additional factors, including erroneous bid assumptions, unclear investor expectations, unrealistic deadlines, equipment failures, and overdesign. These underscore the need for strategic, technology-driven waste mitigation.

Keywords:

waste; construction site; waste reduction; BIM; lean construction; AEC; construction efficiency 1. Introduction

For years, researchers, practitioners, and legislators have deliberated on optimising construction efficiency [1,2]. How can escalating costs and project delays be avoided while ensuring the quality of completed works? Waste, and intrinsic aspects of any construction project, significantly impact costs, timelines, and the quality of works [3,4,5]. While its complete elimination may be challenging, efforts can be made to reduce it.

Current research on construction projects typically focuses on waste treatment and recycling but rarely adopts a comprehensive approach that also considers waste in management, steering, stakeholder collaboration, and external factors, responding to the need for waste prevention and quantitative trends [3,5,6]. This trend, combined with the drive for sustainable development [7] and improving the efficiency of construction process, served as the motivation for this study.

The objective of this study is to identify existing sources of construction waste based on those previously discussed in the literature, while also identifying new ones. This allows for a verification of their presence in the Polish construction market and, through comparison with findings from other countries, paves the way for identifying universal challenges affecting the construction sector. Findings from the 2024 survey conducted among construction contractors were compared with earlier results from 2016 and 2021. Furthermore, solutions prosed in the literature for reducing the most significant waste, as identified by respondents, were examined. The study concludes with a recommendation.

The findings provide valuable guidance for improving construction processes through waste reduction, offering significant insights for researchers, practitioners, and legislators alike. By identifying and addressing these issues, the study aims to promote more efficient, cost-effective, and high-quality construction processes.

Literature Review

A key breakthrough of its time was the identification of Ohno’s wastes in manufacturing plants [8], which laid the foundation for the so-called Lean Thinking [9]. In the Architecture, Engineering and Construction (AEC) sector, the essence of Lean Construction (LC) lies in eliminating activities that do not add value and are not essential [1].

Li et al., in their study on policies for reducing hazardous waste in construction projects (Construction waste reduction CWR), identified key factors such as the professional ethics of stakeholders, waste management behaviour, and efficient source planning significantly impact waste minimisation [3]. Similarly, Bajjou and Chafi conducted a survey-based study, presented in an article published in 2021, which examined the impact of waste factors on their occurrence in Moroccan construction projects. Their findings highlighted late payments, lack of training, raising awareness on social sustainability and environmental impacts for employees, and strategies for waste management as the primary causes of waste [5]. The findings of our study, which examined the occurrence and impact of waste (e.g., on cost, time, and quality of works) among Polish construction contractors, contribute to ongoing efforts to prevent waste generation. Daoud et al. conducted an in-depth investigation in 2023 into the cause-and-effect relationships among the following six key factors influencing the construction sector: materials procurement measures; materials procurement models; green building practices; legislation; culture and behaviour; and awareness. The study was based on a survey carried out within the Egyptian construction sector, targeting a representative sample of construction professionals across various roles and specialisations [10].

Current research on waste elimination primarily focuses on the application of Building Information Modelling (BIM) [11,12], including Digital Twin [13], Life Cycle Assessment (LCA) [14], and the use of Lean Principles, often integrated with other methodologies such as Lean-BIM [15,16,17], the Last Planner System (LPS), Lean Premise Design (LPD) [18], and Integrated Project Delivery (IPD). Bang and Andersen, for instance, recommend incorporating certain artificial intelligence tools for waste reduction [19]. The adoption of green and digital transitions aligns with the latest European Commission proposal for Industry 5.0 [20].

2. Materials and Methods

In response to the need for comprehensive quantitative research on waste factors [6], a survey study was conducted in 2024 among construction contractors in Poland. This survey was based on similar questions to those used in 2016 and 2021 (except for the absence of a question regarding the use of Building Information Modelling in the 2016 survey). The survey targeted companies acting as construction contractors, who actively encounter waste-related issues on construction sites (Horman and Kenley’s metanalysis demonstrated that, on average, 49.6% of construction project time is lost due to waste [21]).

The survey was completed by individuals with construction site experience, with the option to complete either online (via a web link [22] sent by email) or in paper format. All methods were carried out in accordance with relevant guidelines and regulations, and informed consent was obtained from all participants, who were assured of the anonymous nature of the survey. The conduct of the study and the report were approved by an institutional committee. Only general information was collected, with no sensitive or personally identifiable data gathered.

The questionnaire consisted of two main sections. The first section focused on the respondents’ profiles, covering their experience, job positions, company details (size and sector), and whether projects were carried out solely in Poland or internationally. Additionally, questions were asked about their knowledge and implementation of Lean Principles, the Toyota Production System (TPS), and Building Information Modelling (BIM), as these methodologies are regarded as critical for waste reduction [23,24,25].

The second section, informed by a preceding literature review to identify waste sources and types, evaluated their frequency and significance (understood as their impact on time, cost and quality of construction works). These assessments were rated on a scale from 1 to 4, where 1 signified either no impact or a negligible one, and 4 indicated a very significant impact. Additionally, the degree of occurrence was also rated on a scale from 1 to 4, with 1 denoting that the specified waste did not occur or occurred very rarely, and 4 suggesting that it was always present. Respondents could also indicate additional waste factors not previously listed, allowing for a broader exploration of current trends and emerging issues. This holistic framework enabled the inclusion of waste factors related to management, steering, production, resources, communication with suppliers, and external factors.

Both quantitative and qualitative analyses of the collected data were conducted. Qualitative insights provided by the respondents regarding waste factors identified in the literature facilitated quantitative analysis by comparing responses and ratings from other participants, enabling contextualisation of the data. The results were subsequently grouped into thematic categories, which were analysed to identify current challenges. New potential risks, indicated by respondents in open-ended questions, enriched the analysis by introducing additional sources of waste.

Subsequently, waste reduction strategies recommended in the literature were reviewed, particularly in relation to the most significant and frequently occurring types of waste, as assessed by respondents. The study concluded with recommendations aimed at optimising construction process efficiency by reducing critical waste factors. The steps involved in the research approach are illustrated in Figure 1.

Figure 1.

Outline of the research approach.

Structure of the article:

Section 3.1—Literature Review: discusses waste factors identified in previous research, providing a theoretical foundation for the study, followed by a summary of key findings.

Section 3.2—Survey: details the respondents’ profiles and present an analysis of the survey results concerning waste observed construction site, accompanied by a concluding summary.

Section 3.3—Literature review for solution to reduce waste: summarises methods proposes in the literature to mitigate the most critical and frequent waste types and presents survey findings on the adoption of these methods by respondents, with a final summary of the section.

Section 3.4—Recommendation: based on the survey results and literature review, this section recommends a specific approach considered most effective for optimising construction project delivery.

3. Results and Discussion

3.1. Waste Factors from Literature Review

Thirty-four sources of waste were identified in the literature, the inclusion of which enabled verification of their current status among practitioners in the survey research. These waste factors encompass various aspects, including those strictly related to production, such as improper storage and making defective products, as well as those associated with management inefficiencies, poor steering, and external factors. Some researchers also introduced specific waste types such as making-do, task diminishment, and buffering. Their definitions, along with a complete list of all identified waste factors, are presented in Table 1.

Table 1.

Waste in the literature review (own study based on [1,8,26,27,28,29,30,31,32,33,34,35,36]).

The review focuses on factors identified before 2016, the year the first survey was conducted, allowing for an analysis of their variability over time in relation to subsequent surveys carried out in 2021 and 2024. Nevertheless, to ensure the relevance of waste sources, respondents were also given the opportunity to add new factors not listed in the questionnaire.

To summarise, Section 3.1 provides a structures overview of 34 waste factors identified through a comprehensive review of literature, laying the foundation for subsequent longitudinal comparisons in the 2016, 2021, and 2024 surveys. These factors reflect a wide range, from those directly related to production processes, such as delays in execution and defective products, to management shortcomings related to resources, communication with suppliers, and external constraints. In addition to more conventional waste categories, several scholars introduced unique conceptualisations of waste, including making-do, task diminishment, and buffering. These were incorporated to capture the complexity of waste across the construction project lifecycle. The full list of waste types and their sources is presented in Table 1. Importantly, to maintain the contemporaneity and relevance of the study, respondents were invited to supplement the list by identifying emerging or previously overlooked waste factors in later stages of the research.

3.2. Waste at the Construction Site: Survey Study

Waste, an inherent facet of construction projects, significantly influences cost, timelines, and the quality of work outcomes [3,4,5]. Despite its inevitability, avenues for mitigation exist. This study delineates current sources of waste at construction sites.

The survey was conducted in Poland among construction contractors in 2016, 2021, and 2024. The first part of the survey focuses on the respondents’ profiles, their organisations, and their participation. The second part assessed the frequency and significance of waste sources at construction sites. In each year of the survey, respondents evaluated the same waste factors to enable comparisons over time, while also being given the opportunity to identify new waste factors.

From the distributed surveys, a 10.22% response rate of correctly filled surveys was achieved (6.67% in 2016, 37.5% in 2021 and 30.56% in 2024), totalling 450 pieces. However, some surveys were distributed electronically via email links, the circulation of which was not recorded. Therefore, the actual response rate is conceivably lower. The limited responsiveness to the scientific study highlights the challenges in conducting the research. Respondents were required to dedicate time to completing the survey. Furthermore, the study was complex, as it included the evaluation of 34 waste factors in terms of their frequency and impact on cost, time, and quality of works. While this was crucial for researchers to verify the relevance of sources mentioned in the literature, it proved labour-intensive for the respondents.

3.2.1. Profiles of Respondents

Table 2 depicts the profiles of respondents who met the criteria (construction work contractors) and correctly completed the survey.

Table 2.

Profiles of respondents.

Most surveyed individuals possessed experience ranging from 6 to 20 years, with the majority occupying senior management positions on construction sites or within contracting firms. Furthermore, these individuals predominantly worked for large firms employing over 250 permanent staff and acted as general construction contractors (85–100%), with some also working internationally. Future research could involve conducting a similar survey among employees of smaller enterprises to examine potential differences in outcomes and compare these to the findings of this study.

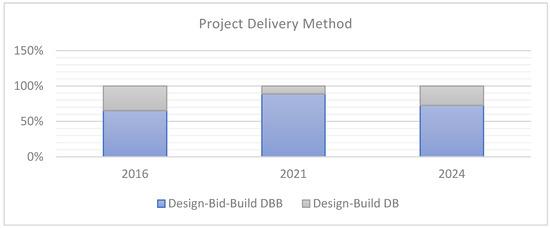

Figure 2 presents the project delivery methods for the construction investments surveyed, with a clear majority (2016: 65%, 2021: 89% and 2024: 73%) opting for the Design–Bid–Build DBB approach, which is the most commonly used in Poland.

Figure 2.

Respondents’ profiles. Project delivery methods.

3.2.2. Waste Factors and Types

Respondents were asked in the surveys to evaluate various sources and types of waste encountered on construction sites, assessing their significance in terms of their impact, for instance, on cost, time, and quality of works. A compilation of the results is depicted in Table 3. The last row introduces sources of waste on construction sites as suggested by the survey participants.

Table 3.

Waste at the construction site. Results of the surveys conducted in 2016, 2021 and 2024.

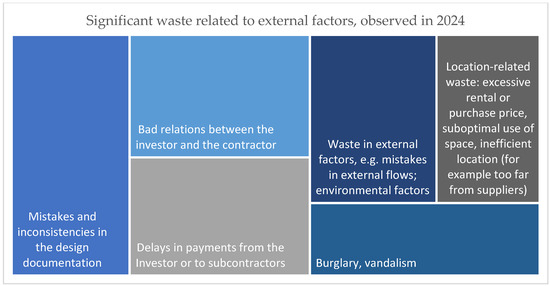

3.2.3. External Factors

Respondents, when evaluating the frequency and importance of various waste factors, deemed some external factors, which are largely beyond the direct control of the site’s internal operational management, as particularly significant. The most important and recurrent form of waste was identified as design errors. It is noteworthy that respondents predominantly operated within the DBB system. Within the DBB framework, the investor’s initial step involves selecting a design office tasked with crafting comprehensive design documentation, followed by the selection of a general contractor to oversee construction execution based on this documentation. Consequently, remediation during the construction phase is associated with laborious information flow among stakeholders and often necessitates approval from both the designer and investor, depending on the construction stage. Early error detection entails less drastic consequences compared to post-commencement scenarios, where repair costs and consequential delays impact subsequent tasks. Thus, across all surveyed years, design errors consistently ranked foremost, with their perceived significance escalating annually.

High on the list of externally influenced waste factors were also payment delays from investor to contractor or for subcontractors and poor relations between the investor and the contractor, both of which can delay decision-making processes, potentially prolonging project timelines and escalating costs related to meeting contractual deadlines.

Significant waste factors related to external factors in 2024 are presented in Figure 3.

Figure 3.

Hierarchical visualisation of significant waste related to external factors, observed in 2024.

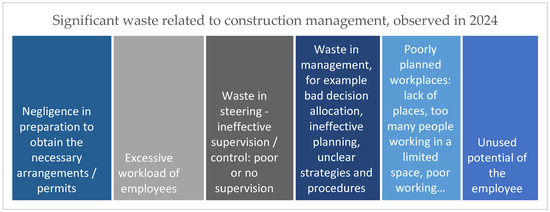

3.2.4. Construction Management

Proper construction management is deemed a pivotal component of any construction project execution. The respondents’ assessments within this segment yielded relatively high scores compared to other sections. The most frequently identified management-related waste factor was ineffective steering, situations where employees are overburdened with tasks or poorly assigned, thereby wasting their potential. Respondents, predominantly from large enterprises, likely engaged in substantial investments, demanding extensive managerial staff to navigate complex information flows among numerous stakeholders and manage various works. This environment, hosting multiple work brigades, renders damages to already completed works a commonality due to intense work pace and deadline pressures.

In evaluating their importance, particular attention was paid to waste in management, where poor decision-making, inadequate planning, and unclear or underdeveloped procedures could prove decisive. Similarly, waste in steering was highlighted as significant. The lack of effective supervision of works and delayed reactions to poorly executed task result in increased rectification costs. Furthermore, negligence in preparations for obtaining necessary permits affects project timelines and can lead to contractual penalties for failing to meet interim or final deadlines.

Significant waste related to construction management in 2024 factors presents Figure 4.

Figure 4.

Hierarchical visualisation of significant waste related to construction management, observed in 2024.

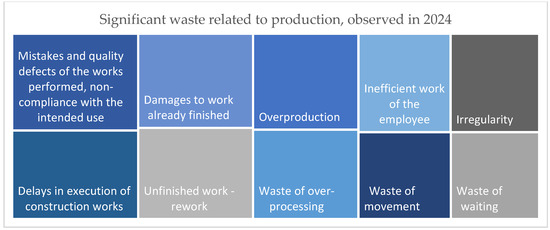

3.2.5. Production

In the construction sector, Ohno’s seven wastes are not as significant and frequent, except for the production of defective products. Their importance was rated highly, especially in 2024, being considered significant and taking second place.

Beyond the wastes identified by Ohno and pertaining to the production category, damages to work already finished was deemed the most frequently occurring waste.

From the perspective of production waste, significant factors identified also include delays in execution of construction works and rework of unfinished work.

Significant waste factors related to production in 2024 are presented in Figure 5.

Figure 5.

Hierarchical visualisation of significant waste related to production, observed in 2024.

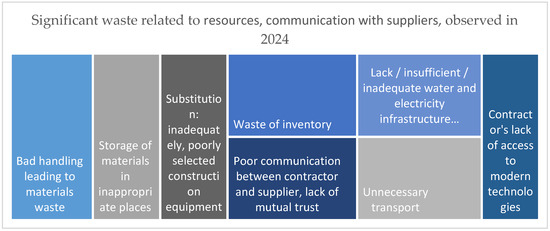

3.2.6. Resources, Communication with Suppliers

Notably, although occasionally observed, poor handling of materials was identified as a form of waste. The storage of materials, understood as the creation of unnecessary stockpiles stored in improper locations, was not regarded as a paramount concern among other identified wastes, but was seen to occur sometimes, especially in the survey conducted in 2021. However, this issue is gaining increasing relevance in light of recent regulatory changes introduced in Poland concerning construction and demolition waste. From 2025 onwards, Polish law mandates the segregation and appropriate subsequent management of such waste [37]. Non-compliance may result in administrative fines of up to PLN 1,000,000 (over EUR 230,000) [38]. These national obligations are aligned with the broader legislative framework established by Directive 2018/851 of the European Parliament and of the Council [39]. The directive requires Member States to establish sorting systems for construction and demolition waste to enhance resource efficiency and minimise environmental impacts. Consequently, the appropriate storage and handling of materials may become not only an economic or organisational concern but also a legal requirement. Unnecessary transportation, though infrequently occurring, impacts the time and costs of construction activities. Respondents also highlighted that poor communication between suppliers and contractors, with sporadic occurrences, has a noticeable effect on project execution. Resource-related issues, such as inadequately selected equipment, insufficient access to modern technologies, and failure to ensure the provision of necessary utilities, were considered as wastes occurring rarely or sometimes, with a generally medium significance level, although poorly chosen equipment was seen as having the most significant impact on cost, time, and work quality. Construction machinery, integral to project realisation, accelerated progress, reduced the need for manual labour, and shortened project timelines. The study results, however, indicated that this is not a trivial topic, especially in relation to other forms of waste.

Important waste factors related to resources and communication with suppliers in 2024 are presented in Figure 6.

Figure 6.

Hierarchical visualisation of significant waste related to resources and communication with suppliers, observed in 2024.

3.2.7. Selected Waste from Literature Review

Respondents evaluated wastes from the literature review such as buffering [33], making-do [30], and task dimishment [31] (with their importance in 2024 illustrated in Figure 7). Among these, making-do was seen as having the most significant impact on cost, time, and quality of work, and as the most frequently occurring factor.

Figure 7.

Hierarchical visualisation of significant waste related to selected waste from the literature review, observed in 2024.

3.2.8. New Wastes

Respondents were also afforded the opportunity to suggest additional sources of waste prevalent on construction sites. The greatest contribution to onsite waste was identified as errors made during the bidding phase. Large corporations, often engaging in large, public tenders, occasionally win bids through cost or time underestimations. The likelihood of underestimation can be reduced if investors implement appropriate mechanisms such as discounting bids that significantly deviate from the rest. However, due to the need for transparency in tenders and ensuring fair competition, such remedial measures are often not implemented.

Considering the evolving perspective on executing construction projects, where there is an increasing focus on sustainable development, the identified over-dimensioning of elements stands out as particularly glaring. Today, contractors are proposing optimisations at the outset of construction works, offering alternative solutions that preserve the intended quality of the planned outcome, and occasionally commissioning also a new structural design to reduce oversized elements, especially in reinforced steel.

Other identified sources of waste included imprecisely defined investor requirements, underscoring the importance of clear specification to avoid dissatisfaction with project outcomes [40]. Noteworthy waste factors also included inaccurately assessed time frames for project completion, dictated by investors, which could introduce further wastes related to hasty execution and insufficient planning, as well as equipment failures during commissioning, potentially damaging work completed to date and extending project deadlines.

3.2.9. Variability of Results over the Years

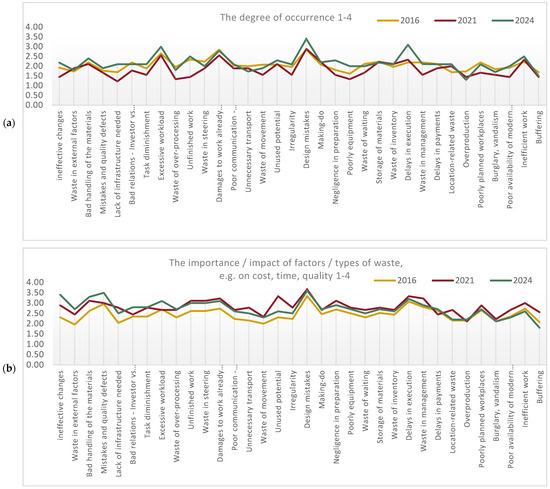

Figure 8 illustrates comparative charts depicting the degrees of occurrence and importance of various waste factors over the surveyed years.

Figure 8.

Charts with waste at the construction site by: (a) occurrence; and (b) importance.

An increase in the occurrence of most waste factors is evident in the last year of the survey, underscoring the ongoing challenge of optimising waste management, as well as the need for further research and the implementation of effective reduction strategies.

These visual representations regarding the frequency of waste consist of a marked decrease in overproduction waste, suggesting a shift towards more efficient production practices. However, an increase in incidences is particularly visible for design mistakes, delays in execution, and negligence in preparation. Conversely, the graph pertaining to importance showcases a diverse range of responses, with a general trend indicating an increase. In particular, the chart reveals a significant rise in the importance of inefficient change implementation. The lack of effective control over the work performed and delayed responses to improperly executed tasks lead to increased costs for their rectification. The increase in value is also visible in waste due to external factors and poor handling of materials, which also leads to waste.

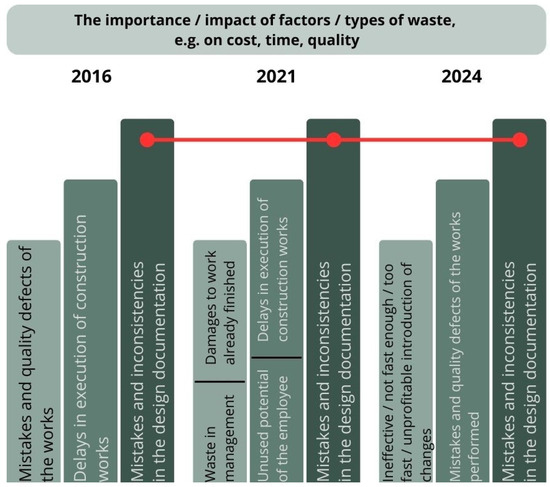

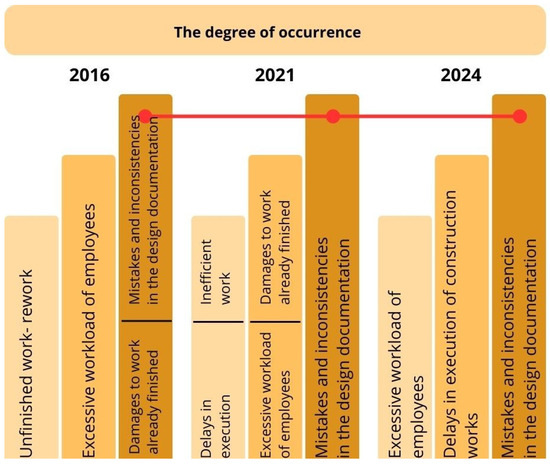

3.2.10. The Most Important and Common Waste Factors

Table 4 and Table 5 and Figure 9 and Figure 10 delineate the waste factors rated highest in terms of both occurrence and impact. From the survey findings conducted in 2016, 2021, and 2024, the most impactful and frequently occurring waste factor was identified as mistakes and inconsistencies in the design documentation. The findings underscore the repetitive nature of certain waste factors, highlighting the importance of delays in the execution of construction works, mistakes and quality defects of the works performed, influencing project costs and timelines through penalties for missed deadlines and corrective work costs, and also non-compliance with the intended use, and waste in management. In addition, design errors, construction delays, employee overwork, and damage to completed works were identified as particularly common.

Table 4.

Top-ranked waste factors by importance on construction sites in 2016, 2021, and 2024.

Table 5.

Most frequently occurring waste factors on construction sites in 2016, 2021, and 2024.

Figure 9.

Top waste factors ranked by importance in 2016, 2021, and 2024.

Figure 10.

Most frequently occurring waste factors in 2016, 2021, and 2024.

For enhanced clarity, Table 6 summarises the most significant and frequent waste factors at the construction site, based on surveys from 2016, 2021, and 2024. Mistakes and inconsistencies in the design documentation, delays in execution of construction works, mistakes and quality defects of the works performed, and non-compliance with the intended use emerged as the predominant waste factors, alongside design mistakes, damages to work already finished, excessive workload of employees as the most commonly encountered issues. Design mistakes, as the most significant and frequent waste factor, may result from the slow adoption of modern technologies that facilitate cross-disciplinary coordination and the early detection of design errors. This is particularly concerning, given that the construction sector remains the least digitised among all economic sectors [41].

Table 6.

Most important and frequent waste factors at construction sites. Based on surveys from 2016, 2021, and 2024.

Bajjou and Chafi’s literature review identified errors and inconsistencies in design documents as the most frequently mentioned waste factor, indicating a significant real-world challenge. Similarly, improper material handling was highlighted, which in our study ranked 4th in terms of importance and 7th in terms of frequency, reflecting a consistently high significance [5]. The researchers also conducted a survey in the construction industry, comprehensively examining waste in Morocco. Their respondents predominantly worked in small companies with fewer than 50 employees and had over 10 years of experience. In Moroccan context, respondents were asked about the occurrence of waste in construction projects, whereas our study focused on the frequency and importance of waste factors, considering their impact on cost, time, and quality of work. The most critical waste factors identified in their study were late payment and lack of training and raising awareness on social sustainability and environmental impacts for employees. In our study, late payment, both in the current results and in those from 2021 (as Bajjou and Chafi’s article was submitted in 2020), was not considered by respondents to be as significant and challenge compared to other waste factors. The second critical waste factor identified by these researchers was not included in our survey.

3.2.11. Summarising Section 3.2—Survey on Construction Site Waste

The section provided a comprehensive examination of construction waste sources based on surveys conducted in 2016, 2021, and 2024. The survey gathered responses predominantly from experienced professionals representing large construction firms, with the Design–Bid–Build (DBB) method prevailing across all periods.

Key findings highlight a persistent and growing prevalence of waste associated with design documentation errors—consistently rated as the most impactful and frequent factor. This underscores systemic deficiencies in design coordination and quality assurance, likely exacerbated by limited adoption of digital tools and early-stage integration mechanisms.

Across management, production, and resource-related dimensions, recurrent issues included damages to completed works, excessive employee workload, poor handling of materials, and inefficiencies in supervisory practices. These were compounded by external factors, notably, investor-related payment delays and ambiguities in project specifications, which disrupted project flow and decision-making.

Furthermore, novel waste factors were identified, including bid-stage miscalculations and structural overdesign, revealing a disconnect between planning assumptions and execution realities. Although some traditional forms of waste (e.g., overproduction, unnecessary transportation) were observed less frequently, their cumulative impact on project outcomes remains non-negligible.

Temporal variability analysis revealed an overall increase in both the occurrence and perceived importance of most waste factors in 2024, underscoring the urgency of implementing robust waste mitigation strategies. In conclusion, the findings indicate the need for improved design validation, proactive project management, enhanced communication with suppliers, and a greater emphasis on digitalisation to foster efficiency and sustainability within the construction sector. Notably, appropriate management of construction and demolition waste is also gaining importance in the light of new Polish regulations, which, from 2025, mandate selective waste collection and further treatment, aligning national practices with EU legislative directives.

3.3. Recommended Methods from the Literature for Reducing Waste

3.3.1. Lean Construction

The cornerstone of managing a construction project through Lean Construction (LC) is the reduction in waste and the maximisation of added value [1]. An example of waste elimination using Lean Construction is a case study described by Nowotarski et al. [42]. They used one of the Lean Principles tools, which allowed for the reduction in waste, improvement in communication among stakeholders, and the hiring of additional personnel to increase work efficiency. Karatas and Budak demonstrated in their study that the application of Lean Principles has the potential to effectively minimise wastes associated with waiting, overprocessing, and overproduction [17]. Berawi et al. shortened project timelines by starting with the identification of Non-Value-Adding (NVA) activities, such as unnecessary processes, transport, waiting, inappropriate inventory management, etc. [23]. Leite et al. identified wastes and then proposed their reduction using Value Stream Mapping (VSM) to study information flow [43]. Challenges associated with implementation, such as a lack of knowledge, can be mitigated though prior training [23]. The use of checklists aligns with Lean Principles, fosters collaboration among stakeholders, and may further facilitate successful implementation [43].

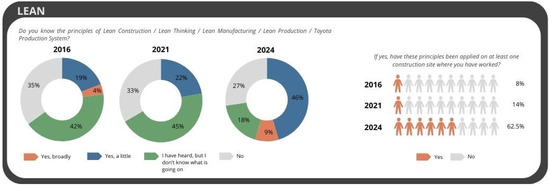

Given the potential benefits of Lean Construction, a key question arises: have the respondents heard of Lean Construction or Lean Manufacturing/Lean Production and the Toyota Production System from which it originates [9,21]? Furthermore, have they implemented construction projects using LC principles? The responses to this question are illustrated in Figure 11.

Figure 11.

Respondents’ knowledge of Lean Principles.

It was found that the number of respondents unaware of Lean Principles, or the Toyota Production System (TPS), has been decreasing year by year. In 2024, 27% of respondents declared a lack of knowledge about Lean and TPS. Interestingly, there was a significant increase in the percentage of respondents implementing Lean/TPS principles in at least one construction project. In 2016, 8% of respondents declared such implementations; in 2024, the figure rose to 63%. This leads to another question: are there more effective methods?

3.3.2. Building Information Modelling

The literature also presents numerous benefits of Building Information Modelling (BIM) implementation, as well as associated challenges. BIM should be understood as a comprehensive process of creating and managing building data throughout the entire lifecycle of a construction project [44]. Eze et al. by identifying wastes such as design mistakes, excessive use of materials, inefficient management, and unnecessary energy consumption, BIM application allows for their reduction through more precise planning, optimising material use, reducing the risk of construction errors through better management, facilitating communication among stakeholders, and optimising energy efficiency [45]. Karatas and Budak observed that the functionalities offered by BIM can contribute to a reduction in unnecessary transportation waste through the use of advanced technologies. Furthermore, they highlighted that the combined implementation of Lean Principles and BIM can efficiently mitigate inventory-related waste and the production of defective work.

The benefits of BIM implementation include the reduction in design errors through the use of BIM 5D, which incorporates cost and time analysis [46], and the application of the scan-to-BIM [47]. A significant reduction in design errors has been demonstrated through the use of an OpenBIM-enabled collaborative design framework [48]; various applications in railway infrastructure have been applied [24]. Koo et al. have shown how to enhance document quality and reduce defects with BIM [49]. Other researchers have highlighted improvements in project delivery times [48,50,51,52,53] and enhanced quality [54,55]. It follows that the application of the BIM methodology helps to reduce the waste factors identified as the most frequent and impactful at the construction site (Figure 6). BIM also brings additional benefits, including better communication among stakeholders [46], more effective construction management, and reduced waste related to steering at the construction site [51].

When implementing BIM, it is essential to anticipate challenges associated with the introduction of digital enhancements, such as resistance to change, lack of knowledge, high initial costs, and technological difficulties, particularly for small firms [56,57]. In Poland, BIM is still in the implementation phase, although its adoption is steadily increasing year by year [58]. In Europe, according to a 2024 study, 35% of countries are either implementing or planning for BIM to be mandated; however, requirements or incentives for its implementation are also gradually increasing over time [59].

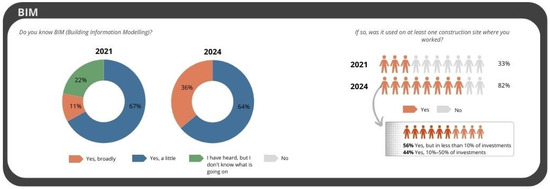

Upon examining the survey results from 2016, the authors began to consider the implementation of BIM to streamline the construction process and reduce waste. Subsequent inquiries sought to determine whether BIM had been applied. The results are depicted in Figure 12.

Figure 12.

Respondents’ knowledge of BIM.

Survey research made it evident that all respondents, to varying extents, had heard of Building Information Modelling. In 2021, 22% of respondents were aware of BIM but lacked a comprehensive understanding of its implications. By 2024, this lack of understanding had completely dissipated, with an increased proportion of respondents (36%) demonstrating a deeper familiarity with BIM. The percentage of respondents utilising BIM on least one project escalated from 33% in 2021 to 82% (56% of them were used in less than 10% of investments and 44% in 10–50% of investments) in 2024, indicating a growing awareness of BIM among construction contractors. Caution is advised when interpreting these findings, given the significant disparities in BIM implementation maturity. If a project is fully conducted within the BIM methodology, the scale of benefits derived from BIM adoption is undoubtedly greater. Respondents who indicated the use of BIM in their projects might have only applied a single tool. This presents a promising direction for verification in the future.

3.3.3. Summarising Section 3.3—Solutions for Waste Reduction

Section 3.3 examines two leading approaches to waste reduction in construction: Lean Construction (LC) and Building Information Modelling (BIM). Both methods are well-documented in the literature and increasingly recognised for their effectiveness in enhancing construction efficiency.

Lean Construction focuses on eliminating non-value-adding activities and improving workflow reliability. Studies demonstrate its capacity to reduce waste factors such as waiting, overprocessing, and overproduction. Tools like Value Stream Mapping and checklists, combined with stakeholder collaboration and training, are identified as supportive mechanisms. Survey findings reflect a growing familiarity with, and use of, Lean Principles among practitioners, with implementation increasing from 8% in 2016 to 63% in 2024.

Building Information Modelling is presented as a comprehensive process of managing building data throughout the project lifecycle. The literature highlights BIM’s effectiveness in reducing design errors, material inefficiencies, communication issues, and energy waste. It allows for the integration of time, cost, and environmental data into planning and decision making. Nevertheless, challenges, such as high initial costs, limited technical knowledge, and barriers for SMEs, are noted. In Poland, while BIM remains in the implementation phase, survey results indicate a marked increase in its use—from 33% in 2021 to 82% in 2024.

This section established both Lean Construction and BIM as conceptually and practically grounded methodologies for mitigating diverse types of waste at the construction site.

3.4. Recommended Solution to Reduce Waste

Building Information Modelling (BIM) is recommended by the authors as a key corrective approach to address waste construction sites, aligning with the most significant waste factors identifies in the survey study. The adoption of BIM offers the potential to reduce the occurrence of design errors, execution delays, material wastage, and poor management practices, which were recognised as critical factors impacting the cost, time, and quality of construction works.

The comprehensive application of BIM, where all project documentation is generated and coordinated based on integrated BIM models, facilitates more effective management of building data throughout the entire lifecycle of projects. Various BIM dimensions reflect the scope of information that can be incorporated, for example BIM 4D integrates scheduling and simulates construction sequences, while BIM 7D supports facility management and maintenance. The extent of digital maturity is additionally reflected in BIM levels, where, for instance, Level 1 refers to managing CAD in 2D/3D model formats, and the highest, Level 3, corresponds to integrated, interdisciplinary, parameterised models (iBIM) [60].

Nonetheless, BIM implementation faces challenges such as resistance to change, insufficient specialised knowledge, high initial costs, and technological barriers, particularly for SMEs. Nevertheless, a progressive implementation trend is evident, with various countries introducing or enforcing requirements and incentives to support its adoption.

Given the nature of the identified waste, BIM presents an effective methodology with which to address and mitigate these inefficiencies. Its application not only fosters better communication among stakeholders, inter-disciplinary coordination, more detailed drawings, but can also support sustainable construction practices, ultimately leading to more efficient, timely, and cost-effective project deliveries. Therefore, a comprehensive, cross-disciplinary implementation of BIM is recommended as a strategic solution for optimising construction project outcomes through waste reduction.

4. Conclusions

This study was initiated to optimise construction efficiency by identifying contemporary sources of waste on construction sites, conducting a comparative analysis with data from 2016, 2021, and 2024, and recommending remedial solutions. It responds to the existing research gap, where current studies on construction projects predominantly focus on waste treatment, and rarely adopt a comprehensive approach that includes waste arising from management, steering, stakeholder collaboration, and external factors. This research addresses the need for waste prevention, long-term monitoring, and alignment with sustainable development principles.

By employing a combination of literature reviews and surveys among construction work contractors, the research meticulously analyses the collected data to propose solutions aimed at reducing or eliminating waste. Surveyed participants evaluated 34 waste factors in terms of frequency and significance—particularly regarding their impact on cost, time, and quality. These variables, derived from prior studies in the literature, allowed for a verification of their continued relevance and an identification of newly emerging waste factors. Additionally, in alignment with the Directive of the European Parliament requiring Member States to establish selective sorting systems for construction and demolition waste, new Polish regulations introduced legal obligations for the proper segregation and management of such waste from 2025 onwards, further reinforcing the need for systematic handling practices in the construction sector.

Based on both quantitative and qualitative analyses, and supported by studies in the literature, we recommend the implementation of Building Information Modelling (BIM) as an effective method to optimise construction efficiency by reducing waste—especially in relation to documentation errors and execution delays. BIM also enhances project quality, improves adherence to schedules, and contributes to the sustainability of construction projects. The analysis also confirmed an increased awareness and adoption of BIM and Lean Principles, with BIM implementation rising from 8% in 2016 to 63% in 2024. Although this growth indicates greater recognition of BIM’s value, its application still remains limited.

The study revealed that the predominant wastes identified included mistakes and inconsistencies in the design documentation, execution delays, and quality defects in the work performed. Errors and inconsistencies in design documentation are also frequently cited in the literature, highlighting an ongoing challenge within the AEC sector and slow adoption of modern technologies that facilitate cross-disciplinary coordination and early detection of changes. Additionally, design mistakes, damages to work already finished, and the excessive workloads of employees were among the most commonly encountered issues. These findings underscore the enduring inefficiencies faced by the construction sector and highlight the need for strategic solutions to optimise project performance by reducing these inefficiencies.

The findings provide valuable guidance for improving construction processes through waste reduction, offering significant insights for researchers and practitioners. By identifying and addressing the most pressing issues, the study contributes to promoting more efficient, cost-effective, and high-quality construction practices aligned with sustainable goals.

Future research directions could involve the most significant and frequent waste factors identified in this survey, further contributing to the global agenda of sustainable and efficient building practices.

Author Contributions

E.M.-K.: Conceptualization; Data curation; Formal analysis; Investigation; Methodology; Project administration; Resources; Software; Validation; Visualization; Roles/Writing—original draft. K.Z.: Writing—review and editing; Supervision. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

The study protocol was approved by the Senate Ethics Committee of the Cracow University of Technology (SKE.0003.2.2024, 7 November 2024).

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

Data provided upon request.

Acknowledgments

The authors sincerely thank all respondents for taking the time to complete our comprehensive survey.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Koskela, L. Application of the New Production Philosophy to Construction; Stanford University: Stanford, CA, USA, 1992. [Google Scholar]

- Ogundipe, O.B.; Okwandu, A.C.; Abdulwaheed, S.A. Optimizing construction supply chains through AI: Streamlining material procurement and logistics for project success. GSC Adv. Res. Rev. 2024, 20, 147–158. [Google Scholar] [CrossRef]

- Liu, J.; Yi, Y.; Wang, X. Exploring factors influencing construction waste reduction: A structural equation modeling approach. J. Clean. Prod. 2020, 276, 123185. [Google Scholar] [CrossRef]

- Carvalho, A.B.; Maués, L.M.F.; Moreira Fde, S.; Reis, C.J.L. Study on the factors of delay in construction works. Ambiente Construído 2021, 21, 27–46. [Google Scholar] [CrossRef]

- Bajjou, M.S.; Chafi, A. Exploring the critical waste factors affecting construction projects. Eng. Constr. Archit. Manag. 2022, 29, 2268–2299. [Google Scholar] [CrossRef]

- Luxiang, W.; Zhende, Z.; Xinghua, X.; Junyu, W. Research trends in the treatment and recycling of construction and demolition waste based on literature data-driven visualization. J. Environ. Manag. 2024, 371, 123018. [Google Scholar]

- Asdrubali, F.; Fronzetti Colladon, A.; Segneri, L.; Gandola, D.M. LCA and energy efficiency in buildings: Mapping more than twenty years of research. Energy Build 2024, 321, 114684. [Google Scholar] [CrossRef]

- Ohno, T. Toyota Production System; Beyond Large-Scale Production; Productivity Press: New York, NY, USA, 1988. [Google Scholar]

- Womack, J.P.; Jones, D.T.; Roos, D. The Machine That Changed the World; Macmillan: New York, NY, USA, 1990. [Google Scholar]

- Daoud, A.O.; Omar, H.; Othman, A.A.E.; Ebohon, O.J. Integrated Framework Towards Construction Waste Reduction: The Case of Egypt. Int. J. Civ. Eng. 2023, 21, 695–709. [Google Scholar] [CrossRef]

- Waqar, A.; Othman, I.; Saad, N.; Azab, M.; Khan, A.M. BIM in green building: Enhancing sustainability in the small construction project. Clean. Environ. Syst. 2023, 11, 100149. [Google Scholar] [CrossRef]

- Borkowski, A.S. Propedeutyka BIM—Filozofia Modelowania Informacji o Obiekcie Budowlanym, 1st ed.; Oficyna Wydawnicza Politechniki Warszawskiej: Warsaw, Poland, 2024. [Google Scholar]

- Barth, L.; Schweiger, L.; Benedech, R.; Ehrat, M. From data to value in smart waste management: Optimizing solid waste collection with a digital twin-based decision support system. Decis. Anal. J. 2023, 9, 100347. [Google Scholar] [CrossRef]

- Hasselsteen, L.; Lindhard, S.M.; Kanafani, K. Resource management at modern construction sites: Bridging the gap between scientific knowledge and industry practice and needs. J. Environ. Manag. 2024, 366, 121835. [Google Scholar] [CrossRef]

- Ismail, N.A.A.; Hasbullah, I.S.; Mohamed, M.A.; Marhani, M.A.; Rooshdi, R.R.R.M.; Sahamir, S.R.; Golizadeh, H. Lean-BIM Collaborative Approach for Sustainable Construction Projects in Malaysia. J. Adv. Res. Appl. Sci. Eng. Technol. 2023, 33, 356–366. [Google Scholar] [CrossRef]

- Hadi, A.; Cheung, F.; Adjei, S.; Dulaimi, A. Evaluation of Lean Off-Site Construction Literature through the Lens of Industry 4.0 and 5.0. J. Constr. Eng. Manag. 2023, 149, 03123007. [Google Scholar] [CrossRef]

- Karatas, I.; Budak, A. Influence on construction waste of the lean–building information modelling interaction. Proc. Inst. Civ. Eng.–Eng. Sustain. 2023, 177, 242–255. [Google Scholar] [CrossRef]

- Lam, E.W.M.; Chan, A.P.C.; Olawumi, T.O.; Wong, I.; Kazeem, K.O. Facilitators and benefits of implementing lean premise design: A case of Hong Kong high-rise buildings. J. Build. Eng. 2023, 80, 108013. [Google Scholar] [CrossRef]

- Bang, S.; Andersen, B. Utilising Artificial Intelligence in Construction Site Waste Reduction. J. Eng. Proj. Prod. Manag. 2022, 12, 239–249. [Google Scholar] [CrossRef]

- European Commission, Directorate-General for Research and Innovation. Industry 5.0, a Transformative Vision for Europe—Governing Systemic Transformations Towards a Sustainable Industry; European Commission, Directorate-General for Research and Innovation: Brussels, Belgium, 2021.

- Horman, M.J.; Kenley, R. Quantifying Levels of Wasted Time in Construction with Meta-Analysis. J. Constr. Eng. Manag. 2005, 131, 52–61. [Google Scholar] [CrossRef]

- Sixpoints Interankiety. Available online: https://www.interankiety.pl/ (accessed on 2 January 2025).

- Berawi, M.A.; Sari, M.; Miraj, P.; Mardiansyah, M.; Saroji, G.; Susantono, B. Lean Construction Practice on Toll Road Project Improvement: A Case Study in Developing Country. Civ. Eng. J. 2023, 9, 3186–3201. [Google Scholar] [CrossRef]

- Shin, M.-H.; Kim, H.-Y.; Liao, J.-F. Performance Measurement and Analysis of Building Information Modeling (BIM) Applications in the Railway Infrastructure Construction Phase. Appl. Sci. 2024, 14, 502. [Google Scholar] [CrossRef]

- Shingo, S. A Study of the Toyota Production System; Productivity Press: New York, NY, USA, 2005. [Google Scholar]

- Serpell, A.; Venturi, A.; Contreras, J. Characterization of Waste in Building Construction Projects. In Proceedings of the 3rd Annual Conference International Group for Lean Construction, Albuquerque, NM, USA, 1995. [Google Scholar]

- Alarcón, L.F. Tools for the identification and reduction of waste in construction projects. In Lean Construction; A.A. Balkema: Rotterdam, The Netherlands, 1997; pp. 365–378. [Google Scholar]

- Formoso, C.; Isatto, E.; Hirota, E. Method for Waste Control in the Building Industry. In Proceedings of the IGLC-7, Berkeley, CA, USA, 26–28 July 1999; pp. 325–334. [Google Scholar]

- Birek, S.; Jaśkowski, P.; Sobotka, A. Zarządzanie W Budownictwie; Wydawnictwo Politechniki Lubelskiej: Lublin, Poland, 2003. [Google Scholar]

- Koskela, L. Making-Do—The Eighth Category of Waste. In Proceedings of the 12th Conference of the International Group for Lean Construction, Helsingør, Denmark, 3–5 August 2004. [Google Scholar]

- Patton, J. Task Diminishment: Construction value loss through sub-optimal task execution. In Proceedings of the IAJC-IJME 2008 Conference, Nashville, TN, USA, 17–19 November 2008; Volume 10. [Google Scholar]

- Leśniak, A. Przyczyny opóźnień budowy w opiniach wykonawców. Czas. Tech. Bud. 2012, 109, 57–68. [Google Scholar]

- Bølviken, T.; Rooke, J.; Koskela, L. The wastes of production in construction—A TRV based taxonomy. In Proceedings of the IGLC22, Oslo, Norway, 25–27 June 2014. [Google Scholar]

- Czaczkowski, W. The implementation of the Kaizen philosophy to quality management in construction enterprise. In Philosophy and Practice of Subjectivity; Zakład Filozofii SGGW Warszawa: Warsaw, Poland, 2014; pp. 144–157. [Google Scholar]

- Ankomah, E.; Baiden, B.; Ofori-Kuragu, J. Lean Techniques Approaches to Managing Ghanaian Contractor Supply Chains. Int. J. Constr. Eng. Manag. 2015, 4, 87–94. [Google Scholar]

- Fireman, M.C.T.; Formoso, C.T.; Isatto, E.L. Integrating production and quality control: Monitoring making-do and unfinished work. In Proceedings of the 21th Annual Conference of the International Group for Lean Construction, Fortaleza, Brazil, 29 July –2 August 2013. [Google Scholar]

- Act of 21 November 2024 Amending the Waste Act and the Act Amending the Waste Act and Certain other Acts; Journal of Laws: Warsaw, Poland, 2024.

- Act of 14 December 2012 on Waste, as Amended; Journal of Laws: Warsaw, Poland, 2013.

- Directive (EU) 2018/851 of the European Parliament and of the Council of 30 May 2018 Amending Directive 2008/98/EC on Waste (Text with EEA Relevance); Official Journal of the European Union: Belgium, Brussels, 2018.

- Zima, K.; Mitera-Kiełbasa, E. Level of Information Need for BIM Models: Australia, New Zealand and ISO 19650. Civ. Environ. Eng. Rep. 2022, 32, 1–3. [Google Scholar] [CrossRef]

- European Commission. Digitalisation in the Construction Sector; European Commission: Belgium, Brussels, 2021.

- Nowotarski, P.; Paslawski, J.; Skwarek, J. Waste Reduction by Lean Construction—Office Building Case Study. IOP. Conf. Ser. Mater. Sci. Eng. 2019, 603, 042061. [Google Scholar] [CrossRef]

- Leite, K.P.; Neto Jde, P.B. Value Stream in Housing Design. In Proceedings of the 21th Annual Conference of the International Group for Lean Construction IGLC, Fortaleza, Brazil, 29 July–2 August 2013; pp. 419–428. [Google Scholar]

- Szóstak, M. Requirements of Ordering Procurers regarding the use of BIM technology in public procurement. Przegląd Bud. 2023, 94, 43–47. [Google Scholar] [CrossRef]

- Eze, E.C.; Aghimien, D.O.; Aigbavboa, C.O.; Sofolahan, O. Building information modelling adoption for construction waste reduction in the construction industry of a developing country. Eng. Constr. Archit. Manag. 2022, 31, 2205–2223. [Google Scholar] [CrossRef]

- Pakhale, P.D.; Pal, A. Digital project management in infrastructure project: A case study of Nagpur Metro Rail Project. Asian J. Civ. Eng. 2020, 21, 639–647. [Google Scholar] [CrossRef]

- Lee, J.H.; Park, J.J.; Yoon, H. Automatic Bridge Design Parameter Extraction for Scan-to-BIM. Appl. Sci. 2020, 10, 7346. [Google Scholar] [CrossRef]

- Jin, M.; Li, B. Dual-Level Framework for OpenBIM-Enabled Design Collaboration. Buildings 2023, 13, 3031. [Google Scholar] [CrossRef]

- Koo, H.J.; O’Connor, J.T. A Strategy for Building Design Quality Improvement through BIM Capability Analysis. J. Constr. Eng. Manag. 2022, 148, 04022066. [Google Scholar] [CrossRef]

- Doukari, O.; Seck, B.; Greenwood, D. The efficient generation of 4D BIM construction schedules: A case study of the Nanterre 2 CESI project in France. Front. Built Environ. 2022, 8, 998309. [Google Scholar] [CrossRef]

- Alnaser, A.A.; Alsanabani, N.M.; Al-Gahtani, K.S. BIM Impact on Construction Project Time Using System Dynamics in Saudi Arabia’s Construction. Buildings 2023, 13, 2267. [Google Scholar] [CrossRef]

- Almusaiabi, H.; Naimi, S. Total Quality Management’s Critical Role in Resolving Delay Issue of Construction Projects Submission. Math. Model. Eng. Probl. 2023, 10, 1419–1426. [Google Scholar] [CrossRef]

- Singh, A.K.; Krishnaraj, L.; Kumar, V.R.P. Design and Energy Analysis of Green Villa Compared with Conventional Villa Using Virtual Design Modelling. In Sustainable Construction Materials; Springer: Singapore, 2022; pp. 257–268. [Google Scholar]

- Choi, J.; Lee, S.; Kim, I. Development of Quality Control Requirements for Improving the Quality of Architectural Design Based on BIM. Appl. Sci. 2020, 10, 7074. [Google Scholar] [CrossRef]

- Li, Y.; Wu, Y.; Gao, X. Measures for the optimization and management of construction safety based on BIM technology. IOP Conf. Ser. Earth. Environ. Sci. 2020, 552, 012018. [Google Scholar] [CrossRef]

- Biswas, H.K.; Sim, T.Y.; Lau, S.L. Impact of Building Information Modelling and Advanced Technologies in the AEC Industry: A Contemporary Review and Future Directions. J. Build. Eng. 2024, 82, 108165. [Google Scholar] [CrossRef]

- Salleh, H.; Ahmad, A.A.; Abdul-Samad, Z.; Alaloul, W.S.; Ismail, A.S. BIM Application in Construction Projects: Quantifying Intangible Benefits. Buildings 2023, 13, 1469. [Google Scholar] [CrossRef]

- Zima, K.; Mitera-Kiełbasa, E. ICT in the AEC industry in Poland. Inżynieria I Budownictwo 2024, 80, 83–87. [Google Scholar] [CrossRef]

- Mitera-Kiełbasa, E.; Zima, K. BIM Policy Trends in Europe: Insights from a Multi-Stage Analysis. Appl. Sci. 2024, 14, 4363. [Google Scholar] [CrossRef]

- Department for Business, Innovation and Skills. A Report for the Government Construction Client Group. Building Information Modelling (BIM) Working Party Strategy Paper; Department for Business, Innovation and Skills: London, UK, 2011.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).