Development of a Classification Model for Value-Added and Non-Value-Added Operations in Retail Logistics: Insights from a Supermarket Case Study

Abstract

1. Introduction

2. Literature Review

2.1. Lean Concepts and Its Types of Wastes

- Transportation (Transport): transporting materials, parts, or finished products into or out of a warehouse or between processes;

- Inventory: materials on hold, whether raw materials, work in progress, or finished products, cause delivery times to increase, obsolescence, damaged goods, and transportation and storage costs. In addition, extra inventory hides problems such as production losses, delays in supplier deliveries, defects, and equipment breakdowns.

- Movement: any wasted movement that a worker must perform during their working day. Workers must carry out during their working day, and walking to a piece of equipment, looking for something, or stacking parts, tools, etc., is waste.

- Waiting: workers serving only to watch a machine, waiting for the next step in a process, a tool, a supplier, etc., or simply not doing any work at all because of a lack of process delays, equipment breakdowns, or bottlenecks.

- Overproduction: producing more than is required by the next process, to produce a product before the required time, or to produce at a faster rate than necessary. This leads to overstaffing and storage and transportation costs due to inventorying because of excess stock.

- Incorrect or unnecessary processing (overprocessing): taking unnecessary steps to process parts. This includes inefficient processing due to poor tooling design, which causes unnecessary movement and producing defects. This waste is also generated when products are supplied with a higher quality than necessary.

- Defect: producing defective parts. Correction, repairing, reworking, scrapping, replacement production, and inspection mean wasted handling, time, and effort.

2.2. Lean Logistics and Its Types of Wastes

2.3. Lean Retail and Its Types of Waste

3. Methodology

- The definition of value in the context of supermarket internal logistics. In this step, the criteria are defined to establish the frontier between value and waste;

- Classification of the types of waste, aligned with the criteria defined in the previous step. Other existing classifications of waste were used as a reference, but a new and more suitable classification is created;

- Identification of all of the activities/tasks carried out by workers in the internal logistics of the chosen supermarket;

- From all activities and tasks observed, as well as inventory, the research team identifies the ones that are adding value and assign to the other ones the corresponding type of waste;

- The research time also performs a multi-moment analysis to measure the percentage of time spent by workers on value-adding activities.

4. Case Study Application

4.1. Background

4.2. Value and Waste Definition

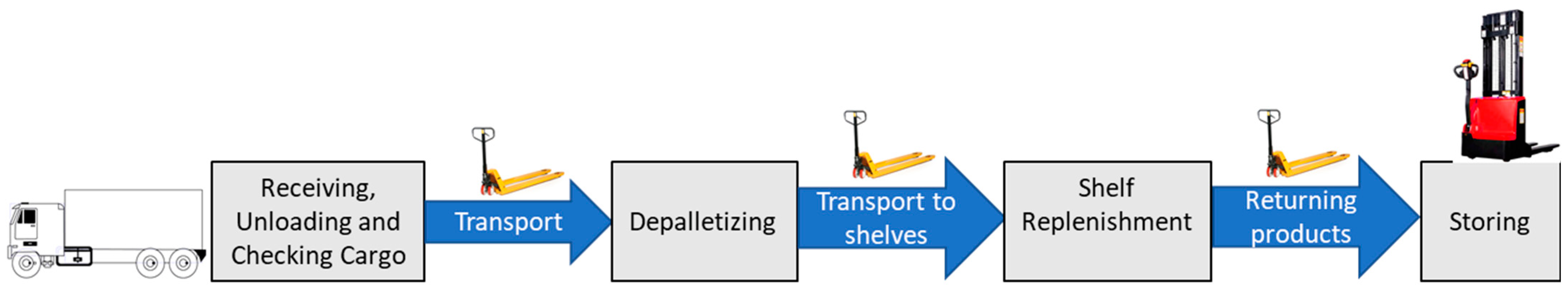

4.3. Process Analysis

5. Results

- Over-production (too many products);

- Over-processing (excessive transport);

- Motion;

- Inventory and stockouts;

- People waiting;

- Errors or defects.

- 10 value-adding activities were identified;

- 28 non-value-adding activities were identified.

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ohno, T. Toyota Production System: Beyond Large-Scale Production; Productivity, Inc.: New York, NY, USA, 1988. [Google Scholar]

- Womack, J.; Jones, D. Lean Thinking: Banish Waste and Create Wealth in Your Corporation; Fee Press: New York, NY, USA, 1996. [Google Scholar]

- Womack, J.; Jones, D.; Roos, D. The Machine that Changed the World; Free Press: New York, NY, USA, 1990. [Google Scholar]

- Lukic, R. The effects of application of lean concept in retail. Economia. Ser. Manag. 2012, 15, 88–98. [Google Scholar]

- Carreira, B. Lean Manufacturing That Works: Powerful Tools for Dramatically Reducing Waste and Maximizing Profits; Amacom: ‘s-Hertogenbosch, The Netherlands, 2004. [Google Scholar]

- Liker, J. Toyota Way: 14 Management Principles from the World’s Greatest Manufacturer; McGraw-Hill Education: New York, NY, USA, 2004. [Google Scholar]

- Klosova, D.; Kozlovská, M. Methods for identifying non-value-adding activities in construction processes. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1209, 012032. [Google Scholar] [CrossRef]

- Nassri, S.; Talebi, S.; Elghaish, F.; Koohestani, K.; McIlwaine, S.; Hosseini, M.R.; Poshdar, M.; Kagioglou, M. Labor waste in housing construction projects: An empirical study. Smart Sustain. Built Environ. 2023, 12, 325–340. [Google Scholar] [CrossRef]

- Park, S.H.; Kim, S. Connected and automated vehicle loading system for improving operational inefficiency from human driven vehicle in roll-on/roll-off port operations. Transp. Plan. Technol. 2024, 47, 258–283. [Google Scholar] [CrossRef]

- Shou, W.; Wang, J.; Wu, P.; Wang, X. Value adding and non-value adding activities in turnaround maintenance process: Classification, validation, and benefits. Prod. Plan. Control. 2020, 31, 60–77. [Google Scholar] [CrossRef]

- Jones, D.; Hines, P.; Rich, N. Lean Logistics. Int. J. Phys. Distrib. Logist. Manag. 1997, 27, 153–173. [Google Scholar] [CrossRef]

- Bauldin, M. Lean Logistics: The Nuts and Bolts of Delivering Materials and Goods; Productivity Press: New York, NY, USA, 2005. [Google Scholar]

- Elfving, J.A.; Ballard, G.; Talvitie, U. Standardizing logistics at the corporate level towards lean logistics in construction. In Challenging Lean Construction Thinking: What Do We Think and What Do We Know? Proceedings of the 18th Annual Conference of the International Group for Lean Construction, IGLC 18, Haifa, Israel, 14–16 July 2010; Technion: Haifa, Israel, 2010. [Google Scholar]

- Cooper, R.; Slagmulder, R. Supply Chain Development for the Lean Enterprise: Interorganizational Cost Management; Routledge: Oxford, UK, 2017. [Google Scholar] [CrossRef]

- Sutherland, J.; Bennett, B. The seven deadly wastes of logistics: Applying Toyota Production System principles to create logistics value. White Pap. 2007, 701, 40–50. [Google Scholar]

- Coimbra, E.A. Total Flow Management: Achieving Excellence with Kaizen and Lean Supply Chains; Howick, N.Z., Ed.; Kaizen Institute: Singapore, 2009. [Google Scholar]

- Adeodu, A.; Maladzhi, R.; Katumba, M.G.K.-K.; Daniyan, I. Development of an improvement framework for warehouse processes using lean six sigma (DMAIC) approach. A case of third party logistics (3PL) services. Heliyon 2023, 9, e14915. [Google Scholar] [CrossRef] [PubMed]

- Tansuchat, R.; Kaewsompong, N.; Panmanee, C.; Nimsai, S.; Rattanasamakarn, T. Applying a Value Stream Mapping (VSM) to improve supply chain performance of agricultural products: A case of Thai exported canned lychee. Int. J. Econ. Res. 2017, 14, 91–102. [Google Scholar]

- Kuaites, T. Application of value stream mapping for improving the efficiency of the supply chain: A case study of Mueang Kao Post Office, Thailand. Asia Pac. J. Sci. Technol. 2022, 27, 1–10. [Google Scholar]

- Sheu, C.; Lee, L.; Niehoff, B. A voluntary logistics security program and international supply chain partnership. Supply Chain. Manag. Int. J. 2006, 11, 363–374. [Google Scholar] [CrossRef]

- Myerson, P. Lean Supply Chain and Logistics Management; Establish Inc.: New York, NY, USA, 2012. [Google Scholar]

- Ugarte, G.M.; Golden, J.S.; Dooley, K.J. Lean versus green: The impact of lean logistics on greenhouse gas emissions in consumer goods supply chains. J. Purch. Supply Manag. 2016, 22, 98–109. [Google Scholar] [CrossRef]

- Cil, I.; Turkan, Y.S. An ANP-based assessment model for lean enterprise transformation. Int. J. Adv. Manuf. Technol. 2013, 64, 1113–1130. [Google Scholar] [CrossRef]

- Rajagopalan, S.; Kumar, K.R. Retail stocking decisions with order and stock sales. J. Oper. Manag. 1994, 11, 397–410. [Google Scholar] [CrossRef]

- Abernathy, F.H.; Dunlop, J.T.; Hammond, J.H.; Weil, D. A Stitch in Time: Lean Retailing and the Transformation of Manufacturing–Lessons from the Apparel and Textile Industries; Oxford University Press: Oxford, UK, 1999; Volume 121. [Google Scholar]

- Marques, P.A.; Jorge, D.; Reis, J. Using Lean to Improve Operational Performance in a Retail Store and E-Commerce Service: A Portuguese Case Study. Sustainability 2022, 14, 5913. [Google Scholar] [CrossRef]

- Jimenez, L.B.; Cuadros, C.C.; Aranibar, M.T.N. Systematic literature review of the application of lean methodologies in the retail sector. In Proceedings of the International Conference on Industrial Engineering and Operations Management, Singapore, 7–11 March 2021. [Google Scholar] [CrossRef]

- Bazán, R.S.E.; Ortiz, N.S.R.; De Pina, J.M.M. Lean Management Practices Applied in Retail Sector Businesses: A Systematic Review of Literature. In Proceedings of the 4th South American International Industrial Engineering and Operations Management Conference, Lima, Peru, 9–11 May 2023. [Google Scholar] [CrossRef]

- Qin, Y.; Liu, H. Application of Value Stream Mapping in E-Commerce: A Case Study on an Amazon Retailer. Sustainability 2022, 14, 713. [Google Scholar] [CrossRef]

| Traditional Lean | Lean Logistics | Lean Retail | Total Flow Management | Lean Retail Logistics |

|---|---|---|---|---|

| Transportation | Transportation or conveyance | - | Material Movement (too much transportation) | - |

| Inventory | Inventory | Inventory and Stockouts | Material waiting (too much inventory) | Inventory and Stockouts |

| Movement | Motion | Unnecessary Movement | People movement (too much motions) | Motion |

| Waiting | Delay or waiting | Waiting Time | People waiting | People Waiting |

| Overproduction | Overproduction | - | Over delivery (too much quantity) | Over-Production (Too many products) |

| Incorrect or unnecessary processing | - | Over-processing | Over processing (difficulties) | Over-Processing (Excessive Transport) |

| Defect | Errors | Defects | Errors and defects | Errors or defects |

| - | Space utilization | - | - | |

| - | - | Underutilized Employees | - |

| Macro-Process | Activity Description | VA/NVA | Proposed Waste Classification |

|---|---|---|---|

| Receiving, Unloading, and Checking Cargo | Receiving sheets with information on incoming cargo | NVA | Motion |

| Check pallet numbers, stamp, and sign reception sheets | NVA | Motion | |

| Place pallet holder inside the truck | NVA | Motion | |

| Transport pallets from truck to the warehouse | VA | ||

| Scan Pallet Support | NVA | Motion | |

| Transporting pallets to the depalletizing area | VA | ||

| Deliver reception sheet guides to the driver | NVA | Motion | |

| Single-product pallet storage | NVA | Inventory and Stockouts | |

| Depalletizing | Gemba walk to identify pre-ruptures and ruptures | NVA | Motion |

| Record found ruptures in the system | NVA | Inventory and Stockouts + Errors or defects | |

| Positioning empty pallets to create depalletized pallets | NVA | Motion | |

| Choose pallet to be depalletized | NVA | Motion | |

| Transporting pallet to the depalletizing area | VA | ||

| Positioning and adjusting pallet | NVA | Motion | |

| Identify VIP products on the pallet | NVA | Motion | |

| Remove products from the received pallet and position them on category-specific pallets. | VA | ||

| Product stored in the warehouse awaiting replenishment | NVA | Inventory and Stockouts | |

| Store products not needed for replenishment | NVA | Over-Production + Inventory and Stockouts |

| Macro-Process | Activity Description | VA/NVA | Proposed Waste Classification |

|---|---|---|---|

| Shelf Replenishment | Check Daily Work Log | NVA | Motion |

| Check status of the supermarket aisles | NVA | Motion | |

| Select depalletized pallets for transportation to the store | NVA | Motion | |

| Transport pallet to replenishment aisle | VA | ||

| Transfer items from pallet to the shelf (replenishment) | VA | ||

| Pull product from back to the front of the shelf | VA | ||

| Fill rupture holes with other products | NVA | Errors or defects; Motion | |

| Price updating | VA | ||

| Check the need for replenishment | NVA | Motion | |

| Search for the product needed for replenishment (warehouse search and movement) | NVA | Motion | |

| Transport replenishment product to the aisles | VA | ||

| Replenish product on the shelf | VA | ||

| Storing | Return surplus products to the warehouse | NVA | Over-Processing |

| Store surplus products | NVA | Over-Processing, Motion | |

| Identify product in pre-rupture and rupture | NVA | Motion | |

| Validate ruptures in the system | NVA | Motion + Errors or defects | |

| Save records of the day’s disruptions | NVA | Motion | |

| Search for the product needed for replenishment | NVA | Motion | |

| Adjust stock records | NVA | Motion + Inventory and Stockouts | |

| Place orders to supplier | NVA | Motion |

| Macro-Process | Number of Non-Value-Added Activities | Number of Value-Added Activities | Total Number of Activities in the Process |

|---|---|---|---|

| Receiving, Unloading and Checking Cargo | 6 | 2 | 8 |

| Depalletizing | 8 | 3 | 11 |

| Shelf Replenishment | 6 | 6 | 12 |

| Storing | 8 | 0 | 8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Macedo, H.; Tomaz, L.; Guimarães, L.; Cerqueira-Pinto, L.; Sá, J.C.; Dinis-Carvalho, J. Development of a Classification Model for Value-Added and Non-Value-Added Operations in Retail Logistics: Insights from a Supermarket Case Study. Sustainability 2025, 17, 3177. https://doi.org/10.3390/su17073177

Macedo H, Tomaz L, Guimarães L, Cerqueira-Pinto L, Sá JC, Dinis-Carvalho J. Development of a Classification Model for Value-Added and Non-Value-Added Operations in Retail Logistics: Insights from a Supermarket Case Study. Sustainability. 2025; 17(7):3177. https://doi.org/10.3390/su17073177

Chicago/Turabian StyleMacedo, Helena, Larissa Tomaz, Levi Guimarães, Luís Cerqueira-Pinto, José Carlos Sá, and José Dinis-Carvalho. 2025. "Development of a Classification Model for Value-Added and Non-Value-Added Operations in Retail Logistics: Insights from a Supermarket Case Study" Sustainability 17, no. 7: 3177. https://doi.org/10.3390/su17073177

APA StyleMacedo, H., Tomaz, L., Guimarães, L., Cerqueira-Pinto, L., Sá, J. C., & Dinis-Carvalho, J. (2025). Development of a Classification Model for Value-Added and Non-Value-Added Operations in Retail Logistics: Insights from a Supermarket Case Study. Sustainability, 17(7), 3177. https://doi.org/10.3390/su17073177