Carbon Assessment of Greek Organic Red Wine with Life Cycle Assessment and Planetary Boundaries

Abstract

1. Introduction

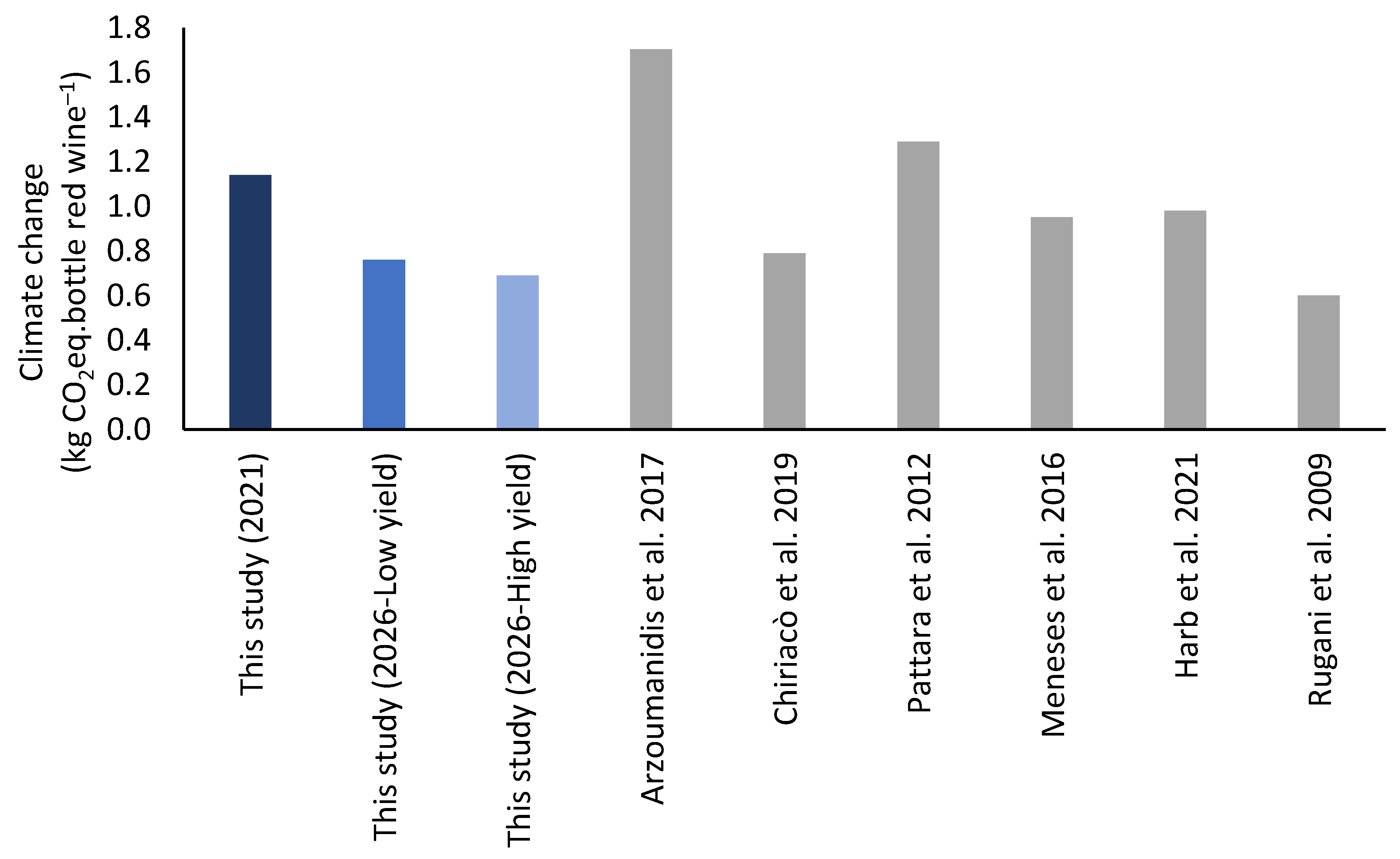

LCA Studies for Wine in the Mediterranean Region

2. Material and Methods

2.1. Case Study

2.2. Life Cycle Assessment

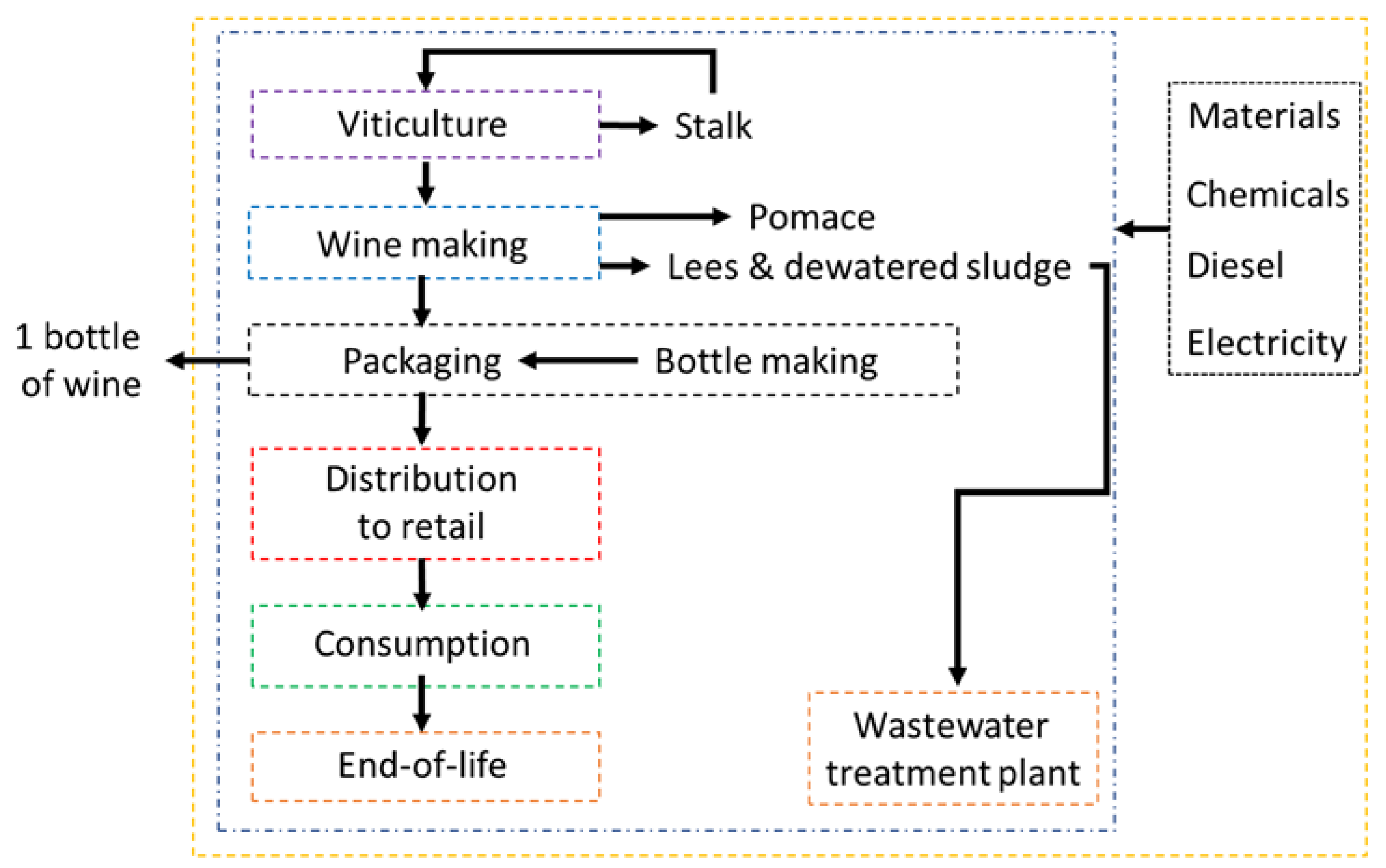

2.2.1. Goal and Scope Definition

2.2.2. Life Cycle Inventory

Viticulture

Winemaking

Packaging

Distribution to Retail

Consumption

End-of-Life

Assumptions

- Viticulture production reaches a steady state with respect to agricultural yield after five years. The vineyard yield was estimated according to the personal experience of the wine producer.

- Wine transportation occurs on a regional level upon consultation with the wine producer; therefore, an average transportation distance of 50 km was selected.

- Disposal of packaging materials was calculated according to what occurs in Greece [30].

Data Quality Requirements (DQR)

2.2.3. Life Cycle Impact Assessment

2.2.4. Perturbation Analysis

2.3. Planetary Boundaries

2.3.1. Downscaling Methods

2.3.2. Sensitivity Analysis

3. Results and Discussion

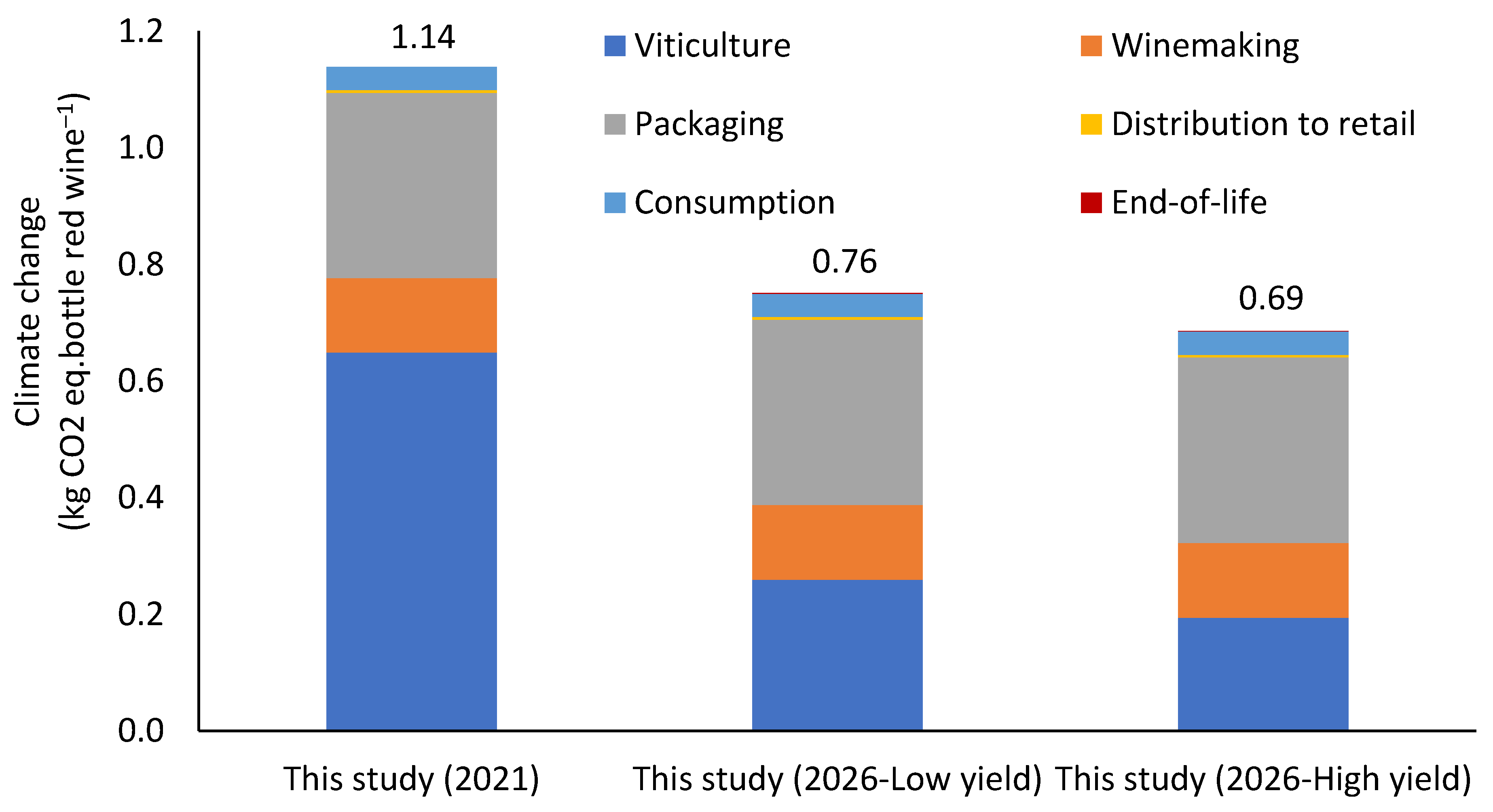

3.1. Life Cycle Assessment

Results of the Perturbation Analysis

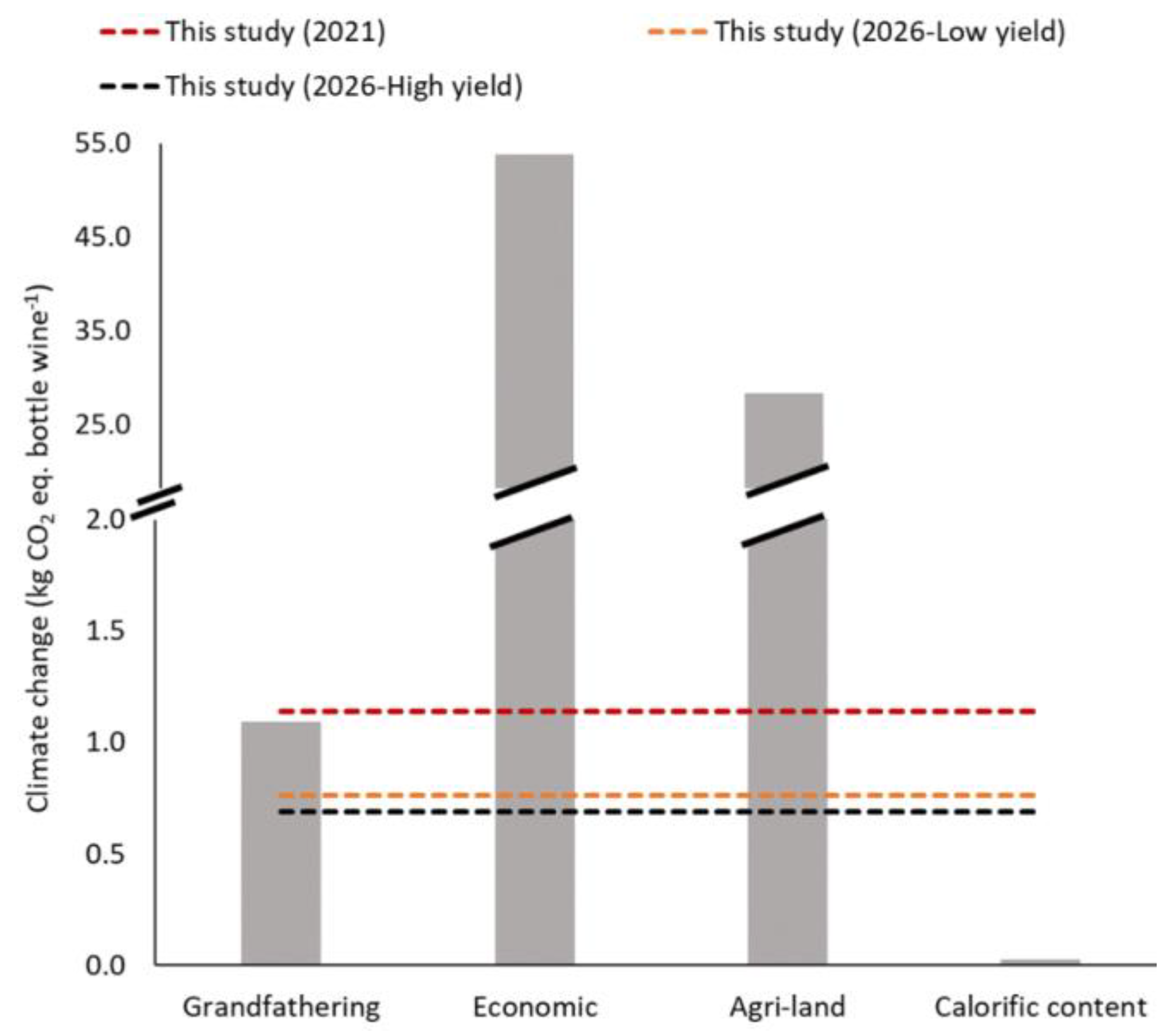

3.2. Planetary Boundaries

Effect of Increased Wine Production on the Safe Operating Space (SOS)

3.3. Data Quality

3.4. Technical Limitations

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Co-products of Winemaking Stage | Mass Allocation Factor (%) |

|---|---|

| Red wine | 84% |

| Pomace | 16% |

| TeR | GR | TiR | P | DQR Per Stage | |

|---|---|---|---|---|---|

| Viticulture (excluding CO2 sequestration) | 1 | 1 | 2 | 2 | 1.5 |

| CO2 sequestration | 2 | 3 | 4 | 3 | 3.0 |

| Wine making | 1 | 1 | 1 | 2 | 1.3 |

| Packaging (bottle making) | 2 | 2 | 5 | - | 2.3 |

| Distribution | 1 | 1 | 5 | - | 1.8 |

| Consumption | 1 | 1 | 5 | - | 1.8 |

| End-of-life | 2 | 1 | 5 | - | 2.0 |

| TeR | GR | TiR | P | DQR Per Stage | |

|---|---|---|---|---|---|

| Viticulture (excluding CO2 sequestration) | 2 | 1 | 1 | 2 | 1.5 |

| CO2 sequestration | 2 | 3 | 4 | 3 | 3.0 |

| Wine making | 1 | 1 | 1 | 2 | 1.3 |

| Packaging (bottle making) | 2 | 2 | 5 | - | 2.3 |

| Distribution | 1 | 1 | 5 | - | 1.8 |

| Consumption | 1 | 1 | 5 | - | 1.8 |

| End-of-life | 2 | 1 | 5 | - | 2.0 |

References

- ISO 14040:2006; Environmental Management—Life Cycle Assessment—Principles and Framework. International Organization for Standardization: Geneva, Switzerland, 2006.

- ISO 14044:2006; Environmental Management-Life Cycle Assessment-Requirements and Guidelines. International Organization for Standardization: Geneva, Switzerland, 2006.

- Rockström, J.; Steffen, W.; Noone, K.; Persson, Å.; Chapin, F.S.I.; Lambin, E.; Lenton, T.; Scheffer, M.; Folke, C.; Schellnhuber, H.J.; et al. Planetary Boundaries: Exploring the Safe Operating Space for Humanity. Ecol. Soc. 2009, 14, 32. [Google Scholar] [CrossRef]

- Rockström, J.; Steffen, W.; Noone, K.; Persson, Å.; Chapin, F.S.; Lambin, E.F.; Lenton, T.M.; Scheffer, M.; Folke, C.; Schellnhuber, H.J.; et al. A Safe Operating Space for Humanity. Nature 2009, 461, 472–475. [Google Scholar] [CrossRef]

- United Nations. Framework Convention on Climate Change (UNFCCC). In The Paris Agreement; United Nations: New York, NY, USA, 2016. [Google Scholar]

- Statistical Review of World Energy Greece: Carbon Dioxide Emissions 1970–2022. Available online: https://www.statista.com/statistics/449732/co2-emissions-greece/ (accessed on 21 August 2023).

- Faostat. The Share of Agri-Food Systems in Total Greenhouse Gas Emissions. In Global, Regional and Country Trends 1990–2019; Faostat Analytical Brief 31; FAOSTAT: Rome, Italy, 2019. [Google Scholar]

- Ministry of Environment and Energy. National Inventory Report (NIR); Ministry of Environment and Energy: Athens, Greece, 2021.

- OECD. OECD Environmental Performance Reviews: Greece 2020; OECD Environmental Performance Reviews; OECD: Paris France, 2020; ISBN 978-92-64-38735-5. [Google Scholar]

- European Commission. Farm to Fork Strategy—For a Fair, Healthy and Environmentally-Friendly Food System; COM/2020/381 Final; European Commission: Brussel, Belgium, 2020. [Google Scholar]

- European Commission. Product Environmental Footprint Category Rules (PEFCR) for Still and Sparkling Wine; European Commission: Brussel, Belgium, 2018. [Google Scholar]

- Weidema, B.P.; Thrane, M.; Christensen, P.; Schmidt, J.; Løkke, S. Carbon Footprint. J. Ind. Ecol. 2008, 12, 3–6. [Google Scholar] [CrossRef]

- Steffen, W.; Richardson, K.; Rockström, J.; Cornell, S.E.; Fetzer, I.; Bennett, E.M.; Biggs, R.; Carpenter, S.R.; de Vries, W.; de Wit, C.A.; et al. Planetary Boundaries: Guiding Human Development on a Changing Planet. Science 2015, 347, 1259855. [Google Scholar] [CrossRef] [PubMed]

- Bjørn, A.; Margni, M.; Roy, P.-O.; Bulle, C.; Hauschild, M.Z. A Proposal to Measure Absolute Environmental Sustainability in Life Cycle Assessment. Ecol. Indic. 2016, 63, 1–13. [Google Scholar] [CrossRef]

- Ryberg, M.W.; Owsianiak, M.; Clavreul, J.; Mueller, C.; Sim, S.; King, H.; Hauschild, M.Z. How to Bring Absolute Sustainability into Decision-Making: An Industry Case Study Using a Planetary Boundary-Based Methodology. Sci. Total Environ. 2018, 634, 1406–1416. [Google Scholar] [CrossRef]

- Chandrakumar, C.; McLaren, S.J.; Jayamaha, N.P.; Ramilan, T. Absolute Sustainability-Based Life Cycle Assessment (ASLCA): A Benchmarking Approach to Operate Agri-Food Systems within the 2 °C Global Carbon Budget. J. Ind. Ecol. 2019, 23, 906–917. [Google Scholar] [CrossRef]

- Bjorn, A.; Chandrakumar, C.; Boulay, A.-M.; Doka, G.; Fang, K.; Gondran, N.; Hauschild, M.Z.; Kerkhof, A.; King, H.; Margni, M.; et al. Review of Life-Cycle Based Methods for Absolute Environmental Sustainability Assessment and Their Applications. Environ. Res. Lett. 2020, 15, 083001. [Google Scholar] [CrossRef]

- Ghani, H.U.; Ryberg, M.; Bjørn, A.; Hauschild, M.Z.; Gheewala, S.H. Resource Efficiency Analysis through Planetary Boundary-Based Life Cycle Assessment: A Case Study of Sugarcane in Pakistan. Int. J. Life Cycle Assess. 2023, 28, 1561–1576. [Google Scholar] [CrossRef]

- United States Environmental Protection Agency. Climate Impacts on Agriculture and Food Supply. Available online: https://19january2017snapshot.epa.gov/climate-impacts/climate-impacts-agriculture-and-food-supply (accessed on 9 March 2022).

- Harb, W.; Zaydan, R.; Vieira, M. Improving Environmental Performance in Wine Production by Life Cycle Assessment: Case of Lebanese Wine. Int. J. Life Cycle Assess. 2021, 26, 1146–1159. [Google Scholar] [CrossRef]

- Arzoumanidis, I.; Salomone, R.; Petti, L.; Mondello, G.; Raggi, A. Is There a Simplified LCA Tool Suitable for the Agri-Food Industry? An Assessment of Selected Tools. J. Clean. Prod. 2017, 149, 406–425. [Google Scholar] [CrossRef]

- Chiriacò, M.V.; Belli, C.; Chiti, T.; Trotta, C.; Sabbatini, S. The Potential Carbon Neutrality of Sustainable Viticulture Showed through a Comprehensive Assessment of the Greenhouse Gas (GHG) Budget of Wine Production. J. Clean. Prod. 2019, 225, 435–450. [Google Scholar] [CrossRef]

- Pattara, C.; Raggi, A.; Cichelli, A. Life Cycle Assessment and Carbon Footprint in the Wine Supply-Chain. Environ. Manag. 2012, 49, 1247–1258. [Google Scholar] [CrossRef] [PubMed]

- Meneses, M.; Torres, C.M.; Castells, F. Sensitivity Analysis in a Life Cycle Assessment of an Aged Red Wine Production from Catalonia, Spain. Sci. Total Environ. 2016, 562, 571–579. [Google Scholar] [CrossRef] [PubMed]

- Rugani, B.; Niccolucci, V.; Pulselli, R.M.; Tiezzi, E. A Cradle-to-Gate Life Cycle Assessment Integrated with Emergy Evaluation: Sustainability Analysis of an Organic Wine Production. In Proceedings of the SETAC Europe 19th Annual Meeting, “Protecting Ecosystem Health: Facing the Challenge of a Globally Changing Environment”, Göteborg, Sweden, 31 May–4 June 2009; p. 274. [Google Scholar]

- Carbone, A.; Quici, L.; Pica, G. The Age Dynamics of Vineyards: Past Trends Affecting the Future. Wine Econ. Policy 2019, 8, 38–48. [Google Scholar] [CrossRef]

- Hatzisavva, K. (Hatzisavva Vineyards and Winery, Alexandoupolis, Greece). Personal Communication, 2021.

- Pre Consultants SimaPro Life Cycle Analysis, Version 7.2; Simapro: Gothenburg Sweden, 2018.

- Wernet, G.; Bauer, C.; Steubing, B.; Reinhard, J.; Moreno-Ruiz, E.; Weidema, B. The Ecoinvent Database Version 3 (Part I): Overview and Methodology. Int. J. Life Cycle Assess. 2016, 21, 1218–1230. [Google Scholar] [CrossRef]

- Eurostat Data Browser. Packaging Waste by Waste Management Operations; European Commission: Brussel, Belgium, 2019. [Google Scholar]

- Huijbregts, M.A.J.; Steinmann, Z.J.N.; Elshout, P.M.F.; Stam, G.; Verones, F.; Vieira, M.; Zijp, M.; Hollander, A.; van Zelm, R. ReCiPe2016: A Harmonised Life Cycle Impact Assessment Method at Midpoint and Endpoint Level. Int. J. Life Cycle Assess. 2017, 22, 138–147. [Google Scholar] [CrossRef]

- Clavreul, J.; Guyonnet, D.; Christensen, T.H. Quantifying Uncertainty in LCA-Modelling of Waste Management Systems. Waste Manag. 2012, 32, 2482–2495. [Google Scholar] [CrossRef]

- Fanning, A.L.; O’Neill, D.W. Tracking Resource Use Relative to Planetary Boundaries in a Steady-State Framework: A Case Study of Canada and Spain. Ecol. Indic. 2016, 69, 836–849. [Google Scholar] [CrossRef]

- Bjørn, A.; Hauschild, M.Z. Introducing Carrying Capacity-Based Normalisation in LCA: Framework and Development of References at Midpoint Level. Int. J. Life Cycle Assess. 2015, 20, 1005–1018. [Google Scholar] [CrossRef]

- CAIT. Agriculture Climate Change Data. Climate Watch. 2018. Available online: https://www.climatewatchdata.org/sectors/agriculture#drivers-of-emissions (accessed on 21 January 2025).

- Alcorn, J.A. Global Sustainability and the New Zealand House. Ph.D. Thesis, School of Architecture, Victoria University of Wellington, Wellington, New Zealand, 2010. [Google Scholar]

- Clift, R.; Wright, L. Relationships Between Environmental Impacts and Added Value Along the Supply Chain. Technol. Forecast. Soc. Change 2000, 65, 281–295. [Google Scholar] [CrossRef]

- Fragopoulou, E.; Choleva, M.; Antonopoulou, S.; Demopoulos, C.A. Wine and Its Metabolic Effects. A Comprehensive Review of Clinical Trials. Metabolism 2018, 83, 102–119. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Xue, T.; Gao, F.; Wei, R.; Wang, Z.; Li, H.; Wang, H. Carbon Storage Distribution Characteristics of Vineyard Ecosystems in Hongsibu, Ningxia. Plants 2021, 10, 1199. [Google Scholar] [CrossRef]

- Smart, R. Are Wineries Environmental Vandals? IWC. 2019. Available online: https://www.internationalwinechallenge.com/Canopy-Articles/are-wineries-environmental-vandals.html (accessed on 21 January 2025).

- The World Bank Group GDP (Current US$)—Greece. Available online: https://data.worldbank.org/indicator/NY.GDP.MKTP.CD?locations=GR (accessed on 6 December 2022).

- Statista Greece—Distribution of Gross Domestic Product (GDP) Across Economic Sectors. 2021. Available online: https://www.statista.com/statistics/276399/distribution-of-gross-domestic-product-gdp-across-economic-sectors-in-greece/ (accessed on 6 December 2022).

- Statista Wine—Greece|Statista Market Forecast. Available online: https://www.statista.com/outlook/cmo/alcoholic-drinks/wine/greece (accessed on 6 December 2022).

- Ritchie, H.; Roser, M. “Land Use” Published Online at OurWorldinData.org. 2019. Available online: https://ourworldindata.org/land-use (accessed on 21 January 2025).

- The World Bank Group Land Area (Sq. Km)—Greece|Data. Available online: https://data.worldbank.org/indicator/AG.LND.TOTL.K2?locations=GR (accessed on 6 December 2022).

- International Organisation of Vine and Wine. State of the World Vitivinicultural Sector in 2019; OIV: Dijon, France, 2020. [Google Scholar]

- Smith, P.; Haberl, H.; Popp, A.; Erb, K.; Lauk, C.; Harper, R.; Tubiello, F.N.; de Siqueira Pinto, A.; Jafari, M.; Sohi, S.; et al. How Much Land-Based Greenhouse Gas Mitigation Can Be Achieved without Compromising Food Security and Environmental Goals? Glob. Change Biol. 2013, 19, 2285–2302. [Google Scholar] [CrossRef]

- Roser, M.; Ritchie, H.; Rosado, P. Food Supply. Our World in Data. 2013. Available online: https://ourworldindata.org/food-supply?ref=lennartorlando.com (accessed on 21 January 2025).

- Gifford, C. How Many Calories Are There in a Bottle of Wine? Pull The Cork: London, UK, 2021; Available online: https://www.theallotment.ie/blogs/wine-blog/how-many-calories-are-there-in-a-bottle-of-wine#:~:text=A%20standard%20750%20ml%20bottle,as%20many%20as%201%2C500%20calories (accessed on 21 January 2025).

- Ruggieri, L.; Cadena, E.; Martínez-Blanco, J.; Gasol, C.M.; Rieradevall, J.; Gabarrell, X.; Gea, T.; Sort, X.; Sánchez, A. Recovery of Organic Wastes in the Spanish Wine Industry. Technical, Economic and Environmental Analyses of the Composting Process. J. Clean. Prod. 2009, 17, 830–838. [Google Scholar] [CrossRef]

- Sánchez, A.; Artola, A.; Font, X.; Gea, T.; Barrena, R.; Gabriel, D.; Sánchez-Monedero, M.Á.; Roig, A.; Cayuela, M.L.; Mondini, C. Greenhouse Gas Emissions from Organic Waste Composting. Environ. Chem. Lett. 2015, 13, 223–238. [Google Scholar] [CrossRef]

- Ritchie, H. Sector by Sector: Where Do Global Greenhouse Gas Emissions Come From? Available online: https://ourworldindata.org/ghg-emissions-by-sector (accessed on 5 February 2021).

- Rehberger, E.; West, P.C.; Spillane, C.; McKeown, P.C. What Climate and Environmental Benefits of Regenerative Agriculture Practices? An Evidence Review. Environ. Res. Commun. 2023, 5, 052001. [Google Scholar] [CrossRef]

| Study | Place | System Boundaries | Climate Change (in kg CO2 eq.) | Application of PEFCR |

|---|---|---|---|---|

| [21] | Italy | Cradle-to-grave | 1.70 | No |

| [22] | Italy | Cradle-to-grave | 0.79 | No |

| [23] | Italy | Cradle-to-grave | 1.29 | No |

| [24] | Spain | Cradle-to-grave | 0.95 | No |

| [25] | Italy | Cradle-to-gate | 0.60 | No |

| [20] | Lebanon | Cradle-to-grave | 0.98 | Yes |

| Input | Amount | Unit | Output | Amount | Unit |

|---|---|---|---|---|---|

| Viticulture | |||||

| Sulfur (powder) | 0.04 | kg | Harvested grapes | 1.06 | kg |

| Zeolite | 0.14 | kg | Stalk (waste) | 0.004 | kg |

| Organic compost | 0.002 | kg | |||

| Diesel | 1.01 | MJ | |||

| Winemaking | |||||

| Harvested grapes | 1.06 | kg | Red wine | 0.75 | L |

| Metabisulphite | 0.19 | g | Pomace | 0.14 | kg |

| Bentonite | 0.13 | g | Lees | 0.03 | kg |

| Electricity a | 0.004 | kWh | Dewatered sludge | 0.03 | kg |

| Diesel | 0.233 | MJ | |||

| Packaging | |||||

| Glass bottle | 0.36 | kg | Bottled red wine | 0.75 | L |

| Red wine | 0.75 | L | |||

| Cork | 0.003 | kg | |||

| Cardboard | 0.001 | kg | |||

| Pallets | 0.001 | unit | |||

| Electricity | 0.017 | kWh | |||

| Distribution to retail | |||||

| Bottled red wine | 0.75 | L | Distributed bottled red wine | 0.75 | L |

| Distance | 0.04 | t.km | |||

| Consumption | |||||

| Distributed bottled red wine | 0.785 | L | Consumed bottled red wine | 0.75 | L |

| Electricity | 0.06 | kWh | Disposed bottled red wine | 0.035 | L |

| Disposed glass bottle | 0.36 | kg | |||

| Disposed cork | 0.003 | kg | |||

| End-of-life | |||||

| Disposed bottled red wine | 0.035 | L | |||

| Disposed glass bottle | 0.36 | kg | |||

| Disposed cork | 0.003 | kg | |||

| Life Cycle Stage | Level of Influence |

|---|---|

| Viticulture | Situation 1: the process is run by the wine producer |

| Winemaking | Situation 1: the process is run by the wine producer |

| Bottle making | Situation 3: the wine producer does not run the process or has access to (company-)specific information |

| Packaging | Situation 1: the process is run by the wine producer |

| Distribution | Situation 3: the wine producer does not run the process or has access to (company-)specific information |

| Consumption | Situation 3: the wine producer does not run the process or has access to (company-)specific information |

| End-of-life | Situation 3: the wine producer does not run the process or has access to (company-)specific information |

| Budget a | Grandfathering | Economic | Agri-Land | Calorific Content |

|---|---|---|---|---|

| Global | 6.8 × 1012 | 6.8 × 1012 | 6.8 × 1012 | 6.8 × 1012 |

| Global agri-food | 8.19 × 1011 | 8.19 × 1011 | 8.19 × 1011 | 8.19 × 1011 |

| Greece | 1.88 × 109 | |||

| Greek agri-food sector | 9.82 × 108 | 7.12 × 107 | 1.10 × 109 | 1.31 × 1+9 |

| Greek wine sector | 3.49 × 105 | 1.72 × 107 | 9.04 × 106 | 7.17 × 103 |

| Wine bottle | 1.09 | 5.38 × 10 | 2.83 × 10 | 2.24 × 102 |

| Grandfathering | Economic | Agri-Land | Calorific Content | |

|---|---|---|---|---|

| 10% increase in wine bottle production | 1.07 | 53.82 | 25.68 | 0.02 |

| 10% decrease in wine bottle production | 1.12 | 53.82 | 31.39 | 0.02 |

| Life Cycle Stage | TeR | GR | TiR | P | DQR Per Stage |

|---|---|---|---|---|---|

| Viticulture (excl. CO2 sequestration) | 2 | 1 | 1 | 2 | 1.5 |

| CO2 sequestration (only for PBs) | 2 | 3 | 4 | 3 | 3.0 |

| Winemaking | 1 | 1 | 1 | 2 | 1.3 |

| Packaging (bottle-making) | 2 | 2 | 5 | - | 2.3 |

| Distribution | 1 | 1 | 5 | - | 1.8 |

| Consumption | 1 | 1 | 5 | 3 | 2.5 |

| End-of-life | 2 | 1 | 5 | - | 2.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tsalidis, G.A.; Kryona, Z.-P.; Hatzisavva, K.; Korevaar, G.; Rapsomanikis, S. Carbon Assessment of Greek Organic Red Wine with Life Cycle Assessment and Planetary Boundaries. Sustainability 2025, 17, 3006. https://doi.org/10.3390/su17073006

Tsalidis GA, Kryona Z-P, Hatzisavva K, Korevaar G, Rapsomanikis S. Carbon Assessment of Greek Organic Red Wine with Life Cycle Assessment and Planetary Boundaries. Sustainability. 2025; 17(7):3006. https://doi.org/10.3390/su17073006

Chicago/Turabian StyleTsalidis, Georgios Archimidis, Zoi-Panagiota Kryona, Kiriaki Hatzisavva, Gijsbert Korevaar, and Spyridon Rapsomanikis. 2025. "Carbon Assessment of Greek Organic Red Wine with Life Cycle Assessment and Planetary Boundaries" Sustainability 17, no. 7: 3006. https://doi.org/10.3390/su17073006

APA StyleTsalidis, G. A., Kryona, Z.-P., Hatzisavva, K., Korevaar, G., & Rapsomanikis, S. (2025). Carbon Assessment of Greek Organic Red Wine with Life Cycle Assessment and Planetary Boundaries. Sustainability, 17(7), 3006. https://doi.org/10.3390/su17073006