Pro-Environmental Solutions in Architecture—The Problem of Decommissioned Wind Blades

Abstract

1. Introduction

2. State of the Art

2.1. The Problem of Ageing of Wind Blades and Their Post-Consumer Development

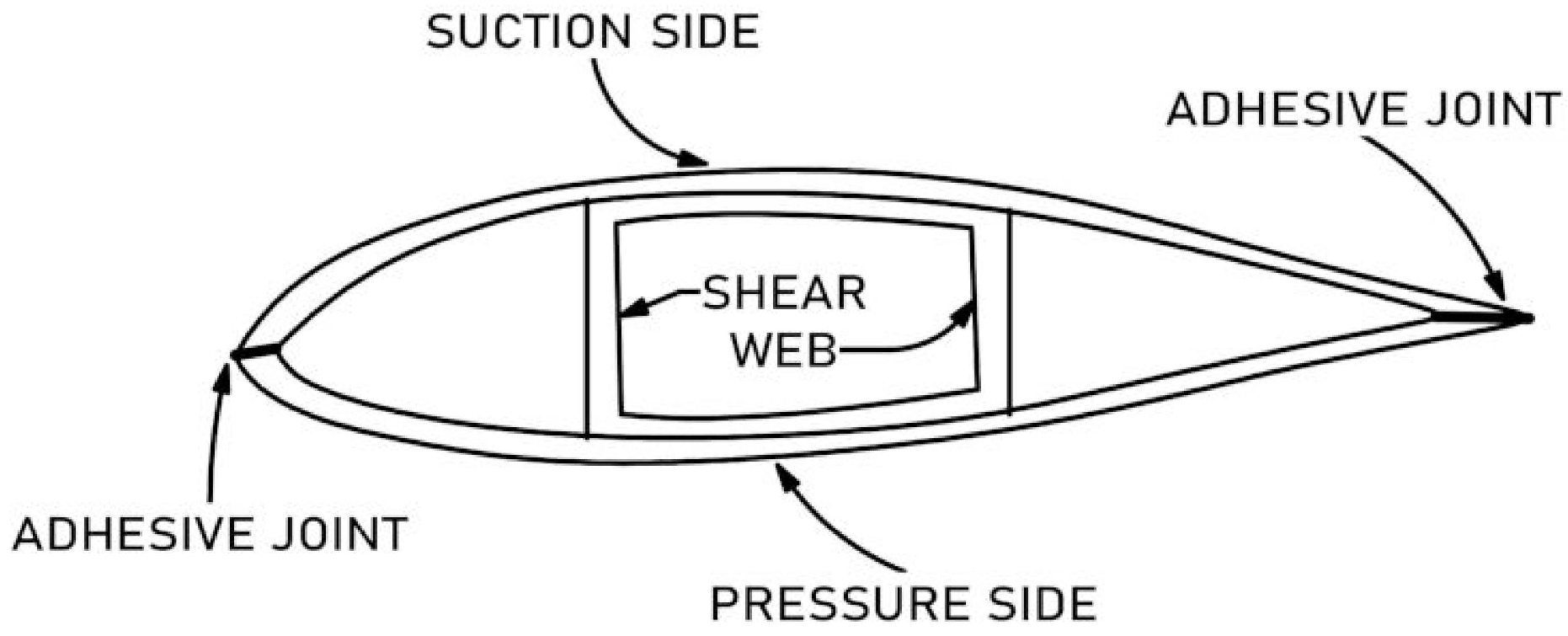

2.2. Onshore Wind Farms and Construction of a Wind Blade

2.3. Analysis of the Presence of the Largest Wind Power Plants and Turbine Types in Poland Between 1991 and 2015

- Bridge in Cork, IrelandOn a 23-km route (under construction) in Cork (Ireland), there was a bridge concept developed based on worn out wind turbine blades. It was created as part of the Re-Wind research project. Laser scanning technology assisted in the analysis of the blade geometry; additionally, a number of studies were carried out on aspects including blade strength and element joining. The five-metre structure is made up of two processed LM13.4 wind blades from Nordex N29 turbines that were handed over to the project. Between two sections of propellers of about 8.5 m length, a platform was built, fixed to the blades at an appropriate height [29,30]. It is worth noting that the concepts developed in the project allow construction of footbridges with a span up to 15 m and a platform width of up to 6 m [29].

- Other concepts developed within the Re-Wind projectAs part of the project, catalogues have been developed that contain a set of concepts for wind blade reuse. This material can be recycled in a multitude of methods, most of which are based on the idea of upcycling. The study presents concepts such as pedestrian/bicycle bridges (two- and multi-girder, tow, suspended), poles, fences, acoustic barriers, small architecture (seats, shelters), cattle partitions, reservoirs, and grain warehouses, as well as stands, embankments, breakwaters, skate parks, foundation piles, barriers, pontoons, and facades. The possibility of using wind blades for production of aggregate or fillings or as a 3D printing material (Figure 3) was also mentioned.A different project was carried out in Mexico, where buildings near the Gulf of Mexico are exposed to strong hurricanes and flooding. So for this area a concept of building affordable housing (using wind turbine blades) was developed. The focus was on the use of large FRP (fibre-reinforced polymer) elements. This solution can be used in both new and renovated housing projects. The concept was based on dividing the prototype of a 100 m long blade in such a way as to show the use of its individual segments in housing [31].

3. Research Methodology

- The development of wind energy in Poland since the 1990s will force the necessity of post-consumer management of wind turbine blades in the near future;

- One of the solutions for the management of decomissioned wind turbine blades, is their reuse in architecture and the construction industry, which, at the same time, contributes to extending their life cycle.

4. Discussion of Results

Overview of Examples of Reuse of Wind Blades in Architecture and Engineering Structures

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Munn, S.; Soebarto, V. The issues of using recycled materials in architecture. In Proceedings of the 38th International Conference of Architectural Science Association ANZAScA, Launceston, TAS, Australia, 10–12 November 2004. Contexts of Architecture. [Google Scholar]

- Chen, J.; Wang, J.; Ni, A. Recycling and reuse of composite materials for wind turbine blades: An overview. J. Reinf. Plast. Compos. 2019, 38, 567–577. [Google Scholar]

- Piasecka, I. Studium Oceny Oddziaływania Cyklu Istnienia Wybranych Obiektów Technicznych Energetyki Odnawialnej, Zorientowane na Główne Aspekty Zrównoważonego Rozwoju; Wydawnictwo Uczelniane Uniwersytetu Technologiczno-Przyrodniczego: Bydgoszcz, Poland, 2019. [Google Scholar]

- Boczar, T.; Szczyrba, T. Evaluation of the Influence of Weather Conditions on the Efficiency of Wind Turbines, Measurement Automation Control Journal No.12/2012 (2012) (Pol.:Ocena Wpływu Warunków Meteorologicznych na Sprawność Turbin Wiatrowych, Pomiary Automatyka Kontrola (PAK)) Vol. 58, No.12/2012. 2012. Available online: https://yadda.icm.edu.pl/baztech/element/bwmeta1.element.baztech-article-BSW4-0125-0004 (accessed on 10 March 2025).

- Bledzki, A.; Urbaniak, M.; Adamcio, A.; Sobczyk, M.; Demski, S.; Boczkowska, A.; Seidlitz, H.; Köhler, M. Reusing and recycling of composite wind turbine blades. A review of current practices and prospects. Part 1. Akademic research. Przemysł Chem. 2024, 1, 75–83. [Google Scholar]

- Cotrell, J.; Stehly, T.; Johnson, J.; Roberts, J.O.; Parker, Z.; Scott, G.; Heimiller, D. Analysis of Transportation and Logistics Challenges Affecting the Deployment of Larger Wind Turbines: Summary of Results; Technical Report of U.S.; Department of Energy Office of Scientific and Technical Information: Oak Ridge, TN, USA, 2014.

- Available online: https://www.cire.pl/artykuly/opinie/155372-lopaty-turbin-wiatrowych-najtrudniejsze-do-recyklingu (accessed on 14 November 2021).

- André, A.; Kullberg, J.; Nygren, D.; Mattsson, C.; Nedev, G. Haghani R. Re-use of wind turbine blade for construction and infrastructure applications. IOP Conf. Ser. Mater. Sci. Eng. 2020, 942, 012015. [Google Scholar]

- Skaf, M.; Espinosa, A.B.; Manso-Morato, J.; Ortega-López, V. Suitability of Raw-Crushed Wind-Turbine Blade for Use in Concrete Production. In Proceedings of the 4th fib International Conference on Concrete Sustainability (ICCS2024), ICCS 2024, Guimarães, Portugal, 11–13 September 2024; Lecture Notes in Civil Engineering; Springer: Cham, Switzerland, 2025; Volume 574. [Google Scholar] [CrossRef]

- Jasińska, D.; Dutkiewicz, M. Waste Management of Wind Turbine Blades—A Review of Recycling Methods and Applications in Cementitious Composites, Special Issue Development of Architectural, Structural and Material Sustainability Solutions. Sustainability 2025, 17, 805. [Google Scholar] [CrossRef]

- Rajchel, M.; Kulpa, M.; Wiater, A.; Siwowski, T. Repurposing a Decommissioned Wind Turbine Blade for Bridge Construction: An Experimental Investigation. J. Compos. Constr. 2025, 29, 04024084. [Google Scholar] [CrossRef]

- Deeney, P.; Nagle, A.J.; Gough, F.; Lemmertz, H.; Delaney, E.L.; McKinley, J.M.; Graham, C.; Leahy, P.G.; Dunphy, N.P.; Mullally, G. End-of-Life alternatives for wind turbine blades: Sustainability Indices based on the UN sustainable development goals. Resour. Conserv. Recycl. 2021, 171, 105642. [Google Scholar] [CrossRef]

- Nagle, A.J.; Mullally, G.; Leahy, P.G.; Dunphy, N.P. Life cycle assessment of the use of decommissioned wind blades in second life applications. J. Environ. Manag. 2022, 302, 113–994. [Google Scholar]

- Khalid, M.Y.; Arif, Z.U.; Hossain, M.; Umer, R. Recycling of wind turbine blades through modern recycling technologies: A road to zero waste. Renew. Energy Focus 2023, 44, 373–389. [Google Scholar] [CrossRef]

- Jastrzębska, G. Odnawialne Źródła Energii i Pojazdy Proekologiczne; Scientific and Technical Publishing Houses: Warszawa, Poland, 2008. [Google Scholar]

- Reintjes, J. Dismantling of wind turbines. An overview of methods. Educ. J. Renew. Energy Short Rev. 2024, 67–72. Available online: https://www.hb.fh-muenster.de/opus4/frontdoor/deliver/index/docId/17636/file/EduJRESR_2024.pdf (accessed on 12 March 2025).

- Ortegon, K.; Nies, L.F.; Sutherland, J.W. Preparing for end of service life of wind turbines. J. Clean. Prod. 2013, 39, 191–199. [Google Scholar]

- Doliński, Ł. Zastosowanie Transformaty Falkowej do Detekcji Uszkodzeń w Kompozytowych Łopatach Turbin Wiatrowych. Ph.D. Thesis, Politechnika Gdańska, Gdańsk, Poland, 2013. [Google Scholar]

- ISO 14044; Environmental Management–Life Cycle Assessment—Requirements and Guidelines. ISO: Geneva, Switzerland, 2006. Available online: https://www.iso.org/standard/38498.html;access14.11.2024 (accessed on 14 November 2024).

- Directive 2008/98/EC of the European Parliament and of the Council of 19 November 2008 on Waste and Repealing Certain Directives. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32008L0098 (accessed on 14 November 2024).

- Bełzowski, A. Zasady doboru współczynników bezpieczeństwa konstrukcji z materiałów kompozytowych. Composites 2004, 4, 12. [Google Scholar]

- Gielnik, A.; Rosicki, R. Energetyka Wiatrowa w Polsce–-Możliwości Rozwoju i Zagrożenia; Adam Mickiewicz University Repository: Poznań, Poland, 2013. [Google Scholar]

- Gronowicz, J. Niekonwencjonalne Źródła Energii; Instytutu Technologii Eksploatacji—PIB Publishing House: Poznań, Poland, 2008. [Google Scholar]

- Lewandowski, W. Proekologiczne Źródła Energii Odnawialnej; Naukowo-Techniczne Publishing House: Warszawa, Poland, 2002. [Google Scholar]

- Flaga, A. Siłownie Wiatrowe; Krakow University of Technology Publishing House: Kraków, Poland, 2012. [Google Scholar]

- Tytko, R. Odnawialne Źródła Energii, 4th ed.; OWG Publishing House: Warszawa, Poland, 2010. [Google Scholar]

- Jastrzębska, G. Energia ze Źródeł Odnawialnych i jej Wykorzystanie; Wyd. Komunikacji i Łączności Publishing Group: Warszawa, Poland, 2017. [Google Scholar]

- Available online: https://szprotawa.pl/PL/3016/4260/80_tysiecy_dofinansowania_na_kladke_i_ciag_rowerowo-pieszy/k/ (accessed on 15 November 2021).

- Siwowski, T.; Rajchel, M.; Kulpa, M.; Adamcio, A. Zastosowanie Zużytych łopat Turbin Wiatrowych. Materiały Budowlane 9/2021 (no. 589); PWN Publishing House: Warszawa, Poland, 2017; pp. 48–50. [Google Scholar]

- Leahy, P.G.; Zhang, Z.; Nagle, A.J.; Ruane, K.; Delaney, E.; McKinley, J.; Bank, L.; Gentry, T.R. Greenway Pedestrian and Cycle Bridges from Repurposed Wind Turbine Blades, Proceedings of ITRN 2021, 26–27 August 2021; University of Limerick, ID-22. Available online: https://cora.ucc.ie/items/e9897067-5a44-4639-9a48-2247bfcf47fd (accessed on 5 February 2025).

- Bank, L.C.; Arias, F.R.; Yazdanbakhsh, A.; Gentry, T.R.; Al-Haddad, T.; Chen, J.-F.; Morrow, R. Concepts for Reusing Composite Materials from Decommissioned Wind Turbine Blades in Affordable Housing. Recycling 2018, 3, 3. [Google Scholar] [CrossRef]

- Wroconsult Ltd.; Ekovert. Recykling Wyeksploatowanych Komponentów Technicznych Odnawialnych źródeł Energii Oraz Akumulatorów Pojazdów Elektrycznych Jako Element Transformacji w Kierunku Gospodarki o Obiegu Zamkniętym; Raport Końcowy; Na Zlecenie Ministerstwa Energii: Wrocław, Poland, 2019. [Google Scholar]

- Szpakowski, A. Gospodarka o Obiegu Zamkniętym 2.0—Aktualizacja Systemu; IGSMiE PAN Publishing House: Kraków, Poland, 2019; pp. 141–150. [Google Scholar]

| Location | Power of the Power Plant | Turbine Type | Turbine Quantity | Blade Quantiry | Impeller Diameter | Bade Length | Year of Commissioning |

|---|---|---|---|---|---|---|---|

| Lisewo near Żarnowiec | 150 | NTK-150/25 | 1 | 3 | 24.6 | 11.5 | 1991 |

| Swarzewo near Puck | 95 | DANmark | 1 | 3 | NO DATA | NO DATA | 1991 |

| Rytro near Nowy Sącz | 160 | EW-160 | 1 | 3 | 22 | 10 | 1992 |

| Wrocki near Toruń | 160 | EW-160 | 1 | 3 | 22 | 10 | 1995–1997 |

| Kwilcz near Poznań | 160 | 1 | 3 | 10 | |||

| Zawoja near Bielsko Biała | 160 | 1 | 3 | 10 | |||

| Będkowo near Wrocław | 160 | 1 | 3 | 10 | |||

| Słup near Legnica | 160 | 1 | 3 | 10 | |||

| Starbienino near Lębork | 250 | N29/250 | 1 | 3 | 29.7 | 13.4 | 1997 |

| Rembertów near Tarczyn | 250 | LW-250 | 1 | 3 | NO DATA | NO DATA | 1997 |

| Swarzewo near Puck | 2 × 600 = 1200 | TW-600 | 2 | 6 | 43 | 20 | 1997 |

| Cisowo near Darłowo | 5 × 132 = 660 | SEEWIND 25/132 | 5 | 15 | 22 | 10 | 1999 |

| Nowogard | 225 | V29-225 | 1 | 3 | 29 | 13 | 1999 |

| Wróblik Szlachecki | 2 × 160 = 320 | EW-160 | 2 | 6 | 22 | 10 | 2000 |

| SUM: | 60 | AVR: | 11.6 |

| Item. | Location | Power of Power Plant [MW] | Turbine Type | Blade Quantiry | Impeller Diameter [m] | Bade Length [m] | Year of Commissioning | Blade Quantiry |

|---|---|---|---|---|---|---|---|---|

| 1 | Barzowice | 5 | Vestas V-52 850 | 6 | 18 | 52 | 25 | 2001 |

| 2 | Cisowo/Energia Eco/EEZ | 18 | Vestas V80/2000 | 9 | 27 | 80 | 39 | 2002 |

| 3 | Zagórze | 30 | Vestas V80/2000 | 15 | 45 | 80 | 39 | 2008 |

| 4 | Lisewo I & II | 10.8 | Enercon E40/600 | 14 | 42 | 40 | ND | 2005/2007 |

| Enercon E48/800 | 3 | 9 | 48 | 22.8 | ||||

| 5 | Tymień | 50 | Vestas V80/2000 | 25 | 75 | 80 | 39 | 2006 |

| 6 | Gnieżdżewo near Puck | 22 | Gamesa G87/2000 | 11 | 33 | 87 | 42.5 | 2006 |

| 7 | Kisielice | 77.5 | GE Energy 1.5 Enercon E82E2 | 47 | 141 | 77 | 37.5 | 2007, 2011, 2014 |

| 8 | Jagniątkowo Lake Ostrowo | 30.6 | Vestas V90/2000 | 17 | 51 | 90 | 44 | 2007 |

| 9 | Kamieńsk | 30 | Enercon E-70 E-4 | 15 | 45 | 71 | 32.8 | 2007 |

| 10 | Malbork (Sztum) | 18 | GE Wind Energy 1.5 sl | 12 | 36 | 77 | ND | 2008 |

| 11 | Łebcz I near Puck | 4 | Enercon E-48/800 | 4 | 12 | 48 | 22.8 | 2007 |

| 12 | Łebcz II near Puck | 4 | Vestas V80/2000 | 4 | 12 | 80 | 39 | 2008 |

| 13 | Zajączkowo | 48 | Vestas V80/2000 | 24 | 72 | 80 | 39 | 2008 |

| 14 | Karścino–Mołtowo | 90 | Vestas V90/3000 | 17 | 51 | 90 | 44 | 2008 |

| 15 | Krzęcin | 14 | Gamesa G90/2000 | 7 | 21 | 90 | 44 | 2008 |

| 16 | Darżyno | 12 | Enecon E-82/2000 | 6 | 18 | 82 | 41 | 2008 |

| 17 | Śniatowo | 32 | Vestas V90/2000 | 16 | 48 | 90 | 44 | 2008 |

| 18 | Inowrocław | 32 | Vestas V90/2000 | 16 | 48 | 90 | 44 | 2008 |

| 19 | Hnatkowice-Orzechowice near Przemyśl | 12 | Gamesa G87-2MW | 6 | 18 | 87 | 42.5 | 2009 |

| 20 | Łęki Dukielskie | 10 | Repower MM92/2050 | 5 | 15 | 92.5 | 45.2 | 2009 |

| 21 | Suwałki | 41 | Siemens SWT-2.3-93 | 18 | 54 | 93 | 45 | 2009 |

| 22 | Tychowo | 50 | Nordex N90/2500 | 20 | 60 | 90 | 43.8 | 2009 |

| 23 | Margonin | 120 | Gamesa G90/2000 | 60 | 180 | 90 | 44 | 2010 |

| 24 | Karnice | 31 | Siemens SWT-2.3-101 | 13 | 39 | 101 | 49 | 2010 |

| 25 | Karcino | 51 | Vestas V90/3000 | 17 | 51 | 90 | 44 | 2010 |

| 26 | Wind Farm Piecki near Suwałki | 32 | Gamesa G90/2000 | 16 | 48 | 90 | 44 | 2011 |

| 27 | Tychowo | 35 | Siemens SWT-2.3-93 Nordex | 20+15 | 105 | 90. 93 | 45 | 2011 |

| 28 | Lipniki | 30 | Repower MM92 | 15 | 45 | 92.5 | 45.2 | 2011 |

| 29 | Wind Farm Łukaszów | 34 | Vestas V90/2000 | 17 | 51 | 90 | 44 | 2011-XII |

| 30 | Wind Farm Modlikowice | 24 | Vestas V90/2000 | 12 | 36 | 90 | 44 | 2011-XII |

| 31 | Pelplin | 48 | Gamesa G90/2000 | 24 | 72 | 90 | 44 | 2012 |

| 32 | Taciewo | 30 | Gamesa G90/2000 | 15 | 45 | 90 | 44 | 2012 |

| 33 | Pągów | 51 | Vestas V112/3000 | 17 | 51 | 112 | 54.7 | 2012 |

| 34 | Wind Farm Nowy Tomyśl | 5 | Fuhrländer FL-2500 | 2 | 6 | 100 | ND | 2012 |

| 35 | Wind Farm Krobia | 33 | Acciona Windpoer 3000 | 11 | 33 | 116 | 56.7 | 2012 |

| 36 | Wind Farm Golice | 38 | Gamesa G90/2000 | 19 | 57 | 85 | 44 | 2012 |

| 37 | Wind Farm Górzyca | 28 | Starke Wind Polska | 14 | 42 | ND | ND | 2012 |

| 38 | Taczalin | 45.1 | Repower MM92/2050 | 22 | 66 | 92.5 | 45.2 | 2013 |

| 39 | Darłowo | 250 | General Electric | 100 | 300 | 103 | ND | |

| Phase I 80 | 2011 | |||||||

| Phase II 95 | 2012 | |||||||

| Phase III 75 | - | |||||||

| 40 | Marszewo | 82 | Vestas V80 & V90 | 41 | 123 | 80/90 | 39/44 | 2013 |

| 41 | Pawłowo | 79.5 | Acciona AW 82/1500 | 53 | 159 | 82 | 40 | 2013 |

| 42 | Iłża | 54 | Vestas V90/2000 | 27 | 81 | 90 | 44 | 2014 |

| 43 | Skurpie near Działdowo | 43.7 | Siemens SWT-2.3-108 | 19 | 57 | 108 | 53 | 2015 |

| 44 | Oprzężów | 5.1 | Gamesa G58 & VestasV66 | 4 | 12 | 58/66 | 28.3/32 | 2015 |

| 45 | Michów–Abramów | 51.2 | Vestas V112/3200 | 16 | 48 | 112 | 54.7 | 2015 |

| SUM: | 2658 | AVR: | 42.1 |

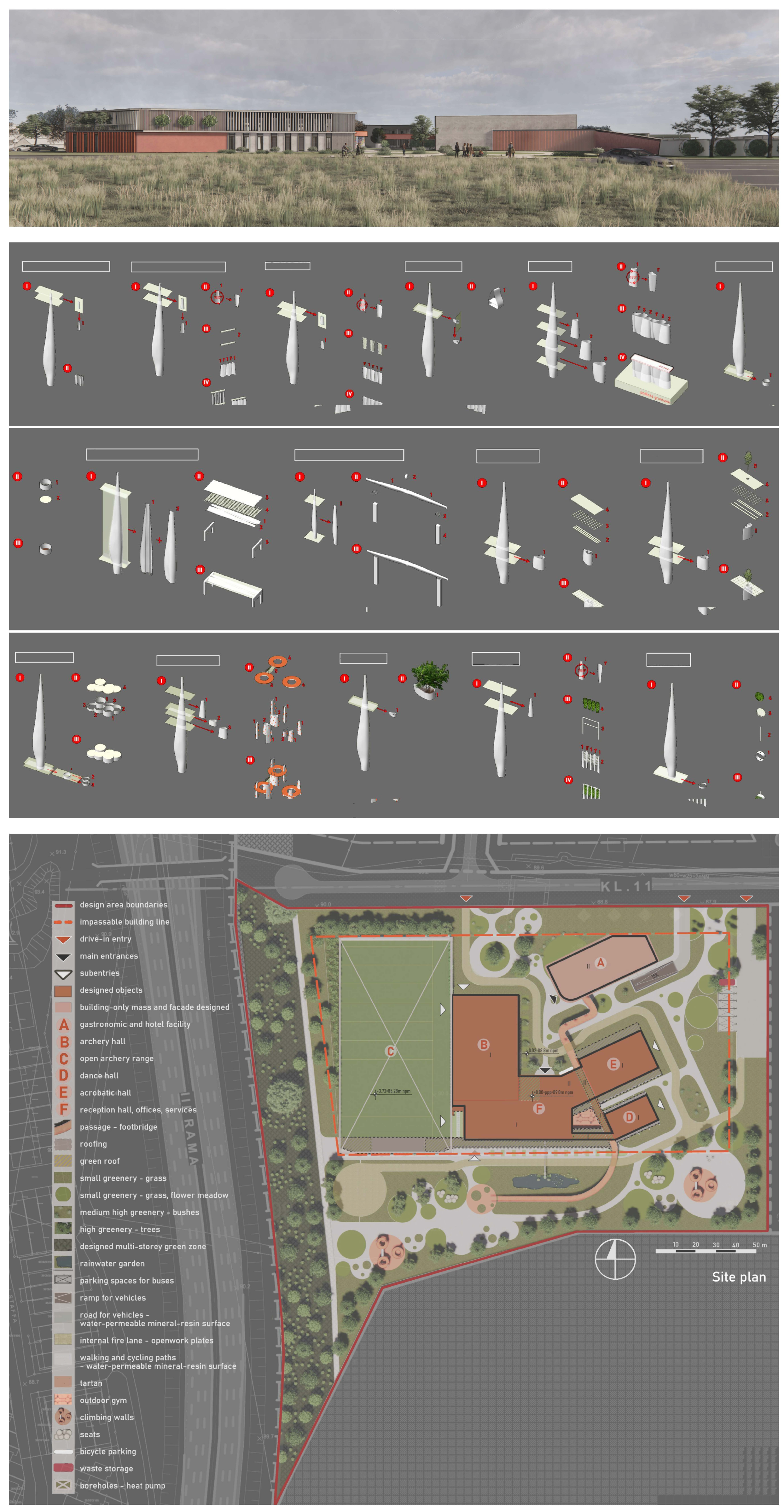

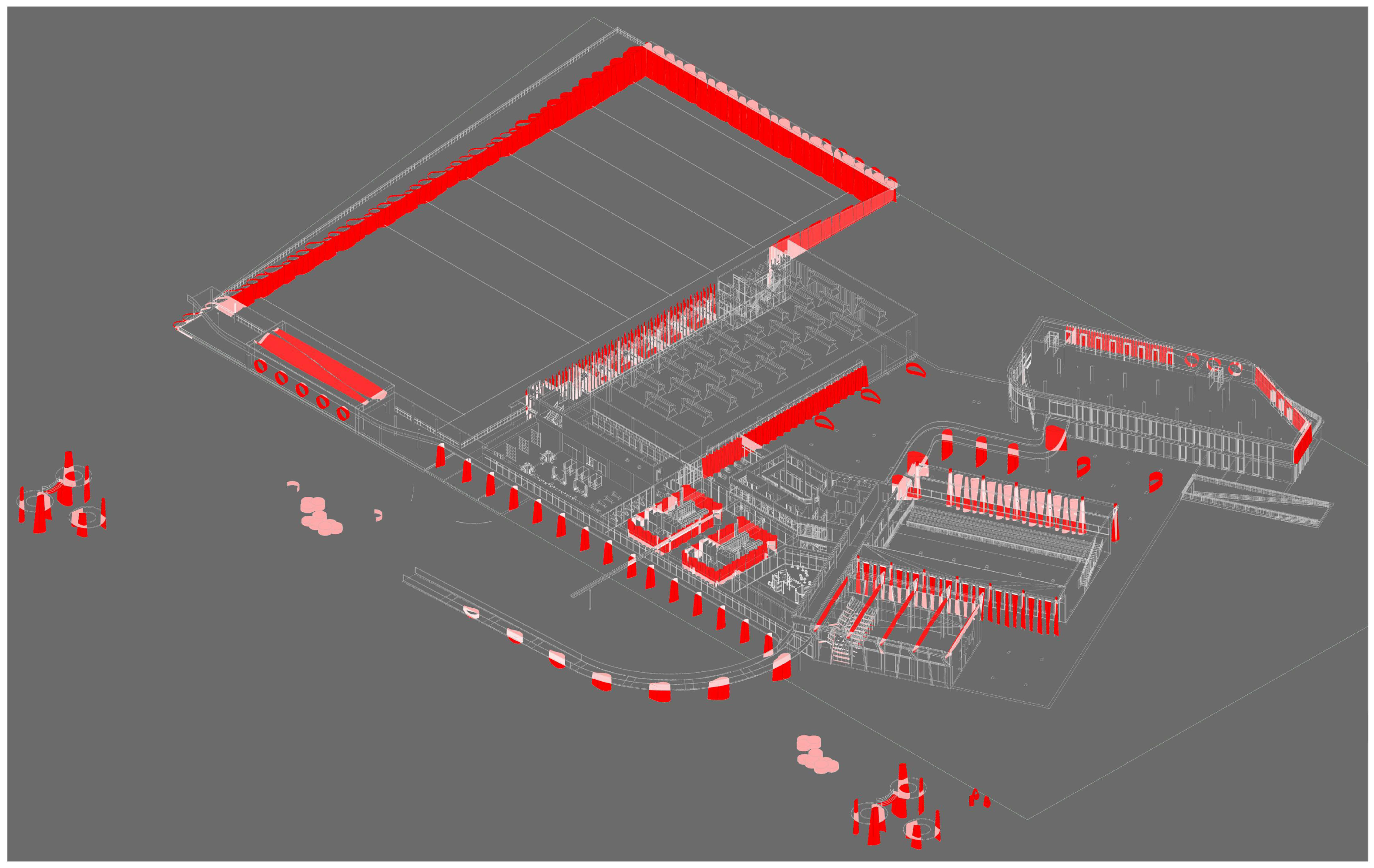

| Blade Type | Characteristic Data | Item Designation | Element Location in the Design | Number of Blades Used |

|---|---|---|---|---|

| Vestas V-90/2 MW | blade length: 44 m largest profile chord: 3.9 m | roof girder | above the audience of archery tracks | 1 |

| SEEWIND 25/132 | blade length: 10 m | roof girder | in the dance hall | 12 |

| Vestas V-80/2 MW | blade length: 39 m blade weight: 6500 kg largest profile chord: 3.5 m | retaining wall | around archery tracks | 31 whole + 65 fragments 7.5 m long from the top of the blade |

| supports | under the footbridge and roof from the south | |||

| sun shades | facade of the archery hall and the front building | |||

| partition wall | locker rooms | |||

| green walls | at the acrobatic hall, with open-air shooting trakcs, north facade of the front building | |||

| plant containers | grounds | |||

| seats | grounds | |||

| climbing walls | grounds | |||

| retention tanks | below ground level |

| Material | Item Designation | Adopted Reference Dimensional Material Consumption | Volume [m3] |

|---|---|---|---|

| reinforced concrete | retaining wall | thickness 40 cm | 268.8 |

| supports | diameter 40 cm | 12.3 | |

| roof grider of 26 m span | cross-section 25 × 40 cm | 7.8 | |

| roof grider of 13 m span | cross-section 30 × 90 cm | 14.0 | |

| climbing wall posts | Diameter >= 10 cm | 0.3 | |

| green wall frame posts | diameter 20 cm | 11.8 | |

| retention tanks | 1.5 m3 by 12 m3 capacity | 16.0 | |

| TOTAL | 331.0 | ||

| concrete architectural, GFRC, cellular, etc. | plant containers | 0.08 m3/item | 1.2 |

| openwork facade slabs | 0.02 m3 for each 1 m2 of surface | 13.2 | |

| seats | 0.04 m3/pc | 0.9 | |

| partition wall | thickness 10 cm | 27.2 | |

| TOTAL | 42.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Śledzik, A.; Banach, M. Pro-Environmental Solutions in Architecture—The Problem of Decommissioned Wind Blades. Sustainability 2025, 17, 2963. https://doi.org/10.3390/su17072963

Śledzik A, Banach M. Pro-Environmental Solutions in Architecture—The Problem of Decommissioned Wind Blades. Sustainability. 2025; 17(7):2963. https://doi.org/10.3390/su17072963

Chicago/Turabian StyleŚledzik, Aleksandra, and Marzena Banach. 2025. "Pro-Environmental Solutions in Architecture—The Problem of Decommissioned Wind Blades" Sustainability 17, no. 7: 2963. https://doi.org/10.3390/su17072963

APA StyleŚledzik, A., & Banach, M. (2025). Pro-Environmental Solutions in Architecture—The Problem of Decommissioned Wind Blades. Sustainability, 17(7), 2963. https://doi.org/10.3390/su17072963