Abstract

The purpose of this paper is to explore the possibilities of bringing house development to a more sustainable and ecological level using the idea of the circular economy (CE) in the construction industry. Housing is an essential aspect of the economy and the building industry. The development of this sector is driven by an increasing urban population and the need to modernize existing residential buildings. Contemporary home situations should address reducing their detrimental impact on the natural environment. This is achievable by minimizing the consumption of natural resources and construction waste. This assumption is part of the core CE work, which allows for the recirculation of building materials. To discuss the underlying topics, this assumption was explored by employing a non-reactive desk research method. The review of scientific articles and studies covered the following topics: (i) the definition of CE, (ii) the shearing layers concept in building, and (iii) design for disassembly (DfD) in home construction. The second stage of evaluating the project “Domus Ex Machina” includes the following: (i) modular dimensions, (ii) prefabricated production, and (iii) adaptive designs and systems. In the discussion, this research identified several barriers to efficient CE adoption in the construction industry. The discussion highlights potential impediments to the application of the CE in housing contexts, including (i) storage and logistics issues, (ii) cost concerns and implementation challenges, (iii) policy inconsistencies across regions, and (iv) market demand and supply chain restrictions. The final paper conclusions demonstrate the significance of implementing the CE idea in housing building, hence reducing the negative impact on the environment.

1. Introduction: Contemporary Notions of Waste and Circularity

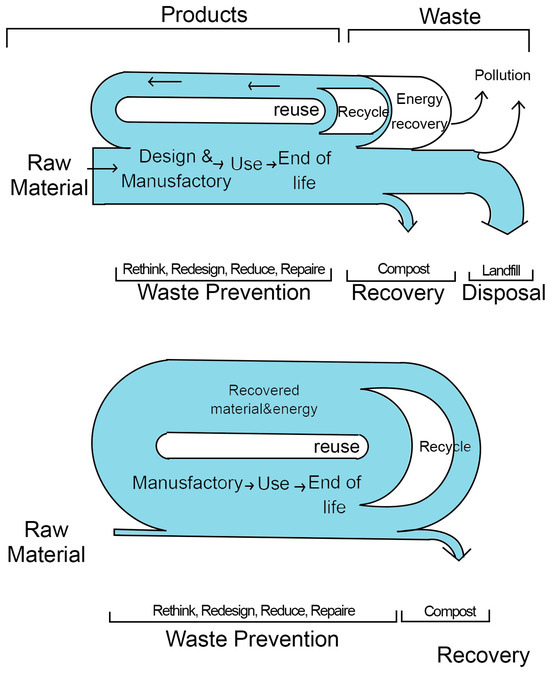

The need to achieve sustainability has increased in recent decades, leading to changes in practices by public and business sectors that are actively striving to achieve sustainability. In recent years, the concept of zero waste has gained significant acceptance as society endeavors to shift away from conventional manufacturing processes that result in disposal once goods end their useful life (Figure 1). Instead, the zero waste mindset advocates for the complete eradication of consumer waste. Various individuals and organizations have interpreted the zero waste message in diverse manners. As exemplified by Mauch in 2016, zero waste refers to the process of redirecting landfill trash toward composting or recycling channels [1]. Alternatively, other viewpoints argue for reducing all forms of waste, encompassing landfill, compost, and recycling. Instead, eliminating materials should be achieved not by diverting or recycling them but by including design components that facilitate the reuse of all materials and are integrated into products from the beginning [1]. This approach necessitates a thorough reimagining of the existing production process.

Figure 1.

The term zero waste has become increasingly common as society tries to move away from the traditional production methods where all products are eventually being disposed of (top) to the recovery model (bottom).

The concept of a circular economy challenges the traditional understanding of the linear progression of a product’s life cycle, advocating for a shift towards a circular model. The culmination of a product’s lifespan includes not just disposing of it but repurposing the object to serve a new function. The circular economy is based on the six Rs notion: reduce, reuse, recycle, redesign, remanufacture, and recover [2]. Reduce indicates limiting the inputs involved in the manufacturing of an object, encompassing both the resources and energy utilized in the production process [3]. Reuse is to use an object or its components once more following the conclusion of its lifespan [4]. This will extend the duration of an item’s existence, decrease the quantity of raw materials required, and minimize the energy consumption for item transformation [4]. Recycling means converting one object’s materials into a different object [3]. Energy is a prerequisite for the recycling process; hence, reuse is often favored if feasible. Recovery is related to both reuse and recycling, as it entails the examining and disassembling of a product at the end of its lifespan to ascertain the appropriate course of action for each component.

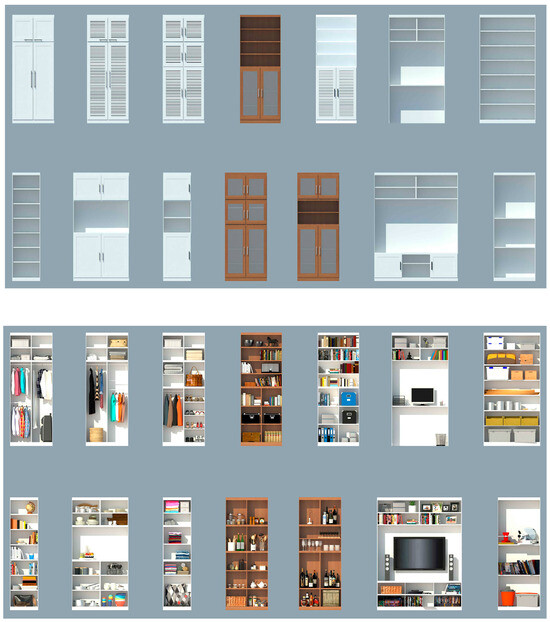

In a circular design, the majority of parts would be repurposed or recycled, while the usage of landfills is frequently inevitable. Redesign is modifying a product’s design by using materials, components, and resources from its past or the prior existence of related goods. Remanufacture is the process of refurbishing non-functional components of a used product to restore it for reuse [3]. This enables the reuse of functioning components and extends the total lifespan of the product. Within the circular economy framework, products that have reached the end of their useful life will be evaluated according to the principles of the six Rs. The product will be disposed of correctly if none of the six methods are practical. Figure 2 illustrates the utilization of each of the “six Rs” in the context of the circular economy. Even after disposal, circularity remains feasible, as future generations can extract garbage and fossil fuels by mining raw materials and energy sources.

Figure 2.

Utilization of each of the “six Rs” in the context of the circular economy.

The concept of the circular economy was formally introduced in the 1970s [2]. The time was marked by a heightened comprehension of ecology, which perhaps inspired the notion. The term circular economy has been interdisciplinary since its inception. Economists such as David Pearce, chemists like Michael Braungart, and architects like Walter Stahel were instrumental in developing the circular economy principle [2]. The circular economy has gained significant traction across different regions and industries, reflecting a global shift towards sustainable practices. North American and European governments have led the way with robust campaigns promoting the principles of reduce, reuse, and recycle, demonstrating a commitment to efficient resource management and environmental conservation. Germany’s early adoption of this model in the 1990s, primarily as an environmental strategy, set a precedent for effectively balancing resource scarcity with economic growth [5]. In Asia, countries like Japan and Korea emphasize consumer responsibility in both the utilization and disposal of products, highlighting a collective effort in sustainable practices [6,7]. As shown in Figure 3, at the top, “build to last” represents the most sustainable approach, which minimizes material use. Below, “repair and reuse” encourages extending product lifespan through maintenance. “Reuse same product” suggests repurposing items without modifications. At the base, “recycle raw materials” is the least preferred option, as it requires energy to break down materials. The pyramid highlights the priority of longevity, reuse, and recycling in sustainable design and circular economy principles.

Figure 3.

In Japan and Korea, the responsibility for product use and waste is placed on the consumers, who are encouraged to use products throughout their full lifecycle.

This paper examines the potential application of circular economy principles in housing construction. This study includes modular dimensions, prefabricated production, and adaptive designs and systems by analyzing the project “Domus Ex Machina.” This examination aims to reduce the negative environmental impacts associated with the construction sector. The number of residential buildings is continuously rising, and existing structures require regular maintenance [8]. The modernization of existing housing structures will increase carbon dioxide (CO2) emissions into the atmosphere. A potential approach to reducing carbon emissions is the implementation of the circular economy concept in the building sector. The United Nations advocates this strategy through directives aimed at improving energy efficiency in buildings and reducing CO2 emissions in the construction sector [9]. This study investigates the potential to improve housing sustainability and ecological integrity by applying circular economy principles in construction.

2. Methods

This study employs a multi-faceted research approach, integrating a systematic literature review, case study analysis, environmental impact assessment, economic feasibility analysis, and industry and policy evaluation to assess the application of circular economy (CE) principles in housing construction. The literature review examines scientific papers, technical reports, and policy documents to define the CE in the construction sector, establish its theoretical foundation, and explore its feasibility in housing. The Domus Ex Machina prefab project serves as a case study to analyze the implementation of CE strategies, including the shearing layers model for adaptable design and design for disassembly (DfD) to enhance modularity, material recovery, and waste reduction. A life cycle assessment (LCA) quantifies the environmental benefits by evaluating carbon emissions, energy savings, and pollutant reduction. Additionally, a life cycle cost analysis (LCCA) assesses the financial sustainability of the CE in housing by considering initial construction, operational, maintenance, and dismantling costs. The author has performed research that discusses the scientific contributions of other experts and identifies three difficulties for the circular economy in housing development. By synthesizing these research components, this study aims to provide a comprehensive understanding of how CE principles can contribute to more sustainable and adaptable housing solutions.

3. Domus Ex Machina: A Dwelling Prototype for the Circular Economy

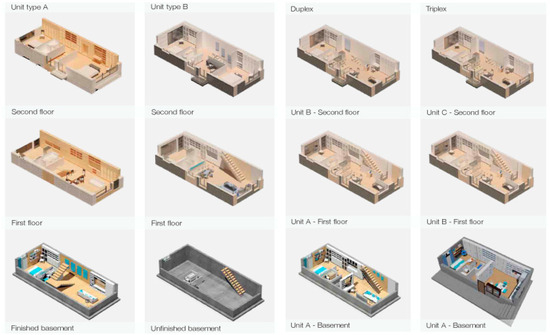

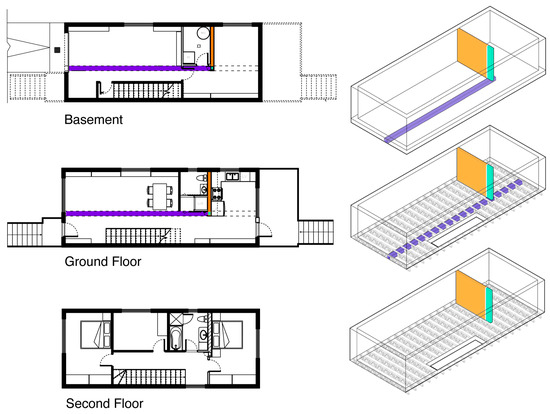

The widespread adoption of circular economy principles across various sectors and geographical regions highlights an increasing recognition of the critical role of sustainable practices [10,11]. An example of these principles in practice is the Domus Ex Machina project, or “home by machine” from Latin, which was designed by the author and integrates choice, flexibility, circularity, and environmental sustainability using sustainable construction methods. The structure measures 4.8 m by 12 m and has three floors, which can be configured into different spatial arrangements, such as a single-family home, duplex, or triplex (Figure 4). Furthermore, the unit interior of Domus Ex Machina has a menu of options that lets households customize the unit according to their financial constraints and spatial requirements.

Figure 4.

Single-family type A and B and two and three family units.

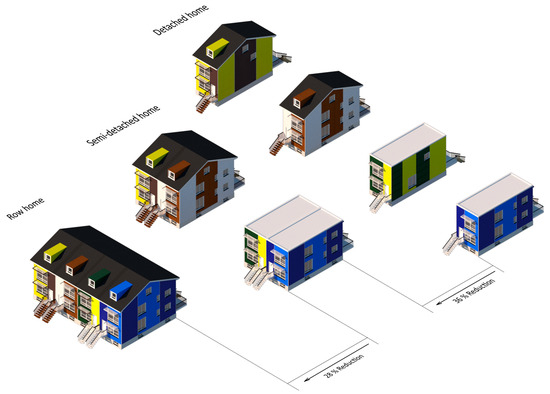

Moreover, Domus Ex Machina is highly versatile, and occupants can choose the number of floors and interior layout of their dwelling units. The design can accommodate the needs of a municipality that may have distinct zoning regulations that call for detached houses rather than row houses (Figure 5). The design exhibits a high degree of adaptability in the pre- and post-occupancy stages. Purchasers can exercise their preferences using a web-based application that enables them to explore diverse arrangements, thereby facilitating their visualization of numerous possibilities throughout the design phase.

Figure 5.

Exterior renderings of Domus Ex Machina.

4. The Shearing Layers Model

Buildings are facing constant technological advancement and innovation. Nevertheless, the expensive materials and labor required in the construction process make it unviable and ineffective to demolish and replace obsolete structures or components repeatedly. Indeed, within the global economy, the construction industry consumes 40 percent of natural resources, 25 percent of water, and 40 percent of energy while contributing to one-third of greenhouse gas emissions [12]. Undoubtedly, the existing construction techniques are environmentally unsustainable.

Like other architectural constructions, the home must continuously adjust to societal demands and technological advancements. During the late 1800s, asbestos gained popularity as an insulation material because of its fire-resistant properties [13]. The United States consumed a total of 804,000 metric tons of asbestos in the year 1973 [13]. Nevertheless, in later years, asbestos was shown to have profoundly detrimental health effects [14]. Alternatives like fiberglass, cellulose, foam, and wool have since replaced asbestos. This shift highlights how construction practices can evolve from harmful to safer methods due to technological advancements and increased awareness of health and environmental impacts. Similarly, the current linear construction approach, characterized by demolishing structures and landfilling waste, poses environmental risks, underlining the need for sustainable development in housing to meet societal and technological changes. There is a need to reassess housing and ensure that subcomponents of a structure may be modified without the requirement of complete demolition.

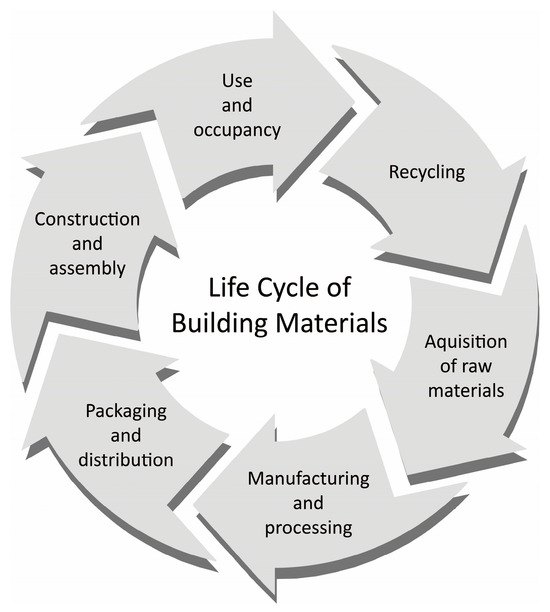

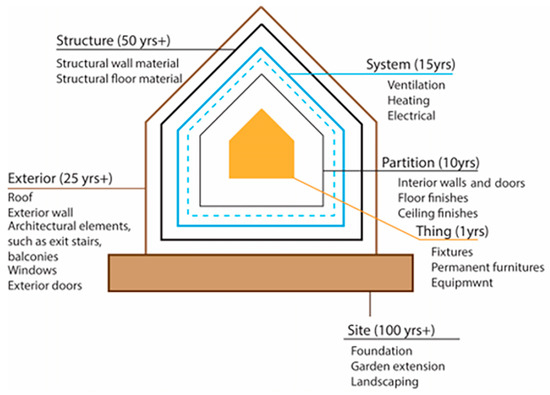

The shearing layers model offers a unique perspective on construction, conceptualizing each building component as a distinct layer that may be modified without causing interference to other elements (Figure 6). Shearing layers was created by Frank Duffy, who outlined four fundamental components: shell, services, scenery, and set [15]. Each layer has its own distinct lifespan, which can be sustained within a unit. In 1994, Stewart Brand expanded upon and solidified the shearing layers model currently employed. This model has six elements: structure, systems, partitions, things, site, and exterior [15].

Figure 6.

The shearing layers model provides a new way of thinking about construction, where each element of a building is simply an independent layer that can be updated without disrupting other aspects.

In the shearing layers model context, “stuff” encompasses many objects within a home, such as chairs and appliances. Homeowners commonly update these items periodically [15]. Space plan pertains to the arrangement and layout of the unit’s interior, including elements such as internal walls, entrances, ceilings, and floors. The projected durability of this layer ranges from 3 to 10 years. Services encompass essential components required for the proper functioning of a residence, such as electrical wiring, plumbing, and Heating, Ventilation, and Air Conditioning (HVAC) systems [16]. The duration of this layer is between 10 and 20 years. Furthermore, the term “skin” pertains to the outside surface of a dwelling, encompassing elements such as facades and roofs. The duration of this layer is between twenty and fifty years, as stated by Pushkar and Shaviv. The term “structure” in the context of a home pertains to the foundation and components responsible for supporting the weight of the building. The durability of this layer might range from 50 to 300 years [15]. The site refers to the specific physical location where the unit is situated. The perpetuity of this phenomenon is evident, as even in the event of demolishing an existing unit, a new one may still be constructed in the same location [15].

The shearing layer model distinguishes between longer-lasting “durable layers” (such as the site, structure, and skin of a building) and shorter-lasting “service layers” (like services, space planning, and movable items). Changes to short-lasting elements can occur with minimal impact on the more enduring aspects of a building. For instance, updating the flooring affects only the room’s layout and necessitates moving furniture, leaving other parts of the building untouched. Conversely, alterations to durable layers, like foundation repairs, can have wide-reaching implications, potentially requiring removing and replacing otherwise functional components like flooring and plumbing. Understanding the lifespan of each layer is key to grasping a building’s lifecycle and designing systems that minimize waste.

Moreover, the layer model allows for the removal or replacement of systems without excessively affecting adjacent layers. A multitude of utilities are consolidated in a unified sequence, facilitating convenient access. Usually, utilities run beneath the floor and can be challenging to move and reach. Substituting services might incur significant expenses, require a substantial amount of time, and include intricate processes.

Domus Ex Machina was designed with the shearing layers model in mind to incorporate an open-web floor joist system throughout all levels of the house (Figure 7). All services will be consolidated in a single accessible chase underneath this system, uniformly present on every level and home type. This enables the services to be conveniently located and accessible via floor traps, and they may be substituted or fixed without causing harm to the flooring above. This pursuit incorporates several services, including plumbing, internet connections, ventilation, and power. In addition to the plumbing pipes running beneath the readily exposed floor chase, all significant plumbing systems are situated on the same common wall. This enables easy access to the systems if any plumbing concerns arise (Figure 8).

Figure 7.

The utility services pass underneath the flooring along the path indicated in this drawing.

Figure 8.

The chaser is a continuous path in the floor where the utility lines are installed (left). The common utility wall between the bathroom and the kitchen (right).

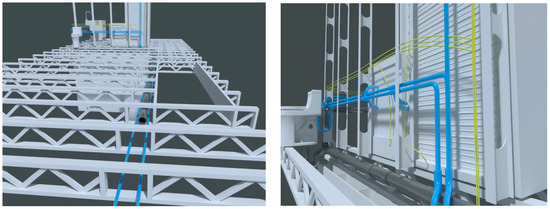

Additionally, the kitchen is equipped with a removable storage unit with separate bins to facilitate garbage sorting and recycling. Garbage sorting entails examining the entirety of the garbage and extracting recyclable materials for proper disposal. The storage facility also encourages the practice of household recycling by easing the sorting of garbage (Figure 9).

Figure 9.

The kitchen recycling storage unit promotes household recycling habits by facilitating waste sorting.

Standalone wood cabinets, an alternative to traditional closets, are another aspect of Domus Ex Machina meant to reduce demolition waste and contribute to circularity. Manufacturing these cabinets entails the process of repurposing engineered wooden products and recycling them when their useful life has ended. Ideally, their materials will be reclaimed and used for subsequent goods (Figure 10).

Figure 10.

The storage cabinets of Domus Ex Machina involve reusing and recycling the materials and redesigning them into usable and visually appealing cabinetry for the occupant.

As part of the home’s utilities, electricity is an indispensable component, and its availability has grown progressively crucial with the proliferation of wireless devices. The design of Domus Ex Machina replaces the practice of passing wires in the dwelling’s wall with baseboards at the bottom of the wall, where wires in a special chaser will be installed. The convenient availability of electrical systems and access points may be designed, added, or eliminated according to the specific requirements of the occupant. It also simplifies the replacement or repair of wires should the need arise. In general, including Brand’s layers model in the design enhances circularity by minimizing waste by avoiding disruption to other layers during the repair of service layers [17]. This feature also enhances the home’s flexibility, since it allows for easy modifications without the risk of damaging other components of the house (Figure 11).

Figure 11.

The easily accessible electrical system allows wiring to be added or removed as needed.

5. Design for Disassembly (DfD) in Domus: Prefabrication, Dry Connection, and Demountable Partitions

A crucial factor in a home’s circularity design is the responsible demolition of a house or part of it, focusing on minimizing waste. Presently, when buildings are demolished, most of their materials are often irreparable and are disposed of in landfills. Design for disassembly (DfD) is an approach that considers the whole lifespan of a structure and clearly defines a method for its dismantling [18]. Deconstruction is a process that takes place after a structure reaches the end of its lifespan. It entails carefully taking apart the building to allow the elements to be reused or upscaled into new materials [18,19]. DfD is inherently linked to the circular economy since it reduces construction waste, incorporates many aspects of it, and consists of five fundamental concepts [20]. As Figure 12 shows, the flow starts with the extraction of raw materials, which are then sent to the refining process [21]. The refined materials are used for building or manufacturing new products. Once in use, products may either generate waste or enter reuse and recycle pathways. Reused materials directly reintegrate into the system, while recycled materials return to the refining process. Any waste that cannot be recovered is sent for disposal. This diagram emphasizes sustainability and resource efficiency, illustrating the importance of circular design to minimize waste and maximize material recovery. Before initiating the deconstruction process, it is imperative to thoroughly record and document all building components, including their corresponding deconstruction methods [22]. Multiple techniques can be enumerated for each substance. Generally, this stage serves as a fundamental blueprint for breaking down various components in a unit. Furthermore, the design of connecting and joining components should prioritize the ease of deconstruction [8]. This might entail utilizing bolts, screws, nails, or modular components instead of relying on chemical bonds or welding [17,20,21]. Furthermore, it is important to segregate non-recyclable, non-reusable, and non-disposal materials, namely mechanical, electrical, and plumbing (MEP) systems. For DfD, a straightforward approach is to employ a basic design with standardized components and sizes. This is because standardized pieces are the most convenient to reuse. Furthermore, the design should accurately represent labor habits, productivity, and safety measures [23,24].

Figure 12.

Design for disassembly (DfD) is inherently connected to the circular economy since it reduces construction waste and incorporates many aspects of circularity.

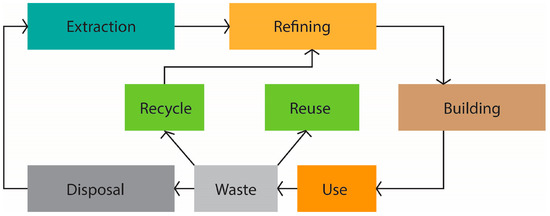

Domus Ex Machina is an example of DfD, utilizing prefabricated and modular elements to simplify the process of construction and deconstruction. This approach is evident in the construction of floors, external and internal walls, and roofs, which minimizes construction waste and aligns with circular economy principles, such as waste reduction and material reuse [25,26]. Due to the limited range of partitions available, it is more convenient to retrieve a panel from one residence and repurpose it in another. Moreover, the utilization of standardized partitions simplifies the process of implementing redesign and remanufacturing [25,27]. Demountable walls can be installed either during construction or later to change the arrangement easily and rapidly [27]. Enabling purchasers to participate in the design process can enhance circularity by providing them with more foresight regarding their usage and occupancy duration of the property.

Furthermore, Domus Ex Machina is constructed using the dry connection building method. This implies that prefabricated components are specifically engineered to seamlessly interlock with each other, eliminating the requirement for drywall installation, plaster, and paint. Figure 13 shows a modern, minimalist interior with prefabricated modular elements designed for efficient assembly without traditional drywall and paint. The walls, built-in shelving, and cabinetry appear to be composed of pre-finished panels that seamlessly clip together, eliminating the need for wet construction processes. This expedites the construction process while promoting a design that facilitates disassembly, as components may be readily dismantled. Modular pieces will maintain their structural integrity, facilitating the recovery cycle and rendering them highly suitable for reuse. Domus Ex Machina generally employs deliberately engineered modular components that can be effortlessly installed, dismantled, substituted, and repurposed across multiple versions. These features enable the application of many aspects of circularity.

Figure 13.

Prefabricated elements are designed to allow for clipping them together instead of needing drywall and paints.

6. Reducing Carbon Footprint and Saving Energy Usage

The design of Domus Ex Machina incorporated energy efficiency as a key consideration to lower its carbon footprint. In addition to the range of sustainable choices available to consumers, the home incorporates sustainable elements in its construction. This encompasses materials that have either a minimal amount of embedded energy required for production or are made from recycled resources. Such materials comprise synthetic roof slate, recycled concrete, particle board, wood joists, recycled metal siding, wood siding, permeable brick paving, linoleum, engineered wood flooring, a crushed gravel stabilization system, carpet made from recycled bottles, and recycled glass countertops. The benefit of reusing these materials is the considerable energy savings compared to producing new materials, which usually demands more energy and leads to increased carbon emissions. This benefit is quantifiable through the formula for calculating embodied carbon emissions per unit. Formula (1):

Embodied Carbon Emission = carbon factor × area × thickness × density.

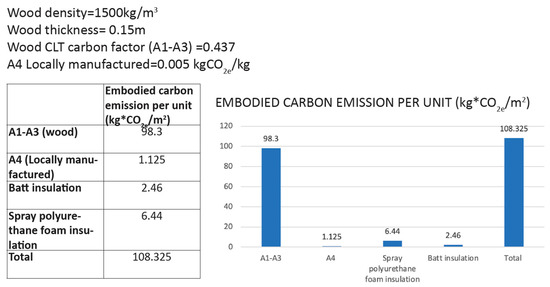

As Figure 14 shows, the A1–A3 manufacturing stages for wood result in 98.3 kgCO2e/m2. Transportation (A4 stage) locally adds 1.125 kgCO2e/m2, while the embodied carbon for batt insulation and spray polyurethane foam insulation stands at 2.46 and 6.44 kgCO2e/m2, respectively. Consequently, the total carbon emissions associated with building a home amount to 108.325 kgCO2e/m2. By reusing materials at the end of a building’s lifecycle, the same amount of carbon emissions (108.325 kgCO2e/m2) can be saved, underlining the significant environmental benefits of material reuse.

Figure 14.

Calculations of embodied carbon emission at different stages.

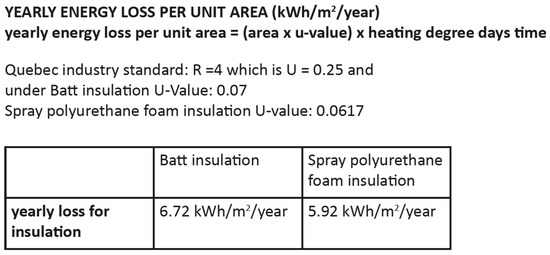

The notion of energy efficiency is closely connected to circularity since it incorporates the reduction principle. In general, the process of heating and cooling a home requires a significant amount of energy. The home’s narrow and lofty structure optimizes air circulation within the interior. The facades are constructed using high-quality materials to effectively insulate the building, preventing exterior temperatures from affecting the interior and reducing the amount of energy required for heating and cooling, thereby ensuring a suitable indoor temperature. The efficiency of these insulated facades can be quantitatively assessed through a formula that calculates yearly energy loss per unit area. Formular (2):

yearly energy loss per unit area = (area × u-value) × heating degree daytime; for Domus Ex Machina, this calculation yields an energy loss ranging from 5.92 kWh/m2/year to 6.72 kWh/m2/year.

Figure 15 shows a significantly lower energy loss than traditional housing, which indicates a substantial improvement in energy efficiency. Traditional buildings, often lacking in adequate insulation, face higher energy demands for temperature control. The reduced energy loss in Domus Ex Machina exemplifies how modern construction practices can lead to more sustainable living environments by significantly cutting down energy requirements.

Figure 15.

Calculations of yearly energy loss per unit area.

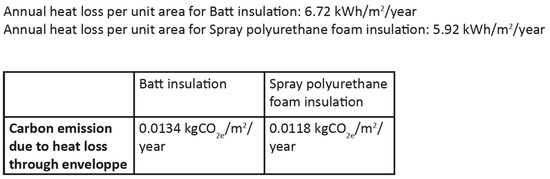

The envelope consists of 10 layers and is constructed in a regulated industrial environment to ensure the utmost quality of coverage. The 10 layers include cement boards, insulation, basement walls, polyethylene and external sheathings, gravel and crushed stones, perforated plastic drain tiles, a key, finish flooring and a subfloor, further insulation, and a concrete slab floor. Combining this shell with premium windows and doors results in exceptionally efficient insulation. To minimize the need for heating and cooling, choosing a suitable site and orientation for the residence is advisable, considering the prevailing wind direction and the quantity of shadow available. In addition, a semi-detached Domus Ex Machina is 36% more energy efficient, while the row home is 64% more energy efficient compared to the single-family home option (Figure 16). In addition, the reduction in energy loss leads to cost savings for occupants and contributes to broader environmental benefits. Lower energy consumption means reduced greenhouse gas emissions from heating and cooling, which is crucial for mitigating climate change. This relationship is quantified using the formula for calculating carbon emissions attributable to heat loss through a building’s envelope. Formular (3):

Carbon emission due to heat loss through envelope = annual heat loss per unit area × emissions factor.

Figure 16.

Calculations of heat loss through envelope.

For this analysis, the calculated carbon emissions range from approximately 0.0118 kgCO2e/m2/year to 0.0134 kgCO2e/m2/year. The energy-conserving strategies significantly diminish carbon footprints and reduce adverse environmental effects. Thus, when feasible, the row home choice most effectively fosters circularity by minimizing energy usage (Figure 17) [10].

Figure 17.

A semi-detached Domus Ex Machina is 36 percent more energy efficient, and the row home is 64 percent more energy efficient than the single-family home option.

Beyond reducing carbon emissions, landfill diversion plays quite a significant role in reducing other environmental pollutants. One obvious advantage is the lowering of leachate contamination, which results from rainwater seeping into landfills. It breaks down heavy metals and other compounds that might contaminate supplies of groundwater [28]. By recycling 1000 tons of building waste, it is determined that 3000 to 4500 cubic meters of leachate contamination is avoided, therefore preserving the water quality of surrounding ecosystems [28].

Building with recyclable materials also drastically reduces air pollution. Studies have shown that if 30 percent of new buildings in Canada used recycled materials, it could lower construction-related air pollution by 40 percent [29]. Reducing emissions of benzene, formaldehyde, and volatile organic compounds (VOCs) can lower the negative impacts on indoor air pollution and climate change [30]. Reducing these pollutants is hence a major public health concern, since they have been linked to environmental degradation, neurological diseases, and respiratory problems [30]. By promoting sustainable material reuse, thereby reducing total environmental effect, the building industry can greatly help to enhance air and water quality.

7. Economic Feasibility Analysis

Construction cost analysis is essential for assessing the economic sustainability of Domus Ex Machina. This method offers a complete financial assessment across the lifetime of the construction by including building construction costs, maintenance expenses, and dismantling and recycling costs. While operation and maintenance expenses cover energy consumption, water use, repairs, and normal maintenance, initial construction costs include expenses for material procurement, labor, design, and permits. Furthermore, included in the consideration are the financial and environmental effects of deconstruction, material salvage, and future use repurposing. To further demonstrate the economic viability of Domus Ex Machina, we compare key financial and performance metrics with conventional homes and other sustainable housing models (Table 1).

Table 1.

Financial comparisons between Domus Ex Machina and traditional homes.

The design strategies used by Domus Ex Machina include prefabrication, modular design, and the use of recycled materials. This leads to much lower initial and ongoing costs than traditional buildings, which can sometimes have high costs for running and shutting down. With prefabricated modular construction, the cost of labor can be cut by 40% and the time it takes to build can be cut by 30–50% [31]. This lowers the cost of funding. Trim waste can go from 10% to 25% of a building to less than 5% when it is built modularly [31]. According to the report from McGrath RentCorp, Inc., Livermore, CA, USA, designing a single-family home with 2200 mm modules and 610 mm stud spacing can save 8% of lumber. Using USD 10 per square meter of gypsum board in a 100-square-meter home can cut waste from 15% to 5%, which saves each unit about USD 100 [31]. Using modular sizes cuts down on the cost of materials, damage to the environment, trash in landfills, and the energy needed for production and shipping. By using passive design ideas, smart energy technologies, and good insulation, Domus Ex Machina homes can cut their energy bills by 50 to 70% compared to more traditional building styles. The idea also lowers the amount of trash that ends up in landfills and the cost of tearing down buildings by making parts that are easy to take apart. This way, 60–80% of the materials can be recovered.

Life cycle modeling shows that over the 50 years that they are built, Domus Ex Machina homes save 20 to 35 percent on costs compared to regular homes. This is because they cost less to run and dispose of at the end of their useful life. Another important economic and environmental benefit is that it cuts down on the cost of getting rid of trash and the overuse of dumps. Every ton of construction trash that is kept out of landfills saves USD 100 to USD 800 in disposal costs [32]. When working on big urban projects, tearing down buildings can reroute thousands of tons of waste, which could save millions of dollars in landfill fees [32].

Overall, these comparisons highlight Domus Ex Machina’s economic advantages, including lower upfront costs, shorter construction periods, reduced operational energy consumption, and significantly higher recyclability at the end of life.

8. Discussions

Because it calls for two independent hubs—one for collecting disassembled components and another for sales—the storage of materials from demolished structures poses logistical and spatial issues. Unlike conventional demolition, which throws away items right away, deconstruction entails methodically deconstructing and saving them for possible reusing. This requires a large space and organization, which are sometimes lacking in cities with limited industrial potential [33]. Managing non-reusable panels is a major challenge Nexii faces. It is a firm focusing on sustainable building materials [33]. While some materials can be used in new buildings, many panels might not satisfy structural criteria for reuse, which begs the question of how best to recycle or reinterpret them. These materials could still wind up in landfills without efficient solutions, running against the ideas of sustainable deconstruction.

Making the approach financially feasible depends on building demand for disassembled materials by public procurement. Uncertainty about whether buildings will be demolished and whether there will be enough demand for the salvaged materials is one of the main challenges facing local governments [34]. Municipalities can be reluctant to apply deconstruction rules without a definite market for recycled goods. The forestry sector clearly shows this difficulty, since businesses sometimes struggle to find consumers for recovered wood even if its sustainability advantages are great. By generating a continuous demand, circular procurement—a tactic where governments give buying recycled or reused materials first priority—may help solve this problem. For instance, the City of Richmond passed a bylaw mandating 75% of demolition materials to be recycled, which was supported by a circular procurement strategy run under its Sustainability Department [34]. Richmond models how public policy may drive demand and make deconstruction financially possible by requiring recycling and guaranteeing a market for recovered materials [34].

Regulatory obstacles hinder the acceptance of recycled products and complicate procurement processes. One main problem is the regrading of salvaged lumber: even if it is structurally good, it needs to be evaluated and certified before it can be applied in new buildings. Specializing in deconstruction, Unbuilders is funding R&D to enhance the regrading and certifying process for recovered wood [35]. Government rules must change, though, to enable the broad use of recovered materials even with technical improvements. Many building rules do not yet acknowledge reused lumber as equal to freshly milled wood, therefore posing administrative challenges for builders wishing to use sustainable resources. Clear national standards help to simplify the complicated web of provincial rules that companies must negotiate in order to scale down deconstruction projects.

One of the main challenges to large-scale deconstruction remains cost. Compared to standard demolition, deconstructing a building requires significantly more time and labor, leading to higher expenses. However, digitally assisted analysis can optimize disassembly design and help to reduce time and labor costs. The effectiveness of such analysis relies on the program’s ability to process explicit BIM data while also recognizing implicit connections that a human would naturally detect [36]. When planning building deconstruction, the relationships between BIM elements become particularly important. While most building analysis techniques define component relationships through formal rules, applications include multidisciplinary design optimization [36] and discrete structural analysis [37]. Additionally, rule-based analysis has been applied at the component level to address connections and construction sequencing [38]. These methods can model the interconnections between different component lifespans within a building and its overall adaptability [39].

Although deconstruction is made possible in great part by policy, uneven building rules and restrictions between several countries impede advancement. Vancouver, for instance, has set aggressive deconstruction and sustainability targets, but other cities have not yet embraced such programs [40]. The process is considerably more complicated at the provincial level, since building projects have to follow several overlapping rules. Like British Columbia’s energy step code, which advances energy-efficient development, governments are starting to include deconstruction in building rules [41]. Establishing a national strategy on recovered lumber would help to unify rules across provinces and simplify builders’ usage of sustainable materials. Still, regional variations in the utilization of reused concrete and wood create other problems. While some provinces lack the required testing facilities to certify recycled goods, others have tougher building safety rules that make it challenging to include salvaged materials. Developing rules that cut red tape will help companies and governments more easily use recycled materials in the building sector, therefore advancing deconstruction.

To guarantee the financial viability of resource recovery, market demand is vital. Major obstacles to deconstruction and material reuse today are supply chain inefficiencies and economic issues. One important but sometimes disregarded element of resource recovery is sorting building and demolition trash. Logistically, without specific facilities, items that could be used repeatedly wind up in landfills. Therefore, it is necessary to create a working supply chain for demolished goods. Governments and companies have to coordinate initiatives to link suppliers with consumers so that recovered materials—instead of being thrown away—find their way back into new building projects.

9. Conclusions

The dominant linear economic model applied in modern times is quite unsustainable. Regarding building, the procurement of new raw materials and the disposal of old ones release significant amounts of fossil fuels and create too much trash. Since design for disassembly (DfD) helps to restore and reinterpret used materials, it is naturally connected to circularity. Domus Ex Machina was ultimately displayed as proof of its adaptability to many sizes, configurations, and integrated technologies. With an eye toward circularity and its goals especially, the design also gives sustainability great thought at every level. Although deconstruction has economic and environmental advantages, major obstacles still exist in storage, procurement, control, cost, policy, and market development. The building sector can head toward a more circular and sustainable economy by putting smart public procurement strategies into effect, simplifying rules, creating automation, and so strengthening supply networks.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Mauch, C. Introduction: The Call for Zero Waste. RCC Perspect. 2016, 3, 5–12. Available online: http://www.jstor.org/stable/26241370 (accessed on 7 March 2025).

- Winans, K.; Kendall, A.; Deng, H. The history and current applications of the circular economy concept. Renew. Sustain. Energy Rev. 2017, 68, 825–833. [Google Scholar] [CrossRef]

- Asante, R.; Faibil, D.; Agyemang, M.; Khan, S.A. Life cycle stage practices and strategies for Circular Economy: Assessment in construction and demolition industry of an emerging economy. Environ. Sci. Pollut. Res. Int. 2022, 29, 82110–82121. [Google Scholar] [CrossRef] [PubMed]

- Coste-Maniere, I.; Croizet, K.; Sette, E.; Fanien, A.; Guezguez, H.; Lafforgue, H. Circular economy: A necessary (r)evolution. In Circular Economy in Textiles and Apparel; Woodhead Publishing: Sawston, UK, 2019; pp. 123–148. [Google Scholar] [CrossRef]

- Rüstemoğlu, H. Factors affecting Germany’s Green Development over 1990–2015: A comprehensive environmental analysis. Environ. Sci. Pollut. Res. 2019, 26, 6636–6651. [Google Scholar] [CrossRef]

- Lim, E.; Arita, S.; Joung, S. Advancing sustainable consumption in Korea and Japan—From re-orientation of consumer behavior to civic actions. Sustainability 2019, 11, 6683. [Google Scholar] [CrossRef]

- Alexander, C. Architecture, society and space—The high-density question re-examined. Prog. Plan. 1985, 24, 71–160. [Google Scholar] [CrossRef]

- Mazur, Ł.K. Circular economy in housing architecture: Methods of implementation. Acta Sci. Pol. Archit. 2021, 20, 65–74. [Google Scholar]

- United Nations. The 17 goals sustainable development. United Nations. 2023. Available online: https://sdgs.un.org/goals (accessed on 7 March 2025).

- Fatourou-Sipsi, A.; Symeonidou, I. Designing [for] the future: Managing architectural parts through the principles of circular economy. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2021; Volume 899, p. 012014. [Google Scholar]

- Morseletto, P. Targets for a circular economy. Resour. Conserv. Recycl. 2020, 153, 104553. [Google Scholar]

- Keena, N.; Friedman, A. Sustainable Housing in a Circular Economy, 1st ed.; Routledge: London, UK, 2024. [Google Scholar] [CrossRef]

- King, D. History of Asbestos. 2023. Available online: https://www.asbestos.com/asbestos/history/ (accessed on 26 January 2024).

- Hardy, J. The History of Asbestos. History Cooperative. 2021. Available online: https://historycooperative.org/the-history-of-asbestos/ (accessed on 26 January 2024).

- Brand, S. The Shearing Layers of Graphic Design Education. 2023. Available online: https://www.jarrettfuller.blog/2023/07/shearing-layers/ (accessed on 1 May 2024).

- Wilson, E.D. AC Feels Great, But It’s Terrible for the Planet. Here’s How to Fix That. Time. 2021. Available online: https://time.com/6077220/air-conditioning-bad-for-planet-how-to-fix/ (accessed on 26 January 2024).

- Fagone, C.; Santamicone, M.; Villa, V. Architecture engineering and construction industrial framework for circular economy: Development of a circular construction site methodology. Sustainability 2023, 15, 1813. [Google Scholar] [CrossRef]

- Dams, B.; Maskell, D.; Shea, A.; Allen, S.; Driesser, M.; Kretschmann, T.; Walker, P.; Emmitt, S. A Circular Construction Evaluation Framework to Promote Designing for Disassembly and Adaptability. J. Clean. Prod. 2021, 316, 128122. [Google Scholar] [CrossRef]

- O’Grady, T.; Minunno, R.; Chong, H.-Y.; Morrison, G.M. Design for disassembly, deconstruction and resilience: A circular economy index for the built environment. Resour. Conserv. Recycl. 2021, 175, 105847. [Google Scholar] [CrossRef]

- Gupta, N.; Kamal, M.A.; Brar, T.S. Exploration of prefabricated building system in housing construction. J. Build. Mater. Struct. 2021, 8, 19–31. [Google Scholar] [CrossRef]

- Pedro, J.; Sergio, G. Mountable and Demountable Construction Systems of Interior Building Partitions: Ecology and Sustainability in the Ephemeral Use of Space. In Sustainable and Digital Building; Gaspar, F., Mateus, A., Eds.; Springer: Cham, Switzerland, 2023; pp. 169–181. [Google Scholar] [CrossRef]

- Cutieru, A. A Guide to Design for Disassembly. ArchDaily. 2020. Available online: https://www.archdaily.com/943366/a-guide-to-design-for-disassembly (accessed on 25 January 2025).

- Smith, R.E. Mass Prefabrication: Investigating the Relationship Between Prefabrication and Mass Customization in Architecture. In Mass Customization and Design Democratization; Kolarevic, B., Duarte, J.P., Eds.; Routledge: New York, NY, USA, 2018; pp. 157–174. [Google Scholar]

- Mesa, J.A.; Esparragoza, I.; Maury, H. Trends and perspectives of sustainable product design for open architecture products: Facing the circular economy model. Int. J. Precis. Eng. Manuf. Green Technol. 2019, 6, 377–391. [Google Scholar] [CrossRef]

- Zhou, Y. Adaptable Prefabricated Interiors in Urban Dwellings; Unpublished M. Architecture Report; McGill University: Montreal, QC, Canada, 2019. [Google Scholar]

- Borrallo-Jiménez, M.; LopezdeAsiain, M.; Herrera-Limones, R.; Lumbreras Arcos, M. Towards a circular economy for the city of seville: The method for developing a guide for a more sustainable architecture and urbanism (GAUS). Sustainability 2020, 12, 7421. [Google Scholar] [CrossRef]

- Shroff, D.N.; Joshi, A.T. Pre-Fabricated Architecture for Urban Adaptability: Factory Built Constructions–Sustainable & Flexible Urban Solutions. Ph.D. Dissertation, Politecnico di Torino, Torino, Italy, 2022. [Google Scholar]

- Nagarajan, R.; Thirumalaisamy, S.; Lakshumanan, E. Impact of leachate on groundwater pollution due to non-engineered municipal solid waste landfill sites of erode city, Tamil Nadu, India. Iran. J. Environ. Health Sci. Eng. 2012, 9, 35. [Google Scholar] [CrossRef] [PubMed] [PubMed Central]

- Natural Resources Canada. Government of Canada. 2025. Available online: https://natural-resources.canada.ca/energy-efficiency/building-energy-efficiency/canada-green-buildings-strategy-transforming-canada-s-buildings-sector-net-zero-resilient-future (accessed on 7 March 2025).

- Pekdoğan, T. Evaluating the impact of building materials on indoor air quality: A critical analysis. Sak. Üniversitesi Fen Bilim. Enstitüsü Derg. 2024, 28, 824–843. [Google Scholar] [CrossRef]

- McGrath RentCorp, Inc. Ultimate Guide to Modular Construction. Modular Buildings Blog and Knowledge Center. 2024. Available online: https://www.mobilemodular.com/blog/guide-to-modular-construction#:~:text=The%20length%20of%20your%20modular,feet%20and%206%20inches%20high (accessed on 20 February 2025).

- Home Advisor. Cost of Junk Removal, Debris, Waste, & Trash Pickup. 2025. Available online: https://www.homeadvisor.com/cost/cleaning-services/remove-waste/ (accessed on 20 February 2025).

- Nexii Building Solutions. Discover Sustainable Building Solutions: NEXII building solutions: Green Construction Company. 2024. Available online: https://www.nexii.com/ (accessed on 20 February 2025).

- Shorthouse, P. Accelerating the Circular Built Environment Sector in Canada. Circular Economy Solutions Series. 2021. Available online: https://www.circulareconomyleaders.ca/wp-content/uploads/2024/03/Accelerating-Circular-Built-Environment-in-Canada-Workshop-Summary-Report-FINAL-1.pdf (accessed on 7 March 2025).

- Unbuilders. Measured Architecture. 2021. Available online: https://measured.ca/collaboration/unbuilders/ (accessed on 7 March 2025).

- Gordon, M.; Batallé, A.; De Wolf, C.; Sollazzo, A.; Dubor, A.; Wang, T. Automating building element detection for deconstruction planning and Material Reuse: A case study. Autom. Constr. 2023, 146, 104697. [Google Scholar] [CrossRef]

- Shea, K.; Cagan, J. Languages and semantics of grammatical discrete structures. Artif. Intell. Eng. Des. Anal. Manuf. 1999, 13, 241–251. [Google Scholar] [CrossRef]

- Essawy, Y.A.S.; Nassar, K. Elemental Graph Data Model: A Semantic and Topological Representation of Building Elements. Zenodo. 2024. Available online: https://zenodo.org/record/1132216 (accessed on 7 March 2025).

- Durmisevic, E. Transformable Building Structures. Design for Dissassembly as a Way to Introduce Sustainable Engineering to Building Design & Construction. Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands, 2006. [Google Scholar]

- City of Vancouver. Greenest City Action Plan. 2024. Available online: https://vancouver.ca/green-vancouver/greenest-city-action-plan.aspx (accessed on 7 March 2025).

- Government of British Columbia. Energy Step Code. Available online: https://energystepcode.ca/ (accessed on 7 March 2025).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).