Abstract

The non-corrosive properties of carbon fibres allow for slimmer concrete components, which may reduce CO2 emissions during production. Given that cement production contributes approximately 8% of global CO2 emissions, finding alternatives is crucial. Textile-reinforced concrete (TRC) employs technical textiles instead of steel reinforcements and has been extensively studied for its mechanical properties. Carbon’s high tensile strength allows for significantly reduced mass compared to steel while eliminating additional cover requirements. Although producing recycled carbon fibres (rCFs) is energy-intensive, it offers significant energy and raw material savings and can lower global warming risks compared to virgin fibres. This study investigates the potential of rCFs in various forms as concrete reinforcement, highlighting both opportunities and challenges based on experimental results and existing studies. The investigations demonstrated that rCFs, whether used as nonwoven or yarn reinforcement, enhance both the tensile and yield strength of concrete. Furthermore, in many instances, a gradual failure mode rather than an abrupt one is observed. Consequently, the use of rCF textiles as reinforcement in concrete presents significant potential for promoting sustainability within the construction industry. The integration of rCF into carbon concrete presents a promising pathway to enhance the sustainability of construction materials.

1. Introduction

Natural resources are a prerequisite for sustaining current and future life on our planet. However, many natural resources are only available in limited quantities [1]. Therefore, the protection of natural resources is also of existential importance for future generations. The term sustainability has now become a part of most areas of life, including the construction industry. The inclusion of sustainability is imperative because the construction sector is a prominent contributor to global CO2 emissions [2]. Some of the reasons for this are the use of fossil raw materials, long delivery routes, outdated construction methods and a waste system whose terminal destination is a landfill. Modern construction means that planners must be more oriented towards the users and the environment, respond to new needs, and build accordingly with the environment and the future in mind [2].

Concrete is the predominant building material and, worldwide, the second most utilised material after water [3]. Concrete primarily consists of cement, sand and water, with cement production being a significant source of CO2 emissions due to its energy-intensive process, contributing to 8% of worldwide CO2 emissions [4]. It boasts high compressive strength but has low tensile strength, which necessitates reinforcement with materials capable of withstanding tensile forces.

Steel is the most prevalent reinforcement material, providing high tensile strength to concrete components but with a major drawback: its susceptibility to corrosion. A thick concrete cover creates an alkaline environment to protect steel from corrosion, which increases concrete usage. The construction industry, including building maintenance and the lifecycle of construction materials, contributes to 38% of worldwide CO2 emissions [5]. Reducing these emissions is critical to achieving the Intergovernmental Panel on Climate Change’s objective of limiting global warming to a maximum of 1.5 °C [6]. The building sector, with its substantial contribution to greenhouse gas emissions, plays a key role in this effort. Given global population growth and urbanisation trends, the demand for concrete is expected to rise [4].

There are several strategies to achieve this goal at the building component level, including minimising resource consumption, using recycled materials and increasing service life. An approach that addresses all three is employing recycled carbon fibre (rCF) as a reinforcement alternative.

Textile-reinforced concrete (TRC) combines a concrete matrix with advanced reinforcement derived from technical textiles instead of steel reinforcements as a composite material. The viability of carbon when used as a reinforcement material has been extensively studied [7,8]. Carbon’s mechanical properties make it particularly suitable for reinforcement. The exceptional tensile strength combined with the low density of carbon fibre (CF) means that, compared to steel, only one-twentieth of the mass is needed to achieve the same tensile strength. Carbon is corrosion-resistant, eliminating the need for an additional concrete cover and potentially saving up to 80% of the concrete [9,10,11]. In addition, the technical service life of carbon-reinforced concrete components is predicted to be 200 years, more than double that of traditional materials [12,13].

TRC transforms the construction landscape by enabling the creation of thin-walled concrete elements with exceptional mechanical performance, which enhances resource efficiency and supports automated production, as shown by Scheurer et al. [8]. This innovative approach facilitates the effective retrofitting of existing structures, eliminating the need for complete demolition, while also allowing for double-curved architectural designs that traditional steel-reinforced concrete cannot achieve due to the flexibility of textiles. The integration of sensors and other functionalities into TRC textiles adds significant value, enhancing usability through the real-time monitoring of structural integrity and facilitating targeted retrofitting efforts. While many advanced applications have been demonstrated in research and pilot projects, the full market adoption of TRC technology is still underway [8].

Traditional disposal methods of carbon fibre-reinforced plastic (CFRP), such as landfilling and incineration, pose risks by generating harmful substances that can damage the environment. Therefore, utilising CFRP in construction offers a beneficial solution that addresses both economic and environmental concerns [14].

Producing CF is energy-intensive, requiring 198–595 MJ/kg. However, using rCF can reduce the global warming risk compared to virgin fibres. The energy consumption is less than 2.05 MJ/k for mechanical recycling, 3–30 MJ/k for thermal recycling and around 19.2 MJ/k for chemical recycling [15]. The quality of rCFs is lower than that of virgin fibres as they are no longer continuous fibres, but the mechanical properties are similar, and they can be processed into semi-finished textile products [16]. Producing yarns and nonwovens from rCFs shows significant promise [16].

This study aims to explore the use of rCF nonwovens and yarns as reinforcement in concrete. rCF consumes less energy compared to producing conventional steel reinforcement or carbon filaments from primary raw materials [16]. Consequently, rCF reinforcement offers potential energy and raw material savings. The non-corrosive nature of carbon fibres allows for slimmer concrete components compared to those reinforced with steel, potentially reducing CO2 emissions during production [7,13]. The aim of this study is to investigate the use of rCFs in different forms of delivery as reinforcement in concrete. The potential and current challenges are explained based on our own test results and existing studies.

2. Carbon Fibre Recycling

Manufacturing CF is an energy-intensive process, which means that CFs have high recycling capability from environmental and economic perspectives [17]. The energy consumption of virgin CF (vCF) production is 198–595 MJ/kg. Compared to virgin fibres, rCF has a lower energy consumption and lower costs [14,15]. To reduce the energy required, it is reasonable to use CF after the first life cycle again. Therefore, a recycling process for the recovery of used fibres is required. In Table 1, the advantages, disadvantages and characteristics of different recycling processes are summarised.

Table 1.

Advantages, disadvantages and characteristics of various fibre recycling methods according to [14,15,18,19,20].

2.1. Mechanical Recycling

As stated in [20], slow-running cutting mills break down end-of-life components into pieces measuring between 50 mm and 100 mm. In contrast, fast-running mills generate fragments with sizes ranging from 50 µm to 10 mm for homogeneous components [20,21]. The first investigations of mechanical laminae separations of laminated composites were made by Imbert et al. to obtain longer recycled CFRP pieces [22].

Mechanical shredding is often preceded by thermal or chemical recycling processes [21]. Therefore, mechanical recycling processes are categorised as pre- and post-treatment processes for waste containing carbon fibres in the recycling sequence [21]. The process involves shredding, sorting, compacting and pelletising waste containing carbon fibres. This process step must be applied to both end-of-life waste and prepreg materials made from carbon concrete. Prior to shredding, the end-of-life products containing carbon fibres, such as car body components, rotor blades or textile concrete, must be shredded into small, manageable pieces. Production waste is processed directly or shredded, depending on its size. CF waste is then cut into short fibres in granulators or reduced to particles in various mills, such as hammer mills, jaw crushers or impact mills [23].

Hammer mills crush materials with several hammers arranged along a grinding path of the rotor axis, allowing control over particle size through screen size. Hammer mills are frequently utilised for coarse and medium size reduction, while jaw crushers involve feeding the materials to be crushed between two plates and crushing them through compressive stress [24,25]. The jaw crusher is suitable for initial coarse to medium crushing. On the other hand, in the impact mill, the material to be ground is fed in from above through a feed hopper and comminution is performed. This process is used for medium size reduction [24,25].

To separate and classify waste into powdery and fibrous components, screens, laser diffraction spectrometry or image analysis are commonly used. Dry waste is typically shredded using grinding units with cutting and shearing functions. When treating wet waste containing carbon fibres, mechanical recycling requires sorting to occur first. Mixing different polymers during the recycling process makes it more difficult to release fibres as they are treated with different process parameters such as temperature and pressure. This results in a reduction in quality [23].

It is not possible to completely separate the resin from the CF with mechanical stress; therefore, the mechanical recycling of wet CF waste is a process in which no individual fibres are recovered. During the recycling process, only the dry and wet waste containing carbon fibre is shredded, and the resulting components are separated based on particle size. The shape and size of the shredded components vary depending on the mechanical shredding method used, which can significantly impact subsequent carbon fibre treatment processes. This process is known as the degradation of carbon fibre.

Isa and Nosbi et al. [26] addressed the degradation of CF during mechanical recycling. The authors emphasised the necessity of degradation studies to assess the mechanical properties of waste containing CF. In the context of this paper, degradation studies refer to the process of the degradation of mechanical properties. Fine-grained waste has the potential to be reused as a reinforcing material in the original matrix application. In contrast, the reinforcing properties of the coarse-grained recyclate are lower compared to vCF [26].

Studies have shown that fibre shortening and damage to the fibre structure during the recycling process result in brittle rCF compared to vCF. Additionally, mechanical rCFs generally have a lower tensile strength and modulus of elasticity than vCF. This reduction in mechanical properties is caused by the recycling process, which leads to damage to the fibre structure. Mechanical shredding causes fibre shortening, which makes it difficult to use rCF [17,18,27]. As Li et al. summarised in [14], mechanical recycling is suitable for glass fibre-reinforced polymers, rather than CFRP. For CFRP recycling, methods are preferred in which the fibres are separated from the matrix and then obtained in fibre form.

2.2. Thermal Recycling

Thermal recycling processes are used to separate CF from thermoplastic matrices in particular [14]. Two procedural options for thermal recycling are the fluidised-bed process and pyrolysis [20]. Both of these processes are described in more detail in the following.

Pyrolysis is a thermal recycling process that separates fibre and matrix through the thermal decomposition of the fibre-binding polymers. The process is carried out at temperatures ranging from 300 to 800 °C under various atmospheric conditions, such as inert gas. The temperature resistance differences between the CF and matrix materials are utilised for the decomposition of the matrix material, which produces oily, solid and gaseous products. The gases in question are primarily composed of carbon monoxide, CO2 and other hydrocarbons. These gases are recycled in a condenser and used as furnace fuel or separated into solid and liquid hydrocarbons. The recirculation of combustible gases causes solid coke residues to adhere to the furnace surfaces, which negatively impacts further processing options. The incomplete exposure and damage of the rCF due to the unclear preparation of the composite material poses a problem when using pyrolysis [28].

Pyrolysis recycling is the only technology currently in use at an industrial scale [14]. Applying pyrolysis on an industrial level presents a challenge as the CF to be recycled often consists of a variety of starting materials, each requiring different temperatures for effective fibre recovery. However, the process is flexible and can be adapted to various fibre–matrix combinations by optimising the process parameters [28,29]. Classic pyrolysis is a process carried out under inert gas, such as nitrogen. The process temperatures depend on the matrix. For polyester resins, low temperatures (approx. 450 °C) are used, while epoxies or thermoplastics are treated at higher temperatures between 550 and 650 °C. Thermal treatments below 450 °C are beneficial as they cause minimal damage to the fibre surfaces and have little effect on the mechanical properties. However, lower temperatures result in longer process times, which can make economic implementation more challenging.

The pyrolysis process presents a challenge due to the formation of soot on the rCF, rendering resulting fibres unsuitable for further processing into yarns or new reinforcement structures. Furthermore, the interfacial bonding is negatively affected [14]. Finding a compromise between the resulting mechanical properties and the remaining matrix residue is necessary as complete soot removal is not possible afterwards. Chemical post-treatment or post-heating of the rCF contributes to a certain reduction of the carbon black [14,27].

Onwudli et al. and Kim et al. investigated the reduction and complete avoidance of soot formation using pyrolysis techniques under different atmospheric conditions. Significant improvements in the composite material were achieved through chemical treatment with additives and light oxidation post-treatment of rCF [14,20,30]. The addition of ZnCl2 as a catalyst in the pyrolysis process reduced the degradation temperature to below 400 °C while retaining 95% of the tensile strength compared to vCF [31].

Over the past two decades, the potential of microwave-assisted pyrolysis has been investigated. It is purported to be a more expeditious, energy-efficient and efficacious method of producing rCF that additionally has a cleaner fibre surface [14]. Another way to produce cleaner fibre surfaces was investigated recently by the use of super-heated water streams in addition to the pyrolysis process [14].

The fluidised bed process is an effective thermal recycling method for recovering CF from polymer composites. This technique involves suspending particulate matter, typically the composite material, in a rising stream of gas, usually air, which creates a fluid-like state and a silica bed. Within this system, the organic matrix is decomposed in the combustion chamber at temperatures generally ranging from 450 °C to 550 °C. The elevated temperatures cause the polymer matrix to decompose, while the carbon fibres are preserved due to their high thermal stability [14,15].

One of the main advantages of the fluidised bed process is its ability to handle mixed and contaminated waste streams, providing a versatile solution for composite recycling. The resulting carbon fibres often retain a significant portion of their original mechanical properties, allowing them to be used in a range of secondary applications [15]. Compared to the pyrolysis process, rCFs from the fluidised bed recycling process have less fibre strength due to the presence of sand [14].

2.3. Chemical Recycling

Solvolysis is a chemical recycling process that dissolves the matrix from the CF using solvents. In comparison to pyrolysed rCF, the rCF surfaces are clean after the recycling process and the rCF mechanical properties are comparable to those of vCF [14]. To increase the surface area for the chemical recycling process, CFRP components are typically mechanically ground before chemical recycling. The processes are divided into low-temperature solvolysis and solvolysis with supercritical fluids [20].

Low-temperature solvolysis is a process that recycles CF under normal pressure at temperatures below 200 °C. Acids or solvents, such as water, alcohol, ammonia, nitric acid or sulphuric acid, are used to separate the fibre from the matrix. Catalysts and additives must be used due to the low process temperatures. The mechanical properties of the recovered fibres and resin are almost identical to those of the original materials. Unlike the pyrolysis process, the matrix resins are also recovered in addition to the fibres during decomposition. The resins that have been recovered can be reused either as fuel or as a chemical raw material [18]. The solvolysis process has the capability of obtaining long fibres but it presents challenges due to the use of harmful substances and the long process time [18,32,33].

Supercritical fluids are used to separate CF from the matrix in CFRP. For example, supercritical water is used with a pressure of 221 bar and temperatures over 374 °C. Besides supercritical water, other solvents, such as different alcohols (methanol, ethanol, propanol), are used with lower pressures and temperatures for the separation of CF and different matrices. But, recycling with supercritical fluids requires reactors that withstand high temperatures as well as high process pressure. Therefore, it is considered a more expensive recycling method due to the required equipment and the necessary processing energy [14].

Recently, electrochemical recycling was investigated for extracting rCF from CFRP. To retain the rCF properties, the parameters of current, temperature and concentration have to be elected properly. This recycling method is considered more sustainable and cost-effective [14].

2.4. Properties of Recycled Carbon Fibre

Nevertheless, the extent of this reduction of the material properties of rCF and vCF is marginal. Table 2 presents a material properties comparison and evaluates them as a percentage. The CFs that are commonly used in the construction industry were used as representatives of vCF.

Table 2.

Quantification of the remaining material properties of CF after recycling [34,35,36].

Currently, there are no known recycling methods that can be used on an industrial scale for CF that allow the fibre to be recovered without shortening its length. Therefore, rCF is typically sold in ground form or as short fibres of varying lengths ranging from less than 100 µm to several centimetres. During the pyrolysis process, any residues from the original composite matrix, impregnation or sizing are typically removed from the rCF. Even in this state, rCF retains 80% of the tensile strength of vCF [23,37]. Accordingly, the main quality losses are not caused by pyrolysis but by the significant shortening of the carbon fibre during recycling.

Due to their mechanical properties, CFs are ideal for use in composite materials in various forms of semi-finished textile products (woven fabrics, scrims, braids, etc.) [38]. The processability in different processes is influenced and partly limited by the fibre lengths. This means that for use in injection moulding or as an additive, maximum fibre lengths limit use. In contrast, for yarn or surface production processes, the processability is limited by a minimum fibre length. The term ‘short’ defines different length ranges depending on the fibre application. In textile and man-made fibre technology, fibres with a length of <40 mm are referred to as short staples, whereas, in plastics technology, fibres with a length of <6 mm are defined as short fibres [38]. The definition of fibre length varies depending on the application. In Table 3, a list of the terms used in this paper is given.

Table 3.

Fibre types sorted by length and application in the construction industry [10].

Milled CFs are produced by mechanical mills and chopped fibres are produced by mechanical separation processes. Ground fibres are in powder form and have a length of less than 0.5 mm [38]. Chopped fibres have a fibre length of more than 0.5 mm. Depending on the parameter settings, the fibre length varies during the cutting process. Milled and chopped fibres are mixed into plastic to, for example, improve the mechanical properties and conductivity of the composite material.

For example, long fibres can be used in the dry-laying process to produce CF nonwovens. A CF nonwoven is defined as a flat, semi-finished product consisting of nonwoven made from CF. In the dry-laid process, the CF is laid on a substrate and then impregnated with a binder or resin [38,39].

Composite materials have been used in the construction industry for centuries. The principle of combining different materials has been continuously developed, from simple building materials like clay and straw. Textile reinforcement elements made of non-metallic fibre materials represent a new generation of reinforcement for concrete components [Sch07]. In addition to alkali-resistant glass fibres (AR-GF), CFs are particularly suitable for use in concrete due to their chemical resistance.

3. Materials and Methods

In this work, different rCFs were tested as textile reinforcements in concrete. The results are presented in Section 4.2. Two nonwovens with different manufacturing processes were tested. Firstly, the nonwovens were pre-impregnated with the matrix in order to increase the textile–matrix bond. In the second manufacturing process, another production variant was used: the two nonwovens were embedded in the concrete using the lamination process, but, as an addition, before the second layer of concrete was added, the nonwoven was manually pressed into the first layer of concrete using a roller. In the third variant, the nonwoven was cut into stripes beforehand and was therefore not embedded over the entire concrete but only as reinforcement strips in the laminating process. Reinforcement with unreinforced slivers in the concrete was also investigated. The specimens were also produced by the laminating process. The slivers were an intermediate product in the production of rCF yarns. Two different rCF yarns, friction and wrapping yarn, were also tested as part of the investigations. The test results of the nonwoven and yarn variants have been published by the authors previously in [40] but are analysed further in this paper. Finally, the use of yarn fragments after recycling was tested as a possible 3rd rCF life cycle.

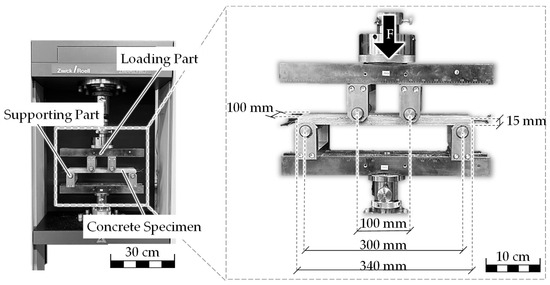

In this work, the four-point bending test of the specimen tested at Institut für Textiltechnik of RWTH Aachen University (ITA), Aachen, Germany adhered to DIN EN 1170-5 [41] for measuring bending tensile strength (shown in Figure 1).

Figure 1.

Four-point bending test according to DIN EN 1170-5.

Elongation was measured during the flexural test by reference to the displacement of the loading member during the four-point bending test. Samples with a size of 34 × 10 × 15 cm3 were produced for each series of tests. The fine concrete mix used was formulated based on an investigation carried out by Brockmann in sub-project C1 of the Special Research Area (SFB) 532 “Textile Reinforced Concrete” at RWTH Aachen University [42]. Within the scope of this paper, this composite is referred to as TRC in the following, though it is also occasionally designated as textile-reinforced mortar or fabric-reinforced cementitious matrices [7]. The quantities and volume proportions of all solid and liquid components are given in Table 4.

Table 4.

Fine concrete mixture.

The samples produced were stored in the mould for 24 h before being demoulded. Afterwards, they were stored in water for approximately 6 days and a further 21 days in room climate before being tested at the age of 28 days.

4. Application of Recycled Carbon Fibre in the Construction Industry

Table 5 gives an overview of different textile versions of rCFs in the construction industry.

Table 5.

Recycled carbon fibre textile application variants: (a) fibre reinforcement; (b) nonwoven reinforcement; (c) textile reinforcement.

4.1. Fibre Reinforcement

Fibre-reinforced concretes (FRCs) belong to the class of building materials known as fibre-reinforced composites. The production process involves adding short fibres ranging from 10 to 40 mm in length to fresh concrete and evenly distributing them in the cement matrix during mixing [43]. The resulting FRC components can be cast or shotcrete and are shown schematically in Table 5. Both standard installation methods create an undirected, three-dimensional reinforcement structure. The random and stochastic distribution of the CF in the concrete results in isotropic material properties in the component [10,44].

The fibre reinforcement typically does not have a structurally load-bearing function in the component, but it does improve both the load-bearing behaviour and the concrete properties of the composite material. This results in the following changes in the material [10,45]:

- Increase in tensile and compressive strength

- Increase in impact resistance

- Increase in ductility

- Avoidance of shrinkage and shrinkage cracks during setting

- Avoidance of cracking in use/reduction of crack widths

- Increased weather-tightness

- Increased fire safety

FRC can be used for almost all types of construction in building construction and civil engineering, both as in situ concrete and in prefabricated construction. The shotcrete construction method is mostly used in specialised civil engineering or repair work [45,46].

There are several problems with the use of CF compared to other macro fibre types that are mainly used. The low density of CF can cause the fibres to float, resulting in varying material properties across the cross-section of the overall component. Additionally, using high fibre volume contents can lead to a change in the consistency of the fresh concrete. The use of rCF in concrete reduces the workability of the concrete [14].

However, the technical advantages of CF in carbon fibre-reinforced concrete (CFRC) lie in its high tensile strength, which allows for the achievement of high strengths in the composite material. Furthermore, the chemical resistance of this material makes it suitable for use in environments that are humid and contaminated with chloride [10].

Despite these design advantages, the use of CF as CFRC is not yet established on the market due to its high cost [46]. Additionally, shortening the endless vCF does not make technical sense. Currently, research is being conducted on the alternative use of rCF for application in FRC [10].

The production of recycled CFRC (rCFRC) is the simplest method of using rCF as an aggregate in FRC. This method only requires the fibres to be recovered from the original matrix material and possibly resized, without the need for processing them into semi-finished textile products.

CFRC is produced by mixing short fibres into fresh concrete, which affects both its fresh and hardened properties. Kimm [10] identified fibre volume content and length as relevant parameters for the resulting properties of rCFRC. As part of the dissertation, the influence of fibre length variation and material on rCF was investigated [10]. Further investigations evaluated the effect of surface modification on rCF adhesion to the concrete matrix and fibre distribution in fresh concrete [10,47].

The properties of FRC are influenced by parameters such as fibre volume content, fibre length and surface modification. A non-linear relationship exists between fibre volume content and flexural tensile strength, with a critical threshold beyond which strength decreases, ranging from 0.5% to 1.0% by volume, depending on fibre length. Longer carbon fibres (>20 mm) improve flexural strength across all tested volumes (0.25–2.0%), achieving increases of 1.3–2.5 MPa compared to shorter fibres (<20 mm). The maximum recorded strengths were 8.47 MPa for short recycled carbon fibres (rCFs) at a 1% volume and 10.32 MPa for long rCFs at 0.5%, exceeding conventional FRC strengths by 40%. Analyses of fibre length variation showed no significant impact on flexural tensile strength when standard deviations were below or above 10 mm; however, extreme fibre contents resulted in over 10% standard deviations in strength. Within the optimal range of 0.5–1.0% by volume, variations in rCF length did not affect the flexural tensile strength of the specimens [10].

Li et al. compared various studies and found that the inclusion of pyrolysed carbon fibre, although it reduces workability, enhances both the flexural and compressive strength of cement-based materials at room and elevated temperatures, with 1% being the optimal dosage. This addition also benefits the strength development in alkali-activated materials. Furthermore, chemically rCFs have also shown an increase in strengthening cementitious matrices. Nevertheless, further research is required to optimise the chemical recycling of rCF for practical use in the construction industry [14].

The objective of a subsequent study was to analyse the fibre–matrix adhesion of rCF in concrete [48]. The utilisation of pyrolysed unsized or acrylate-sized fibres facilitated an enhanced fibre–matrix adhesion, exceeding the adhesion observed for vCF. In general, these pyrolysed fibres demonstrated superior absolute and average shear strengths. Notably, an increase in apparent interfacial shear strength between 150 and 250% was observed in comparison to vCF. In comparison, Li et al. stated that the inferior bonding behaviour of rCF compared to vCF exhibits less adhesive behaviour with cement [14]. It appears that the addition of sizing has a beneficial effect on the homogeneity of the fibres, as evidenced by the consistency observed in the apparent interfacial shear strength values for sized fibres, without the presence of outliers. The fibre distribution affects the resulting strength values. In the event of fibre agglomeration, the bond between fibres facilitates their extraction rather than direct fracture at the fracture edge. The distribution of fibres within cells results in a strong bond between the fibre and matrix within composite components, which can cause fibres to break at the breaking edge [48].

The findings demonstrated that the sizing type, in addition to the resulting fibre–fibre adhesion, influences the test outcomes. When fibres undergo resizing subsequent to pyrolysis, they demonstrate a reduced capacity to adhere to one another in comparison to vCF fibres treated with sizing during the production process and were subsequently cut to short fibres [48].

Li et al. showed that acidic and alkaline treatments enhance the bonding of mechanically recycled carbon fibres with mineral matrices, thereby improving composite properties. Surface modification is of particular importance for inert pyrolysed fibres, with variations based on recycling methods influencing the selection of an appropriate treatment. For pyrolysed fibres, electrochemical modification and oxygen plasma treatment were compared. Chemical recycling could achieve fibre recovery and modification simultaneously. But, regardless, fibre surface modification was crucial for hydrophobic rCF. Li et al. stated that further research is required to improve fibre–matrix stress transfer efficiency in cement-based composites [14].

In terms of the durability of rCF in FRC, further investigation is needed. Regarding durability, there is still a lack of publications on the use of rCF in cementitious matrices as well as the use of rCF in alkali-activated composites [14].

4.2. Textile Reinforcement

‘Textiles’, according to the standard [49], is the collective term for textile fibres, semi-finished products and finished products made of textiles. This study examined textiles based on recycled carbon fibres with untreated and treated rCF at the fibre level for use in fibre-reinforced concrete. At the semi-finished product level, linear and flat structures were distinguished. Staple fibre yarns were examined at the linear level. Nonwovens were flat, semi-finished products that were examined at the textile level.

Different rCF textiles were used for the reinforcement of concrete. Nonwovens were used as whole, flat textiles and also cut into stripes and yarns as one-dimensional reinforcements. As part of this research, other rather unusual variants for the use of rCF as reinforcement in concrete were investigated. Variants that had fewer process steps in textile production were tested. The approach aimed to make better use of the fibre orientation and position of the fibres in relation to the mechanical properties than with isotopically distributed fibres in the FRC. Slivers from a pre-production process in the nonwoven production were used. Furthermore, recycled rCF yarn pieces after the second life cycle were tested as reinforcement in concrete. Here, the pieces were lain in a given orientation in one layer and were not distributed isotopically.

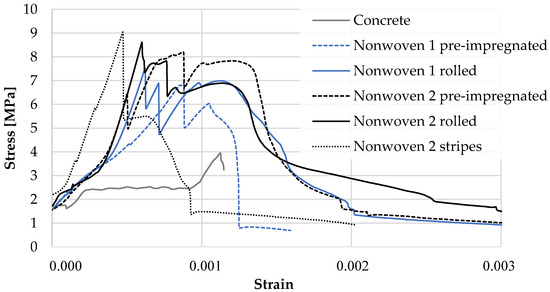

Nonwoven 1 was composed of 100% rCF with a grammage of 100 g/m2 and was not subject to any additional bonding after needling. In contrast, nonwoven 2 was bonded using the Maliwatt process. Consequently, the composition of the material was 96% rCF and 4% polyethylene terephthalate (PET) via the binder thread. The grammage remained consistent at 100 g/m2. In Figure 2, the variants of nonwoven 1 are shown in blue, the nonwoven 2 in black and the plain concrete in grey. Pre-impregnated nonwovens are visualised with a dashed line. The samples in which the nonwoven was additionally rolled in the laminating production process are shown by the solid line. The nonwoven that was cut into strips beforehand and not applied over the entire surface is shown by the dotted line. A representative curve is shown for each variant. All detailed curves can be found in [40]. Furthermore, the mean values and standard deviations of nonwoven reinforced concrete variants are listed in Table 6.

Figure 2.

Comparison of flexural stress–strain curves of nonwoven reinforced concrete in accordance with [40].

Table 6.

Mean value, standard deviation and fracture energy of nonwoven reinforced concrete variants.

The findings for nonwoven sample 1 demonstrated a progressive failure mechanism. In the rolled variation, three distinct peaks were observed in the range of 7–8 MPa, with this variant achieving a tensile strength mean value of 7.95 MPa compared to 5.97 MPa for pre-impregnated nonwoven 1. When comparing this with nonwoven 2, it was noted that the pre-impregnated version exhibited the greatest plastic deformation zone and exhibited a yield strength greater than its tensile strength. Conversely, after reaching the tensile strength, other variations exhibited a faster decline in strength. Therefore, the yield strength was also represented by the tensile strength. The mean value of the tensile strength of both rolled nonwoven 2 with 8.79 MPa and striped nonwoven 2 with 9.59 MPa slightly surpassed that of pre-impregnated nonwoven 2 with 8.10 MPa. But the standard deviation was three times as high for rolled nonwoven 2. This was probably due to the greater variation that occurred when rolling by hand. Remarkably, the highest tensile strength was reached by striped nonwoven 2 while utilising only half the amount of nonwoven material compared to other variants. This observation suggests that the bonding between the concrete layers was significantly enhanced in this instance, preventing the striped nonwoven from functioning as a separating layer and thereby facilitating its superior tensile strength performance [40].

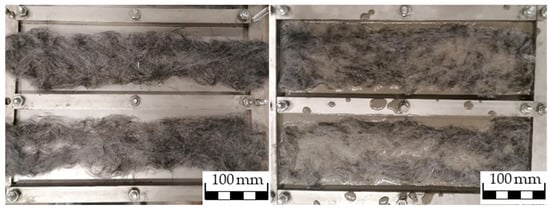

Slivers are similar to nonwoven without the needling or Maliwatt bonding processes. Initially, the sliver from the rCF yarn pre-production was tested as a reinforcement. The challenge here was the instability of the textile because the fibres were not consolidated with each other. Therefore, handling was very difficult and even the smallest movements had an influence on the fibre orientation. Figure 3 shows the sliver in the mould (left), while the slivers during concreting are shown in the picture on the right. The bottom concrete layer was in the mould and the sliver lay on top of it. This picture was taken during the concrete lamination process. The upper concrete layer was added on top of the sliver following the step in the illustration.

Figure 3.

Tape from the rCF slivers without concrete (left) and on top of one layer of concrete during the laminating process (right).

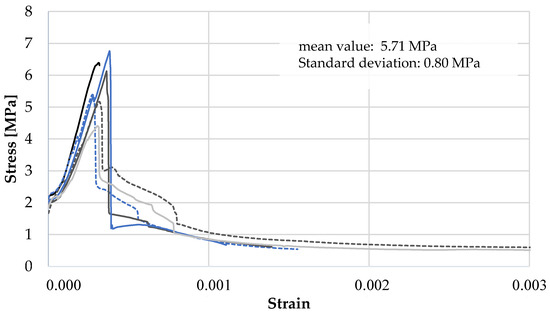

The test results for the flexural stress elongation curve are shown in Figure 4.

Figure 4.

Flexural stress–strain curves of rCF slivers as reinforcement in concrete.

The first test results of sliver-reinforced concrete showed a positive effect. The height of the peaks varied between 4.5 and almost 7 MPa. Therefore, the mean value was 5.71 MPa with a standard deviation of 0.80 MPa. However, the strength values achieved were lower than those of nonwoven reinforcements. The fracture energy varied between 232 J/m2 and 461 J/m2.

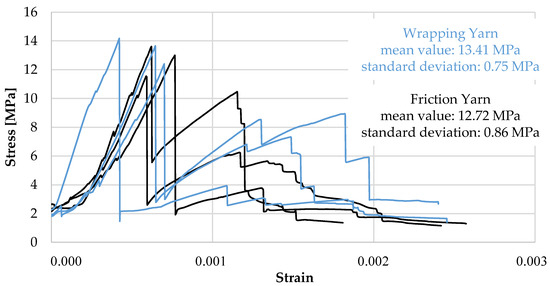

rCF yarn-reinforced concrete specimens (shown in Table 5 (c)) exhibited an increase in flexural strength across all tested variants. Figure 5 illustrates the flexural stress–elongation curves. Yarn 1, shown with the black curves, was a friction-spun yarn composed of a blend of rCF and polyamide 6 (PA6). In contrast, yarn 2 was produced as a wrapping yarn whereby a filament encased a core material; this yarn maintained the same material composition. The production of the yarns was conducted within the framework of the CarboYarn project. Prior to their integration into the concrete matrix with the lamination process, both yarns received an epoxy resin coating [40].

Figure 5.

Flexural stress–strain curves of wrapping yarn (blue curves) and friction yarn (black curves) as reinforcement in concrete according to [40].

Comparing both results for yarn reinforcement, the flexural stress–elongation curves exhibited a comparable gradient, and a gradual failure was discernible in all samples. The tensile strength was equivalent to the yield strength for both yarn reinforcements. The mean value for the tensile strength of the wrapping yarn reinforcement was 13.41 MPa, slightly higher than the tensile strength of the friction yarn reinforcement with 12.72 MPa. The standard deviations were comparable, with 0.75 MPa and 0.86 MPa. The fracture energy was around 1205 J/m2 for the wrapping yarn and 996 J/m2 for the friction yarn.

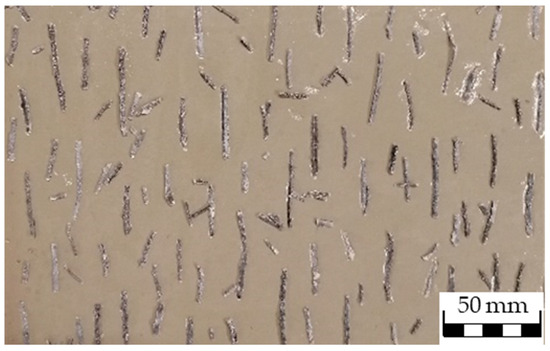

However, in contrast to the yarn reinforcement, the impregnated yarn was recycled as short rCFs following the comminution process. The short rCF pieces were not isotopically distributed within the concrete matrix; rather, they were oriented mostly in a single direction within the tensile zone, with the majority of their length aligned in the same direction, as shown in Figure 6. The aim was to achieve the greatest possible reinforcement influence.

Figure 6.

Recycled rCF yarn pieces as reinforcement in concrete.

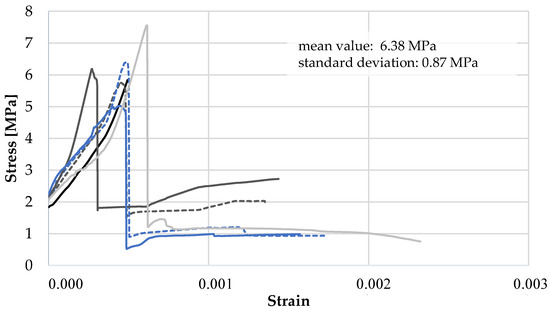

Recycled rCF yarn pieces after the second recycling process were also tested as reinforcement. There was a possibility of using this material without the whole recovery of the fibres after the second life cycle with the rCF yarn pieces. The used material was the output of the recycling of TRC in the study by Bayram et al. [50]. The corresponding flexural stress-strain curve is shown in Figure 7.

Figure 7.

Flexural stress–strain curves of recycled rCF yarn pieces as reinforcement in concrete.

The first test results for the recycled rCF pieces as reinforcement in concrete showed a positive effect. The height of the peaks varied between 5 and almost 8 MPa with a mean value of 6.38 MPa and a standard deviation of 0.87 MPa. The fracture energy varied between 311 J/m2 and 786 J/m2. Therefore, the strength values and the fracture energy achieved were higher maximum forces than those of the sliver reinforcements. The energy absorption capacity was not examined in this study and could be considered in future studies in order to ensure a comprehensive overview.

5. End of Life of CFRC

In the framework of the circular economy, it is essential to consider the manufacturing of components, encompassing material extraction and production and their end-of-life phase. This encompasses the potential for recycling and the utilisation of recycled materials in lieu of new materials.

In order to investigate the possibility of separating textile-reinforced concrete at the end of its first life cycle, Kimm et al. [37,51] and Kortmann [37] conducted studies on separability. It was demonstrated that the separation of coated textiles from concrete is a viable process. The separability of materials is significantly influenced by factors such as material composition, construction methods and comminution techniques. Appropriate coatings were found to have a positive effect on separability, with epoxy coatings giving the highest recovery rates. In addition, increasing the cross-sectional area of the roving improved the efficiency of the recycling process. The best recovery rates for carbon reinforcements were achieved using a hammer mill, resulting in a textile recovery rate of over 90% and a residual organic fibre content in the minerals of less than 0.2% [51].

As previously mentioned, while these recycled fibre materials can be used as short fibres in FRC, at present, there is currently no immediate reuse of the textile structure due to the resulting strength losses and cutting.

The potential of rCF over two or more life cycles was considered by Bayram et al. [50]. In this study, the end-of-life separability of rCF yarns in concrete was investigated for the second life cycle [50]. rCFs were employed as wrapping yarn for concrete reinforcement. Subsequently, mechanical processing was utilised to determine the potential for separation of the rCF from the concrete. The results demonstrated that the separation efficiency of rCF yarns varied between 69% and 97%, depending on the machine settings employed. It is important to note that the proportion of the fine fraction (less than 2 mm) also increased with increasing separation efficiency. The separation of TRC made from rCF could only be achieved when the yarn material was coated, in contrast to unimpregnated rCF yarns, which did not allow for effective separation. Additionally, the study conducted a comparative LCA between the utilisation of recycled and virgin CF, establishing that rCFs are environmentally beneficial when a substitution coefficient of over 10% can be achieved [50]. In the study by Bayram et al. [50], the same yarn material and mechanical results were used.

Within the framework of the FaBeR project (funded by the German Federal Ministry of Education and Research (BMBF)), the recycling of CFRC into a recycled CFRC industrial floor was demonstrated.

The project goal was the utilisation of mostly all fractions of recycled concrete components. The fine fraction was investigated for further processing in the cement industry and the coarse fraction was investigated as an alternative to natural aggregates in recycled concrete. The fibre residues were also reused. Floor slabs were produced as part of the project, which were analysed by Luthin et al. as part of a circular life cycle sustainability assessment [52]. The study showed that the recycled CFRC industrial floor demonstrated significant circularity, primarily due to the use of recycled materials and their potential for future recycling. In terms of environmental impact, the global warming risk was lower, whereas the human toxicity potential was higher compared to similar products [52].

Additionally, production costs were notably higher than those of comparable products, likely due to the laboratory-scale production process during the development phase [52]. But, as soon as a higher technology readiness level is reached and production shifts to an industrial scale, the costs would change accordingly.

6. Discussion

FRCs are composites formed by adding short fibres, typically 10–40 mm in length, to fresh concrete, creating a three-dimensional reinforcement structure that enhances the material’s properties. While fibre reinforcement is not primarily load-bearing, it significantly improves tensile and compressive strength, impact resistance, ductility, crack prevention, weather resistance, and fire safety. FRC can be utilised in various construction applications but faces challenges such as fibre floatation due to low density and changes in concrete consistency with high fibre volumes.

CFRC benefits from high tensile strength and chemical resistance, making it suitable for harsh environments. However, its high cost limits market adoption. Research is ongoing into using rCF, which simplifies production by recovering fibres without extensive processing. The properties of rCFRC are influenced by factors like fibre volume content and length; longer fibres improve flexural strength significantly compared to shorter ones.

Further studies have shown that surface modifications enhance the adhesion of rCF to a concrete matrix. Pyrolysed or sized rCFs demonstrate improved interfacial shear strengths compared to virgin fibres. Fibre distribution also affects strength outcomes; proper distribution leads to stronger bonds within the composite material. Overall, optimising these parameters can enhance the performance of FRC using recycled materials.

Investigations have demonstrated that rCFs, whether used as nonwoven or yarn reinforcement, enhance both the tensile and yield strength of concrete. Furthermore, in many instances, a gradual failure mode rather than an abrupt one is observed. Consequently, the use of rCF textiles as reinforcement in concrete presents significant potential for promoting sustainability within the construction industry.

For the nonwoven variants, the highest tensile strength with a standard deviation of 9.59 MPa was reached by nonwoven 2, which was cut into stripes and inserted into the laminating process using the entire surface. Although the amount of rCF nonwoven was smaller in this variant, the highest tensile strength was reached because the nonwoven in this case did not act as a separating layer and the concrete matrix bonded together. Compared to the nonwoven, the sliver reinforcement had no progressive failure and a lower highest tensile strength with a mean value of 5.71 MPa. The highest tensile strength was reached with the wrapping rCF yarn variants, with results of 13.41 MPa, closely followed by the friction yarn, with a tensile strength mean value of 12.72 MPa. Both yarns showed a gradual and direct failure. When the rCF yarn specimens were recycled with the hammer mill and the resulting rCF yarn pieces were used as a short fibre reinforcement, they still reached a tensile strength mean value of 6.38 MPa. Therefore, in this investigation, the different variants of rCF were examined and the first results were analysed.

Based on the research carried out so far, further investigations can now be made into the durability, long-term use, weathering resistance and chemical erosion resistance of the materials. Based on this, suitable use cases can then be evaluated for the variants and investigations can be carried out considering the entire life cycle.

In the context of the circular economy, it is essential to evaluate the entire life cycle of components, including material extraction, production and end-of-life recycling. Studies by Kimm et al. [51] and Kortmann [32] demonstrated that separating TRC at the end of its life cycle is feasible, with factors such as material type and construction method significantly influencing separability. An epoxy coating was found to enhance recovery rates, with hammer mills achieving over 90% recovery for carbon reinforcements.

Although recycled fibre materials can be utilised as short fibres in FRC, the immediate reuse of the textile structure is constrained by associated strength losses. However, the mineral content derived from recycled TRC can be repurposed as aggregates for a range of construction applications. Bayram et al. [50] explored the potential for recycling rCF yarns from concrete in a second life cycle. The use of the recycled rCF yarn pieces after the second life cycle was also tested as reinforcement in concrete for a quasi third life cycle. The mechanical properties showed an increase in the mechanical properties.

Once the mechanical properties, including durability and long-term behaviour, have been investigated in more detail, a further LCA as well as an economic assessment will be carried out.

The FaBeR project demonstrated the successful recycling of CFRC into industrial flooring, aiming to utilise all fractions of recycled components. Although initial production costs were high compared to similar products, advancing technology could lead to cost reductions. This study confirmed the significant circularity and lower global warming risks of recycled CFRC compared to conventional options.

Future research topics include the utilisation of textile surface structures made from rCF, i.e., grid structures such as those used in new TRCs made from recycled yarns. This would enable reinforcement in 2D instead of just 1D. The positioning of the yarn in the test specimen will also be possible more precisely than with 1D yarns due to the textile structure, as these partly float in the centre, and the 2D textiles achieve greater stability, especially after impregnation.

Furthermore, the electrical conductivity of the carbon fibres can also be used as a sensor system. There are already several approaches for new carbon rovings. The transferability to recycled fibres due to the difficulty of the short fibre lengths also requires in-depth research and is planned for the future.

7. Conclusions

Carbon fibres’ non-corrosive properties enable the creation of slimmer concrete components, potentially reducing the CO2 emissions associated with cement production, which contributes about 8% of global emissions. While steel is the primary reinforcement material due to its high tensile strength, its corrosion susceptibility requires thicker covers, increasing material use. The construction sector accounts for 38% of global CO2 emissions, necessitating effective emission reduction strategies. TRC uses technical textiles as reinforcements and has been studied for its mechanical advantages. Although producing rCF is energy-intensive, it offers significant energy savings and can lower global warming potential compared to virgin fibres. This study explored rCF’s potential as a concrete reinforcement, addressing both opportunities and challenges.

In summary, the integration of recycled carbon fibres into carbon concrete presents a promising pathway to enhance the sustainability of construction materials. This approach not only reduces the environmental impact associated with fibre production but also improves the mechanical properties of concrete, offering both ecological and economic benefits. The continuous development and optimisation of recycling technologies are essential to fully realise these advantages and promote the adoption of sustainable practices in the construction sector.

Author Contributions

Conceptualisation, V.O. and T.G.; methodology, V.O. and T.G.; validation, V.O.; formal analysis, V.O.; investigation, V.O.; resources, T.G.; data curation, V.O.; writing—original draft preparation, V.O. and T.G.; writing—review and editing, V.O. and T.G.; visualisation, V.O.; supervision, T.G.; project administration, T.G.; funding acquisition, T.G. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the German Federal Ministry of Education and Research (BMBF) in the framework of the FONA Research for Sustainability Resource-efficient circular economy (ReMin) as part of the project FaBeR (Faser-und Beton-Recycling von Carbon-und Textilbeton) (grant no. 033R253A) and the PhD-program “Forschungskolleg Verbund. NRW—Verbunde im Bauwesen—Von der Ressourceneffizienz zur validierten Nachhaltigkeit”, supported by the Ministry of Innovation, Science and Research North Rhine-Westphalian The financial support from the BMBF and the Ministry of Innovation, Science and Research North Rhine-Westphalian are gratefully acknowledged.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

All relevant data are available in the article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- United Nations Environment Programme. Global Resources Outlook 2019: Natural Resources for the Future We Want; United Nations: New York, NY, USA, 2020; ISBN 978-92-807-3741-7. [Google Scholar]

- United Nations Environment Programme. Building Materials and the Climate: Constructing a New Future; United Nations: New York, NY, USA, 2023; ISBN 978-92-807-4064-6. [Google Scholar]

- Hensen, F.; Kolbmüller, H.; Stahr, M.; Weber, J.; Wild, U. Beton- und Stahlbeton. In Bausanierung: Erkennen und Beheben von Bauschäden; mit 145 Tabellen, 4., vollst. überarb. und aktualisierte Aufl.; Stahr, M., Hensen, F., Eds.; Vieweg + Teubner: Wiesbaden, Germany, 2009; pp. 115–147. ISBN 978-3-8348-0246-0. [Google Scholar]

- WWF Deutschland. Klimaschutz in der Beton- und Zementindustrie Berlin (2019); WWF Deutschland: Berlin, Germany, 2019. [Google Scholar]

- United Nations Environment Programme. 2020 Global Status Report for Buildings and Construction Nairobi (Kenia) (2020); United Nations Environment Programme: Nairobi, Kenya, 2020. [Google Scholar]

- Intergovernmental Panel on Climate Change (IPCC) Global Warming of 1.5 °C.—(UK); Cambridge University Press: Cambridge, UK; New York, NY, USA, 2018.

- Friese, D.; Scheurer, M.; Hahn, L.; Gries, T.; Cherif, C. Textile reinforcement structures for concrete construction applications—A review. J. Compos. Mater. 2022, 56, 4041–4064. [Google Scholar] [CrossRef]

- Scheurer, M.; Friese, D.; Penzel, P.; Dittel, G.; Bhat, S.; Overhage, V.; Hahn, L.; Heins, K.; Cherif, C.; Gries, T. Current and Future Trends in Textiles for Concrete Construction Applications. Textiles 2023, 3, 408–437. [Google Scholar] [CrossRef]

- Porta, N.W. Sustainability and Flexural Behaviour of Textile Reinforced Concrete. Bachelor’s Thesis, Department of Civil and Environmental Engineering, Division of Structural Engineering, Concrete Structures, Chalmers University of Technology, Gothenburg, Sweden, 2012. [Google Scholar]

- Kimm, M.K. Ressourceneffizientes und Recyclinggerechtes Design von Faserverbundwerkstoffen im Bauwesen. Ph.D. Dissertation, Rheinisch-Westfälische Technische Hochschule Aachen, Aachen, Germany, 2021. [Google Scholar]

- Aschebrock, G.C. Textile Reinforced Concrete: A Review; Engineering School, Universidade Federal do Rio Grande do Sul (UFRGS): Porto Alegre, Brazil, 2022. [Google Scholar]

- Haist, M.; Bergmeister, K.; Curbach, M.; Forman, P.; Gaganelis, G.; Gerlach, J.; Mark, P.; Moffatt, J.; Müller, C.; Müller, H.S.; et al. Nachhaltigkeit, Digitalisierung, Instandhaltung; 111. Jahrgang; Ernst & Sohn a Wiley Brand: Berlin, Germany, 2022. [Google Scholar]

- Seifert, W.; Lieboldt, M. Ressourcenverbrauch im globalen Stahlbetonbau und Potenziale der Carbonbetonbauweise. Beton Stahlbetonbau 2020, 115, 469–478. [Google Scholar] [CrossRef]

- Li, H.; Yang, J.; Yang, D.; Zhang, N.; Nazar, S.; Wang, L. Fiber-reinforced polymer waste in the construction industry: A review. Environ. Chem. Lett. 2024, 22, 2777–2844. [Google Scholar] [CrossRef]

- Meng, F.; McKechnie, J.; Turner, T.A.; Pickering, S.J. Energy and environmental assessment and reuse of fluidised bed recycled carbon fibres. Compos. Part A Appl. Sci. Manuf. 2017, 100, 206–214. [Google Scholar] [CrossRef]

- Meiners, D.; Eversmann, B. Recycling von Carbonfasern. In Recycling und Rohstoffe; TK-Verl.: Neuruppin, Germany, 2014; ISBN 978-3-944310-09-1. [Google Scholar]

- Rani, M.; Choudhary, P.; Krishnan, V.; Zafar, S. A review on recycling and reuse methods for carbon fiber/glass fiber composites waste from wind turbine blades. Compos. Part B Eng. 2021, 215, 108768. [Google Scholar] [CrossRef]

- Qureshi, J. A Review of Recycling Methods for Fibre Reinforced Polymer Composites. Sustainability 2022, 14, 16855. [Google Scholar] [CrossRef]

- Gharde, S.; Kandasubramanian, B. Mechanothermal and chemical recycling methodologies for the Fibre Reinforced Plastic (FRP). Environ. Technol. Innov. 2019, 14, 100311. [Google Scholar] [CrossRef]

- Karuppannan Gopalraj, S.; Kärki, T. A review on the recycling of waste carbon fibre/glass fibre-reinforced composites: Fibre recovery, properties and life-cycle analysis. SN Appl. Sci. 2020, 2, 433. [Google Scholar] [CrossRef]

- Baumgaertel, E.; Marx, S. The Recycling of Carbon Components and the Reuse of Carbon Fibers for Concrete Reinforcements. Appl. Sci. 2023, 13, 7091. [Google Scholar] [CrossRef]

- Imbert, M.; Hahn, P.; Jung, M.; Balle, F.; May, M. Mechanical laminae separation at room temperature as a high-quality recycling process for laminated composites. Mater. Lett. 2022, 306, 130964. [Google Scholar] [CrossRef]

- Quicker, P.; Stockschläder, J. Möglichkeiten und Grenzen der Entsorgung Carbonfaserverstärkter Kunststoffabfälle in Thermischen Prozessen: Abschlussbericht; Umweltbundesamt: Dessau-Roßlau, Germany, 2021. [Google Scholar]

- Einführung in die Kreislaufwirtschaft: Planung-Recht-Verfahren; Kranert, M., Ed.; 5. Auflage; Springer Vieweg: Wiesbaden/Heidelberg, Germany, 2017; ISBN 3834818372. [Google Scholar]

- Horstmann, V. Vergleichende Untersuchungen zur Mechanischen Aufbereitung von Carbonbeton. Master’s Thesis, Bauhaus-Universität Weimar, Weimar, Germany, 2018. [Google Scholar]

- Isa, A.; Nosbi, N.; Che Ismail, M.; Md Akil, H.; Wan Ali, W.F.F.; Omar, M.F. A Review on Recycling of Carbon Fibres: Methods to Reinforce and Expected Fibre Composite Degradations. Materials 2022, 15, 4991. [Google Scholar] [CrossRef] [PubMed]

- Rabe, D.; Häntzsche, E.; Cherif, C. Recycling of Carbon Fibres and Subsequent Upcycling for the Production of 3D-CFRP Parts. Materials 2022, 15, 5052. [Google Scholar] [CrossRef] [PubMed]

- Benka, C. Systematische Untersuchung Thermischer Prozesse für das Recycling von Kohlenstofffaserverstärkten Kunststoffen. Bachelor’s Thesis, University of Applied Sciences, Augsburg, Germany, 2015. [Google Scholar]

- Almushaikeh, A.M.; Alaswad, S.O.; Alsuhybani, M.S.; AlOtaibi, B.M.; Alarifi, I.M.; Alqahtani, N.B.; Aldosari, S.M.; Alsaleh, S.S.; Haidyrah, A.S.; Alolyan, A.A.; et al. Manufacturing of carbon fiber reinforced thermoplastics and its recovery of carbon fiber: A review. Polym. Test. 2023, 122, 108029. [Google Scholar] [CrossRef]

- Onwudili, J.A.; Miskolczi, N.; Nagy, T.; Lipóczi, G. Recovery of glass fibre and carbon fibres from reinforced thermosets by batch pyrolysis and investigation of fibre re-using as reinforcement in LDPE matrix. Compos. Part B Eng. 2016, 91, 154–161. [Google Scholar] [CrossRef]

- Kim, K.-W.; Lee, H.-M.; An, J.-H.; Chung, D.-C.; An, K.-H.; Kim, B.-J. Recycling and characterization of carbon fibers from carbon fiber reinforced epoxy matrix composites by a novel super-heated-steam method. J. Environ. Manag. 2017, 203, 872–879. [Google Scholar] [CrossRef]

- Liu, Y.; Meng, L.; Huang, Y.; Du, J. Recycling of carbon/epoxy composites. J. Appl. Polym. Sci. 2004, 94, 1912–1916. [Google Scholar] [CrossRef]

- Feraboli, P.; Kawakami, H.; Wade, B.; Gasco, F.; DeOto, L.; Masini, A. Recyclability and reutilization of carbon fiber fabric/epoxy composites. J. Compos. Mater. 2012, 46, 1459–1473. [Google Scholar] [CrossRef]

- Mitsubishi Chemical Advanced Materials GmbH. Produktdatenblatt CarboNXT Chopped NP 5; Mitsubishi Chemical Advanced Materials GmbH: Lotte, Germany, 2019. [Google Scholar]

- Mitsubishi Chemical Advanced Materials GmbH. Produktdatenblatt CarboNXT Chopped PURE; Mitsubishi Chemical Advanced Materials GmbH: Lotte, Germany, 2021. [Google Scholar]

- Teijin Carbon Europe GmbH. Produkttadenblatt (EU): Tenax Filament Yarn: Version 1.2; Teijin Carbon Europe GmbH: Wuppertal, Germany, 2020. [Google Scholar]

- Kortmann, J. Verfahrenstechnische Untersuchungen Zur Recyclingfähigkeit Von Carbonbeton; Springer Fachmedien Wiesbaden GmbH: Wiesbaden, Germany, 2020; ISBN 9783658301255. [Google Scholar]

- Veit, D. Fasern: Geschichte, Erzeugung, Eigenschaften, Markt; Springer Vieweg: Berlin/Heidelberg, Germany, 2023; ISBN 978-3-662-64468-3. [Google Scholar]

- Gries, T.; Veit, D.; Wulfhorst, B. Textile Fertigungsverfahren; Carl Hanser Verlag GmbH & Co. KG: Munich, Germany, 2018. [Google Scholar]

- Overhage, V.; Gries, T. Use of Recycled Carbon Fibres in Textile Reinforced Concrete for the Construction Industry. In Proceedings of the International RILEM Conference on Synergising Expertise Towards Sustainability and Robustness of Cement-Based Materials and Concrete Structures: SynerCrete’23—Volume 1, 1st ed., Milos, Greece, 14–16 June 2023; Jędrzejewska, A., Kanavaris, F., Azenha, M., Benboudjema, F., Schlicke, D., Eds.; Springer Nature Switzerland, Imprint Springer: Cham, Switzerland, 2023; pp. 540–551. ISBN 978-3-031-33210-4. [Google Scholar]

- DIN EN 1170-5; Precast Concrete Products—Test Method for Glass-Fibre Reinforced Cement—Part 5: Measuring Bending Strength by the ‘Complete Bending Test’ Method. Deutsches Institut für Normung: Berlin, Germany, 1997.

- Brockmann, T. Mechanical and Fracture Mechanical Properties of Fine Grained Concrete for Textile Reinforced Composites; Verlag Günter Mainz: Mainz, Germany, 2006; ISBN 3-86130-631-X. [Google Scholar]

- Kimm, M.; Bhat, S.; Gries, T. Recycling von Textilbeton; Thomé-Kozmiensky Verlag GmbH: Neuruppin, Germany, 2020. [Google Scholar]

- Cuntze, R. Fachbegriffe Für Kompositbauteile—Technical Terms for Composite Parts: Glossar Für Bauwesen und Maschinenbau—Glossary for Civil- and Mechanical Engineering; Springer Fachmedien Wiesbaden GmbH: Wiesbaden, Germany, 2019; ISBN 9783658256357. [Google Scholar]

- Wietek, B. Beton—Stahlbeton—Faserbeton: Eigenschaften und Unterschiede; Springer Fachmedien Wiesbaden GmbH: Wiesbaden, Germany, 2019; ISBN 9783658277079. [Google Scholar]

- Wietek, B. Faserbeton: Im Bauwesen, 3rd ed.; Springer Fachmedien Wiesbaden GmbH: Wiesbaden, Germany, 2020; ISBN 9783658308759. [Google Scholar]

- Kimm, M.; Overhage, V.; Gries, T.; Sodagar, M. Recycled carbon fibers with improved surface characteristics as reinforcing material for fiber concrete. In Proceedings of the 2021 Optical Fiber Communications Conference and Exhibition (OFC), San Francisco, CA, USA, 6–11 June 2021. [Google Scholar]

- Overhage, V.; Heins, K.; Kimm, M.; Ryu, G.-S.; You, Y.-J.; Kim, H.-Y.; Gries, T. Investigation of pull-out and mechanical performance of fibre reinforced concrete with recycled carbon fibres. Mater. Struct. 2024, 57, 184. [Google Scholar] [CrossRef]

- Textilnorm, Fachnormenausschuß Textil- und Textilmaschinenindustrie im Deutschen Normenausschuß. In Textilien: Grundbegriffe; Deutsche Normen: Berlin, Germany, 1969.

- Bayram, B.; Overhage, V.; Löwen, M.; Terörde, K.; Raulf, K.; Greiff, K.; Gries, T. Recycling potential of carbon fibres in the construction industry: From a technical and ecological perspective. Waste Manag. Res. 2024, 42, 726–737. [Google Scholar] [CrossRef]

- Kimm, M.; Gerstein, N.; Schmitz, P.; Simons, M.; Gries, T. On the separation and recycling behaviour of textile reinforced concrete: An experimental study. Mater. Struct. 2018, 51, 122. [Google Scholar] [CrossRef]

- Luthin, A.; Crawford, R.H.; Traverso, M. Demonstrating circular life cycle sustainability assessment—A case study of recycled carbon concrete. J. Clean. Prod. 2023, 433, 139853. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).