Sustainability-Oriented Port Management: Biomass Gasification as a Strategic Tool for Green and Circular Maritime Logistics

Abstract

1. Introduction

- i.

- How can biomass gasification be integrated into sustainable port management strategies to enhance energy efficiency, waste valorization, and emissions reduction?

- ii.

- What are the key technical, economic, and policy challenges affecting the adoption of biomass gasification in ports, and how can they be addressed to promote a circular maritime economy?

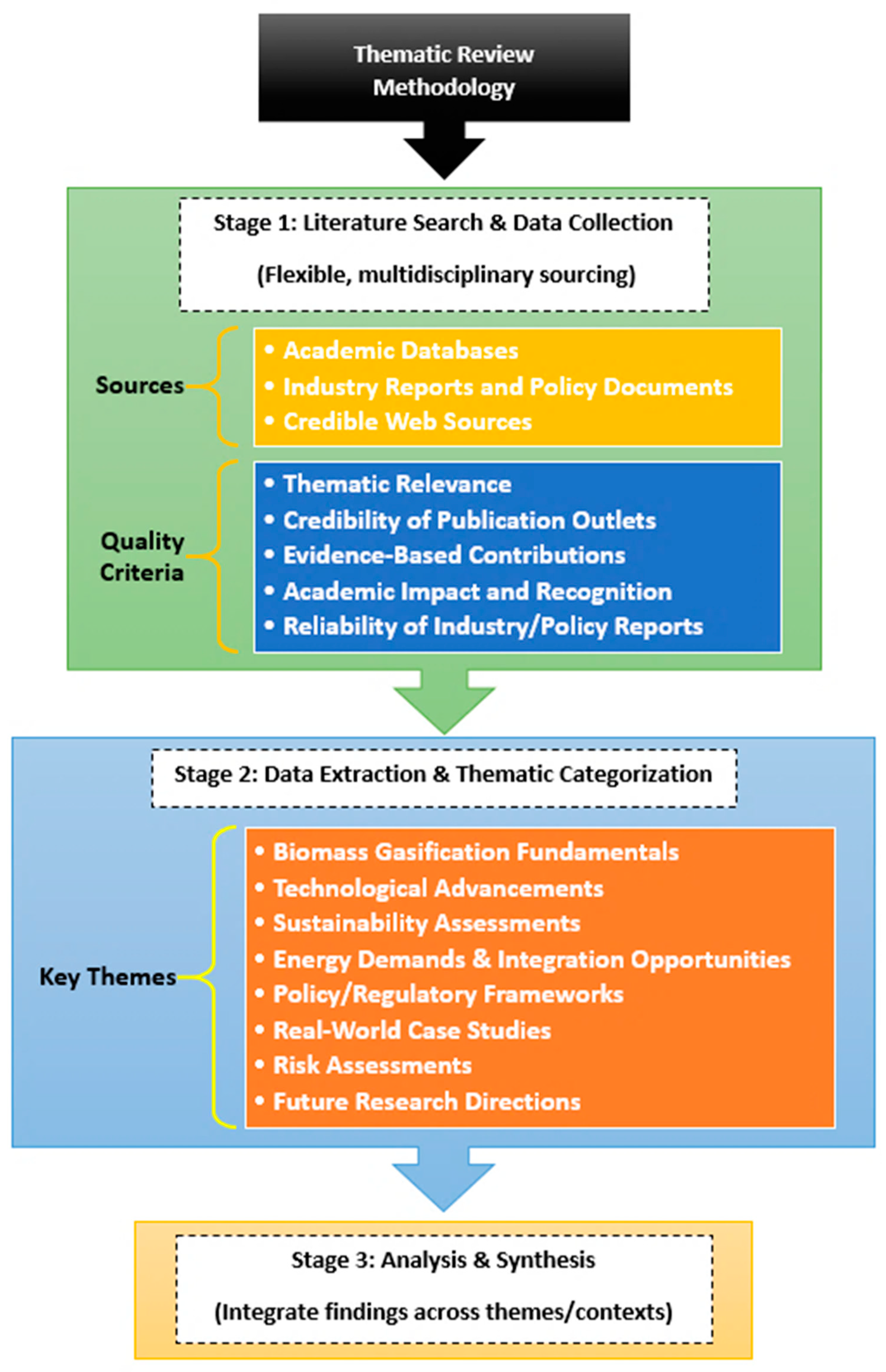

2. Research Approach

2.1. Literature Search and Data Collection

- Thematic Relevance: Sources were selected based on their direct relevance to biomass gasification, sustainable port management, and maritime logistics. Studies on general biomass technologies were considered if they provided transferable insights applicable to port operations;

- Credibility of Publication Outlets: Peer-reviewed journal articles and conference proceedings were prioritized;

- Evidence-Based Contributions: Preference was given to studies that demonstrated empirical evidence, methodological rigor, or technical analysis, including experimental research, lifecycle assessments, techno-economic evaluations, and case studies on biomass gasification;

- Academic Impact and Recognition: Frequently cited studies were considered significant contributions to the field, but newer studies were also included if they introduced novel insights or emerging trends in biomass gasification and port sustainability;

- Reliability of Industry and Policy Reports: Reports were included only if published by governmental agencies, regulatory bodies, or internationally recognized organizations, ensuring credibility.

- The primary sources of information were:

- Academic Databases: Scopus, Web of Science, and Google Scholar, which provided peer-reviewed journal articles, conference proceedings, and technical work on biomass gasification, sustainable port management, and maritime logistics.

- Industry Reports and Policy Documents: Publications from port authorities, government agencies, and industry stakeholders, such as reports on port sustainability initiatives, renewable energy adoption, and waste-to-energy strategies;

- Credible Web Sources: Reports and articles from recognized organizations such as the International Maritime Organization (IMO), the European Commission, the International Renewable Energy Agency (IRENA), and the United Nations (UN).

2.2. Data Extraction and Thematic Categorization

2.3. Analysis and Synthesis of Findings

3. Biomass Gasification Fundamentals

4. Recent Advancements in Biomass Gasification

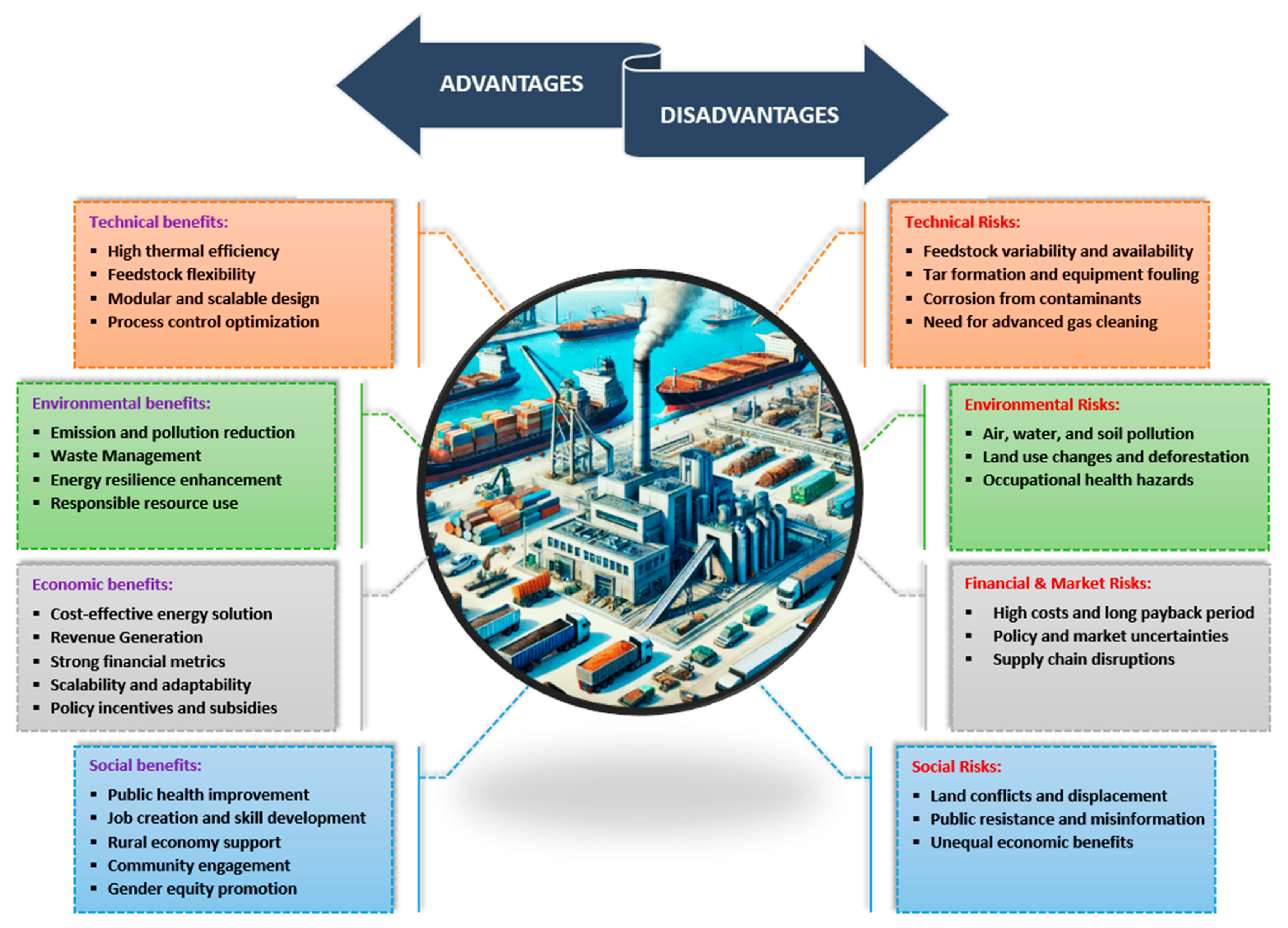

5. Sustainability Assessment of Biomass Gasification in Ports

5.1. Environmental Impact

5.2. Economic Feasibility

5.3. Social Implications

6. Key Energy Demands in Ports and Integration Opportunities of Biomass Gasification

7. Policy and Regulatory Frameworks

7.1. Global Policies and International Agreements

7.2. Regional and National Policies

7.3. Incentives and Financial Mechanisms

7.4. Compliance and Standards

8. Projects and Case Studies in Maritime Biomass Gasification

9. Risk Assessment and Mitigation Strategies

9.1. Technical Risks

9.2. Financial and Market Risks

9.3. Environmental Risks

9.4. Social Risks

9.5. Regulatory and Compliance Risks

10. Future Prospects and Research Directions

11. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Verschuur, J.; Koks, E.E.; Hall, J.W. Ports’ Criticality in International Trade and Global Supply-Chains. Nat. Commun. 2022, 13, 4351. [Google Scholar] [CrossRef] [PubMed]

- Yusup, M.F. Bin Sustainable Shipping Practices: A Review of Environmental Initiatives in the Maritime Industry. Marit. Park. J. Marit. Technol. Soc. 2023, 140–142. [Google Scholar] [CrossRef]

- Misra, A.; Venkataramani, G.; Gowrishankar, S.; Ayyasam, E.; Ramalingam, V. Renewable Energy Based Smart Microgrids—A Pathway to Green Port Development. Strateg. Plan. Energy Environ. 2017, 37, 17–32. [Google Scholar] [CrossRef]

- Bengue, A.A.; Alavi-Borazjani, S.A.; Chkoniya, V.; Cacho, J.L.; Fiore, M. Prioritizing Criteria for Establishing a Green Shipping Corridor Between the Ports of Sines and Luanda Using Fuzzy AHP. Sustainability 2024, 16, 9563. [Google Scholar] [CrossRef]

- Gore, A. Towards Sustainable Port Management: Comparative Evidence from Italy, UAE and India. Int. J. Technol. Manag. Sustain. Dev. 2022, 21, 331–351. [Google Scholar] [CrossRef]

- McCallum, P. Green Ports—Sustainable Port Development. In Proceedings of the Ports 2022, Honolulu, HI, USA, 18–21 September 2022; American Society of Civil Engineers: Reston, VA, USA, 2022; pp. 592–600. [Google Scholar]

- Chakravarty, A.K. Sustainable Supply Chains. In Supply Chain Transformation; Springer: Berlin/Heidelberg, Germany, 2014; pp. 273–305. [Google Scholar]

- Dvorak, J.; Burkšienė, V. Sustainability Factors Shaping Port Security: A Case Study of Baltic Ports. In Global Challenges in Maritime Security; Springer: Berlin/Heidelberg, Germany, 2024; pp. 81–111. [Google Scholar]

- Pivetta, D.; Dall’Armi, C.; Sandrin, P.; Bogar, M.; Taccani, R. The Role of Hydrogen as Enabler of Industrial Port Area Decarbonization. Renew. Sustain. Energy Rev. 2024, 189, 113912. [Google Scholar] [CrossRef]

- Alavi-Borazjani, S.A.; Adeel, S.; Chkoniya, V. Hydrogen as a Sustainable Fuel: Transforming Maritime Logistics. Energies 2025, 18, 1231. [Google Scholar] [CrossRef]

- Yildiz, R.O.; Koc, E.; Der, O.; Aymelek, M. Unveiling the Contemporary Research Direction and Current Business Management Strategies for Port Decarbonization Through a Systematic Review. Sustainability 2024, 16, 10959. [Google Scholar] [CrossRef]

- Abood, K.A. Sustainable and Green Ports: Application of Sustainability Principles to Port Development and Operation. In Ports 2007: 30 Years of Sharing Ideas: 1977–2007; American Society of Civil Engineers: Reston, VA, USA, 2007; pp. 1–10. [Google Scholar]

- Arfelli, F.; Tosi, C.; Ciacci, L.; Passarini, F. Life Cycle Assessment of a Wood Biomass Gasification Plant and Implications for Syngas and Biochar Utilization. Energies 2024, 17, 2599. [Google Scholar] [CrossRef]

- McKendry, P. Energy Production from Biomass (Part 3): Gasification Technologies. Bioresour. Technol. 2002, 83, 55–63. [Google Scholar] [CrossRef]

- Dai, J.; Saayman, J.; Grace, J.R.; Ellis, N. Gasification of Woody Biomass. Annu. Rev. Chem. Biomol. Eng. 2015, 6, 77–99. [Google Scholar] [CrossRef] [PubMed]

- Hameed, Z.; Aslam, M.; Khan, Z.; Maqsood, K.; Atabani, A.E.; Ghauri, M.; Khurram, M.S.; Rehan, M.; Nizami, A.-S. Gasification of Municipal Solid Waste Blends with Biomass for Energy Production and Resources Recovery: Current Status, Hybrid Technologies and Innovative Prospects. Renew. Sustain. Energy Rev. 2021, 136, 110375. [Google Scholar] [CrossRef]

- Marcantonio, V.; Di Paola, L.; De Falco, M.; Capocelli, M. Modeling of Biomass Gasification: From Thermodynamics to Process Simulations. Energies 2023, 16, 7042. [Google Scholar] [CrossRef]

- Sikarwar, V.S.; Zhao, M.; Clough, P.; Yao, J.; Zhong, X.; Memon, M.Z.; Shah, N.; Anthony, E.J.; Fennell, P.S. An Overview of Advances in Biomass Gasification. Energy Environ. Sci. 2016, 9, 2939–2977. [Google Scholar] [CrossRef]

- Balat, M. Gasification of Biomass to Produce Gaseous Products. Energy Sources Part A Recovery Util. Environ. Eff. 2009, 31, 516–526. [Google Scholar] [CrossRef]

- Farzad, S.; Mandegari, M.A.; Görgens, J.F. A Critical Review on Biomass Gasification, Co-Gasification, and Their Environmental Assessments. Biofuel Res. J. 2016, 3, 483–495. [Google Scholar] [CrossRef]

- Kirsanovs, V.; Žandeckis, A.; Rochas, C. Biomass Gasification Thermodynamic Model Including Tar and Char. Agron. Res. 2016, 14, 1321–1331. [Google Scholar]

- Yao, X.; Zhao, Z.; Chen, S.; Zhou, H.; Xu, K. Migration and Transformation Behaviours of Ash Residues from a Typical Fixed-Bed Gasification Station for Biomass Syngas Production in China. Energy 2020, 201, 117646. [Google Scholar] [CrossRef]

- Sultan, S.H.; Palamanit, A.; Techato, K.; Amin, M.; Ahmed, K.; Asadullah, A. Syngas Production from Rubberwood Biomass in Downdraft Gasifier Combined with Wet Scrubbing: Investigation of Tar and Solid Residue. JSM 2020, 49, 1729–1743. [Google Scholar] [CrossRef]

- Klinghoffer, N.; Castaldi, M.J.; Nzihou, A. Beneficial Use of Ash and Char from Biomass Gasification. In Proceedings of the 19th Annual North American Waste-to-Energy Conference, Lancaster, PA, USA, 16–18 May 2011; ASMEDC: Washington, DC, USA, 2011; pp. 13–17. [Google Scholar]

- Antal, M.J.; Royere, C.; Vialaron, A. Biomass Gasification at the Focus of the Odeillo (France) 1-Mw (Thermal) Solar Furnace. In Thermal Conversion of Solid Wastes and Biomass; Jones, J.L., Radding, S.B., Takaoka, S., Buekens, A.G., Hiraoka, M., Overend, R., Eds.; American Chemical Society: Washington, DC, USA, 1980; pp. 237–255. [Google Scholar]

- Zhao, S.; Luo, Y. Systematic Mass and Energy Evaluation of Biomass Staged Gasification System Based on Thermodynamic and Kinetic Equilibrium Approaches. SSRN Electron. J. 2021, 1–15. [Google Scholar] [CrossRef]

- Molino, A.; Chianese, S.; Musmarra, D. Biomass Gasification Technology: The State of the Art Overview. J. Energy Chem. 2016, 25, 10–25. [Google Scholar] [CrossRef]

- Kumar, R.N.; Aarthi, V. From Biomass to Syngas, Fuels and Chemicals—A Review. AIP Conf. Proc. 2020, 2225, 070007. [Google Scholar] [CrossRef]

- Rauch, R.; Hrbek, J.; Hofbauer, H. Biomass Gasification for Synthesis Gas Production and Applications of the Syngas. WIREs Energy Environ. 2014, 3, 343–362. [Google Scholar] [CrossRef]

- Gao, Y.; Wang, M.; Raheem, A.; Wang, F.; Wei, J.; Xu, D.; Song, X.; Bao, W.; Huang, A.; Zhang, S.; et al. Syngas Production from Biomass Gasification: Influences of Feedstock Properties, Reactor Type, and Reaction Parameters. ACS Omega 2023, 8, 31620–31631. [Google Scholar] [CrossRef]

- Kumar, A.; Eskridge, K.; Jones, D.D.; Hanna, M.A. Steam–Air Fluidized Bed Gasification of Distillers Grains: Effects of Steam to Biomass Ratio, Equivalence Ratio and Gasification Temperature. Bioresour. Technol. 2009, 100, 2062–2068. [Google Scholar] [CrossRef]

- Nguyen, M.; Duddy, G.; Karam, C. Analysis of Industrial Syngas Production from Biomass. PAM Rev. Energy Sci. Technol. 2015, 2, 67–91. [Google Scholar] [CrossRef]

- Ramos, A.; Rouboa, A. Syngas Production Strategies from Biomass Gasification: Numerical Studies for Operational Conditions and Quality Indexes. Renew. Energy 2020, 155, 1211–1221. [Google Scholar] [CrossRef]

- Casleton, K.H.; Breault, R.W.; Richards, G.A. System Issues and Tradeoffs Associated with Syngas Production and Combustion. Combust. Sci. Technol. 2008, 180, 1013–1052. [Google Scholar] [CrossRef]

- Chopra, S.; Jain, A.K. A Review of Fixed Bed Gasification Systems for Biomass. Agric. Eng. Int. CIGR E-J. 2007, 9, 1–23. [Google Scholar]

- Sharma, P.; Gupta, B.; Pandey, M.; Singh Bisen, K.; Baredar, P. Downdraft Biomass Gasification: A Review on Concepts, Designs Analysis, Modelling and Recent Advances. Mater. Today Proc. 2021, 46, 5333–5341. [Google Scholar] [CrossRef]

- Afzanizam, B.S.; Nazri, B.M.; ChongCheng, T.; Jo-Han, N. A Review of Biomass Gasification Technology to Produce Syngas. Am. Eurasian J. Sustain. Agric. 2014, 8, 69–74. [Google Scholar]

- Neathery, J.K. Biomass Gasification. In Thermochemical Conversion of Biomass to Liquid Fuels and Chemicals; The Royal Society of Chemistry: London, UK, 2010; pp. 67–94. [Google Scholar]

- Heidenreich, S.; Foscolo, P.U. New Concepts in Biomass Gasification. Prog. Energy Combust. Sci. 2015, 46, 72–95. [Google Scholar] [CrossRef]

- Trippe, F.; Fröhling, M.; Schultmann, F.; Stahl, R.; Henrich, E. Techno-Economic Assessment of Gasification as a Process Step within Biomass-to-Liquid (BtL) Fuel and Chemicals Production. Fuel Process. Technol. 2011, 92, 2169–2184. [Google Scholar] [CrossRef]

- Sansaniwal, S.K.; Pal, K.; Rosen, M.A.; Tyagi, S.K. Recent Advances in the Development of Biomass Gasification Technology: A Comprehensive Review. Renew. Sustain. Energy Rev. 2017, 72, 363–384. [Google Scholar] [CrossRef]

- Rubiera, F.; Pis, J.J.; Pevida, C. Raw Materials, Selection, Preparation and Characterization. In Syngas from Waste: Emerging Technologies; Springer: London, UK, 2011; pp. 11–22. [Google Scholar]

- CIB. BioSFerA Project BIOfuels Production from Syngas FERmentation for Aviation and Maritime Use; CIB: Madrid, Spain, 2020. [Google Scholar]

- Liu, J.; Dai, P.; Jiang, W. Modeling of Biomass Gasification Polygeneration. J. Phys. Conf. Ser. 2024, 2835, 012006. [Google Scholar] [CrossRef]

- Chen, H.; Dahlquist, E.; Kyprianidis, K. Retrofitting Biomass Combined Heat and Power Plant for Biofuel Production—A Detailed Techno-Economic Analysis. Energies 2024, 17, 522. [Google Scholar] [CrossRef]

- Rakesh, N.; Dasappa, S. A Critical Assessment of Tar Generated during Biomass Gasification—Formation, Evaluation, Issues and Mitigation Strategies. Renew. Sustain. Energy Rev. 2018, 91, 1045–1064. [Google Scholar] [CrossRef]

- Marcantonio, V.; Del Zotto, L.; Ouweltjes, J.P.; Bocci, E. Main Issues of the Impact of Tar, H2S, HCl and Alkali Metal from Biomass-Gasification Derived Syngas on the SOFC Anode and the Related Gas Cleaning Technologies for Feeding a SOFC System: A Review. Int. J. Hydrogen Energy 2022, 47, 517–539. [Google Scholar] [CrossRef]

- Paisley, M.A. Advanced Biomass Gasification for the Production of Biopower, Fuels and Chemicals. In Proceedings of the AIChE Annual Meeting, Salt Lake City, UT, USA, 4–9 November 2007; pp. 1–4. [Google Scholar]

- Gupta, R.P.; Turk, B.S.; Portzer, J.W.; Cicero, D.C. Desulfurization of Syngas in a Transport Reactor. Environ. Progress 2001, 20, 187–195. [Google Scholar] [CrossRef]

- Li, L.; King, D.L.; Liu, J.; Huo, Q.; Zhu, K.; Wang, C.; Gerber, M.; Stevens, D.; Wang, Y. Stabilization of Metal Nanoparticles in Cubic Mesostructured Silica and Its Application in Regenerable Deep Desulfurization of Warm Syngas. Chem. Mater. 2009, 21, 5358–5364. [Google Scholar] [CrossRef]

- Woolcock, P.J.; Broer, K.M.; Johnston, P.; Brown, R.C. Process Development Unit for Integrated Studies of Syngas Cleaning. In Proceedings of the Annual ASABE International Meeting, Louisville, KY, USA, 7–10 August 2011; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2011; p. 1100019. [Google Scholar]

- Layne, A.W.; Alvin, M.A.; Granite, E.; Pennline, H.W.; Siriwardane, R.V.; Keairns, D.; Newby, R. Overview of Contaminant Removal From Coal-Derived Syngas. In Volume 6: Energy Systems: Analysis, Thermodynamics and Sustainability; ASMEDC: New York, NY, USA, 2007; pp. 397–407. [Google Scholar]

- Chen, Y.; He, H.; Wu, S.; Ning, X.; Chen, F.; Lv, Y.; Yu, J.; Zhou, R. Mn/Ce Oxides Decorated Polyphenylene Sulfide Needle-Punching Fibrous Felts for Dust Removal and Denitration Application. Polymers 2020, 12, 168. [Google Scholar] [CrossRef] [PubMed]

- Brand, J.F.; van Dyk, J.C.; Waanders, F.B. Conceptual Use of Vortex Technologies for Syngas Purification and Separation in UCG Applications. J. South. Afr. Inst. Min. Metall. 2018, 118, 1029–1039. [Google Scholar] [CrossRef]

- Kwakye, J.M.; Ekechukwu, D.E.; Ogundipe, O.B. Reviewing the Role of Bioenergy with Carbon Capture and Storage (BECCS) in Climate Mitigation. Eng. Sci. Technol. J. 2024, 5, 2323–2333. [Google Scholar] [CrossRef]

- Linjala, O.; Kajolinna, T.; Hiltunen, P.; Silvennoinen, J. Experimenting Bioenergy with Carbon Capture at Small Pilot Scale Using Three Novel Scrubbing Technologies Based on Water, Sodium Carbonate and Kleener-Liquid. In Proceedings of the 16th Greenhouse Gas Control Technologies Conference 2022 (GHGT-16), Lyon, France, 23–27 October 2022; SSRN: Rochester, NY, USA, 2022; pp. 1–11. [Google Scholar]

- Pfeifer, C.; Puchner, B.; Hofbauer, H. In-Situ CO2-Absorption in a Dual Fluidized Bed Biomass Steam Gasifier to Produce a Hydrogen Rich Syngas. Int. J. Chem. React. Eng. 2007, 5, 1–14. [Google Scholar] [CrossRef]

- Senthilkumar, V.; Prabhu, C. Optimization of Design and Development of a Biomass Gasifier—A Review. Biofuels 2024, 15, 1079–1097. [Google Scholar] [CrossRef]

- Chan, W.P.; Veksha, A.; Lei, J.; Oh, W.-D.; Dou, X.; Giannis, A.; Lisak, G.; Lim, T.-T. A Novel Real-Time Monitoring and Control System for Waste-to-Energy Gasification Process Employing Differential Temperature Profiling of a Downdraft Gasifier. J. Environ. Manag. 2019, 234, 65–74. [Google Scholar] [CrossRef]

- Chaiwong, K.; Karnjanapiboon, C.; Wichan, N.; Jaiinta, N.; Thawonngamyingsakul, C. The IoT Based Temperature Monitoring and Air Inlet Optimization Controlling for Gasification Stove. In Proceedings of the 2019 Joint International Conference on Digital Arts, Media and Technology with ECTI Northern Section Conference on Electrical, Electronics, Computer and Telecommunications Engineering (ECTI DAMT-NCON), Nan, Thailand, 30 January–2 February 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 387–391. [Google Scholar]

- Praks, P.; Brkic, D.; Najser, J.; Najser, T.; Praksova, R.; Stajic, Z. Methods of Artificial Intelligence for Simulation of Gasification of Biomass and Communal Waste. In Proceedings of the 2021 22nd International Carpathian Control Conference (ICCC), Ostrava, Czech Republic, 31 May–1 June 2021; IEEE: Piscataway, NJ, USA, 2021; pp. 1–4. [Google Scholar]

- Wen, H.-T.; Wu, H.-Y.; Liao, K.-C. Using XGBoost Regression to Analyze the Importance of Input Features Applied to an Artificial Intelligence Model for the Biomass Gasification System. Inventions 2022, 7, 126. [Google Scholar] [CrossRef]

- Fang, Y.; Ma, L.; Yao, Z.; Li, W.; You, S. Process Optimization of Biomass Gasification with a Monte Carlo Approach and Random Forest Algorithm. Energy Convers. Manag. 2022, 264, 115734. [Google Scholar] [CrossRef]

- Abdul Malek, A.; Hasanuzzaman, M.; Rahim, N.A.; Al–Turki, Y.A. Energy, Economic, and Environmental Analysis of 10-MW Biomass Gasification Based Power Generation in Malaysia. Energy Environ. 2021, 32, 295–337. [Google Scholar] [CrossRef]

- Valente, A.; Iribarren, D.; Dufour, J. Comparative Life Cycle Sustainability Assessment of Renewable and Conventional Hydrogen. Sci. Total Environ. 2021, 756, 144132. [Google Scholar] [CrossRef]

- Patel, A.R.; Maurya, R.K.; Sarkar, P.; Singh, H.; Tyagi, H. Biomass Gasification and Sustainability Assessment of Biomass Utilization. In Biorefining of Biomass to Biofuels; Springer: Berlin/Heidelberg, Germany, 2018; pp. 53–85. [Google Scholar]

- Shahbeig, H.; Shafizadeh, A.; Rosen, M.A.; Sels, B.F. Exergy Sustainability Analysis of Biomass Gasification: A Critical Review. Biofuel Res. J. 2022, 9, 1592–1607. [Google Scholar] [CrossRef]

- Adams, P.W.R.; McManus, M.C. Small-Scale Biomass Gasification CHP Utilisation in Industry: Energy and Environmental Evaluation. Sustain. Energy Technol. Assess. 2014, 6, 129–140. [Google Scholar] [CrossRef]

- Shakirov, V.; Kozlov, A. Multicriteria Assessment of Biomass Gasification-based Hybrid Energy Systems in Remote Areas. Biofuels Bioprod. Biorefin. 2023, 17, 380–388. [Google Scholar] [CrossRef]

- AlNouss, A.; McKay, G.; Al-Ansari, T. A Comparison of Steam and Oxygen Fed Biomass Gasification through a Techno-Economic-Environmental Study. Energy Convers. Manag. 2020, 208, 112612. [Google Scholar] [CrossRef]

- You, S.; Ok, Y.S.; Chen, S.S.; Tsang, D.C.W.; Kwon, E.E.; Lee, J.; Wang, C.-H. A Critical Review on Sustainable Biochar System through Gasification: Energy and Environmental Applications. Bioresour. Technol. 2017, 246, 242–253. [Google Scholar] [CrossRef] [PubMed]

- Vinayak, A.K.; Ashokan, H.; Sinha, S.; Halkara, Y.; Gurumoorthy, A.V.P. Role of Biomass Gasification in Achieving Circular Economy. Recent Innov. Chem. Eng. 2024, 17, 170–189. [Google Scholar] [CrossRef]

- Yang, K.; Zhu, N.; Yuan, T. Analysis of Optimum Scale of Biomass Gasification Combined Cooling Heating and Power (CCHP) System Based on Life Cycle Assessment(LCA). Procedia Eng. 2017, 205, 145–152. [Google Scholar] [CrossRef]

- Barahmand, Z.; Eikeland, M.S. A Scoping Review on Environmental, Economic, and Social Impacts of the Gasification Processes. Environments 2022, 9, 92. [Google Scholar] [CrossRef]

- La Scalia, G.; Adelfio, L.; La Fata, C.M.; Micale, R. Economic and Environmental Assessment of Biomass Power Plants in Southern Italy. Sustainability 2022, 14, 9676. [Google Scholar] [CrossRef]

- Ducruet, C.; Polo Martin, B.; Sene, M.A.; Lo Prete, M.; Sun, L.; Itoh, H.; Pigné, Y. Ports and Their Influence on Local Air Pollution and Public Health: A Global Analysis. Sci. Total Environ. 2024, 915, 170099. [Google Scholar] [CrossRef] [PubMed]

- Mueller, N.; Westerby, M.; Nieuwenhuijsen, M. Health Impact Assessments of Shipping and Port-Sourced Air Pollution on a Global Scale: A Scoping Literature Review. Environ. Res. 2023, 216, 114460. [Google Scholar] [CrossRef] [PubMed]

- Mallett, A. Technology Cooperation for Sustainable Energy: A Review of Pathways. WIREs Energy Environ. 2013, 2, 234–250. [Google Scholar] [CrossRef]

- Jenssen, T. The Good, the Bad, and the Ugly: Acceptance and Opposition as Keys to Bioenergy Technologies. J. Urban. Technol. 2010, 17, 99–115. [Google Scholar] [CrossRef]

- Luo, X.; Wu, T.; Shi, K.; Song, M.; Rao, Y. Biomass Gasification: An Overview of Technological Barriers and Socio-Environmental Impact. In Gasification for Low-Grade Feedstock; Yun, Y., Ed.; InTech: London, UK, 2018; pp. 3–17. [Google Scholar]

- International Renewable Energy Agency (IRENA). Renewable Energy and Jobs—Annual Review 2020; International Renewable Energy Agency (IRENA): Abu Dhabi, United Arab Emirates, 2020. [Google Scholar]

- The U.S. Department of Energy. Bioenergy Workforce Development Strategy. Available online: https://www.energy.gov/eere/bioenergy/bioenergy-workforce-development-strategy (accessed on 15 January 2025).

- Blair, M.J.; Gagnon, B.; Klain, A.; Kulišić, B. Contribution of Biomass Supply Chains for Bioenergy to Sustainable Development Goals. Land 2021, 10, 181. [Google Scholar] [CrossRef]

- Shailaja, R. Women, Energy and Sustainable Development. Energy Sustain. Dev. 2000, 4, 45–64. [Google Scholar] [CrossRef]

- Baruah, B. Creating Opportunities for Women in the Renewable Energy Sector: Findings from India. Fem. Econ. 2015, 21, 53–76. [Google Scholar] [CrossRef]

- Lee, Y.J.; Husain, Z.; Dutta, M. Does Improved Cooking Fuel Empower Women? Evidence from India. Sustain. Dev. 2024, 32, 574–587. [Google Scholar] [CrossRef]

- Chairunnisa, A.S. Green Technology Opportunities and Challenges in Sustainable Marine Logistics. Collab. Eng. Dly. Book Ser. 2024, 2, 34–41. [Google Scholar] [CrossRef]

- Alsheikh Yousef, A.N. The Impact Of The Development Of Maritime Logistics On The Aqaba Port’s Trade Movement And The Sustainability. Strateg. Financ. Rev. 2024, 1, 108–161. [Google Scholar] [CrossRef]

- Ghimire, P.; Park, D.; Zadeh, M.K.; Thorstensen, J.; Pedersen, E. Shipboard Electric Power Conversion: System Architecture, Applications, Control, and Challenges [Technology Leaders]. IEEE Electrif. Mag. 2019, 7, 6–20. [Google Scholar] [CrossRef]

- Selén, V. Addressing Ship Emissions at Berth: Onshore Power Supply Where It Makes Sense. IEEE Electrif. Mag. 2023, 11, 25–32. [Google Scholar] [CrossRef]

- Nguyen, D.-H.; Lin, C.; Cheruiyot, N.K.; Hsu, J.-Y.; Cho, M.-Y.; Hsu, S.-H.; Yeh, C.-K. Reduction of NOx and SO2 Emissions by Shore Power Adoption. Aerosol Air Qual. Res. 2021, 21, 210100. [Google Scholar] [CrossRef]

- Fikiin, K.; Stankov, B. Integration of Renewable Energy in Refrigerated Warehouses. In Handbook of Research on Advances and Applications in Refrigeration Systems and Technologies; Gaspar, P.D., da Silva, P.D., Eds.; IGI Global Scientific Publishing: Hershey, PA, USA, 2015; pp. 803–853. [Google Scholar]

- Meneghetti, A.; Dal Magro, F.; Simeoni, P. Fostering Renewables into the Cold Chain: How Photovoltaics Affect Design and Performance of Refrigerated Automated Warehouses. Energies 2018, 11, 1029. [Google Scholar] [CrossRef]

- Lindstad, E.; Eskeland, G.S.; Rialland, A.; Valland, A. Decarbonizing Maritime Transport: The Importance of Engine Technology and Regulations for LNG to Serve as a Transition Fuel. Sustainability 2020, 12, 8793. [Google Scholar] [CrossRef]

- Melnyk, O.M.; Shumylo, O.M.; Onishchenko, O.A.; Mykhailova, I.V.; Obniavko, T.S.; Korobko, T.O. Concept and Prospects for the Use of Hydrogen Fuel in Maritime Transport. Collect. Sci. Work. Ukr. State Univ. Railw. Transp. 2023, 96–105. [Google Scholar] [CrossRef]

- Pei, Y.; Wang, S.; Chen, X.; Lu, F.; Wang, S. Evaluation of a Green Methanol Production System Using the Integration of Water Electrolysis and Biomass Gasification. Therm. Sci. 2024, 28, 4685–4694. [Google Scholar] [CrossRef]

- Kermani, M.; Shirdare, E.; Parise, G.; Bongiorno, M.; Martirano, L. A Comprehensive Technoeconomic Solution for Demand Control in Ports: Energy Storage Systems Integration. IEEE Trans. Ind. Appl. 2022, 58, 1592–1601. [Google Scholar] [CrossRef]

- Sadek, I.; Elgohary, M. Assessment of Renewable Energy Supply for Green Ports with a Case Study. Environ. Sci. Pollut. Res. 2020, 27, 5547–5558. [Google Scholar] [CrossRef]

- International Maritime Organization (IMO). Initial IMO Strategy on Reduction of GHG Emissions from Ships; International Maritime Organization (IMO): London, UK, 2018. [Google Scholar]

- International Maritime Organization (IMO). Improving the Energy Efficiency of Ships. Available online: https://www.imo.org/en/OurWork/Environment/Pages/Improving%20the%20energy%20efficiency%20of%20ships.aspx (accessed on 17 January 2025).

- International Maritime Organization (IMO). IMO2020 Fuel Oil Sulphur Limit—Cleaner Air, Healthier Planet. Available online: https://www.imo.org/en/MediaCentre/PressBriefings/pages/02-IMO-2020.aspx#:~:text=entering%20into%20force.-,The%20upper%20limit%20of%20the%20sulphur%20content%20of%20ships’%20fuel,sulphur%20oxide%20emanating%20from%20ships (accessed on 17 January 2025).

- United Nations. Paris. Agreement; United Nations: New York, NY, USA, 2015. [Google Scholar]

- European Parliament & Council of the European Union. Directive (EU) 2018/2001 of the European Parliament and of the Council of 11 December 2018 on the Promotion of the Use of Energy from Renewable Sources (Recast); European Parliament & Council of the European Union: Strasbourg, France, 2018. [Google Scholar]

- European Commission. The EU ETS and MRV Maritime: General Guidance for Shipping Companies; European Commission: Brussels, Belgium; Luxembourg, 2024. [Google Scholar]

- U.S. Department of Energy. Inflation Reduction Act of 2022. Available online: https://www.energy.gov/lpo/inflation-reduction-act-2022#:~:text=The%20President’s%20Inflation%20Reduction%20Act,energy%20manufacturing%2C%20and%20putting%20the (accessed on 19 January 2025).

- Maritime Administration. Port Infrastructure Development Program. Available online: https://www.maritime.dot.gov/PIDPgrants (accessed on 19 January 2025).

- Energy Foundation China. China’s 14th Five-Year Plans on Renewable Energy Development and Modern Energy System. Available online: https://www.efchina.org/Blog-en/blog-20220905-en (accessed on 19 January 2025).

- JapanGov. Japan’s Green Growth Strategy Will Accelerate Innovation. Available online: https://www.japan.go.jp/kizuna/2021/09/green_growth_strategy.html (accessed on 19 January 2025).

- Li, M.; Luan, J.; Li, X.; Jia, P. An Analysis of the Impact of Government Subsidies on Emission Reduction Technology Investment Strategies in Low-Carbon Port Operations. Systems 2024, 12, 134. [Google Scholar] [CrossRef]

- Lu, H.; Huang, L. Optimization of Shore Power Deployment in Green Ports Considering Government Subsidies. Sustainability 2021, 13, 1640. [Google Scholar] [CrossRef]

- Wang, Y.; Ding, W.; Dai, L.; Hu, H.; Jing, D. How Would Government Subsidize the Port on Shore Side Electricity Usage Improvement? J. Clean. Prod. 2021, 278, 123893. [Google Scholar] [CrossRef]

- Yin, M.; Wang, Y.; Zhang, Q. Policy Implementation Barriers and Economic Analysis of Shore Power Promotion in China. Transp. Res. D Transp. Environ. 2020, 87, 102506. [Google Scholar] [CrossRef]

- UNFCCC. Clean Development Mechanism (CDM). Available online: https://cdm.unfccc.int/index.html?_gl=1*is8xx7*_ga*NDY0Nzc4MjAyLjE3MzcxNDQxMzA.*_ga_7ZZWT14N79*MTczNzMxODcxNy4zLjEuMTczNzMxODk4Ni4wLjAuMA (accessed on 19 January 2025).

- International Capital Market Association. Green Bond Principles-Voluntary Process Guidelines for Issuing Green Bonds. Available online: https://www.icmagroup.org/assets/documents/Sustainable-finance/2022-updates/Green-Bond-Principles-June-2022-060623.pdf (accessed on 19 January 2025).

- Othman, K.; Khallaf, R. A Review of Public-Private Partnerships for Renewable Energy Projects in Developing Countries. Proc. Int. Struct. Eng. Constr. 2022, 9, 2022. [Google Scholar] [CrossRef]

- Port of Rotterdam Collaboration between Port of Rotterdam Authority and Rotterdam The Hague Airport for More Sustainable Aviation Fuel. Available online: https://www.portofrotterdam.com/en/news-and-press-releases/collaboration-between-port-rotterdam-authority-and-rotterdam-hague-airport (accessed on 20 January 2025).

- The Port of Los Angeles and Port of Long Beach. Clean Air Action Plan 2017; 2017. Available online: https://sustainableworldports.org/project/ports-of-los-angeles-and-long-beach-clean-air-action-plan-2017/ (accessed on 24 January 2025).

- Nikopoulou, Z. Incremental Costs for Reduction of Air Pollution from Ships: A Case Study on North European Emission Control Area. Marit. Policy Manag. 2017, 44, 1056–1077. [Google Scholar] [CrossRef]

- Viana, M.; Fann, N.; Tobías, A.; Querol, X.; Rojas-Rueda, D.; Plaza, A.; Aynos, G.; Conde, J.A.; Fernández, L.; Fernández, C. Environmental and Health Benefits from Designating the Marmara Sea and the Turkish Straits as an Emission Control Area (ECA). Environ. Sci. Technol. 2015, 49, 3304–3313. [Google Scholar] [CrossRef]

- California Air Resources Board. Ocean-Going Vessels At Berth Regulation. Available online: https://ww2.arb.ca.gov/our-work/programs/ocean-going-vessels-berth-regulation (accessed on 20 January 2025).

- Drax Group. MOU Agreed to Develop ‘Bioship’ Technology and Plans to Construct the World’s First Biomass-Fuelled Ship. Available online: https://www.drax.com/press_release/mou-agreed-to-develop-bioship-technology-and-plans-to-construct-the-worlds-first-biomass-fuelled-ship/ (accessed on 26 January 2025).

- Conti, D.; Harahap, F.; Silveira, S.; Santasalo-Aarnio, A. A Techno-Economic Assessment for Optimizing Methanol Production for Maritime Transport in Sweden. In Proceedings of the ECOS 2019—Proceedings of the 32nd International Conference on Efficiency, Cost, Optimization, Simulation and Environmental Impact of Energy Systems, Wroclaw, Poland, 23–28 June 2019; Institute of Thermal Technology: Moscow, Russia, 2019; pp. 4703–4712. [Google Scholar]

- de Fournas, N.; Wei, M. Techno-Economic Assessment of Renewable Methanol from Biomass Gasification and PEM Electrolysis for Decarbonization of the Maritime Sector in California. Energy Convers. Manag. 2022, 257, 115440. [Google Scholar] [CrossRef]

- European Energy Innovation. BioSFerA Project: A Successful Project Implementation Towards The Deployment Of Biomass-To-Liquid (BtL) Technologies. Available online: https://www.europeanenergyinnovation.eu/Latest-Research/Summer-2024/BioSFera-project (accessed on 6 January 2025).

- Rhatwal, B. Biomass-Derived Hydrogen to Power Cargo Vessel. Available online: https://bioenergytimes.com/biomass-derived-hydrogen-to-power-cargo-vessel/?utm_source=chatgpt.com (accessed on 9 January 2025).

- Saadeldin, M.A.-N.; Elgohary, M.M.; Abdelnaby, M.; Shouman, M.R. Biofuels and Electrofuels as Alternative Green Fuels for Marine Applications: A Review. Mar. Technol. Soc. J. 2023, 57, 51–68. [Google Scholar] [CrossRef]

- Simone, M.; Biagini, E.; Nicolella, C.; Tognotti, L.; Guerrazzi, E.; Nicolella, C. Technological Barriers of Biomass Gasification. Int. J. Heat. Technol. 2009, 27, 127–132. [Google Scholar]

- Lim, C.H.; Ngan, S.L.; Ng, W.P.Q.; How, B.S.; Lam, H.L. Biomass Supply Chain Management and Challenges. In Value-Chain of Biofuels; Elsevier: Amsterdam, The Netherlands, 2022; pp. 429–444. [Google Scholar]

- Williams, C.L.; Westover, T.L.; Emerson, R.M.; Tumuluru, J.S.; Li, C. Sources of Biomass Feedstock Variability and the Potential Impact on Biofuels Production. Bioenergy Res. 2016, 9, 1–14. [Google Scholar] [CrossRef]

- Falcone, P.M.; Sica, E. Assessing the Opportunities and Challenges of Green Finance in Italy: An Analysis of the Biomass Production Sector. Sustainability 2019, 11, 517. [Google Scholar] [CrossRef]

- Rey, J.R.C.; Pio, D.T.; Tarelho, L.A.C. Biomass Direct Gasification for Electricity Generation and Natural Gas Replacement in the Lime Kilns of the Pulp and Paper Industry: A Techno-Economic Analysis. Energy 2021, 237, 121562. [Google Scholar] [CrossRef]

- Meerman, J.C. Perspectives on Gasification Systems to Produce Energy Carriers and Other Chemicals with Low CO2 Emissions: Techno-Economic System Analysis on Current and Advanced Flexible Thermo-chemical Conversion of Fossil Fuels and Biomass. Ph.D. Thesis, Utrecht University, Utrecht, The Netherlands, 2012. [Google Scholar]

- Agrawal, A. Risk Mitigation Strategies for Renewable Energy Project Financing. Strateg. Plan. Energy Environ. 2012, 32, 9–20. [Google Scholar] [CrossRef]

- Desclaux, L.; Pereira, A.O. Residual Biomass Gasification for Small-Scale Decentralized Electricity Production: Business Models for Lower Societal Costs. Energies 2024, 17, 1868. [Google Scholar] [CrossRef]

- Gai, C.; Dong, Y. Experimental Study on Non-Woody Biomass Gasification in a Downdraft Gasifier. Int. J. Hydrogen Energy 2012, 37, 4935–4944. [Google Scholar] [CrossRef]

- Sikarwar, V.S.; Zhao, M.; Fennell, P.S.; Shah, N.; Anthony, E.J. Progress in Biofuel Production from Gasification. Prog. Energy Combust. Sci. 2017, 61, 189–248. [Google Scholar] [CrossRef]

- Arena, U. Process and Technological Aspects of Municipal Solid Waste Gasification. A Review. Waste Manag. 2012, 32, 625–639. [Google Scholar] [CrossRef]

- Shackley, S. Characterisation of Waste Water from Biomass Gasification Equipment: A Case-Study from Cambodia. World Rev. Sci. Technol. Sustain. Dev. 2015, 12, 126. [Google Scholar] [CrossRef]

- Immerzeel, D.J.; Verweij, P.A.; van der Hilst, F.; Faaij, A.P.C. Biodiversity Impacts of Bioenergy Crop Production: A State-of-the-art Review. GCB Bioenergy 2014, 6, 183–209. [Google Scholar] [CrossRef]

- Casson, A.; Muliastra, Y.I.K.D.; Obidzinski, K. Large-Scale Plantations, Bioenergy Developments and Land Use Change in Indonesia; Center for International Forestry Research (CIFOR): Bogor, Indonesia, 2014. [Google Scholar]

- AP News. South Korean Politician Calls for Investigation of Biomass Energy Material Imported from Indonesia. Available online: https://apnews.com/article/biomass-deforestation-indonesia-south-korea-wood-pellets-a5c2ade399922da0fe0cc45203f09a0d (accessed on 10 March 2025).

- Dauber, J.; Jones, M.B.; Stout, J.C. The Impact of Biomass Crop Cultivation on Temperate Biodiversity. GCB Bioenergy 2010, 2, 289–309. [Google Scholar] [CrossRef]

- Gaba, S. Review of the Impacts on Biodiversity of Land-Use Changes Induced by Non-Food Biomass Production; Springer: Cham, Switzerland, 2018; pp. 195–212. [Google Scholar]

- Rohr, A.; Campleman, S.; Long, C.; Peterson, M.; Weatherstone, S.; Quick, W.; Lewis, A. Potential Occupational Exposures and Health Risks Associated with Biomass-Based Power Generation. Int. J. Environ. Res. Public. Health 2015, 12, 8542–8605. [Google Scholar] [CrossRef]

- Kasedde, H. Hazard and Safety Evaluation of Gasifier Installations in Uganda. Ph.D. Thesis, Royal Institute of Technology, Stockholm, Sweden, 2009. [Google Scholar]

- Rahman, M.M.; Henriksen, U.B.; Ciolkosz, D. Startup Process, Safety and Risk Assessment of Biomass Gasification for off-Grid Rural Electrification. Sci. Rep. 2023, 13, 21395. [Google Scholar] [CrossRef]

- Alves, O.; Gonçalves, M.; Brito, P.; Monteiro, E.; Jacinto, C. A Review on Occupational Risk in Gasification Plants Processing Residues of Sewage Sludge and Refuse-Derived Fuel. In Occupational Safety and Hygiene VI; CRC Press: Boca Raton, FL, USA, 2018; pp. 29–34. [Google Scholar]

- Zhang, W.; Liu, H.; Ul Hai, I.; Neubauer, Y.; Schröder, P.; Oldenburg, H.; Seilkopf, A.; Kölling, A. Gas Cleaning Strategies for Biomass Gasification Product Gas. Int. J. Low-Carbon. Technol. 2012, 7, 69–74. [Google Scholar] [CrossRef]

- Safarian, S.; Ebrahimi Saryazdi, S.M.; Unnthorsson, R.; Richter, C. Gasification of Woody Biomasses and Forestry Residues: Simulation, Performance Analysis, and Environmental Impact. Fermentation 2021, 7, 61. [Google Scholar] [CrossRef]

- Karagkouni, K.; Boile, M. Classification of Green Practices Implemented in Ports: The Application of Green Technologies, Tools, and Strategies. J. Mar. Sci. Eng. 2024, 12, 571. [Google Scholar] [CrossRef]

- Jacquet, J.B.; Stedman, R.C. The Risk of Social-Psychological Disruption as an Impact of Energy Development and Environmental Change. J. Environ. Plan. Manag. 2014, 57, 1285–1304. [Google Scholar] [CrossRef]

- Axon, S.; Morrissey, J. Just Energy Transitions? Social Inequities, Vulnerabilities and Unintended Consequences. Build. Cities 2020, 1, 393–411. [Google Scholar] [CrossRef]

- De Meo, E.; Lopolito, A.; Prosperi, M.; Giannoccaro, G.; Ciccone, R.A. How to Promote Community Social Acceptance of Solid Biomass in Europe? Identifying Firms’ Best Practices. Econ. Bull. 2014, 34, 2080–2092. [Google Scholar]

- Fedorova, E.; Aaltonen, K.; Pongrácz, E. Social Sustainability Dilemma: Escape or Communicate? Managing Social Risks Upstream of the Bioenergy Supply Chain. Resources 2020, 9, 7. [Google Scholar] [CrossRef]

- Mancini, E.; Raggi, A. Out of Sight, out of Mind? The Importance of Local Context and Trust in Understanding the Social Acceptance of Biogas Projects: A Global Scale Review. Energy Res. Soc. Sci. 2022, 91, 102697. [Google Scholar] [CrossRef]

- Villeneuve, J.; Palacios, J.H.; Savoie, P.; Godbout, S. A Critical Review of Emission Standards and Regulations Regarding Biomass Combustion in Small Scale Units (<3 MW). Bioresour. Technol. 2012, 111, 1–11. [Google Scholar] [CrossRef]

- Bhatt, A.; Zhang, Y.; Heath, G.; Thomas, M.; Renzaglia, J. Federal Air Pollutant Emission Regulations and Preliminary Estimates of Potential-to-Emit from Biorefineries, Pathway #2: Conversion of Lignocellulosic Biomass to Hydrocarbon Fuels: Fast Pyrolysis and Hydrotreating Bio-Oil Pathway; National Renewable Energy Lab. (NREL): Golden, CO, USA, 2017. [Google Scholar]

- Intelligent Energy for Europe. Guideline for Safe and Eco-Friendly Biomass Gasification; Intelligent Energy for Europe: Loughborough, UK, 2009. [Google Scholar]

- Pyykkö, H.; Hinkka, V.; Uotila, T.; Palmgren, R. Foresight-Driven Approach to Support the Proactive Adaptation of Future Sustainability Related Regulatory Frameworks: European Port Cluster Study. Int. J. Technol. 2021, 12, 914. [Google Scholar] [CrossRef]

- Muller, S.; Supatgiat, C. A Quantitative Optimization Model for Dynamic Risk-Based Compliance Management. IBM J. Res. Dev. 2007, 51, 295–307. [Google Scholar] [CrossRef]

- Tarifa, P.; Ramirez Reina, T.; González-Castaño, M.; Arellano-García, H. Catalytic Upgrading of Biomass-Gasification Mixtures Using Ni-Fe/MgAl2O4 as a Bifunctional Catalyst. Energy Fuels 2022, 36, 8267–8273. [Google Scholar] [CrossRef] [PubMed]

- Micheli, F.; Mattucci, E.; Courson, C.; Gallucci, K. Bi-Functional Catalyst/Sorbent for a H2-Rich Gas from Biomass Gasification. Processes 2021, 9, 1249. [Google Scholar] [CrossRef]

- Yang, G.; Hu, Q.; Hu, J.; Yang, H.; Yan, S.; Chen, Y.; Wang, X.; Chen, H. Hydrogen-Rich Syngas Production from Biomass Gasification Using Biochar-Based Nanocatalysts. Bioresour. Technol. 2023, 379, 129005. [Google Scholar] [CrossRef]

- Liu, Z.; Ling, J.-L.; Liu, Y.-Y.; Zheng, B.-H.; Wu, C.-D. Incorporation of Enzyme-Mimic Species in Porous Materials for the Construction of Porous Biomimetic Catalysts. Chem. Commun. 2024, 60, 12964–12976. [Google Scholar] [CrossRef]

- Danso-Boateng, E.; Achaw, O.-W. Bioenergy and Biofuel Production from Biomass Using Thermochemical Conversions Technologies—A Review. AIMS Energy 2022, 10, 585–647. [Google Scholar] [CrossRef]

- Shen, Y. Biomass Pretreatment for Steam Gasification toward H2-Rich Syngas Production—An Overview. Int. J. Hydrogen Energy 2024, 66, 90–102. [Google Scholar] [CrossRef]

- Medipally, S.R.; Yusoff, F.M.; Banerjee, S.; Shariff, M. Microalgae as Sustainable Renewable Energy Feedstock for Biofuel Production. Biomed. Res. Int. 2015, 2015, 519513. [Google Scholar] [CrossRef]

- Kumar, M.; Sun, Y.; Rathour, R.; Pandey, A.; Thakur, I.S.; Tsang, D.C.W. Algae as Potential Feedstock for the Production of Biofuels and Value-Added Products: Opportunities and Challenges. Sci. Total Environ. 2020, 716, 137116. [Google Scholar] [CrossRef]

- Freitas, S.R.; Soria, J.A. Development of a Gasification System for Utilizing Fish Processing Waste and Coastal Small Diameter Wood in Rural Areas. Energy Fuels 2011, 25, 2292–2300. [Google Scholar] [CrossRef]

- Baruah, D.; Baruah, D.C. Decision Support System Based Planning of Biomass Gasification System for Decentralised Energy Generation. Renew. Energy Focus. 2021, 38, 22–35. [Google Scholar] [CrossRef]

- Buragohain, B.; Mahanta, P.; Moholkar, V.S. Biomass Gasification for Decentralized Power Generation: The Indian Perspective. Renew. Sustain. Energy Rev. 2010, 14, 73–92. [Google Scholar] [CrossRef]

- Mossavar-Rahmani, F.; Zohuri, B. Artificial Intelligence Integration Driven Smart Grid Alternative Transforming the Future With Renewable, and Non-Renewable Energy Sources. Int. J. Adv. Eng. Manag. Res. 2024, 09, 14–25. [Google Scholar] [CrossRef]

- Alsulaiman, N.; Reddy, K.; Odi, U.; Rabines, J.; Temizel, C. Opportunities in Utilization of Digital Twins in Unconventional Gas Fields: Enhancing Efficiency and Performance through Virtual Replication. In Proceedings of the International Petroleum Technology Conference (IPTC), Dammam City, Saudi Arabia, 12–14 February 2024. [Google Scholar]

- Sulieman, N.A.; Ricciardi Celsi, L.; Li, W.; Zomaya, A.; Villari, M. Edge-Oriented Computing: A Survey on Research and Use Cases. Energies 2022, 15, 452. [Google Scholar] [CrossRef]

- Modupe, O.T.; Otitoola, A.A.; Oladapo, O.J.; Abiona, O.O.; Oyeniran, O.C.; Adewusi, A.O.; Komolafe, A.M.; Obijuru, A. Reviewing the Transformational Impact of Edge Computing on Real-Time Data Processing and Analytics. Comput. Sci. IT Res. J. 2024, 5, 693–702. [Google Scholar] [CrossRef]

- CE Delft. Benchmark for Seaport Sustainability Edition 2023; CE Delft: Delft, The Netherlands, 2023. [Google Scholar]

- Ozgoli, H.A.; Safari, S.; Sharifi, M.H. Integration of a Biomass-Fueled Proton Exchange Membrane Fuel Cell System and a Vanadium Redox Battery as a Power Generation and Storage System. Sustain. Energy Technol. Assess. 2020, 42, 100896. [Google Scholar] [CrossRef]

- Perna, A.; Minutillo, M.; Lubrano Lavadera, A.; Jannelli, E. Combining Plasma Gasification and Solid Oxide Cell Technologies in Advanced Power Plants for Waste to Energy and Electric Energy Storage Applications. Waste Manag. 2018, 73, 424–438. [Google Scholar] [CrossRef]

- Lashgari, F.; Babaei, S.M.; Pedram, M.Z.; Arabkoohsar, A. Comprehensive Analysis of a Novel Integration of a Biomass-Driven Combined Heat and Power Plant with a Compressed Air Energy Storage (CAES). Energy Convers. Manag. 2022, 255, 115333. [Google Scholar] [CrossRef]

- Karvounis, P.; Tsoumpris, C.; Boulougouris, E.; Theotokatos, G. Recent Advances in Sustainable and Safe Marine Engine Operation with Alternative Fuels. Front. Mech. Eng. 2022, 8, 994942. [Google Scholar] [CrossRef]

- Ramsay, W.; Fridell, E.; Michan, M. Maritime Energy Transition: Future Fuels and Future Emissions. J. Mar. Sci. Appl. 2023, 22, 681–692. [Google Scholar] [CrossRef]

- World Bank; Ecofys; Vivid Economics. State and Trends of Carbon. Pricing; World Bank: Washington, DC, USA, 2016. [Google Scholar]

- Ladanai, S.; Vinterbäck, J. Certification Criteria for Sustainable Biomass for Energy; Rapport; Department of Energy and Technology, Swedish University of Agricultural Sciences: Uppsala, Sweden, 2010. [Google Scholar]

- Porcu, A.; Sollai, S.; Marotto, D.; Mureddu, M.; Ferrara, F.; Pettinau, A. Techno-Economic Analysis of a Small-Scale Biomass-to-Energy BFB Gasification-Based System. Energies 2019, 12, 494. [Google Scholar] [CrossRef]

| Dimension | Key Implications | Refs. |

|---|---|---|

| Environmental |

| [16,18,64,65,68,71] |

| ||

| ||

| ||

| Economic |

| [40,68,69,71,73] |

| ||

| ||

| ||

| ||

| Social |

| [76,78,79,83,84] |

| ||

| ||

| ||

|

| Energy Demand in Ports | Integration Opportunities of Biomass Gasification | Refs. |

|---|---|---|

| Onshore Power Supply (Cold Ironing) |

| [89,90,91] |

| Refrigerated Storage |

| [92,93] |

| Fuel Supply for Maritime and Land Vehicles |

| [94,95,96] |

| Cargo-Handling Equipment |

| [97] |

| Administrative and Lighting Systems |

| [98] |

| Aspect | Key Policies/Initiatives | Implications for Biomass Gasification | Refs. |

|---|---|---|---|

| Global Policies |

|

| [99] |

|

| [100] | |

|

| [101] | |

|

| [102] | |

| Regional/National Policies |

|

| [103] |

|

| [104] | |

|

| [105] | |

|

| [106] | |

|

| [107] | |

|

| [108] | |

| Incentives/Financial Mechanisms |

|

| [109,110] |

|

| [113] | |

|

| [114] | |

|

| [115,116,117] | |

| Compliance/Standards |

|

| [118,119] |

|

| [120] |

| Project/Initiative | Description | Key Outcomes/Contributions | Ref. |

|---|---|---|---|

| BIOSHIP Project (Japan) |

|

| [121] |

| Green Methanol Production (China) |

|

| [96] |

| Methanol from Sawmill Residues (Sweden) |

|

| [122] |

| Renewable Methanol Production (California) |

|

| [123] |

| BioSFerA Project (EU Horizon 2020) |

|

| [124] |

| Compact Syngas Solutions (CSS) (UK) |

|

| [125] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alavi-Borazjani, S.A.; Adeel, S.; Chkoniya, V.; Tarelho, L.A.C. Sustainability-Oriented Port Management: Biomass Gasification as a Strategic Tool for Green and Circular Maritime Logistics. Sustainability 2025, 17, 2634. https://doi.org/10.3390/su17062634

Alavi-Borazjani SA, Adeel S, Chkoniya V, Tarelho LAC. Sustainability-Oriented Port Management: Biomass Gasification as a Strategic Tool for Green and Circular Maritime Logistics. Sustainability. 2025; 17(6):2634. https://doi.org/10.3390/su17062634

Chicago/Turabian StyleAlavi-Borazjani, Seyedeh Azadeh, Shahzada Adeel, Valentina Chkoniya, and Luís A. C. Tarelho. 2025. "Sustainability-Oriented Port Management: Biomass Gasification as a Strategic Tool for Green and Circular Maritime Logistics" Sustainability 17, no. 6: 2634. https://doi.org/10.3390/su17062634

APA StyleAlavi-Borazjani, S. A., Adeel, S., Chkoniya, V., & Tarelho, L. A. C. (2025). Sustainability-Oriented Port Management: Biomass Gasification as a Strategic Tool for Green and Circular Maritime Logistics. Sustainability, 17(6), 2634. https://doi.org/10.3390/su17062634